Page 1

Consultation with SebaKMT

User Manual

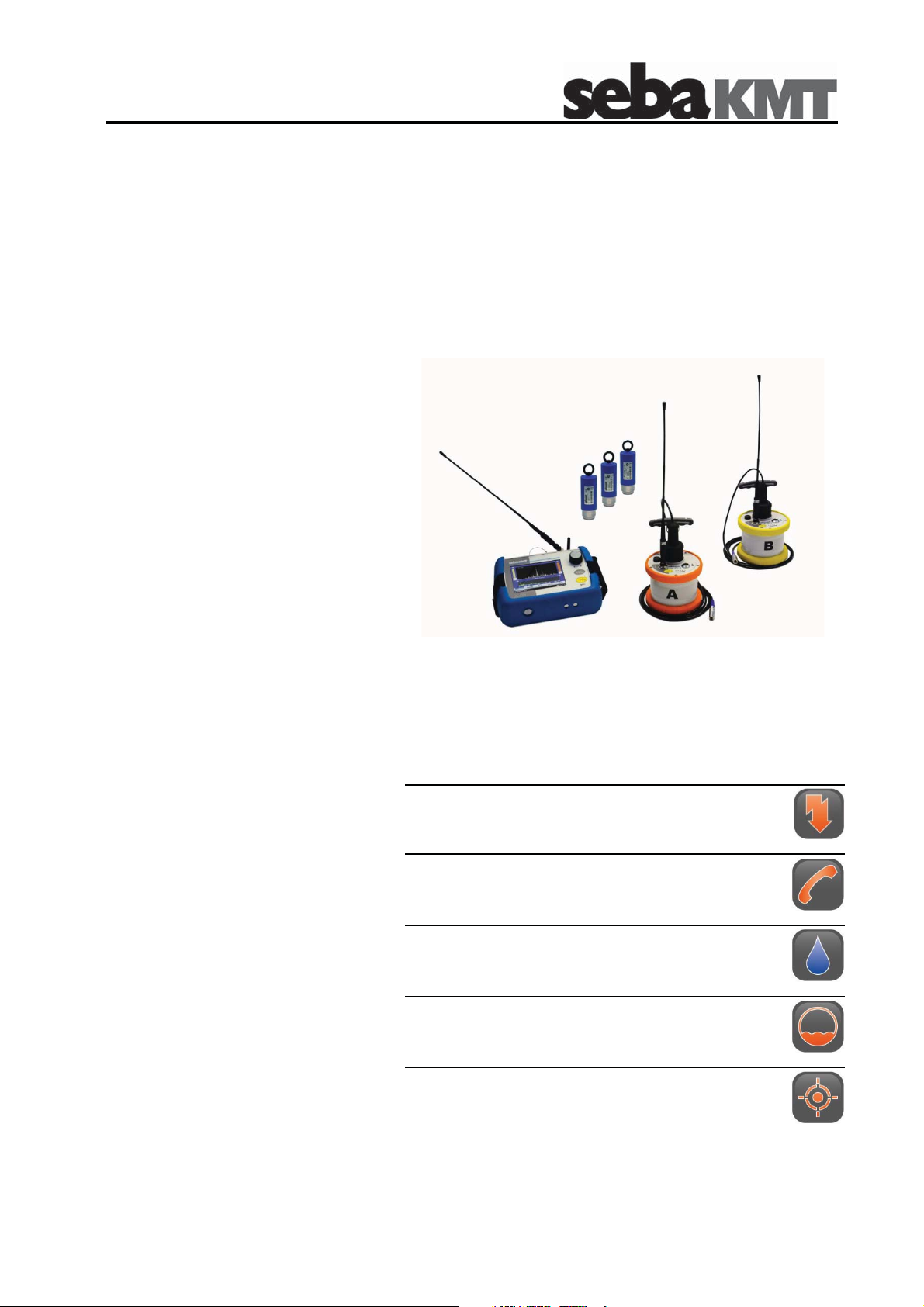

Correlator

Correlux C-3

Mess- und Ortungstechnik

Measuring and Locating Technologies

Elektrizitätsnetze

Power Networks

Kommunikationsnetze

Communication Networks

Rohrleitungsnetze

Water Networks

Abwassernetze

Sewer Systems

Leitungsortung

Line Locating

Issue: 3.2 (02/2016) - EN

1

Article number: 84416

Page 2

Consultation with SebaKMT

2

Page 3

Consultation with SebaKMT

Consultation with SebaKMT

The present system manual has been designed as an operating guide and for

reference. It is meant to answer your questions and solve your problems in as fast and

easy a way as possible. Please start with referring to this manual should any trouble

occur.

In doing so, make use of the table of contents and read the relevant paragraph with

great attention. Furthermore, check all terminals and connections of the instruments

involved.

Should any question remain unanswered or should you need the help of an authorized

service station, please contact:

Seba Dynatronic

Mess- und Ortungstechnik GmbH

Dr.-Herbert-Iann-Str. 6

D - 96148 Baunach

Phone: +49 / 9544 / 68 – 0

Fax: +49 / 9544 / 22 73

E-Mail: sales@sebakmt.com

http://www.sebakmt.com

Hagenuk KMT

Kabelmesstechnik GmbH

Röderaue 41

D - 01471 Radeburg / Dresden

Phone: +49 / 35208 / 84 – 0

Fax: +49 / 35208 / 84 249

© SebaKMT

All rights reserved. No part of this handbook may be copied by photographic or other means unless SebaKMT

have before-hand declared their consent in writing. The content of this handbook is subject to change without

notice. SebaKMT cannot be made liable for technical or printing errors or shortcomings of this handbook.

SebaKMT also disclaims all responsibility for damage resulting directly or indirectly from the delivery, supply,

or use of this matter.

3

Page 4

Terms of Warranty

Terms of Warranty

SebaKMT accept responsibility for a claim under warranty brought forward by a

customer for a product sold by SebaKMT under the terms stated below.

SebaKMT warrant that at the time of delivery SebaKMT products are free from

manufacturing or material defects which might considerably reduce their value or

usability. This warranty does not apply to faults in the software supplied. During the

period of warranty, SebaKMT agree to repair faulty parts or replace them with new parts

or parts as new (with the same usability and life as new parts) according to their choice.

This warranty does not cover wear parts, lamps, fuses, batteries and accumulators.

SebaKMT reject all further claims under warranty, in particular those from consequential

damage. Each component and product replaced in accordance with this warranty

becomes the property of SebaKMT.

All warranty claims versus SebaKMT are hereby limited to a period of 12 months from

the date of delivery. Each component supplied by SebaKMT within the context of

warranty will also be covered by this warranty for the remaining period of time but for 90

days at least.

Each measure to remedy a claim under warranty shall exclusively be carried out by

SebaKMT or an authorized service station.

This warranty does not apply to any fault or damage caused by exposing a product to

conditions not in accordance with this specification, by storing, transporting, or using it

improperly, or having it serviced or installed by a workshop not authorized by SebaKMT.

All responsibility is disclaimed for damage due to wear, will of God, or connection to

foreign components.

For damage resulting from a violation of their duty to repair or re-supply items,

SebaKMT can be made liable only in case of severe negligence or intention. Any liability

for slight negligence is disclaimed.

Since some states do not allow the exclusion or limitation of an implied warranty or of

consequential damage, the limitations of liability described above perhaps may not

apply to you.

For FCC:

- User Information acc. to FCC15.21:

Changes or modifications not expressly approved by the party responsible for

compliance could void the user's authority to operate the equipment.

- Part 15 Statement gem. FCC 15.19/RSS Gen Issue 3 Sect. 7.1.3

This device complies with Part 15 of the FCC Rules and with Industry Canada

license-exempt RSS standard(s). Operation is subject to the following two

conditions:

(1) this device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause

undesired operation

4

Page 5

Terms of Warranty

Contents

Consultation with SebaKMT ........................................................................................... 3

Terms of Warranty ........................................................................................................... 4

1

1.1

1.2

2

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

3

3.1

Safety Instructions ........................................................................................... 9

General Safety Instructions and Warnings ......................................................... 9

General Notes .................................................................................................... 9

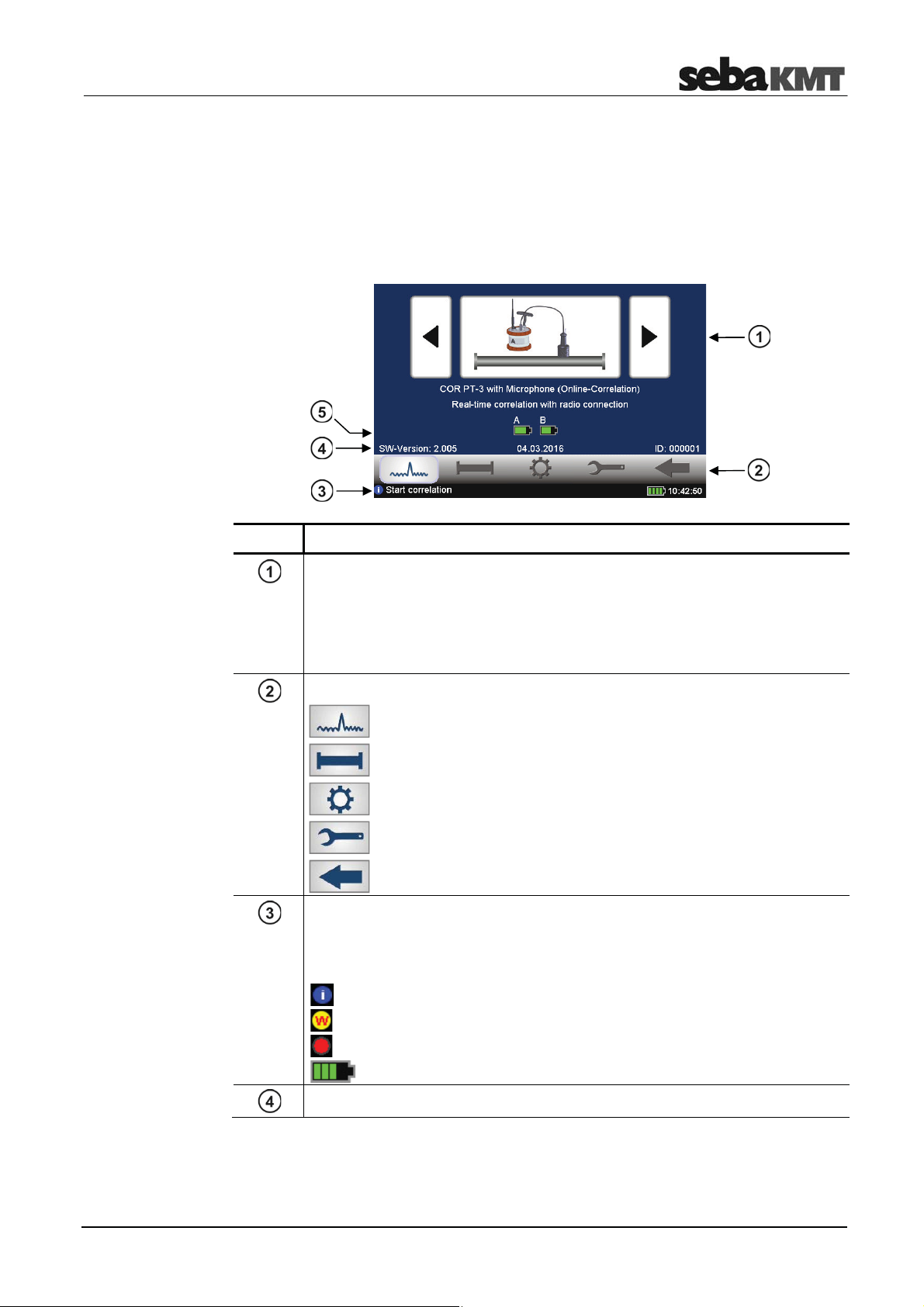

Frequently used menus ................................................................................. 11

Start menu ........................................................................................................ 11

Pipe data menu ................................................................................................ 13

Correlation menu .............................................................................................. 15

Correlation menu (Offline correlation) .............................................................. 17

Correlation analysis menu ................................................................................ 19

Frequency analysis menu ................................................................................ 21

Audio menu ...................................................................................................... 23

Audio menu (when ground microphone is connected) ..................................... 25

Technical description .................................................................................... 27

Function ............................................................................................................ 27

3.2

3.3

3.4

3.5

3.6

4

4.1

4.2

4.3

4.4

4.5

5

5.1

5.2

5.3

5.4

Features of the set ........................................................................................... 28

Communication of the components .................................................................. 29

Power supply .................................................................................................... 29

Scope of delivery .............................................................................................. 30

Technical data .................................................................................................. 31

The Power transmitters ................................................................................. 33

Function and Design ........................................................................................ 33

Identification number (ID) ................................................................................. 35

Power supply .................................................................................................... 35

Commissioning ................................................................................................. 36

Installation ........................................................................................................ 36

The Multi sensors ........................................................................................... 37

Design and function .......................................................................................... 37

Identification number (ID) ................................................................................. 37

Power supply .................................................................................................... 38

Switching ON/OFF ........................................................................................... 38

5.5

5.6

6

6.1

Installation ........................................................................................................ 39

Angle adapter ................................................................................................... 39

The Correlator ................................................................................................. 41

Design and function of the device .................................................................... 41

5

Page 6

Terms of Warranty

6.2

6.3

6.4

6.4.1

6.4.2

6.4.3

6.4.4

6.4.5

6.5

6.5.1

6.5.2

6.5.3

6.5.4

6.5.5

6.6

6.6.1

6.6.2

6.6.3

Power supply .................................................................................................... 43

Design of the user interface ............................................................................. 44

Basics of operation ........................................................................................... 45

Input methods ................................................................................................... 45

Entering identification numbers ........................................................................ 45

Entering text ..................................................................................................... 46

Sorting devices in lists and tables .................................................................... 47

ESC pushbutton and "Back" button ................................................................. 47

Commissioning ................................................................................................. 48

Switch the Correlator ON/OFF ......................................................................... 48

Basic settings at initial start-up ......................................................................... 48

Change the language ....................................................................................... 49

Activate the display light ................................................................................... 49

Enable/Disable the touch screen (touch sensitivity) ........................................ 50

System settings ................................................................................................ 51

Basic settings ................................................................................................... 51

System info ....................................................................................................... 53

Saving the settings ........................................................................................... 53

6.7

6.7.1

6.7.2

6.8

7

7.1

7.2

7.3

7.4

7.5

8

8.1

8.2

8.3

9

10

Communication ................................................................................................ 54

Connection between the Correlator and the sensors ....................................... 54

Connection between the Correlator and the computer .................................... 54

Hardware reset ................................................................................................. 54

Sensor management ...................................................................................... 55

Introduction ....................................................................................................... 55

Access the sensor pool .................................................................................... 55

Register sensors .............................................................................................. 57

Replace / Delete sensors ................................................................................. 58

Additional functions .......................................................................................... 59

Online correlation ........................................................................................... 61

Measurement with 2 Power transmitters .......................................................... 61

Measurement with only 1 Power transmitter .................................................... 65

How to exchange A - B on the screen .............................................................. 67

Offline correlation (Multipoint measurement) ............................................. 69

GPS position data .......................................................................................... 77

10.1

10.2

10.3

11

12

12.1

Introduction ....................................................................................................... 77

Determine and save GPS coordinates ............................................................. 77

Distance measurement and navigation via GPS ............................................. 79

Real-time measurement ................................................................................. 81

Sound velocity measurement ....................................................................... 85

Velocity measurement in Online measurement mode ..................................... 85

6

Page 7

Terms of Warranty

12.2

Velocity measurement in Offline measurement mode ..................................... 88

12.2.1Introduction ....................................................................................................... 88

12.2.2Procedure ......................................................................................................... 89

12.2.3Notes and examples ......................................................................................... 91

13

14

14.1

14.2

14.2.1Call up and display a correlation ...................................................................... 98

14.2.2Rename a correlation / Create a comment ...................................................... 99

15

16

16.1

16.2

16.3

Map function ................................................................................................... 93

Storage / Management of correlations (History) ......................................... 97

Storing a correlation ......................................................................................... 97

Managing stored correlations ........................................................................... 98

Reset of correlation settings and data ....................................................... 101

Pinpointing .................................................................................................... 103

Introduction ..................................................................................................... 103

Pinpointing using the ground microphone ...................................................... 103

Pinpointing using Multi sensor s ...................................................................... 107

17

18

18.1

18.2

18.2.1Work step 1: Download and store the update-file .......................................... 115

18.2.2Work step 2: Transfer and run the update-file................................................ 116

19

19.1

19.2

19.2.1Storage location for application database ...................................................... 123

19.2.2GPS receiver port ........................................................................................... 123

19.2.3System of units ............................................................................................... 123

19.2.4Logarithmic/linear display ............................................................................... 124

19.3

19.4

19.5

19.6

19.6.1Perform / display correlation........................................................................... 127

19.6.2Display / select audio blocks (Offline measurements only) ............................ 128

19.6.3Calling up the correlation analysis menu ....................................................... 129

19.6.4Selecting correlation method (Offline measurements only) ........................... 130

Query the status of a device ....................................................................... 111

Firmware update ........................................................................................... 113

How to update the Correlator ......................................................................... 113

How to update Power transmitters or Multi sensors ...................................... 115

CorreluxView Software ................................................................................ 121

User interface ................................................................................................. 121

Basic settings ................................................................................................. 123

Creating, renaming and deleting directories .................................................. 124

Importing data ................................................................................................ 125

Editing a map ................................................................................................. 125

Correlation ...................................................................................................... 127

7

Page 8

Terms of Warranty

8

Page 9

Safety Instructions

1 Safety Instructions

1.1 General Safety Instructions and Warnings

•

Do not drop the device / the system’s components or subject it / them to

strong impacts or mechanical shocks.

•

The limits described under Technical Data may not be exceeded.

•

The device / system must be in a technically perfect condition for

measurement.

•

The indicated degree of protection can only be ensured if plugs or the

provided protection caps are put in all sockets of the device.

•

The plugs of the supplied connection cables are only compliant to the

indicated degree of protection as long as they are plugged in. Plugs

which are not connected or which are connected in a wrong way are not

protected from water and dust ingress.

•

If the O-ring seal of a socket is obviously damaged, it must be replaced

in order to ensure the total protection against water and dust ingress.

1.2 General Notes

Safety precautions

Labelling of safety

instructions

This manual contains basic instructions for the commissioning and operation of the

device / system. For this reason, it is important to ensure that the manual is always

available to the authorised and trained operator. He needs to read the manual

thoroughly. The manufacturer is not liable for damage to material or humans due to nonobservance of the instructions and safety advices provided by this manual.

Locally applying regulations have to be observed!

The following signal words and symbols are used in this manual and on the product

itself:

Signal word /

Description

symbol

CAUTION

Indicates a potential hazard which may result in moderate or minor injury

if not avoided.

NOTICE

Indicates a potential hazard which may result in material damage if not

avoided.

Serves to highlight warnings and safety instructions.

As a warning label on the product it is used to draw attention to potential

hazards which have to be avoided by reading the manual.

Serves to highlight important information and useful tips on the operation

of the device/system. Failure to observe may lead to unusable

measurement results.

Check contents

Working with products

from SebaKMT

Check the contents of the package for completeness and visible damage right after

receipt. In the case of visible damage, the device must under no circumstances be taken

into operation. If something is missing or damaged, please contact your local sales

representative.

It is important to observe the generally applicable regulations of the country in which the

device will be operated, as well as the current national accident prevention regulations

and internal company directives (work, operating and safety regulations).

9

Page 10

Safety Instructions

Use genuine accessories to ensure system safety and reliable operation. The use of

other parts is not permitted and invalidates the warranty.

Repair and

maintenance

Special transportation

requirements

Electromagnetic

radiation

Repair and maintenance work has to be carried out by SebaKMT or authorised service

partners using original spare parts only. SebaKMT recommends having the system

tested and maintained at a SebaKMT service centre once a year.

SebaKMT also offers its customers on-site service. Please contact your service centre if

needed.

The lithium batteries of the device are dangerous goods. The transport of the batteries

itselves and of devices which contain such batteries is subject to regulations based on

the UN Model Regulations “Transport of Dangerous Goods” (ST/SG/AC.10-1).

Please inform yourself about the transportation requirements and follow them when

shipping the device.

This device is designed for industrial use. When used at home it could cause

interference to other equipment, such as the radio or television.

The interference level from the line complies with the limit curve B (living area), the

radiation level complies with the limit curve A (industrial area) according to EN 55011.

Given that living areas are sufficiently far away from the planned area of operation

(industrial area), equipment in living areas will not be impaired.

10

Page 11

Frequently used menus

2 Frequently used menus

2.1 Start menu

The Start menu appears on the screen after the device has been switched on. In

addition, the ESC pushbutton takes you back directly to the Start menu from every

menu level.

Element Description

Measuring mode selection

Arrow buttons ... To go forward / backward through the available

Large central button ... Opens the relevant measuring mode menu or starts

Main menu

Starts the Correlation

Opens the Pipe data menu

Opens the Tools menu

Opens the System settings menu

Goes Back to the previous menu

Info line

This line provides information on the display, comments and notes on how to

proceed. On the right, the Correlator's battery status and the time are

shown.

measuring methods.

the correlation.

this symbol indicates info texts

this symbol indicates warnings

this symbol indicates that an Offline measurement is in progress

shows the Correlator battery level

Firmware version / Date / Identification number (ID) of the device

11

Page 12

Frequently used menus

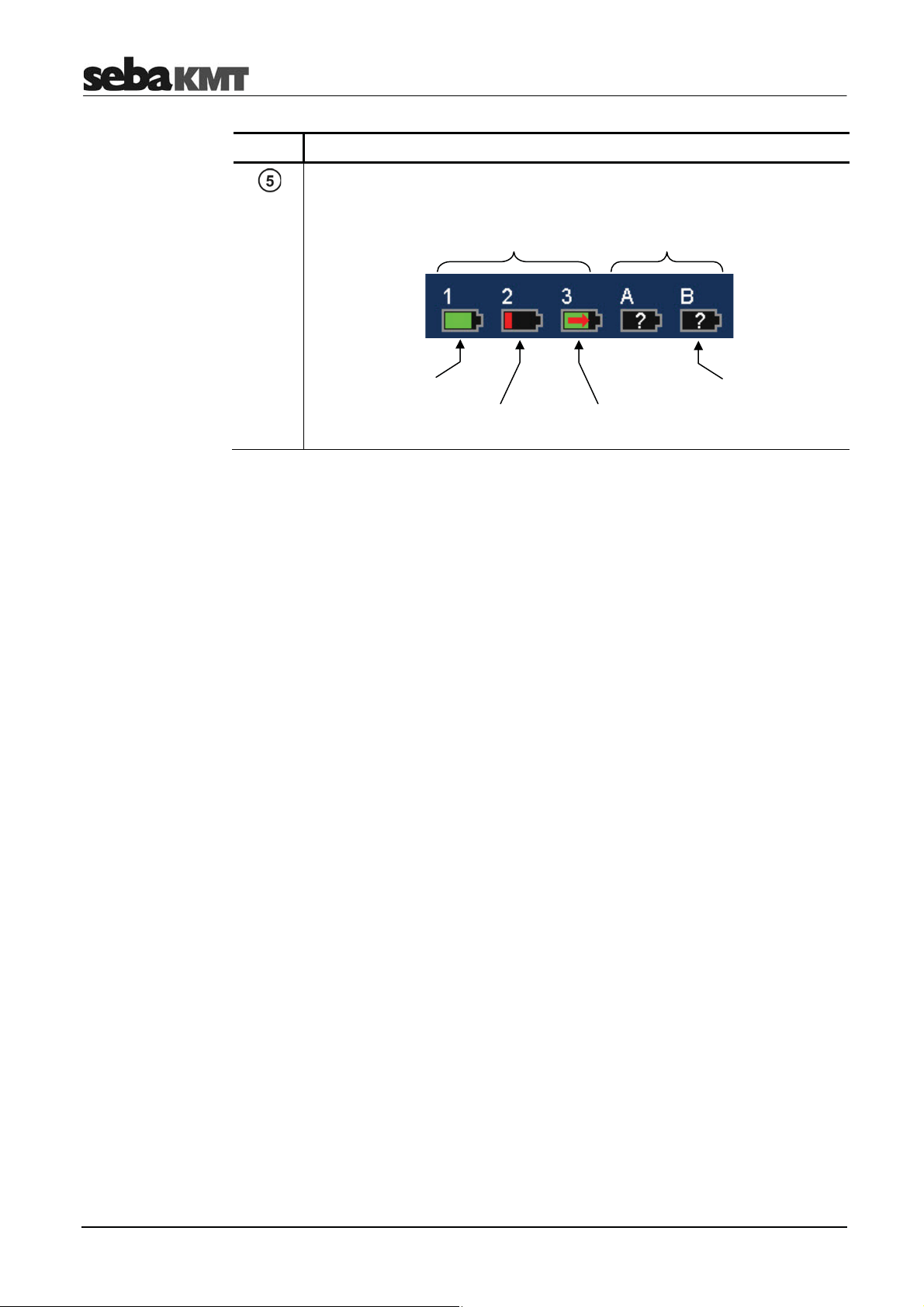

Element Description

Battery level of the received Power transmitters or Multi sensors.

Multi sensors

No.1 to 3

Fully charged

Critical

Power transmitters

"A" and "B"

Charging

No information

available about the

status of the device

12

Page 13

Frequently used menus

g

pip

pip

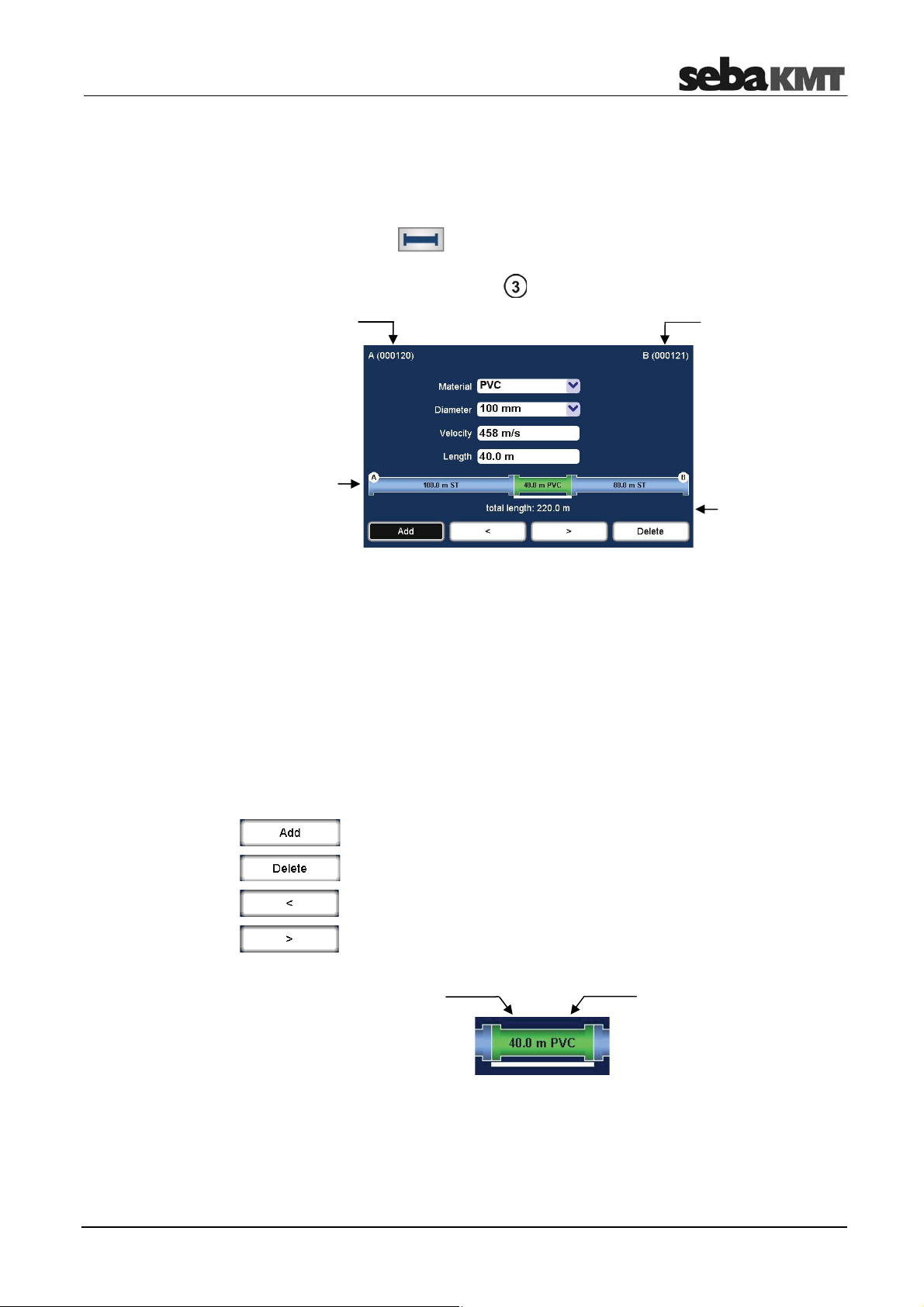

2.2 Pipe data menu

In the Pipe data menu the properties of the pipe can be specified.

The menu can be opened by:

•

tapping the button in the main menu

•

tapping the button between the two diagrams in the Correlation menu, representing

the pipe (see next section: button )

Drop down lists

Input fields

ID of the sensor

at the first

measuring point

Visual

illustration of

eline

the

Material

Diameter

Velocity

Length

ID of the sensor

at the second

measuring point

Totallength of

the

the measuring

points

... Select the pipe section's material.

... Select the pipe section's diameter.

... Input field for the pipe section's sound velocity.

The displayed value automatically adjusts to the selected pipe

material. The value can be entered manually when needed as well. To

do so, tap the field. A numeric keypad opens.

... Input field for the pipe section's length.

Tap the field. A numeric keypad opens.

e between

Buttons

Use these buttons to divide the pipe line displayed in up to 12 sections.

Use these buttons to move from one pipe section to the next.

Len

ths of the

pipe section

Pipe section

material

The selected pipe section is "highlighted" with a white bar. The pipe parameters in the

four input fields refer to this section.

13

Page 14

Frequently used menus

14

Page 15

Frequently used menus

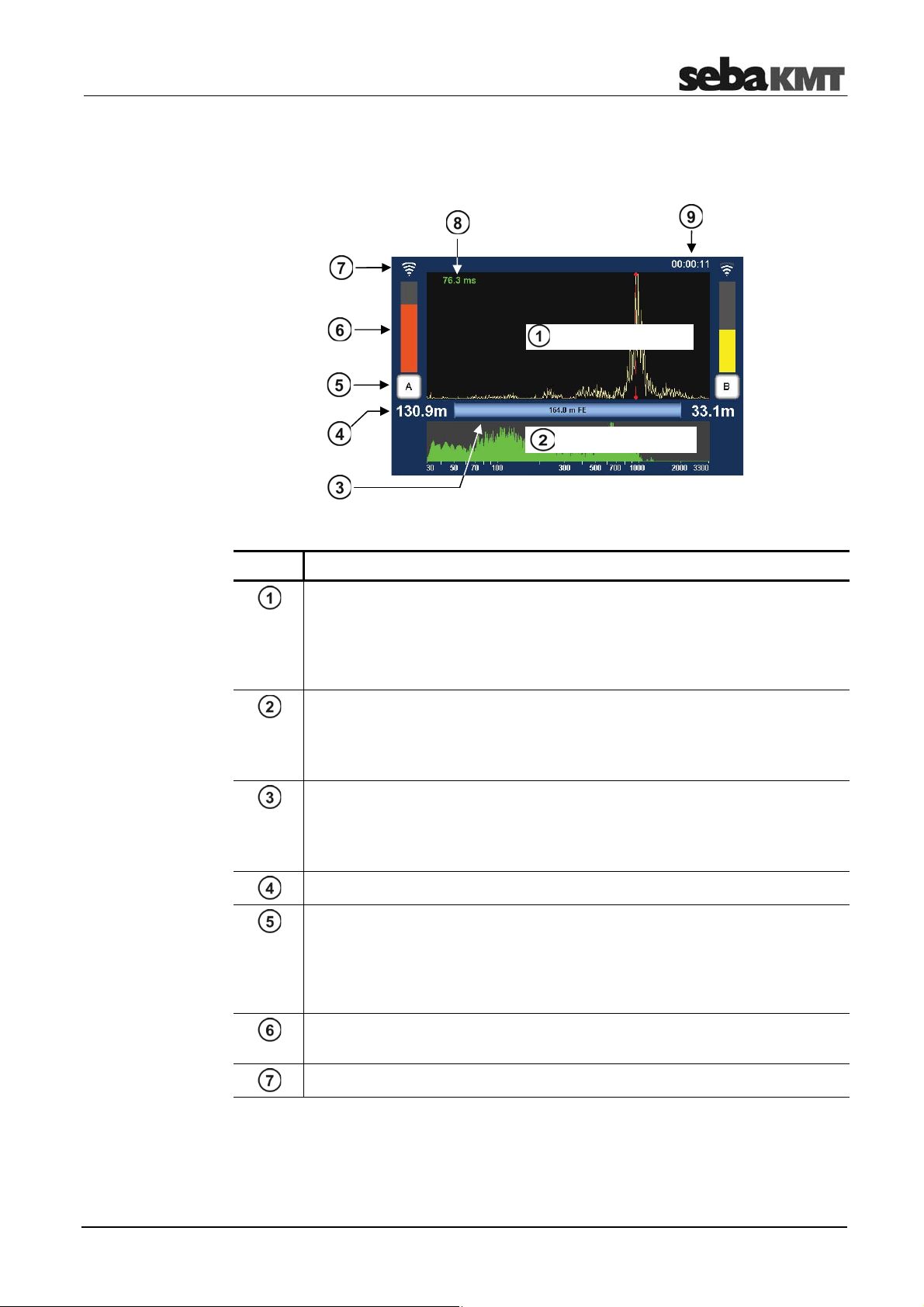

2.3 Correlation menu

After starting a correlation the result is displayed in the following view:

Correlation curve

Coherence curve

Element Description

Correlation curve

Result from comparing the recordings of the two sensors with regard to the

delay time of the signals.

Tap to open the Correlation analysis menu which provides a number of

analysis tools.

Coherence curve

Result from comparing the recordings of the two sensors with regard to the

frequency range of the recordings.

Tap to open the frequency filter settings menu.

Pipeline between A and B

The graphic illustrates the pipeline between the measuring points A and B

with all its sections.

Tap to open the Pipe data menu.

Distance from the measuring point to the leak

Measuring point A / B

Indicates whether the Power transmitter A or B is installed at this measuring

point.

Tap the button to open the Audio menu which can be used to listen to the leak

noise.

Noise level at the measuring point

The height of the bar reflects the noise level at the measuring point.

Quality of the radio link between transmitter and Correlator

15

(continued on next page)

Page 16

Frequently used menus

Element Description

Lag value

Indicates the delay of the leak noise between the two sensors. The color of

the numbers shows how reliable the result of this correlation is:

green

yellow

red

negat. sign

posit. sign

Term of the correlation

... "good" correlation, reliable result

... correlation is not optimal

... "bad" correlation; no leak or unreliable result

... The leak is on the left from the center of the line.

... The leak is on the right from the center of the line.

Specifies how long the displayed correlation is already running.

Any interruption resets the counter to 00:00:00.

16

Page 17

Frequently used menus

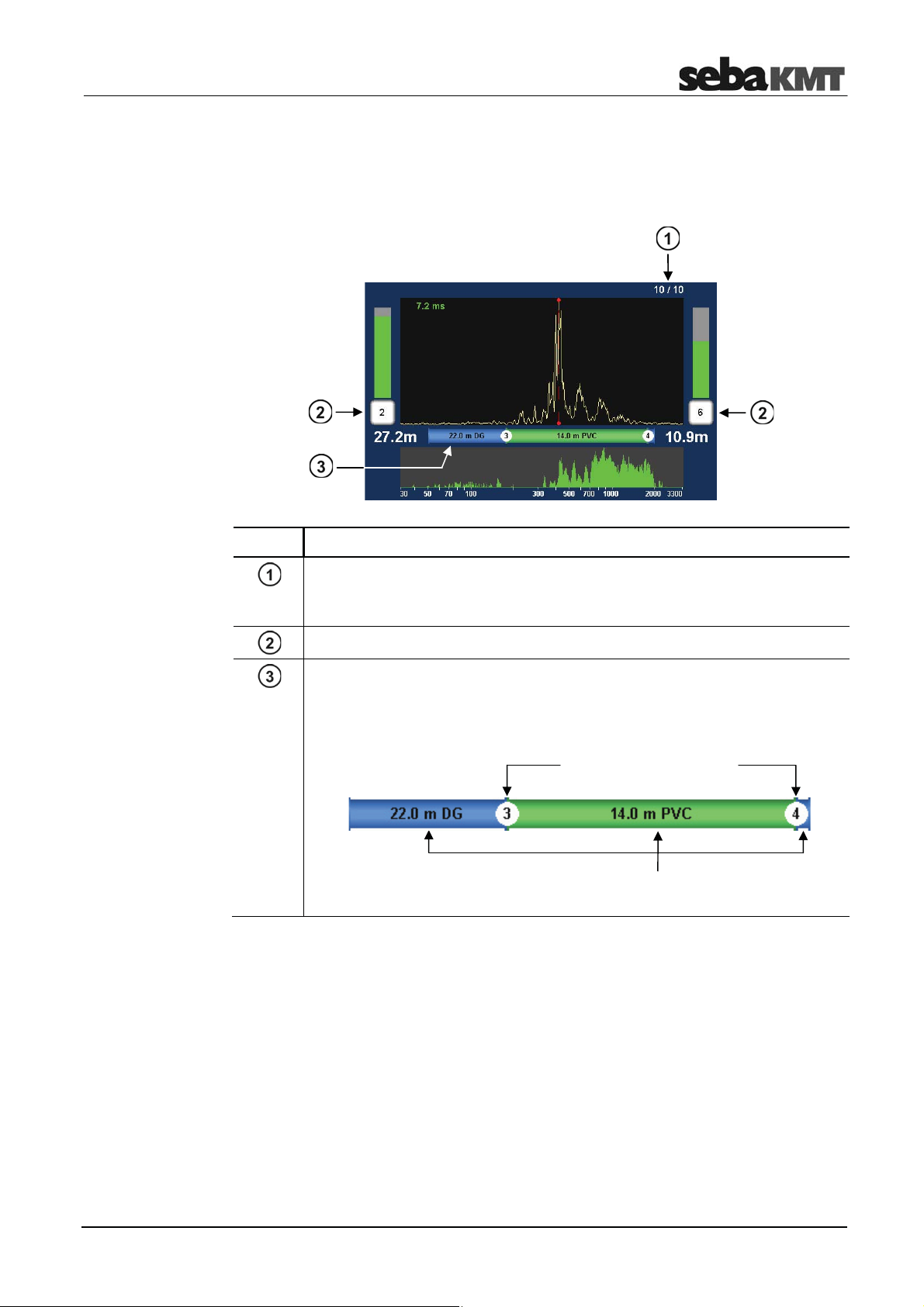

2.4 Correlation menu (Offline correlation)

In Offline measurement mode with Multi sensors, the Correlation menu differs in the

following aspects from the menu in Online measurement mode.

Element Description

Number of correlated audio blocks

The displayed curve is the result of an averaging from up to 10 single

correlations.

Number of the sensor at the measuring point

Pipeline between the measuring points

The graphic illustrates the pipeline between the measuring points.

Tap to open the Pipe data menu.

Installation points of

sensors No.3 and 4

Pipeline sections

17

Page 18

Frequently used menus

18

Page 19

Frequently used menus

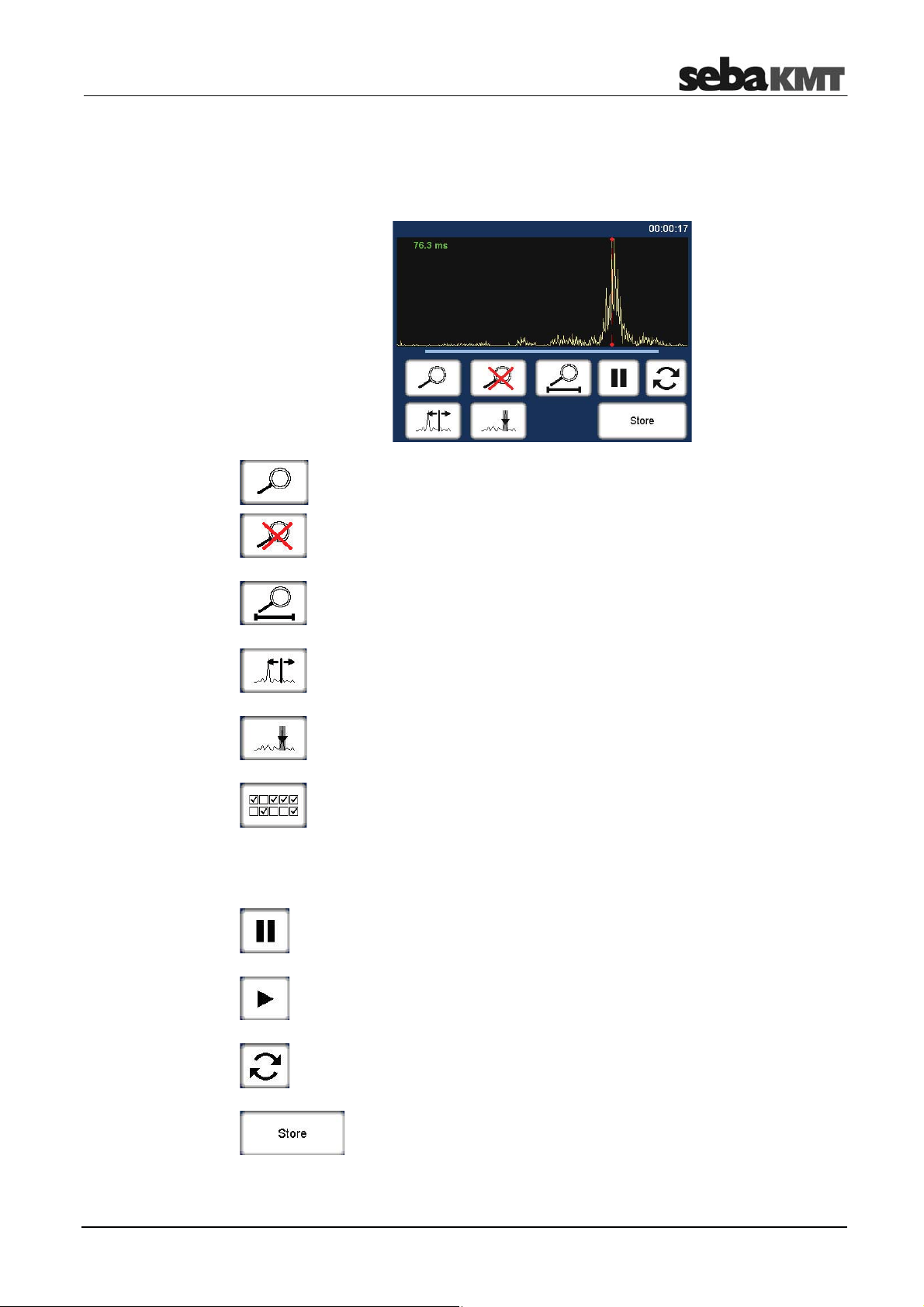

2.5 Correlation analysis menu

Tapping the Correlation curve always opens the following menu. This provides tools

for analyzing the correlation.

Zoom … to magnify a section of the curve

Tap the button, then mark the area to be magnified in the diagram.

Zoom-Reset … to reset the curve to its initial state

Magnification and suppression are abolished. The entire correlation curve

is displayed.

Zoom opt. ...magnifies length of the pipeline

Exactly the part of the correlation curve is shown, which refers to the pipe

between the two measuring points.

Move cursor … to read the lag value or the distance to the leak at any

point of the curve

Tap the button, then move the vertical red line in the diagram.

Suppress … to hide a section of the curve

Tap the button, then mark the area to be suppressed in the diagram,

i.e. tap and draw out the required range.

Suppress individual audio blocks (only Offline correlation)

Opens a menu showing the 10 single correlations of this pair of sensors.

"Bad" single-correlations can be 'deactivated' and, by this means,

excluded from the total-correlation.

Tap the buttons to remove/set the checkmark. Use the arrow button to

return back to the correlation analysis menu.

Pause

Interrupts the current correlation.

Continue

Continues the interrupted correlation, but does not reset the averaging

interval.

Refresh

Resets the averaging interval and restarts the correlation.

Store

Opens the Correlation management menu to store the displayed

correlation data in the Correlator's data base.

19

Page 20

Frequently used menus

20

Page 21

Frequently used menus

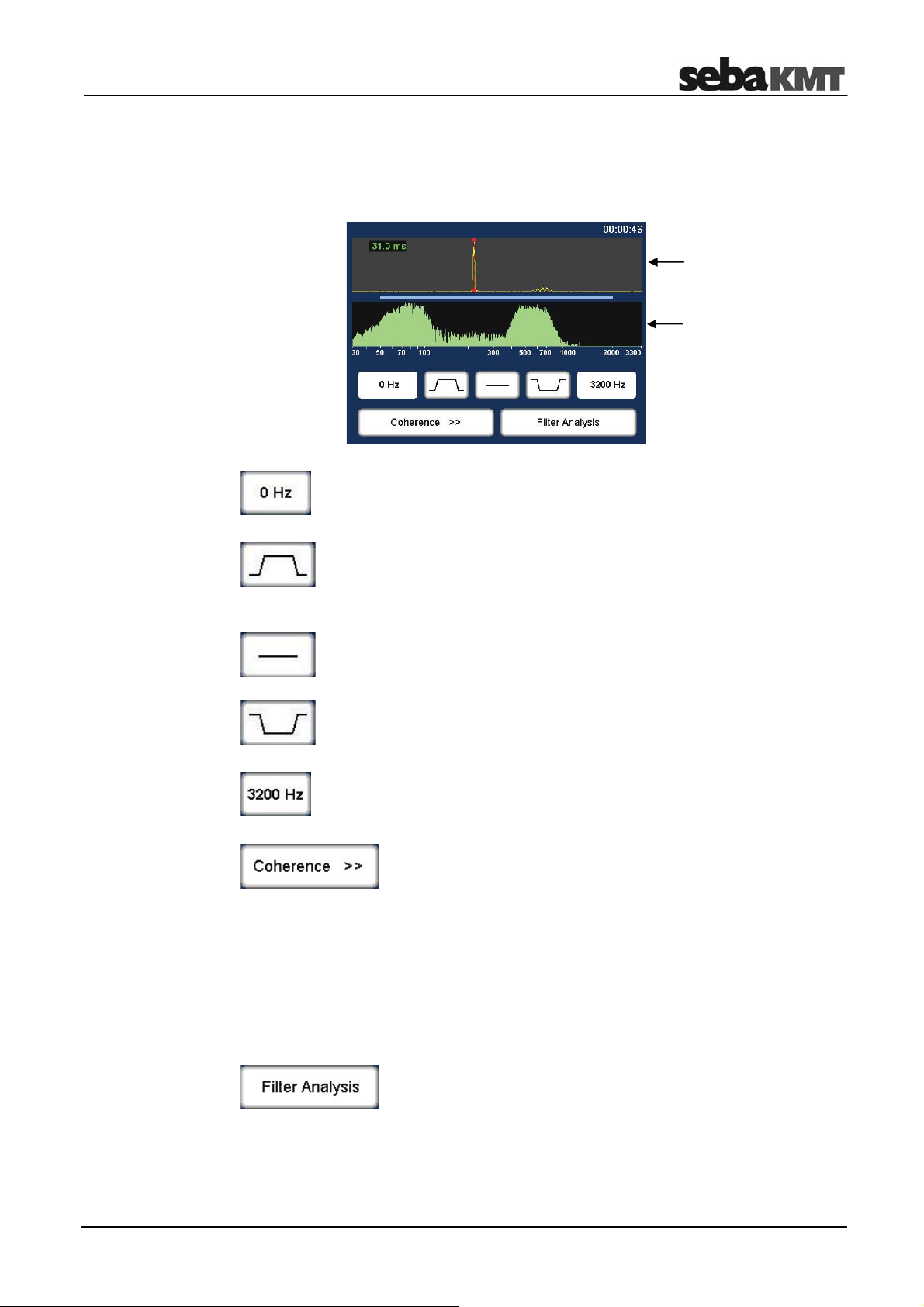

2.6 Frequency analysis menu

Tapping the Coherence curve always opens the following menu. This provides tools for

analyzing the frequency range.

Correlation

curve

Coherence

curve

Lower frequency limit

Shows the lower limit of the frequency range.

Tap the button to change the value.

Bandpass … to isolate a frequency range

Tap button. Then mark the required range in the frequency diagram.

The correlation is updated. The frequencies outside the selected range

are suppressed.

Filter reset

Tap the button to reset the frequency filter settings to the initial state.

Bandstop … to suppress a frequency range

Tap button. Then mark the required range in the frequency diagram.

The correlation is updated. The selected frequency range is suppressed.

Upper frequency limit

Shows the upper limit of the frequency range.

Tap the button to change the value.

Frequency spectrum

Allows to change between the following frequency diagram

options:

Coherence ... Coherence of the recordings of both sensors.

Spectrum L ... Frequency spectrum of the sensor on the left.

Spectrum R ... Frequency spectrum of the sensor on the right.

Spectrum L+R ... Frequency spectra of both sensors.

•

Orange curve … Sensor A

•

Yellow curve … Sensor B

Automatic search for filter

Provides 10 possible filter settings for selection

21

Page 22

Frequently used menus

22

Page 23

Frequently used menus

2.7 Audio menu

Tapping the buttons A / B / Sensor number in the Correlation menu opens the Audio

menu. It is used to listen to the leak noise via the supplied headphones.

Headphone

volume

(slide control)

Frequency

curve

Listen only to the left sensor

Only the noise recorded by the sensor on the left is reproduced.

Listen to both sensors

The combined noise of both sensors is reproduced.

Listen only to the right sensor

Only the noise recorded by the sensor on the right is reproduced.

Headphones ON / OFF

Button to enable/disable the connected headphones

Pitching function ON / OFF

This function lifts very low frequencies artificially up to a higher

frequency range to make them more audible to the user.

Audio filter: Lower limit

Shows the lower limit of the frequency range.

Tap the button to change the value.

Audio filter: Bandpass

Specify the frequency range to be reproduced. Frequencies outside this

range are suppressed.

Audio filter: Reset

Tap the button to reset the audio filter settings to the initial state.

Audio filter: Bandstop

Specify the frequency range to be suppressed, i.e.frequencies in this

range are suppressed.

Audio filter: Upper limit

Shows the upper limit of the frequency range.

Tap the button to change the value.

23

Page 24

Frequently used menus

24

Page 25

Frequently used menus

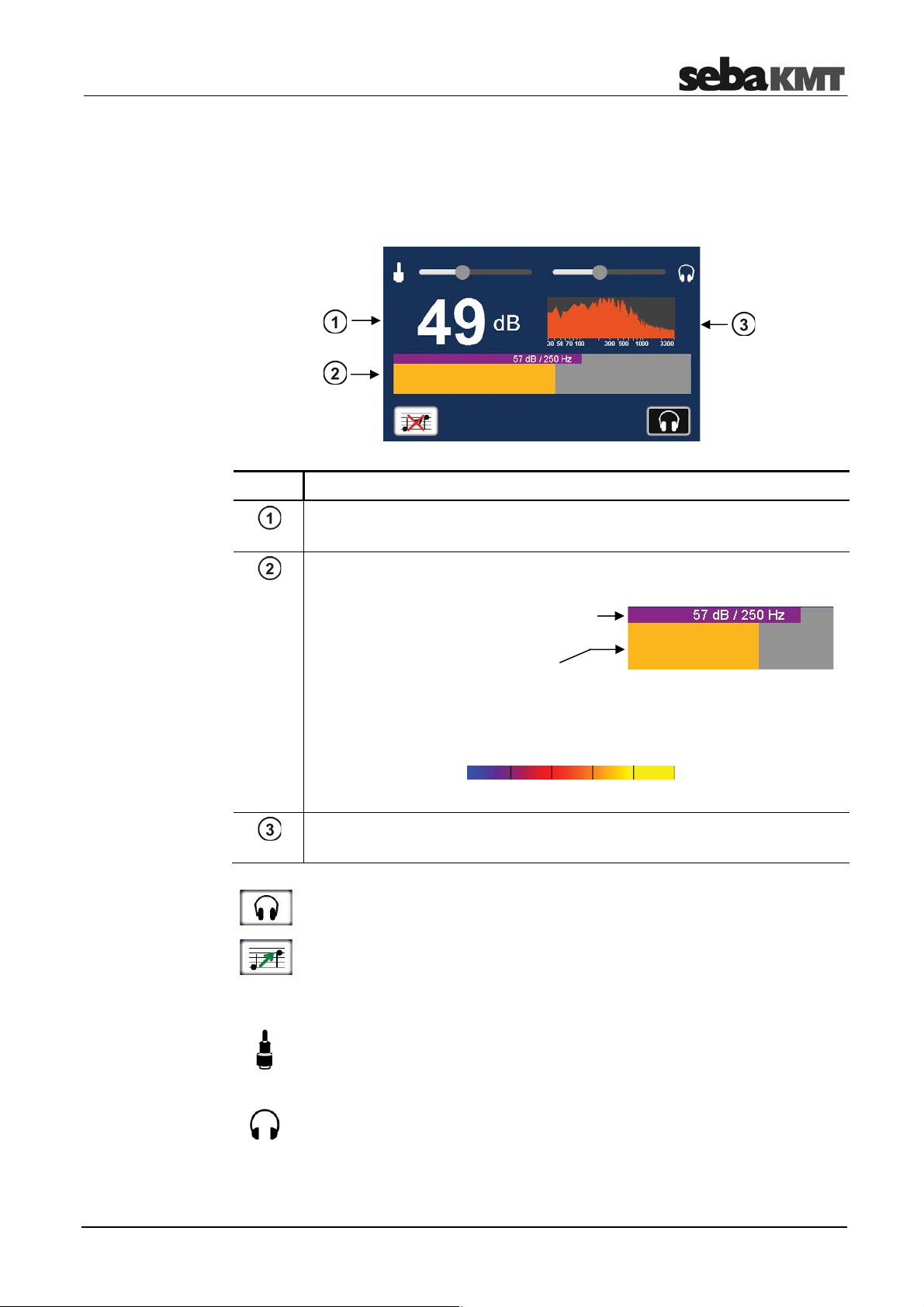

2.8 Audio menu (when ground microphone is connected)

A ground microphone can be connected to the Correlator. When you open the

Pinpointing function, at first this audio menu appears. It is used to listen to the leak noise

via the supplied headphones.

Indicators

Buttons

Element Description

Minimum value

lowest noise level of the measurement as a numeric value in dB

Bar graph display

Narrow bar: Instantaneous value

(currently measured level and frequency)

Broad bar: Minimum value

(lowest level and frequency of measurement)

The bar's height represents the noise level.

The bar's color illustrates the frequency of the noise.

blue yellow

0 Hz 3300 Hz

Frequency spectrum

Tap to open the menu for adjusting the frequency filter.

Headphones ON / OFF

Button to enable/disable the connected headphones

Slide controls

Pitching function ON / OFF

This function lifts very low frequencies artificially up to a higher frequency

range to make them more audible to the user.

Microphone gain

slide to the left ... reduces the gain

slide to the right ... increases the gain

Headphone volume

slide to the left ... lower

slide to the right ... louder

25

Page 26

Frequently used menus

26

Page 27

Technical description

3 Technical description

3.1 Function

The Correlux C-3 is a digital Correlator to locate leaks in drinking water pipes.

Pressurized water at the leak location creates a noise which travels out in all directions

of the pipe. This noise is recorded, amplified and sent wirelessly to the Correlator by two

sensors (piezo microphone, hydrophone) which are attached to the pipe (e.g. valve,

hydrants).

The Correlux C-3 compares both signals (correlation) and calculates the exact distance

to the leakage on the basis of the delay time of the signals, the sensor spacing and the

sound velocity in the pipe.

The Correlux C-3 is suitable for both immediate measurement ("Online measurement")

as well as time-delayed measurement ("Offline measurement").

Online measurement

In a so-called Online measurement, the noise recording and the correlation of the data

take place at the same time.

Step Description

1

Installing the Power transmitters "A" and "B" at two measuring points.

2

Noise recording, at the same time data transfer and live data correlation on the

Correlator.

Offline measurement

In a so-called Offline measurement, the correlation of the measured data takes place

only after the noise recording has been terminated.

Step Description

1

Programming the sensors (Multi sensors and Power transmitters)

2

Installing the Power transmitters and/or Multi sensors at up to 8 measuring points.

3

Noise recording, immediately or at a preset time (e.g. at night).

4

Collecting the sensors.

5

Reading and analyzing the measured data using the Correlator.

Pinpointing

To determine the exact location of the leak after the correlation, a pinpoint search can

be performed using the Multi sensors or the ground microphone connected to the

Correlator.

27

Page 28

Technical description

3.2 Features of the set

The Correlux C-3 set mainly comprises the following components:

•

Correlator

•

2 Power transmitters with microphone (Transmitter A / Transmitter B)

for recording the leak noise at two measuring points and sending the recorded data

to the Correlator

The set can be extended by the following components:

•

up to 8 multi sensors

for recording the leak noise of up to 8 measuring points at the same time followed

by an "Offline-correlation"

•

hydrophones

for recording the leak noise directly at the water column

•

a ground microphone

for pinpointing the leak after correlation

The Transport case offers space for the Correlator, 2 Power transmitters and

3 Multi sensors. The case is not only for storage and transportation purposes, but also

functions as a charging station for the devices.

Using the CorreluxView analysis software measurement data can be displayed and

processed on the computer. The software can be downloaded from the SebaKMT

Internet page:

www.sebakmt.com >> Information > User area > Software > Leak localization

28

Page 29

Technical description

3.3 Communication of the components

The components of the system communicate with each other in the following ways:

Participating devices Communication channel

Correlator ļ Power transmitter Short range radio (digital or analogue)

Correlator ļ Multi sensors Short range radio (digital)

Correlator ļ Computer USB cable

Correlator ļ Ground microphone Connection cable

3.4 Power supply

The Correlator, the Power transmitters and the Multi sensors come with internal

rechargeable Li-Ion batteries.

The storage places of the individual devices in the transport case function as charging

stations. As soon as a device is placed in/on its station in the case, the device is

automatically charged, provided the case is connected to the mains.

The case can be connected via the connection socket and the supplied connection

cable to either a 12 V connector of a vehicle or to the mains

NOTE

When connected to the electrical system of a car, the transport case is

powered by the vehicle's battery, even while the vehicle is not in

operation. This could result in the complete discharge of the vehicle

battery.

When you park the car, disconnect the Correlux transport case from the

vehicle power supply.

NOTE

Use inductive charging units inside for COR PT-3 and COR MS-3 only!

NOTE

Close cover of transport case if it is raining!

You can find more information in the chapters which describe the individual devices.

29

Page 30

Technical description

3.5 Scope of delivery

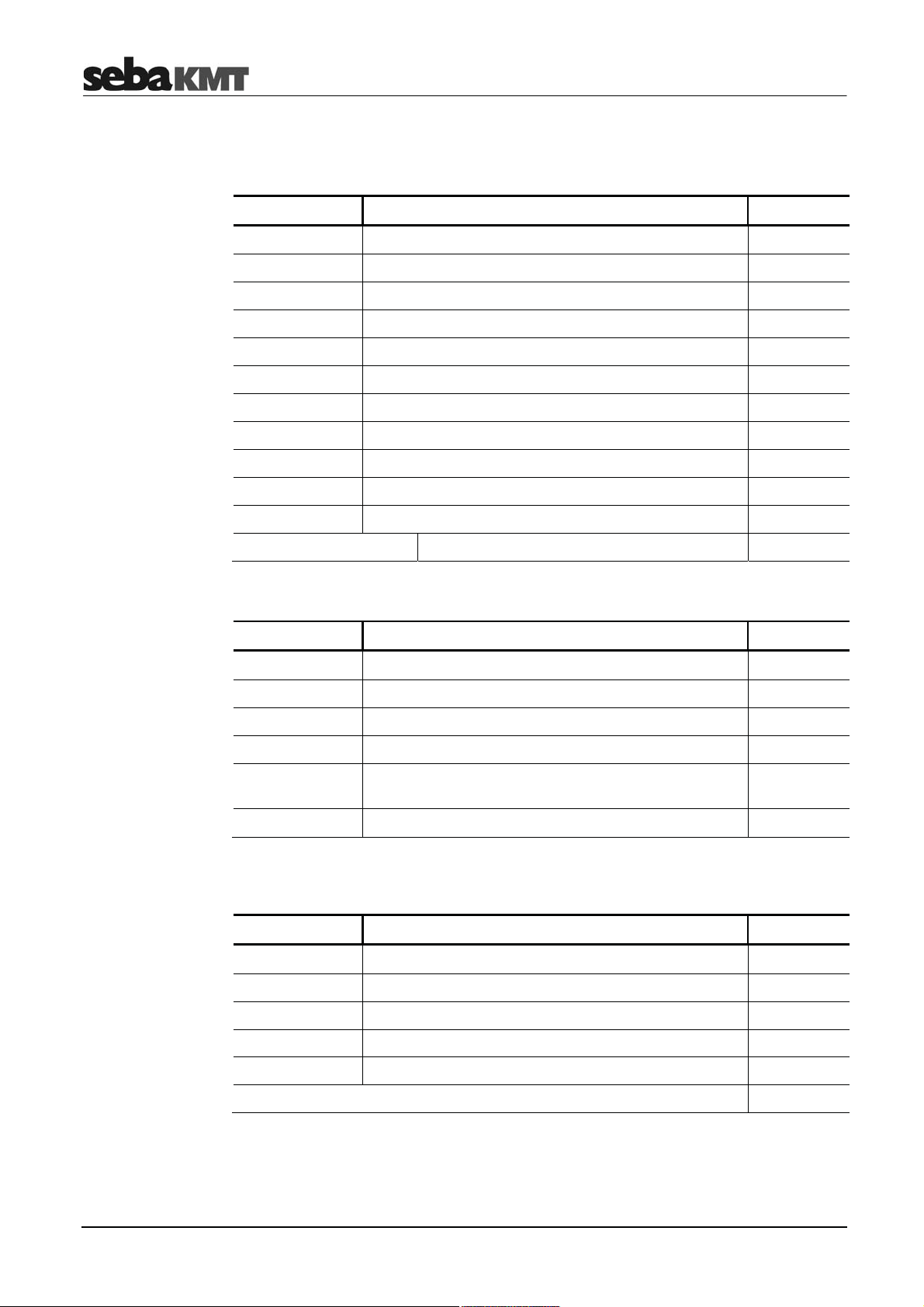

Standard accessory

Additional accessory

The basic set comprises the following devices and accessories:

Accessory Description Art.no.

COR C-3 Correlator 1006550

COR PT-3A Power transmitter A 1004779

COR PT-3B Power transmitter B 1004780

PAM CORR-2 2 x active universal microphone for PT-3 820019615

CPK 3-B Case for COR C-3 (Basis) 2007235

LG C-3 Charging unit for CPK 3/CMK 3 1006646

LK 13 Car charging adaptor, 3.5m 810000006

KR 22-5 Stereo headphones 810002087

VST T-1 2 x extension rod for PAM CORR-2 810000103

VK 77 Connection cable set Sebalog D (USB) 820012451

2 x nylon cord 3mm blue, 2m 304035025

CSW CorreluxView C-3 PC software 1006584

The following devices and accessories are available to extend the basic set.

PAM W-2

ground microphone set

Accessory Description Art.no.

COR MS-3 Multi sensor 1004815

CMK 3-8-MS Case for 8 Multi sensors COR MS-3 2005301

LOG TP Trivet adaptor for Sebalog Corr 128309877

LOG MWA Magnetic angled adaptor 118303355

Mounting set for COR MWA

(Screws for angled adapters)

Set of labels COR C-3 (1 - 8) 2007321

The PAM W-2 ground microphone set is available to extend the basic set. It consists of

the following parts:

Part Description Art.no.

PAM W-2 Windproof ground microphone 820013157

PAM W-2 D Trivet adapter for PAM W-2 820013234

VK 65 Connection cable 820000936

Carrying rod 210100071

VK 100 Connection cable 118302742

2007393

Article number of the complete set: 128310702

30

Page 31

Technical description

3.6 Technical data

Correlux C-3 is specified by the following parameters:

Correlator

COR C-3

Parameter Value

Indicators 5,7'' VGA color display

640 x 480 pixels

Entry Touch display,

Rotary encoder with enter function

Power supply Internal rechargeable Li-Ion battery,

12 V DC charging pins

Operating time min. 16 h

Power transmitter

COR PT-3A/B

PC interface

Connections

Dimensions

Weight

Degree of protection

Parameter Value

Sensor Piezo sensor with active amplifier (standard) /

Indicators I/O LED (device On/Off)

Operation On/Off pushbutton

Power supply Internal rechargeable Li-Ion battery,

USB

Sensor (microphone/hydrophone),

12 V DC / headphones (combined)

USB / GPS (combined)

External antenna 1 (digital radio)

External antenna 2 (analogue radio)

250 x 190 x 100 mm

1.9 kg

IP 65

hydrophone (optional)

Radio LED (radio module On/Off))

Row of LEDs (battery status or measured noise level)

inductive charging

Operating time min. 12 h

Connections

Dimensions (without

handle)

Weight (without sensor)

Degree of protection

Sensor (microphone/hydrophone),

Radio antenna

Ø 125 x 111 mm

0.9 kg

IP 65

31

Page 32

Technical description

Sensor

PAM CORR-2

Ground microphone

PAM W-2

Multi sensor

COR MS-3

Parameter Value

Type Piezo sensor with magnetic adaptor

(to be connected to Power transmitter or Correlator)

Active amplification yes

Dimensions Ø 38 x 78 mm

Weight 0.4 kg

Degree of protection IP 68

Parameter Value

Type Wind shielded piezo sensor

(to be connected to Correlator)

Dimensions Ø 185 x 165 mm

Weight 4 kg

Parameter Value

Sensor Integrated piezo sensor with active amplifier

Adapter Magnetic adaptor

Indicators Status LED

Operation On/Off magnetic switch

Power supply Internal rechargeable Li-Ion battery,

inductive charging

Operating time min. 16 h

Dimensions

Weight

Degree of protection

Ø 45 x 115 mm

0.4 kg

IP 68

32

Page 33

The Power transmitters

4 The Power transmitters

4.1 Function and Design

Each Power transmitter has an active amplifier for the microphone signal, a data

memory, a rechargeable Li-Ion battery, a digital radio module and an analogue radio

module with antenna inside.

The sensors have the following external characteristics:

Element Description

Microphone storage place

Sensor socket

for connecting the microphone / hydrophone

I/O pushbutton

short pressing ... switches the device on

long pressing ... Switches the device off

Antenna socket

Antenna socket for connecting the analogue radio antenna

Ventilation/venting membrane

33

Page 34

The Power transmitters

Indicator lights

The Power transmitters have the following lights (LEDs):

Element Description

LED bar

lit green ... represents the current battery level

lit red ... represents the noise level

I/O LED

lit green ... the transmitter is switched on

flashing ... the device is charging

not lit ... the transmitter is switched off

Radio LED

lit red ... the transmitter is in "Active" mode,

not lit ... the transmitter is in "Stand-by" mode,

noise measurement in progress,

measurement data is being sent to the Correlator

no measurement in progress,

no radio traffic

34

Page 35

The Power transmitters

4.2 Identification number (ID)

Each Power transmitter has its own six-digit identification number (short: ID). Using this

ID the device can be managed and clearly identified in the Correlator, computer and

within the SebaKMT-Cloud.

The ID is deduced from the last six digits of the device's serial number (short: SN). You

find the serial number on the nameplate of the device.

When entering an ID on the Correlator or computer, the preceding zero digits can be

omitted.

4.3 Power supply

Battery level

Charging

The Power transmitters are fitted with internal rechargeable Li-Ion batteries This can

power the device for approximately 12 hours.

In the Start menu of the Correlator two battery icons indicate the current battery status

of the Power transmitters.

On the Power transmitters, the current battery status is indicated by the LED bar

when it is green. If only one of five LEDs is lit, the device should be charged. Otherwise,

it switches itself off automatically.

Red light represents the recorded noise during the measurement and not the battery

status.

The Power transmitters are charged wirelessly in the transport case. The case must be

connected to a power supply. As soon as the Power transmitters are situated at their

storage places in the case, they are recharged inductively.

Charging takes approximately 12 hours. The I/O LED flashes when loading. The

LED bar indicates the progress of charging The I/O LED turns back to permanent

light as soon as the battery is full.

CAUTION

No objects must be put into empty charging stations.

Risk of fire!

The charging stations are for transport and charging of the devices only.

NOTE

Any repairs must be carried out by SebaKMT or an authorized service

partner.

Otherwise, the devices' resistance against water and dirt cannot be

guaranteed.

Do not open the device yourself. If you have problems with the battery,

please contact your SebaKMT service partner.

35

Page 36

The Power transmitters

4.4 Commissioning

Switching ON/OFF

Stand-by

4.5 Installation

To turn on, briefly press the I/O pushbutton . The I/O LED is lit green when the

device is turned on. To turn the device off, press the button until the LED goes out.

The microphone's storage place is fitted with a magnetic switch. As a result, the

Power transmitter "knows" whether the microphone is currently in use or not.

As long as the microphone rests in its storage place, the Power transmitter remains in

"Stand-by" mode. The internal analogue radio module stays off as no measuring data

needs to be transferred to the Correlator. This saves battery power.

As soon as the microphone is taken from the storage place, the Power transmitter

switches from "Stand-by" to "Active" mode. The radio module is activated. From now on,

the recorded data are directly sent to the Correlator. The row of LEDs switches from

green to red and represents the recorded noise level.

The sensors should be installed directly on the pipe but, however, you can also attach

them to valve rods or hydrants, for example, or any other position along the pipeline that

is easily accessible.

There must be the best possible contact between the sensor foot or the mounted

adapter (see below) and the pipe. If need be, clean the contact point thoroughly

(preferably with a wire brush).

In some situations it might be helpful to use one of the supplied magnetic angle

adapters.

36

Page 37

The Multi sensors

5 The Multi sensors

5.1 Design and function

Each Multi sensor has a highly sensitive piezo microphone with active amplifier, a data

memory, a rechargeable Li-Ion battery and a radio module with antenna inside.

The sensors have the following external characteristics:

Element Description

Status LED

flashes green ... Battery OK

flashes yellow ... Battery critical

flashes red ... Device needs to be re-charged

flashes rapidly ... Device is charging

no light ... Device is turned off

ON/OFF contact area I/O

Magnetic foot (detachable)

Type plate

Carrying ring (detachable)

5.2 Identification number (ID)

Each Multi sensor has its own six-digit identification number (short: ID). Using this ID the

device in the Correlator and the CorreluxView PC software can be managed and clearly

identified.

The ID is deduced from the last six digits of the device's serial number (short: SN). You

find the serial number on the nameplate of the device.

When entering an ID on the Correlator or computer, the preceding zero zero digits can

be omitted (see page 45).

37

Page 38

The Multi sensors

5.3 Power supply

Battery level

Charging

The Multi sensors are fitted with internal rechargeable Li-Ion batteries This can power

the device for at least 16 hours.

In the Start menu of the Correlator up to eight battery icons can be seen. They indicate

the current battery status of the registered Multi sensors in reach. To know the exact

battery state of a Multi sensor, read the unit's configurations menu (see page 111). In

the line battery status the battery level of the sensor is shown as a percentage.

When the battery level of a Multi sensor falls below a certain threshold, the indicator

light of the device will flash red. The device must be charged. Otherwise, it switches

itself off automatically.

To charge the Power transmitters place them in the transport case. The case must be

connected to a power supply. As soon as the sensors are situated at their storage

places in the case, they are recharged inductively.

Charging takes approximately 6 hours. The units' indicator lights are rapidly flashing

during the charging process. The indicator lights turn to permanent green light as soon

as the battery is full.

CAUTION

No objects must be put into empty charging stations.

Risk of fire!

The charging stations are for transport and charging of the devices only.

NOTE

Any repairs must be carried out by an authorized service partner.

Otherwise, the devices' resistance against water and dirt cannot be

guaranteed.

Do not open the Multi sensors yourself. If you have problems with the

battery, please contact your SebaKMT service partner.

5.4 Switching ON/OFF

The Multi sensors have an internal magnetic switch.

To turn a Multi sensor on, briefly hold a magnet (e.g. the foot of another Multi sensor) in

front of the sensor's I/O area . The device turns on. The indicator light flashes

3 times.

To turn the device off, hold a magnet in front of the I/O area for approximately

2 seconds. The indicator light will flash 2 times before it goes out.

38

Page 39

The Multi sensors

5.5 Installation

The Multi sensors should be installed directly on the pipe However, you can also attach

them to valve rods or hydrants, for example, or any other position along the pipeline that

is easily accessible. Due to their powerful magnet, the sensors can also be attached

horizontally.

There must be the best possible contact between the sensor foot or the mounted

adapter (see below) and the pipe. If need be, clean the contact point thoroughly

(preferably with a wire brush).

5.6 Angle adapter

In some situations, the Multi sensor cannot be attached directly to the desired

measurement point due to its size, e.g. in very narrow shafts or similar. In such cases, it

can be helpful to use one of the supplied angle adapters.

Magnetic connection

Screw connection

Thanks to its magnetic foot, the sensor is simply placed on the

adapter. Then, the magnetic adapter can be attached to the

pipe or fitting etc.

NOTE

The sensor's type plate and I/O area must face

away from the angle adapter - as can be seen on

the picture.

Otherwise, the magnet of the angle adapter would

You can screw the angle adapter firmly to the sensor.

This can be useful as the holding strength between the angle adapter and the pipe in

general is higher than the holding strength between the angle adapter and the sensor.

When collecting the sensors, it may happen that you pull the sensor from the angle

without intention. The adapter then remains on the pipe and it could be difficult to

remove it.

Unscrew the magnetic foot from the sensor. Take one of the

supplied screws from the Correlux C-3 set to screw the angle

adapter on the sensor.

turn off the Multi sensor unintentionally.

Make sure that the sensor's type plate does face away from the

angle adapter.

39

Page 40

The Multi sensors

40

Page 41

The Correlator

6 The Correlator

6.1 Design and function of the device

The COR C-3 Correlator is the central control unit for the Correlux C-3 system.

The device has the following control elements and external features:

Element Description

Rotary encoder

Turning ... Guides through the buttons and input fields displayed

Pressing ... Executes the selected button or enters the input field

ESC pushbutton

Exits the current menu and returns to the Start menu

I/O pushbutton

Short pressing ... Switches the device on or activates the back light for the

Long pressing ... Switches the device off

Charging indicator light

Charging pins

To charge the device wirelessly in the transport case

Ventilation/venting membrane

Touch screen

(the Touch function can be enabled/disabled in the sytem settings (see

page 50))

screen

41

Page 42

The Correlator

Element Description

Antenna 1 (digital radio)

Data transfer in Offline measurement mode

Antenna 2 (analogue radio)

Measurement data transfer in Online measurement mode

Microphone

Connection socket for ground microphone

12V DC /

Connection socket for headphones

USB / GPS

Combined connection socket for

•

USB cable

•

GPS receiver

42

Page 43

The Correlator

6.2 Power supply

Internal supply

Charging

The Correlator is fitted with an internal rechargeable Li-ion battery. This can power the

devices for at least 16 hours. The battery’s present charge level is shown by the battery

symbol bottom right of the screen.

When the battery is low, a warning tone is heard and a warning message appears on

the screen. The device must be charged. Otherwise, it switches itself off automatically.

The Correlator is charged wirelessly in the C-3 transport case.

As soon as the device is situated at its storage place in the case, it is recharged via the

two pins , provided the case is connected to mains or a 12 Volt vehicle power

supply. The red indicator light is lit while the device is charging.

The Correlator is switched on during the entire charging process and can not be

deactivated. After the end of charging, the device remains switched on for the Auto-OFF

period specified in the system settings before it switches off.

Charging takes approximately 9 hours.

Heat is generated while charging. The charging station in the case therefore has a

temperature switch. The charger switches off automatically when it gets too warm inside

the case. It turns back on as soon as the degree of heat has fallen below a certain level.

NOTE

In order to prevent damage, observe the following precautions when

charging:

•

Use only the charging station in the transport case. Do not use other

chargers.

•

The ambient temperature should be between 10°C and 35°C

(50°F and 95°F).

•

To avoid heat accumulation, do not close the lid of the case at high

ambient temperatures during charging.

•

If you experience problems with the battery, please contact your

SebaKMT sales or service partner. Do not open the Correlator yourself.

43

Page 44

The Correlator

6.3 Design of the user interface

All the menu levels on the Correlator's user interface consist of a large display area, the

main menu and an info bar.

Display

area

Main menu

Info bar

Info bar

Help text ++ Help text ++ Help text

Using the buttons in the main menu you can access the individual functions of the

device.

Main menu

Correlation

Quick start

to begin a

correlation

Pipe data

Menu to enter

pipe parameters

(length, material,

diameter etc.)

Measurement

functions

Functions to

arrange, perform

and analyze

measurements

Settings

Functions to

manage devices,

correlation data and

system settings

Back

Return

to previous

menu level

The info bar provides the user with the following information (from left to right):

•

A help text with short explanations for the selected element (button / field / box) or

on how to proceed

•

The battery symbol indicates the charge level of the battery

•

The Correlator's internal time

44

Page 45

The Correlator

6.4 Basics of operation

6.4.1 Input methods

Entries can be made directly on the screen or via the rotary encoder.

2 ways of entering data

Touch display Rotary encoder

The Correlator screen is touch-sensitive.

All entries can be made directly on the

screen.

The buttons or fields displayed

can be accessed or executed by tapping

with your finger.

You can always switch between operating via touch screen and operating via rotary

encoder.

6.4.2 Entering identification numbers

Introduction

Various functions require the identification numbers (IDs) of the Power transmitters or

Multi sensors to be specified.

The ID is deduced from the last six digits of the device's serial number (short: SN). You

find the serial number on the nameplate of the relevant device.

Example:

The Correlator has a rotary encoder.

All entries can be made using the rotary

encoder.

Turn the rotary encoder to navigate

through the displayed buttons.

Press the encoder to access the selected

button (ENTER function).

Serial number (SN):

Identification number (ID):

Entry on Correlator / PC:

You can enter device IDs manually or you can use the "Automatic device detection".

Automatic detection means that once a device is activated its ID is immediately sent to

the Correlator. There, it is detected and displayed.

0888000225

000225

45

225

Page 46

The Correlator

For entering a device ID the following screen view, or a similar one, opens:

Manual entry

Automatic detection

6.4.3 Entering text

DEL

ENTER

Accept

Decline

Finish

For the manual entry of IDs, use the number pad displayed. Confirm with the ENTER

button.

To the right of the number pad, there are fields and buttons for the automatic sensor

detection. The devices concerned must be close to the Correlator.

To register a Power transmitter, briefly press the I/O pushbutton of the device. To

register a Multi sensor, briefly move a magnet past the sensor's I/O area, so that the

LED lights up briefly. As a result, the device's ID is sent, detected by the Correlator and

displayed on the screen. Using the buttons the detected ID can be accepted or declined.

This way several device IDs can be added to the Correlator in quick succession.

To enter comments or similar, a virtual keyboard appears on the screen. Enter the

required text and confirm with OK.

... Deletes the last character

... Confirms and completes the entry

... Accepts and enters the automatically detected ID

... Does not accept the automatically detected ID

... Completes the automatic detection

46

Page 47

The Correlator

6.4.4 Sorting devices in lists and tables

In various menus, device IDs or other information are listed in a kind of table.

For example, the following picture shows the Correlator's sensor pool with all registered

Multi sensors listed.

If a black triangle can be seen in the header of a column, you have the option to change

the sort order (ascending / descending). Just tap the respective header.

Example:

Tapping this header changes the sort order of the displayed devices from 1-3 to 3-1.

In the picture, a triangle can be seen in the Number header.

Changing the sort order is only possible via touch screen, not via the rotary

encoder.

6.4.5 ESC pushbutton and "Back" button

By pressing the ESC pushbutton of the Correlator you can cancel or end any

process. The button closes the displayed menu and opens the start menu.

You can use the Back button in the main menu to return to the previous menu

level.

47

Page 48

The Correlator

6.5 Commissioning

6.5.1 Switch the Correlator ON/OFF

Switching ON

Switching OFF

Auto-OFF

The Correlator is switched on with the I/O pushbutton . The device requires a few

seconds to boot. Then the Start menu appears on the screen. The device is now ready.

To switch the Correlator off, press the I/O pushbutton until the screen turns off

(approx. 2 seconds).

The Correlator automatically switches off if no entry is made within a specified time

period. This timespan can be configured in the system settings (see page 51).

6.5.2 Basic settings at initial start-up

When the Correlator is switched on for the first time, two consecutive Welcome menus

appear on the screen. There, some basic system settings have to be made before the

Start menu can be entered.

Language,

date and time

Select your language in the first of the two menus. Use the first pull down list to do so.

The Correlator's operating language immediately adapts to your selection. After that,

enter the remaining requested details.

Line Description

Daylight saving time

Date format

Date / Time

Confirm with OK. The menu is closed. The settings are accepted.

Select whether it is currently winter or summer time.

Select the date format to be used by the Correlator.

DD

MM

YYYY

Enter the current date and time (hour:minute:second) for the

Correlator.

Day

...

Month

...

Year

...

48

Page 49

The Correlator

You have the option to change these settings again in the Correlator's system settings

menu, at any time.

Devices of your set

Specify in the next menu which devices are part of your Correlux C-3 set. Tick the

relevant checkbox/es.

The statements made here determine which measuring methods will be offered in the

Correlator's Start screen.

Example: If you select no checkbox except "COR PT-3", the Online measurement

method "COR PT-3 with microphone" will be the only available method in the Start

screen.

Confirm with OK. The menu is closed. The settings are accepted. The Start menu of the

Correlator appears.

You have the option to change these settings again in the Correlator's system settings

menu, at any time.

6.5.3 Change the language

The operating language can be changed in the system settings of the device.

If currently a foreign language is set, call the Start menu and follow these symbols:

Next to the second flag you find a pull-down list with all available languages.

6.5.4 Activate the display light

The display light is switched on once

•

the screen is touched (provided the touch function is not disabled)

•

the rotary encoder is turned

•

the I/O pushbutton is briefly pressed

The light remains on for a certain time period. The length of this period can be adjusted

in the system settings.

Î Î

49

Page 50

The Correlator

6.5.5 Enable/Disable the touch screen (touch sensitivity)

The touch function of the screen can be disabled/enabled if needed. The screen will no

longer respond to tapping. The device can only be operated using the rotary encoder.

Enable/disable

touch function

To enable/disable the touch function, proceed as follows:

Step Description

1

In the main menu, select the button .

2 In the displayed menu, select the System settings button.

Result: The system settings menu is opened.

Use the buttons Next and Previous to browse through the available settlings.

3 Look for the Touch option.

Enable/Disable the corresponding checkbox.

50

Page 51

The Correlator

6.6 System settings

By means of the System settings various device settings can be customized to the

needs of the user. Furthermore, the menu provides useful information on the status of

the device and the firmware used.

To access the System settings menu, proceed as follows:

Step Description

1

In the main menu, tap the button .

2 In the displayed menu, tap the System settings button.

Result: The system settings menu is opened.

Use the buttons Next and Previous to browse through the available settlings.

6.6.1 Basic settings

The following basic settings can be made

Line Description

Backlight

Auto-OFF

Key beep

Language

Backlight switch

off

Turn off autom.

after

Key beep

Language

Select a period of time for the backlight until it is switched off

automatically.

Explanation:

automatically after a period of time. Specify the length of this period

here.

If you select never, the backlight will remain on permanently.

Select a period of time for the Correlator until it is switched off

automatically.

Explanation:

automatically after a period of time. Specify the length of this period

here.

If you select never, the Correlator will remain switched on

permanently.

Activate/deactivate the key tone that sounds when a button is

tapped or the rotary encoder is pressed.

Select your language.

If no entry is made, the display light is switched off

If no entry is made, the device switches itself off

51

Page 52

The Correlator

Time and date

Format of units

Reset system settings

Touch screen ON/OFF

Averaging during

correlation

Timezone

Daylight saving

Select the time zone for where you are.

Select whether it is currently winter or summer time.

time

Date format

Date / Time

Select the date format to be used by the Correlator.

DD

MM

YYYY

...

...

...

Day

Month

Year

Enter the current date and time (hour:minute:second) for the

Correlator.

Measurement

units

Select the system of units to be used by the Correlator.

Metric

Imperial

...

Used in Europe and most countries around the world

...

Used in the US

Factory settings Tap the Reset button if you want to reset all system settings to

factory defaults.

Touch

Enable/Disable the touch function (touch sensitivity) of the screen.

If this function is disabled, the screen only works as a display. The

device can only be operated using the rotary encoder.

Averaging

Select the averaging interval.

Explanation:

When performing an Online measurement, the

calculation will automatically be restarted and the displayed

correlation curve will be updated at regular intervals. Here you set

the time interval

no averaging

20 s

unlimited

No averaging takes place.

...

Averaging of the correlation curve takes place in

...

a 20 seconds interval.

Averaging of the correlation curve takes place

...

with every new received measuring data

package.

52

Page 53

The Correlator

Frequency scale

linear / logarithmic

Available measuring

methods

in Start menu

Frequency scale

Available quick

start buttons

Select if the X-axis of the coherence diagram in the Correlation

menu shall ascend in a linear or logarithmic way.

Explanation:

from 0 to 3300 Hz. Based on experience the frequency of leak

noise ranges from 0 to 1000 Hz. The logarithmic view results in a

wider display area for lower frequencies.

logarithmic:

linear:

Specify which devices are part of your Correlux C-3 set.

Enable/Disable the relevant checkbox/es.

Explanation:

measuring methods will be offered in the Correlator's Start screen.

Example: If you select no checkbox except "COR PT-3", the Online

measurement method "COR PT-3 with microphone" will be the only

available method on the Start screen.

The frequency range of the Correlux C-3 system is

The statements made here determine which

6.6.2 System info

The System settings menu has the following information on the device and the

firmware currently in use:

Line Description

Free space

Software Version

Software date/time

ID

The Correlator's free memory space in MB

Firmware version of the Correlator

Date of the last firmware updates

Identification number of the Correlator

6.6.3 Saving the settings

When leaving the system settings menu all the settings are automatically saved and

accepted.

53

Page 54

The Correlator

6.7 Communication

6.7.1 Connection between the Correlator and the sensors

Short range radio is used for communication between the Correlator and the sensors

(Power transmitters and Multi sensors).

Analogue short range radio is used for Online measurements. Digital short range radio

is used for Offline measurements. Therefore, the Correlator is equipped with two radio

antennas.

Antenna 1 ... Digital radio

Antenna 2 ... Analogue radio

6.7.2 Connection between the Correlator and the computer

The included VK 77 connection cable is used to connect the Correlator to a PC/laptop.

This connection is needed for

•

correlation data transfer to the computer

•

firmware update file transfer to the Correlator

Connecting

Disconnecting

To connect the Correlator to a computer, proceed as follows:

Step Description

1

In the main menu, tap the button .

2 In the displayed menu, tap the Connect Correlator to PC button.

3

Establish the cable connection.

Connect the round plug of the cable to the USB/GPS socket of the Correlator.

Observe the markings on the plug and socket. You must feel the plug engage.

4 Tap the Connect button on the Correlator.

Result: The connection is established. The Correlator is automatically detected

by the computer as a mass storage device. As soon as the Connected message

on the Correlator’s screen appears, data can be transferred.

If no connection is made, check the cable connection again. If necessary, disconnect

the Correlator from the computer, restart it or perform a reset, and follow steps 1 to 4

once again.

To end the connection, select the Disconnect button on the Correlator. As soon as the

Disconnected message appears, the connection cable can be removed.

6.8 Hardware reset

If the Correlator stops responding to inputs (neither from touch screen nor from rotary

encoder or pushbuttons), a hardware reset can be performed.

Hold down the rotary encoder and the ESC pushbutton at the same time for

about one second. The Correlator restarts automatically. This usually rectifies the

malfunction.

If the device still malfunctions after resetting the device, try the following: Hold down the

rotary encoder and the ESC pushbutton at the same time for about 3 seconds. The

Correlator switches off. Wait about a minute before switching the Correlator back on.

The Correlator should now function correctly again.

54

Page 55

Sensor management

7 Sensor management

7.1 Introduction

All Power transmitters and Multi sensors of your Correlux C-3 set have to be registered

in the Correlator.

Two Power transmitters and up to 8 Multi sensors can be registered. The units make up

the so-called "sensor-pool". The Correlator can only communicate with registered

devices.

7.2 Access the sensor pool

To access the sensor pool, proceed as follows:

Step Description

1

In the main menu, tap the button .

2 In the displayed menu, tap the Sensor management button.

Result: One additional menu appears, if the Correlator currently is in

Offline measurement mode. There, tap the Edit / Manage button.

Indicators

Result: The Correlator's sensor pool appears.

The sensor pool is divided into two sections:

Element Description

"Online" pool

Under the Power transmitter tab the two Power transmitters of your set are

managed which are used for Online correlations.

"Offline" pool

Under the Multi sensor tab the Multi sensors and Power transmitters are

managed which can be used for Offline correlations.

55

Page 56

Sensor management

The registered sensors are listed respectively. The columns of the table have the

following definitions:

Element Description

Index / Number of the device

A / B

1 - 8

... indicates whether this is the Power transmitter A or B

... shows the number of this Multi sensor which was assigned to the

device during the registration

Identification number of the device

Type designation of the device (as it is also found on the nameplate)

COR PT-3A

COR PT-3B

COR MS-3

Sensors which are marked with an X have been used in the last

measurement.

... Power transmitter "A"

... Power transmitter "B"

... Multi sensor

56

Page 57

Sensor management

7.3 Register sensors

Add sensors for

Online measurements

To register a Power transmitter for Online measurements, proceed as follows:

Step Description

1 In the Sensor pool menu, select the Power transmitter tab.

2 Tap the Add button.

Result: A question appears on the screen. You must decide whether the

Power transmitter in question shall be added to the "Online pool" only or to both

the "Online pool" and "Offline pool" at the same time.

3 Use the buttons Yes or No to answer the question displayed.

No

Yes

... The device will only be added to the Online pool.

... The device will be added to both pools at the same time

Result: The menu for entering device IDs opens.

Add sensors for

Offline measurements.

4

Enter the ID of the Power transmitter.

Via manual input:

•

Enter the ID.

•

Confirm with the ENTER

button.

Via „Automatic detection“:

•

Briefly contact the I/O field of the