Page 1

Consultation with SebaKMT

Abwassernetze

User Manual

Noise Level and Frequency Logger

Sebalog N3

Mess- und Ortungstechnik

Measuring and Locating Technologies

Elektrizitätsnetze

Power Networks

Kommunikationsnetze

Communication Networks

Rohrleitungsnetze

Water Networks

Sewer Systems

Leitungsortung

Line Locating

1 (08/2011) - ENG

1

Page 2

Consultation with SebaKMT

2

Page 3

Consultation with SebaKMT

Consultation with SebaKMT

The present system manual has been designed as an operating guide and for

reference. It is meant to answer your questions and solve your problems in as fast and

easy a way as possible. Please start with referring to this manual should any trouble

occur.

In doing so, make use of the table of contents and read the relevant paragraph with

great attention. Furthermore, check all terminals and connections of the instruments

involved.

Should any question remain unanswered, please contact:

Seba Dynatronic

Mess- und Ortungstechnik GmbH

Dr.-Herbert-Iann-Str. 6

D - 96148 Baunach

Phone: +49 / 9544 / 68 – 0

Fax: +49 / 9544 / 22 73

E-Mail: sales@sebakmt.com

http://www.sebakmt.com

Hagenuk KMT

Kabelmesstechnik GmbH

Röderaue 41

D - 01471 Radeburg / Dresden

Phone: +49 / 35208 / 84 – 0

Fax: +49 / 35208 / 84 249

SebaKMT

All rights reserved. No part of this handbook may be copied by photographic or other means unless SebaKMT

have before-hand declared their consent in writing. The content of this handbook is subject to change without

notice. SebaKMT cannot be made liable for technical or printing errors or shortcomings of this handbook.

SebaKMT also disclaim all responsibility for damage resulting directly or indirectly from the delivery, supply, or

use of this matter.

3

Page 4

Terms of Warranty

Terms of Warranty

SebaKMT accept responsibility for a claim under warranty brought forward by a

customer for a product sold by SebaKMT under the terms stated below.

SebaKMT warrant that at the time of delivery SebaKMT products are free from

manufacturing or material defects which might considerably reduce their value or

usability. This warranty does not apply to faults in the software supplied. During the

period of warranty, SebaKMT agree to repair faulty parts or replace them with new parts

or parts as new (with the same usability and life as new parts) according to their choice.

SebaKMT reject all further claims under warranty, in particular those from consequential

damage. Each component and product replaced in accordance with this warranty

becomes the property of SebaKMT.

All warranty claims versus SebaKMT are hereby limited to a period of 12 months from

the date of delivery. Each component supplied by SebaKMT within the context of

warranty will also be covered by this warranty for the remaining period of time but for 90

days at least.

Each measure to remedy a claim under warranty shall exclusively be carried out by

SebaKMT or an authorized service station.

To register a claim under the provisions of this warranty, the customer has to complain

about the defect, in case of an immediately detectable fault within 10 days from the date

of delivery.

This warranty does not apply to any fault or damage caused by exposing a product to

conditions not in accordance with this specification, by storing, transporting, or using it

improperly, or having it serviced or installed by a workshop not authorized by SebaKMT.

All responsibility is disclaimed for damage due to wear, will of God, or connection to

foreign components.

For damage resulting from a violation of their duty to repair or re-supply items,

SebaKMT can be made liable only in case of severe negligence or intention. Any liability

for slight negligence is disclaimed.

4

Page 5

Contents

Contents

Consultation with SebaKMT ........................................................................................... 3

Terms of Warranty ........................................................................................................... 4

Contents ........................................................................................................................... 5

1

1.1

1.2

1.3

2

3

3.1

3.2

3.3

3.4

3.5

4

Technical description ...................................................................................... 7

Technical data .................................................................................................... 9

Scope of delivery and accessories ................................................................... 12

Optional accessories ........................................................................................ 12

Important and common terms ...................................................................... 13

The loggers ..................................................................................................... 15

Function ............................................................................................................ 15

Design .............................................................................................................. 16

Switching on and off ......................................................................................... 17

Memory............................................................................................................. 17

Power supply .................................................................................................... 17

The Commander ............................................................................................. 18

4.1

4.2

4.3

4.4

4.5

4.6

4.6.1

4.6.2

4.7

4.8

4.8.1

4.8.2

4.8.3

4.8.4

4.9

4.10

4.11

4.12

Function ............................................................................................................ 18

Device design ................................................................................................... 19

Design of the user interface ............................................................................. 20

Basics of operation ........................................................................................... 21

User mode ........................................................................................................ 23

Making a connection ........................................................................................ 24

Connection between the Commander and logger ........................................... 24

Connection between the Commander and PC................................................. 24

Switching on the display lighting ...................................................................... 25

System settings ................................................................................................ 25

Basic settings ................................................................................................... 26

Extended settings in Professional mode .......................................................... 27

System info ....................................................................................................... 28

Saving settings ................................................................................................. 28

Performing a hardware reset ............................................................................ 28

Updating the firmware ...................................................................................... 29

Memory............................................................................................................. 30

Power supply .................................................................................................... 30

5

5.1

5.1.1

5.1.2

Working in Easy mode ................................................................................... 31

Starting up the Commander ............................................................................. 31

Switching on the Commander .......................................................................... 31

Checking the basic settings ............................................................................. 31

5

Page 6

Contents

5.1.3

5.2

5.3

5.4

5.4.1

5.4.2

5.5

5.5.1

5.5.2

6

6.1

6.1.1

6.1.2

6.1.3

6.2

6.2.1

6.2.2

Defining a workgroup ....................................................................................... 32

Programming the loggers ................................................................................. 33

Installing the loggers ........................................................................................ 35

Reading out the measured data ....................................................................... 37

Reading out a “Lift&Shift” group ....................................................................... 38

Reading out a “Patrol” group ............................................................................ 39

Evaluating the measured data ......................................................................... 41

Calling up the measured values ....................................................................... 41

Displaying the measured values ...................................................................... 42

Working in Professional mode ..................................................................... 44

Starting up the Commander ............................................................................. 44

Switching on the Commander .......................................................................... 44

Checking the system settings .......................................................................... 44

Registering loggers in the Commander and specifying the workgroup ........... 44

Managing the loggers ....................................................................................... 45

Managing logger groups in the Commander .................................................... 45

Managing the loggers in the Commander ........................................................ 47

6.3

6.4

6.5

6.5.1

6.5.2

6.5.3

6.6

6.6.1

6.6.2

7

7.1

7.2

7.2.1

7.2.2

7.2.3

7.2.4

8

Programming the loggers ................................................................................. 50

Installing the loggers ........................................................................................ 53

Reading out the measured data ....................................................................... 54

Quick query of the workgroup .......................................................................... 54

Standard query of a single logger .................................................................... 55

Standard query of a “Lift&Shift” group .............................................................. 55

Evaluating the measured data ......................................................................... 56

Calling up the measured values ....................................................................... 56

Displaying the measured values ...................................................................... 57

Additional measuring functions ................................................................... 58

Real time measurement ................................................................................... 58

Audio recordings .............................................................................................. 60

Reading out the audio data .............................................................................. 60

Playing back the audio data ............................................................................. 61

Displaying the frequency spectrum of the leak noise (in Professional mode

only) .................................................................................................................. 62

Recording a noise directly (in Professional mode only) ................................... 63

Increasing the wireless range of the loggers with repeaters when

patrolling (in Professional mode only) ......................................................... 64

8.1

8.2

Repeater design ............................................................................................... 65

Installing the wireless extension ....................................................................... 66

6

Page 7

Technical description

1 Technical description

Function

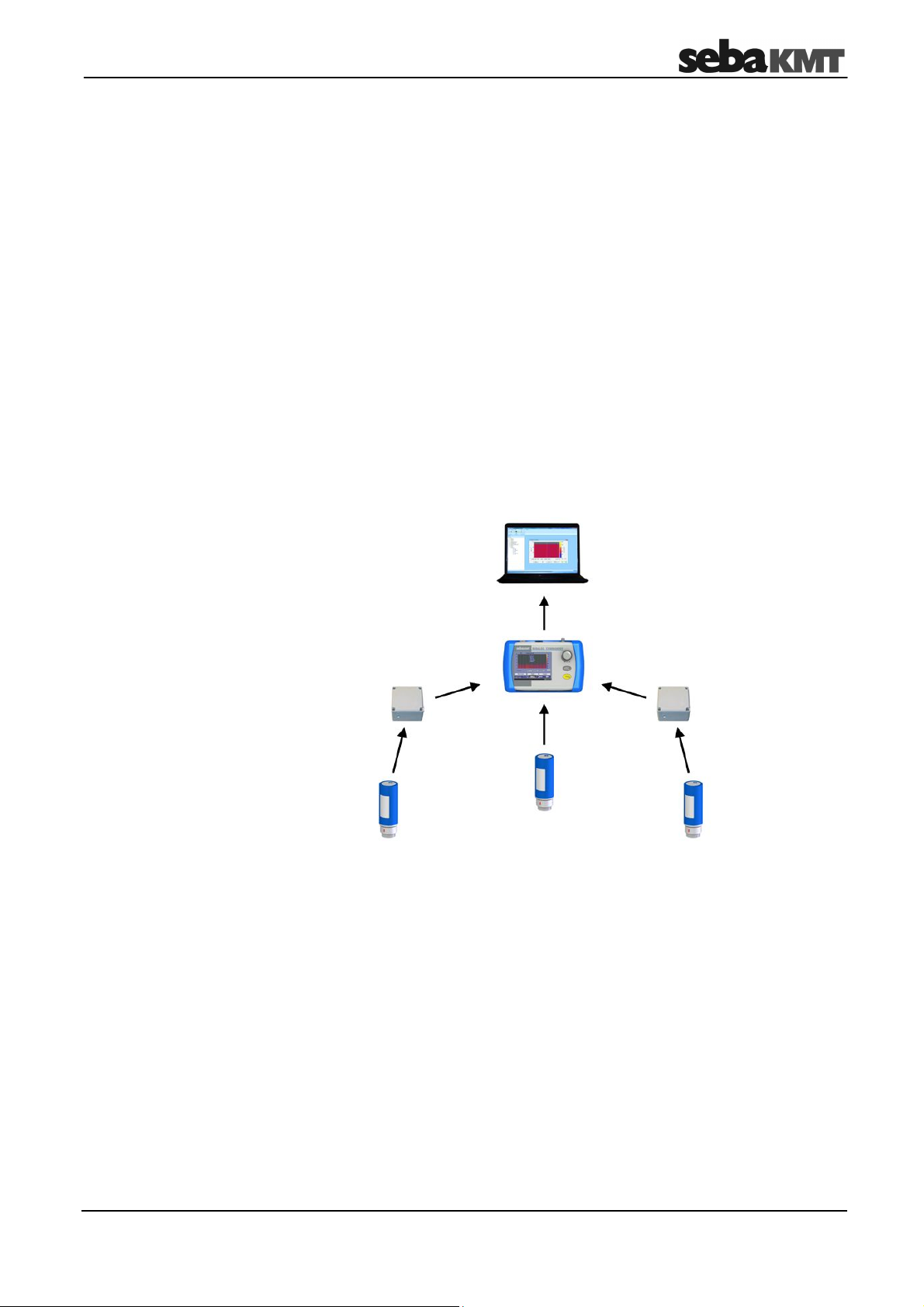

Sebalog N-3 is a system for acoustically monitoring pipe systems. It has Log N-3 noise

level loggers and the Commander-3 as its basis. The Commander is used for

programming the loggers as well as reading out and analysing the recorded

measurements.

To monitor a zone, you can attach as many noise level loggers along the pipe as you

wish. They then perform regular noise measurements within a certain time window. The

user can set the exact measurement time window and other parameters before

measuring begins. The level and frequency of the individual measurements are saved in

the logger. Even the quietest noise is saved as an audio recording.

After measuring, you can collect the loggers, call up the readings and check for leak

noises, and then put them back in a new zone, for example. This allows all the zones in

a pipe system to be checked in succession for leaks.

However, the loggers can also be left in the same zone to monitor it permanently. The

measurements from the individual loggers are then read out on site. Just approaching

the installed loggers with the Commander or another reader will suffice. Wireless data

transfer takes place automatically. Ideally, all you have to do is drive by where the

loggers are being used.

Features

The Sebalog N-3 system has the following features:

• Loggers can be used temporarily, permanently or in the network

• Wireless communication between all components

• Audio data recorded directly in the logger

• “Commander-3” with colour display, USB port, large memory capacity, and

much more.

• Complete group/logger management without a PC

• History function

• Extended wireless range using repeater

• Logger available as TNC version with external antenna

7

Page 8

Technical description

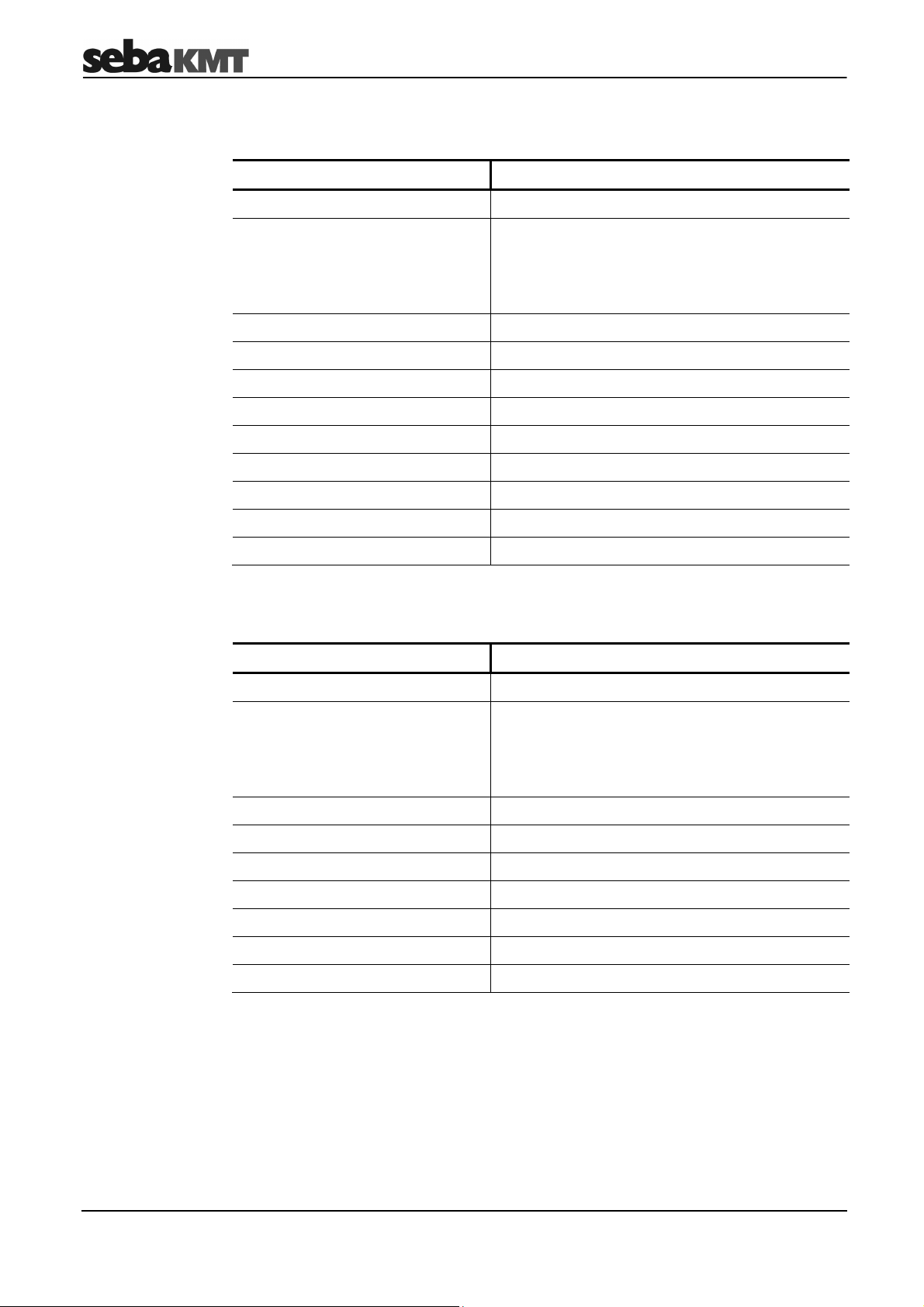

Components

The Sebalog N-3 system consists of the following components:

Component

Log N-3

noise loggers

Commander-3 is the portable device for programming the loggers before measuring,

Repeaters-3 forward the radio signals from the loggers and therefore extend the

GSM box-3 is used as the interface between the logger network and control

SebaDataView-3

software

Reader-3 is a convenient device for reading out the measurements taken by

Log RI is used as the wireless interface to the loggers or repeaters when

Use

measures regularly the volume level and frequency of the noise in

the pipe during the programmed measuring window.

and for reading out and analysing the recorded data after measuring.

wireless link between the loggers and Commander.

centre during wireless remote data transmission.

is the application software for programming the loggers before

measuring, and for reading out and analysing the recorded data with

a PC or laptop.

the Sebalog series of loggers.

connected to a PC/laptop.

8

Page 9

Technical description

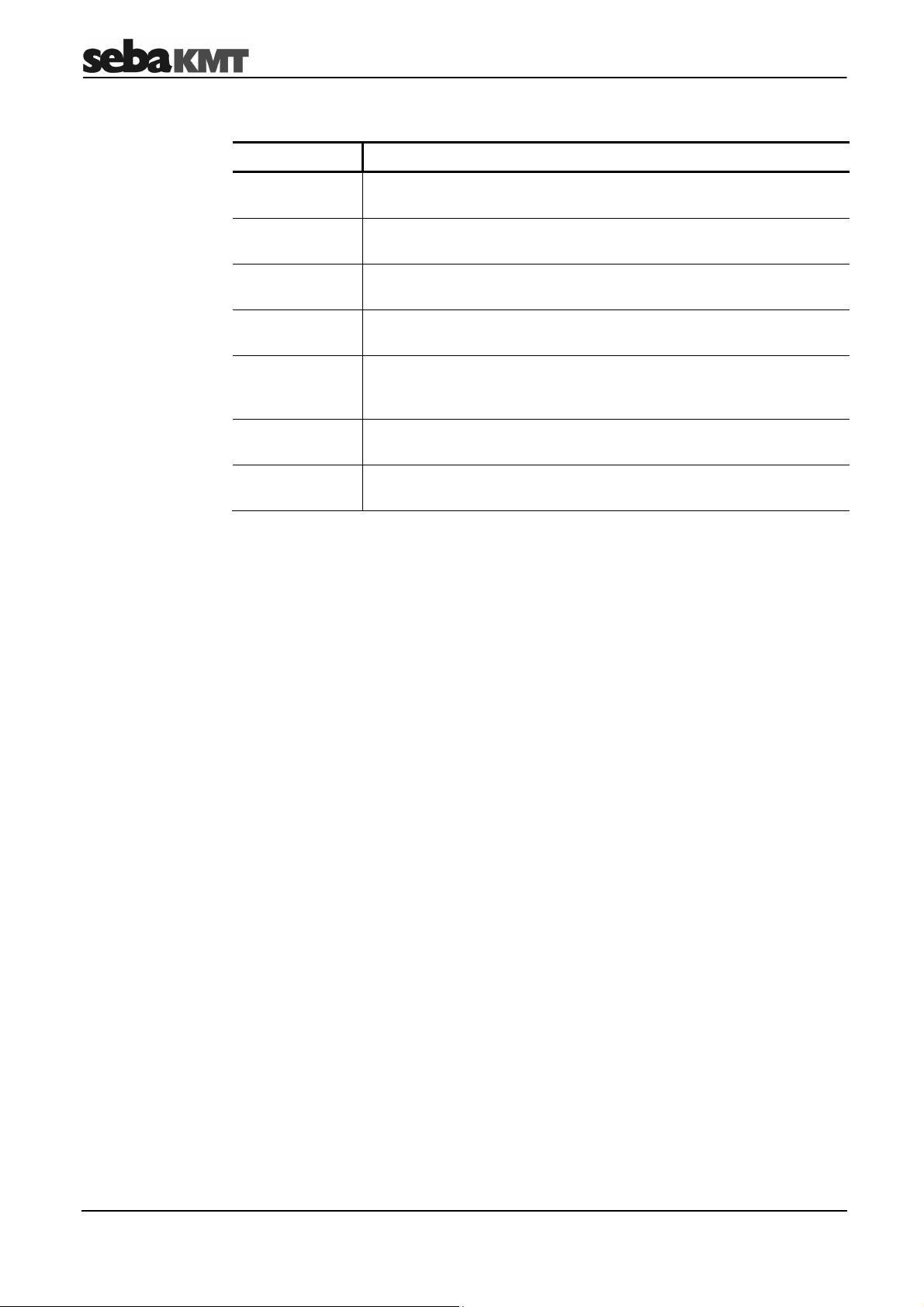

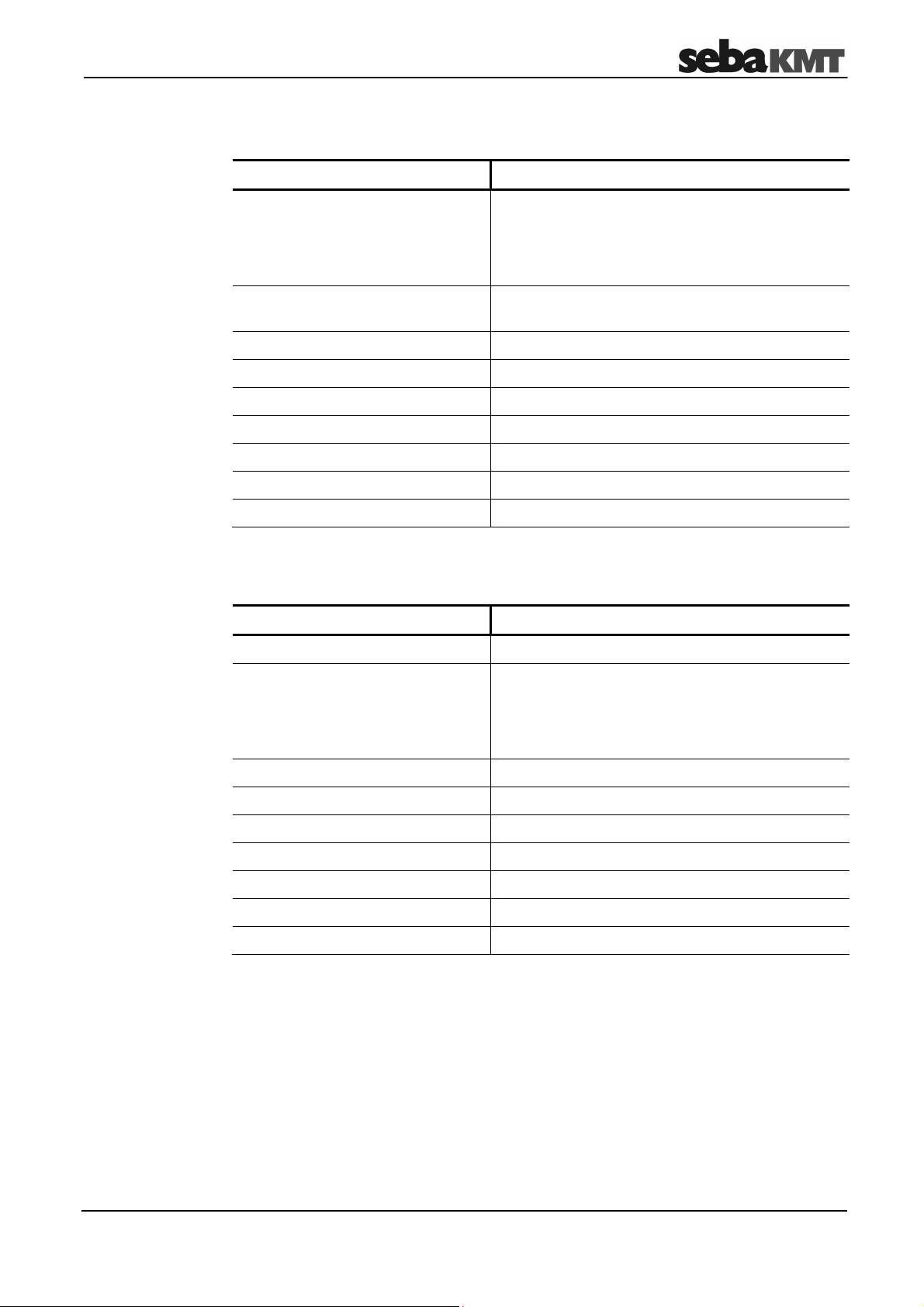

1.1 Technical data

Logger

The noise level loggers in the Sebalog N-3 system are specified by the following

technical parameters:

Parameter

Wireless interface (bidirectional)

•

Frequency

•

Transmitting power

•

Range

Value

868 MHz (915 MHz optional)

10 mW

Approx. 80 m (depends on the surroundings)

Memory capacity Max. 100 measuring days

Audio recording Possible

Power supply Lithium battery

Battery life Max. 5 years (depending on use)

Operating temperature -20 to 60°C (-4°F to 140°F)

Storage temperature -25 to 70°C (-13°F to 158°F)

Dimensions (W x H) 115 x 45 mm

Weight 400 g

Degree of protection IP68

Commander-3

The Sebalog N-3 Commander is specified by the following technical parameters:

Parameter Value

Display 6’’ VGA colour display, 640 x 480 pixels

Wireless interface (bidirectional)

•

Frequency

•

Transmitting power

•

Range

868 MHz (915 MHz optional)

10 mW

Approx. 100 m (depends on the surroundings)

USB port USB 2.0 for connecting to a PC

Memory capacity 2 GB (corresponding to approx. 1,000 groups,

each with 1,000 loggers, including audio data, etc.)

Power supply Li-ion rechargeable battery (7.4 V / 12.25 Ah);

connection to 110-240 V supply using charger

(input: 50-60 Hz, 700 mA)

Operating time Approx. 20 hours

Operating temperature -20 to 60°C (-4°F to 140°F)

Storage temperature -25 to 70°C (-13°F to 158°F)

Dimensions (L x W x H) 250 x 190 x 100 mm

Weight 2,100 g

Degree of protection IP65

9

Page 10

Technical description

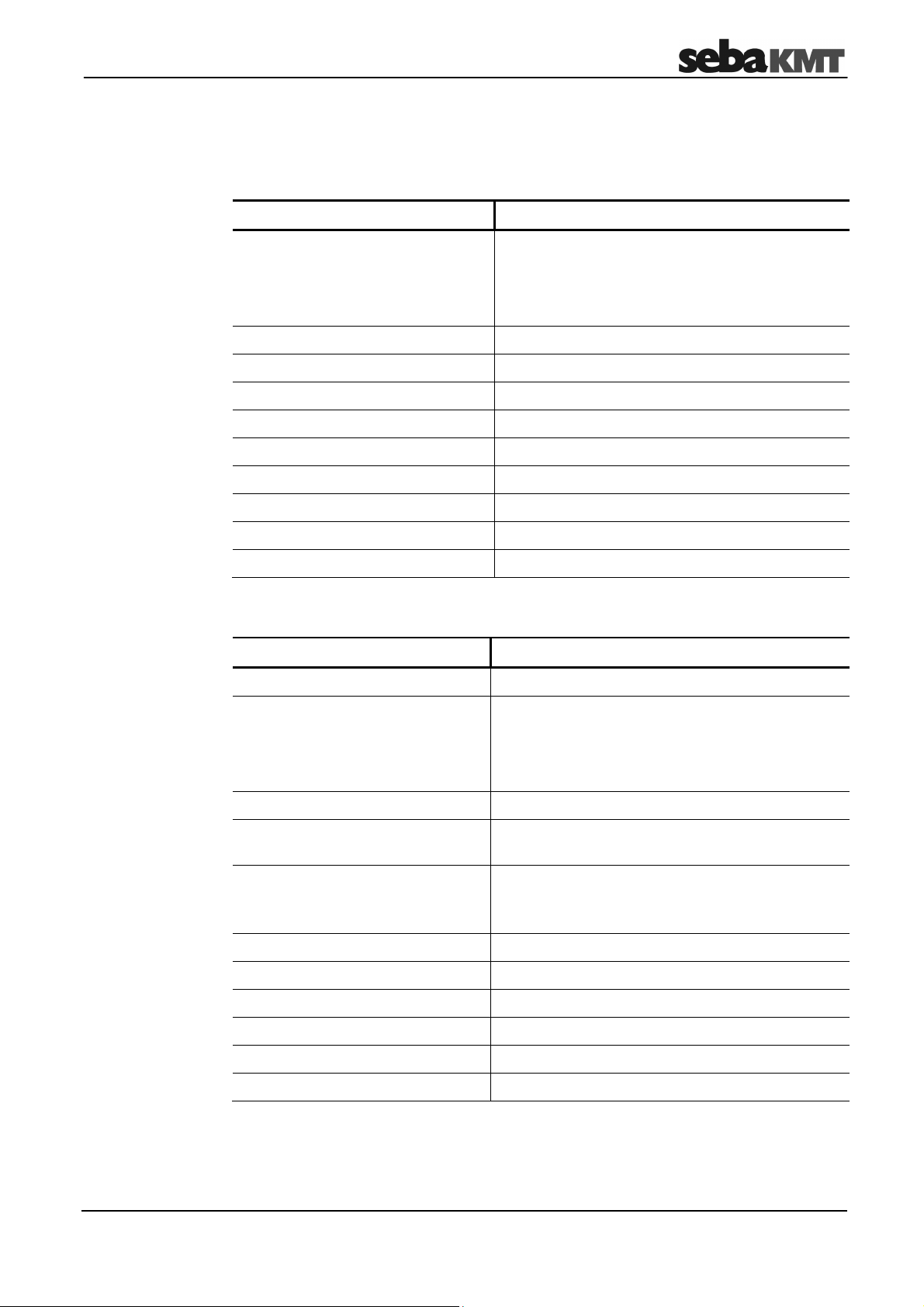

Reader-3

The Reader-3 reading device in the Sebalog N-3 system is specified by the following

technical parameters:

Parameter Value

Display LCD display (b/w), 128 x 32 pixels

Wireless interface (bidirectional)

•

Frequency

•

Transmitting power

•

Range

868 MHz (915 MHz optional)

10 mW

Max. 100 m (depends greatly on the surroundings)

USB port USB 2.0 for connecting to a PC via docking station

Memory capacity 1 GB (SD memory card)

Power supply Li-ion rechargeable battery (7.2 V / 12 Ah)

Operating time 10 hours

Operating temperature -20 to 60°C (-4°F to 140°F)

Storage temperature -25 to 70°C (-13°F to 158°F)

Dimensions (L x W x H) 200 x 100 x 60 mm

Weight 450 g

Degree of protection IP22

Repeater-3

The repeaters in the Sebalog N-3 system are specified by the following technical

parameters:

Parameter Value

Display Status LED

Wireless interface (bidirectional)

•

Frequency

•

Transmitting power

•

Range

868 MHz (915 MHz optional)

10 mW

Max. 400 m (depends on the surroundings)

Power supply Lithium battery (replaceable)

Battery life Max. 5 years (depending on use)

Operating temperature -20 to 70°C (-4°F to 158°F)

Storage temperature -25 to 70°C (-13°F to 158°F)

Dimensions (L x W x H) 80 x 80 x 55 mm

Weight 250 g

Degree of protection IP67

10

Page 11

Technical description

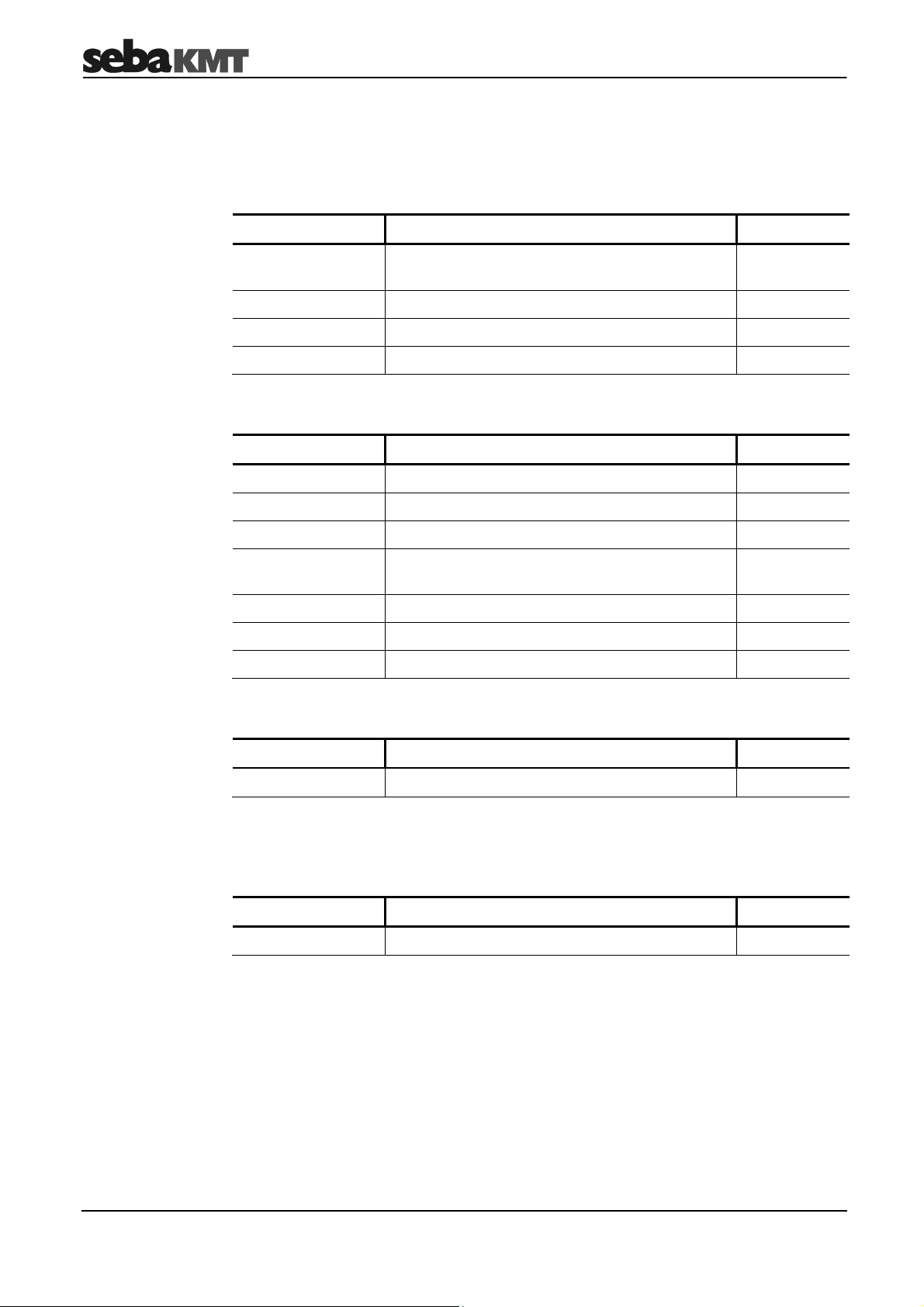

GSM box-3

Log RI

The GSM box in the Sebalog N-3 system is specified by the following technical

parameters:

Parameter Value

Wireless interface (bidirectional)

•

Frequency

•

Transmitting power

•

Range

868 MHz (915 MHz optional)

10 mW

Max. 400 m (depends on the surroundings)

Memory capacity 2 GB (corresponds to the data from approx.

50 loggers)

Power supply Lithium battery (replaceable)

Battery life Up to 4 years

Operating temperature -20 to 70°C (-4°F to 158°F)

Storage temperature -25 to 70°C (-13°F to 158°F)

Dimensions (L x W x H) 170 x 140 x 100 mm

Weight 1,000 g

Degree of protection IP67

The Log RI wireless interface in the Sebalog N-3 system is specified by the following

technical parameters:

Parameter Value

Display Status LED

Wireless interface (bidirectional)

•

Frequency

•

Transmitted power

•

Range

868 MHz (915 MHz optional)

10 mW

Max. 10 m (depending on surroundings)

USB port USB 2.0 for connecting to a PC

Power supply Via USB

Operating temperature 0 to 40°C (32°F to 104°F)

Storage temperature 0 to 40°C (32°F to 104°F)

Dimensions (L x W x H) 83 x 17 x 47 mm

Weight 50 g

Degree of protection IP22

11

Page 12

Technical description

1.2 Scope of delivery and accessories

The Sebalog N-3 system is delivered with the following as standard:

Logger set

Commander set

A logger set consists of the following components:

Designation Description Item No.:

LOG N-3 Noise level logger

(number depending on set size)

LOG TB-240 Transport box 118303892

MWA LOG N-3 Magnetic angle adaptor 118303355

Thread cap M6 118304578

A Commander is delivered with the following components:

Designation Description Item No.:

LOG CDR-3 Commander-3 820024391

LOG CDR-3-T Carrier bag for Commander-3 820025752

LK 14 Vehicle charger cable (3.5 m long) 81003758

Antenna 868 MHz

with magnet (MAG3-900 TNC)

LG SEBALOG Charger for Commander-3 810919

VK 77 Connection cable (USB output) 820012451

820019682

122010060

KR 22-5 Stereo headphone 810002087

User software

The SebaDataView-3 software for PC/laptop is part of the scope of delivery:

Designation Description Item No.:

CSW DATAVIEW-3

1.3 Optional accessories

The following optional accessories are available:

Designation Description Item No.:

GPS module

SebaDataView-3 user software

118302210

12

Page 13

Important and common terms

2 Important and common terms

User mode

Level and frequency

ESA value

Group mode

The Commander-3 can be operated in two different user modes (see page 23):

• Easy mode

• Professional mode

You can switch between these modes in system settings menu (see page 25).

These two values are identified each time a noise logger performs a measurement:

• “Level”

• “Frequency”

ESA stands for “Extended Spectral Analysis” and means that noise level and frequency

are combined in one reading using a mathematical formula. This results in an extended

view of the measured data, which makes the leak probability and position visible in

relation to other loggers. The dimensionless ESA value can be between 0 and 100. The

higher the ESA value, the higher the leak probability and the shorter the distance from

the logger to the leak.

In order to analyse the recorded measurements, the noise loggers must be read after

measuring, i.e. the data in the loggers is accessed wirelessly with a reading device

(Commander/Reader/PC). It is possible to do this in the following ways:

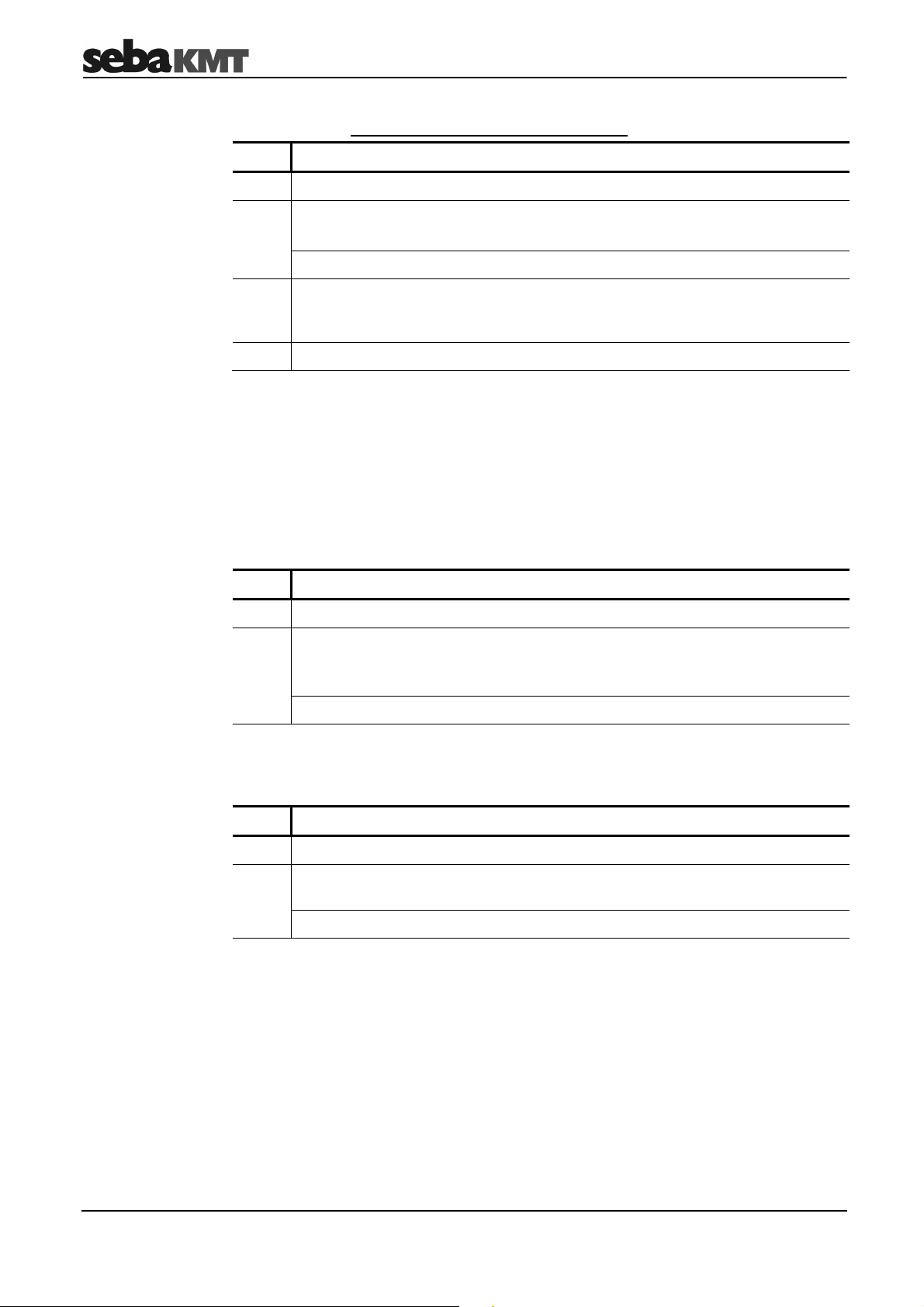

Group mode

… is the noise level (volume) of a measurement

… is the frequency in the measurement’s frequency spectrum with

the greatest deflection

“Lift&Shift” “Patrol” “Network”

The loggers are collected;

data is read out wirelessly

in the office

The method must be chosen for reading out the measured data before the measuring

work is performed. Before measuring, the mode decided on is permanently assigned to

the loggers or logger groups. After that, only loggers that have been configured for

reading using “Patrol” can be read with “Patrol”, for example, and not with “Lift&Shift” or

“Network”. The same applies to the other group modes.

The loggers remain at

the place of use;

data is read out

wirelessly while

“driving by”

All the installed loggers

are networked with each

other and connected to

a GSM box;

data is read out via

mobile radio from the

office

13

Page 14

Important and common terms

Workgroup

Measuring window

Measuring period

Leak threshold

Leak status

Leak value

Configuration mode

The Commander can only ever interact with a single registered logger group. This group

is called the “workgroup”. It is not possible to program or read loggers from another

group.

The “measuring window” is the time during which a logger is programmed to carry out

measurements, e.g. from 2 a.m. until 4 a.m. in the morning.

A measuring window could also be referred to as a “measuring day”.

A measuring period refers to the time span that passes between programming and

reading a logger. A measuring period can therefore last 1 to 100 measuring days.

There is a certain basic noise level in each pipe system. This basic noise level is

referred to as the “leak threshold”. This level may be known or estimated based on

experience. If the lowest measured noise level in a section of pipe is above the leak

threshold, there is presumed to be a leak.

If the level of the quietest noise in a measuring window is above the previously found

leak threshold (see above), the logger goes into “leak status”. This means, for example,

that when this logger is read, a warning appears on the reader indicating that there is an

increased probability of a leak close to the logger.

The term “leak value” combines the three measurement results – level, frequency and

ESA value – determined for the quietest noise in a measuring period.

If a noise logger has been switched off (i.e. it has stood “on its head” for at least

3 minutes), it is in “configuration mode” after it is switched back on. This means:

• The previous programming has been deleted. The logger is now unprogrammed.

• Switching off has not deleted the previously saved measurement results. They are

still in the logger’s memory and can be accessed by a reading device, but only by

single interrogation (see page 54).

• The logger is ready for wireless operation and waiting to be contacted by the

Commander or PC.

The logger remains in configuration mode until it is reprogrammed.

Identification number

Each device in the Sebalog N-3 series has a unique serial number (SN). You will find it

on the type plate of the device.

All loggers, repeaters and GSM boxes also have an identification number (ID) which can

be used by the Commander or the SebaDataView software to manage them. You will

also find the ID on the type plate, or on a separate plate on the device. The identification

number is identical to the last six digits of the serial number.

When inputting an ID, the preceding zero digits can be omitted.

Thus, if the ID is “000815”, you need only enter “815”.

14

Page 15

The loggers

3 The loggers

3.1 Function

The noise loggers are installed along a section of pipe directly on the pipe, or directly on

fittings on the pipe.

Within the configured measuring window, they perform regular noise measurements,

each 3 seconds in length. The volume level and frequency of each measurement are

saved in the logger. While the noise level alone only records the general existence of a

leak, together with the frequency it also provides information on the approximate

distance in relation to other loggers.

The measurement results gathered by the logger can be queried later using a reading

device (Commander/Reader/PC).

The quietest noise of the last measuring window is saved as an audio file. After reading

out the data, you can actually listen to the assumed leak noise and immediately decide if

it is a leak noise or background noise.

The “Real time measurement” function can be used to observe a logger “live” as it

measures (see page 58).

With the “Direct recording” function can be used to listen to a noise in a pipe (see page

63).

Communication with the loggers is performed with short range radio only.

15

Page 16

The loggers

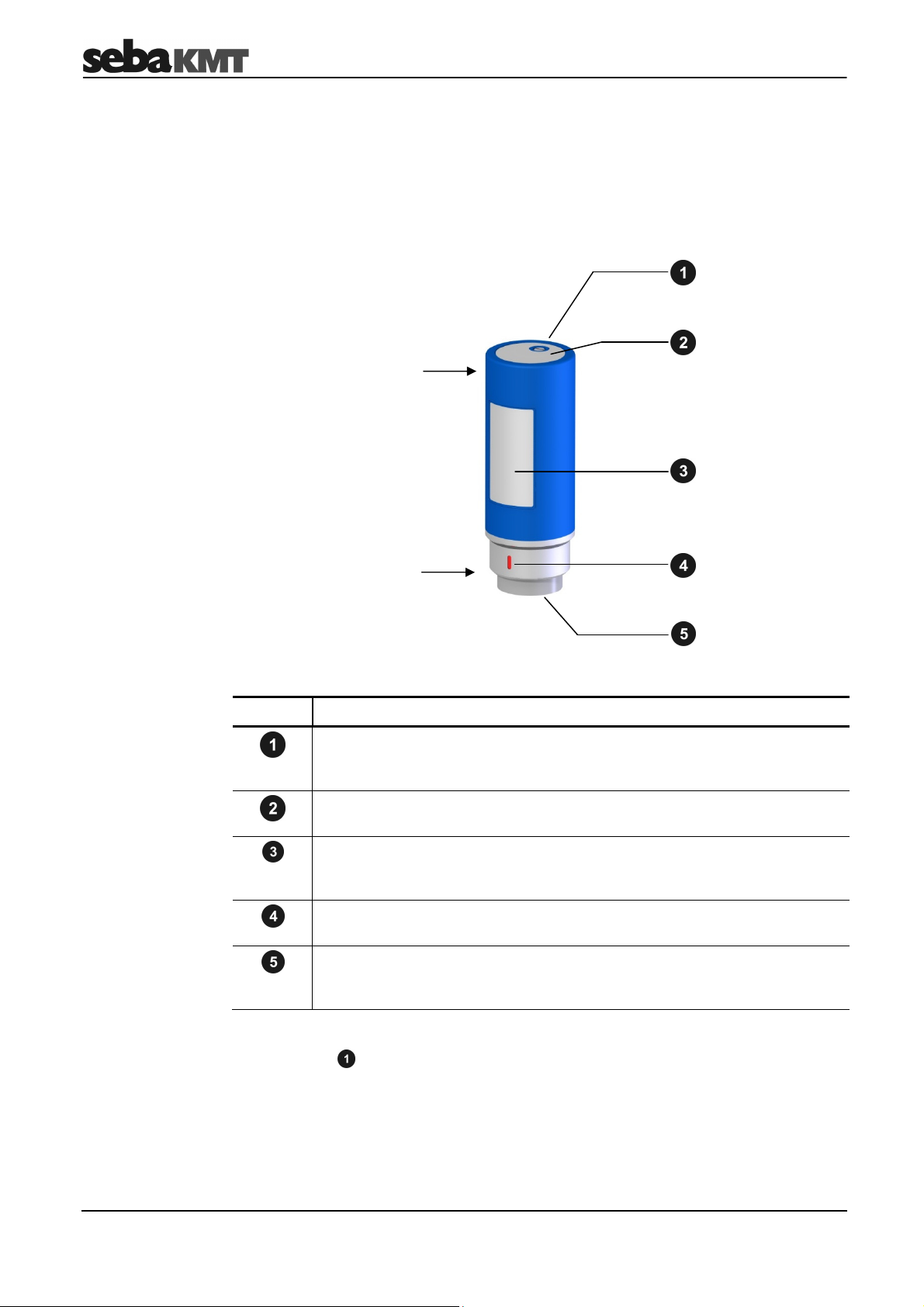

3.2 Design

Introduction

Standard version

All noise loggers have a highly sensitive microphone with a large dynamic range, a data

memory and a lithium battery inside. The standard loggers also have an internal radio

antenna.

The loggers have the following external characteristics:

“Head” of the logger

“Foot” of the logger

TNC version

Element Description

Hole (M5 thread)

For fitting the supplied ring, which can be used for carrying the logger and

pulling it out of the shaft.

Label with identification number (ID)

Each logger has its own six-digit identification number.

Type plate

The last six digits of the serial number (SN) on the type plate of the device

are identical to the ID.

Marking

Must always face upwards when the logger is fitted horizontally.

Magnetic foot

Can be unscrewed and replaced by an adapter, or similar, from the

assembly accessories.

The special TNC version of loggers have no internal antenna. Instead of the hole for the

assembly ring they have an antenna socket for connecting an external antenna.

16

Page 17

The loggers

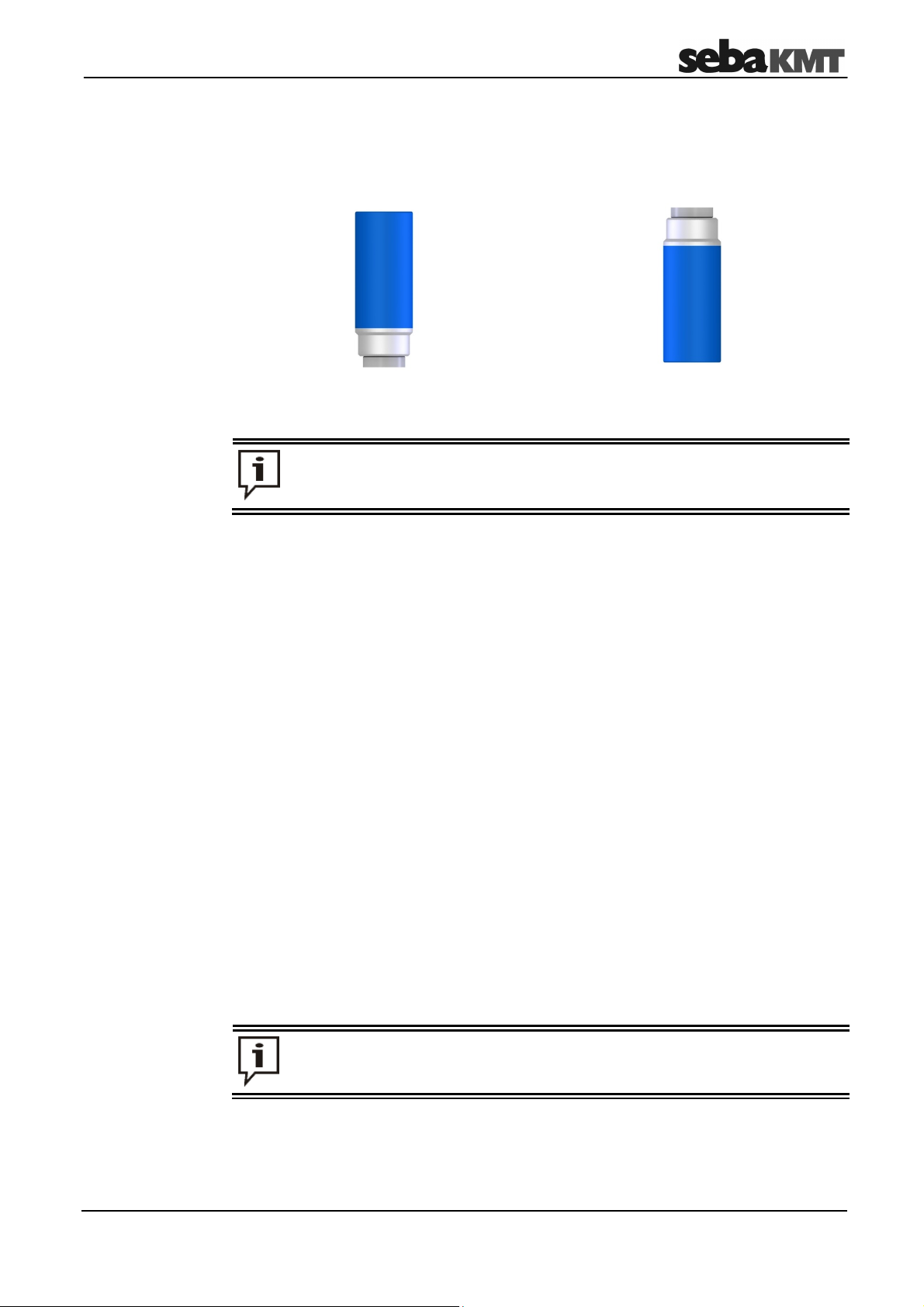

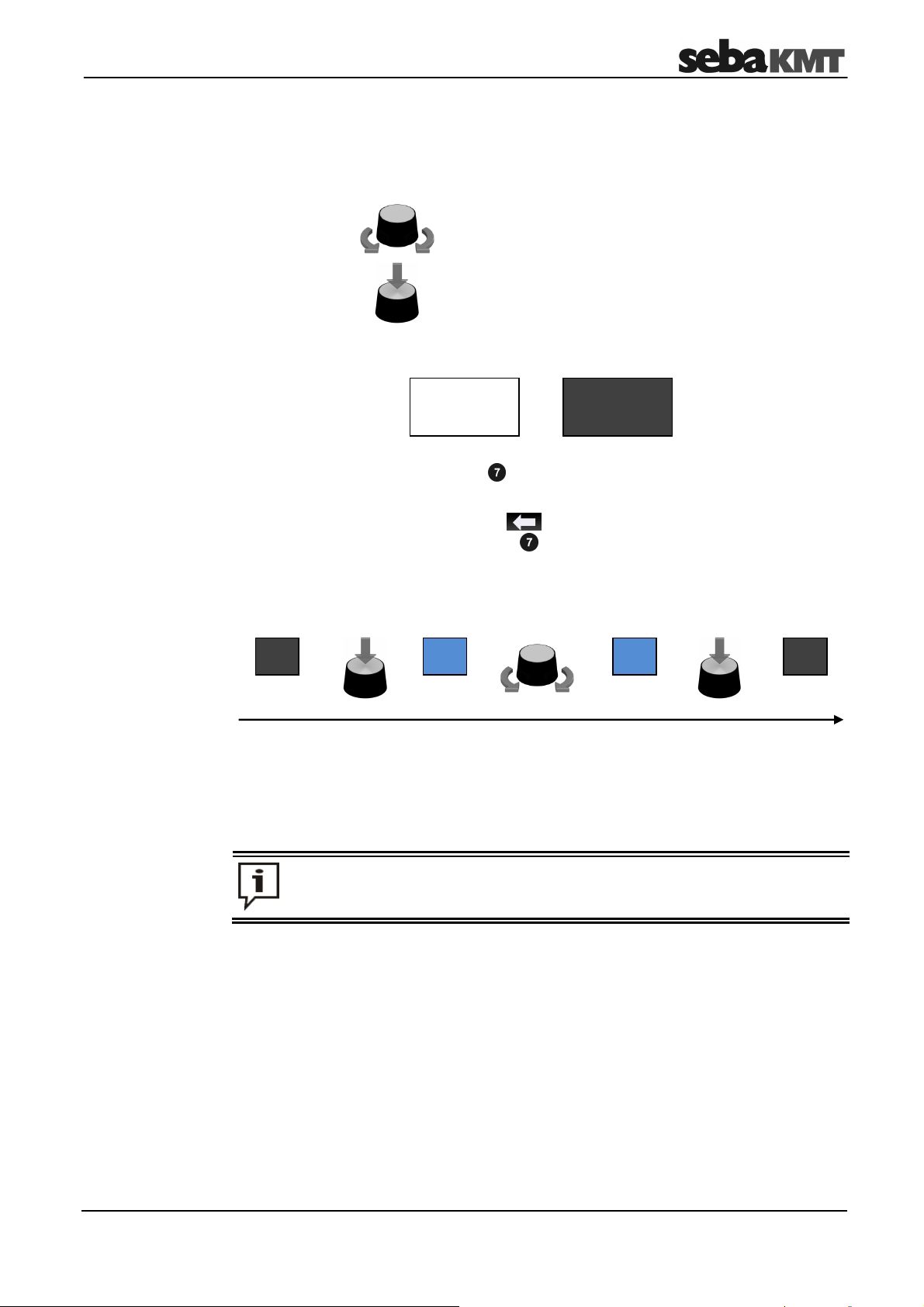

3.3 Switching on and off

The noise loggers have an internal tilt switch and are switched on and off simply by

turning them over.

Loggers standing on their foot are

switched on.

Each time a logger is switched on, its configuration data is reset to the default

values. The time internally is also lost. Therefore, whenever the logger is

switched back on, it must be reprogrammed (see page 50).

3.4 Memory

A logger’s internal memory allows a maximum of 100 pairs of values (the level and

frequency of a measurement) to be recorded.

Furthermore, the quietest recording of the last measuring window is saved as an audio

file (3 seconds in length).

Circular buffering is used, with the oldest stored measuring window being deleted after

100 measurements.

3.5 Power supply

Loggers standing on their head for longer

than 3 minutes are switched off.

Each logger has an internal lithium battery.

The actual battery lifetime depends on the intensity of use.

If a logger is always operated using the default configuration data, factory-set in the

Commander, a battery lifetime of up to 5 years is possible.

Longer measuring periods and increased wireless activity/availability shorten the life of

the logger battery. Severe fluctuations in climatic conditions also have a negative

impact.

Flat batteries cannot be recharged. They must be replaced.

SebaKMT or an authorised service partner must change the batteries.

Otherwise, water- and dirt-resistance of the logger cannot be guaranteed.

17

Page 18

The Commander

4 The Commander

4.1 Function

The Sebalog Commander 3 is the mobile programming and reading device for noise

loggers in the Sebalog N-3 series. The Commander is used to program the noise

loggers before measuring. After measuring, the recorded data in the loggers can be

queried with the Commander. Both current and older data can be displayed on the

device’s screen and analysed in greater detail. Furthermore, a real time measurement

can be performed (see page 58).

After connecting the supplied headphones, you can play back audio files of leak noises.

It is also possible to listen to the current noise in a pipe (see page 63).

18

Page 19

The Commander

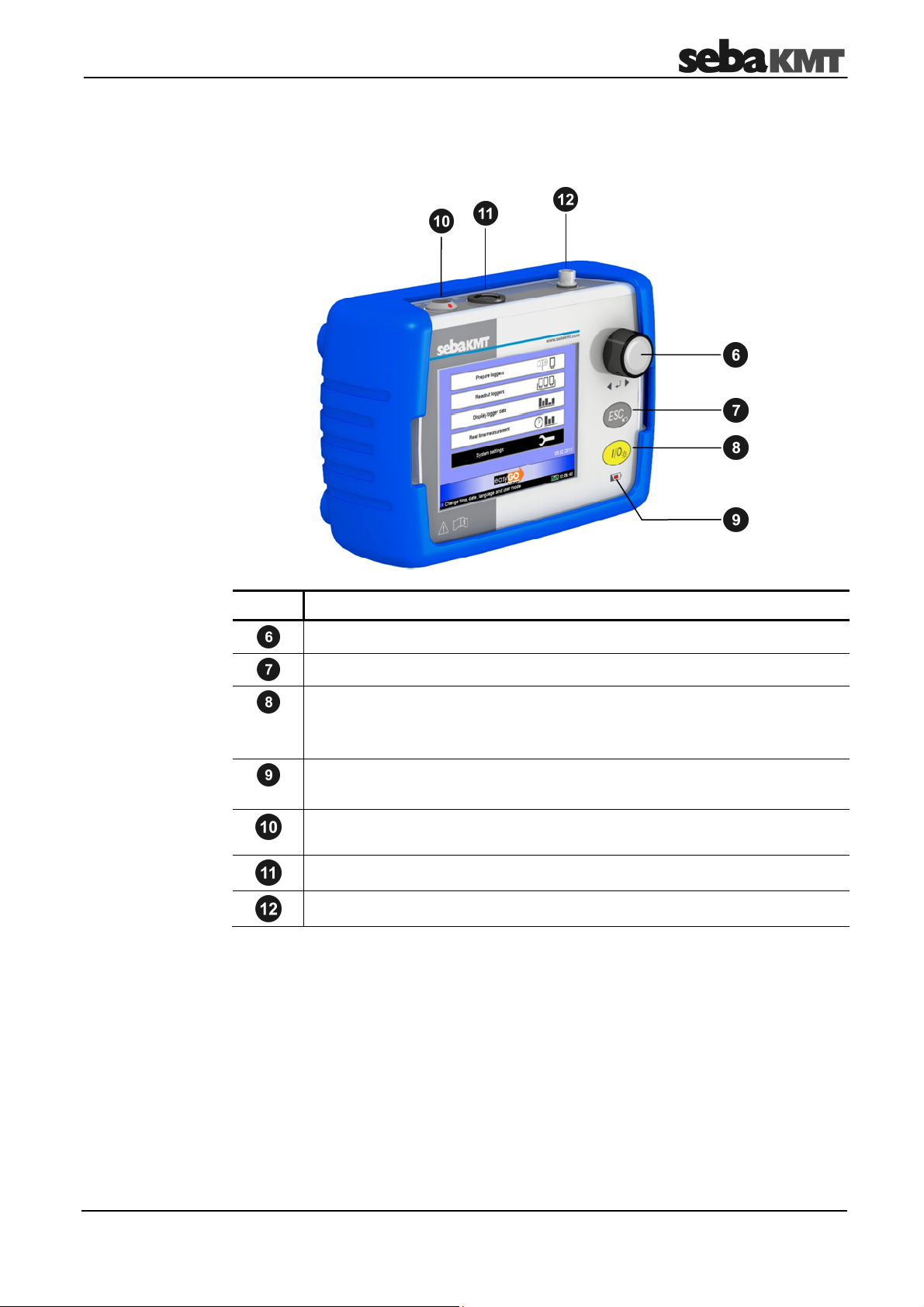

4.2 Device design

Controls and

connections

The Commander has the following controls and connections:

Element Description

Selector knob

ESC button

I/O button

•

Device on/off

•

Backlight on/off

Charging indicator light

•

Lights up red … external supply, battery is being charged

Socket for USB link to PC and for connecting an optional GPS module

(combined)

Headphone and charging socket (combined)

Antenna socket

19

Page 20

The Commander

N

P

L

al mode

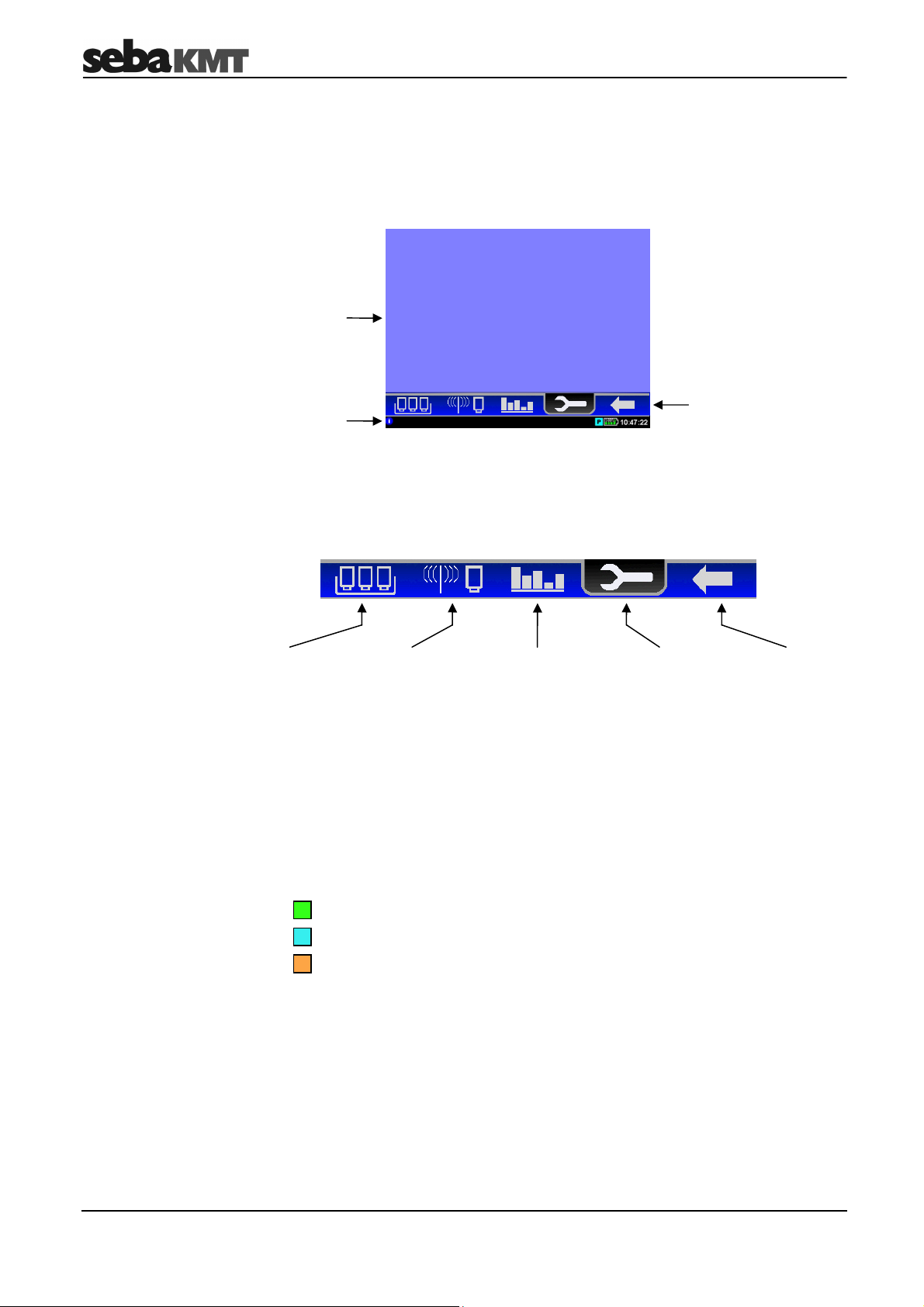

4.3 Design of the user interface

All the menu levels on the Commander’s user interface consist of a large display area

and an infobar on the bottom edge of the screen. The content and structure of the

display area change depending on the system status.

Display area

Main menu bar

Infobar

Help text ++ Help text ++ Help text

(Profession

only)

Main menu

Infobar

In Easy Mode, the main menu can be selected in the display area of the start screen.

In Professional Mode, the “Main menu bar” is between the display area and infobar. You

can access the individual functions of the device using the symbols shown.

Quick start

for reading out

the measured

data of the

workgroup

Functions for

programming

and reading

loggers

Functions for

displaying,

playing back and

analysing data,

etc.

Functions for

managing

loggers in the

Commander,

etc.

Back to the next

higher menu

level

The infobar structure remains the same in each menu and continuously provides the

user with the following information (from left to right):

• A help text gives short explanations on the selected element or on how to

proceed further.

• A coloured symbol indicates the group mode (see page 13) of the workgroup

… “Lift&Shift”

… “Patrol”

“Network”

…

• The battery symbol indicates the charge level of the battery.

• The Commander’s internal time.

20

Page 21

The Commander

4.4 Basics of operation

Navigation within the

menus

Exiting the menu

Adjustable parameters

The Commander is very simple to operate and intuitive in principle. Navigation within the

menus is done exclusively with the aid of the selector knob as follows:

The selected element appears on a black background:

In Easy Mode, use the ESC button to exit each menu. This immediately returns you

to the start screen. Any functions started are cancelled.

In Professional Mode, you can use the symbol at any time to return to the previous

menu level. Pressing the ESC button once makes the hidden main menu bar

reappear. Pressing it a second time takes you back directly to the start screen.

With the aid of the selector knob, not only can individual menu items be accessed but

also settings can be changed and parameters adapted. Please proceed as follows:

Turning = select

Pressing =

Not

selected

open/confirm

(ENTER function)

Selected

select

element

In some cases, the parameter can be changed directly in the input field. In others, a pulldown list opens where you can select a new setting.

→ ENTER

If in doubt, you can always cancel a procedure with the ESC button.

→ change parameter → ENTER

20 20 5 5

21

Page 22

The Commander

Virtual keyboard

Sorting loggers

To input comments or similar, a virtual keyboard appears on the screen, which is also

operated with the selector knob.

… deletes last character

… switches between upper- and lower-case

… inserts space

… confirms and completes input

Various menus list the individual loggers of a logger group. This appears in a table-like

form. You are able to re-sort these loggers by the criteria “Comment”, “Time of data

read-out” or “ESA value”. This can be useful for identifying certain loggers straightaway,

e.g. all loggers where a leak is suspected, etc.

To change the sort, apply the Sort button repeatedly. A small triangular symbol in the

header of a column indicates which criterion is selected and whether the loggers are

arranged in descending ▼ or ascending ▲ order.

Entering an

identification number

Examples of possible settings:

“ESA ▼” … sorting by ESA value (descending),

i.e. the loggers with a suspected leak are at the top of the list

“Date/time ▼” … sorting by time of the data read-out (descending),

i.e. the loggers most recently read are at the top of the list

“Date/time ▲” … sorting by time of the data read-out (ascending),

i.e. the loggers not yet read are at the top of the list

Various functions require the identification numbers (IDs) of loggers, repeaters or GSM

boxes to be given. When inputting an ID, all the preceding zero digits can be omitted.

Thus, if the ID is “000815”, you need only enter “815”.

22

Page 23

The Commander

4.5 User mode

Introduction

How to identify

the user mode?

The Commander-3 can be operated in two different user modes.

Easy mode Professional mode

In Easy mode all the main functions of the

device are available. They can perform

most day-to-day work quickly and simply from programming a logger group to

analysing measured data on the

Commander. The individual applications

are structured very clearly; the user is

partly guided step-by-step from one action

to the next. Easy mode is therefore not just

suited to first-time users but also

experienced operators who prefer to use its

simpler menu structure.

If the Commander is in Easy mode, the following symbol is permanently displayed

above the infobar:

If the EasyGo symbol isn’t shown on the screen, the Commander is in Professional

mode.

In Professional mode all the functions of

the device are available to the user. This

allows the system to be better adapted to

the user’s requirements and conditions on

site. Difficult measurements can be

prepared more exactly and the results

evaluated and documented in more

different ways, etc. Some applications can

only be used in Professional mode, such

as using Repeaters or building a logger

network.

How to change the

user mode?

The user mode can be switched in the system settings (see page 26).

23

Page 24

The Commander

4.6 Making a connection

4.6.1 Connection between the Commander and logger

Short range radio is used for communication between the Commander and loggers.

The Commander has an integrated radio module. After the antenna is connected

(standard or vehicle antenna), the device is ready for wireless operation.

The loggers must be switched on and wirelessly available (see page 52). The radio

range of a logger is affected by the conditions where it is used. To extend the range a

repeater can be used (see page 64).

4.6.2 Connection between the Commander and PC

Purpose

Making a connection

The connection between the Commander and a PC/laptop is made using the VK 77

connection cable supplied and is needed for the following tasks:

• Transferring measured data from the Commander to the PC.

• Transferring configuration data from the SebaDataView-3 software to the

Commander.

• Installing a firmware update on the Commander.

The Commander must be operated in Professional mode to connect it to the PC.

Proceed as follows:

Step Description

1

Select the button in the main menu bar.

2 In the next menu, select the Connect to PC button.

3

Use the USB socket on the Commander for connecting the cable to the PC.

Markings on the plug and socket ensure that the plug is lined up correctly. You

must feel the plug engage.

4 Select the Connect button on the Commander.

Result: The connection is made. The Commander is automatically detected by

the PC as a mass storage device. As soon as the Connected message on the

Commander’s screen appears, data can be transferred between the

Commander and PC.

If no connection is made, check the cable connection again. If necessary, disconnect

the Commander from the PC, restart it again, or perform a reset, and follow steps 1 to 4

once again.

Disconnection

To end the connection, select the Disconnect button on the Commander.

As soon as the Disconnected message on the Commander’s screen appears, the

connection cable can be removed.

24

Page 25

The Commander

4.7 Switching on the display lighting

The Commander’s screen has a backlight. It is activated by using the selector knob or

briefly pressing the I/O button . The lighting then remains on for a certain time period.

The length of this period (a maximum of 4 minutes) can be adjusted in the system

settings (see page 26).

4.8 System settings

You can use the System settings menu to customise various device settings to the

needs of the user.

Beginning at the start screen, follow the symbols.

The System settings menu opens:

When the Commander is in Professional mode, more settings can be changed

than in Easy mode. Use the Next button to go to the second page of the menu.

25

Page 26

The Commander

4.8.1 Basic settings

The following basic settings can be made in both Professional mode and Easy mode:

Line Description

User mode

Language

Time and date

settings

Select a user mode for the device (see page 26).

Select a language for the user interface.

If you cannot read the preset language, you can go to

the language selection - starting from the main menu via the following symbols:

In the Timezone line, select the timezone for where you are.

In the Daylight saving time line select whether it is currently

winter or summer time.

In the Date format line, select the date format to be used by the

Commander.

DD … Day

MM … Month

YYYY … Year

In the Time line, enter the current time for the Commander

(hour:minutes:seconds).

Backlight switch off

Turn off autom.

after

Keybeep

History

In the Date line, enter the current date for the Commander

(day:month:year).

Select a period of time for the backlight until it is switched off

automatically (never = continuous backlight).

Select a period of time for the auto-off function.

If no entry is made for longer the specified time, the Commander

switches off automatically (never = automatic switch off

deactivated).

Activate/deactivate the key tone that sounds when the selector

knob is pressed.

Activate/deactivate the “History” function.

If the “History” function is activated, the measured data from

loggers remains stored in the Commander after they are read

out. They can then be called up at any time and displayed again.

If the function is deactivated, the previous data set is overwritten

when new data is read. Deactivating the function can be useful

because this saves memory space and the Commander can

work faster in certain situations.

26

Page 27

The Commander

4.8.2 Extended settings in Professional mode

The following extended settings are only available in Professional mode:

Line Description

Logger list visibility

Logger found beep

Additional hints

Select table columns to be shown/hidden.

Various menu levels list the loggers of a group in a table on the

screen. The columns contain information about the loggers,

such as the logger ID and logger comment. To make the table

clearer, you can specify which columns are actually shown.

Switch the acoustic signal on/off that occurs when a logger is

found.

An acoustic signal sounds each time the Commander detects a

logger when reading out data. A corresponding message is

shown briefly on the screen.

When “patrolling”, this can happen several times in succession

because the loggers send data packets to the Commander at

regular intervals.

You can specify how often there is a signal or a message:

• always … acoustic signal each time the Commander

detects a logger

• only once if logger found … acoustic signal only when a

logger is detected the first time

• never … no acoustic signal

• beep and display only once … acoustic signal and

message on the screen only when a logger is detected the

first time

Decide if additional information shall be shown or not.

At various positions in the menu, special displays appear on the

screen, providing additional information about the current

functions. These displays can be deactivated.

Sorting order

Factory settings

Select the standard sorting order for loggers in tables.

Various menu levels list the loggers of a group in a table on the

screen. The criterion by which the loggers are sorted within the

table as standard can be specified..

Restore factory settings.

The settings on the Commander can be reset to the factory

settings, to the state when the Commander was delivered.

27

Page 28

The Commander

4.8.3 System info

When the Commander is operated in Professional mode, the System settings menu

has the following information on the device and the firmware currently in use:

Line Description

Free space

Software version

Software date/time

ID

Commander’s free memory space in MB

Firmware version of the Commander

When the firmware was last updated

Identification number of the Commander

4.8.4 Saving settings

To save any changed settings in Easy mode, apply the OK button before exiting the

System settings menu with the ESC button .

In Professional mode, saving is automatic when exiting the menu.

4.9 Performing a hardware reset

If the Commander stops responding to inputs (from the selector knob or buttons), a

hardware reset can be performed.

Hold down the selector knob and the ESC button at the same time for about one

second. The Commander restarts automatically. This usually rectifies the malfunction.

If the malfunction persists after this normal reset, try the following: Hold down the

selector knob and the ESC button at the same time for about three seconds. The

Commander switches off. Wait about a minute before switching the Commander back

on with the I/O button . The device should now function correctly again.

28

Page 29

The Commander

4.10 Updating the firmware

Visit regularly the Downloads section at www.sebakmt.com for information about new

versions of firmware. You can install any updated versions of the firmware on the

Commander if they are available.

The current version of the Commander firmware installed can be found in the system

settings (see page 28).

To update the firmware, proceed as follows:

Step Description

1

First ensure that the Commander’s battery has sufficient power to update the

firmware (at least one bar on the battery symbol on the infobar (see page 20)).

If in doubt, recharge the battery first (see page 30).

2 Download the latest firmware archive from www.sebakmt.com and extract it to a

directory on your PC.

3

Connect the PC and Commander together via USB- (see page 24).

4

Copy the extracted files directly into the Commander’s main directory.

5

Disconnect the Commander from the PC (see page 24).

6

Switch the Commander off and then on again, or perform a reset (see above).

Result: The firmware update begins. A bar indicator shows the progress on the

screen.

During the update, no entries whatsoever must be made on the

Commander! This could cause the device irreparable damage.

CAUTION

After the procedure is complete, the device switches back on automatically.

Check the version number in the start screen to see if the Commander is

actually using the new firmware.

29

Page 30

The Commander

4.11 Memory

The Commander has a 2 GB internal memory. This is sufficient to manage the data of

up to 1,000 logger groups, each with 1,000 loggers.

You can query the available memory space at any time in the system settings (see page

25).

4.12 Power supply

Internal supply

External supply

Automatic switch off

The Commander is fitted with an internal Li-ion rechargeable battery. This can power

the device for approximately 20 hours. The battery’s present charge level is shown

continuously by the battery symbol in the infobar on the screen.

If the battery is low, a warning on a coloured background appears on the screen:

• Yellow background … device can still operate for a few hours

• Red background + warning sound ... device will shortly switch off

The Commander can be operated using an external electricity source. Connect it to the

mains voltage or to your vehicle’s 12 volt socket. A guide on the round plug of the

charging cable and a groove on the charging socket of the Commander specify the

correct alignment of the plug.

As soon as the Commander is connected to the external power supply, its battery is

charged up automatically. This is shown by the red charging indicator light and by the

arrow in the battery symbol at the bottom right of the screen. Charging takes

approximately 12 hours. The battery is fully charged once four bars are shown in the

battery symbol. After the battery is fully charged, the Commander switches to trickle

charging.

During charging, the ambient temperature should be between

10°C and 40°C (50°F and 104°F). Otherwise the device could be damaged!

Only use the supplied charging cable to connect the Commander to

CAUTION

The Commander automatically switches off if no input is made within a specified time

period. This timespan can be configured in the system settings (see page 26).

external power sources.

If you experience problems with the battery, please contact your SebaKMT

sales partner. Do not open the device yourself. The stated water- and dirtresistance can only be guaranteed if any work on the device is performed

solely by service departments authorised to do so.

30

Page 31

Working in Easy mode

Name of the

5 Working in Easy mode

5.1 Starting up the Commander

5.1.1 Switching on the Commander

Switch on the Commander by pressing the I/O button .

The Easy mode main menu appears on the screen:

Changing the

user mode

Changing the language

5.1.2 Checking the basic settings

workgroup

In Easy mode, the symbol is continuously shown at the bottom of the screen. If

you do not see this symbol, the Commander is in Professional mode. To switch to Easy

mode, open the system settings menu. Starting from the start screen, follow the

symbols and, in the first line of the menu, select the “Easy mode” setting

from the list.

The screen might not be displaying the correct language. The language can be changed

in the system settings menu. Beginning at the start screen, follow the

symbols and select your language from the list.

Before a measuring session, check that the Commander’s system settings are up-todate and correct (see page 26). The date and time settings in particular must be correct.

Beginning at the start screen, follow the symbols to open the system

settings menu.

System date

31

Page 32

Working in Easy mode

5.1.3 Defining a workgroup

More than one group of loggers can be registered in the Commander. However, the

Commander can only work with one of these groups at a time. This group is called the

“workgroup”.

Specify the workgroup for the impending measurement session. Please proceed as

follows:

Step Description

1

In the main menu, select the System settings button.

2 In the next menu, select the Change group button.

Result: A list with all the registered logger groups opens.

The current workgroup is indicated by an X.

3

Select a logger group for the measurement session.

Result: The selected group is now registered in the Commander as the

workgroup. In the main menu, the name of the workgroup is shown at the

bottom left of the display area.

Each logger group in the list has already been assigned its group mode (see

page 13).

Groups with an “L” before the name can only be read using “Lift & Shift”, i.e. all

the loggers in the group are collected and then read together.

Groups with a “P” before the name can only be read using “Patrol”, i.e. all the

loggers in the group remain in the shaft and are read on location individually.

The loggers of a group with an “N” before the name are networked together and

connected to a GSM-Box. These loggers can’t be read by a reading device but

send their data regularly to a FTP server.

32

Page 33

Working in Easy mode

5.2 Programming the loggers

Introduction

Procedure

The loggers in the workgroup must be reprogrammed before each session. This means

that the Commander sends basic data for the session wirelessly to the loggers (e.g. the

measuring window).

To program the workgroup proceed as follows:

Step Description

1

In the main menu, select the Prepare loggers button.

Result: The workgroup is shown. The name of the group is at the very top of

the display, and all the loggers in the group are listed underneath.

2 Select the Prog. Group button.

Result: The next step is shown.

3

Switch off all the loggers in the group, i.e. place them “on their head” for about

three minutes.

As an aid, a three-minute countdown on the screen can be started with the

Start button.

Then select the OK button.

Result: The next step is shown.

33

(continued on the next page)

Page 34

Working in Easy mode

Step Description

4

Switch on all the loggers in the group, i.e. place them “on their foot”.

Select the OK button to confirm.

Result: The next display provides information about the data used to program

the loggers.

(It is not possible to change this configuration data in Easy mode).

5 Select the Program button.

Result: The next display opens and the Commander automatically begins

transferring data to the loggers.

Possible sources of

error

The flashing antenna symbol on the bottom left of the display area indicates

that the data transfer is in progress. The left-hand window shows all the loggers

in the group already programmed. The right-hand window contains all the

loggers with which no contact has yet been possible.

The Stop button can be used to cancel programming at any time. It can be

recommenced with the Start button.

The procedure ends automatically once all the loggers in the group have been

successfully programmed.

The loggers are now ready to be installed for use on location.

Use the ESC button to return to the main menu.

From now on, do not place the loggers on their head because switching off

would cause them to lose their configuration data and they would need to be

reprogrammed.

If a logger could not be programmed, it may be because it was not in “Configuration

mode” at the time of programming, (see page 14) i.e. it had not been properly switched

off and switched back on 3 minutes later. It is also possible that the logger is not within

the wireless range of the Commander. The ideal distance between a logger and the

Commander is about one meter.

34

Page 35

Working in Easy mode

5.3 Installing the loggers

Basics

Horizontal installation

Install the loggers of the workgroup in succession along the stretch of pipe. It is best to

fit them directly on the pipe. However, you can also attach the loggers to valve rods or

hydrants, for example, or any other position along the pipeline that is easily accessible.

There must be the best possible contact between the logger foot or the mounted

adapter (see below) and the pipe.

If the logger is attached to a valve rod, for example, make sure the surface is as flat as

possible. Clean the rod thoroughly (preferably with a wire brush).

Due to their powerful magnet, the loggers can also be attached horizontally to

ferromagnetic surfaces. You must however make sure the red mark on the logger is

facing upwards. Otherwise the internal tilt switch will switch the logger off after

3 minutes.

Loggers with the mark facing upwards are

switched on.

Loggers with the mark facing downwards are

switched off.

Special cases

If the logger cannot be attached anywhere directly, the accessories for the Sebalog N-3

set have various adapters.

If, for example, the surface of the valve rod is not flat, or not magnetic, unscrew the

magnet on the foot of the logger and fit the 20 mm or 42 mm valve rod adapter

(optionally available) instead.

When installing the logger on an underground hydrant, you can fit it on the valve rod or

on the side of the rod, depending on the height of the shaft. Use the magnetic angle

adapter, for example, for side mounting.

For underground hydrants with bayonet fittings, you can use the underground hydrant

adapter. Fit the adapter in the hydrant claw.

For plastic domestic pipes (water meter fittings), use the plastic fitting, if necessary in

combination with the angle adapter.

35

Page 36

Working in Easy mode

Installation examples

The following pictures show a few methods for installing N-3 noise loggers:

Logger on the valve rod of an

underground hydrant

Logger on an underground hydrant

Logger with an angle adapter

on the valve rod

Logger with an angle adapter

horizontally on the valve rod

Logger with an angle adapter

on the hydrant claw

36

Page 37

Working in Easy mode

5.4 Reading out the measured data

After the loggers have been installed on location for at least one measuring day, the

recorded measured data can be read out with the Commander. The exact same group

mode (“Lift&Shift”/“Patrol”/”Network”) for which the workgroup was programmed is used.

Groups with an “L” before the name can only be read using “Lift & Shift”, i.e. all the

loggers in the group are collected and then read together.

Groups with a “P” before the name can only be read using “Patrol”, i.e. all the loggers in

the group remain in the shaft and are read on location individually.

The loggers of a group with an “N” before the name are networked together and

connected to a GSM-Box. These loggers can’t be read by a reading device but send

their data regularly to a FTP server.

37

Page 38

Working in Easy mode

5.4.1 Reading out a “Lift&Shift” group

To read out the measured data in the loggers, proceed as follows:

Step Description

1

Collect up all the loggers of the group and place them next to the Commander.

Avoid placing the loggers on their head! The stored data would not be

lost if the loggers were switched off, but it would no longer be indicated

if a logger is in leak status or not (see page 14).

2 In the main menu of the Commander, select the Readout loggers button.

Result: The Commander and the loggers are connected. Data transfer begins

automatically. The antenna symbol in the bottom left of the display flashes.

As soon as the Commander detects a logger, it receives its measured data. The

corresponding logger switches from the right-hand to the left-hand window on

the screen.

The coloured background of the read data in the left-hand window reflects the

probability of a leak.

No colour … Leak probability low, leak threshold was not exceeded

Grey … Leak probability not available, logger in configuration mode

(was switched off during or after the measurement)

Other

colour

… Leak probability high! Leak threshold exceeded!

The colour reflects approximately the frequency of the leak

noise:

Blue

0 Hz

2,500 Hz

Yellow

If a logger’s comment is on a red background, this means that its battery is

weak.

3 The Stop button can be used to cancel reading at any time. It can be continued

with the Start button.

The procedure finishes automatically once the Commander has received and

saved the measured data from all the loggers in the group.

If a logger could not be read, it may have been switched off, not ready for

wireless operation or it was outside the Commander’s wireless range.

4

You can immediately view the data of a logger that has just been read. To do so,

select the left-hand window on the screen and then select the respective logger.

Result: The logger’s measured data is shown (see page 42).

Use the ESC button to return to the main menu.

38

Page 39

Working in Easy mode

5.4.2 Reading out a “Patrol” group

To read out the measured data in the loggers, proceed as follows:

Step Description

1 In the main menu of the Commander, select the Patrol Loggers button.

Result: The Commander is ready to receive the measured data from the

individual loggers. The antenna symbol in the bottom left of the display flashes.

2

Move into the wireless range of each logger one after the other.

If the radio signals of the loggers are strong enough, the data can also be

collected while in the car, simply by driving past where the loggers are installed.

The Commander’s standard antenna can be replaced with the supplied vehicle

antenna to do this.

As soon as the Commander has detected a logger, the following message

appears on the screen:

Logger comment

Logger ID

Level/frequency of the

quietest noise in the

measuring period

The message has a coloured background. The colour shows straightaway

whether the programmed leak threshold has been exceeded or not during the

measuring period.

• Yellow … Attention! Leak threshold exceeded!

• Blue ... Leak threshold not exceeded

There is an acoustic signal along with the message:

• Long tone ... Attention! Leak!

• Short tone … No leak

As standard, the tone sounds each time a logger is detected. It can be

deactivated in the system settings of Professional mode (see page 27).

If the displayed message contains a battery symbol, this means the battery of

the particular logger is weak.

If the displayed message contains a clock symbol, this means the logger’s

internal clock differs from the system time of the reading device by more than

30 minutes. The logger group concerned should be reprogrammed. The logger’s

clock is synchronised with that of the Commander. It is only possible to change

the time of individual loggers in Professional mode.

39

(continued on the next page)

Page 40

Working in Easy mode

Step Description

The detected logger switches from the right-hand to the left-hand window on the

Commander screen. The coloured background of the read data reflects the

probability of a leak.

No colour … Leak probability low,

leak threshold was not exceeded

Grey … Leak probability not available,

logger in config. mode,

(was switched off during or after the measurement)

Other colour … Leak probability high!

Leak threshold exceeded!

The colour reflects approximately the frequency of the

leak noise:

Blue

0 Hz

2,500 Hz

Yellow

If a logger’s comment is on a red background, this means its battery is weak.

3 The Stop and Start buttons can be used to cancel and continue reading at any

time.

The procedure finishes automatically once the Commander has received and

saved the measured data from all the loggers in the group.

During “Patrolling”, the complete measured data set is only transferred

to the Commander from loggers in leak status (see page 14). To save

power, if the quietest noise in a measurement is below the programmed

leak threshold, the loggers will only send a small packet to the

Commander, with the level and frequency of this noise. If necessary, the

complete measured data of these loggers can be called up using single

interrogation in Professional mode (see page 54).

If a logger could not be read, it may have been switched off, not ready for

wireless operation or it was outside the Commander’s wireless range.

4

You can immediately view the data of a logger that has just been read. To do so,

select the respective logger in the left-hand window on the screen.

Result: The logger’s measured data is shown (see page 42). Use the ESC

button to return to the main menu.

40

Page 41

Working in Easy mode

5.5 Evaluating the measured data

You can use the Commander to view the measured data read out from a logger and to

analyse it in greater detail.

5.5.1 Calling up the measured values

To call up the measured data of a logger, proceed as follows:

Step Description

1

In the main menu, select the Display logger data button.

Result: The loggers in the workgroup are listed in the next view.

2 Call up the data of the highlighted logger using the View button or select

another logger in the list.

Result: The logger’s measured data is shown (see page 42).

41

Page 42

Working in Easy mode

4

3

2

1

5.5.2 Displaying the measured values

View

The measured data from the loggers are shown as a bar diagram on the screen.

1

2

Element Description

4

3

4

Identification number and comment of the displayed logger

Diagram

Each bar represents a single noise recording.

X-axis ... course of measurement over time

Y-axis ... noise level in dB

The colour of the bar shows the approximate frequency of the noise.

Blue

0 Hz

Yellow

2,500 Hz

The point where the two green lines intersect marks the quietest recording in

the displayed measurement, the so-called “leak value”.

Leak value (lowest value to be displayed)

The leak value refers to the quietest recording in the displayed measuring

period. The values of this recording are shown in the three fields directly

under the diagram:

Left-hand field … ESA value of the recording

Centre field … Noise level in dB for the quietest measurement

Right-hand field … Frequency of the noise in Hz

Buttons to access individual functions (see below)

42

Page 43

Working in Easy mode

Functions

There are the following functions for analyzing the displayed data:

Button Description

Scroll

You can use this function to view in the diagram the measurement

results of the other loggers in the group.

To do so, apply the button and turn the selector knob to select a logger.

Apply the button again to confirm your selection.

Move

Cursor

You can use this function to move the vertical green line in the diagram

from one bar to the next. The values of the particular noise measurement

(volume, frequency, ESA) and the time of the recording are shown.

To do so, apply the button and turn the selector knob. Apply the button

again to end the function.

Details

This function opens a new window on the screen. It shows the

configuration data of the particular logger at the time of the measurement.

You can use the Scroll button to view the configuration data of the other

loggers in the group. Use the OK button to return to the measured data

display.

Mode

You can use this function to change the measurement unit on the Y-axis

in the diagram.

Standard view … The Y-axis shows the volume of the noises. Each bar

in the diagram represents a single recording.

ESA view

… The Y-axis shows the ESA value.

Each bar represents the quietest recording of a

measuring day.

43

Page 44

Working in Professional mode

6 Working in Professional mode

6.1 Starting up the Commander

6.1.1 Switching on the Commander

Switching on

Changing the

user mode

Changing the language

Use the I/O button to switch on the Commander.

The Professional mode start image appears on the screen:

Workgroup

Firmware version,

Main menu bar

If the symbol is shown at the bottom in the middle of the screen, the

Commander is not in Professional mode but Easy mode instead. To switch to

Professional mode, open the system settings menu. Beginning at the start screen, follow

the symbols and, in the first line of the menu, select the “Professional

mode” setting from the list.

The screen might not be displaying the correct language. The language can be changed

in the system settings. Beginning at the start screen, follow the

symbols and select your language from the list.

System date,

Identification number of

the Commander

6.1.2 Checking the system settings

Before a measuring session, check that the Commander’s system settings are up-todate and correct (see page 25). The date and time settings in particular must be correct.

6.1.3 Registering loggers in the Commander and specifying the

workgroup

The loggers to be used for an impending measurement must be registered and

combined in a group (see page 23) in the Commander.

To specify the workgroup (see page 14), select the symbol in the main menu bar,

open the Group Management menu and select a group in the list of registered logger

groups (marked with an X).

However, a lot of menus in Professional mode also have a drop-down list at the very top

of the screen. It can be used to access a group list directly and select a workgroup.

44

Page 45

Working in Professional mode

6.2 Managing the loggers

All loggers to be used for a measurement must be registered in the Commander

beforehand. Only registered loggers can be programmed and read. Registration is

performed either by manually inputting the logger ID or by automatic wireless detection.

The registered loggers are combined in groups.

6.2.1 Managing logger groups in the Commander

Introduction

Managing groups

Defining a workgroup

Creating a new group

All loggers registered in the Commander must be assigned to a group. The Commander

can only communicate with one of the logger groups created, the so called “workgroup”

(see page 14).

Logger groups can be created, deleted, copied and renamed directly on the

Commander.

Select the symbol in the main menu, and the Group Management button in the

next view, to go to the menu for managing logger groups. All the registered logger

groups are listed.

The workgroup is marked with an X in the view. To turn another logger group into the

workgroup, select the list and then a group.

To create a completely new logger group in the Commander, proceed as follows:

Step Description

1 Select the Add button.

Result: A new view opens.

2

Select the group mode (see page 13) for the new group and confirm with OK.

After the group is created, the group mode can no longer be changed.

All loggers in a group must belong to the same group mode as the

group itself (e.g. a “Lift&Shift” group may only contain “Lift&Shift”

loggers).

Result: A new view opens.

3

Enter a name for the new group. Use the virtual keyboard for this.

To complete the input, select the ENTER button.

Result: The new group is now created in the Commander. The display jumps

automatically to the Logger Management menu.

4

Use this menu to assign loggers to the newly created group (see page 47).

45

Page 46

Working in Professional mode

Renaming a group

Copying a group

Deleting a group

You can rename an existing logger group.

First select the particular group in the list and then select the Rename button. In the

following screen views, enter a group mode (see page 13) and the new name of the

group.

The group then appears with the new name in the group list.

You can copy an existing logger group, with all its loggers, within the list and allocate a

new name and new group mode to this copy. (This can be useful if, for example, you

wish to use the loggers of an existing “Lift&Shift” group for the next measuring

assignment, but would like to read out data by “Patrolling”.) The new group

automatically adopts the configuration data of the original group but contains no

measured data at all.

First select the particular group in the list and then select the Copy button. In the

following screen views, enter the group mode (see page 13) and the name of the new

group.

The new group then appears in the group list. If needed, more new loggers can now be

allocated to it (see page 47).

You can delete a logger group from the Commander.

First select the particular group in the list. Then select the Delete button and answer the

confirmation query with Yes.

If the loggers in this group are not contained in any other existing groups, deleting

simultaneously de-registers them from the Commander. The measured data of the

group is retained in the history as long as the “History” function is active (see page 26).

Otherwise the data will be lost.

46

Page 47

Working in Professional mode

6.2.2 Managing the loggers in the Commander

Select the symbol in the main menu, and the Logger Management button in the

next view, to go to the menu for managing loggers. The loggers of the workgroup (see

page 45) are listed.

If the incorrect group is displayed, you can use the pull-down menu at the top edge of

the screen to change the workgroup.

If you do not wish to allocate a new logger to an existing but to a completely new group

instead, this new group must be created beforehand (see page 45).

Registering loggers

using automatic

detection

A logger can be registered using “automatic detection”. For this purpose, it has to be

close to the Commander and switched off. Proceed as follows:

Step Description

1 Apply the Add logger button.

2

Switch the logger on.

Result: Directly after it is switched on, the logger sends a signal with its

identification number a few times. Once the logger is detected by the

Commander, New ID found appears on the screen. The ID of the logger is

displayed underneath.

3 Select Accept to add the logger to the group or Decline to discard it.

4

If you want to number the loggers consecutively, stick the supplied selfadhesive label with the number of the automatically assigned comment on the

logger (see below).

5

Use the same method to add all the other new loggers to the group. When

loggers need to be switched on, always bring them close to the Commander

singly. This is because only the last detected ID is shown on the screen and

able to be registered.

6 Apply the Finish button to complete the procedure.

Result: The registered loggers are now shown in the list.

47

Page 48

Working in Professional mode

Registering loggers

manually

Numbering loggers

Changing a comment

A logger can be registered manually by entering its ID. Proceed as follows:

Step Description

1 Apply the Add logger button.

2

Type in the logger’s six-digit ID using the displayed keyboard (see page 14).

Confirm the input with the ENTER button.

Result: The registered logger is now shown in the list.

3

If you want to number the loggers consecutively, stick the supplied selfadhesive label with the number of the automatically assigned comment on the

logger (see below).

4