Designed exclusively for and sold only by SEARS, ROEBUCK AND CO.—Chicago, Illinois 60607 U.S.A. and SIMPSONS-SEARS LIMITED—Toronto

GUARANTEE

CRAFTSMAN PORTABLE ELECTRIC TOOLS ARE UNCONDITIONALLY GUARANTEED FOR ONE YEAR TO GIVE COMPLETE SATISFACTION OR RETURN FOR FREE REPLACEMENT.

THIS GUARANTEE SERVICE IS AVAILABLE BY SIMPLY RETURNING THE TOOL TO ANY SEARS STORE.

SEARS, ROEBUCK AND CO. and SIMPSONS-SEARS LTD.

introduction DOUBLE INSULATION

Double Insulation is a concept in safety, replacing the standard grounded supply system, in electric power tools. The construction of a double insulated tool affords compatible protection to a properly grounded tool without the necessity for using a grounded conductor. The double insulation system eliminates the need for the usual three wire grounded power cord and grounded supply system. Whenever there is electric current in the tool there are two complete sets of insulation to protect the user. All exposed metal parts are isolated from the internal metal motor components with protecting insulation. The lead wires, switch,

MULTI-SPEED

This saw has the unique feature of continuously variable speed controlled by its electronic circuit assembly. The circuit assembly which has a reserve power feature automatically maintains constant speed and power to maximum as the load increases. The speed control knob is located in the rear end of saw where it remains readily available for immediate speed selection. Speeds may be changed while the saw is running.

The speed selector is conveniently numbered 1 through 12 and is easily visible through the opening in speed control knob. Number 1 corresponds to the lowest speed. Rotation of the knob from 1 to 12 will progressively increase the speed and power. Any intermediate knob setting may be used when so desired.

AVOID RUNNING AT SLOWER SPEEDS FOR EX-TENDED PERIOD OF TIME WHEN POSSIBLE. AT

etc. with their functional insulation have the added protection of non-conductive sleeving or housings to complete the double insulation system.

SERVICING OF A TOOL WITH DOUBLE INSULA-TION REQUIRES EXTREME CARE AND KNOWL-EDGE OF THE SYSTEM AND SHOULD BE PERFORM-ED ONLY BY A QUALIFIED SERVICE TECHNICIAN. FOR SERVICE WE SUGGEST YOU RETURN THE TOOL TO YOUR NEAREST SEARS STORE FOR RE-PAIR WHICH WILL BE DONE WITH ORIGINAL FACTORY REPLACEMENT PARTS.

SLOWER SPEEDS UNDER CONSTANT PROLONG-ED, USAGE, THE UNIT MAY BECOME OVER-HEATED. SHOULD THIS OCCUR, RUN TOOL WITH NO LOAD AT MAXIMUM SPEED TO COOL THE UNIT. THIS WILL ACCELERATE COOLING PROCESS

During use, transit or storage of the saw provide a reasonable amount of protection around the speed control knob to prevent any possible damage.

The trigger switch controls 'On - Off' operation of this saw, is double pole for added safety and has lock button with safety release for added utility. The lock button may be engaged when trigger is fully depressed. The trigger lock is convenient when sawing soft woods or soft metals. DO NOT LOCK THE TRIGGER ON HEAVY JOBS WHERE THE SAW MAY NEED TO BE STOPPED QUICKLY. The locking mechanism may be disengaged by applying additional inward pressure to the trigger.

RULES FOR SAFE OPERATION

KNOW YOUR POWER TOOL - Read owner's manual carefully. Learn its applications and limitations as well as the specific potential hazards peculiar to this tool.

GROUND ALL TOOLS - UNLESS DOUBLE-INSULATED. If tool is equipped with three-prong plug, it should be plugged into a three-hole electrical receptacle. If adapter is used to accommodate two-prong receptacle, the adapter wire must be attached to a known ground. (Usually the screw securing receptacle cover plate). Never remove third prong. KEEP GUARDS IN PLACE and in working order.

- KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

- AVOID DANGEROUS ENVIRONMENT. Don't use power tool in damp or wet locations. And keep work area well lit.

- KEEP CHILDREN AWAY. All visitors should be kept safe distance from work area.

- STORE IDLE TOOLS. When not in use, tools should be stored in dry, high or locked-up place-out of reach of children.

- DON'T FORCE TOOL. It will do the job better and safer at the rate for which it was designed.

- USE RIGHT TOOL. Don't force small tool or attachment to do the job of a heavy duty tool.

- WEAR PROPER APPAREL. No loose clothing or jewelry to get caught in moving parts. Rubber gloves and footwear are 10. ecommended when working outdoors.

- USE SAFETY GLASSES with most tools. Also face or dust mask if cutting operation is dusty

- DON'T ABUSE CORD. Never carry tool by cord or yank it to disconnect from receptacle. Keep cord from heat, oil and sharp

- 13. SECURE WORK. Use clamps or a vise to hold work. It's safer than using your hand and it frees both hands to operate tool.

- DON'T OVERREACH. Keep proper footing and balance at all times.

- 15. MAINTAIN TOOLS WITH CARE. Keep tools sharp at all times, and clean for best and safest performance. Follow instrucions for lubricating and changing accessories.

- 16. DISCONNECT TOOLS. When not in use, before servicing: when changing attachments, blades, bits, cutters, etc. REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see that keys and adjusting wrenches are remov-

- 18. AVOID ACCIDENTAL STARTING. Don't carry plugged in tool with finger on switch. COPYRIGHT. 1969. BY POWER TOOL INSTITUTE. INC ALL RIGHTS RESERVED

CUSTOMER INSTRUCTIONS

- 1. DO read thoroughly ASSEMBLY, OPERATING IN-STRUCTIONS AND PARTS LIST before beginning operation of your AUTO SCROLLER SAW.

- 2. DO be sure the voltage of the power supply agrees with the dataplate marking on the unit.

- 3. DO use only specified replacement parts.

- 4. DO use goggles when cutting any metal.

- DO be sure switch is in "OFF" position before connecting tool to power supply.

- 6. DO replace both brushes when either is worn to about 1/4 inch in length.

- DON'T begin operation of your AUTO SCROLLER SAW before reading thoroughly ASSEMBLY, OP-ERATING INSTRUCTIONS AND PARTS LIST.

2. DON'T lift tool from work with motor running. This can cause the surface of the work to be marred and may break blades.

3. DON'T leave the line cord plug connected to the power supply while making tool adjustments or changing motor brushes.

CAUTION

The operation of any power tool can result in foreign objects being thrown into the eyes, which can result in severe eye damage. Always wear safety glasses or eye shields before commencing power tool operation. We recommend Wide Vision Safety Mask for use over spectacles, or standard safety glasses . available at Sears retail or catalog stores.

AVOID USE OF ALL SOLVENTS WHEN CLEANING PLASTIC PARTS. USE CLEAN CLOTHS AND WIPE PARTS AS MUCH AS POSSIBLE TO REMOVE DIRT, CARBON DUST, ETC. MOST PLASTICS ARE SUSCEPT-IBLE TO VARIOUS TYPES OF COMMERCIAL SOLVENTS AND MAY BE DAMAGED BY THE USE OF THESE SOLVENTS.

THIS PRODUCT, or any electrical product, requires extreme care when service repairs are made. A dangerous electrical hazard can be created by tampering with the electrical or insulating systems or in the replacement or substitution of repair parts. Repairs should be made only by a qualified technician. If service is required we suggest you return the tool to your nearest Sears store for approved service with original factory replacement parts.

WHEN ELECTRIC TOOLS ARE USED ON FIBER-GLASS boats, sports cars, etc. it has been found that they are subject to accelerated wear and possible premature failure, as the fiberglass chips and grindings are highly abrasive to bearings, brushes, commutator, etc. Consequently it is not recommended that this tool be used for continuous production work on any fiberglass material. During any use on fiberglass it is extremely important that the tool is cleaned frequently by blowing with an air jet.

EXTENSION CORDS—The use of any Extension cord will cause some loss of power. To keep this to a minimum and to prevent overheating and motor burn-out, use the table below to determine the MIN-IMUM wire size (A.W.G.) Extension Cord.

| xtension Cord Length | Wire Size A.W.G. | |||

|---|---|---|---|---|

| 25-100 Feet | 16 | |||

Extension cords suitable for use with your Auto-Scroller Saw are available at your nearest Sears Catalog Order or Retail Store.

Another time saving convenience is a cord-lock offered by Sears which prevents separation of cord. Cord-lock is available at your nearest Sears Retail Store or Catalog Order House.

operating

INSTALLING BLADES—IMPORTANT—BE SURE POWER CORD IS DISCONNECTED FROM POWER SUPPLY. (See Fig. 1) Loosen blade screw (A) with a screwdriver, and insert saw blade into slot in blade clamp (B) as far as it will go. All blades except flush cutting blade catalog no. 2877 should be installed with cutting edge of blade toward saw bar. Tighten blade screw (A) securely.

Excessive pressure on blade during operating of the saw can break blade. In the event this happens all saw blades except the 10-tooth tapered back, 6" blade, and scroller blade can be reused by loosening the blade screw until portion left in clamp drops out, then putting the remainder of the blade back into the clamp and retightening the blade screw. It may be necessary to flatten tooth set in area to be inserted into clamp when reusing broken blade.

NOTE: CRAFTSMAN SABRE SAW BLADES HAVE A UNIVERSAL SHANK THAT IS DESIGNED TO FIT ALL SABRE SAWS AND ALL SCROLLER SAWS.

INSTALLING CHIP SHIELD—IMPORTANT—BE SURE POWER CORD IS DISCONNECTED FROM POWER SUPPLY. (See Fig. 2) The chip shield, Key No. 38, (See parts list, page 9) is attached to the gear housing cover with screw Key No. 39. To install chip shield (A), place chip shield on bottom of gear housing cover (B) with hole in chip shield over hole in bottom of gear housing cover. Insert screw (C) through hole in chip shield into hole in bottom of gear housing cover and tighten securely.

LUBRICATION—All of the bearings in this tool are lubricated with a sufficient amount of high grade lubricant for the life of the unit under normal operating conditions, therefore, no further lubrication is required.

AUTO-SCROLL CUTTING-(See Figs. 3 & 5) YOUR AUTO-SCROLLER SAW IS DESIGNED TO PERMIT 360° SWIVEL OF THE SAW BLADE EITHER BY ROTATING THE CONTOURED TOP SWIVEL KNOB FOR SCROLL CUTTING OR GUIDING THE DIRECTION OF THE CUT WITH APPLIED PRESSURE AT THE HANDLE FOR AUTO-SCROLL CUTTING. THE GUIDING AT THE HANDLE APPROACH LEAVES ONE HAND FREE TO CHANGE SPEEDS, HOLD MATERIAL BEING CUT SECURE, ETC. THE SCROLLING AND AUTO-SCROLLING FEATURE MAKES YOUR SAW IDEALLY SUITED FOR MAKING FANCY CUTS AND SCALLOPS WITH RADII AS SMALL AS 3/16 INCH. IT IS DE-SIGNED TO CUT IN CORNERS AND CLOSE PLACES WITHOUT THE NECESSITY OF ROTATING AND TURNING THE COM-PLETE SAW (See Fig. 5). IT IS IDEAL FOR CUTTING ELEC. TRICAL OUTLET AND SWITCH BOX HOLES, SINK AND LAV. ATORY CUT-OUTS AND MANY OTHER USES.

The saw is equipped with a sliding thumb operated lock for locking the knob in four (4) positions (90° apart). The white indicator mark on front of swivel knob indicates direction of blade cutting edge. For scroll cutting and auto-scroll cutting the slide lock must be in the rear (unlocked) position for free rotation of saw bar. Use sufficient forward pressure to permit blade to cut freely and follow the scribed line with gentle rotation of swivel knob or directional guidance at handle.

NOTE: WHEN USING FLUSH CUTTING BLADE, CATALOG #2877, SWIVEL KNOB MUST BE ROTATED 180° FROM NORM-AL FORWARD CUTTING POSITION AND LOCKED. (SEE FIG. 4)

METAL CUTTING-Many kinds of metals can be cut with your saw. Be careful not to twist or bend the blades. DO NOT FORCE. If the blade chatters or vibrates excessively, use a finer-tooth blade or higher speed. If blade heats excessively use lower speed. If blade teeth become filled or clogged when cutting soft metals, such as aluminum, use a coarser-tooth blade or lower speed. We recommend use of kerosene when cutting most soft metals and oil when cutting steel to keep blades cool, increase cutting action, and prolong blade life. Hold the work firmly and saw close to the holding point to eliminate any vibration of the work being cut. When cutting conduit, pipe or angle iron clamp work in a vise if possible and saw close to the vise. To cut thin sheet material "sandwich" the material between hard board or plywood and clamp the layers to eliminate vibration and material tearing. In doing this, the material will be cut smoothly. Lay out your pattern or line of cut on top of the "sandwich."

IMPORTANT—When cutting metal keep exposed portion of saw bar clean and free of metal chips by wiping frequently with an oily cloth. Use extreme caution in disposing of oily cloth after completion of job to prevent potential fire hazard.

GENERAL CUTTING—The angle of cut on your saw may be set at any point from 0° to 45° right or left. (See Fig. 6). Setting for required angle may be accomplished by loosening two base pivot screws, Key No. 49. (See parts List, Page 9), and adjusting base until index mark is in line with required angle on quadrant. Retighten base pivot screws. Base pivot screws are readily accessible through two holes in saw base.

NOTE: ANGLE CUTS MAY BE MADE ONLY WHEN WHITE IN-DICATOR MARK ON SWIVEL KNOB IS SET DIRECTLY IN FRONT OR BACK POSITION AND SCROLLER MECHANISM IS LOCKED.

For straight and miter cutting the slide lock must be in the locked position and the white indicator mark on swivel knob toward direction of cut. Rest the front of the base on the work and align cutting edge of blade with line on work. Move saw forward with a firm downward pressure on the base and with sufficient forward pressure to permit blade to cut freely. DO NOT FORCE. Be sure to keep base flat on work.

To make a straight cut, clamp a piece of wood or straight-edge on the work, and guide the edge of the saw against the straightedge or use edge guide provided. When cutting against a straight edge or board, cut in one direction only across the material, don't cut half way and continue cut from the opposite end. For best results, clamp work to bench.

NOTE: BECAUSE THE TAPERED BACK BLADE, CATALOG #2876, HAS NO SET IN THE TEETH, IT SHOULD NOT BE USED WHEN USING A BOARD TO GUIDE THE SAW.

PLUNGE CUTTING—(See Fig. 7) To cut an inside hole in work, mark the line of cut clearly, rotate swivel knob into normal forward cutting position and slide lock into locked position. Choose a convenient starting point and place the tip of the blade over that point and inside the line on the waste. Rest curved end of base on work and hold firmly in position. Depress trigger switch, and with saw blade in motion, slowly tilt saw downward until tip of blade starts cutting work. After blade penetrates work, tilt saw until the blade is perpendicular to the work. Use only 7-teeth per inch blade for plunge cutting.

BRUSH REPLACEMENT—Periodically check the brushes for wear and replace both brushes when either is worn to about 1/4 inch in length. To check length of brushes they must be removed from tool (see instructions below). Replacement of these relatively inexpensive parts, when necessary, will keep your tool operating more efficiently and prolong the life of the motor.

Replacement of worn-out brushes is considered normal operating maintenance and is not therefore covered by guarantee.

IMPORTANT —BE SURE POWER CORD IS DISCON-NECTED FROM POWER SUPPLY. To replace carbon brushes (See Fig. 8) unscrew brush caps, Key No. 29, (See parts list, page 9). Remove washer, Key No. 68. The washer is a tight fit in the brush holder and its purpose is to prevent the brush spring twisting when replacing brush caps. Remove old brush, Key No. 30. Reassemble new brush and spring making sure that curvature of brush matches curvature of the suface of the motor to which it is mated and that the bush moves freely in holder. Replace washers and caps. Be sure that brush caps are tight.

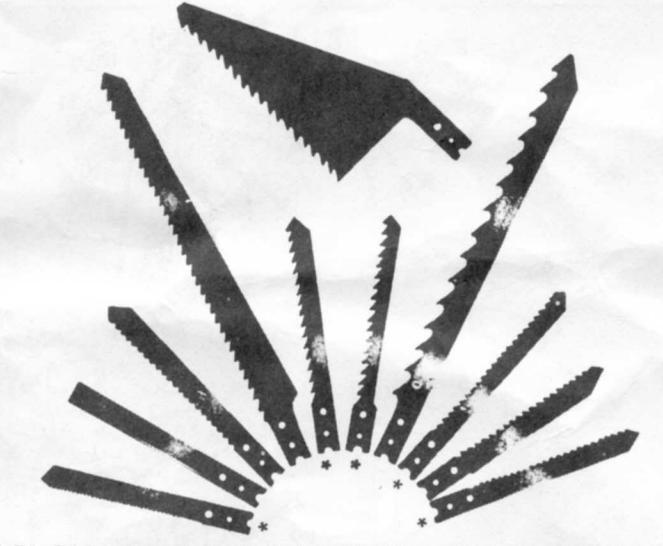

BLADE AND SPEED SELECTION —To obtain the best performance from your saw it is important to select a specific blade and speed for the particular application and type of material you wish to cut. By doing this you will get a smoother faster cut and prolong blade life. Replacement blades for this saw are available from your nearest Sears retail store or catalog order house. Order by model number of saw and number of teeth per inch of blades required.

READ CHART DOWN AND BLADES CLOCKWISE

| IDEALLY SUITED FOR: |

Teeth

Per Inch |

Blade

Length |

Speed | |

|---|---|---|---|---|

| : | Steel Rods, Pipe, Sheet Steel, etc. | 32 | 3 | 1 thru 4 |

| 1 | Rubber, Leather, Tile, Cardboard, Wallboard | Knife | 3 | 9 thru 12 |

| All Purpose—Wood, Steel, Non-Ferrous Metals (1/8" or thicker) | 14 | 31/2 | 5 thru 8 | |

| Tree Branches, Logs, Wall Partitions, etc. | 7 | 6 | 5 thru 8 | |

| : | Soft Wood (1x4's, 2x4's Plaster Board). Ripping | 7 | 31/2 | 9 thru 12 |

| - | Flush Cutting | 7 | 31/2 | 5 thru 8 |

| Kromedge® Scroller Blade Specially for Intricate Scroll Cuts | 10 | 3 | 9 thru 12 | |

| 1 | Deep Angle Cuts for 1 Inch Stroke Sabre Saws | 3 | 6 | 5 thru 8 |

| 1 | Hardwood, Wallboard, General Crosscutting (NOT PLYWOOD) | 10 | 31/2 | 9 thru 12 |

| 1 | Finish Cuts In Plywood, Veneer To 11/2" Thick. Tapered Back | 10 | 3 | 9 thru 12 |

| All Non-Ferrous Metals (Brass, Copper, Aluminum, etc.) | 24 | 3 | 9 thru 12 |

ACCESSORIES ADD VERSATILITY

FOR PARTS LIST—SEE PAGE 9 Page 8

The Model Number will be found on a plate attached to the motor housing. Always mention the Model Number in all correspondence regarding your AUTO-SCROLLER SAW or when ordering repair parts.

SEE BACK PAGE FOR PARTS ORDERING INSTRUCTIONS

PARTS LIST

| Key | 1 | - | |

|---|---|---|---|

| No. | Part Number | Description | Quan |

| 1 | 2-606111-01 | Sour Bar Bushing | 1 |

| 2 | 2.606107.03 | ||

| 2 | 2-000107-03 | Knob Complete | . 1 |

| 3 | 1-93068/-02 | *Set Screw (#8-32 x 3/16 Hex Socket Headless) | . 2 |

| 4 | 3-606348-02 | Dataplate | . 1 |

| 5 | 3-606449-01 | Crownplate | 1 |

| 6 | 1.795247-06 | ||

| 7 | 1 414459 07 | . 0 | |

| 2 | 1-014030-0/ | Screw (#8-32 x 3/4 Pan Hd.) | . 3 |

| 8 | 1-614658-06 | *Screw (#8-32 x 3/8 Pan Hd.) | . 3 |

| 9 | 1-706404-07 | *Nut (#8-32) | . 4 |

| 10 | 4-606126-01 | Handle | 1 |

| 11 | 2-622824-01 | Bend Relief | · i |

| 12 | 2 614702 01 | ||

| 12 | 2-014/03-01 | Cord | |

| 13 | 2-6060/0-01 | Switch | . 1 |

| 14 | 1-940049-33 | Screw (#8-18 x 3/8 Fil. Hd. T.F.) | . 2 |

| 15 | 4-606120-01 | Handle Cover | . 1 |

| 16 | 1-614658-09 | *Screw (#8-32 x 1-34 Pap Hd) | i |

| 17 | 1.614658.08 | *Scrow (#9.32 x 1 /4 Grindd) | · |

| 10 | 1 414040 01 | ||

| 10 | 1-010908-01 | -Screw (#6-20 x % Pan Hd. 1.C.) | . 2 |

| 19 | 1-621047-00 | Grommet | . 2 |

| 2.0 | 1-613813-01 | Retaining Ring | . 1 |

| 21 | 1-606786-01 | Lead with Terminals | 1 |

| 22 | 1-622739-01 | *Screw (#6.32 x 3/16 Pan Hd) | |

| 22 | 2 606160 01 | ||

| 23 | 2-000100-01 | Quadrant | . ! |

| 24 | 3-000180-01 | Speed Control Index | . 1 |

| 25 | 2-613811-05 | Speed Control Knob | . 1 |

| 26 | 1-616968-02 | *Screw (#6-20 x 1 / 4 Pan Hd, T.C.) | 1 |

| 27 | 2-606130-02 | Lock Button | i |

| 28 | 2 606110 01 | ||

| 20 | 2-000119-01 | Lock spring | . ! |

| 29 | 1-614008-01 | Brush Cap | . 4 |

| 30 | 2-606113-01 | Brush with Spring | . 2 |

| 31 | 2-606822-01 | Circuit Board and Knob Assembly (Includes Key Nos. 20, 24 and 25) | 1 |

| 32 | 1-941401-813 | Boll Pin | |

| 33 | 1 031037 00 | Washar | . 4 |

| 24 | 1 /0/101 01 | · 2 | |

| 34 | 1-000121-01 | Gear with Shaft and Pin | . 2 |

| 35 | 1-606294-01 | Cross Slide Roller | . 2 |

| 36 | 2-606166-01 | Saw Bar Complete | . 1 |

| 37 | 1-940038-804 | Screw (#8-32 x 5/8 Fil Hd.) | 6 |

| 38 | 2-606174-02 | Chip Shield | |

| 30 | 1 703429 02 | *Serous (49.22 x 5/14 Elet Hd.) | |

| 40 | 1-/03420-02 | Screw (#0-32 x 3/10 Flat Ha.) | . 1 |

| 40 | 1-000112-01 | Saw Bar Bushing | . 1 |

| 41 | 1-621645-03 | Screw (#8-32 x 3/8 Truss Hd.) | . 1 |

| 42 | * * | **Saw Blade | |

| 43 | 1-613931-04 | *Screw (#8-32 x 5/16 Rd Hd) | 1 |

| 44 | 2 606127 02 | Auto Scrollar Blade Clam (Includes One Key No. 2 and Key No. 42 | |

| 44 | 2-00012/-03 | Auto Scroller Blade Clamp (Includes One Key No. 3 and Key No. 43) | ). [ |

| 45 | 2-606122-01 | Quadrant Clamp Bar | . 1 |

| 46 | 3-606140-03 | Cross Slide Balance | . 1 |

| 47 | 1-703768-801 | *Screw (#6-32 x 1/2 Rd. Hd.) | 1 |

| 48 | 1-703473-28 | Lock Washer | 2 |

| 49 | 1-930330.18 | Screw (#10-32 x 5% Fil Hd) | . 2 |

| 50 | 2 414700 00 | Bose Complete | . 2 |

| 50 | 3-010/88-02 | base complete | . 1 |

| 51 | 2-606102-01 | Brush Tube | . 2 |

| 52 | 1-616968-03 | *Screw (#6-20 x 5⁄8 Pan Hd. T.C.) | . 4 |

| 53 | 2-606110-01 | Brush Tube Retainer | 2 |

| 54 | 2.606103.01 | Brush Cap Holder | . 4 |

| 55 | 1 714004 007 | Scrow (#10.16 v 1 Eil Hd.) | . 2 |

| 22 | 1-/14096-807 | Sciew (#10-10 X I FII, Hd.) | . 2 |

| 56 | 3-606068-03 | Motor Housing | . 1 |

| 57 | 3-606094-02 | Field Core Complete | . 1 |

| 58 | 1-606132-02 | Strip Nut | 1 |

| " 50 | 1.621442.02 | Loading Spring | |

| 60 | 1 740042 07 | Ball Bearing (Hower 7029) 14(2) | . 1 |

| 00 | 1-/40943-01 | buildedring (Hoover / USBLIACZ) | . 1 |

| 61 | 2-606969-01 | Armature Complete | . 1 |

| 62 | 1-621221-01 | Ball Bearing (Hoover 97038RSNL1AC2) | 1 |

| 63 | 3-606117-01 | Fan Baffle | 1 |

| 64 | 3 606127 07 | Gear Case and Cover Assembly (Includes Kou Nes 27 and (5) | |

| 64 | 3-00013/-0/ | Closue Bearing | . 1 |

| 05 | 1-60/145-01 | Sleeve bearing | . 2 |

| 66 | 1-940038-803 | Screw (#8-32 x 1/2 Fil. Hd.) | . 2 |

| 67 | 1-940038-815 | Screw (#8-32 x 3/8 Fil. Hd.) | . 2 |

| 68 | 1-706382-813 | Washer | 2 |

| EN-621 | Instruction Sheet | ||

"A"-Parts listed in this assembly are shown in the exploded view as Key Numbers 51 through 68 and represent an important part of the Double Insulated Safety System. To Avoid the possibility of alteration or damage to the Safety System, service requiring these parts should be performed by a qualified service technician. Service required on these parts should be performed by a qualified service technician. Service required on these parts should be performed by your nearest Sears Electric Motor Shop. Contact your nearest Catalog Order House or Retail Store for servicing of any parts shown in Section "A".

*Standard Hardware Item-May Be Purchased Locally

**Complete Assortment Available At Your Nearest Catalog Order House or Retail Store

FOR ILLUSTRATION-SEE PAGE 8

Sears

owners manual

AUTO-SCROLLER SAW DOUBLE INSULATED 1 INCH STROKE – MULTI-SPEED

MODEL NO. 315.17280

HOW TO ORDER REPAIR PARTS

SEARS SERVICE IS AT YOUR SERVICE WHEREVER YOU LIVE OR MOVE IN THE U.S.A.

The Model Number will be found on the plate attached to the motor housing. Always mention the Model Number when requesting service or repair parts for your Auto-Scroller Saw.

All parts listed herein may be ordered through SEARS, ROEBUCK AND CO. and SIMPSONS-SEARS LIMITED. When ordering parts by mail, selling prices will be furnished on request or parts will be shipped at prevailing prices and you will be billed accordingly.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE FOLLOWING INFORMATION AS SHOWN IN THIS LIST.

- 1. The PART NUMBER

- 2. The PART DESCRIPTION

- 3. The MODEL NUMBER-315.17280

- 4. The NAME of ITEM-AUTO-SCROLLER SAW

All fine tools, on occasion, may require service or the replacement of parts due to wear from normal use. To prolong the life of your tool when repairs are needed, call on your nearest Sears Catalog Order or Retail Store. Please do not risk possible electrical hazards, additional cost or damage to the tool through inexperienced repairs.

Your Sears merchandise takes on added value when you discover that Sears has over 2,000 Service Units throughout the country. Each is staffed by Sears — trained, professional technicians using Sears approved parts and methods.

SEARS, ROEBUCK AND CO.—Chicago, Illinois 60607 U.S.A. and SIMPSONS-SEARS LIMITED—Toronto

Loading...

Loading...