application brief AB20-5

replaces AN1149-5

Secondary Optics Design

Considerations for SuperFlux LEDs

Secondary optics are those optics which exist outside of the LED package, such as reflector

cavities, Fresnel lenses, and pillow lenses. Secondary optics are used to create the desired

appearance and beam pattern of the LED signal lamp.

The following section details the optical characteristics and optical model creation for Lumileds

SuperFlux LEDs. In addition, simple techniques to aid in the design of collimating reflectors,

collimating lenses, and pillow lenses are discussed.

Table of Contents

Optical Characteristics of SuperFlux LEDs 2

LED Light Output 2

SuperFlux LED Radiation Patterns 2

Optical Modeling of SuperFlux LEDs 3

Point Source Optical Model 3

Detailed Optical Models 4

Secondary Optics 5

Pillow Lens Design 9

Design Case—Pillow Design for an LED CHMSL 9

Non-symmetric Pillow Lenses 11

Selecting the Size of the Pillow Optic 11

Recommended Pillow Lens Prescriptions 12

Other Diverging Optics 13

Reflector Design 14

Design Case—Reflector for a CHMSL Application 14

Reflector Cavities with Linear Profiles 15

Reflector Cavities with Square and Rectangular Exit Apertures 15

Other Reflector Design Techniques 16

Collimating Lens Design 17

Fresnel Lens Design 18

Design Case—Collimator Lens 19

Other Lens Design Options 19

Appendix 5A 21

Optical Characteristics of

SuperFlux LEDs

LED Light Output

The light output of an LED is typically described

by two photometric measurements, flux and

intensity.

In simple terms, flux describes the rate at which

light energy is emitted from the LED. Total flux

from an LED is the sum of the flux radiated in all

directions. If the LED is placed at the center of a

sphere, the total flux can be described as the

sum of the light incident over the entire inside

surface of the sphere. The symbol for

photometric for flux is Φv, and the unit of

measurement is the lumen (lm).

In simple terms, intensity describes the flux

density at a position in space. Intensity is the

flux per unit solid angle radiating from the LED

source. The symbol for photometric intensity is

Iv, and the unit of measurement is the candela

(cd).

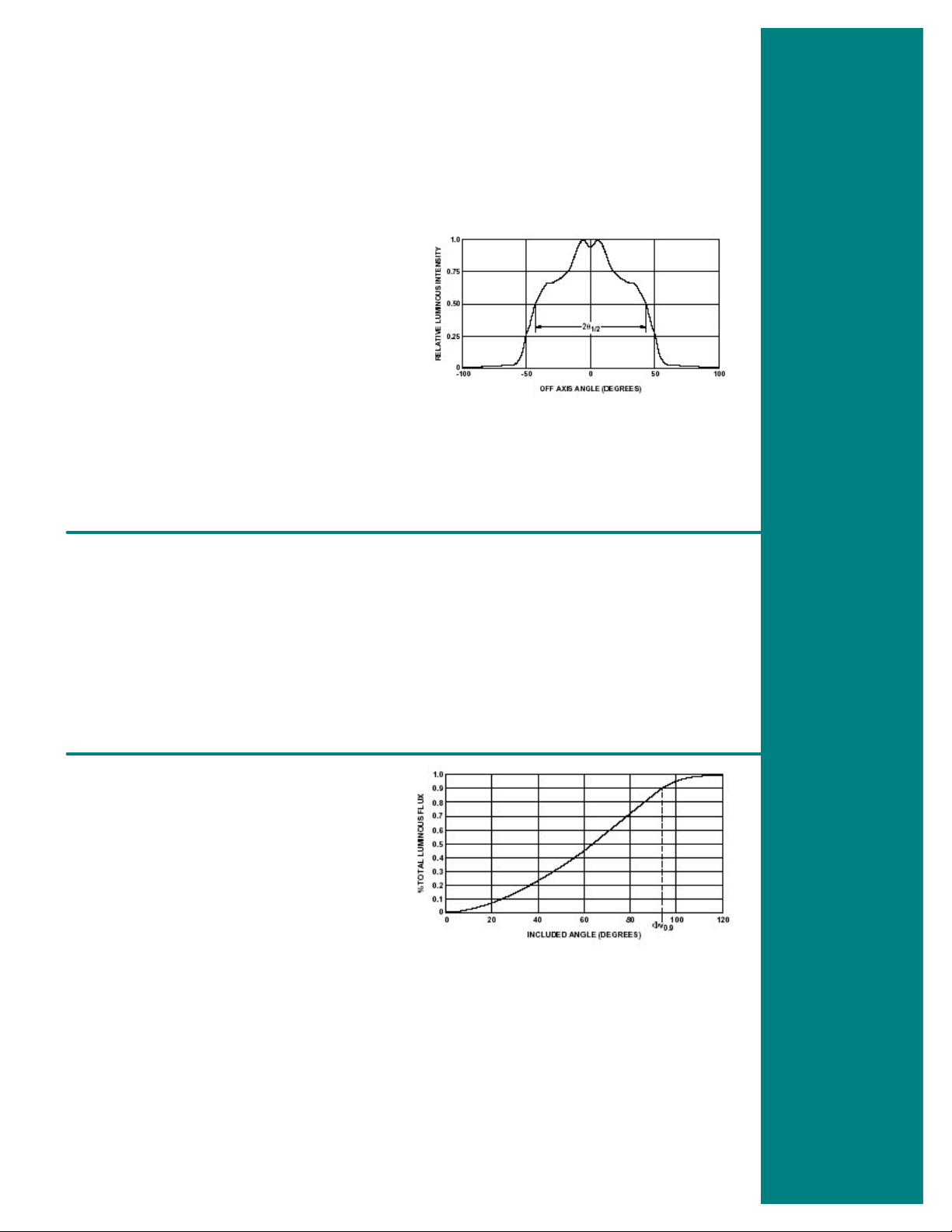

SuperFlux LED Radiation Patterns

The radiation pattern of an LED describes

how the flux is distributed in space. This is

accomplished by defining the intensity of the

LED as a function of angle from the optical axis.

Since the radiation pattern of most LEDs is

rotationally symmetric about the optical axis, it

can be described by a simple, two-axis graph of

intensity versus angle from the optical axis.

Intensity is normalized in order to describe the

relative intensity at any angle. By normalizing

Solid angle is used to describe the amount of

angular space subtended. Angular space is

described in terms of area on a sphere. If a solid

angle ω, with its apex at the center of a sphere of

radius r, subtends an area A on the surface of

that sphere, then ω = A/r

angle are steradians (sr).

To put some of these concepts into perspective,

consider the simple example of a candle. A

candle has an intensity of approximately one

candela. A candle placed in the center of a

sphere radiates light in a fairly uniform manner

over the entire inner surface (ω = A/ r

4π steradians). With this information, the flux from

a candle can be calculated as shown below:

intensity, the radiation pattern becomes a

description of how the flux is distributed,

independent of the amount of flux produced.

Figure 5.1 shows a graph of the radiation pattern

for an HPWA-Mx00 LED.

An attribute of the radiation pattern that is of

common interest is known as the full-width, half-

max, or 2θ

angular width of the radiation pattern at the half

power, or half maximum intensity point. Looking

1

/2. This attribute describes the full

2

. The units for solid

2

= 4π r

2

2

/ r

=

at Figure 5.1, the 2θ

is approximately 90°.

Another attribute that is of common interest is

the total included angle, or θ

describes the cone angle within which 90% of

the total flux is radiated. Using Figure 5.1, the

percent of total flux versus included angle can

be calculated and graphed. (The derivation of

this graph is shown in Appendix 5A.) This graph

is included in the data sheet of SuperFlux LEDs

and is shown in Figure 5.2 for the HPWA-Mx00

LED.

1

/2 of the HPWA-Mx00 LED

. This attribute

v 0.9

Looking at Figure 5.2, the total included angle is

approximately 95°. This implies that 90% of the

flux produced by an HPWA-Mx00 LED is emitted

within a 95° cone centered on the optical axis.

Figure 5.1 Graph of the radiation pattern for an

HPWA-MxOO LED.

Optical Modeling of SuperFlux LEDs

An optical model of the LED is useful when

designing secondary optic elements such as

reflector cavities and pillow lenses. The optical

output of an LED can be approximated as a

point source of light passing through an

aperture, but modeling errors may be

Point Source Optical Model

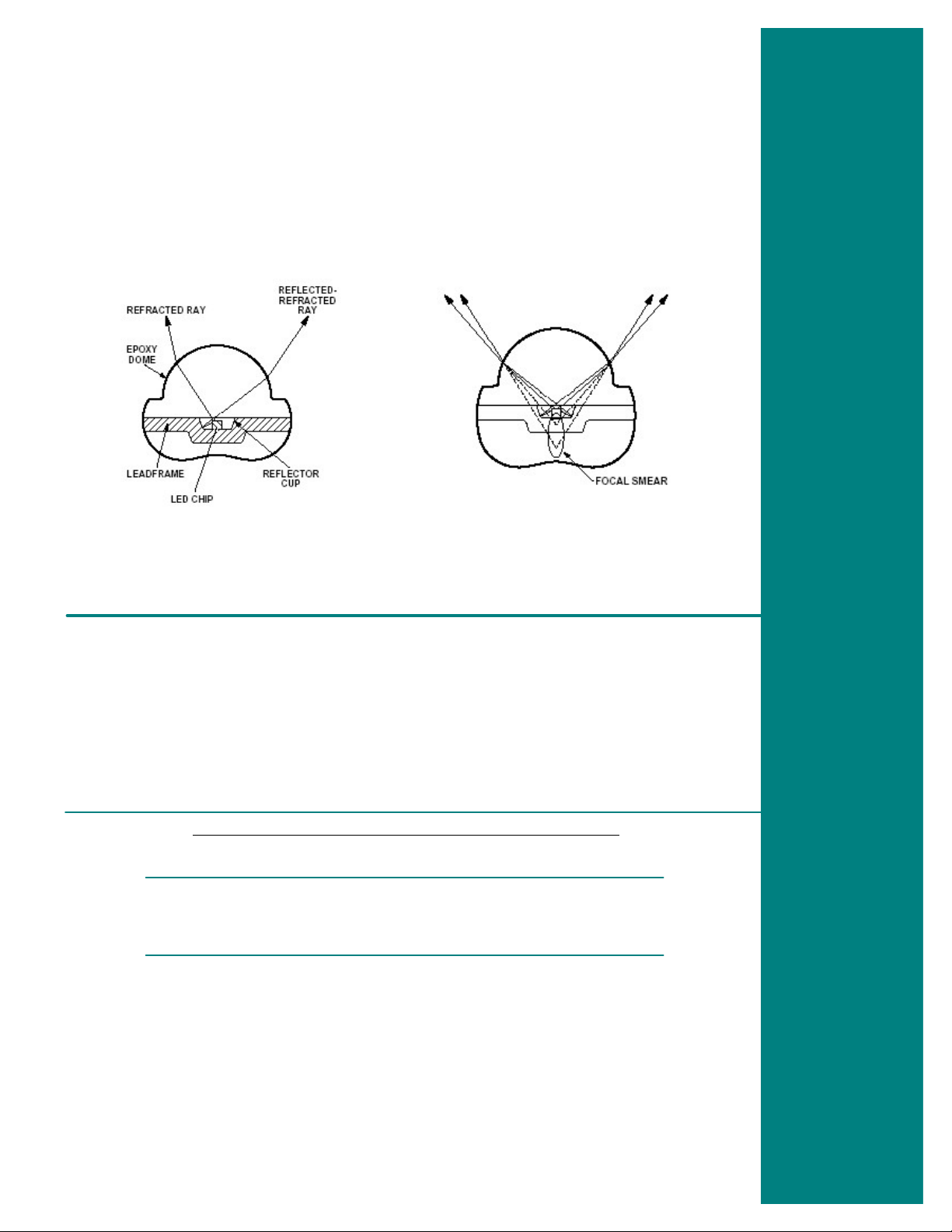

The internal structure of a SuperFlux LED is

shown in Figure 5.3. Light is produced in the

LED chip. A portion of this light goes directly

from the chip and is refracted by the epoxy

dome (refracted-only light). The remainder of

the light is reflected by the reflector cup and

then refracted by the epoxy dome (reflected-

refracted light).

The light that is refracted appears to come from

a certain location within the LED, while the light

which is reflected and refracted appears to

come from a different location. In addition,

because the LED chip itself has physical size

unacceptable when lenses or reflectors are

placed within 25 mm of the SuperFlux LED. A

more accurate technique involves using an

optical model, which takes into account the

extended source size of the LED.

Figure 5.2 Percent total flux vs. included angle for

an HPWA-MxOO LED.

and is not a point source, the refracted-only light

does not appear to come from a single location,

but a range of locations or a focal smear. This is

true for the reflected-refracted light as well.

3

These focal smears overlap, creating an

elongated focal smear as shown in Figure 5.4.

To create the best approximation using a point

source model, the center point of the focal

smears should be chosen as the location of the

points source; and the aperture size should be

equal to that of the epoxy dome at its base as

shown in Figure 5.5.

The optimal position of the point source for each

SuperFlux LED is shown in Table 5.1.

Figure 5.3 Internal structure of a SuperFlux

LED.

Figure 5.4 Focal smear produced by reflected

and reflected-refracted light.

Detailed Optical Models

Detailed optical models of LEDs include all

the internal optical structures within the LED

including the chip, the reflector, and the dome.

In order to accurately construct such a model,

detailed information about the chip, the reflector

surface, and the epoxy encapsulant must be

known. The process usually involves a tedious

trial and error technique of changing parameters

in the model until empirical measurements are

matched.

Table 5.1

HPWA-MxOO 1.03

HPWA-Dx00 1.13

HPWT-Mx00 0.99

HPWT-DxOO 1.17

Due to the complexity of this process, Lumileds

Lighting provides customers with rayset files for

SuperFlux LEDs. The raysets contain spacial

and angular information on a set of rays exiting

the device at the dome surface. These raysets

Position of Point Source for SuperFlux LEDs

SuperFlux LED

Part Number

Position of Point Source

“Z” (mm)

can be used by many optical-modeling software

packages. Contact your local Lumileds

Applications Engineer for more information and

copies of the raysets.

4

Secondary Optics

Figure 5.6 Cross section of an LED signal

This section contains practical design tools for

secondary optic design. More accurate and

sophisticated techniques exist which are beyond

the scope of this application note. The design

methods discussed here are proven, but no

analytical technique can completely replace

empirical testing. Designs should always be

prototyped and tested as early in the design

process as possible.

Secondary optics are used to modify the output

beam of the LED such that the output beam of

the finished signal lamp will efficiently meet the

desired photometric specification. In addition,

secondary optics serve an aesthetic purpose by

determining the lit and unlit appearance of the

signal lamp. The primary optic is included in the

LED package, and the secondary optics are part

of the finished signal lamp. There are two

primary categories of secondary optics used,

those that spread the incoming light (diverging

optics), and those that gather the incoming light

into a collimated beam (collimating optics).

The most common type of diverging optic used

in automotive signal lamp applications is the

pillow lens. The pillow lens spreads the incoming

light into a more divergent beam pattern, and it

breaks up the appearance of the source

resulting in a more uniform appearance. A cross

section of an LED signal lamp with a pillow lens

is shown in Figure 5.6.

Figure 5.5 Point source model of a SuperFlux

LED.

lamp with a pillow lens.

Figure 5.7 Cross section of an LED

signal lamp with a reflector cavity and

pillow lens.

5

Figure 5.8 Cross section of an LED signal

As the spacing between the pillow and the

LEDs is increased, each LED will illuminate a

larger area of the pillow lens. As the spot

illuminated by each LED grows and as the

adjacent spots begin to overlap, the lens will

appear more evenly illuminated. The trade-off

between lamp depth and lit uniformity is a

common consideration in LED design, where

both unique appearance and space-saving

packages are desired.

Collimating optics come in two main varieties:

reflecting and refracting. Reflecting elements are

typically metalized cavities with a straight or

parabolic profile. A cross section of an LED

signal lamp with a reflector cavity and a pillow

lens is shown in Figure 5.7.

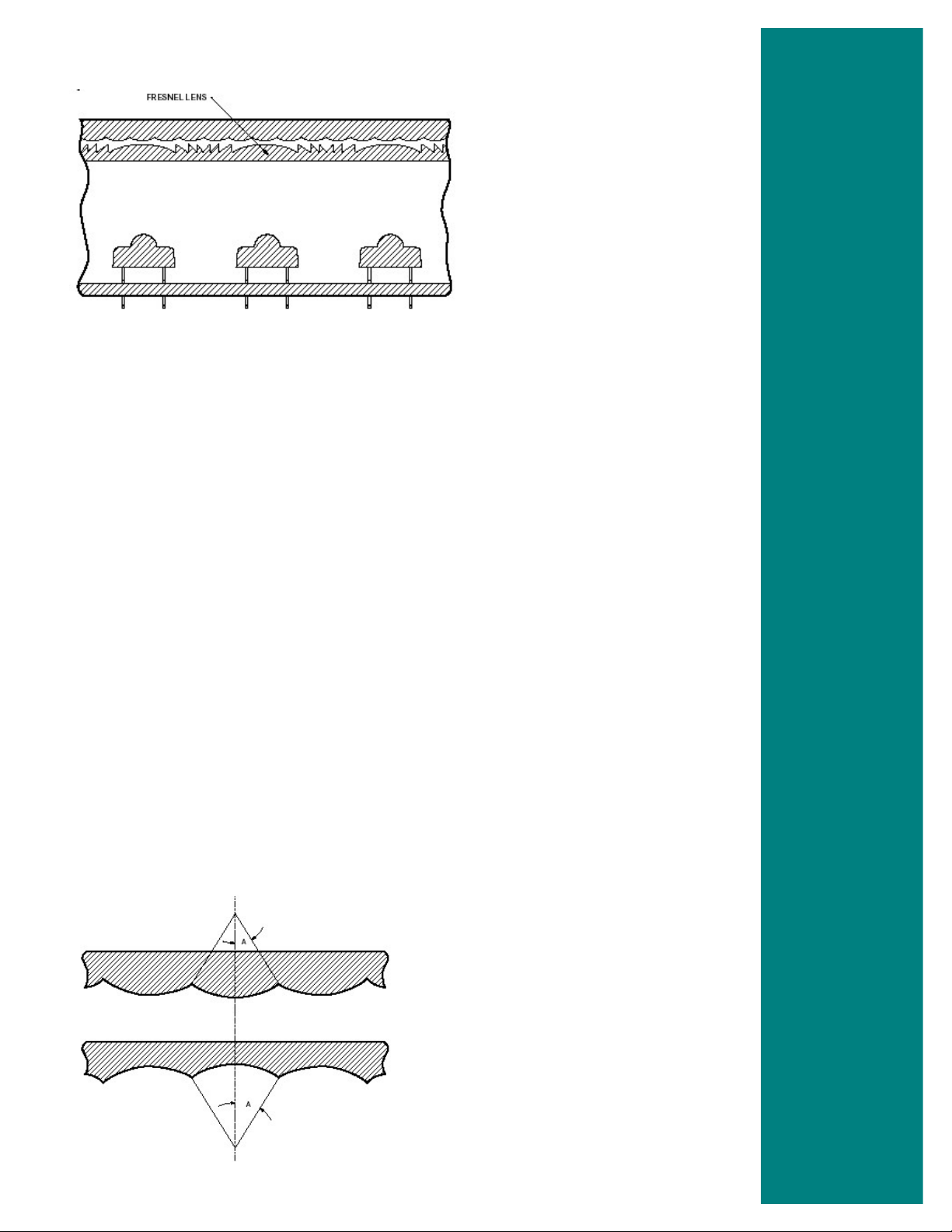

Refracting, collimating optics typically used in

LED signal lamp applications include plano-

convex, dualconvex, and collapsed plano-

convex (Fresnel) lenses. A cross section of an

lamp with Fresnel and pillow lenses.

LED signal lamp with a Fresnel lens and a pillow

lens is shown in Figure 5.8.

In general, designs that use collimating

secondary optics are more efficient, and produce

a more uniform lit appearance than designs

utilizing only pillow or other non-collimating

optics. Fresnel lenses are a good choice for thin

lamp designs and produce a very uniform lit

appearance. Reflectors are a good choice for

thicker lamp designs and are more efficient than

Fresnel lenses at illuminating non-circular areas.

This is because reflectors gather all of the light,

which is emitted as a circular pattern for most

SuperFlux LEDs, and redirect it into the desired

shape. In addition, reflectors can be used to

create a unique, “jeweled” appearance in both

the on and off states.

The dependency of reflector height on reflector

efficiency will be covered later in this section.

Figure 5.9 Half-angle subtended by an individual

pillow (A) for convex (upper) and concave (lower)

pillow lenses.

6

A(n

A(n

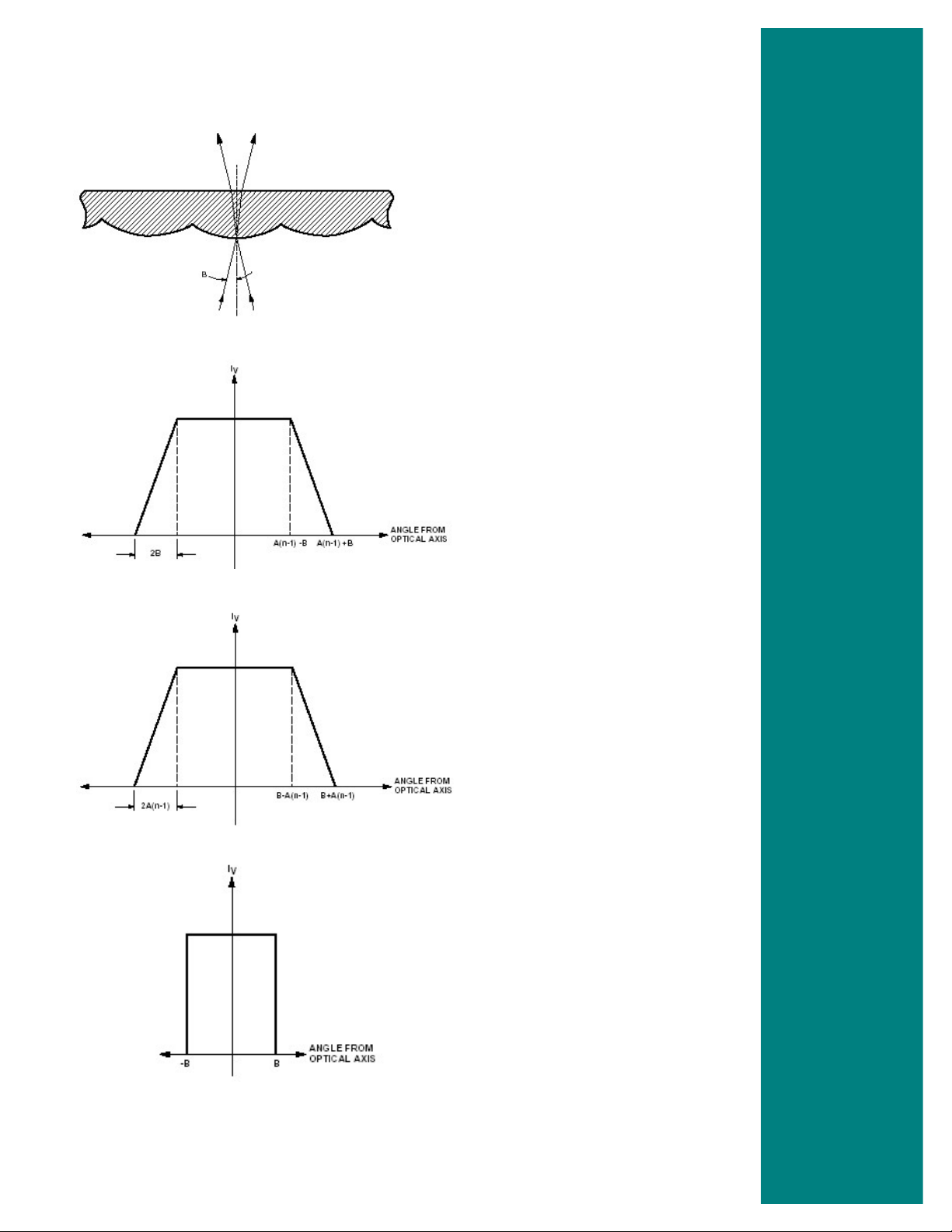

Figure 5.10 Half-angle divergence of the

input beam (B).

Figure 5.11 Ideal radiation pattern

produced by a pillow optic where

-1) > B.

7

Figure 5.12 Ideal radiation pattern

produced by a pillow optic where

-1) < B.

Figure 5.13 Ideal input beam with halfangle divergence B.

Loading...

Loading...