CRAFTSMAN ....

- . . MOLDING HEAD FOR BENCH SAW

- . . CARBIDE TIPPED SAW BLADES

- . . MOLDING HEAD FOR RADIAL ARM SAWS

- . . CIRCULAR SAW BLADES AND DADOES

- . . MOLDING HEAD FOR WOOD SHAPER AND DRILL PRESS

Highest Possible Quality at Lowest Possible Price

Available in Sears, Roebuck and Co. Mail Order Catalogs and Retail Stores.

Craftsman Tools Are Sold Only By SEARS, ROEBUCK AND CO., U.S.A. SIMPSONS-SEARS LIMITED, CANADA

YOUR CRAFTSMAN CIRCULAR SAWS AND DADO SETS

The Craftsman circular saw blades and dado sets have been developed over a period of many years research, testing, and new methods of manufacture to become leaders in their field. Made from the finest quality saw steel and manufactured by revolutionary production methods, result in lower costs and allow us to offer the best values in saw blades and dado sets on the market.

Periodical tests are made of Craftsman Saw Blades and Dadoes comparing their performance with higher priced saw blades and dado sets and results obtained prove Craftsman superiority in cutting quality and longer service.

Sears is proud of their enviable achievement in becoming headquarters for circular saw blades and dado sets and will maintain their extremely high standard of quality that is backed up by their policy of Satisfaction Guaranteed.

Craftsman Professional blades for every purpose.

CHOOSE THE RIGHT BLADE TO DO THE JOB RIGHT

While there are relatively few basic types of circular saw blades, it is important that you use the proper blade for different jobs. Some blades are designed to do specific cutting work, such as ripping. Others will do a combination of cutting tasks.

TYPES OF CIRCULAR SAW BLADES

No one type of blade will do every kind of cutting equally well. Experienced woodworkers prefer an assortment of blades. With the exception of blades for cutting grooves and other specialized work, the following basic types of CRAFTSMAN blades will give the average home shop a good start: The Chisel-Tooth Blade The Cross-Cut Blade The Ply-Tooth Blade The Ply-Tooth Blade

The Rip-Saw Blade The Cabinet Combination Blade The Flat-Ground Combination Blade Fine Tooth Blade

WHAT THESE BLADES WILL DO

The Chisel-Tooth Blade is a recently developed combination blade with fewer teeth with strong backing and bevel filed for free smooth and fast rip and cross-cutting. It is one of the easiest of all blades to maintain. The Cross-Cut Blade is for general cutting, straight across or diagonally across the grain of the wood. It has shallow teeth somewhat similar to those of an ordinary cross-cut hand saw

The Rip-Saw Blade is for cutting with the grain, or lengthwise. Its fewer teeth are deeper than those of the Cross-Cut and more claw-like in shape. The deep gullets take the saw dust out of the cut so the next tooth will have a clear path to cut the wood.

Dress properly. Avoid accidents.

The Flat-Ground Master Combination Blade is for general purpose wood cutting, including ripping. Its teeth combine the cutting characteristics of both the Cross-Cut and Pie Scare Blades For the Cross-Cut and

teeth and raker tooth, is separated by deeper slots going toward the center of the disc. These slots are called gullets and removes the saw dust from the cut to permit the teeth to produce a smooth cut.

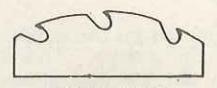

The Hollow-Ground Master Combination Blade, like the Flat-Ground Blade, is for general purpose cutting. However, it produces an exceptionally smooth cut that can be glued without sanding. The hollow-

ground blade is thicker at the teeth than it is toward the center of the disc, tapering downward to a thicker collar near the middle. This produces a smooth cut that makes the blade ideal for fine cabinet and finishing work.

CRAFTSMAN Chisel-Tooth Cross-Cut, Rip, and Combination Blades are made of chrome-nickel-molybdenum steel alloy for super-hardness. They stay sharp, stand up under heavy daily production work, and are designed to run true and cut straight. They are accurately set and filed, with deep gullets for clearing out sawdust. Like all CRAFTSMAN blades, they are machined to a high degree of mechanical precision and must pass the most rigid inspections.

THIN BLADES

Ply-Tooth BLADES

designed especially for cutting Plywood with the absolute minimum of splintering necessary for fine cabinet work, pattern making, glue joints, picture framing, etc. Ideal for fine line sawing of Celotex, woods, veneers, etc.

For extremely accurate splinter free work the use of a piece of masking tape on the out going side of your material is recom-

Use the tool designed for the job.

mended. The use of Craftsman Stabilizer (Cat. No. 9-4952) is recommended for extra fine smooth accurate cuts with 7 inch blade. Practically no planing or sanding is required.

Cabinet COMBINATION BLADES

especially designed for extremely smooth finish rip, crosscut or miter cuts in hard and soft woods. Ideal for Cabinet Making, Model Making and Pattern Making where fine work is absolutely essential. For even

more accurate and smooth work we recommend the use of Craftsman Stabilizers (Cat. No. 9-4952) with this and all blades.

Gine Tooth CROSS CUT BLADES

designed to give the smoothest possible cut on trim work of hard and soft woods, Wallboards, Celotex and fine grain dry materials. Extra smooth cuts for glue joints and miter joints. Used by professional carpenters,

contractors, home owners and anyone desiring the finest possible quality cuts from power hand saws and table saws.

DADO SETS

The well-equipped home shop would also have a Craftsman Dado Set. With the Dado Set you can make virtually all the common cuts in the woods normally used in woodworking. The Dado Set is for cutting grooves (cross-cut, diagonal, or rip) in a flat wood surface. CRAFTSMAN Dado Sets are made of tempered steel, are precision-ground, and have perfectly matched chipper blades. See page 17 for additional information on Dado Sets.

Never stop being careful.

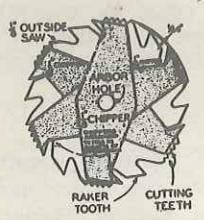

The CRAFTSMAN 6" Dado Set will cut grooves from 1/6" to 13/16" wide. It consists of two outside saw blades and five inside chipper blades. The width of the cut is determined by the number of chipper blades inserted between the outside saw blades. A more precise adjustment can be obtained by using paper washers.

The CRAFTSMAN 8" Dado Set is designed for large bench saws, builders saws, radial arm and swing saws. It will cut grooves from 1/8" to 1" wide, and consists of two outside saw blades and six inside chippers. See page 17 for additional information on Dado Sets.

Craftsman Dado Sets are designed to cut grooves with "glue pockets" to give better fitting joints (see page 7, Fig. A.)

The CRAFTSMAN Saw Blade Stabilizers (Cat. No. 9-4952). Craftsman Stabilizers make your saw blade run truer, resulting in smoother cuts. They are recommended for carbide tipped blades because they reduce rim vibration preventing damage to the carbide tips, give longer life to the blade and result in accurate, smoother cuts.

Use the Craftsman Stabilizers for truer, smoother cuts on 7, 8 and 10 inch carbide tipped blades and all types of flat ground blades. (Not recommended for Hollow Ground Saw Blades.)

These stabilizers are placed on each side of the saw blade.

Craftsman mass production gives you finest quality blades at lowest cost.

HERE ARE CUTS YOU CAN MAKE WITH CRAFTSMAN DADO SETS

Notice glue pockets on illustration Fig. A. The cut on the outside edges are slightly deeper than the center of the groove. This is an advantage because it makes for square, flat fits and allows space for the glue to flow as the parts are forced together.

SPECIAL PURPOSE BLADES

To the home craftsman who does a good deal of general work on a variety of materials, the CRAFTSMAN line offers the Nail-Cutting Blade and the Carbide-Tipped Safe-Saw .

The Nail-Cutting Blade is for sawing lumber containing nails or wire, and is a good allaround blade for rough work, both cross-cut and rip. It is a deep-toothed blade with teeth slightly more upright than those of the cross-cut blade. This improved tooth design, the result of long research, makes it, in the belief of the manufacturer, the best nail-cutting blade on the market. It is made of special steel, heat-treated to proper hardness.

CARBIDE-TIPPED

The Carbide-Tipped Safe-Saw is for cutting non-metallic composition materials such as wallboard, plastic, Transite, masonite, etc., and all types of wood. Its teeth are tipped with tungsten carbide, the hardest

metal made, giving it revolutionary cutting and lasting qualities. The design practically eliminates "kickback" and the tendency to pull articles into the blade. It rarely needs sharpening, if used properly, and vastly outwears ordinary blades. Should your safe saw require sharpening, we recommend you return it to Sears for factory sharpening.

The CRAFTSMAN Stabilizers (Cat. No. 9-4952) are highly recommended for use with the Carbide-Tipped Blade to obtain smoother truer cuts and longer tooth life.

Use the blade that fits the job.

REFITTING YOUR CRAFTSMAN CIRCULAR SAWS AND DADO SETS

The modern power saw blade, while capable of prolonged cutting, is a precision tool and must not be abused. Your CRAFTSMAN blades are made of the finest saw steel available, carefully heattreated and tempered to hold a sharp cutting edge. They have been carefully set and filed at the factory. Keep them sharp and round, and they will repay you in better work and will last longer. Dull saws give slow, poor cuts, and require more power. If teeth are occasionally touched up with a file, longer cutting life between refitting will result.

Occasionally it will be necessary to make certain adjustments to put your blades back in top cutting condition. In other words, to refit them. This procedure is relatively simple, and involves the following steps:

JOINTING — This means equalizing the height of the teeth so that they will all cut alike. It is very important, because it determines the behavior of the saw in the cut. The illustrated method of jointing is applicable to your circular saw blades and dado sets. With the saw mounted on the mandrel, slowly turn the saw backward by hand, holding an emery stone or flat file lightly

against the tips of the teeth. Continue turning until all teeth have touched the stone or file. Do not take off more metal than necessary. With Dado Sets, assemble all separate cutters on the arbor and use the coarse side of the stone, following the same backward-turning procedure. See page 17 for additional information on Dado Sets.

Don't let sawdust accumulate, it is a fire hazard.

8

9

SHAPING—After jointing, put saw in wood clamp as illustrated and file the teeth as near to the original shape as possible. Do not use a metal work vise in refitting because it is likely to ruin the blade tension, mar the finish, or bend the teeth. Make all teeth the same shape with gullets the same width and depth. There are two general types of teeth—chisel point for ripping and needle or spear point for cutoff or cross-cut saws. The master combination blade com-

bines the features of both. See SHARPENING for recommended files to use.

HOW TO SET YOUR CRAFTSMAN CIRCULAR SAW BLADES

SETTING—After shaping the teeth, they should be set by bending the tips alternately, right and left, to provide clearance for the blade when cutting. Generally speaking, a medium set is best for most work in most woods. A wide set is more useful for cutting green and gummy woods or fruit woods such as apple or cherry, and for fast, rough cuts, usually on construction lumber. A narrow set is best on dense, hard woods where fine finish is more important than speed. Cutting in hard, dense, wood will dull the blade more quickly than cutting softer woods.

Setting should be done before sharpening. The normal set for various blade types is illustrated below.

Craftsman blades last longer with proper care.

Where the blade is to be used almost entirely on soft woods, the amount of set can be slightly greater; that is, the teeth should be bent out more. If used mostly on seasoned hardwood, use less set than normal. Blades used on electric hand saws should be set slightly more than blades for saw tables. Only the tips of the teeth are bent and should never involve more than 1/3 of the tooth. Bend every other tooth tip in the same direction so that adjacent teeth are set in opposite directions.

When setting a master combination blade, do not set raker teeth. No set is required on the hollow-ground master combination blade since hollow-grinding provides proper clearance. When setting the teeth on nail-cutting blades, and 8" Dado Sets, reset as nearly as possible to the original set. This should be done carefully, since this blade is very hard.

The normal set, shown on page 10, for the chisel-tooth combination and the utility combination blades is for electric hand saw use. If these blades are to be used on saw tables, the set should be less (approximately that shown for Rip-Saws).

Blades are carefully set at the factory for average use. All are set for saw table use on average woods except the nail-cutter, chisel-tooth combination, and utility combination blades which are set for electric hand saws.

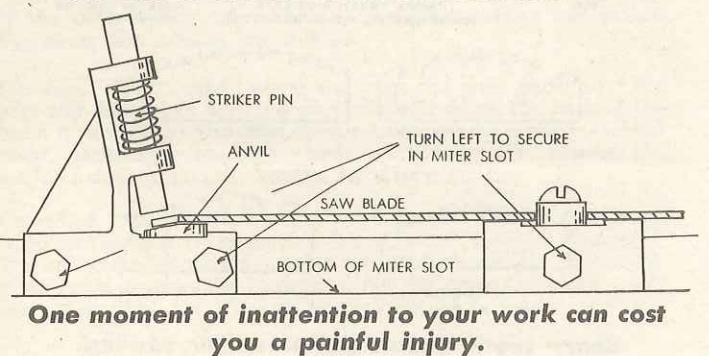

SIDE VIEW OF SAW SET POSITIONED IN MITER SLOT

11

We recommend the use of the new Craftsman circular saw blade setter No. 9-3530 for all flat ground saws and Craftsman 8" dadoes. The setter is so designed as to set teeth from 4" to 12" in diameter and with ½", 5%", 34", or 1" arbor. The setter will fit the miter slot on bench saws with 34" to 1" miter slot. The only other tool required is a hammer.

With 6" Dado Sets, the setting procedure differs in that you are bending groups of teeth. The procedure is known as blocking . It can be done with a Craftsman Saw Setter, Cat. No. 9-3530, setting each tooth separately, but caution must be exercised to achieve the same set within each bank of teeth and the same set for all banks.

Sharpening—Place saw in wood clamp as for shaping. Use a good, fine-cutting file of the proper size and shape. (Craftsman files, available in retail or mail order stores, are recommended). File carefully, and never remove more metal than is necessary because this will reduce tooth height and may result in an out-of-round blade. Follow these recommended filing procedures for different type blades:

Master Combination and Hollow-Ground Combination. Normally filed with a slight bevel on the front of the cutting tooth and a larger bevel on the back, resulting in a "spear point" type tooth. The softer the wood, the more pointed the tooth can be. Raker teeth are filed straight across, keeping the rakers 1/64" to 1/32" lower than the cutting teeth. Normal filing is shown in the accompanying illustration. The chip space or gullet depth is increased, when necessary, by using a round file, catalog No. 9-6760, of the proper diameter to fit the radius of the gullet. File cutting teeth with a slim taper file, catalog No. 9-6743. On

raker teeth, use a flat mill file, catalog No. 9-6758, and grind one edge to prevent damage to the leading cutting tooth.

Chisel-Tooth Combination. Normally filed with a straight-filed front and bevel-filed back, as shown in the accompanying illustration. With very hard woods, the bevel should be less than normal; on very soft woods, or where cutting is mainly cross-grain, the bevel can be increased beyond normal. Use Sears file, catalog No. 9-6756.

Utility (Combination Rip and Cross-Cut). Normally filed with a straight-filed front and bevel-filed back, as illustrated. Bevel can be reduced slightly for very hard woods; increased for very soft woods or cutting cross-grain. A slight bevel added to the front of the tooth is also helpful when cross-grain cutting soft woods. Use Sears file, catalog No. 9-6756.

Rip-Saw. Filed straight across the front and back, as shown. For very soft and tough fibre woods, a slight bevel on the back of the tooth is advantageous. The rip-saw tooth should cut like a chisel point, particularly on hard woods. Use Sears file, catalog No. 9-6756 for teeth, and catalog No. 9-6760 for gullets.

Cross-Cut. Filed with a slight bevel on the front and a larger bevel on the back. This gives a "spear point" tooth, as illustrated. The softer the wood, the sharper the point should be. File every other tooth, reverse the blade, and file the remaining teeth. Use Sears slim taper file, catalog No. 9-6743.

Low blade is safest.

Wood and Nail-Cutter. Sharpening of the nail-cutting blade must be done carefully, as the bevel angles are very important. Templates, as illustrated, can be used as guides to achieve the correct back angle and back bevel. The front of the tooth should not be beveled. The back bevel should be slightly more than one-half the thickness of the blade. Use Sears mill file, catalog No. 9-6764.

WOOD AND NAIL CUTTER TEMPLATES

THIN BLADES

Ply-Tooth BLADE

This blade is normally filed with a straight file, front and back. File every other tooth, reverse the blade and file the remaining teeth. Use Sears Slim Taper File, catalog No. 9-6743. Very important to keep this blade round and sharp for best results.

The best work requires sharp blades.

This blade is normally filed with a straight file, front and back. File every other tooth, reverse the blade and file the remaining teeth. Use Sears Slim Taper File—catalog No. 9-6743. Very important to keep this blade round and sharp for best results. When cleaning or shaping gullet of the Cabinet Combination, use round file catalog No. 9-6760 of proper diameter to fit radius of gullet.

Gine Tooth BLADE

This blade is normally filed with a straight file, front and back. File every other tooth, reverse the blade and file the remaining teeth. Use Sears Slim Taper File—catalog No. 9-6743. Very important to keep this blade round and sharp for best results.

Dado Heads. A dado head may be jointed and filed by using practically the same method as for a saw blade. Carefully file the outside cutters. Be sure to maintain the original shape of the teeth. When filing is complete, give each raker tooth an additional stroke with a flat file. Assemble all inside cutters on saw arbor and joint them with dado running backward. Then, remove and file top of each tooth straight across, just back of the cutting edge, to remove rounded portion caused by jointing.

Gumming — Gumming is deepening the gullets between ripping teeth, as illustrated. After the first two or three filings of a ripping blade, gullets should be filed with a round file of suitable diameter, catalog No. 9-6760. Make strokes straight across. Two or three strokes per gullet should be sufficient. Cutting teeth of master combination and crosscut blades are more or less gummed automatically by each filing.

The use of a push stick will avoid many accidents.

THINGS TO LOOK FOR and LOOK OUT FOR

Saw Blades—Most saw blade troubles come from using blades set for ordinary operating conditions under conditions that are not ordinary. Four principal troubles most often encountered are: Burning. Symptoms: Blue tips on blade. Burned gum sticking on blade. Blue rim on blade in severe cases. Will show burn marks on wood. If the blade is sharp, clean, and with enough set for the job done, but still shows traces of burning, the saw speed is probably too high. If just a few teeth are burned, the saw probably needs jointing. Inspection will usually show high teeth, or that the blade is out-of-round. If the blade is burned uniformly toward the center, insufficient set is likely the cause. Dullness will give a similar result, though the burn will show more severely toward the tips. Binding will also cause burning.

If there is evidence of extensive gum on a burned blade, unseasoned or fruit woods are probably to blame and a wider set is needed. If the gum extends near the tooth tips and the burning is severe at the same point, then the blade needs filing as well as setting. Hollow-ground blades, if used on unseasoned, kiln-dried fruit woods or very resinous woods, should be kept free of gum and very sharp at all times to prevent burning. We suggest the use of Sears No. 9-4918 Gum and Pitch Remover to keep blades clean.

Binding. Symptoms: Sometimes slight blue tinge on blade. Usually very bright and polished sides to depth of cut. Rusty, showing evidence of polishing on the rust to depth of cut. Binding is often caused by dull teeth not cutting wood fibres clean on cross-cuts, thus allowing the wood to "close up" on the blade. Insufficient set, even though the blade is sharp, will also cause binding. This 'is particularly true when the saw is under-powered and slows down in the cut. Inaccurate alignment of the rip fence with the blade is another frequent cause of binding and is indicated if the blade is rubbed on one side only.

Rough Cutting. Symptons: Fold over of grain of wood on crosscut or tearing out of fibers. Wavy kerf, or clearly defined tooth marks on wood. Poor setting is the main cause of rough cutting saws. Uneven set in rip cuts; uneven set and dull blades in cross-

Every job deserves fine workmanship.

cuts. If a saw blade is placed on a flat saw table and rocks when pressure is applied at points around the blade edge, it is unevenly set. Rough cutting can also be caused by too much set, but the cut will usually be more even in appearance.

Chattering. Symptoms: Very uneven or wavy kerf. Characteristic hum or sing while in cut, and much wider kerf than thickness over set. The blade may need jointing, or it may have too sharp an angle on the point of the teeth. On a 36-tooth rip blade, the back-off angle should be about 15 degrees. If more than this, chattering is likely to occur. Too much set will accentuate this condition and continued use of the blade will eventually cause cracks to appear at the base of the teeth.

Dado Sets—Difficulties with Dado Set operation usually fall in one or another of the following categories:

Burning. Symptoms are the same as for circular saw blades and the causes are similar. When the outside cutters are uniformly burned around the edges and the sides of the groove in the wood show traces of burning, the outside cutters probably do not have sufficient block or set. Dull teeth also cause burning.

Rough Bottom Grooves. An undersized arbor, or turning shaft, that allows the Dado Set parts to get off-center and uneven, will cause this condition. If the parts fit snugly and a rough bottom groove is still noticed, the set is probably out-of-round.

Rough Sides of Grooves. Usually caused by uneven blocking of outside cutters or because the rip fence is out of parallel with the Dado Set.

Out-of-Square Grooves. Undersized arbor or rip fence out of parallel with Dado Set.

Inaccurate Groove Widths. The use of paper washers in adjusting the width of the groove will enable you to correctly cut grooves to the exact width desired. Use of washers is essential.

Glue Pockets. This refers to a Dado cut that is slightly deeper on the outside edges than in the center of the groove. It is an advantage because it makes for square, flat fits and allows space for the glue to flow as the parts are forced together.

Always support work when end cutting.

THINGS TO DO and NOT TO DO

DO:

Keep mandrel and collar clean to insure a true running saw. Keep the saw sharp, round, and free of gum for better work and longer blade life.

Examine each blade carefully before attempting to file it, if you sharpen your own blades. If a blade is to be filed for the first time, all that may be required is a touching up of the points. Set the teeth only when necessary—not every time the saw is filed. Use only the best tools in refitting your CRAFTSMAN blades. Clean and oil blades after using them to prevent rust that can cause binding or burning.

DON'T:

Wear floppy sleeves and loose ties when using power equipment; the whirling blades can pull the operator into contact with their cutting edges.

Twist the workpiece out of line when feeding the saw by hand. Let the fence and the blade get out of alignment when sawing. These precautions will help avoid "kickbacks" which can fling work from the saw with considerable force.

Use your hand to push work through unless the room between the blade and the rip fence is equal to the maximum width of your hand.

Advance unwieldy work into the saw without providing a good support to keep it from being upset or kicked back.

Leave a long board unsupported so that its resilience causes it to shift on the table when being sawed.

Reach up to the saw blade to grab a piece of wood until the blade has stopped.

Let the floor become littered so that your feet might turn or slip. Let sawdust accumulate; it is a fire hazard, especially after being damp.

Run blades at excessive speeds or let them become dull or clogged.

Good work requires sharp tools.

Loading...

Loading...