Page 1

Installation Manual

®

ENFORCER

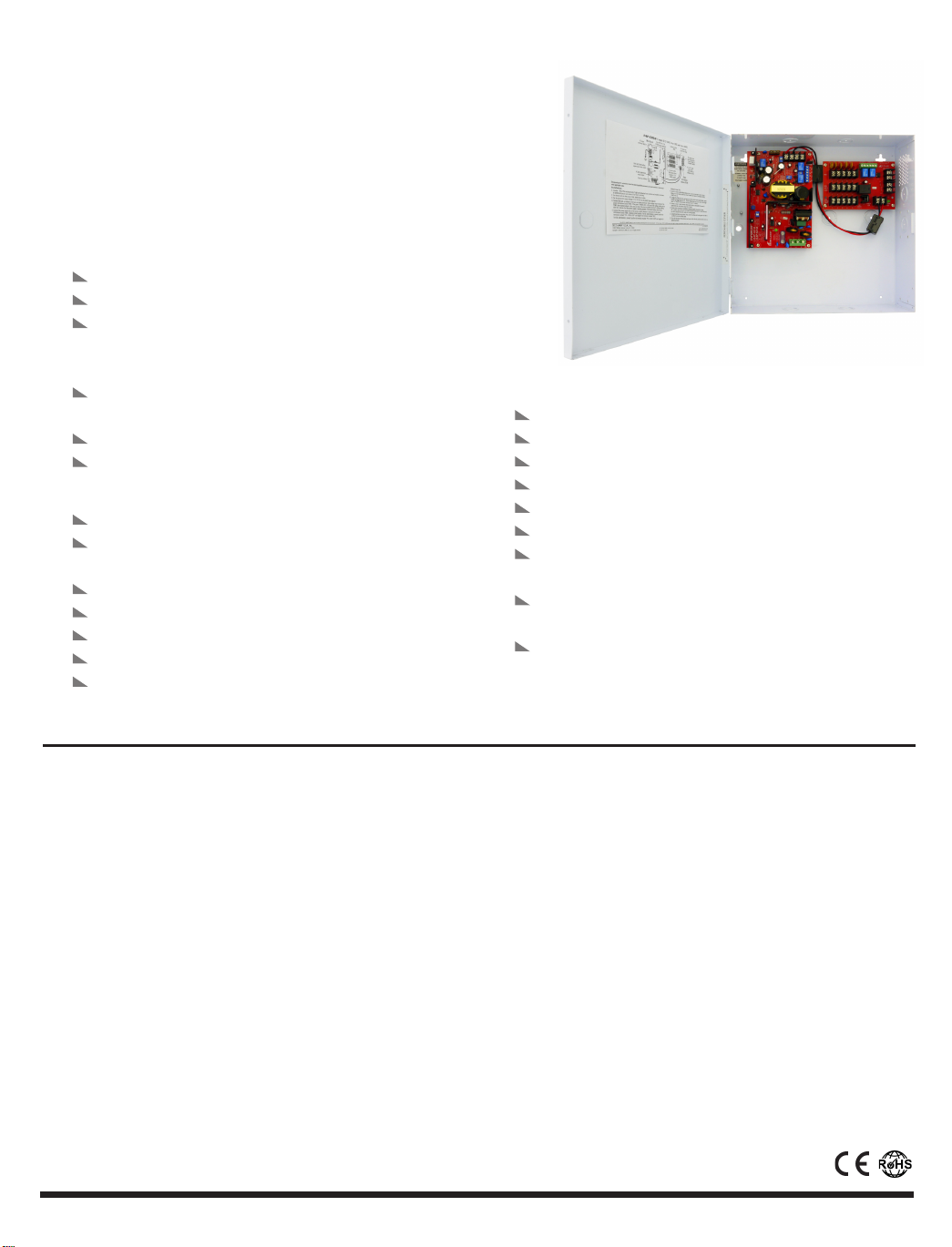

EAP-5D5Q (5A@12VDC, 2.5A@24VDC)

Access Control Power Supply

SPECIFICATIONS:

POWER:

Input: 110~240VAC.

Output: Field selectable 12VDC or 24VDC output.

Five individually fused (PTC*-type fuses) power

outputs. Each output operates both in fail-safe and

fail-secure modes.

Each individually fused (PTC*-type fuses) output

rated at 1.1 Amp.

AC input fuse rated at 3.15 Amps (glass fuse).

Filtered and electronically regulated outputs.

ENCLOSURE:

Heavy-duty steel case to protect the power connections.

Removable steel cover for easy access to power

connections.

Ventilation holes to prevent heat build-up.

Room for two 7AH batteries (not included).

6-foot power cord and battery leads included.

Dimensions - 121/8"x121/4"x

Knock-out on the cover for optional cam lock.

* Positive Temperature Coefficient

39/16"(308x311x90 mm).

FEATURES:

AC power failure supervision relay.

Battery fail / low battery supervision relay.

DC output fail supervision relay.

Auxiliary output relay.

Adjustable voltage range to compensate for voltage drop.

Built-in back-up battery charger (batteries not included).

DIP switch selectable 2.2kΩ End-of-Line (EOL) resistor for

AC failure and battery failure supervision relays.

DIP switch selectable delay timer (5 sec., 5 min., 5 hours)

for AC failure supervision relay.

LED status indicator for AC input, DC outputs, and

channel outputs.

What it is:

The ENFORCER Access Control Power Supply centralizes the power

sources for multiple 12 or 24 VDC-powered electronic locks or

accessories used in access control system. The power input and all fused

power outputs are enclosed in one heavy-duty, easy-to-install enclosure.

As a result, an ENFORCER Access Control Power Supply can replace

multiple separate individual power sources.

Note before installation:

The ENFORCER Power Supply is not waterproof or weatherproof.

Therefore, it must be mounted indoors where it cannot be exposed to

rain or other moisture.

Installation must be done by qualified personnel, and should

conform to local and all other applicable codes.

Installation:

1. Find a good location for the enclosure. The enclosure should be

mounted where it is out of sight and protected from moisture and

the weather, but where an authorized person can have access for

servicing in the future.

Note: Products with model numbers that end with "Q" or that have a round green “Q” sticker are RoHS compliant.

NOTE: Make sure the space where the enclosure is to be

mounted has adequate ventilation. Otherwise, heat buildup inside

the enclosure could damage the electronic parts or cause the PTC

fuses to trip needlessly.

2. Locate the enclosure mounting holes. Using these holes as a

template, mark the location of the 4 screws on the wall with a

pencil. First fasten two

included) until the gap between the wall and the screw head is

approximately 1/4" (6mm). Hang the enclosure on the 2 screws

using the enclosure's upper screw holes and adjust the proper

location of the enclosure. Then securely fasten the upper and

lower screws. Use larger sized screws if backup batteries will be

placed inside the enclosure.

5

/32" x 1" (4 x 26mm) upper screws (not

Page 1

Page 2

Access Control Power Supply Installation Manual Access Control Power Supply Installation Manual

Knock-out

for optional

cam lock

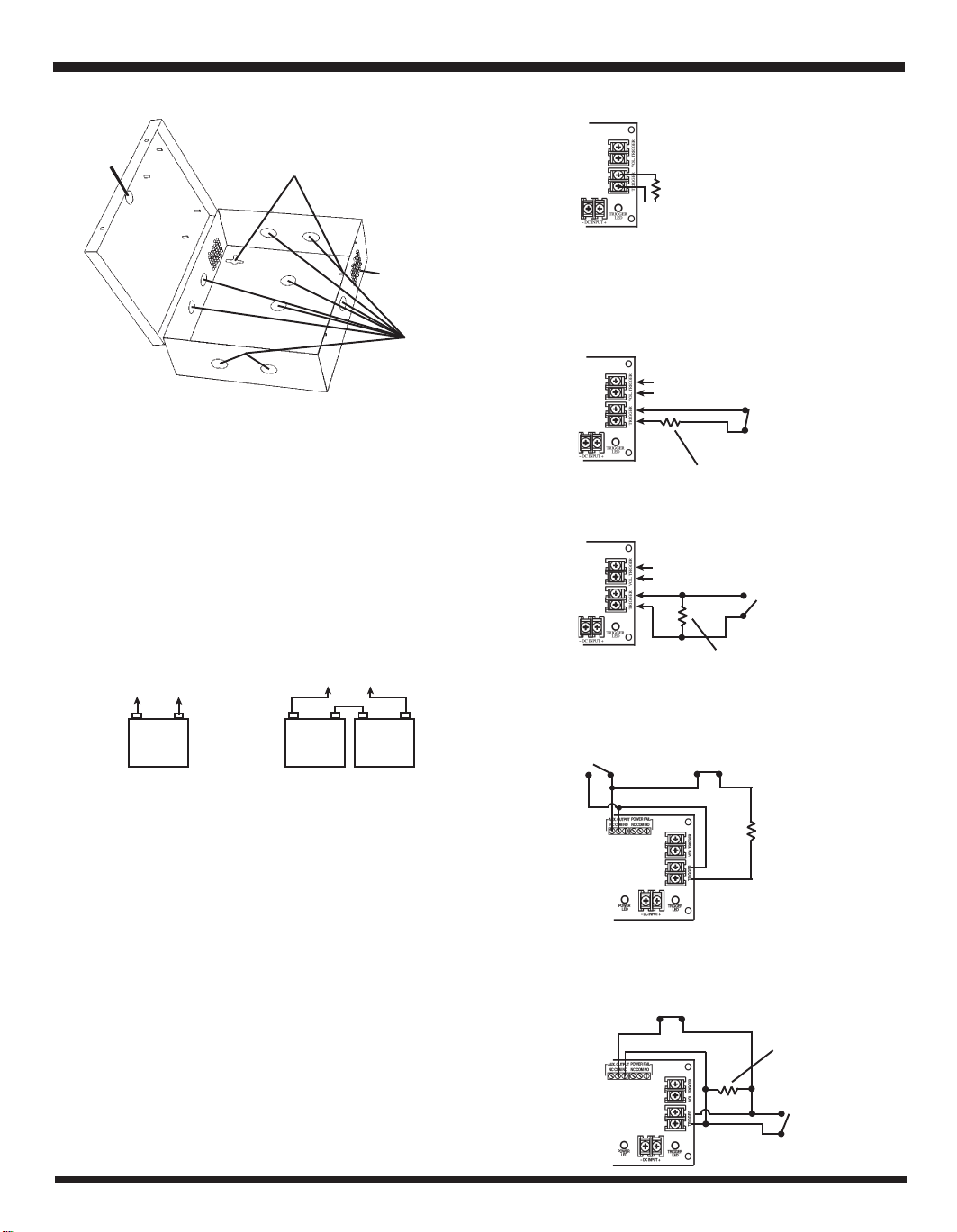

FIG. 1

Enclosure

Mounting Holes

Ventilation

Holes

Cable &

Power

Knock-outs

NOTE: For concrete walls, first drill four holes on the concrete wall in

the location of the screws. Then insert a "plastic anchor" in each of the

holes before fastening the screws.

3. Set the desired DC output voltage (12 or 24 VDC) via DIP switch (see Fig.10).

4. Connect the back-up battery (not included) to the back-up battery

terminal (see Fig.2 & Fig.10). Check the voltage output reading of the

Power Distribution Module (PDM). If the “POWER LED” is ON, and if the

voltage reading of the PDM's five channel output is the same as that of

the back-up battery terminal's voltage reading, then this indicates that the

power supply is working properly. Disconnect battery after testing.

Fig. 2 – Back up battery configuration.

+

12 VDC

Battery

24 VDC

-

+

12 VDC

Battery

-

12 VDC

+

12 VDC

Battery

-

Fig. 3

2.2kΩ (EOL)

resistor

8. Follow the connection diagrams shown on Fig. 4~9 to trigger the PDM

from a wet and/or dry contact switch from the control station:

Fig. 4 – Momentary trigger wiring diagram for wet and / or dry N.C. switch.

DC voltage input from control station

N.C.

switch

2.2kΩ (EOL) resistor(supplied)

Fig. 5 – Momentary trigger wiring diagram for wet and / or dry N.O. switch.

DC voltage input from control station

N.O.

switch

2.2kΩ (EOL) resistor(supplied)

Fig. 6 – Latch trigger wiring diagram for wet and / or dry N.C. switch.

N.O. switch

for RESET

N.C. switch from access

control panel

5. Connect the power input wires of the access control devices or

accessories to the Power Distribution Module (PDM) (see Fig.10). Observe

correct polarity. For fail-secure devices, connect positive to terminals

marked "POS. OPEN LOOP" and negative to terminals marked "NEG."

For fail-safe devices, connect positive to terminals marked "POS. CLOSE

LOOP" and negative to terminals marked "NEG".

Maximum total current connected to all terminals must not exceed the

power supply's total current capacity (see Table 1).

6. Connect a visual or audio indicator device (such as siren or strobe light)

to the AC-fail and battery-fail / low battery supervision relays if needed

(see Fig.10). Use between 22AWG to 18AWG wire size.

7. Connect a visual or audio indicator device (such as siren or strobe light)

to the power fail supervision relay and Auxiliary output relay if needed

(see Fig.10). Use between 22AWG to 18AWG wire size.

IMPORTANT NOTE: If the "TRIGGER" terminal block

function is not going to be used, then a 2.2kΩ

resistor must always be connected to the "TRIGGER"

terminal block as shown below in Fig.3.

Page 2

2.2kΩ (EOL)

resistor (supplied)

Fig. 7 – Latch trigger wiring diagram for wet and / or dry N.O. switch.

N.C. switch

for RESET

2.2kΩ (EOL)

resistor (supplied)

N.0. switch from access

control panel

Page 3

Fig. 8 – Multiple PDM momentary trigger wiring diagram for wet and / or dry

N.O. switch.

For Additional

PDM if needed

DC voltage

Second

PDM

2.2kΩ

(EOL) resistor

(supplied)

First

PDM

input from

control station

2.2kΩ (EOL)

resistor (supplied)

N.O.

switch

IMPORTANT:

a. To avoid risk of electrical shock, the ground terminal of the

"AC INPUT" MUST be connected to earth via the power cord.

b. The included core clamp must be installed on the power cord as

shown below.

Clamp core

Fig. 9 – Multiple PDM momentary trigger wiring diagram for wet and / or dry

N.C. switch.

For Additional

PDM if needed

DC voltage

Second

PDM

2.2kΩ

(EOL) resistor

(supplied)

NOTE: Output LEDs on the PDM will turn ON when fuse

has been tripped.

First

PDM

input from

control station

2.2kΩ

(EOL) resistor

(supplied)

N.C.

switch

9. Double check connections to ensure everything is connected properly.

10. Connect the AC power (110~240VAC). The AC LED and DC LED on the

mainboard and the power LED on the PDM should turn ON to indicate the

power supply unit is working properly.

11. Connect the back-up battery wiring. Check the voltage output reading of

the PDM to ensure it is within the normal working range.

Table 1: Max. supply current chart

Model

EAP-5D5Q

Max. supply

current at

12VDC

5 Amp.

Max. supply

current at

24VDC

2.5 Amp.

Power cord

Programmable/Adjustable Features:

A. AC-failure Relay Output Delay Timer — Programmable AC-failure

relay delay timer can be set at 5 sec., 5 min. or 5 hr. using the DIP

switch. See Fig. 10. Default setting is at 5 sec.

B. 2.2k

Ω End-of-Line (EOL) resistor — End-of-line 2.2kΩ resistor for

AC-failure relay and battery-failure / low battery supervision relays

can be activated independently using the DIP switch. See Fig. 10.

C. Battery presence and low battery monitor — When the LB MODE

DIP switches are in the ON position, the power supply will monitor

the battery to verify if it has sufficient voltage to run the power

supply in case of AC power failure. It can take up to 5 minutes to

send a battery failure alert. The length of time the system will run

will be limited by the overall capacity and the age of the batteries

and the amount of load being drawn off the power supply. See

Fig. 10.

D. VR1 rotary knob for DC voltage output adjustment -- Use to increase

or decrease the voltage of the outputs. Measure voltage output at

the device located furthest from the power supply.

Table 2: Terminal Functions

Mainboard

Terminal Legend

A E N

BAT. FAIL

AC FAIL

-

BAT +

-

DC +

Functions

To connect 110~240 VAC power. ( "A" for active wire, "E" for earth or ground wire, and "N" for neutral wire)

Used to notify battery failure. Dry contact relay rated at 3Amp.@24VDC. If back-up battery is not connected properly or if voltage output falls below 10.8VDC for 12VDC

setting (or 21.6VDC for 24 VDC setting), the connected warning device will be activated.

Used to notify loss of AC power. Dry contact relay rated at 3Amp.@24VDC

If AC power is cut-off, the connected warning device will be activated.

Used to charge the back-up battery. Maximum charging current is 3.5 Amp.

12 or 24VDC output terminal from main board.

Page 3

Page 4

Access Control Power Supply Installation Manual

Power Distribution Module (PDM)

Terminal Legend

TRIGGER

Functions

Used to connect N.O. or N.C. input trigger signal (2.2kΩ EOL resisitor) from access control panel.

A short or open circuit will transfer power from "POS. CLOSE LOOP" to "POS. OPEN LOOP.

VOL. TRIGGER

POWER FAIL

AUX OUTPUT

-

DC INPUT +

Used to connect wet (5-30VDC) input trigger signal from access control panel.

A short or open circuit will transfer power from "POS. CLOSE LOOP" to "POS. OPEN LOOP.

U

sed to notify loss of DC power. Dry contact relay rated at 3Amp.@24VDC

If VDC input to the PDM is interrupted, the connected warning device will be activated.

Used to activate other auxiliary device when trigger signal is received from the "TRIGGER" or "VOL TRIGGER" terminals.

12 or 24 VDC input from main board.

FIG.10: Power Connections and Dip Switches for Mainboard & Power Distribution Module (PDM)

Five Fail-Safe &

Fail-Secure Fused

Outputs at 12 or 24VDC output

AC input

MainboardMainboard

Mainboard

MainboardMainboard

Auxiliary Output Relay

DC Power Fail Supervision

LB MODE

ON PRESENT

OFF FAIL

EOL RES

1 2

ON OΩ OΩ

OFF 2.2KΩ

AC FAIL Timer

1 2

5H OFF OFF

5m ON OFF

5s ON ON

V. OUT.

ON 24V

OFF 12V

1

Battery presence

OFF

and low battery

NO

ON

monitor DIP switch

OFF

ON

NO

End-of Line (EOL)

1 2

2.2kΩ resistor

DIP switch

NO

AC failure delay

1 2

timer DIP switch

ON

OFF

VR1 rotary knob for DC

output voltage range

adjustment

NO

ON

DIP switch for 12 or

24 VDC output selection

1

OFF

Back-up

battery terminal

DC output

terminal block

Terminal Block

Relay

PowerPower

Power

PowerPower

DistributionDistribution

Distribution

DistributionDistribution

Module (PDM)Module (PDM)

Module (PDM)

Module (PDM)Module (PDM)

Parts List

2 x Screws for the enclosure door

1 x Plastic cable clamp (to secure power cord)

1 x Nut (to fasten cable clamp)

1 x Plastic snap bushing

3 x Wires for back-up battery

(red, black, white)

1 x Spare glass fuse (for AC input)

1 x Spare 5A blade fuse

(for back-up battery input)

1 x Clamp core (for power cord)

1 x 6-ft. power cord with ground wire

Ω

resistor

1 x 2.2k

DC voltage input signal from

Access Control Station

or emergency switch

N.C. or N.O. input from

Access Control Station

or emergency switch

Note: If an overload occurs, such as the total current connected to the power supply exceeds the power supply's total current capacity, the

mainboard's voltage output will start to drop. The voltage drop will depend on the extent of the overload. The greater the overload the bigger the output

voltage drop. If the overload is extensive, the voltage output will become intermittent and the red LED will start flashing. When the overload is

removed, the mainboard will automatically restart normal output.

If an output short-circuit occurs, the mainboard will automatically shut the output down and the red LED will turn off. When the short-circuit is

removed, the mainboard will automatically come back on line.

The SECO-LARM® policy is one of continual development and improvement. For that reason, SECO-LARM reserves the right to change specifications without notice. SECO-LARM is not responsible for misprints.

WARRANTY: This SECO-LARM product is warranted against defects in material and workmanship while used in normal service for a period of one (1)

year from the date of sale to the original consumer customer. SECO-LARM’s obligation is limited to the repair or replacement of any defective part if the unit is

returned, transportation prepaid, to SECO-LARM.

This Warranty is void if damage is caused by or attributed to acts of God, physical or electrical misuse or abuse, neglect, repair, or alteration, improper or

abnormal usage, or faulty installation, or if for any other reason SECO-LARM determines that such equipment is not operating properly as a result of causes other

than defects in material and workmanship.

The sole obligation of SECO-LARM, and the purchaser’s exclusive remedy, shall be limited to replacement or repair only, at SECO-LARM’s option. In no event

shall SECO-LARM be liable for any special, collateral, incidental, or consequential personal or property damages of any kind to the purchaser or anyone else.

SECO-LARMSECO-LARM

SECO-LARM

SECO-LARMSECO-LARM

®

U.S.A., Inc., U.S.A., Inc.,

U.S.A., Inc., 16842 Millikan Avenue, Irvine, CA 92606

U.S.A., Inc., U.S.A., Inc.,

Tel: 800-662-0800 / 949-261-2999 Fax: 949-261-7326

Page 4

Website: www.seco-larm.com

@

E-mail: sales

Copyright 2011 SECO-LARM U.S.A., Inc. All rights reserved.

seco-larm.com

MiEAP-5D5QUS_1110.pmd

Order Part #764-034-2%

PITSW1

Loading...

Loading...