Page 1

PARTS LI

i2 INCH

-- Model Number 103.24280 ......................._......

This _ the mode! number of your Band Saw. It will be

found on a plate on the back cover, mention

model number when communicatJ-ng wlth us _ga._g

"four Band _w or when o_ering parts.

- InS_cfions for Ordering Parts-

All p_s listed herein must be ordered through a Sears

retail store or mali order house_ Parts are shipped p_-

paid. _en ordering repair par_s, always _ve _e _ollow-

ing information:

t. The Part Nun'Lber.

2. The Part Name and Price.

3. _e Mode! Number 103.24_3.

_ l_t _ v_u_le. It w_l _u_ your being _le to'

obta_ proof parts _ice_ We sugg_t you _ep it _th

oth_ v_u_le paper.

SEARS, ROEBUCK and CO.

Page 2

BAND SAW

MODEL NUMBER

LIST FOR

You now own a Band Saw which is the product of

extensive engineering research and thorough test_

ing_ Accurately machined parts built to high in-

spection standards are carefully assembled to make

sure this Band Saw will deliver top quality perform_

ance. These features have all been combined with

an attractive appearance to create a tool that is a

pleasure to operate and a welcome addition to your

shop. This Band Saw can be used for cutting curves,

circles, or any irregular shape as well as straight rip-

ping or cutoff.

To prevent damage in shipment some of the parts

were disassembled from the tool, These parts are

listed below, Be sure they are all accounted for be-

fore discarding any of the packing material.

I. Saw Blade; item 3 see page 5_

2. Table and Mounting Bracket Assembly com-

plete; items 4, 6, 7, 11 (4), 12, 13, 14,

15, I6, 17, 18, 19 (2), 20 (4), 31, 32, 33,

34, 36, 73, 74, 77, 78 and 79,

3. Bag of miscellaneous small parts consisting

of items 5, 30_ 38 (4), 49 and 76,

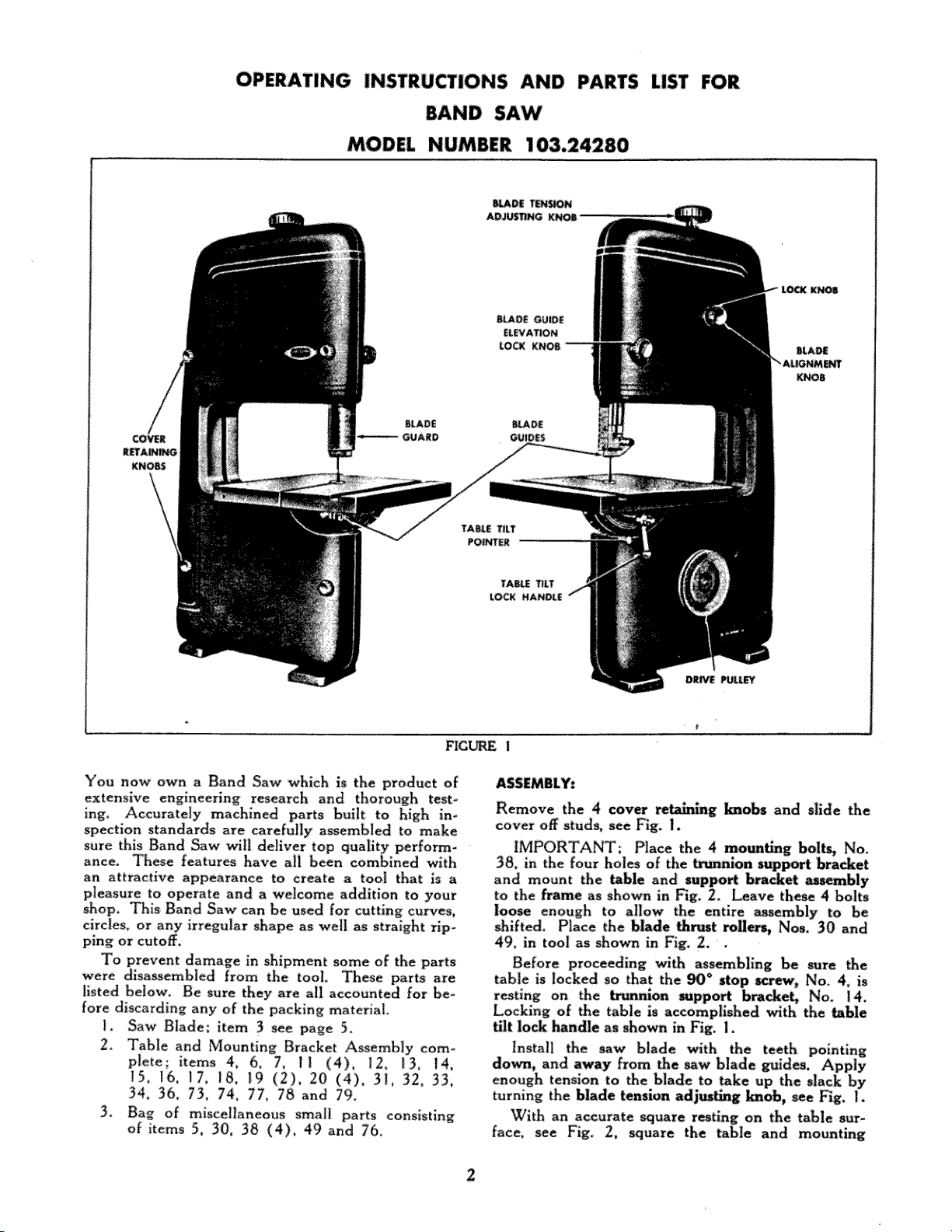

FIGURE i

ASSEMBLY:

Remove the 4 cover knobs and slMe the

cover off studs, see Fig. I,

Place the 4 mounting bol_, No.

38_ in the four holes of the trunnion support bracket

and mount the _bh and suppo_ bracket assembly

to the frame as shown in Fig_ 2. Leave thee 4 bolts

loose enough to a|Iow the entire assembly to be

shifted. Place the blade _ntst rolle_ Nos. 30 and

49, in tool as shown in Fig. 2_ .

Before proceeding wi_ ass_bllng be sure the

table is locked so that the _ stop v:.rew, No_ 4, is

resting on the support bracket, No_ 14.

Locking of _e table h accomplished _th the _ble

flit lock handle as shown in Fig. I.

install the saw blade with the teeth pointing

down_ and away from d_e saw blade guides. Apply

enough tension to the blade to take up the slack by

turning the blade adjus_ kn_, see Fig. I.

With an accurate _uare resting on the table sur_

face, see Fig_ 2, square the ruble and mounting

Page 3

bracketassemblywith the sawblade,and finish

tighteningthemounting_lts, Nor 3&

Placetheknurledscrew,No. 5, in thetablesaw

slot.

Beforereplacingthe coverchecktheblade for

"Tension'"and"Tracking"asexplainedunder"Ad-

INSTALLATION=

Securely "bolt the Band Saw to a solidly "built bench

checking each foot and adding spacers if necessary

to provide good contact with the bench, it is sug-

gested that the bench be of sufficient height to bring

the saw table about elbow level.

Three holes have been provided to secure Band

Saw to bench. There are two holes in the front foot

on the outside of the tool. The rear foot has one: hole

accessible from inside the:cover.

We suggest that a 3-inch square hole be cut in the

bench top directly back of the front foot to prevent

the accumulation of saw dust,

The motor may be installed behind or below toot.

termined after the motor position has been selected

by measuring with a steel tape around the outside

of the pulleys, not in the grooves,

LUBRICATION:

A special double row bail bearing built into the drive

shaft and the two single row ball beatings in the idler

wheel have been packed with lubricant and sealed at

the factory_ They require no further attention.

The blade thr_troiled, as shown in Fig. 2, should

be lubricated occasionally. Other moving and slid-

ing parts such as the guide slide bar, No. 46, and

table trunnions_ Nos. 12 and 16, may require occa_

sional lubrication to maintain smooth operation.

CONTROLS=

The table tilt lock handle locks the table in any posi-

tion from 90* to 45* with _w blade.

The table _t pointer indi_tes the: table angle on

the calibrated trunnion scale.

The blade back up the blade: for both lateral

and direct thrust.

The blade guide el lo_k knob controls the

upper assembly in relation _ table surface for vari-

ous work piece thicknesses.

The blade ali_ment knob provides a means of

tilting the upper wheel for correct _w blade tracing.

BOLTS

FIGURE 2

MOTOR:

A I/3 horsepower 1750 R.P,M. motor is recom-

mended for general usage.

Install the motor so that the direction of rotation

of the drive pulley, see Fig. I, is counter-clockwise

when viewed from the drive pulley side of the tool.

SPEED=

The above motor equipped with a 2-inch diameter

pulley .will give an arbor speed of approximately

640 R,P,M, This is recommended for general use

with wood and similar matetial.

When purchasing the motor pulley be sure to spe-

cify the shaft diameter of your motor and that the

pulley is for a l/2-inch V-belt,

BELT:

The drive pulley is designed for use with a standard

N-inch V_belt, The length of this belt may be de-

ADJUSTMENTS:

This tool was completely checked and tested under

power at the factory. Rough handling in shipment

may have caused some misa]ignmenL Check the fol-

lowing points to insure proper operation.

Proper Made tension may be _t by raising or

lowering the upper wheal assembly. This is done by

turning the bhde tension adjusfmg knob as shown in

Fig. |. When properly adjusted the blade should de_

press the rubber facings on the wheels slightly and

also may be deflected by thumb pressure exerted be-

tween the first two fingers.

The saw blade must run consistently on the approx-

imate center of the wheals. The wheels are c_owned

to accomplish this, with the upper wheel being tilt-

able. Rotate the mechanism by hand and if the saw

blade tends to ride off d-_e wheels loosen the lock

_ob, as shown in Fig. I. Turn the blade _gnment

knob slightly in or out until _e blade returns to its

proper position.

When blade tracks consistently 6ghten the lock

knob.

Saw guide _emMies are provided both above

and below the table to support the blade against

lateral and direct thrust,

_'_e upper saw guide a_mbly, Fig. 3, m_t operate

so that the distance from the back of the saw blade

to the _rust roller remains the same throughout the

entire up and down movement of the a_embly. If

3

Page 4

adjustment is nece_ remove the cover and _rn

the upp_ _w ra_de _ g _, Fg. 3,

either in or out as required._ When adjustment is

completed lock the adju_.ing screw log nut, Fig. 3,

to maintain adjustment.

NOTE: After a f_€ hou_ of op_a_on tighten all

pulley set screws.

Following are several common _es of Band _w

blade br_kag_ Avoid thee _tuafions by fr_uenfly

and _mce from your blade.

F1GUFt£ 3

Adjust the saw guide as_mblies so that the hte_l

saw g-_des_ see Fig. 2, when adjusted, will contact the

blade on the solid portion only, not on the: teeth or

necessary. Lock the saw guide assemblies in position.

The hteral saw gmd_ must be set as dose as pos-

sible to the blade without binding it at any point or

deflecting it sideways. Lock _e set screws securing

the lateral saw guides.

The bhde thrust rollers _ shown h Fig. 2 should

be set the thickness of a piece of newspaper, _e Fig.

3, from the back edge of _e blade. Adjustment of

the blade thrust rollers may be accomplished by

loosening the holder set _ews (Fig, 2) and

moving both _e holder bearing and thr_t taller in

or out by turning the back Up scrcw_ Fig. 3, until the

roller is in the correct position. Re-lock the holder

tighten the hold_ b_.ng s_ _ _e Fig. 2, only

slightly in bo_ the upper and lower saw _ide hrack-.

eta as any undue pressure may _use the thrust roller

to bind,

T'he above adjustments shodd result in a free run-

sing saw blade when no cut6ng is being done_

The table h square _ h Wtade and at

the _me time the pointer indicate zero on the _le.

If correction is necessary it may be made _th an

accurate square resting on the table surface: and

a_inst the saw blade. Adjust the _o slop sc-rew_see

Fig, 2, until co has been made,

The _ble _t polnte_, _ shown in F_g. l, may now

be readjusted to the zero mark on the s_le by loosen-

ing the screw which holds _e pointer to the tool

After' making adjustments on the Band Saw, check

_refuily by turning the mechanism by hand several

revolutions before appl_ng power.

Failure to bring the upper g_a_de _ y down

" 1

dose to _e work allo_ dhto_on of _e blade

which encourag_ brae,

_xce-_ve feed pressure C_US_ _e blade to _de

hard on _e thPa_ rolle_ _u_ng cra&ing and _en-

t_l br_k_e. A dull blade, or one that has been

Both of _e gdd_ and _e blade _I1 be dan,aged

if _e _id_ touch the tee_ rather than _e _ooth

_d_ of the blade.

If the blade is allowed to _ tither on the tool or

F_.na!ly, one of t,he most common _ of blade

difficulty is the practice of cutting too sha_ a radius

or turning the work pi_e too f_t when catting a

rad.i_ thus binding or twisting _e blade, Follow_

ing h a table _owing _e approximate minimum

diameters which _ould be cut _th vario_ wid_

binds,

WIDTH iNCH_

DIAMETER INCH_

I/8

I/4

i/2

OP|RAIIOH:

Hold the work pie_ firmly ag_-_st _e table surface

during cutting operatior, s.

Do not force the -.-cork aga_st the blade beyond

the cutting _pad_ of the bhde _ thi_ will make

the following of the _ttem extremely difficul_

A few practice cuts h ad'dsable tO get the hd of

Band

SAFe:

operator proteete& It _ a good practice to stop the

tool before raising or lowering the upp_ blade wade.

ACC _-_S for this rod are a fence for ripping

and a miter gage for angular cuts. _ acc_ori_

are list_ in our catalog and may be purchased _m

your nearest _rs retail store or _l order hou_e_

Page 5

Q

%

55

0

\

7

I

Page 6

PARTS LIST

No_

i0

l|

12

13

!4

t5

16

!7

18

19

2O

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

I

2

3

4

5

6

7

8

Oi-d_r

P_rt: No_

18619

4 {230

41716

_X-309

4{628

_X-4 i 7

41260

X437

412!4

41215

X,746

41150

38416

41421

41616

41417

X-606

X-432

41813

x-!o0

41625

41220

_X-383

41213

41718

38716

41711

41624

38812

18232

41130

41416

X-162

_X-420

'_X-377

41621

41130

)(-745

41414

X-736

X-607

SsUfn*

Knob ............................................................ ............ $ ,45

Cover ................................................... ........ 14.00

Band Saw Blade---avai|able in widths of l./S"+

PART NAME _eh

I/_" 3,_" and ½" x 80" long_ Purchase from

nearest Sears retail store or mail order house.

Ask for catalog No. 9-262 $, State width wanted.

Machine _rew 5/16+ 18x1 square head .............. 10

Knurhd s_:rew ................................... _....................... ! 5

H_, nut 5/16-18 ...................................................... |0

Table .................................................................... {4.50

Machine screw 5/16-! 8x3/4 hew head _th _-

temal !ock washer .................................................. 10

Right foot ...........................................................1.20

_ft foot .............................................................. t.20

Machine screw 5/16-1 8x3/4 round head with ex-

ternal lock washer ............................................. 10

Table trunnion with scale ....................................... 1.50

Table inert .....................................................................15

Trunnion support bracket ...................................... 2.50

Guide: holder stud ................................................. 20

Table trunnion plain ............................................ !.30 6! 41612

Plain w_her 3/8 I.D. x 7/80.D ......................10 62 41611

Hex, nut: 3/8-24 ................................................... 10 63 41419

Saw _ide .................................................................. 15 64 38715

Set screw 1/4-20xl/4 slotted head cup point ...... 10 66 41619

Cover stud_lower fight ................................... 20 67 38120

Bearing and key assembly_rive wheel .......... 5.00 68 X-182

Machine _rew 1/4_20x3/8 slotted truss head ...... 10 69 4 | 811

Lower wheel .............................................................. 8,00 70 41413

Lower wheel retaining ring .................................. 15 71 41250

Retaining ring ................................................. 15 72 41210

Spring washer .! 5 7 3 18922

Cover stud left .......................................................... l 5 75 X- 179

Drive shaft key ...................................................... 15 76 *X-1403

Blade thrust roller ................................................. 35 77 X-606

Holder beating ........................................................... 25 78 384 {7

Lower _w guide bracket .................................... 60 79 384{4

Set screw 1/4-20x5/8 slotted head half dog point ,10 80 41140

Hex. nut 1/4-20, ................................................... 10

Much, _rew No, ! _24x3/8 slot'd binding hd, , I 0

%unnion l_k screw ........................................ 30

Holder bearing ...................................................... 25 81 41715

........................................................ 74 *X-516

llt_t*

tl+atlorl Order

No. Part No,

42 41813

43 X.162

44 *X-420

45 41816

46 41617

47 41050

48 X.100

49 18232

50 )(-193

5 ! _X-420

52 *X-382

53 41712

54 18211

55 41812

56 41270

_8 41815

59 _X-417

60 X-745

41020

Ms&, _rew 5/|6-18x! hew hd. with ext. lock 82 41030

washer ................................................................... 10 83 41004

Upper s_w guide bracket ....................................65

Much. _rew 1/4-20x I l hex. hd. with ex- 84 4 i 005

ternal !ock washer .....................................................! 0

Plain washer 17/64 I.D, x 19/32 O,D ................ 10

S,_llinS

PART NAME _h

Saw guide ...................................................... $ .15

Set screw I !4-20x518 slotted hd. half dog point , ! 0

H_ nut 1/4_20 ...............................................10

" Guide bar tension spring .......................................... l 5

Upper mW _ide bar .............................................1. I 0

_ver stud a_embly--upper right .......................40

Set screw 1/4-20x!/4 slotted head cup point ...... 10

Blade thrust roller ..................................................35

Set _r_ 1/4-20xl/2 slotted hd. round point .10

Hex nut l/4-20 ..................................................10

Prt_s

Much, screw 1/4-20x3/8 slotted binding hd ........ 10

Blade guard 35

Bearing---upper wheel I_80

Beating spacing ring =........................................... 15

Upper Wheel and beafing assembly ...................i2.00

_'heel tire ........................................................ 75

Upper wheel fulcrum assembly ..........................1,85

Hex, nut 5/!6-18 10

Much. screw 5/16.18x1 hex, hd. with external

lock washer ........................................................ 10

Upper wheel guide rod .......................................20

Upper wh_l ten_oner rod ...................................25

Upper wheel bracket ........................................1.50

Upper wheel guide rod retaining ring ............ 15

Tension knob bushing ..2.o.._+.......................35

Hand wheel with set screw ................. _............. 2.25

_t screw 5116-18x5116 socket head cone point +10

_w blade tension spring .......................... 35

Wh_l adj, lock knob 40

Upper wheel adL knob with stud .................. 85

Upper saw _ide lock knob ...................................75

Protractor pointer ............................................. ! 5

Much. screw No. _32x I/4 slotted round hd. oI 0

Set screw 5/16-|8x5/16 socket head cup point _10

Allen v,_ench_5i32 ..........................................15

Plain washer 3/8 LD, x 7/80.D .........................!0

Trunnion lock nut. ................................................35

Table ti!t lock handle ..........................................75

Pulley _th set screw_5 inch single groove V-

pulley 5/8 in_ bore. Purchase from your n_r-

_t _ars re_ii store or mail order house, Ask

for Catalog No. 9-2805_5/8 inch hare, ...........

Driva wheel bearing retaining ring .................20

Frame ......................................................25.00

Upper _w guide assembly complete consisting

of: 37, 39, 42, 43, 44, 48, and 49. .....................1.50

Lower saw guide a_embiy complete consisting

of; t9, 20, 30, 3t, 32, 33, and 34 .................... 1.40

35Z

Loading...

Loading...