Sears | Craftsman Handbook of Circular Saw Blades and Power Tool Accessories Instruction Guides

CIRCULAR SAW FILING

The bevel angles h shape and file exactly clearance A CRAFTSMAN SAW VISE is gone the guide for proper ō maintain med; this 1110 t the origin y in the sar and t

on a home workshop bench. However, if you use a clamp or regular vise, always protect the blade by sandwiching between scrap pieces of wood. The following chart gives the normal filing instructions and recommended files for use in resharpening your Craftsman blades. For best results, use Kromedge files. table in the same manner as the saw setter or it can be mounted stationary we suggest using the Craftsman

eeth of the set.)

cut

ahead of

the bottom cuttin

| Filing I | nstructions | ||

|---|---|---|---|

| Type of Blade | Top of Teeth | Face of Tooth | Recommended File |

| Chisel Tooth | Bevel Filed | Straight Filed |

Mill File (Round edges)

Round Bastard for gullets |

| Rip |

Straight Filed

or Low Bevel |

Straight Filed |

Mill File (round edges)

for teeth Round Bastard for gullets |

| Cross Cut | Bevel Filed | Slightly Beveled | Slim Taper |

| Tenoning Blade | Straight Filed | Straight Filed | Slim Taper |

|

Plytooth and

Fine Tooth Blade |

Bevel Filed | Slightly Bevelec | Slim Taper |

| Cabinet Combination | Bevel Filed | Straight Filed |

Slim Taper for teeth

Round Bastard for gullets |

|

Free Cut,

Free-Smooth Cut, Master Combination, and Hollow Ground Combination* |

Straight File

Rakers Bevel Filed Cutting Teeth |

Straight File

Rakers Slightly Revelec Cutting Teeth |

Round Bastard for gullets

Slim Taper for cutting teeth I Flat Bastard for raker teeth |

| Non-Ferrous | Straight Filed | Straight Filed | Slim Taper |

| Nail Cutter** | Bevel Filed | Straight Filed |

Slim Taper

Round Bastard for gullet |

SEARS, ROEBUCK AND CO., SIMPSON-SEARS, LIMITED

De sure to maintain the original tooth shape.

USE THE RIGHT BLADE FUR THE JUB

MASONITE SIDING BLADE – Especially made for cutting Masonite siding, decorative hardboard, and waterproof plywood. Kromedge treated blade with flame-hardened teeth – outlasts ordinary steel saw blades many times. For all electric hand, here and radial arm same

CUNDER .

FOR METAL SAWING, CHOOSE THE RIGHT BLADES

STEEL SLICER BLADES MUST ALWAYS EXTEND BEYOND WORK

CUT SHEET METAL, ROOFING, GUTTERING, PIPE

KROMEDGE METAL CUTTING BLADES

BE WORN TO tion of Steel Slicer is not recommended for cutting alumi-num, copper, brass, and other non-ferrous metals. STEEL SLICER - cuts and une the radial-ari edge of the PROTECT with sneet heat Iron For electric s cutting process SSES SHOULD UR EYES. The and steel by by frichand

GLASSES Moderate feeding rate of ror cump aum NON-FERROUS METAL CUTTING produce smooth cut. taper-ground, made of extra-hard and other non-terrous metals. ses TO PROTECT YOU feeding rate of prass, such as a tallow candle. materiat A protessiona prolize, copper WEAH -8 blade BLADE r, zinc and WIL

NAIL-CUTTING BLADE — Ideal for flooring, lumber salvage, and rough timber that may contain an occasional nail or wire. Rip or crosscut. Made of extra-hard alloy steel . outlasts ordinary wood-sawing blades. Use with power hand, bench, and radial-arm saws.

SAFETY GLASSES ARE GOOD INSURANCE

PROFESSIONAL CABINETMAKER'S BLADES

For The Home-Workshop and Master Craftsman

Craftsman Kromedge Free-Cut blades have been developed to meet the exacting needs of master craftsmen. They are made to the most rigid manufacturing standards. Made in all popular diameters to fit electric hand, bench, and radial-arm saws.

accurate cutting vibration and wobble. ting clearance, with FREE-CUT RIP BLADE ting of all solid woods wi practically eliminated. Ext the teeth remove sawdust nave a heavy hub a free path for cutting Cuts both hard and so for greater stability --- m ds with Laper Used woods. Free SO set deep the grain For clean, that each for fast, also for tor Cut free, tooth has Binding is ets between faster cut anc

over the sdu minimizes vibration and rately. FREE-CUT COMBINATION BLADE or miters nard binding - cuts popular flat and set - a great and square cut. SOIL combination, neavy trims stock. more accu-Cuts

UNPLUG MOTOR WHEN CHANGING BLADES

TWO-SIZE PUSH STICK

The handiest "extra" you can have at the circular saw table is the simple push stick. You can safely handle stock in a wide range of thicknesses by having two notches in the end instead of the usual one. Make one notch for handling stock up to ¼" thick. Turn the stick over and you have a ½" notch for stock up to 2" thick.

KEEP HANDS AWAY FROM CUTTING TOOLS

PROFESSIONAL CABINETMAKER'S BLADES

for longer life; to resist tars, pitch, rust. Practically no splintering extra heavy body for stability. Teeth need no set. Kromedge treated blades are made especially for fine finish work. Taper ground with CRAFTSMAN THIN-RIM BLADES - The two Craftsman Thin-Rim

- Our FREE-SMOOTH eaves a smooth square cut xtra-heavy center Our finest profession "glue-joint" when cutting oles and slots insure free, CUT COMBINATION I fessional combination blade. cuts - rip, crosscut tough woods or blade run truer. true, quiet operation plastics BLADE le. Makes Expan miter

THIN-RIM SATIN-CUT VENEER BLADE extra for mitering and cutting laminates, sensitive materials without splintering and radial-arm saws Blades lor power veneers plastics hand Use Bes

to it power cuts, miters - An Idea THIN-RIM SATIN-CUT COMBINATION BLADE for smooth cabinetmaker's blade for use on solid fine trim and finish work. Rips, cross-Extra heavy body for stability - thin Dencn, and radiat-arm saws. ish cuts. Available in diameters

0-1N. hair-line joints. Especially useful in making joints, mortises, splines, tenons, etc. Use on radial-arm or bench saw with 5%-1/2-in, arbor, best results on bench saw use with Craftsman Inicker than au-purpose biaues. Cut tom grooves 1/8-in. wide in one cut hair-ling inints Especially useful in versal Jig fixture (page 25). KROMEDGE TENONING Ose on all woods Curo adnare . assures For botbox

Composition Board Masonite Flake Board Gypsum Board Wallboard

Cement Board Asbestos Board Asbestos Siding Asphalt Tile Woodrock Transite

Non-ferrous Metals Asbestos Installation Fiberglass Cork Asphalt Roofing All kinds of wood

OLLOW THESE DIRECTIONS FOR YOUR OWN SAFETY, AND FOR BEST POSSIBLE RESULTS

- be sure that your machine is in perfect condition free from end

- Saw blade must run bearing play. true on mandrel and in pertect line with

- ience of saw guide.

- For truest, smoothest cuts and longest cutting life use Crafts-man Saw Stabilizers.

- YOUR EYES. SHOULD BE WORN OI. PROTECT

it can be broken. Protect carbide tips from sharp blows. l'ungsten carbide is the hardest, most abrasive material ever used in saws, but

order store. resharpennig you many umes With proper use and care, your Craftsman Carbide-Tipped Saw Blade will give and repair service is available through any SEARS retail or mail the life of conventional blades between sharpenings. rompt

errous materials, DO NOT USE ON MASONRY, CONCRETE, STONE CAUTION: DO NOT USE ON NAILS, IRON OR STEEL and other BRICK, FLAGSTONES, CERAMIC TILE, ETC S

CRAFTSMAN CARBIDE-TIPPED BLADES

Outlast ordinary steel blades up to 20 times. Use them to rip, crosscut, miter, and bevel all woods, most plastics, Masonite, Formica, aluminum, brass, transite, asphalt, asbestos, wallboard, plywood. Not for masonry or ferrous metals. Kromedge finish for rust resistance, less gumming, faster cutting, easier feeding . use less power.

8-TOOTH CARBIDE - TIPPED 'BLADE SAFE SAW — Excellent for contractors' use on-site and for home owners who do a lot of sawing. Gives many more cuts between blade changes than ordinary blades, cutting almost any material. Blade sizes for electric hand, bench, and radial-arm saws. (12-in. diameter blade has 12 teeth.)

MASONITE CARBIDE-TIPPED BLADE — Make fast straight cuts with this long-lasting industrial quality blade. Designed for smooth cutting of Masonite and other similar abrasive materials. Blades have alternate top-bevel grind — recommended for all crosscutting and mitering of hard and soft woods, plywoods, veneers, Celotex, plastics,

ormica and plastic laminates

LIZER — Reduces wobble for truer, smoother cuts, and longer blade life. Tapered steel disc stabilizes the blade reduces rim vibration. Ideal for carbidetipped and all flat ground blades. Not recommended for hollow-ground or freecut style blades. Stabilizers are 4 in. diameter with center hole bushed for 5%-1½ in. Use with 7 in., 8 in . 9 in. 10 in. and larger diameter blades.

CRAFTSMAN KROMEDGE DADO SETS

For grooving, dadoing, ploughing, tenoning and decorative cutting on bench, radial-arm and power hand saws

The most common use of the dado is for cutting grooves: across the grain, diagonally, and with the grain. Craftsman Dado Sets are available to make cuts from 1/8 in. up to 11/8 in. wide. The dado is a work-saver in making wide tenons for lap joints, rabbets for dado and rabbet joints, box or drawer joints, decorative cuts, etc.

Craftsman Dado Sets are Kromedge treated and will outlast ordinary dado sets 5 to 1. Sets are professional quality with precision ground blades and perfectly matched chippers. Dado sets are available to fit most popular bench, radial-arm, and power hand saws. For plywood, fine veneers, mosaics, and other sensitive vaterials we recommend the Thin-Rim Satin-Cut Dado Set illustrated. 7

| C | 1 |

|---|---|

| 23 | X. |

| Þ | 1 |

| i. | |

| 9 | |

| - | |

| 11 | |

| Z | |

| ъ | |

| H | |

| U | |

| 2 | |

| - | |

| G | |

CRAFTSMAN DADO SETS are precision manufactured from the finest saw steel. Craftsman sets are available to perform almost any type of grooving, for various materials, and to fit most popular radial saws, bench saws, and power hand saws.

The THIN RIM SATIN CUT DADO SETS are designed uts grooves up to 13/16" width Available in 6" and 7" nard and ust-resistance. The dado for ccurate splinter free cuts on plywood, soft wood. These sets ster, fits all bench and radial saws with 5%" arbor the master craftsman are Kro veneers, dge tres furniture and cabinet maker uted for WO for and

The THIN RIM SATIN CUT POWER HAND SAW DADO, new and exclusive for Sears, makes dado cuts formerly only possible on radial and bench saws. This dado set will fit most 5%" arbor power hand saws and is Kromedge treated for maximum life and rust resistance, cuts grooves up to 9/16" width. It will make your power hand saw more versatile.

prooves up to plocked to give ned for heavy duty dadoing of all kinds. The cutting teeth are alternately fits all bench and radial arm saws with 5% 13/16" width, free and CRAFTSMAN FLAT GROUND KROMEDGE accurate cuts with the 8" set cuts grooves up to 11/8" widths out binding. Available in 6" arbor. The 6" DADO set cuts and 8" is

The full 11%" cut with the 8" dado requires saw arbor length of at least 11%" plus the arbor nut thickness. (Approximately 11½" total.)

CUT. It is not necessary to remove the dado from the machine to change the width of cut " arbor CRAFTSMAN CARBIDE TIPPED 7" ADJUSTABLE DADO is new and ive with Sears. This dado fits all The width of dado The long lasting tungsten carbide tips will last up to 20 tin the groove is adjustable from 1/4" to 13/16 Cuts plastic, bench and radial arm saws with 5%" plywood and all hard and 6" by DIAL THE nes as long Sof OF

See following pages for "how to use" information and typical dado uses.

PURCHASE YOUR DADO SET AT SEARS. SATISFACTION GUARANTEED.

DADO CUTS AND JOINTS

HOW TO USE THE DADC

manufactured to fill exacting requirements. As with other precision HOW TO USE THE DADO - Craftsman Dado Sets are designed and help you get the most from your dado set. tools, correct use leads to best results. The following steps will

board washers to make side cutter alone. Setting the positioned between outside cutters - never alone. For grooves wider to make of cut. For Dado desired width of cut. Use paper or card For Head - Sele In adjustments. Always use chip width groove, use one out-idth groove use two outside In. add enough correct parts Inside

Mounting the Dado cutters without a chipper, stagger ter next to inside saw flange ge the teeth of the other cutter so that the teeth of one cutter do not touch and Start by placing as one outside

the chippers evenly, as the inside chippers are in line with the this position while tightening dado on saw arbor. When more than one inside chipper, space the cutting edge e chippers evenly, as shown. This equalizes the cut of the outside cutters as shown in Photo Inside Chippers - When inside chippers are the outside De the outting edges Main

hen chippers are used, both outside cutters must Securing the Assembly - Photo C shows complete assen remove chippers. hers between the outside blades and the inside chippers before turning on machine to be sure nut , guard, or motor nousing and does not strike against any part of the table arn asn it is standard is ugniened rotation arrows on outside Width of Arm Saw. Dado ightened securely. If arbor is to obtain maximum e flange. Cut - For large adjustments Rotate the dado one run practice to leave fine If the aroor thread oti use thin paper Blade Guaro IOF the auor 1011 SI Be sure the uauo sufficient be used outsid nut add

eeper the cut, the slower the speed epth of cut de Making the Cut - Operate the dad ou do a circular saw blade. Position other cuts. F iumper. desired. Check your settings with a piece of When making deep cuts, do so in successive ent overloading of machine and to obtain speed — the wider and nead to obtain the Sumo

Omby simple to make straight dado prougning, also grooving, liuting . ... and rappet cuts tongue-and-groove lieavy cuts on do angle the

ALWAYS USE BLADE OR MULDING GUARD

HOW TO USE DADO

FLUTING

LAP

GAIN CUI

hub for exact-size laps,

rooves, joints, rabbets, other cuts

machine to reset for new Tipped in. up dado, In

only of Saw

Cut

How To install the Adjustable Dad

ange rection of next to the dado adn IOF the the arbor on the arbor the the of

the w t width to on type

ant table, msert and saw, or blade guard dado one guard, or strike

be in your work piece * く **** new setting on arbor

saw blades. Observe all cut molding head, rules as pracon

USE DADO INSERT ON BENCH SAW

SPECIAL DADO SET FOR ELECTRIC HAND SAWS

Use your electric hand saw with this specially designed Craftsman dado. Cut grooves up to 9/16-in. wide and up to 1-in. deep, depending on the machine used. (About 9/16 in. deep on your Craftsman Electric Hand Saw.) Make wide tenons for lap, dado, and rabbet joints; plough, bevel, and make decorative cuts formerly possible only on bench and radial-arm saws. Fits most popular electric hand saws with 5/8-in. round arbor. Dado set comes complete with two outside cutters, three chippers, necessary bushings, flange washer, and arbor screws.

Mounting — Always use a bushing, selecting correct bushing for desired width of cut. Place desired assembly on saw arbor, making sure the bushing extends into the recess of the flange washer. For 1/8-in.-width groove, use the shortest bushing and one outside cutter as in Photo A. Place on machine as you would a circular saw blade.

To make a ¼-in.-wide groove, use next larger bushing and the two outside cutters as in Photo B. Rotate these cutters as shown, so that the teeth of one cutter does not touch and damage the teeth of the other cutter.

For grooves wider than 1/4 in., place largest bushing on saw arbor and add enough inside chippers to make desired width of cut. As shown in Photo C, position the cutting edges of the inside chippers so that they are evenly spaced. This equalizes the cutting load and makes a smoother cut.

USE CHIPPERS ONLY BETWEEN TWO OUTSIDE CUTTERS! Photo D shows complete assembly. After mounting outside blades, add flange washer, then tighten the arbor screw securely. Before starting machine, be sure the dado is installed in the correct rotating direction and clears all parts of the machine.

To adjust depth of cut, raise or lower the base plate the same as you do when using a circular saw blade.

Cutting — The dado operates the same way as your circular saw blade. Do not feed too fast. The wider and deeper the groove, the slower you push the machine. Do not twist or bind the dado. We strongly recommend that you use the Craftsman Portable Saw Guide or a straight edge to insure straight cuts. Check your settings by making a cut on scrap lumber.

CRAFTSMAN MOLDING HEAD AND CUTTER BITS

Make Your Own Moldings and Trim

Convert your bench or radial-arm saw to a jointer, planer, or shaper with the Craftsman Molding Cutter Head. Make picture frames, interior trim, moldings, etc. Copy. a variety of designs or create your own. Each cutter bit is made of selected tool steel, and properly heat treated for maximum toughness and long life. Patented Safety Screw Lock aligns cutter bits and locks them securely in position. Each set comes complete with wrench, spacer washer, and bushings in a sturdy plastic package.

The Craftsman Mono-Cutter Molding Head Set. Made especially for the Craftsman Radial-Arm Saw, but fits any bench or radial-arm saw with 1/2-in. or 5/8-in. arbor. Comes with 18 bits. Operates chatterfree and is designed to stay in perfect alignment turns out trim or moldings uniform in size and shape.

Three-Bit Cutterhead Set. Our best, most efficient cutter head. Get professional results. Use your bench or radial-arm saw as a jointer-planer or shaper. Packaged in plastic case with storage space for six sets of cutter bits. Wrench, spacer washer, bushings included. Fits most bench and radial-arm saws with 1/2 in., 5% in., or 3/4 in. round arbors.

INSERTING CUTTERS IN MOLDING HEAD. Insert the cutter bit into your Craftsman molding head as shown in Figs. A and B and tighten the Safety Lock Screws with wrench provided. Be sure cutters are seated squarely and lock screws tightened securely before starting saw. CAUTION: Be sure the groove in back side of cutter

CAUTION: Be sure the groove in back side of cutter bit is opposite the lock screw and that the rotation is correct. Running the molding head backwards or with bits installed backwards will permanently damage the bits and head.

CRAFTSMAN MOLDING HEADS AND CUTTER BITS

cutter changes accidentally be 1 Tighten the saw arbor nut securely. Bef nachine, revolve the head by hand to oes not touch or bind on any part of place with cutters pointing in Then slip on molding head as shown INTING MOLDING HEAD ON other cutter voui Replace It is not spacer wash side next to arbor s needed cutters pointing ce outside flange washer and w arbor nut securely. Before starting ve the head by hand to be sure it we hind on any part of the table. turned on snapes while that the power cannot es on saw arbor first. the bushing or arbor head as shown in Figs. he you are making BENCH tab andun Slide flange. insert the

ARM SAW. If on arbor first accidentally see that it is change ore starting machine shers on the machine spindle. I is pointing in the direction of arbor nut securely and repl shing or arbor gs. D and E. I chine or otherwise make sure it cannot be turned thing. It is not cutter MOLDING Then place spacer washer over If space permus tree and bits t nec then the IS does not bind required, orve the head replace molding head s, use both flange Be sure the cutter f rotation. Tighten first unplug NO blade guard t should go the head or strike by hand as the s in

LOCKING NUT BORN Fig.

er operate molding head on bench saw without molding head insert

- Never operate

- Use wood auxiliary fence, pages 17 and 22, instead of metal rip fence. Whenever possible use at least a 4-in.-wide board and then rip to desired

- Use Craftsman Universal Jig, page 25, on all strips shorter than 12 in width after making molding cut.

- Never turn on power until you revolve the molding head by hand to be sure the cutters are tight and the head is running true.

- Feed material into the molding cutters slowly and steadily for smooth, , even

- 8 Remember that the best work requires sharp cutters. On large moldings, take two or three shallow cuts rather than one deep cut

- 9. ivever stop being careful

- Always oil your molding head cutters before storing

not your regular tence to one illustrated MAKING AN III AUXILIARY head motiding operations. auxiliary you can easily adapt FENCE. fence If like the

CRAFTSMAN MOLDING HEADS AND CUTTER BITS

cular notch in the bottom edge of cutter clearance. Prepare the other For additional detailed instructions see page 23. manner and mount the two facings on opposite sides of your fence with countersunk bolts and nuts. Straight-grained hard Make two 1-in.-thick facings wood is the other facing fit your fence. Cut a semi-cir-of the facing for opposite ш like

It su used wherever possible table is called for the various widths vice that upports the work at all times against the impact the cutter. Some form of hold-down should be YOUR OWN HOLD-DOWNS. Any olds the work against the fence or led a "hold-down." The hold-down rated in Fig. G is an adjustable de is an adjustable device and de-

and controls the depth of cut. On all cuts, be sure to turn the head by hand to make sure the cutters do not strike the table saw bed, or insert. clamped on Fig. H shows a ing edge cuts on the depth of cut. The strip of the depth of cut. The auxiliary n wide boards hold-down where it is difficult

enough lestred and guide s best width. for strip holding. The groove is just large to hold the strip securely as it is fed. If not use a stripping guide, cut the moldings of at least 4 inches wide, using hold-down ide as in Fig. G, then cut off strips the hold-down like the one shown H Fig.

saws and jointers on page 22. See the Craftsman Hold-Down for bench and radial-arm

head a little at a time. Always use the fence as a guide. When work must be placed on edge, move the fence back so that cutting is done on the side away from the fence. This leaves a square edge against the fence for better support. Be sure the work faced against the fence is straight; otherwise the cut will not be true. If work is to be molded all around make the cut will not be true. erably with a backup of scrap wood certain exceptions, teed the work as you blade. Avoid making too deep a cut or Make your deep cuts in easy stages, rai JSING THE CUTTER FOR VARIOUS occur īp cuts Trom the cross-cuts then remove make the cross-grain cuts firs o of scrap wood, to minimize sp any MOLDING slight splinters that from the fence. fence for better st the fence is If work is to be uts first prefto a too fast. saw

CRAFTSMAN HOLD-DOWNS

CRAFTSMAN HOLD-DOWNS

The Univ

Jig has

been

desi

to safely the

making difficult

nent slides

De

ĕ

miter gauge

CRAFTSMAN UNIVERSAL JIG FOR DIFFICULT CUTS

For Use on Bench Saw Tables and Shapers

for

UNIVERSAL JIG

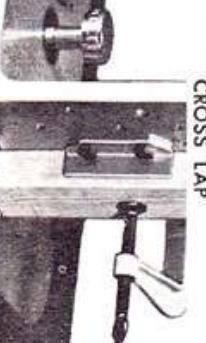

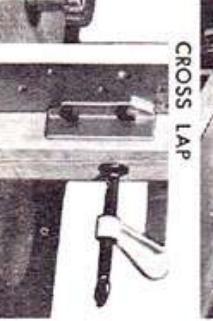

LAP JOINT

Following illustrations show how to make basic cuts simply and safely. BASIC CUTS USED IN WOOD JOINTING WITH THE UNIVERSAL JIG

grooves 1/8 in. wide to form hairline joints.

1n.-1/2 in.

saw

Thicker than general

pu

it cuts square

on page

dad

The ter WILD

die

RADIAL SAW BEADING

24

JUINIER

BENCH SAW BEADING

board behind wood being cut keeps cutter away from Universal Jig

MORTISE

CRAFTSMAN UNIVERSAL JIG FOR DIFFICULT CUTS

Make fran лаке

s with per

CRAFTSMAN MITER VISE

for extra-strong

up to 3 in.,

plus

SCREENS WITH PERFECT JOINTS MAKE YOUR OWN FRAMES AND

MITERING SCREEN FRAME

26

GLUE JOIN

DRAWER FRONT

MITERING PICTURE FRAME

FEATHER SPLINE

CRAFTSMAN TAPER JIG FOR ANGLE, TAPER CUTS

use. Cuts tapers up to 3 in. per foot or 15 degrees. Has easy-to-read tapered waste baskets, magazine racks pieces. radial-arm saw. Simplifies making molding or dado cuts on tapered Makes accurate taper cutting and sanding easy on any The ideal jig for making Hepplewhite tapered , etc. Easy to adjust and table legs, bench or

aper Cutting On Bench Saw

Taper Cutting On Radial-Arm Saw

HOW TO ASSEMBLE AND USE THE TAPER JIG:

CRAFTSMAN SANDING WHEEL

Use shaping the Craftsman The wheel has medium Sanding Wheel for easier, better results in grit on one side, coarse grit on the other sanding

the Wheel on bench sc. To the wheel shape a curve, take many hold work flat on table Feed

aping a curve

surface sanding

Craftsman Taper Jig 29

a board end

re lacement discs are availab

scale. Made of sturdy aluminum.

one of You can fiberglass, shapes and dadoes outperforms sandpaper groove, shape laminates, etc. without . 40 5 changing to clean plaster

- no teeth to snag or drag l'ough One carbide grits side and edge are permanently brazed to steel wheel - will not work coarse grit; other side medium grit. Safe in operation

would Bench Saw Saw would a

a circular saw blade, U erate as you aw, groove,

tate For arm saws, use lock inclion guide Inonoli surface 5 to Fage the on radia Delow 5

CRAFTSMAN JOINTER-SANDER

man that requires the finest in straight, smooth finishes The JOINTER-SANDER is for the cabinet maker, furniture maker, the Crafts

of the jointer-sander disc is conical shape for true straight line sanding. Other sanding, etc side is conventional flat disc sander for the sanding of curves, shapes, free hand Convert your bench or radial saw into a jointer-sander or One side

Requires little if any additional hand sanding before applying finish Sanded WITH sander. All marks are straight and parallel

Sanded with conventional sanding disc. lapping. Requires hand sanding before applying Sanding finish marks are curved and over-

SMOOTHER SANDING - LONG LIFE WITH JOINTER-SANDER

REFITTING CIRCULAR SAW BLADES AND DADOES

Craftsman Circular Saw Blades are precision: manufactured, properly tempered, not, and filed. To obtain best results it is necessary to resharpen occasionally when blade is dulled from prolonged

SHARPENING OPERATIONS—Usual-ly three separate steps are required: Maght and allow restores the proper edges, is re-gri wider of the blade Setting, tu, than the blade to run Will alternately cut de to 2

IOINTING ON BENCH SAWS—Mount he blade on the arbor so that you can and turn the blade backward. Lower he blade, place an oilstone on two blocks over table insert, and raise blade

blocks over table insert, and raise blade until the tips of teeth barely brush the stone. Rotate blade by hand until all teeth have touched the stone. Do not take off more metal than is necessary. When tops of teeth have "shine", jointing operation is finished. Similar procedure is followed on radial-arm saw, except that the blade is lowered to stone. To joint a Dado Set, place the entire set on the arbor, and joint all cutters together.

UNPLUG MOTOR WHEN JOINTING BLADE

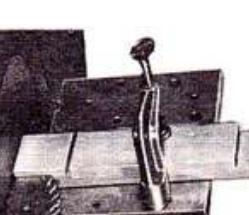

for quick, accurate setting of blades with 1/2 hole. The tool consists of a steel anvil, zinc wrench, 4 bushings, and 2 striker pins (on THE CRAFTSMAN CIRCULAR SAW SETTTER, shown in Photo for quick, accurate setting of blades with 1/2 in., 5% in., 3/4 in., an hole. The tool consists of a steel anvil, zinc die-cast body and construction of the tool consists of a steel anvil, zinc die-cast body and construct the tool consists of a steel anvil, zinc die-cast body and construct the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of the tool construction of tool construction of the tool construction of tool co coun). Daw Setter ints into any bench saw miter (one slot large teeth 5% in. to and and centering H In. IOI center fine

inder the striking pin meh hex hould be n order to use the saw setter, cap securely. ecurely. Place the unit screw to the the set for various type in for the proper post of the left until the unit is hel distance from the proper H depth the mater on Burusna set, of yo ugnuy in fit lock in place. Diagram B your. the circular saw arbor the round saw table and turn each tooth extends the slot. head Place the screw

The teeth are set by tapping striker pin with a light hammer, using enough force to set tooth without damaging it. Rotate blade to set every other tooth to one side. Then turn blade over and set the remaining teeth.

When setting the ooth Cut teeth; otades 0 Da Free-Cut 10U 0D IS Flat OF Carton require a set Combin round th Dado ation Blade, alternate directions, same as chiseltooun Thin Rim Satin Cut Dadoes and the Free-Sat Sets differs in that Exercise caution to do not set raker teeth. for all banks. you are the Setting

Loading...

Loading...