Ares 3 system

Operators Guide

Professional Fluid Head & Tripod

SC-Video-10/100VP

SC-ENG/CF 100M

Read this first before using and save it

www.secced.com

Copyright Beijing Secnovo Co., Ltd 2007

All right reserved throughtout the world. No part of this document may be stored in a retrieval system,

transmitted, copied or reproduced in any way including, but not limited to, photocopy, photograph,

magnetic or other record without the prior agreement and permission in writing of

Beijing Secnovo Co., Ltd

Secced is registered trademark of Beijing Secnovo Co., Ltd

Printed in People Republic of China by Secnovo, Beijing.

C

Ares 3

Fluid Head & Tripod

SC-Video-10/100VP

SC-ENG/CF 100M

Fluid Head

Page 3

Tripod

Page 15

Mid-level Spreader

Page 26

Page 22Floor spreader

Safety – Read this first

Warning Symbols in this Operators Guide

Where there is a risk of personal injury, injury to others, or damage to the Ares 3

system or associated equipment, comments appear, highlighted by the word.

WARNING! And supported by the warning triangle symbol.

1

Technical Data

Further information

For further information or advice regarding this Ares 3 system, please contact

Beijing Secnovo Co., Ltd or your local distributor.

For full details on maintenance and spare parts, please refer to the Ares 3 system

Maintenance Manual and Illustrated Parts List. This is obtainable from

Beijing Secnovo Co., Ltd or your local distributor.

www.secced.com

Fluid Head

Tripod

Weight(complete with pan bar and bowl clamp) 3 kg / 6.6 lb

Payload range 5 to 10kg / 11 to 22lb

Counterbalance 0 to 4 step

Blance plate 60mm

Grades of drag

Horizontal 0 to 3 grades

Vertical 0 to 3 grades

Tilt range -75 to +90 under maximum payload capacity

Diameter of bowl 100mm

Weight 3.9kg / 8.6lb

Payload capacity 40kg / 88lb

Height 40-150cm

2

Introduction

The Ares 3 system include SC-Video-10/100VP fluid head, SC-ENG/CF 100M tripod,floor spreader

and padded bag.

The SC-Video-10 /100VP embodies 5 steps counterbalancing mechanism and the adjustable drag

aseemblies for pan and tilt motions.

The balance system is easily adjusted by a knob on the right-hand side of the head. The drag

system ensures smooth movement of the camera about pan and tilt axes and are fitting with

control knobs to adjust the drag setting.

Friction brakes on each axis allow the head to be locked at any position. The camera is attached

to the

head by means of a Quicklock wedge fitted into camera plate of head.

The SC-ENG/CF 100M features the fast clamping mechanism for locking the leg. The rubber foot,

dolly and floor spreader are available as accessories. The 100mm bowl base is an ideal support

for 100mm fluid head of all brands.

3

Fluid Head

SC-Video 10/100VP

Contents

Operation ……………………………………………… Page 6

Installing the head on a tripod ……………………………………………… Page 6

Opening the pan bar ………………………………………………………… Page 7

Mounting the camera ……………………………………………………… Page 9

Balancing the head ………………………………………………………… Page 11

Pan and tilt brakes ………………………………………………………… Page 13

Pan and tilt drag ………………………………………………………… Page 13

Servicing ……………………………………………… Page 14

Routine maintenance ……………………………………………………… Page 14

Cleaning ………………………………………………………………… Page 14

4

SC-Video 10/100VP (Left-Hand Side)

Fig 1

(1) Slide plate clamp

(2) Tilt drag adjustment knob

(3) Pan drag adjusment knob

(4) Bowl clamp

(5) Pan bar mounting

(6) Tilt brake knob

(7) Pan brake knob

(8) Head bowl

(1)

(6)

(5)

(3)

(4)

(2)

(7)

(8)

5

SC-Video 10/100VP (Right-Hand Side)

Fig 2

(9) Quick release knob

(10) Balance knob

(11) Level bubble

(12) Quicklock wedge

(13) Pan bar clamping sleeve

(14) Pan bar clamping lever

(9)

(10)

(11)

(12)

(13)

(14)

6

Operation

Installing the head on a tripod

The Ares 3 fluid head is supplied with an integral 100mm ball mount, designed for installation

on a compatible Secnovo tripod.

To install the head, remove the bowl clamp (4) from the head (turn bowl clamp anti-clockwise

as in Figure 3), position the head on the tripod and

refit the bowl clamp from below. Level the

head with aid of level bubble (11) and apply the bowl clamp (turn bowl clamp clockwise as

in Figure 3).

Fig 3

Installing the head on a tripod

Ares 3 head (SC-Video 10/100VP)

Ares 3 tripod (SC-EN/CF 100M)

(4)

Loosen the bowl clamp (Anti-clockwise)

Tighten the bowl clamp (Clockwise)

Opening the pan bar

Open the black clamping lever (14) of the pan bar and move the pan bar into the desired position.

Apply the clamping lever of the pan bar. During transportation the pan bar can be moved next to

the tripod legs.

WARNING! Open the clamping lever of the pan bar far enough. The teeth of the pan bar

clamp should not clatter while moving the pan bar. However, a plastic protector,

clamping washer (15) prevents against wear of metal toothed ring. Make sure that

the teeth interleave with each other when closing the clamping lever of the pan bar.

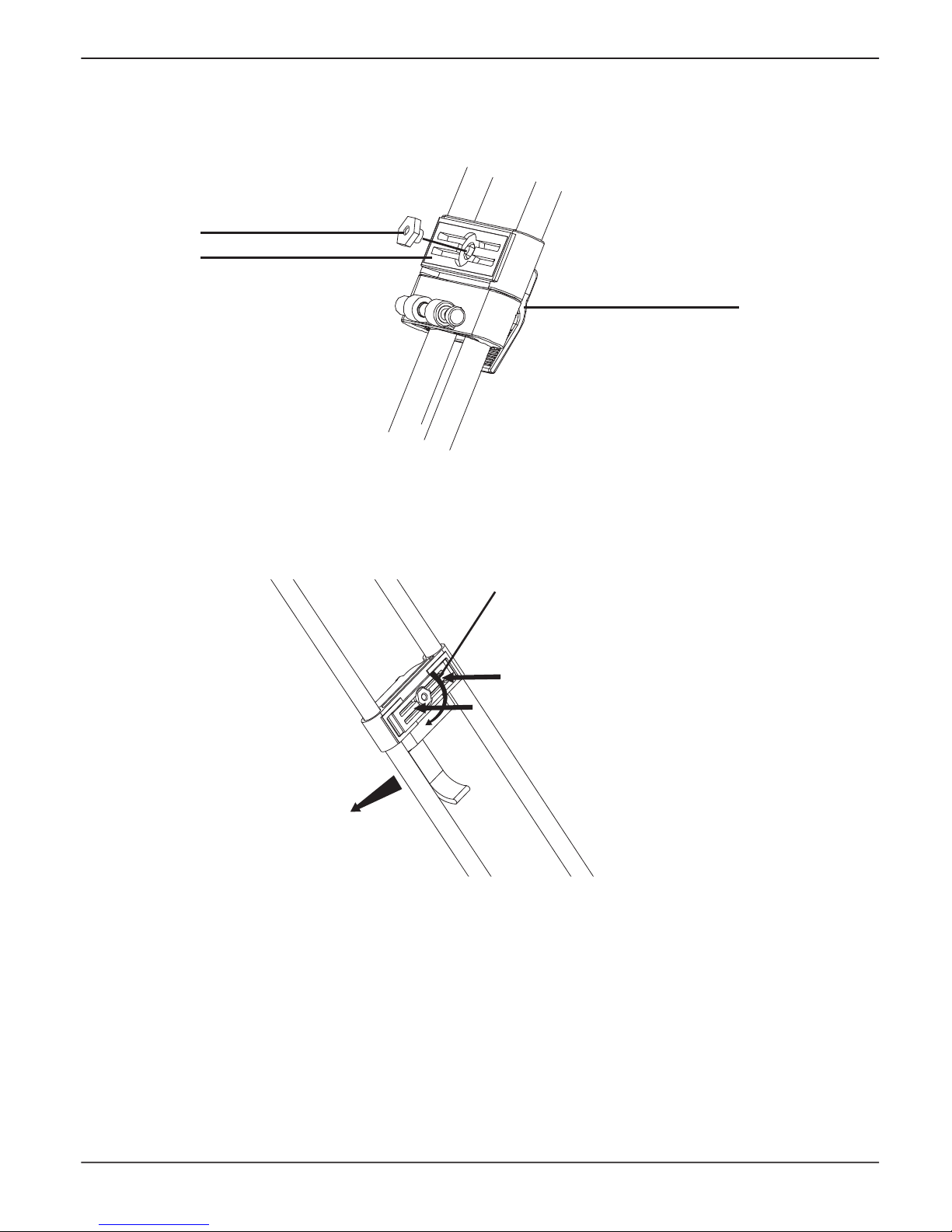

Fig 4

Installing the pan bar on a head

7

(16)

(15)

(14)

(13)

Tighten the clamping lever (Clockwise)

Fig 5

Use of the enclosed pan bar on the left side of the fluid head is also possible. For this, it is

advisable to relocate the clamp on the pan bar. The pan bar has to be removed from the head

and the black plastic cap (16) on its top should be opened and removed with a coin or screwdriver.

The toothed clamping sleeve (13) should be removed and relocated as in Figure 5. The plastic

screwed cap need to be tightened again.

(16)

(13)

Left-handed pan bar

8

Tighten the tilt brake before mounting the camera

Free the Quicklock wedge (12) from slide plate (17) by pulling the locking button down (9.2)

and then operating the wedge-releasing lever (9.1) to another end.

Fit the wedge either to the camera or the camera adaptor with two screws provided. If using

the camera adaptor, just mount the camera on the camera adaptor after the wedge is attached

with the camera adaptor.

Mounting the camera

Fig 6

9

Pulling down (9.2)

Turning (9.2)

(9.1)

(9.2)

(12)

(17)

10

Insert the wedge into the camera plate until an audible click indicates that the Quicklock wedge

is locked in position.

WARNING! When mounting the camera/placing the wedge, make sure not to hold fingers

within the range of the locking lever (9.1) and camera plate receptacle, since the

lever may snap back.

When the camera is mounted, the bowl clamp must only be released if camera

and tripod are secured against falling away.

Fig 7

WARNING! No finger allowed here

Balancing the head

Balancing the head achieves two objectives. Firstly, when the head is correctly balanced the

operator will need a minimum amount of effort to move the head. Secondly, once balanced,

the head and its payload can be set to any tilt position and the head will maintain this position

with ‘hand off’.

Prior to balancing the head ensure that the pan bars and ancillary equipment have been fitted

in order to prevent upsetting the balance once it has been achieved.

WARNING! Be prepared to prevent the head falling away suddenly.

I. Release the tilt brake knob (6).

II. Turn the balance knob to position 0 and keep holding the camera.

III. Turn the tilt drag to position 0.

IV. Hold the camera in the horizontal position by securing the pan bar. Release

the slide plate clamp (1) and slide the camera backwards or forward until it

balances horizontally. Tighten the slide plate clamp.

V. Turn the balance knob to the number which best compensates for the weight of

the camera, i.e. for as little movement upward or downword in any position.

VI. Select the tilt drag level by turning the tilt drag adjustment knob (2). In the correctly chosen

position the camera should not perform any tilt movement.

Fig 8

I II

11

Release the tilt brake knob

Position 0

0

1

2

12

Fig 8 continued

III.

IV

V

VI

0

1

2

Position 0

1

2

3

4

0

1

2

3

Release slide plate clamp

Tighten slide plate clamp

Friction brakes (6,7) on each axis allow the head to be locked at any chosen position.

To apply the brake, turn the lever fully clockwise. To release the brake, turn the lever

counter-clockwise.

Pan and tilt brakes

WARNING! When the brakes are not in use, make sure the brakes is at the released status.

DO NOT use the brakes to supplement drag.

Both drag knobs (2,3) are provided with graduated scales.

By turning the vertical setting and the horizontal setting, selects the desired drag level.

Make sure that you always turn the setting to the next indexed position (arrow). Engage the

retainer pins by slowly panning or tilting the camera.

Pan and tilt drag

NOTE: Panning or tilting the camera with settings between the indexed positions can damage

the retainer pins and/or disks. Reduce drag to a minimum when the head is out of use

for long periods.

Release the tilt or

pan brakes

Tighten the tilt or pan brakes

Increase pan

or tilt drag

13

Fig 9

Servicing

14

Fig 10

Routine maintenance

During use, check the following

Check the condition of the clamping washer (15) and the pan bar clamping sleeve (13),

replace them if the teeth of the clamping washer and clamping sleeve are almost weared away.

Check the effectiveness of the slide plate, add some grease lubricant onto the slide plate if

slide plate do not move when tilting to +45° and -45° (as shown in Figure 10).

Check the effectiveness of the pan and tilt drag controls. Repair as necessary.

Check the effectiveness of the pan and tilt brake knob. Repair as necessary.

No further routine maintenance is required.

Cleaning

During indoor use the only cleaning required should be a regular wipe over with a lint-free cloth.

Dirt accumulated during storage may be removed using a semi-stiff brush. Particular attention

should be given to the leveling bowl and mounting face of the head.

Use out-of-doors under adverse condition will require special attention. Salt spray should be

washed off with fresh water at the earliest opportunity. Sand and dirt acts as an abrasive and

should be removed using a semi-stiff or vacuum cleaner.

NOTE: Use only detergent-based cleaners. DO NOT use solvent- or oil-based cleaners,

abrasives or wire brushers to remove accumulations of dirt, as these damage

the protective surfaces.

Tripod

Contents

Operation …………………………………………… Page 17

Servicing ……………………………………………… Page 19

Cleaning ………………………………………………………………… Page 19

Routine maintenance ……………………………………………………… Page 19

Adjusting the leg clamps …………………………………………………… Page 19

15

SC-ENG/CF 100M

16

SC-ENG/CF 100M Tripod

Fig 11

(18) Tripod bowl

(19) Top clamp assembly

(20) Bottom clamp assembly

(21) Floor spreader

(22) Locking clip

(23) Mid-level spreader attachment assembly

(24) Clamping knob

(18)

(19)

(22)

(23)

(24)

(20)

(21)

Operation

Lift the complete tripod and head out of the case and keep the floor spreader (21) attached

to the tripod.

Release the three locking clips (22), open out the legs while holding the legs. Gentle foot or hand

pressure on the spreader will ensure that the legs are fully spread.

NOTE:

Always use the spreader where possible as this increases rigidity of the tripod.

Being flexible, the spreader compensates for uneven ground. It can be removed

and a dolly fitted. At the fullest extension of the spreader and with all legs fully

retracted, the tripod can be used at its lowest operating height. Although the tripod

can be set up lower than this without the spreader, it is NOT recommended as

the tripod geometry becomes unstable.

(22)

Release the locking clips

Spread the legs

Fig 12

17

Adjust the operating height by undoing the leg clamps (19.1, 20.1) and pulling the tripod up to the

desired height. Adjust the spreader if necessary. Level the head with aid of the level bubble.

Apply the clamps (19.1, 20.1) to lock the tripod.

Pull up

(19.1)

Lift up to release

Press down to lock

(20.1)

Lift up to release

Press down to lock

18

Fig 13

Servicing

Routine maintenance

During normal use, check the effectiveness of the leg clamps and adjust as necessary.

Cleaning

During indoor use the only cleaning required should be a regular wipe over with a lint-free cloth.

Dirt accumulated during storage may be removed using a semi-stiff brush. Particular attention

should be given to the mounting bowl of tripod.

Use out-of-doors under adverse condition will require special attention. Salt spray should be

washed off with fresh water at the earliest opportunity. Sand and dirt acts as an abrasive and

should be removed using a semi-stiff or vacuum cleaner.

NOTE: Use only detergent-based cleaners. DO NOT use solvent- or oil-based cleaners,

abrasives or wire brushers to remove accumulations of dirt, as these damage

the protective surfaces.

Adjusting the leg clamps

Bedding-in occurs with leg clamps, which may necessitate resetting the clamp. Check the

effectiveness of each leg clamp as follows:

Extend all three tripod legs fully and apply the clamps.

Position each leg in turn vertically on a set of weighting scales.

Gradually apply body weight to the leg until either or both clamps begin to slip. Note the

reading on the scales at which this occurs.

A reading of less than 30 kg (66 lb) will necessitate adjustment.

19

Top clamp

Fig 14

20

(2) Press the leg lock board down

(1) Lift the top clamp up

(3) Tighten the screw with

a hexagon bow wrench (Clcokwise)

Adjust a top clamp as follows:

Lift the clamping lever (19.1) up. Press down the top leg lock board (19.2), use either

suitable spanner or hexagon box wrench to tighten the screw (19.3) (as shown in Fig 14).

(19.2)

(19.3)

(19.1)

Bottom clamp

Adjust a bottom clamp as follows:

Press the bottom clamp down (20.1) and use the suitable box wrench to tighen the screw

(20.2) as shown in Fig 15.

(20.1)

(20.2)

Fig 15

(2) Tighten 4 screws with

a hexagon bow wrench (Clcokwise)

(1) Press the bottom clamp down

21

Floor Spreader

Contents

SC-FS100

Operation …………………………………………… Page 24

Installing the floor spreader ……………………………………………… Page 24

Adjusting the spreader………………………………………………………Page 25

22

SC-FS100 Floor Spreader

Fig 16

(25) Foot retaining strap

(26) Clamping knob

(27) Inner leg

(28) Outer leg

(29) Lift ring

(30) Core connecting assembly

(31) Foot support

(25)

(26)

(27)

(30)

(31)

(28)

(29)

23

(31)

(25)

(32)

Fig 17

Operation

Installing the floor spreader

To install a floor spreader onto a tripod proceed as follows:

Unfold legs of spreader and place flat on the ground. Ensure three clamping knobs (26) are

engaged.

Lower tripod onto the spreader and locate the spike (32) onto the three foot supports (31).

Secure tripod onto spreader by engaging three foot retaining straps (25) to each foot of the

spreader.

(26)

24

Adjusting the spreader

NOTE: Always use the spreader where possible as this increases rigidity of the tripod. At the

full extension of the spreader and with all legs fully retracted, the tripod can be used

at its lowest operating height. Although tripods can be set lower than this without

spreader, it is NOT recommended as the tripod geometry become unstable.

NOTE: Floor spreaders protect floors and carpets as well as protecting the tripod legs sinking

into soft ground and should be used at all time. If the floor spreader cannot be used,

use secnovo rubber feet and middle-level spreader.

Once the tripod is installed, the floor spreader can be adjusted as follows:

Slacken three clamping knobs (26) on spreader.

Set legs of tripod to required position and height and ensure they are locked.

Once the tripod is positioned correctly, apply three clamping knobs. The spreader does not have

to be removed when collapsing the tripod.

Tighten the clamping knob (Clockwise)

Release the clamping knob (Anti-clockwise)

(26)

Fig 18

25

Mid-Level Spreader

SC-MS100

Contents

Operation …………………………………………… Page 28

Installing the mid-level spreader ………………………………………… Page 28

Adjusting the spreader………………………………………………………Page 29

26

SC-MS100 Mid-level Spreader

Fig 19

(33) Spread-locking knob

(34) Extension release knob

(35) Attachment head

(36) Outer arm

(37) Inner arm

(38) Attachment assembly

(33)

(34)

(36)

(37)

(35)

(38)

27

Operation

Installing the mid-level spreader

The spreader may be installed on any tripod provided with attachment points.

To install the spreader

Grip the ends of each arm in turn and press in the attachment release buttons (38.1) on

the tripod.

Push the arm into the tripod attachment point (38.2) until the arm engages.

The rubber foot has to be used when adopting the mid-level spreader, just locate the spike

(32)

onto the three rubber feet (39) and engage the three foot retaining straps (25) to each foot of

tripod

NOTE:

Ensure the open slot of attachment upward.

(38.1)

(39)

(38.2)

Installing the mid-level spreader

(32)

(35)

Fig 20

(25)

28

Adjusting the spreader

There are two controls on the spreader.

Spread-locking knob (33) and extension release knob (34)

Spread-locking knob locks the mid-level spreader in position. With the particular length of arm,

by turning the spread-locking knob, the height of the spreader can be adjusted

The spreading scope of tripod can be adjusted by turning the spread-locking knob.

Extension release knobs are fitted on each arm of the mid-level spreader. When slackened, the

arm can be extended or retracted. This facility is particularly useful when the tripod is in use on

uneven ground.

Fig 21

Retracting the arm

Extending the arm

(34)

(33)

29

Loosen the extension release knob (Anti-clockwise)

Tighten the extension release knob (Clockwise)

30

Parts List

The following lists include main assemblies, user-replaceable spare parts and optional accessories.

For further information regarding repair or spare parts, please contact Beijing Secnovo Co., Ltd or

your local distributor.

For information on-line,visit our website at

www.secced.com

Main assemblies

User-replaceable spare parts

Ares 3 Fluid head SC-Video 10/100VP

Ares 3 Tripod SC-ENG/CF 100M

Pan bar SC-PB 15

Floor spreader SC-FS100

Padded bag

Mild-level Spreader SC-MS100

Rubber foot SC-RF 100

Camera Plate(3940) SC-VCT-U18

Camera Plate(3950) SC-VCT-18

Dolly SC-Dolly 100L

Dolly SC-Dolly 100H

Battery

Brake knob

Optional accesseries

Printed in China

Beijing Secnovo Co., Ltd

Loading...

Loading...