The Practical Handyman's Encyclopedia, Vol. 1. Greystone Press, 1965, 1968, 1971.

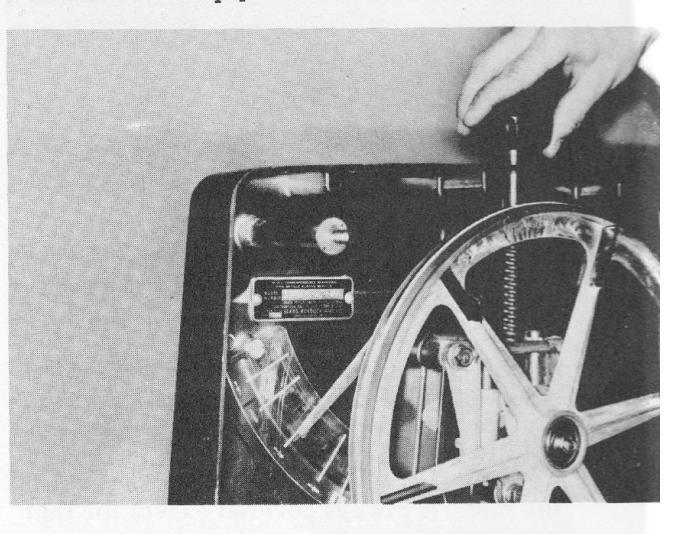

Pictured is 12-inch Craftsman band saw available at Sears, Roebuck and Co. Motor is ½ hp, 1725 rpm. Attached is vacuum with 3-bushel capacity.

Curved ribs on frame and vanes on the wheels will direct flow of sawdust through exhaust elbow.

THE band saw, one of the oldest of the woodworking machines, is still basically the same as the one on which William Newberry was granted a patent way back in 1808 in England.

Band saws are now made in many sizes varying from the smallest, such as the little bench models with 9-inch wheels, to the giants used in mills with wheels that are 84 inches and more in diameter. The blades on these large models are as much as 16 inches wide and 50 feet long.

The band mill is used for sawing logs into planks and the band re-saw is used to cut thick stock into thinner boards. A third kind is the band-scroll saw, used for sawing curved or straight work, a combination of both, and on occasion for re-sawing. This third kind is the one illustrated and described in this article. The machine is so named because the cutting blade is actually a narrow, flexible, endless band of steel with teeth on one edge. This blade runs over revolving pulleys or wheels which have rubber tires stretched over their rims.

The size of a conventional band saw is indicated by the diameter of each of its two wheels. For instance, an 18-inch band saw has 18-inch diameter wheels and will cut 18 inches, less the width of the blade guard. In some instances, the size is given as the actual throat opening rather than the wheel size.

Several models of band saws have three, rather than two wheels. This makes possible a much larger throat opening in a smaller, more compact, less expensive machine. A band saw, because it is so well guarded, is one of the safest woodworking

Knob at top tightens or relieves the blade tension, which is shown by pointer on the tension scale.

Knob at side adjusts spring tension against the hexagon blade support bar, holds bar where set.

Unlock set screw, turn the knob shown, and blade guides move in or out to set blade for good cut.

Pick up circular table insert, release lock screw, position lower ball thrust roller, relock in place.

machines to operate. The doors enclose the blade and wheels. The upper guide assembly contains a blade guard which travels with it when raised or lowered. If used in its correct position, just above the work, the blade is always covered except for that part which does the actual cutting.

Adjustments, while not complicated, must be carefully made in the order given and should never be made while the machine is running. Once made, re-adjustments are seldom necessary while using the same blade. The first of these is to make the blade run in the center of the track by tilting the upper wheel either in or out while turning the machine by hand. Tension is next. On saws that do not have an indicator scale, tension may be judged by pressing on the side of the blade. A flex of about ¼-inch in a 6-inch span is just about correct.

The third step is to adjust the two sets of side guides that are located one above and one below the saw table. The side guide pins should each clear the blade by about the thickness of a thin piece of paper. They should also be positioned 1/16 inch or less back of the gullets of the teeth to avoid any injury to them. The blade should not touch the roller guide wheels, usually located just above and back of the side

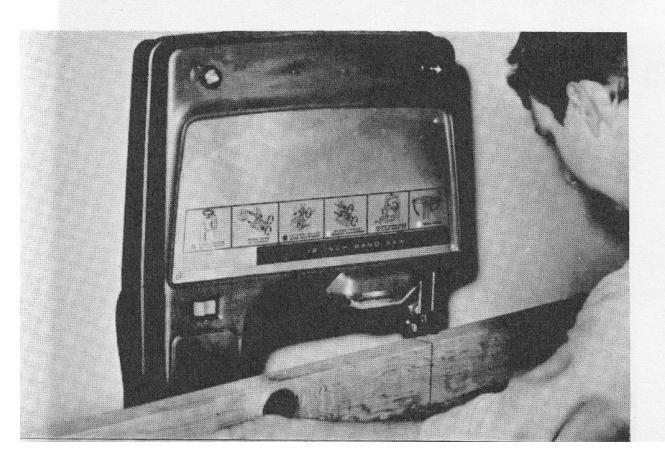

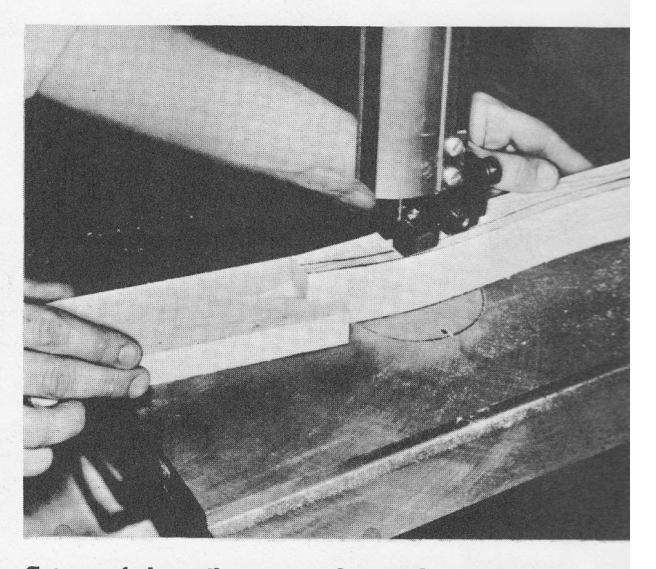

Band saw has normal 6-inch capacity. For a cut of this type, use a rip fence to support heavy stock.

guards, except when material is being sawed. A clearance of about the thickness of a piece of writing paper should be sufficient. If permitted to continually touch, the back of the blade will become hardened which will hasten its breakage.

The final check on the saw travel is to run the machine by hand. If all seems correct, and provided the doors are closed, a short trial run should be made under power. The table on most saws may be tilted up to an angle of 45 degrees and returned to a right angle to the blade when it is lowered to an adjustable stop screw. It is advisable to check the accuracy of the setting with a square. At least one band saw has a blade which may be tilted 7 degrees forward and 46 degrees backward while the table remains flat. This angle may even be varied while the saw is in motion to make cuts that are impossible on a conventional saw.

Blades for cutting wood on a small band saw include widths from ½ to ¾ inch, and from 3 to 7 teeth per inch. If the selection is limited, a ¼ and ‰-inch size will prove to be satisfactory for most jobs. Tooth styles are the standard and the buttress (skip tooth). The standard is used for regular woodworking operations and

To cross cut 2x6 planks, stand work on edge, then cut across any length. Later, trim angle to size.

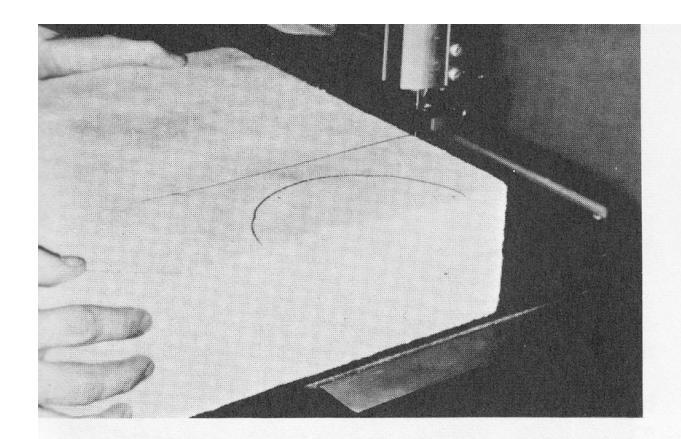

Foam plastics in various thicknesses are easily cut. Vary blades and speeds to test new materials.

skip tooth for cutting aluminum or brass, plastic, or any other soft material which may plug up the teeth.

A broken blade may be successfully hard soldered or brazed at home but most people prefer to send these jobs out. Even though new blades are inexpensive and dull ones can be sharpened at little cost, some people like to do the job at home. A simple rig may be made with discs to hold the blade in position as one section at a time is clamped in a small vise for either setting or filing. Teeth are set to alternate sides and are filed straight across as on a ripsaw, using a blunt triangular file with rounded edges.

Blades should be coiled for storage. To do this, hold the blade in a vertical position and with the teeth pointed away, stand on the bottom of the loop. Twisting the blade inwards, you will cause the upper section to bend down toward the lower. Next, place this upper loop inside the lower, move the hands until they cross each other, and three loops will be formed on the floor.

On larger blades where five loops may be desired, one of the three loops formed should be pulled out from the others and twisted as before.

Band saw work is very simple, yet proper technique will result in a saving of time

When cutting paper tubing, be sure to hold the

tube securely in a V-block guided by miter gauge.

Vinyl, rubber, cork, asphalt and other floor tiles are readily shaped to fit door jambs, bad corners.

and material. First, a blade should be selected that is the widest that will do the job. It may help to know that a 3/4-inch blade will cut a 134-inch radius and a 1/4-inch blade will cut one 3/4-inch, but also that it is not wise to run quite this small. The complete cut should be thought out in advance to eliminate the necessity of backing out of long stock. Also, a little advance thinking will prevent sawing a piece in the direction that will cause it to run into the column. Similar planning will show the necessity for making the shortest cuts first. Many cuts that do not involve curves may be made by using a miter gauge or a rip fence. Boards may be ripped with their edges square or they may be beveled or chamfered by tilting the blade or table. They may also be re-sawed after first being sawed from both sides on the circular saw.

Many wood joints can be entirely cut on the band saw even though this operation probably can be done more accurately on the circular saw. These joints include endlap, middle-lap, cross-lap, and slip joints. Parts of others such as tenons and tails of dovetail joints are also possible. When only one curved piece is to be sawed, the outline may be drawn directly on the wood. If this same outline will be duplicated many times,

To cut corrugated paper sheets, form rolls up to 6 inches in diameter and saw to length as shown.

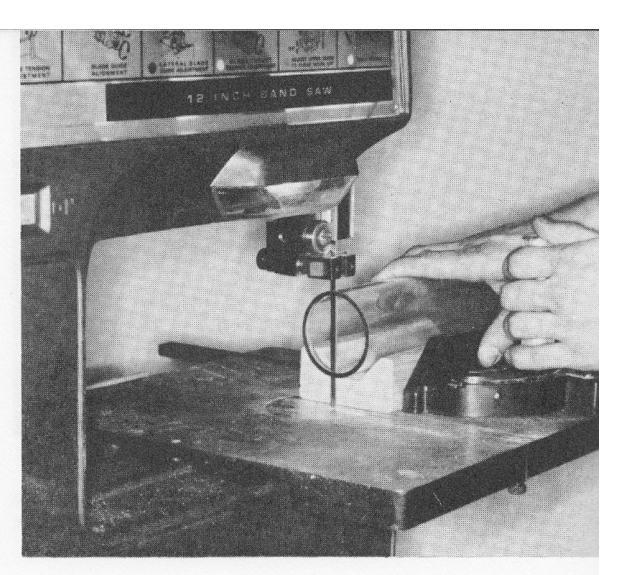

Since metal cutting requires slower peripheral speeds, mount a slow speed converter on saw.

Most ordinary plastics can be cut with ease sheets, extrusions, moldings, tubing, rounds, etc.

Free form decorative shapes are simple to render on a band saw. Cabriolet furniture legs are easy.

To make a salad fork, use 1½x3x10-inch piece of dressed maple. Draw an outline of the design.

First cut inside fingers. Then proceed with outside cuts, making each cut in a single clean pass. Place the three pieces back together with masking tape to form original rectangular shape of stock.

a pattern or template should be made of cardboard, hardboard or metal. When two or more pieces are to be sawed to the same shape, work will be more accurate and time will be saved if they are nailed together and sawed as one unit. The nails should, if possible, be in the waste and so located that they will not interfere with the sawing.

Many jigs may be constructed. Some of these make the work easier and some are necessary to perform certain operations. V blocks in various positions may be used to split round stock, to cut triangular pieces, to cut the corners off a square block that is to be turned, or for making diagonal cuts in the end to receive the live center of work to be turned in the lathe.

Circular discs of any predetermined size may be cut accurately by means of a simple ig made of a board clamped to the table The pivot point is made with a brad driven through the bottom of the board, located at right angles to the blade and at a distance equal to the radius of the circle. If the disc radius is larger than the table, an extension may be made with boards clamped to the table and built up even with its surface. Other jigs include those for doing multiple sawing by using a pattern, for cutting circular arcs or segments, for cutting either parallel or beveled curves and for trimming the ends of glued-up stock, and for cutting tapers or wedges.

The band saw can be used for cutting metal by changing the blade to one suitable for this work. These blades look like and cut like hack saw blades. The same rules apply in their selection. The teeth should not be too fine on heavy work or they will clog, nor should they be too coarse on thin work or they will strip. A good rule to follow is to use a coarse blade whenever possible but always to make certain that at least two teeth are in contact with the stock at all times.

Three styles of sets obtainable are: "every tooth set," which is similar to that on saws used for wood; "regular," has one unset tooth for each pair that is set; and "wavy," where groups of teeth are formed in waves, first to the right and then to the left. If the number of saw blades must be limited, a group of three regular set, one with 14, one with 18 and one with 24 teeth will do most metal cutting jobs in a home shop. Metals are sawed at a slower speed than wood. If the saw is not equipped with a speed control, you can get around this with a set of pulleys used like back gears, or by the use of separate countershaft, or by a drive from the spindle of a metal cutting lathe.

Now that you have a flat side to support project, proceed with profile cuts. Cuts are 5/16" thick.

Cut one fork, scribe next outline and repeat the process. As piece narrows, use wood push block.

Replace saw blade with band sander and bring each fork to smooth finish. Make matching spoons.

Loading...

Loading...