Sears | Craftsman 9-3532 Craftsman Saw Sharpener (Quick-Way Model PG-12) Instruction Guides

HOW TO SHARPEN CIRCULAR SAWS

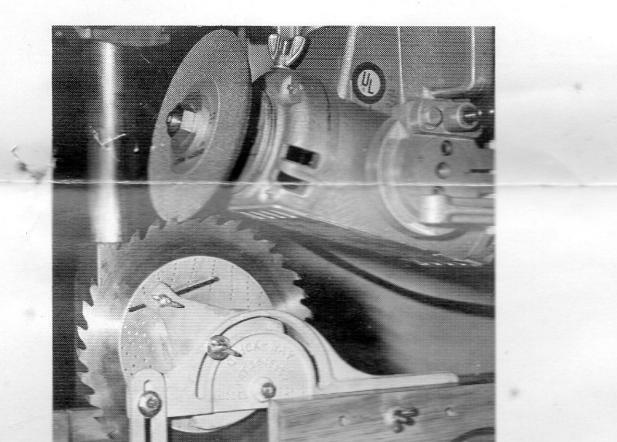

Now, it is possible to sharpen most circular saw blades—easily and expertly. The patented CRAFTSMAN Circular Saw Sharpener fits on your own power saw table or radial saw. The CRAFTSMAN sharpener has a fixture to hold the saw blades, two index dials (discs with several rows of precision-drilled holes which fix the position of the saw for exact sharpening), and a special abrasive grinding wheel which attaches to your power table. Full instructions for use are given inside this folder.

PROFESSIONAL SHARPENING GUARANTEED

Ideal for Home Craftsmen—Carpenters—School Shops—Industrial Woodworking. Model PG-12 CRAFTSMAN Circular Saw Sharpener Incorporates features found in no other sharpener at 5 times its cost. • Adjustable for most types of circular saws

- Fast—easy—gives precision results

- Uses your own power saw table—no hand filing

- Rugged all-aluminum castina

- Non-rusting cadmium-plated nuts, bolts, and dials

- 1/2", 5%", 3/4" and 1" round bushings furnished. Special bushings for diamond or square arbor available.

Two Dials Furnished One for Miter and Mas

Now sharpen these saw blades:

Cross Cut Standard Combination

Master Combination

Sturdy Mounting Block Fits Any Size Bench Saw, Table or Radial Saw

Safety Guide Leg Prevents Tilting

THE CRAFTSMAN TO Sharpen CIRCULAR SAWS SEARS ROEBUCK AND COMPANY CHICAGO, ILLINOIS

GENERAL INSTRUCTIONS FOR ASSEMBLY AND USE OF MODEL PG-12 CRAFTSMAN SAW SHARPENER

This unique unit has been engineered for safety and accuracy. It requires no special skill or equipment, however, a few simple rules MUST be followed to give you the fullest advantage of the CRAFTSMAN Sharpener's precision results and utmost protection. Observance of these rules will guarantee that your CRAFTSMAN Sharpener will give lasting service, save you time and money, and increase your sense of accomplishment. After all, a craftsman's ability is only

The CRAFTSMAN Sharpener comes to you partially assembled. To complete the assembling, follow the procedure given below under "CRAFTSMAN MOUNTING,"

CRAFTSMAN MOUNTING AND SHARPENING

- 1 Remove saw blade from power table and replace with grinding wheel furnished with the CRAFTSMAN unit. Top of bevel should be at left.

- 2 Drill holes in block () (figure 2) to correspond with those in miter gaug If the miter gaug does not have holes, they may be drilled through the gauge and block () and fastened with flat headedbolts and nuts or clamped. Position the holes so that the CRAFTSMAN unit may be moved

- either to the right or left. 3 After block ① is firmly affixed to the miter gauge, place the CRAFTSMAN unit on the block ① as shown in Figure 2. Bolt and wing nut ③ may be inserted in any of the 3 holes depending on distance

- Remove index plate which is on the CRAFTSMAN unit for shipment by removing wing nut Q, lock washer C and washer C. 5 - Take blade to be sharpened and if it is a blade with evenly spaced teeth

-

such as the standard combination, rip or cross cut variety, mount the blade on index dial (1) (the dial with 8 rows of holes) by putting the blade on the index dials threaded spindle. The direction of the points of the teeth on the blade may be determined by placing the blade on the After the blade is correctly placed on the index dial spindle, secure it in place with nut

O

. If the blade to be sharpened has an arbor hole , insert correct bushing provided prior to securing the blade on the spindle. Nut D should be tight enough so that blade will

- If the blade to be sharpened has a diamond or square arbor hole that correspond to the ½", %" or ¾" round arbor holes, the bushings provided may still be used since they will touch on four points of the arbor hole and keep the blade in proper position.

- For blades of the master combination variety, i.e. those with grou small teeth with a large raker tooth in each group, use index plate 🕲 . (The dial with 5 rows of holes.) Refer to charts (1) or (2) to determine which row of holes to use in sharp-mine the ROM NUMBER IS DETERMINED BY COUNTING FOOM THE

(Figure 2)

Since most blades have more teeth than there are holes in the index loosen wing nut leaving the index arm inserted in the starting point hole and slowly rotate the index dial and blade unti! the next unground tooth is adjusted to the grinding wheel. Tighten wing nut () and proceed with grinding operation. If necessary, the same adjustment and procedure is used on the other unground teeth. At the time of this operation and adjustment, no other adjustment should be required other than loosening wing nut

CRAFTSMAN MOUNTING AND SHARPENING

- 1 Remove saw blade from power table and replace with arinding wheel furnished with the CRAFTSMAN unit. Top of bevel should be at left

- 2 Drill holes in block () (figure 2) to correspond with those in miter gauge If the miter gauge does not have holes, they may be drilled through the gauge and block (1) and fastened with flat headedbolts and nuts or clamped. Position the holes so that the CRAFTSMAN unit may be moved either to the right or left

- 3 After block () is firmly affixed to the miter gauge, place the CRAFTSMAN ter block () is tirmly attixed to the miter gauge, place the CRAFISMAN unit on the block () as shown in Figure 2. Bolt and wing nut () may be inserted in any of the 3 holes depending on distance unit needs to be moved to left.

- 4 Remove index plate which is on the CRAFTSMAN unit for shipment by removing wing nut () , lock washer () and washer ()

-

5 Take blade to be sharpened and if it is a blade with evenly spaced teeth such as the standard combination, rip or cross cut variety, mount the blade on index dial (1) (the dial with 8 rows of holes) by putting the blade on the index dials threaded spindle. The direction of the points of the teeth on the blade may be determined by placing the blade on the dial and holding it over the grinding wheel prior to securing it in place. After the blade is correctly placed on the index dial spindle, secure it

-

in place with nut

D

. If the blade to be sharpened has an arbor hole other than 1/2", insert correct bushing provided prior to securing the blade on the spindle. Nut D should be tight enough so that blade will not rotate on the index dial.

- If the blade to be sharpened has a diamond or square arbor hole that correspond to the 1/2", 5%" or 3/4" round arbor holes, the bushings provided may still be used since they will touch on four points of the arbor hole and keep the blade in proper position.

- For blades of the master combination variety, i.e. those with groups of small teeth with a large raker tooth in each group, use index plate 🕑 .

-

in place with nut

D

. If the blade to be sharpened has an arbor hole other than 1/2", insert correct bushing provided prior to securing the blade on the spindle. Nut D should be tight enough so that blade will not rotate on the index dial.

- (The dial with 5 rows of holes.) 6 Refer to charts (1) or (2) to determine which row of holes to use in sharpening. THE ROW NUMBER IS DETERMINED BY COUNTING FROM THE ARBOR HOLE TO THE OUTSIDE CIRCUMFERENCE. The letter S is engraved on each dial and this should be the starting

row when sharpening.

It is suggested that the number of teeth be marked on the blade for future sharpenings.

- 7 After the blade is securely affixed to proper index plate, place on post and secure this unit with washer (), lock washer () and wing nut (). Wing nut () should be tightened enough so that the blade and index dial may be rotated but not so loose that it will rotate without effort. and may be rotated but not so loose that it will rotate without enorm. 8 — Loosen wing nut ① and insert index arm ① into predetermined row of

- osen wing nut U and insert index arm U into predetermined row of holes for the blade to be sharpened. The index arm may be inserted in starting hole either to right or left of wing nut U , whichever is easier after adjustments are made and which leaves the greatest distance between wing nut and starting hole. 9 — Safety guide rest () is provided to make the unit steady on the saw table,

- if any adjustment on this item is needed it may be done at this time, but ordinarily if the CRAFTSMAN unit is affixed to block f and tightened, the safety rest should adjust itself to the table and all that is needed is to tighten the bolt which holds the rest to the CRAFTSMAN unit.

- 0 Adjust the first tooth to be ground to the grinding wheel by loosening wing alust the first footh to be ground to the grinding whee by loosting whey nut () and wing nut (), and turning index plate with blade affixed so that the tooth to be sharpened will contact the grinding wheel in the desired position, normally as near the original sharpening as possible. The grinding wheel may be raised or lowered so that proper contact is made. If the saw has a tilting arbor, this feature may also be used to gain adjustments.

- gain adjustments. 11 After the desired adjustments of the tooth to grinding wheel is obtained, tighten wing nut ① and wing nut ③ . Since the index arm has been in the pre-determined starting hole on the index dial, tighten wing nut so that arm is securely held.

Make certain that index arm is at right angles to the index plate and not slanting either up or down.

- 12 Prior to the start of the actual sharpening, adjust the height of the grinding wheel so that it barely touches the first tooth. REMEMBER THERE IS A POSSIBILITY THAT THE TIP OF THE TEETH WILL BURN IF TOO MUCH IS GROUND AT ONE TIME. IT IS BEST TO GO OVER A BLADE TWICE THAN TO GRIND TOO MUCH AT ONE TIME.

- 13 With the CRAFTSMAN unit attached, the proper adjustment of the first tooth to be ground to the grinding wheel made, the index arm inserted in the to be ground to the grinning wheel made, the index arm inserted in the starting hole and firmly secured by wing nut () , the blade is ready to be sharpened. Prior to turning on the power, push entire unit over the arinding wheel to make certain adjustments are correct and that the first tooth contacts the grinding wheel properly.

- 14 Since all set-up adjustments are done with unit in front of grinding wheel, turn power on and push entire unit over the grinding wheel and the first tooth will be sharpened. Pull the unit back to starting point, raise the index arm from the first hole and rotate index plate and blade to the right until the arm drops into the next hole in the same row. Push entire unit over grinding wheel and return to starting point and second tooth will have been sharpened. Repeat this operation until starting point is reached.

Since most blades have more teeth than there are holes in the index dial, it will sharpen every second, third or possibly fourth tooth. After you have rotated and around the teeth once around the index dial. you have rotated and ground the teem once around the maex ald, loosen wing nut leaving the index arm inserted in the starting point hole and slowly rotate the index dial and blade until the next unaround tooth is adjusted to the grinding wheel. Tighten wing nut () and proceed with grinding operation. If necessary, the same adjustment and procedure is used on the other unground teeth. At the time of this operation and adjustment, no other adjustment should be required other than loosening wing nut

ADAPTING THE CRAFTSMAN SAW SHARPENER TO RADIAL SAWS

- Construct a jig from wood using I" stock and making two pieces approxi First: mately 3" x 8". Screw these two pieces together at right angles the long matery 3" x 8". Screw these two pieces together at right angles the long way. The purpose of this jig is to take the place of the miter gauge on a table saw and to have the upright piece of the wooden jig accommodate the aluminum casting which holds the index plate, blade, etc., when a table saw and to have the upright piece of the wooden lig accommodate the aluminum casting which holds the index plate, blade, etc., when sharpening. The wood jig also replaces the masonite block furnished with the device. Holes are drilled in the upright piece of the wooden jig to compare with the ones drilled in the masonite block furnished.

- Second After the jig is constructed and the aluminum casting affixed in the some manner as it is on the miter gauge of a table saw, the assembly is then either clamped or screwed on the radial saw table in line with the motor either clamped or screwed on the radial saw table in line with the motor arbor. The grinding wheel is installed on the motor arbor instead of the saw blade. It is suggested that a blade be put in the CRAFTSMAN Sharp-ener during this operation so that the sharpener may be aligned with the arinding wheel which should pass over the blade at a 90 degree angle. If there is not enough clearance with the unit directly in front of the motor it there is not enough clearance with the unit directly in front of the motor arbor, place it to the right of the arbor and tilt arbor to obtain proper adjust ment of the grinding wheel to the blade. (see illustration).

- After the CRAFTSMAN Saw Assembly is lined up with the grinding wheel, the wooden jig is then clamped or securely screwed to the radial saw table. Grinding the saw is accomplished by drawing the grinding wheel over the blade and using the same directions as on a table saw. The only over the blace and using the same directions as on a table saw, the c difference is that the grinding is done from above rather than below.

NOTE: There have been instances where there is not enough clearance NOTE: There have been instances where there is not enough clearance between the grinding wheel furnished with the CRAFTSMAN unit and the assembly when affixed to the radial saw table. To overcome this, it is suggested that a smaller diameter grinding wheel be obtained and dressed to a bevel similar to the wheel furnished with the CRAFTSMAN

| PR | ECISION IN | DEX DIAL | CHART | G-1 | |

|---|---|---|---|---|---|

|

Index Row

to Use |

Number of | Saw Teeth | |||

| 8 | 25 🔷 | 50 | 75 | 100 | |

| 7 | 24 | 48 | 72 | 96 | |

| 6 | 22 | 44 | 66 - | 88 | |

| 5 | 20 | 40 | 60 | 80 | |

| 4 | 18 | 36 | 54 🕴 | 72 | |

| 3 | 16 | 32 | 48 | 64 | |

| 2 | 15 | 30 | 45 | 60 | |

| 1 | 14 | 28 | 42 | 56 | |

See over for sharpening Master Combination And Miter saw blades

IMPORTANT

- The first rule with any precision power tool is: READ ALL INSTRUCTIONS THOROUGHLY.

- PROCEED SLOWLY. Your CRAFTSMAN Sharpener will last a lifetime. thoroughly familiar with it first. Do not attempt to hurry assembling it or trying it out. Become

- C. MAKE ALL ADJUSTMENTS WITH POWER OFF.

- PRACTICE THE TECHNIQUE OF SAW SHARPENING by working the saw around with power OFF and grinding wheel barely touching the teeth

- E. GRIND VERY LITTLE AT A TIME. This will prevent chattering and burning Sometimes when a saw is first sharpened with the CRAFTSMAN Sharpener. just as if you were actually sharpening.

- the CRAFTSMAN Sharpener may be needed to give uniform, precision PREVIOUS NONPRECISION FILING. In this case, 2 or 3 grindings by some teeth are ground more than other teeth. THIS IS UUE

- G. As in any indexing device, the various rows of holes in the index dial have a definite relation to the position of the teeth on a saw blade, thus it is essential to start with the correct row of holes on the index dials and

- To tamiliarize one with the device, it is suggested that to learn the theory type with evenly spaced teeth. and operation of the CRAFTSMAN Saw Sharpener, that one begin the sharpening operation on a blade with the minimum of teeth and of the

- For some types of blades such as the chisel tooth variety with rounded gullets, a grinding wheel with a rounded face and approximately

- thick may be used so that a rounded grind will result in the gullet. PROPER SAFETY PRECAUTIONS SHOULD BE USED AS IN ANY GRINDING OF METAL OR PARTICLES FROM THE GRINDING WHEEL OPERATION THERE IS A DANGER AND POSSIBILITY OF FLYING PIECES

- Various angles may be utilized in grinding blades gauge and obtaining the angle by adjusting to the existing angle on the blades teeth. by using your miter

11 — Lift index arm from first hole, rotate index dial with blade to right (clockwise) until arm drops into next hole.

After the basic directions for assembling the CRAFTSMAN Unit to the saw table are accomplished, the following procedure for the Master Combination and Miter

MASTER COMBINATION AND MITER SAWS

ened. Index dial No. 2 (dial with 5 rows of holes) is used for this type

1 — Count the number of groups or sections of teeth in the blade to be sharp-

2 – Refer to Precision Index Dial Chart (1) for proper row of holes to be used. REMEMBER TO COUNT ROWS OF HOLES FROM ARBOR HOLE TO

of blade.

Blades is used:

4 - Place dial and blade on spindle () and secure with washer (), lock-washer () and wing nut (). 5 - Most all teeth of these blades may be sharpened with miter gauge set at

3 – Mount blade on index dial No. 2 and securely fighten nut 0.

OUTSIDE CIRCUMFERENCE.

90 degrees. 6 - Set index arm with wing nut loose in correct row of holes at starting row which is engraved with 7 - Loosen wing nut and and adjust first small tooth or last small tooth in a section to the grinding wheel. If your saw has a tilting arbor, this in a section to the grinding wheel. If your saw has a tilting arbor, this in a section to the grinding wheel. If your saw has a tilting arbor, this in a section to the grinding wheel. If your saw has a tilting arbor, this in a section to the grinding wheel. If your saw has a tilting arbor, this in a section to the grinding wheel. If your saw has a tilting arbor, this in a section to the grinding wheel. If your saw has a tilting arbor, this is a section to the grinding wheel. If your saw has a tilting arbor, this is a section to the grinding wheel. If your saw has a tilting arbor, this is a section to the grinding wheel. If your saw has a tilting arbor, this is a section to the grinding wheel. If your saw has a tilting arbor, this is a section to the grinding wheel. If your saw has a tilting arbor, this is a section to the grinding wheel. If your saw has a tilting arbor, this is a section to the grinding wheel arbor was a tilting arbor.

feature may also be used to adjust the blade to the grinding wheel.

8 – After proper adjustments have been made, tighten wing nuts (0) and (3)

- Push unit over grinding wheel and return to starting point. Repeat operation by lifting index arm, revolving disc and blade until starting row is reached again and all comparative teeth in each section will have 12 -

-

Turn power off, loosen wing nut

1

and adjust next unsharpened tooth to required. After proper adjustment is made, tighten wing nut and proceed with the grinding wheel. This is the only adjustment necessary or been sharpened. 3

- sharpening as explained before.

- 14 Continue the above procedure until all small teeth in each section has been ground.

- 15 The same procedure is followed for the large or raker teeth. These teeth should be ground so that they are approximately 32nd of an inch lower than the small cutting teeth.

|

of Sections

18 16 14 |

101 | |

|---|---|---|

| 0 | nber | |

| CHART | Nun | |

| DIAL | ||

| INDEX | ||

| PRECISION | to use for | |

|

Index row

5 3 3 3 |

- - |

| NO | NDEX | DIAL CH | ART G-2 | ||

|---|---|---|---|---|---|

| row to use f | or | * * | Number 4 | of Sections | |

| 5 | 18 | ||||

| 4 | 9 | ||||

| m c | 12 | ||||

| 4 | 2 |

tain first tooth to be ground is adjusted properly to the grinding wheel. REMEMBER - DO NOT GRIND TOO MUCH AT ONE TIME OR POINT

9 - Check your adjustments by pushing unit over grinding wheel to make cer-

and wing nut O .

grinding wheel and return unit to starting point and first tooth will be

10 — If your adjustments are correct, turn power on and push entire unit over

OF TOOTH MIGHT BURN.

| Suo | |

|---|---|

| - | ecti |

| * 8 9 4 0 0 | |

| 0 | |

| 0 | ber |

| L | E . |

| AH | Z |

| Ċ | |

| AL | |

| DI | |

| × | |

| DE | K. S. |

| ₹ | |

| Z | |

| 0 | 5 |

| CIS |

e

t |

| RE | S |

| Р | $ 6400F |

| 1 | Ň |

| × | |

| de | |

| 1 | 5 |

| Section | ||

|---|---|---|

| · |

of

18 16 12 12 |

2 |

| 2-2 | er | |

| 0 | dr | |

| RT | in the | |

| ¥ | 2 | |

| Ū | ||

| - | and a state of the | |

| A IO | ||

| and the second second | ||

| EX | N 8. 9. 1 | |

| 9 | the second second | |

| 4 | ||

| Z | ||

| 0 | 5 | |

| S | + | |

|

L

L L L L L L L L L L L L L |

156 | |

| PR | 0 | |

| , 0400 | - | |

| · · | Ň | |

| 1 | × *** | |

| 0 | ||

| E . | ||

| 1. 1 |

to make proper adjustments at the time you begin the sharpening

Loading...

Loading...