C-Stat 11-M | C-Stat 17-M

Installation Instructions

Mains Operated Programmable Room Thermostat

Programmable room thermostats are widely recognised as one

of the best ways in which to control central heating. C-Stat

programmable room thermostats have a large display and

intuitive user interface, making them easy to set up and use. CStat uses a sophisticated load compensation (LC) algorithm for

accurate temperature control and energy efficiency. Being

mains powered these models won't need the batteries changing

every two years.

Installation and connection should only be carried out by a

suitable qualified person and in accordance with the edition of

the IEE wiring regulation.

Warning: Isolate mains supply before commencing installation.

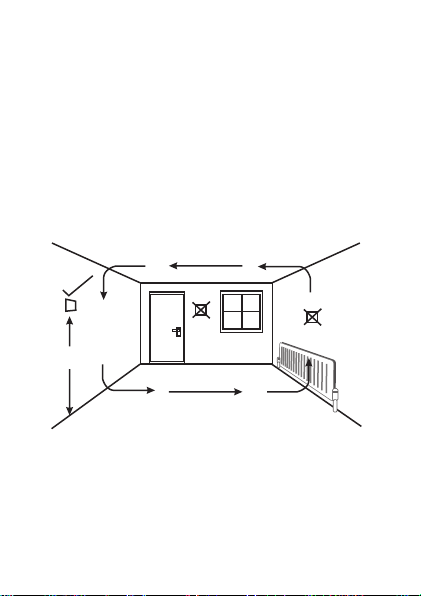

Positioning the C-Stat programmable room

thermostat

The C-Stat should be mounted on an internal wall

approximately 1.5 metres from floor level and should be

in a position away from draughts, direct heat and

sunlight. Ensure that there will be enough space to allow

access to the two retaining screws located at the base of

the wall plate.

1.5m

2

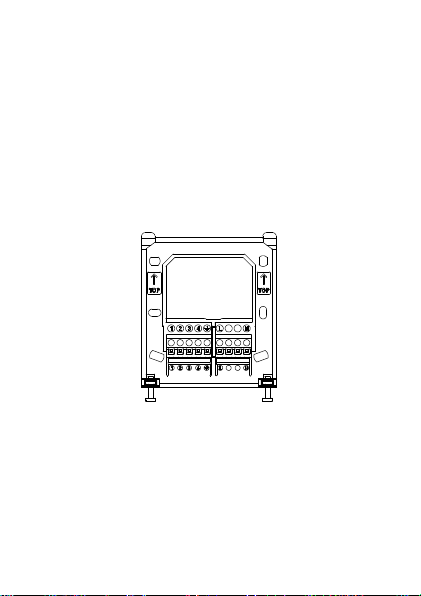

Fitting the wall plate

To remove the wall plate from the C-Stat undo the two retaining

screws located on the underside, the wall plate should now be

easily removed. Once the wall plate has been removed from the

packaging please ensure the C-Stat is resealed to prevent

damage from dust, debris etc.

The wall plate should be fitted in a position which allows a total

clearance of at least 50mm around the C-Stat programmable

thermostat.

Direct Wall Mounting

Offer the plate to the wall in the position the C-Stat is to be

mounted and mark the fixing positions through the slots in the

wall plate. Drill and plug the wall, then secure the plate in

position. The slots in the wall plate with compensate for any

misalignment of the fixings.

3

Wiring Box Mounting

The C-Stat wall plate may be fitted directly on to a single gang

steel flush wiring box complying with BS4662, using two M3.5

screws. The C-stat is suitable for mounting on a flat surface only;

it must not be positioned on an unearthed metal surface.

Electrical Connections

All necessary electrical connections should now be made. Flush

wiring can enter from the rear through the aperture in the wall

plate.

A Pattress is supplied to allow mains surface wiring to enter the

unit.

The mains supply terminals are intended to be connected to the

supply by means of fixed wiring.

The C-Stat is mains powered and requires a 3 Amp fused spur.

The recommended cable size is 1.0mm².

The C-Stat is double insulated and does not require an earth

connection, an earth connection block is provided on the

backplate for terminating any cable earth conductors. Earth

continuity must be maintained and all bare earth conductors

must be sleeved. Ensure that no conductors are left protruding

outside the central space enclosed by the backplate.

4

Internal wiring diagram

These diagrams are schematic and should be used for guidance

only. Please ensure that all wiring complies with current IEE

regulations

CALL

1 2 3 4 L N

230V

MAINS

CALL FOR

HEAT

Ÿ The C-Stat have voltage free contacts

Ÿ For mains voltage switching applications, link terminal L-1

Ÿ For low voltage switching applications, apply low voltage to

terminal 1 with no links.

SUPPLY

5

C-Stat

Remove link

if Fitted

1 3N2 4

N

L

E

L

N

L

E

L

N

L

PUMP

N

&

BOILER

L

1 3N2 4

L

Mains

N

Supply

E

E

E

L

N

COMBINATION BOILDER

Programmer

HOT

WATER

OFFONOFF

ON

C CN

CYL

STAT

CALL

SAT

TERMINALS

1 2

N

COOLING LOAD

CENTRAL

HEATING

ROOM

STAT

ROOM

STAT

CALL

SAT

3

4

L

MAINS

SUPPLY

C-Stat controlling typical combination boiler installation. For precise termination

connection information please refer to the boiler manufactures instructions

E

Mains

L

Supply

N

C-Stat wired to control a cooling load. When necessary the C-Stat should be used in

conjunction with a contactor.

N L

N

MAINS

L

SUPPLY

E

C-Stat controlling a secondary heating zone on a fully pumped system with existing

programmer and two spring return valves with auxiliary switches.

6

Mains

Supply

Programmer

HOT

CENTRAL

WATER

HEATING

OFF

ON

N L

N

MAINS

L

SUPPLY

E

W

BL

0

GR

C-Stat replacing a conventional room thermostat on a fully pumped system with an

existing programmer and 3 port mid-position valve.

C

CALL

OFF

ON

C-Stat

CYL

1

STAT

3

4

CALLSAT

SAT

L

N

PUMP

&

BOILER

230V

L

MAINS

SUPPLY

N

Programmer

HOT

CENTRAL

WATER

HEATING

OFFONOFF

ON

N L

N

MAINS

L

SUPPLY

E

C-Stat replacing a conventional room thermostat on a fully pumped system with an

existing programmer and two spring return valves with auxiliary switches

N

PUMP

BOILER

C

CYL

STAT

CALL

L

&

C-Stat

1

4

3

CALLSAT

SAT

230V

L

MAINS

SUPPLY

N

7

All wiring diagrams are schematic and should be used for guidance only.

INSTALLATION AND CONNECTION OF THE C-STAT MUST BE CARRIED OUT BY A

SUITABLY QUALIFIED PERSON.

WARNING: ISOLATE MAINS SUPPLY BEFORE COMMENCING INSTALLATION

LC Temperature control software

Thermostats using LC (Load Compensation) control algorithms

will reduce the temperature swing that normally occurs when

using traditional bellows or thermally operated thermostats. As a

consequence, a LC regulating thermostat will maintain the

comfort level far more efficiently than any traditional thermostat.

When used with a condensing boiler, the LC thermostat will help

to save energy as the control algorithm allows the boiler to

operate in condensing mode more consistently compared to

older types of thermostat.

Ÿ For Gas boilers ser the LC setting to 6 cycles per hour (default

setting)

Ÿ For Oil boilers set the LC setting to 3 cycles per hour

Ÿ For Electric heating set the LC setting to 12 cycles per hour

To adjust this setting go to the SET UP MENU and select LC

CYCLES

8

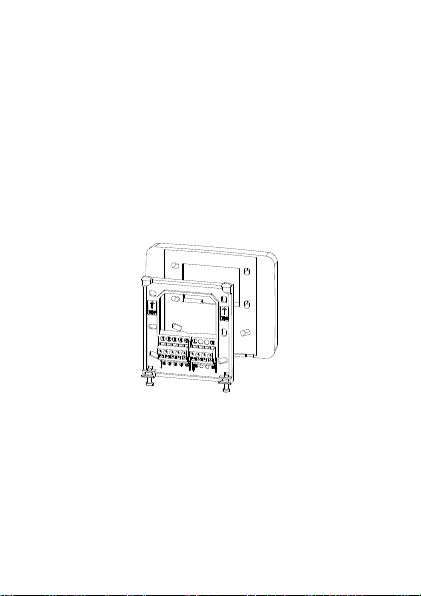

Fitting the C-Stat to the wall plate

Complete the installation by swinging the C-Stat into position by

engaging the lugs at the top of the wall plate before pushing it

firmly home into its plug-in terminal block.

Tighten the 2 captive screws on the underside of the unit.

Now ensure that the heating system is responding to the On/Off

commands from the C-Stat. Explain its operation to the

householder and hand over the users operating instructions to

the user.

9

Installer Settings

There are a number of 'Installer Settings' that should be set on

installation.

These can be found under the 'SET UP MENU' on page 15 of the

user instructions.

Clock Format AM/PM or 24 Hour clock display - Default

Daylight saving On or Off - Default setting ON for UK Market

Standby temperature Frost protection setting – Default setting 5°C

Upper and Lower Default settings 30°C and 5°C

Temperature limits

LC Cycles This setting will change according to the

For Gas boiler this setting should be 6

For Oil boilers this setting should be 3

For Electric panel heaters this should be 12

Optimum Start On or Off – Default setting Off

The LC Cycles setting and Optimum Start settings should be carefully

set on installation as this will affect system performance.

10

setting AM/P

type of boiler being used - Default setting 6

cycles per hour

cycles per hour

cycles per hour

Resetting the thermostat

Electronic equipment can in some circumstances be affected by

electrical interference.

If the display becomes frozen or scrambled simply press both

the BACK and ENTER button simultaneously.

Using this procedure will restore the C-Stat to the original factory

settings, the Time and Date will remain correct.

BACK

ENTER

11

Specification – C-Stat 11-M | C-Stat 17-M

NP0 08 48 73 00 0

Purpose of Control Thermostat

Power Supply 230V 50Hz

Contact type Micro-disconnection

Wiring configuration Voltage free c/o contacts (SPDT)

Contact voltage rating 230V ac 50Hz (30V dc)

Contact current rating 8A (1A inductive)

Temperature differential 0.5°C

Temperature accuracy +/- 0.5°C to 21°C

Impulse rating Category II 2500 V

Standards BS EN 60730-2-9, EN 60730-2-9

Dimensions (WxHxD) 120mm x 100mm x 26.5mm

Weight 0.3kg (approx)

Enclosure Flame retardant thermoplastic

Ingress protection IP30

Pollution degree Degree 2

Insulation class Class II (Double Insulated)

Software class Class A

Control type Type 2B

Temperature range 0°C to 40°C

Electronic Control

Ball Pressure Temperature 75 °C

Construction of Control Electronic control

Secure Meters (UK) Ltd

Secure House, Lulworth Close,

Chandler's Ford,

Eastleigh, SO53 3TL, UK

t: +44 1962 840048 f: +44 1962 841046

www.Securemeters.com

Part Number P84873 Issue 6

Loading...

Loading...