owners manual

Sears CRAFTSMAN.

GRINDER ACCESSORY

GRINDER NOT INCLUDED

CAT. NO. 9 6660 ROUTER BIT

Sears

SHARPENER

CAUTION:

Read Rules for Safe Operation and Instructions Carefully

Sold by SEARS, ROEBUCK AND CO., Chicago, IL 60684 U.S.A. and SIMPSONS—SEARS LIMITED, Toronto, Ontario, Canada

Wt. 1 LB 7025.

Safety Rules

WEAR YOUR SARTY ELASSES FORESIGHT IS BETTER THAN NO SIGHT

Do not grind on side of wheels. Use guard and shatterproof shield. Stand aside for one minute after starting wheel. Follow safety rules of your grinder manufacturer. Follow safety rules on grinding wheels.

WE RECOMMEND THE GRINDING WHEEL BE DRESSED BEFORE SHARPENING

Standard grinding wheels which come on grinders will BURN YOUR ROUTER BITS. YOU MUST USE ONE OF THE WHEELS LISTED BELOW.

These wheels will cut faster than the wheels which come on bench grinders and will not burn or round the cutting edge of the router bit.

DRESSING STICK MODEL 96491

ROUTER BIT SHARPENER PICTURED WITH A 7" GRINDER

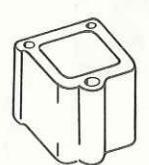

HEIGHT SPACER (USE WITH 6"-7" & 8" Grinders)

NOTE: When using 5" grinders, fasten the PIVOT SHAFT ASSEMBLY directly to the BASE using (3) #10-24 x 5/8 ROUND HEAD SCREWS.

ASSEMBLY:

- 1. Screw the THUMB NUT , head first, on the STOP SCREW . Assemble the SPRING and 3/16 WASHER on the stop screw. Place a SQUARE NUT behind the EAR of the PIVOT BRACKET and assemble the stop screw thru the hole and into the square nut. (figure 1)

- For Sears 6"-7" and 8" grinders, place the HEIGHT SPACER on the BASE and the PIVOT SHAFT ASSEMBLY on the height spacer. Fasten the three pieces together using (3) 2¼" long ROUND HEAD SCREWS and SQUARE NUTS. (figure 2)

ROUTER BIT SHARPENER PICTURED WITH A 5" GRINDER

3 Assemble the BARREL ASSEMBLY to the SWIVEL BRACKET with the PIN in the PIVOT HOLE. Secure using the SHOULDER THUMB SCREW and WASHER thru the circular slot, and into a square nut.

- 4. Slide a SQUARE NUT in the slot of the SWIVEL BRACKET and start the ROUND HEAD SCREW into the nut.

- SWIVEL BRACKET SQUARE NUT ROUND HEAD SCREW SWIVEL BRACKET BARREI SQUARE NUT BARREL HOUSING SQUARE NUT THUMB SCREW SPRING FEED SCREW SHOULDER OF PIVOT SHAFT THUMB NUT IOUSING STOP LEDGE STOP SCREW VERTICAL FIGURE 3 PAGE 3

WASHER

PIN

PIVOT HOLF

SHOULDER THUMB SCREW

BARREL ASS'Y.

5. With the BARREL pointed up, slide a SQUARE NUT along side the barrel and into the slot of the BARREL HOUSING. Assemble a SHOULDER THUMB SCREW thru the spring, into the hole and in the NUT. (This thumb screw is to secure the barrel while grinding.)

- 6. Turn the FEED SCREW back until the SHOULDER of the PIVOT SHAFT is against the HOUSING. Set the STOP SCREW so the STOP LEDGE (the stop ledge is the open part of the under side of the pivot shaft shoulder.) is vertical when it is against the stop screw. Secure the stop screw with the THUMB NUT. (figure 3)

- 7. You will use the ROUTER BIT SHARPENER on the right hand wheel. Be sure to use the proper wheel for router bits. To mount the unit in proper relation to the grinding wheel, place the ROUTER BIT SHARPENER on the bench in front of the grinding wheel with the feed screw to the right and the stop screw toward you. (figure 4)

-

GRINDING WHEFT 4 4 / 0 8 This step describes the BOUTER BIT SHARPENER position to the grinding wheel when using 7" or 8" HOUSING grinders (To mount this unit to a 5" or 6" grinder read step 26) Position the base so the HOUSING is 1-1/8" from the right side of the grinding wheel and the pivot shaft is 1-1/8" from the grinding wheel face. With the nivot shaft parallel to the front of the grinding wheel DARALLE mark the two mounting slots on the bench. Predrill 1-1/8 with a 1/8" drill and secure the base to the bench using (2) wood screws and washers (figure 5) EOD 7" 0 0" FIGURE 5 GRINDERS ONLY SWIVEL BRACKET ASS'Y. DIVOT SHAFT 9 Assembly the SWIVEL BRACKET ASSEMBLY on the PIVOT SHAFT with the barrel assembly up and the tapered end of the

BARREL

toward the grinding wheel, Snug the lower round head screw (figure 6)

- 10. We will sharpen a 1/2" diameter straight flute router bit first Loosen the two THUMB SCREWS, the two SOCKET SET SCREWS and the lower ROUND HEAD SCREW. You now have freedom to adjust the router bit cutting flute at the proper relation to the arinding wheel for sharpening. (figure 7)

Insert the 1/4" shank of the router bit into the barrel.

-

11 Setting the router bit in relation to the grinding wheel.

BEFORE PROCEEDING READ THE HELPFUL HINTS

ON PAGE 6 & 7

- A. We want the router bit up on the wheel so the full length of the cutting edge is sharpened. The Router Bit Sharpener is shipped to you with the INDEX SPRING in one of the two locating grooves on the INDEX COLLAR. Check to be sure the index spring is still in a groove. Rotate the barrel (index collar does not move) until its SET SCREW is to the right side for access when tightening later. Push the barrel toward the grinding wheel until the full length of the cutting flute will contact the wheel (figure 8). Do not allow the barrel to go up inside the swivel bracket. If it does read step 20. Tighten the SET SCREW in the index collar. The set screw should tighten on one of the flats of the hexagon barrel. Tighten the THUMB SCREW on the right side of the barrel housing.

FIGURE 7

FIGURE 6

THUMB SCREW

ROUND HEAD SCREW

B. Rotate the router bit in the barrel (barrel does not turn) until the face of the cutting flute is parallel to the side of the grinding wheel. (Index spring is still in the notch of the index collar). Secure the router bit with the SET SCREW in the barrel. (figure 9)

C. Screw the FEED SCREW in against the shoulder until the pivot shaft is moved 1/16" to the left. Check to be sure the swivel bracket slides freely on the pivot shaft and the BARREL ASSEMBLY swivels freely on the swivel bracket. To get the cutting flute straight to the wheel, push the cutting edge against the wheel with your right thumb allowing the barrel assembly to swivel and the swivel bracket to slide. Secure the cutter position by tightening the SHOULDER THUMB SCREW on the barrel assembly. (figure 10)

FIGURE 10

RIGHT THUMB

D. Your right thumb is still holding the face of the router bit cutting edge against the wheel. Turn the pivot shaft until the STOP LEDGE is against the STOP SCREW. Tighten the lower ROUND HEAD SCREW to secure the swivel bracket to the pivot shaft.

STOP LEDGE IS AGAINST THE STOP SCREW

Turn the stop screw in until the router bit is lifted slightly. (figure 11)

Turn the feed screw back until the router bit's cutting edge is slightly off the wheel. (figure 12)

13. Rotate the PIVOT KNOB back until the router bit is up. Blacken the flutes of the router bit using a marking pen (or match). (So you can see where you have ground).

Review the safety rules in your grinder instruction manual. Then start the grinder.

"EASY DOES IT."

- 14. Advance the router bit toward the grinding wheel by rotating the pivot knob. The stop screw will stop the router bit before it touches the grinding wheel. Rotate the router bit back and turn the fine feed screw in 1/8" of one turn. (This advances the router bit toward the grinding wheel .005) When sharpening keep the bit moving when it is in contact with the wheel. If the bit stops while in contact with the wheel, heat is created and rounding of the cutting edge may occur. Repeat turning feed screw in 1/8" of one turn until there are a few sparks as the router bit touches the wheel. Repeat the .005 in feed one more time and rotate the router bit straight up for inspection.

-

15. We want the face of the router bit flute to be sharpened at the cutting edge. If the black is removed at the cutting edge as shown in figure 13, proceed to step 16. If not, read A & B to determine the minor adjustment needed.

- A. Figure 14 shows black still along the cutting edge and removed back near the root. To correct back up the feed screw and loosen the barrel set screw. Rotate the router bit cutting edge slightly toward the wheel. Retighten the set screw.

- B. Figure 15 shows black removed at one end or the other but not along the length of the cutting edge as wanted. To correct, back up the feed screw and loosen the shoulder thumb screw on the swivel bracket. Turn the swivel bracket slightly to correct and retighten the thumb screw.

- 16. Continue to rotate router bit on and off the grinding wheel. Each time the bit is off the wheel, advance the fine feed screw .005. Check the bit face often and grind the minimum amount needed to sharpen the CUTTING EDGE .

- 17. Back up the fine feed screw until the pivot shaft shoulder is back against the housing. Loosen the THUMB SCREW on the right side of the barrel and rotate the barrel 180° to the SECOND LOCATING NOTCH . Retighten the thumb screw. Repeat step 16 until the second cutting edge is resharpened.

HELPFUL HINTS

18. Before sharpening a tool we recommend you dress the wheel.

Sears has this silicon carbide stone for dressing all grinding wheels.

19. Figure 16 shows other router bits and their angle to the wheel when set up to sharpen. Note we always grind off the face not the end or outside diameter, this is so the shape of the bit is not changed.

- 20. It is possible on some grinders that some router bits will have to be pulled out of the barrel up to 1/4" to get the entire cutting edge on the wheel, without the barrel going up inside the swivel bracket.

- 21. After sharpening the router bit it is recommended practice to stone the burr off the cutting edge using a fine hand stone.

- 22. To use the grinder attachment with a pedestal mounted grinder you will need a plywood board between the grinder and pedestal for mounting the router bit sharpener. (figure 17) The PLYWOOD will serve as the work bench.

- 23. On single flute cove or veining bits there will be a SMALL STEP ground behind the cutting edge. This step is o.k. and will not change the routed groove. (figure 18)

- 24. In step 15 we are setting the radial position of the router bit. The test is how the grind looks in figure 13. The cutting edge can be ground and still not be set right. Figure 19 shows the cutting edge being ground too much, be aware of this and in this case rotate the router bit back a little.

25 TROUBLE SHOOTING

Rounding of the cutting edge of the router bit can be caused by:

- Feeding more than .005 per cut

- or using the wrong grinding wheel

- or your bench grinder has too much end play

- or grinding wheel needs to be dressed

Burning the cutting edge of the router bit can be caused by:

- Feeding too fast

- or using the wrong grinding wheel.

26 Mounting dimensions for Sears 5" and 6" grinders

Position the base so the HOUSING is 1-1/8' from the right side of the grinding wheel and the pivot shaft is 3/4" from the grinding wheel face. With the pivot shaft parallel to the front of the grinding wheel, mark the two mounting slots on the bench. Predrill with a 1/8" drill and secure the base to the bench using (2) wood screws and washers.

OTHER GRINDER ACCESSORIES

Use the tool holder attachment with any grinders to sharpen screw drivers, chisels, long blades, planner blådes, and other tools.

MASONRY BIT AND WOODBORING BIT SHARPENER

Use with any grinder to sharpen Masonry Bits and Wood Boring Bits.

DRILL BIT SHARPENER

to sharpen drills from 1/8 to 1/2 (incl. letter & number) using the front face of grinding wheel. ROTARY MOTION ensures concentricity.

Position the base so the HOUSING is 1-1/8" from the right side of the grinding wheel and the pivot shaft is 1-7/16" from the grinding wheel face. With the pivot shaft parallel to the front of the grinding wheel, mark the two mounting slots on the bench. Predrill with a 1/8" drill and secure the base to the bench using (2) wood screws and washers.

919596

96672

Loading...

Loading...