Page 1

®

Features:

Mechanical Keypad Door Lock

SD-962H-8LAQ

Manual

Non-handed installation

External and internal entry lever

13 code buttons, over 8,000 possible codes

Lock code easily changed

Suitable for door thicknesses from

13/16"~21/8" (30~54 mm)

Tubular latchbolt included

Heavy-duty steel case US32D/630

Fully mechanical

No batteries or other power source required

Free egress from inside

Simple Installation

Page 2

SECO-LARM Mechanical Keypad Door Lock

The

SECO

-

LARM

Mechanical Keypad Door Lock provides secure locking while avoiding the

letters/digits can be entered in any order. Since it is completely mechanical, there is no need to run

Specifications:

Overview:

Introduction:

1x Exterior handle assembly

4x Code tumblers

4x Wood screws

1x Interior handle assembly

1x

Latchbolt support post

2x

Machine screws (36mm)

1x Strike plate

2x

Hexagonal mounting posts

2x

Machine screws (48mm)

1x Strike dust box

3x

Spindles (75, 85, 100 mm)

2x

Neoprene door seals

1x Latchbolt

1x

Code card

1x

Tweezers

1x Hex wrench

1x

Manual

43/4" (120mm)

hassle and cost of dealing with providing, duplicating, or replacing keys. Unlike keyed locks, the

lock code can be easily changed by the user at any time. The code is not sequential, so the code

wires from a power supply or replace batteries. The inside handle always operates to allow safe

egress in an emergency.

Parts List:

(with buttons)

(2 red, 2 blue)

(2 for latchbolt, 2 for plate)

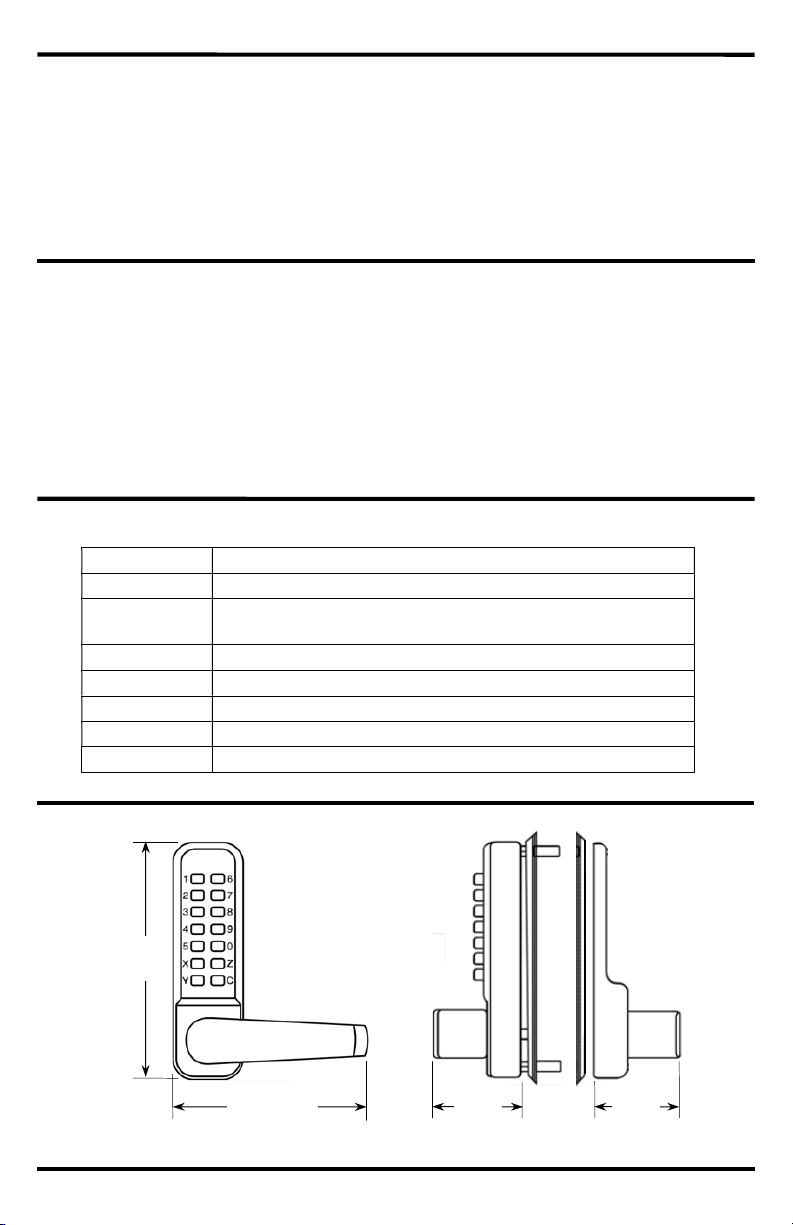

Type Fully mechanical keypad lock

Code length 4~6 Digits (0~9, X, Y, and Z)

Handed

Bolt throw

Backset 23/4" (70mm)

Housing Heavy-duty satin finish stainless steel US32D/630

Dimensions 2" x 43/4" x 51/2" (50x120x140 mm)

Weight 3-lb 1-oz (1.35kg)

(factory default – internal, right-handed / external, left-handed)

Field reversible

1

/2" (13mm)

51/2"

(140mm)

2"

(50mm)

2"

(50mm)

2 SECO-LARM U.S.A., Inc.

Page 3

SECO-LARM Mechanical Keypad Door Lock

The Lock Code:

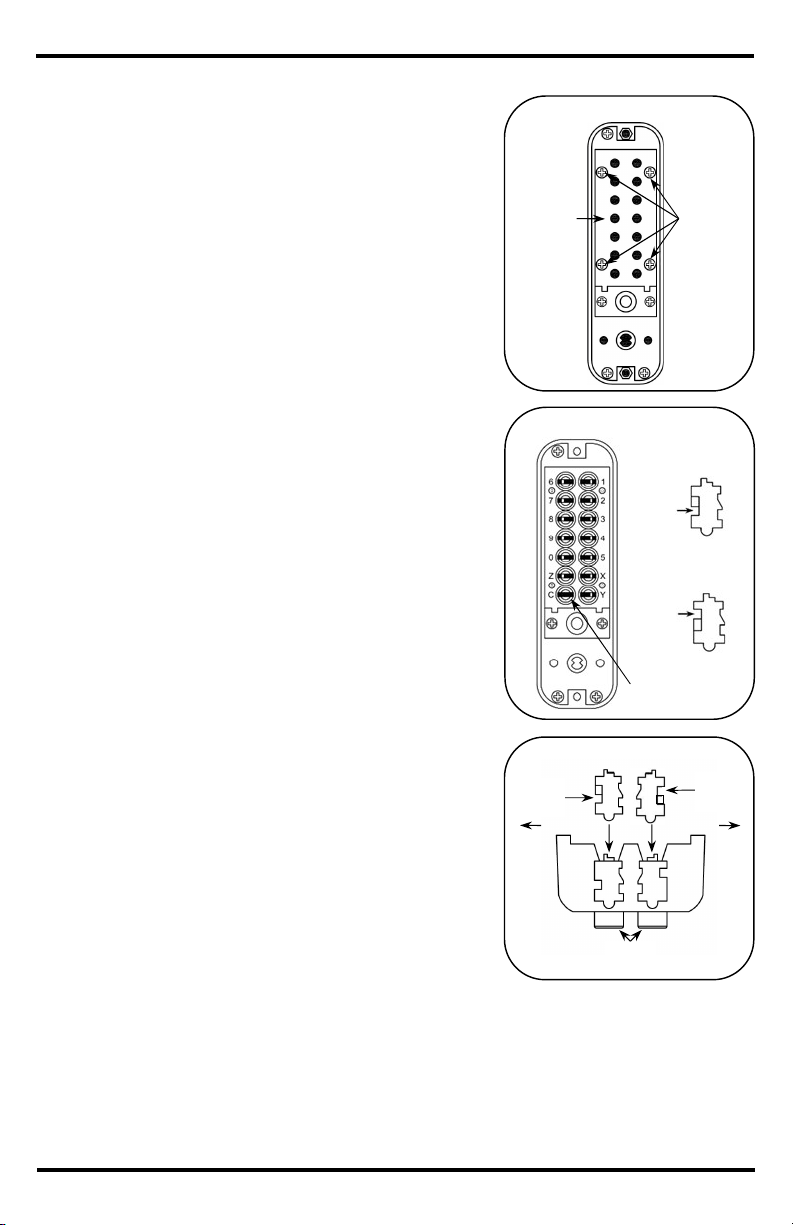

Each lock assembly is given a random code at the factory

Blue

Red

Square

Square

Never remove the

plate

Square

Keypad

and that code is printed on a card shipped with the lock. The

Fig. 1

code can be easily changed as shown below.

NOTES:

A. When changing the lock code, it is crucial that you

Lock code

press and hold the "C" button throughout the duration

of the code changing process. Failure to do so will

damage the lock code module.

B. Never remove the tumbler from the "C" position (Fig. 2).

C. Take care to insert the lock code tumblers properly. The

red or blue marks on the code tumblers should all be in

line if the code tumblers are inserted correctly.

D. Place a drop cloth on a good, flat surface to help

Fig. 2

prevent screws and code tumblers from accidentally

bouncing off the table and getting lost.

E. The lock code is not sequential. In other words, if the

cut

lock code numbers are 135Y, any sequence (Y135,

513Y, 3Y51, etc.) will unlock the door

IMPORTANT: Failure to adhere to the above could result in

a damaged lock code module or lost parts.

Changing the Lock Code

1. From the back of exterior assembly, remove the 4 RED

cut

tumbler from this

"C" position.

lock code plate retaining screws (see Figs. 1 and 2).

2. The factory setting uses 5 RED active lock code

Fig. 3

tumblers, 8 BLUE inactive lock code tumblers, and 1

code clearing tumbler in the "C" position.

IMPORTANT: Never remove the code clearing tumbler

cut

Outside

Outside

from the "C" position.

3. Determine the desired lock code and write it down to

avoid any mistake. Use that to determine which code

tumblers must be replaced. Red code tumblers

represent the code and blue code tumblers represent

buttons

the numbers/digits that are not part of the code.

4. While pressing the “C” button, use the provided tweezers to remove one or more code

tumblers as needed for the desired lock code (the numbers for each button are etched into

the housing next to its corresponding code tumbler, see Fig. 2).

5. While continuing to hold the "C" button down, insert the appropriate colored code tumbler(s)

as needed. Ensure that each code tumbler is inserted such that the side with one square cut

is facing the outside of the housing (see Fig. 3).

SECO-LARM U.S.A., Inc. 3

Red lock

code plate

screws

tumbler

tumbler

Square

cut

Page 4

SECO-LARM Mechanical Keypad Door Lock

Determine Door Swing and Handedness:

Prepare the Door and Install the Latchbolt:

Setting the Lock Code (Continued):

Fold the template on the dotted line and place it on the door

D

etermine whet

her the door is right

- or

When facing the door from the outside, if the hinge

Replace

the lock code plate and

secure

it

with the 4 RED screws.

button followed

Use chisel

to form holes

Latch

center

line

(3mm)

6.

7. Check the code to ensure accuracy before installing. First press the "C" (Clear)

by the chosen code and move the handle on the keypad assembly to test the lock.

IMPORTANT NOTES:

A. Spare code tumblers are provided to increase the number of code digits if needed.

B. Carefully note each code tumbler's orientation as it is inserted into the lock code assembly.

The square cut should be oriented toward the outside of the housing.

C. Do not leave any code tumbler position empty.

D. Store the manual, actual code, and unused code tumblers in a safe place.

left-handed.

is on your right, then the door is right-handed. If

the hinge is on your left, the door is left-handed

Fig. 4

Right-handed

Inside

Left-handed

Outside

(see Fig. 4).

1.

so that the line marked "Latch center line" is aligned with the

Fig. 5

latch strike plate's center line when the door is closed. Use

tape to hold the template temporarily in place (see Fig. 5).

2. Drill the six

3. Viewing the door from the latch edge, mark the horizontal

3

/8" (10mm) holes as shown on template.

center point on the "Latch center line" and drill a 1" (25mm)

hole to a depth of 33/4" (95mm).

4. Use a chisel to form the 4 horizontally-aligned

3

/8" (10mm)

into a slot

holes into a single slot.

5. Insert the latch into the latch hole and mark around the

faceplate to determine the size of the recessed area needed

to allow the faceplate to be flush with the door.

6. After marking around the faceplate, remove the latch and

Fig. 6

Cut a

1

deep hole

use a chisel to cut a 1/8" (3mm) deep hole as marked. This

will ensure that the faceplate fits flush with the door (Fig. 6).

7. Insert the latch assembly, ensuring that curved part of the

latchbolt is correctly oriented for the door's swing. Secure

the latch assembly with 2 wood screws provided.

4 SECO-LARM U.S.A., Inc.

/8"

Page 5

SECO-LARM Mechanical Keypad Door Lock

Prepare the Lock for Mounting:

Prepare the Door and Install the Latchbolt (Continued):

Changing the Interior Latchbolt Handedness (for left

-

handed doors)

Positioning the Spindles

8. Choose the correct spindle that best matches the door's thickness.

Fig. 7

For doors less than 17/16" (37mm), use the shorter spindle 215/16"

(75mm). For doors 17/16"~115/16" (37~50mm) use the 33/8" (85mm)

spindle. For thicker doors, use the 315/16"(100mm) spindle.

9. Position the spindle in the center, through the latch hub (Fig. 7)

according to the door's handing as shown in Figs. 8 and 9.

Fig. 8

Spindle orientation for right-handed door

(viewed from outside)

Fig. 9

Spindle orientation for left-handed door

Latch hub

(viewed from outside)

NOTES:

A. The interior lock assembly is set for right-handed doors from the factory. You should only

need to set the handedness of this unit if your door is left-handed.

B. The exterior lock assembly is already set for left-handed doors from the factory.

Interior Lock Assembly

1. Hold the interior handle assembly as it would be oriented for the handedness and swing of the

door to determine the correct handle orientation.

2. Loosen the set screw (see Fig. 10) and rotate the handle to its correct horizontal position if

necessary (see Fig. 11). Tighten the set screw to maintain handle position.

3. Check that the lever handle now turns in a clockwise direction and returns freely.

4. Viewing the interior handle assembly from the back, note the blue handing screw's location—

right side for left-handed and left side for right-handed doors (see Fig. 11).

5. If necessary, remove and change the location of the blue screw depending on the orientation

of the interior handle.

Fig. 10

Set screw

Fig. 11

Left handed

Blue handing

screw

Right handed

SECO-LARM U.S.A., Inc. 5

Page 6

SECO-LARM Mechanical Keypad Door Lock

Mount the Lock:

Prepare the Lock for Mounting (Continued):

Select the appropriate screws depending on

handed doors, the

Outside

Inside

Neoprene seals

Exterior Handle Assembly

The handedness of the external handle assembly (default,

left-handed) will be set after installation.

Installing the Latchbolt Support Post

From the back of the exterior handle assembly, fit the latchbolt

support post in the correct position. For rightsupport post should be fitted on the left. For left-handed doors,

the support post should be fitted on the right (Fig. 12 and 13).

Fig. 12

Right-handed

Fig. 13

Left-handed

1.

Fig. 14

the door's thickness. For doors less than 17/8"

(48mm), use the shorter 17/16 (36mm) screws.

2. Fit the neoprene seals to both the exterior and

the interior handle assemblies (see Fig. 14).

3. Screw the two hexagonal mounting posts in

place to the exterior handle assembly (Fig. 14).

4. Hold the exterior handle assembly onto the

door with the spindle in place and ensure that

the latchbolt support post engages the hole in

the latchbolt assembly.

5. Hold the interior handle assembly in place on

the inside of the door so that the spindle is

properly set in the handle interior handle

assembly hub.

6. Screw both sides together using the machine

In-swing, left-handed door installation shown

Fig. 15

Hexagonal

mounting posts

Rotate

screws on the top and bottom.

7. Before final tightening of screws, make sure

the door lock is vertical. Test to make sure the

lock functions correctly and moves easily.

NOTE: DO NOT over-tighten the machine screws as this can lead to poor operation or damage

the lock assembly.

8. For right-handed doors, change the exterior lever handing at this time.

a. To prevent damage from forced entry the external handle is fitted with a clutch.

b. To change the handle's orientation, simply apply force to rotate the handle to its proper

handing (see Fig. 15).

9. Check that the set code is able to unlock the door before closing it to avoid being locked out.

6 SECO-LARM U.S.A., Inc.

Page 7

SECO-LARM Mechanical Keypad Door Lock

Install the Strike Plate:

Frame

Door

Frame

Door

User Operation:

Latchbolt

/16" (1

mm)

deep

deep

Partially close the door and mark where the

To unlock the door:

each key in the lock code in any order. The lock code is not sequential and therefore the

1.

latchbolt contacts the door frame.

2. Close the door. With the door in a closed

position, measure the distance from the

door latch to the edge of the door frame.

This is the door latch line. This is shown as

“X” in Figs. 16 and 17.

3. Open the door and mark the door latch line

on the frame.

4. Using the strike plate as a template, mark

the outer edges of the strike plate, the inner

hole and the screw holes.

5. Using a chisel, cut a

recess for mounting the strike plate so that it

1

/16" (1mm) deep

fits flush with the frame. (Fig. 18.)

6. Use the strike dust box as a template to

mark, drill, and chisel out the latchbolt hole

to a depth of at least 1/2" (13mm) to

accommodate the strike dust box (Fig. 18,

dotted lines).

7. Insert the strike dust box into place along

with the strike plate. Secure both with the

provided wood screws.

8. Test that the door closes easily and that

latchbolt fits securely into the strike plate

aperture. Ensure that that the deadlatch

(Fig. 19) does not enter the strike plate

aperture. If it does, loosen and reposition

the strike plate as necessary.

Fig. 16

Fig. 17

Fig. 18

Strike

plate

Fig. 19

X

X

Door latch

line

X

X

Door latch

line

1

1/2" (13mm)

Strike

dust box

Deadlatch

1. Press the "C" (clear) key to make sure that no keys are already pressed or partially pressed.

2. Press

keys can be pressed in any order. For example, if the lock code numbers are 135Y, any

combination of these numbers (Y135, 513Y, 3Y51, etc.) will unlock the door.

3. Turn the lever to open the door.

In case of an error or if the door doesn't unlock, press the "C" (clear) key and press the keys in the

lock code again.

SECO-LARM U.S.A., Inc. 7

Page 8

SECO-LARM Mechanical Keypad Door Lock

Troubleshooting:

16842 Millikan Avenue, Irvine, CA 92606

Website:

www.seco

-

larm.c

om

Phone: (949) 261

-

2999 | (800) 662

-

0800 Email: sales@seco

-

larm.com

PITSW9

MI_SD-962H-8LAQ_181224.docx

NOTICE

:

The SECO

-

LARM policy is one of continual development and improvement. For that reason, SECO

-

LARM

rademarks

Inc. All

LIMITED LIFETIME

WARRANTY:

This SECO

-

LARM product is warranted against defects in material and workmanship

LARM’s obligation is limited to the repair or replacement of any defective part if the unit is returned,

is caused by or attributed to acts of God, physical

ny

erly as a result of causes other than

and the purchaser’s exclusive remedy, shall be

le for any special,

For

IMPORTANT

:

that the installation and configuration of

Door Closers

Surface Mount

Recessed

-

Mount

Miniature Single

SD-C121-S shown

SM-

S200Q/W shown

SM-

207-5Q/BR shown

E-

964-S50TB shown

The code doesn't unlock the door.

The latch lever turns, but the latchbolt

does not retract

Also Available from

Magnetic Contacts

Press the "C" (clear) key and enter the passcode again.

Ensure that each key (including the "C" key) has been fully

pressed.

Remove the lock and the lock code plate to ensure that each

letter/digit in the chosen code is represented by a red code

tumbler and all other code tumblers are blue.

Remove and reinsert the code tumblers, ensuring that they are

correctly oriented and fully inserted.

The spindle used is too short for the door's thickness. The

spindle must be long enough to simultaneously engage both

the interior and exterior levers. Use a longer spindle.

®

:

Magnetic Contacts

Photobeam Sensors

this product complies with all national, state, and local laws and codes related to locking and egress devices. SECO-LARM

will not be held responsible for the use of this product in violation of any current laws or codes.

while used in normal service for the lifetime of the product (one (1) year from the date of sale to the original customer for

the finish). SECOtransportation prepaid, to SECO-LARM. This Warranty is void if damage

or electrical misuse or abuse, neglect, repair or alteration, improper or abnormal usage, or faulty installation, or if for a

other reason SECO-LARM determines that such equipment is not operating prop

defects in material and workmanship. The sole obligation of SECO-LARM

limited to the replacement or repair only, at SECO-LARM’s option. In no event shall SECO-LARM be liab

collateral, incidental, or consequential personal or property damage of any kind to the purchaser or anyone else.

products sold in countries other than the US, the warranty is 1 (one) year from the date of sale to the original customer.

reserves the right to change specifications without notice. SECO-LARM is also not responsible for misprints. All t

are the property of SECO-LARM U.S.A., Inc. or their respective owners. Copyright © 2018 SECO-LARM U.S.A.,

rights reserved.

Users and installers of this product are responsible for ensuring

®

U.S.A., Inc.

8 SECO-LARM U.S.A., Inc.

Loading...

Loading...