Here's an easy way to Power Tool Know-How

Sears' Power Tool Handbooks

give you complete, up-to-the-minute instructions for set-up, adjustments and proper handling of each tool — including hundreds of standard operations, short-cuts and special operations. All fully illustrated and described. Ask for these handbooks:

The Circular Saw The Drill Press The Wood Lathe The Jig Saw and Band Saw The Jointer. Shaper and Thickness Planer How to Sharpen Power Tools — How to Use Them

AVAILABLE AT ALL SEARS RETAIL AND MAIL ORDER STORES

OVER A HUNDRED WAYS TO USE THEM..

CRAFTSMAN

HANDBOOK

国。目为目的

A

COMPLETELY ILLUSTRATED

HOW TO JUDGE ANY POWERED HAND TOOL

Why the (often big) difference in cost between one tool and another seemingly like it?

First, there is the motor. Every hand power tool must have its own motor . and herein lies most of the real value of the tool. It costs less to build a weak motor . less to build one that will overheat quickly or burn out in short time . less to design a tool around an existing motor even though this means sacrificing balance, lightness and/or ease of handling. But the top quality tools have motors especially designed for the tool's needs: lightweight, balanced, compact ... with ample power for all jobs, and the ability to "take it" when run continuously. Don't be fooled by meaningless ratings; insist upon knowing the actual horsepower (H P). This is the only power rating that is reliable for all hand tools. A high ampere rating alone may mean only that the motor will overheat rapidly.

such as the types of bearings, kind and toughness of gears and other operating parts. Ball and needle bearings and similar precision-ground, especially-hardened parts cost money . but long outlast inferior substitutes. And the same is true of the third cause for difference, the "convenience features" such as: sure-grip, quick-action drill chucks; sturdy, easy-to-use switches; ample length, safety-plug cords . and all the other features which make one tool so much handier and more usable than another tool which lacks them.

..............

Think of these points before you buy. A lowpriced tool cannot be expected to perform like one that is higher because it is better built. Think also of the Guarantee and the Service Policy that will back-up your purchase. It is seldom a waste of money to have too good a tool; but one not good enough may soon become a total loss!

Next there are the "ruggedness features",

SEARS GUARANTEE

We guarantee all Croftsmon Portable Electric Tools to be free from defects in Material or workmanship and to render satisfactory service when properly used, cared for, and maintained. We will repair or replace at our option and install, for a period of one (1) year from date of sale, any part which proves, upon our examination, to be defective under normal use. This guarantee does not cover burn-outs from low or improper voltage or from the tool being forced or improperly used. Blades, cords, and other parts subject to abuse are not covered by this guarantee.

WHAT CONSTITUTES ABUSE OR OVERLOAD?

• DULLNESS: A dull bit or blade requires much very much - more power (as you well know if you've ever tried to hand saw with a badly dulled blade). Just because the tool is "taking" the additional strain, don't think that it doesn't matter. It does! It shortens motor life, bearing life, etc. . and makes a poor job, to boot.

• TOO BIG A TASK: Every tool has its limit . for instance, an "economy" 1/4-in, drill can't push a 1/2in. bit through steel (even if the bit does happen to have a 1/4-in, shank). Nor can it swing a 10-in, grindstone (even though you have an arbor with which to set it up). If in doubt, listen to your motor. It's easy to hear it "complain" when its overloaded.

etc. of tools are all designed for certain anticipated types of strain to be encountered in normal usage. For instance, a hand drill spindle bearings usually are intended for a pushing thrust, not a side thrust. Trying to force a bit sideways (to elongate a hole) will quickly damage these bearings. Don't make tools do things they are not designed to do!

FORCING: Most power tools depend upon speed rather than force to get a job done (thousands of little "blows" instead of a few big ones). If you add the strength of your arm to the job (like bearing down on one of the power sanders) you simply stall the tool and accomplish nothing. Such forcing overheats the motor; and so does long, continuous operation of a tool intended only for intermittent duty. Don't over-

• WRONG USAGE: The bearings, gears, housings

DULLNESS TOO BIG A TASK COPYRIGHT 1960 -- MIDWEST TECHNICAL PUBLICATIONS

FORCIN

THE REVERSIBLE IMPACT TOOL

A PORTABLE POWERHOUSE

Here is a truly powerful, light-inweight tool that furnishes the kind of brute hitting force needed to do the toughest jobs:

- Frees broken studs or frozen bolts or nuts

- Tightens or removes nuts, bolts, studs

- Installs or removes screws of all kinds

- Safely drives various size taps and dies in any metal

- Drills holes in wood or metal just like a 1/2-in. drill

- Bores through the hardest concrete, etc. easier and faster than any drill will

111000000 0 == =

The 4 amp. motor gives impact power to spare - as much as 150 ft-lbs of torque at 1900 rotary impacts per minute. When a stalling resistance is met, this drive "hammers its way through" with the same wallop packed into a sledge moving faster than the eve could follow. Operates on 25-60 cycle, AC or DC; has long (10-ft.) cord with safety plug and adapter. OFF-ON trigger switch in handle, and a separate reversing switch. Auxiliary handle permits two-hand operation when needed. Available accessories include: 6-pt. impact sockets, sizes 7/16, 1/2, 9/16, 5/8, 11/16, 3/4, 13/16 and 7/8-in., a 6-in. extension for the sockets; a die holder; a stud driver and remover that will grip short or broken stude or bolts 3/8 to 1/2in, in dia : a screwdriver chuck with bits: and 1/2-in, capacity drill chuck.

This tool is especially useful on the farm, in a service station or garage, or for contractors, maintenance men, etc. who do machinery installation and/or repair. Can be operated from practically any farm or portable type generator.

CARRYING CASE

And don't forget that for every power tool, there is a carrying case. Not only will a carrying case provide the most convenient method of transporting your tool from job to job, but it will give the best protection to your investment – keep your tool from being damaged – keep it clean, and provide a place for all accessories and so prevent loss. Each case is sturdily built and designed especially for the tool intended. For a small additional investment, here is a way to prolong the life of your tool and insure satisfactory service.

3

FLECTRIC HAND SAWS

SELECTING A HAND SAW

Used primarily for on-the-job sawing, your electric hand saw will do the job 10 times faster than hand sawing. It may be used for pre-sizing of lumber, or for trimming off the uneven ends of boards and forms already nailed in place (thus eliminating much meas-

blade - which determines its maximum denth of cut. A 6-1/2-in. blade will normally cut a 2x4 at 90°: larger blades make proportionally bigger cuts. But blade size alone does not make a saw useful - it takes power to do the rough work, and precision adjustments to do it right. A good saw develops at least 3/4 hp - and is designed for safe easy cutting of straight (guided) lines and accurate hevels . and will cut to the desired depth.

saw is rated principally by the size of its

----- TYPICAL

There is a Craftsman Electric Hand Saw for every need . from budget priced, homeshop models up to the big, super-powered 7-1/2-in, industrial model. Smallest model develops a full 1 hp; and largest develops 2 hp. All have light, sturdy aluminum frame; durable, heat-treated drive gears; and safety clutches to prevent motor burn-out. Each also has a firm steel baseplate with a graduated scale for quick setting of the sliding rin guide ... and fast accurate knob adjustment of the baseplate for 90° to 45° bevel angle cutting with another knob setting for depth-of-cut. The telescoping guards permit blind cuts but offer complete protection from the whirling blade. Better models have ball and needle bearings throughout. All have convenient in-handle squeeze-ON switches, and will operate on 110-120 V., 25-60 cycle AC or DC Two vopular models are shown.

TIPS ON USING YOUR HAND SAW

For a cleaner, faster cut, keep the saw moving steadily forward, at its optimum cutting sheed - that is, as fast as it can cut without losing too much speed. You can "hear" the ontimum cutting speed with a little practice. Hold your saw with both hands whenever possible and, if using the rip guide, bear just enough to the left to keep the guide firmly against the right (guiding) edge of the work.

When making a cut longer than your arms can reach, either walk with the saw - or stop the breaking the cutoff wheel.

PEPEECTION .....

Does the nameplate show the HP . and is it enough The GUARANTEE . and the Service offered

saw, pull it back in the kerf a few inches. take a new position. then resume.

When using a cutoff wheel (inplace of the saw blade) take extra pains to hold the saw true and steady on the cutting line - to avoid

HAND-SAW OPERATIONS

OPERATION AND CARE

Connect your saw with a 110-120 Va-cor d-c source. Should you use an extension, have it 12 gage or larger, if up to 100 feet: 10 gage or larger if up to 150 feet. Too small an extension will result in too low a voltage - can overheat and burn out your saw motor. Also, use the ground connection provided on your saw plug - especially when working in a damp place. Lubricate vour saw regularly, per instructions packaged with it. Keep the air passages open to assure proper cooling. Clean them with an air jet, if necessary. Above all, keep the blade sharp, clean and properly set . and preferably use Kromedge blades since their superior keenness prevents saw overloading. GENEDAL

Before pressing the switch, rest the front of the base plate on the work - then squeeze the switch and let the blade come up to full speed before starting the cut. Allow the blade to cut its way through the work without forcing. Forcing only results in inaccurate work and overloading of the motor. If the blade slows, back it out and re-start If the motor stalls do not release the switch – back out the blade and let it run free For cutting plywood with a minimum of splintering use a very thin (.030-in, gage) blade: and for sawing used lumber, preferably use a nail-cutting blade. A carbide-tipped blade is the finest for making fast, smooth cross-grain or rin cuts

CROSSCUTTING

The flat inset guide edge of the baseplate is exactly in line with the saw blade when the blade is set at 45° or 90°. Use this edge as a guide - and follow a line drawn on the work, the same as with a hand saw At other angles, the blade will be up to 3/64 inch to the right of the guide edge. The graduated scale makes it easy to make cuts at odd bevel angles. Simply offset your guide line on the work to the left by the distance from the blade edge to any convenient mark on the scale.

RIPPING

Either use the procedure above (following a line) or use the rip guide on your saw. Set the desired cut on the graduated scale of this guide, using the guide edge of the baseplate for an index. The right edge of the work must be true for the rip guide to follow it. Be careful to prevent the blade from binding in the kerf at the end of a cut

POCKET CUTTING

Pocket cuts are easy with your electric hand saw. Swing the guard out of the way and rest the front edge of the baseplate on the work. Start the saw and slowly lower the blade into the stock. After making a cut. clean out the corners with a hand-saw. Be sure to release the switch and let the blade stop before lifting the saw out

FLECTRIC HAND-SAW ACCESSORIES

A RENCH-SAW TABLE TOP

This saw table top converts your electric hand saw into a useful bench saw Solidly built for professional use - as well as serious hobby work - it has a large work surface with two miter gage grooves. The table top comes with a rip fence and a splitter, and will take most of the accessories (miter, gage, saw guard, etc.) that are made for regular bench saws.

STEEL WORKBENCH & CARRYING CASE

Folds suitcase style with saw inside (only 10-1/2 x 16-1/2 x 20) . but opens out to a sturdy 20 x 33-inch work surface on six 30-inch high tubular steel legs. Makes a portable shop of your saw with saw slot and miter gage slot for bench-saw type operations. Miter gage saw guard assembly, rip fence and hold-down are all avail-

MITER GAGE & SAW GUARD ASSEMBLY

Not shown here, these two items are available for use with either the bench-saw table The miter gage sets to miter angles from 90° to 0° in either direction. The saw guard automatically adjusts to the workpiece to keen blade safely covered

PLANER ATTACHMENT

Designed to produce professional type planing work, this precision attachment will enable you to do accurate straight or bevel planing - on the job. Makes cuts up to 1/8-inch deep in a single pass; and the 2-1/2-inch width of cut will handle the edges of most common lumber Stock up to 5 inches wide can be handily planed in only two passes. The fence is removable for surface planing of wider stock. Once installed it can be quickly removed and reinstalled. Operates just as easily as any hand planer - but now vou have power!

A PORTABLE SAW GUIDE

Accurate angular cuts can be made rapidly with this portable saw guide. But the slide bar against an edge of the work, set the guide to your desired line of cutting and lock it - then guide your saw along the straight edge of the guide. The guide can be set for any angle from 0° to 75°, left or right. It is especially useful for making compound miters in conjunction with the bevel adjustment on the saw. It is also useful as a regular protractor on jobs requiring accurate angle measurement

The above bench planer conversion kit will convert your electric hand saw with planer attachment into a professional quality, bench-

PLANER

KIT

CHAIN SAW ATTACHMENT

Converts any but the smallest model into portable chain saw capable of slicing through logs or lumber up to 10inch diameter. Will riv or crosscut, or start its own hole for cutting into walls, floors, etc. An exceptionally fine tool for farm pruning jobs or for on-the-job construction work.

SABRE SAW ATTACHMENT

Converts any Sears saw into a powerful sabre saw. quickly and easily - and at a fraction of the usual cost. Will do all that a regular sabre saw will do (see section

KROMEDGE SAW BLADES FOR ALL USES

blade 5 times: cuts smoother, no overload- ting blades ... for these special jobs.

CRAFTSMAN Kromedge line offers a com- ing! We particularly recommend the carbideplete selection of saw blades for every use. tipped, free-cut sytle for the smoothest. None finer made. The superior wearing fastest cuts you've ever made. Also, the quality of Kromedge outlasts an ordinary nail-cutting and the extra-thin plywood cut-

SANDER-POLISHER-DRILL ... With 2 Speeds

converted into a high-low speed drill. The 1/5 hp motor has a high speed of 2700 rpm ... excellent for smooth, fast sanding or drilling holes up to 1/2in. in wood or up to 1/4-in. in metal. At low speed of 750 rpm you can polish or buff without danger of burning the wax can drill holes up to 1-in in wood or up to 3/8-in. in metal. The auxiliary handle can be mounted at either side or be left off for closequarter work. When sanding or polishing keep the tool in constant motion (without excessive pressure) and lift the disk edge so that only the trailing half of the disk contacts the work. Use long sweeping strokes whenever possible.

Truly the most important improvement in modern sanding materials. New manufacturing process makes it possible to braze tungsten-carbide grits onto thin (sheet) steel backings. The steel backing and the bonding will last until the diamond-hard grits, themselves, are worn down (and these will stay sharp for finishing and rotary sanders shown here. Will do both fast cutting and smoothing.

ORDINARY

Here is a rotary sander-polisher that can - with a key-chuck and adapter separately available - be

PORTABLE ELECTRIC SANDERS

SELECTING A SANDER

jobs in any woodworking project. With the finishing and sanding around edges corners proper sander you can save hours of dif- and the like or on delicate plywoods. Sandficult hand work can "smooth out" minor ers which have limited, more delicate and cutting and fitting errors by sanding finish- precise motions are preferable for such jobs. ed joints to perfection - and can obtain the Then. too. don't judge a sander by the amount high-gloss finishes so often desirable

medium or fine) is the chief factor in deter- by the smoothness of the finished work it mining the type of work (rough or finish will produce. sanding, etc.) that a sander will do the weight, size, power, and type of motion Each type of sander has certain advantages. of the sander, itself, are also quite impor- Every shop should have at least two types: tant. Continuous motion sanders – like the One for rough work and another for fine straight-line belt or rotary disc sanders - finishing work and for sanding between coats usually have a violent action . excellent of paint, varnish, etc.

Sanding and polishing are very important for fast, rough work, but too rapid for fine of dust it kicks up Judge instead by the amount of wood it actually removes ... by Although the grit of sandpaper (coarse, the ease with which you can handle it . and

FINISHING-TYPE SANDERS

WITH RECIPROCATING ACTION

Available in light-duty, medium-duty and heavy (continuous-duty) models, these sanders are actuated by a reciprocating-type motor which delivers 14,400 double-arc strokes per minute to the platen Enough "scrubbing" action to quickly produce a glass-smooth sanded finish: or (with coarser paper) to smooth out the roughness of sawed lumber easily and effectively!

Because each of the three models is relatively lightweight, and will not "walk away from you," it is ideal for vertical and overhead sanding. It requires no pressure: vou simply guide it over the surface and let it do the work. Cannot burn, gouge or mar the finest surface. Fitted with a polishing pad, it is excellent for waxing and polishing of your rarest wood pieces, and for wet or dry finish sanding between coats of paint, lacquer or varnish. Can also be used for metal, glass and plastic finishing for etching designs on these materials - or as a benchmounted (in a vise) stationary sander.

Powerful universal motor drives pad at 3500 orbital strokes per minute for rapid wood or dry-wall sanding paint removal, waxing, eral-purpose tool. Has convenient lock-ON switch in handle and auxiliary knob mounts as shown or at either side. Light weight and verfect balance make it easy to use in any position. "Dustless" Vacuum Pick-Up Acce

CONTINUOUS-BELT SANDERS

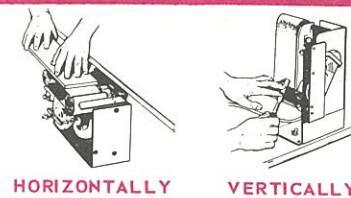

Designed for heavy-duty construction work, this sander is intended primarily for rough or fine sanding of wood ally excellent for finishing hardwood floors solid (not veneered) wood walls, large benches, and the like. With the accessory stand shown it may be converted

into an excellent bench tool . mounted horizontally on bench top or on bench side. or on top in a vertical position. Vacuum accessory also available for dustless sanding.

both hands ... and move it steadily in a straight line with the grain. Don't allow it to droop over an edge: use caution when sanding edges or corners.

TIPS ON SANDING

HORIZONTALLY

Don't ruin scissors or shears cutting sandpaper. Crease and tear it along a sharp edge, as illustrated.

If an edge is narrow, clamp the work between two boards to provide a flat surface to sand against. This will prevent splintering when sanding end grain, and will produce square (instead of rounded) corners.

Always start with the finest grit paper that will do your job. Coarser papers necessarily scratch, requiring the use of finer papers to finish up with a real smooth job.

Sand with the grain, using a "skimming" motion (rather than a "digging" one) to guide the sander

Come up to edges squarely without allowing the tool to overhang. If purposely rounding an edge, support some of the sander weight with your hands to prevent cutting too fast. Better take many light passes than one that is

To remove wood fuzz, dampen, then dry the surface then sand. You may have to repeat this several times

To sand finish paint, varnish, etc. use a waterproof paper and soapy water, made with a mild soap, and as sudsless as possible. Sand without pressure until satiny smooth. Wine dry with a lintless rag apply next coat and repeat

Always use an oben-coated paper to remove old paint. selecting grit coarsness to correspond with the thickness and/or gumminess of the paint.

CLOSED COAT

ELECTRIC SABRE SAW

This lightweight, easy - to - handle saw of many uses easily cuts straight or curved lines and intricate designs in wood. plastic, soft metals, composition board, even thin steel It can be taken right to the work for such jobs as cutting blind holes for electrical outlet boxes, cutting ductwork openings for registers trimming pipes and conduit to length etc. It is especially useful for sawing A POWERED nlywood as the small blade teeth and rapid action serve to produce smooth-cut edges.

The tool operates exactly like a powered jig saw . but has all the advantages of portability to greatly

SABRE-SAW EDGE-CIRCLE GUIDE & THE TABLE TOP

Three models are shown. The smallest is a medium-duty size that is excellent for cutting others are heavy-duty models, the largest being JIG SAW. HACK SAW. the large model has a 1-in. stroke and, with logs, limbs, etc. Both have counter-balanced BAND SAW the cutting line. Both also come with the edge-ALL IN ONE

SMALL

The edge-circle guide fits all three sabre saws and serves as a positive guide for following along an edge or for swinging a circle.

The table top converts any of the three sabre saws into a bench-type iig saw to which work can be fed along a straight line or at various miter angles. And the miter gage can be or swinging circles.

Shown are various types of blades: Size 1 (7 teeth per in.) for soft woods or ripping. Size 2 (10 teeth) for plywood, wallboard, hard woods or crosscutting. Size 3 (32 teeth) for brass, aluminum or steel rods or sheets, and the Knife-Edge blade for rubber, leather. cardboard, etc. There is also a special, hollowground (no tooth set) blade for fine cabinet work with plywood or veneer . cuts very smoothly without splintering. All except the knife edge are available in various lengths for the different saws, and there is a 6-in. Size 1 for large saws only. One size knife blade fits all three saws.

TYPICAL OPERATIONS

CUTTING LONG, STRAIGHT

ROTARY

RIPPING AND CROSSCUTTING WOOD

For these operations, have the saw blade teeth facing forward (away from motor end) and pointing upward (the cutting action should be on the up stroke). The saw then cuts forward - making it easy for you to closely follow the most intricate guide line (by observing the line through the opening between the feet at the front of the baseplate).

Place the front feet on the edge of your workpiece. aligning the saw blade with your guide line. Start the saw, and advance it along the guide line at a steady pace, not fast enough to slow the motor appreciably but fast enough to keep the blade always cutting new wood (not just moving up and down in a place already cut). Hold the baseplate firmly down on the work. Ston the saw before removing it.

If you have a long straight line to cut, use a straightedge guide (clamped or nailed to the work) to guide one edge of the baseplate.

Inside cuts can be started at a bored hole: or can be started with your saw. Rock the saw forward so that it rests, on the work, on its front feet - with the blade end just above your guide line. Start the saw and slowly rock it back to let the blade cut its way down through the work - until the baseplate is flat on the surface. Then finish the cut in the usual manner

METAL CUTTING

Sheet metal cutting is much the same as above except that inside cuts should be started at a hole. For sawing off tubing, conduit and similar narrow objects, reverse the blade (teeth facing backward but still pointing up) - so that you can rest the center of the baseplate on the work, and pull the saw toward you to make the cut.

Small files, the ends of which will (or can be ground to) fit the blade lock, can be used to big advantage for filing in hard-to-get-at places, removing burrs, etc.

TTFR-GRINDFR

at 13,000 rpm. Positive locking chuck takes 3/32-, 1/8- and 1/4-in shank tools

With the wide variety of cutters and grinding wheels available you can carve, rout, sand, mill, sharpen and grind - in wood, This compact. powerful tool plastic, glass and metals (expacks a wealth of usefulness - cept hardened steel). Simply for professional tool and die grasp the tool in one hand, and makers and home "handvmen." maneuver it much like you would alike. The 110-120 V. 25-60 a pencil - using enough prescycle AC or DC motor develop- sure for the job, without apes a full 1/14 hp - operates preciably slowing the motor.

RENCH STAND & TOOL-POST HOLDER

ELECTRIC CU

Two accessories that more than double your grinder's usefulness. The bench stand mounts on any bench to hold the grinder vertically upward, horizontally, or at 45° above or below horizontal. It also tilts to either side. Leaves hands free to guide the work.

The post holder slips into a metalworking lathe tool post to hold the grinder securely for accurate inner CUTTING TOOLS OF OUTEr diameter grinding,

THE ELECTRIC HAND DRILL

Your Most Used. "All-Around" Shop Tool

SELECTING A DRILL

Your drill will be, quite likely your most used, most relied upon all-around tool. Consider carefully the kind of work you will expect of it. and select one with sufficient power and built-in ruggedness for the toughest of your jobs. Moreover, if you expect to take full advantage of the drill's many uses - to drive the various attachments available (b. 5-7) - a suitable, heavy-duty drill will be well worth the slight extra invest-

Drills are rated in several ways

1) By the size of the drill chuck 1/4- 5/16-3/8-, 1/2-inch. etc. size — the larger sizes usually being for very heavy industrial work. Chuck size determines the largest size hole the drill should be used to drill in metal; but not necessarily the largest it can drill in wood.

2) By the hp (horsepower) developed by the drill at its chuck. Small light-duty drills may develop as little as 1/8 (or less) hp: a

PEPEECTION .....

TYPICAL

possible selection. There is a size, type have quick-change industrial-type chucks, and quality of drill for every need from the Some models are reversible. All of the light-duty 1/4-in. "economy" model de- larger-capacity models have hardened steelsigned for "handy-man" use up to the big, alloy reduction gears. A few of our popular production-duty 3/4-in. model designed for models are illustrated. continuous shop use. Each is precision built for the type of usage intended - and all drills are jobtested. All of the industrial rated drills are for continuous operation.

Craftsman best quality drills have ball and needle bearings throughout to withstand rough usage; the lighter-duty models have oil-impregnated sleeve bearings. All of the models have spindle locks (for easy use of accessories): and all also have balanced, light-weight aluminum housings and convenient trigger-type switches with lock-ON buttons for effortless operation. Most are

Does the nameplate show the HP . and is it enough Is motor for AC or DC, or for AC/DC? Type of bearings . especially the chuck-end spindle bearings. Will they last? Type of chuck . does it hold, is it fast and easy Type of switch . is it convenient? Extra features, like the Spindle Lock or the Switch

Lock-ON Button . or a rever Length of cord and type of plug. Will drilloperate the accessories you may want to own?

The GUARANTEE . and the Service offered.

good, heavy-duty 1/4-in. size develops 1/3 hp; larger sizes develop up to 2/3 (or more) hn. This alone determines how "tough" a

3) By the rbm (speed) of the chuck. Smaller hp drills necessarily have high-speed, noload chuck ratings (up to 2500 or 3000 rpm) depend largely upon this speed (using highspeed cutting bits) to accomplish light-duty drilling tasks; but "bog down" quickly when the going gets tough. Heavier and larger drills

4) By the styling and construction features of the drill. Styling can be important insofar as the weight and balance, usefulness in tight corners, protection of the motor from dust. and similar considerations are concerned. Construction features - such as the type of chuck, gears, or bearings - are very important to the serviceability of a drill.

100

OPERATION AND CARE

In any use of your drill it is important not to overload it so that it slows down to the point of overheating and stalling. Unless it is a continuous operation model, lift it from the work whenever it feels quite warm and let it run at no-load speed to cool it off (this cools it faster than stopping it). If the bit iams. stop the drill and free the bit . never try to make the drill break it loose. Keep your drill lubricated according to instructions packed with it: regularly clean it by blowing an air jet through the frame or by shaking out internal dust.

Don't use your drill as a router. or try to elongate a hole by twisting the bit sideways - unless you know the drill has been designed to take side thrusts (light-duty drills and some heavy models aren't). Also, don't use it to drive an unbalanced tool (like a fly cutter), too big a tool (like a large grindstone), or a tool which could be dangerous if it should get away from you (like a circular saw blade held in the chuck).

For safety, always use the grounding connection provided or comply with instructions given - especially if you are on a damp floor or ground.

DRILL OPERATIONS

OTHER BORING OPERATIONS

Masonry Drills

Carbide or tungsten-carbide tipped drills Each bit makes the proper size hole for the slowing the drill too much.

Counterbores, Hones Countersinks Reamers

All of these tools can be used with a hand drill. As each, however, is intended for a precision operation good results can be obtained only when you take extra and steady. Cutting should the drill running to avoid marring of the work surface. Delicate handling is required.

Screw Pilots

make short work of boring through cement. root, body, and countersink of a common wood tile brick, marble and the like. For best screw, in one simple operation. An autoresults alternately press the drill in (to cut), matic stop prevents your drilling to deeply then pull it partially out (to unload the dust). - and can be set for flush or sunken head Use as heavy a pressure as necessary to screws. Instructions packaged with the bits keep the bit steadily "biting" in - without show which is just right for each of the most popular wood screws.

Expansive Bits and Hole Saws

These tools present two

problems First the drill

bling. Second the point is

using a delicate feed.

cutting edges - will break through first. Preferably. finish a through hole from the second side, using the break through of the point as your centering hole, and

When attachments are used, the drill loses its original identity and becomes, in effect, merely a conveniently handled motor which both holds and drives the attachment. These attachments increase the drill's versatility immensely make it truly the most useful tool in your shop

Be Sure Your Drill Has Power Enough To Drive These Attachments!

FINISH SANDING ATTACHMENT ANGLE DRIVE SET

PULL OUT

nector keeps pressure equalized. prevents drills). gouging. Uses 5-in. stick-on sanding discs.

DRILL ARBOR

Held in the drill chuck, this arbor adapts your drill for many additional operations both hand held and bench mounted. It holds wire brushes, grinding wheels, buffs, and rubber polishing wheels.

Here is an entirely Sanding, buffing, and polishing are easy with new idea ... a fin- this angle drive and the equipment furnished ishing sander that with it. The angle is just right for fast. you can use flat on comfortable operation, and the tool adds the work surface, two different speeds to your drill. With a Leaves no swirl high-speed drill it should be driven from marks. Sands glass the small end, which cuts the drill's speed smooth very fast, in half. When driven from the large end the Flexible rubber con- drill's speed is doubled (for slow speed

Start hole with a center-punch mark to keep the drill point steady (otherwise it may suddenly side slip and break off). If the point is too big to center in the

Never use an auger bit (screw pointed) - use types

which must be pressure fed. Feed with light pres-

sure - both for the sake of a cleaner job and to prevent overloading. Be extra careful when drilling deep

holes, especially if the wood is gummy and tends to

bind the bit. Properly secure the workpiece, and

hold the bit as straight and steady as possible (to obtain a true round hole and to prevent side binding). Clean the chips occasionally by momentarily backing

the bit out. To prevent chipping the back it is best

to use a backing board - or stop just short of a break-through and finish by boring from the back.

they will not "hog in."

power wood bits, as illustrated. Screw pointed

bits may be used if the screw threads are filed

off to leave the points without threads, so that

RD AGAINST

mark, start the hole with a smaller drill. If the drill does wander off the mark, you can recenter it by using a cape chisel to remove some metal on the side toward which the drill should go.

Use firm, steady pressure - relieving the feed regularly to clear the chips and to let the drill pick up lost speed. Generally, the harder the metal, the more pressure you can apply without stalling the tool. Jamming the drill must be guarded against: but it is equally important not to let it run too freely (without really cutting) as this will burn up the cutting edge. Best practice is to observe the chips - and keep them falling at a regular rate which will allow the drill to run without overheating. Soft metals (espe-

groups: 1) Fractional sizes: 2) Numbered sizes:

different selection of sizes so that, on the whole,

you can readily obtain any size in increments

of 1/64 inch, up to 1-1/4 inch. All drills are

either: 1) Carbon steel, or 2) High speed. Use

Lettered sizes. Each provides a slightly

cially some aluminums) are often gummy and the chips will glob up in the drill flutes. In such case the drill should be removed and the chips dug out - or they will accumulate and expand to break off the bit. Always ease up for the break-through (this is when the bit is most apt to jam).

to 80° angles. There are also several types of

DRILL ATTACHMENTS (Cont.)

CIRCULAR SAW ATTACHMENT

Clean, accurate cutting of woods up to 1-1/2in. thick can be done with a minimum of effort when your electric drill is equipped with this circular saw attachment. It has depth of cut and bevel adjustments, similar to those of the larger electric hand saws.

Since it is not intended for heavy-duty or production use, it will give top efficiency only when used properly. Do not force your saw through a cut – particularly on heavier stock. Guide it lightly so that it cuts freely at top speed. Jamming will only slow down your work, and can seriously overload your drill.

Attached to a work bench, this attachment makes an excellent, light-duty bench saw.

SANDER-POLISHER ATTACHMENT

Does excellent sanding and polishing of flat surfaces — and is especially useful for cabinet finishing and similar operations (refer to page 9). Use fine (300 grit) to medium (180 grit) sandpaper for finishing operations. Change to a cloth pad covered with cheesecloth or a portion of a lambs wool polishing bonnet. Makes hand rubbing unnecessary. Always use light (hand-weight) pressure.

SABRE SAW ATTACHMENT

Converts your drill into an efficient tool for use as a jig, scroll, coping, crosscut, rip, or keyhole saw. With it, you can quickly cut curves, circles, intricate designs in plastics, hard rubber, plywood, wall board and metals.

Bored holes for inside cuts are not necessary. Simply rock the saw on its front feet thus allowing the blade to cut its way down through the work. When the blade has cut through the work and the baseplate is flat on the surface, finish the cut as usual.

PLANER ATTACHMENT

Edge planing of doors, windows, etc. — up to 1-13/16-in. wide — which is generally such a chore with hand equipment, is made easy with this compact attachment. It assures professional results every time at a fraction of the work of hand planing.

The tool is equipped with an adjustable fence that serves as a guide for making accurate cuts, including mitters up to 15° in either direction. Its depth of cut is adjustable up to a maximum of 1/8 in. Once it has been fitted to your drill, it can be removed and remounted with little effort.

To plane an edge wider than the tool, but less than twice as wide, make a pass along one edge then the other edge, rather than cut too deeply on one edge alone.

REVERSING SCREWDRIVER & SPEED REDUCER KITS

with this kit your drill, becomes a reversible ner or tap driver . . or a slow-speed drill with 6 to 7 times its normal torque for heavy work. Included are: The reversible ment Phillips bits sizes 1, 2 and 3, two standard screwdriver bits, one screwfinding bit, a 1/2-in, key chuck with key, two arbors. one square drive adapter, and nine drive

sockets sizes 1/4, and 5/16 in 8-point and sizes 7/32, 1/4, 9/32, 5/16, 11/32, 3/8 and 7/16 in six-point. All in a steel carrying case. You can power install or remove all common wood or machine screws or nuts that this large assortment will fit, can power tap or ream, or can drive drilling tools up to 1/2-in. shank size. Also available in a smaller size kit without case. Full instructions included with kit.

The smaller attachment shown above is a nonreversible screwdriver which can, be fitted with either a standard or a size 2 Phillips bit for quick easy installation of wood screws.

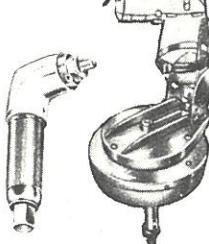

ANGLE DRIVE ATTACHMENT

Many tough drilling problems can be solved with the new angle head drill attachment. It will literally "drill around corners". Much disassembly time can be saved on jobs where a drill hole is necessary in an ordinarily inaccessible place.

Avoids the bad practice of attempting to drill at an angle around a corner, with the probability of a broken bit as a result.

USES OF A DRILL STAND

A drill stand like the one illustrated (for most drills up to 1/2-in. size) enables you to do bench-type drill-press work . or to do accurate, on-the-job drilling in a variety of positions (as illustrated). Increases precision; relieves you from tiresome holding; adapts a heavy-duty drill for production-type work.

Other models and bench stands are also available. All are especially useful for adapting many of the drill attachments (following pages) to bench-type uses for faster, better work. It is easier, too, when you have both hands free to hold the work.

ROTO-SAW ATTACHMENT

This tool converts your drill into a useful saw and filing machine for metal, wood, plastics and similar building materials. It uses sections of standard hacksaw blades and small files.

With a stiff blade, rocking the tool upward (to thrust the blade end downward) will start a cut in thin materials (making a starting hole unnecessary). Thin, flexible blades are used for detail scroll saw work. Fast hacksaw work and filing can also be done with the proper blades and files.

HEDGE-TRIMMER

Now you can take most of the tedious labor out of hedge trimming! Once the heavy growth

timber has been cut out, this attachment will make fast work of keeping your hedges in shape.

SEWER AUGER Fits any 1/4 or 3/8-in.

drill to drive a 25-foot steel auger that will make quick work of unstopping sinks, tubs, to ilet bowls or any drain lines that are clogged with grease, paper, sand, etc. Avoids costly service and repair calls.

PORTABLE POWER SHOP Router, Shaper, Sander, Planer & Jointer

THE POWER UNIT

As everyone who has used hand tools knows, it takes power lots of power — to cut and shape workpieces quickly, accurately and tirelessly. But such a motor that is designed to be compact and lightweight enough for hand tool use costs

money ... often more than the usage of the tool will justify. Then, too, such a separate motor on each and every tool takes space, and adds weight that must be carried around to each new job.

THE ROUTER

Routers were originally intended for mortising and grooving — but a compact, light-weight router (such as illustrated) has many "bonus" uses which make it a very versatile workshop tool. The router shown is designed for mortising door locks, rabbeting, dovetail grooving, tenon grooving, edge shaping, preparing inlays, pattern and freehand wood carving and shaping — and allied jobs. The novel, simple device for raising or lowering the cutter, together with the in-handle switch, extra guide knob, and adjustable edge guide, all make this an easily handled tool for production or general shop use.

TYPICAL ROUTER USES

Shown here are three of the many operations a router will do faster and better than any other tool. It is excellent for inlay work and other workpiece decorations.

ATTACHMENTS FOR USE WITH THE ROUTER BASE

FORMICA CUTTER ATTACHMENT Will cut and edge formica, phenolics or laminates.

CUTTER GRINDING ATTACHMENT Quickly sharpens shaper cutters — for smoother, faster cutting.

ROUTER WITH SHAPER TABLE

With this attachment the router becomes a set-up shaper with center spindle and a tilting base for shaping bevel edges. Includes depth-of-cut adjustment, movable fence, miter gage, detachable guard, contour guide and hold-down fingers.

Can be mounted in your workbench or in a homemade porttable stand. Instructions are included. Operations are much the same as with bench shaper.

THE SANDER

This is a heavy-duty belt-type sanding unit using 3 x 25-inch belts in various (fine, medium and coarse) grits. Built-in dust pick up collects all dust in the bag. Also has belt alignment, adjustment and quick change features which make it a truly professional - type tool. Excellent both for rapid reducing of roughest surfaces and for fine finishing work.

DOVETAIL TEMPLATE

SASH & DOOR HOLDER

BUTT-HINGE & LOCK-FACE TEMPLATES

Not illustrated are three other very useful accessories for use with the router, etc. The Dovetail Template fits onto any bench edge to set up workpieces for fast,

The unique Sash and Door Holder will support a

THE PLANER-JOINTER

This is a professional type edge planer – excellent for quickly straightening and smoothing the roughest and crookedest of edges. Takes cuts up to 3inch wide in one pass – 6-inch wide in two passes. Depth-of-cut is ad-

justable from 0 to 1/8-inch, in 1/64-inch increments. The fence, which mounts at either side, is adjustable from 0° to 45° for bevel planing. Furnished with the planer, the Jointer Attachment mounts on a workbench or plank to hold the planer stationary for feeding of workpieces to it.

Here is a truly lightweight router - complete with its own 1/5 HP, high-speed motor - with which to do all those occasional homeshop and hobby projects that you have been doing tediously with chisels, gouges and other hand tools. Priced for economy, it nevertheless is a sturdy, ball-bearing chuck tool that will give years of smooth, chatter-free routing in hard or soft woods, plastics and similar materials.

It is equipped with depth-of-cut adjustment and an edge guide – can be used with all the same router base attachments and tools listed in this book, Will do grooving, dovetailing, rabbeting and the other edge shaping operations described in this book. Especially excellent for freehand decorating work. Saves many hours of hard labor!

Here is your perfect answer to

these problems Here is the new

idea that is revolutionizing the

usefulness of powered hand tools: One motor...one super-

powered, dependable power back

to drive all those occasionally

used but desperately needed

nower tools that you must have for nearly

every finish carpentry or cabinetmaking job.

For attachment to this power pack you can

have all or any one of the following profes-

Removable Handle

Loading...

Loading...