CABINETMAKING, CARPENTRY AND CONSTRUCTION-WORK KNOW-HOW WITH CRAFTSMAN

"JOB-FITTED" BENCH SAWS

OVER 200 ILLUSTRATIONS

THIS BOOK COVERS SET-UPS AND OPERATIONS FOR ALL CRAFTSMAN BENCH SAWS. FOR CONVENIENCE, HOWEVER, ONLY THE 10-INCH BENCH SAW IS ILLUSTRATED HEREIN.

A MIDWEST TECHNICAL PUBLICATION

for

SEARS, ROEBUCK AND CO. – U. S. A. IN CANADA – SIMPSON-SEARS LIMITED

CAT. NO. 9-2929

PRINTED IN U.S.A.

CABINETMAKING, CARPENTRY AND CONSTRUCTION-WORK KNOW-HOW WITH CRAFTSMAN 'JOB-FITTED'' BENCH SAWS

OVER 200 ILLUSTRATIONS

THIS BOOK COVERS SET-UPS AND OPERATIONS FOR ALL CRAFTSMAN BENCH SAWS. FOR CONVENIENCE, HOWEVER, ONLY THE 10-INCH BENCH SAW IS ILLUSTRATED HEREIN.

A MIDWEST TECHNICAL PUBLICATION for

SEARS, ROEBUCK AND CO. – U. S. A. IN CANADA – SIMPSON-SEARS LIMITED

CAT. NO. 9-2929

PRINTED IN U.S.A.

SEARS

CRAFTSMAN BEN

JOB-FITTING A

STANDARD SAWI

DADO SAWING

PROBLEM SAWIN

SPECIALIZED SAV

MOLDING AND

WORK HELPERS F

BENCH-SAW KNOW-HOW

FIRST EDITION - 1967

COPYRIGHT 1967 - SEARS, ROEBUCK AND CO.

All rights in this book are reserved. It may not be used for dramatic, motion-, or talking picture purposes without written consent of the copyright holder. Nor may this book or any part thereof be reproduced in any manner whatsoever without permission in writing from the copyright holder, excepting cases in which brief quotations may be embodied in critical articles and reviews.

For information, address Legal Department 766, Sears, Roebuck and Co., Homan and Arthington Aves., Chicago, Illinois 60607.

A CRAFTSMAN HANDBOOK

CONTENTS

| E | |

|---|---|

| CRAFTSMAN BENCH SAWS AND ACCESSORIES | С |

| CHAPTER 1 | |

| JOB-FITTING A BENCH SAW TO YOUR REQUIREMENTS | 1 |

| CHAPTER 2 | |

| STANDARD SAWING OPERATIONS | 9 |

| CHAPTER 3 | |

| DADO SAWING OPERATIONS 2 | 0 |

| CHAPTER 4 | |

| PROBLEM SAWING OPERATIONS 2 | 5 |

| CHAPTER 5 | |

| SPECIALIZED SAWING OPERATIONS 3 | 3 |

| CHAPTER 6 | |

| Molding and sanding with your bench saw | 8 |

| CHAPTER 7 | |

| WOOD JOINTING - 32 WAYS 4 | 6 |

| CHAPTER 8 | |

| 3 |

o co.

be used without is book tsoever holder, nbodied

Sears, hicago,

INTRODUCTION

SEARS FINEST FOR HOMESHOP OR MEDIUM-DUTY PROFESSIONAL USE CRAFTSMAN 10-IN. BENCH SAW

• CUTS UP TO 3-3/8-IN. THICK • FREE-SLIDING MITER GAUGE

Truly a fine cabinetmaker's tool, but priced for the homeshop buyer. Convenient, large-handled controls make it easy to raise and lower or to tilt the blade to precise settings. Rip fence locks front and rear in accurate alignment with the blade . can be vernier set and locked, or be removed at any position. Accurate-setting miter gauge slides freely in table groove at either side of blade. Furnished with 10-in. Kromedge blade for fast, smooth cutting. Motor is not included.

• POSITIVE-LOCKING FENCE SPECIFICATIONS Blade Size – 10" with 5/8" hole Blade Speed – 9,000 ft./min. Blade Tilt – 45° left Table Size – 20" wide x 27" long Ence L ength – 34"

Fable Size – 20" Wide X 2/" long Fence Length – 34" Dado Capacity (7" Size) – 13/16" wide x 1¾" deep Overall Size – 15"Hx23¾"Wx28"L

- EXTRAS -1. Guard and Splitter

• EASY-TO-USE TILTING ARBOR

- 2. Miter-Gauge Hold-Down

- 3. Adjustable Table Extension .

- increases width up to 20 inches 4. Grid-Type Table Extension .

- adds 10 inches to width

- 5. Miter-Gauge Stop Rod

- 6. Bench or Pedestal (page A-3)

– ALSO AN 8-INCH MODEL –

Similar in design to the 10-in. model — with the same extras available — this model provides a cutting depth of up to 2½ in. and a table area of 17x20 in.

A compact, portable craft shops. Has self-aligning fence t setting miter gauge in. Kromedge Blade, with Overload Prote shown.

CRAFTSMA HEAVY-

12-IN. FLOOR S

- INTEGRAL, DIRECT-MOTOR — Develop

- INTEGRAL, STURDY

- BUILT-IN ON-OFF S • EXTRA LARGE TAB width when extend

- MICRO-ADJ. RIP FE

- EXTREMELY ACCUR QUICK-ACTING CO

- BUILT-IN SAWDUS (For Use With Hom

Built for the profess in. cut to center of Micro-adj. fence el sion. Electro-Mag Guard with Splitter and stop rod availab

)P L USE

TING ARBOR

CATIONS with 5/8" hole 000 ft./min. left wide x 27" long 34" "Size) – 13/16" tep "Hx23¾"Wx28"L RAS – litter old-Down ble Extension ... th up to 20 inches ole Extension ... s to width top Rod estal (page A-3)

e – this 7x20 in.

INTRODUCTION

CRAFTSMAN 7%-IN. BENCH SAW

- INTEGRAL MOTOR -Develops 1 H.P.

- LARGE 14x26-IN. TABLE (inc, 2 furnished extensions)

- CUTS TO 1-5/8 IN. THICK

- · CONVENIENT SWITCH

- ALUMINUM GUARD

- DUAL MITER-GAUGE SLOTS

A compact, portable, precision-built tool especially designed for home and craft shops. Has separate controls for blade elevation and blade tilt . a self-aligning fence that lifts off at any point . and a free-sliding, accurate-setting miter gauge for 45° right- or left-angle miters. Furnished with 7-1/2-in. Kromedge Blade, Swing-Away Guard and Splitter, Built-In Capacitor Motor with Overload Protector, convenient Off-On Switch and Table Extensions as shown.

CRAFTSMAN HEAVY-

DIITY

12-IN. FLOOR SAW

- INTEGRAL, DIRECT-DRIVE MOTOR - Developes 3 H.P.

- INTEGRAL, STURDY NON-TIP STAND

- BUILT-IN ON-OFF SWITCH

- EXTRA LARGE TABLE up to 57 in. width when extended as shown

- MICRO-ADJ. RIP FENCE

- EXTREMELY ACCURATE, QUICK-ACTING CONTROLS

- BUILT-IN SAWDUST COLLECTOR (For Use With Home-N-Shop Vac p. A-4)

- (For Use With Home-N-Shop Vac p. A-4)

Built for the professional . priced for the homeowner. Allows up to a 3-9/16in. cut to center of 76-in. workpiece, with 13-1/2 in. of table in front of blade. Micro-adj. fence eliminates trial runs; also an extra fence on adj. table extension. Electro-Magnetic Brake; Overload Protector; 12-In. Kromedge Blade; Guard with Splitter; 8-Ft. Cord — for 110 or 220 V. (Miter-gauge hold-down and stop rod available extra.)

INTRODUCTION

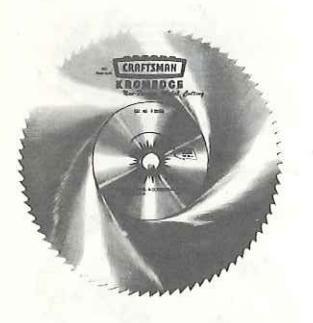

CRAFTSMAN KROMEDGE SAW BLADES

Whatever your cutting requirements, there is a quality Croftsman blade especially designed for the job. Craftsman blades stay clean (gum and rust resistant) and sharp longer, and cut smoother than ordinary steel blades. Each is made of finest saw steel and is Kromedge treated to increase the hardness and wearability of the surface and cutting edges. Blades listed below are available for 71/2, 10 and 12-in. Sears Bench Saws.

- 1. FREE SMOOTH-CUT COMB.

- 2. FREE-CUT RIP

- FREE-CUT COMBINATION

- CABINET COMBINATION

- 5. OLD-WOOD, NAIL CUTTING

- 6. CHISEL-TOOTH COMBINATION THIN-RIM VENEER

- 8. THIN-RIM CABINET COMB.

- 10. CARBIDE-TIPPED

- 11. STEEL SLICER

- 12. MASONITE CUTTING

- 13. NON-FERROUS METAL

DADO HEAD SETS

No. 1 is best, professional-quality, satin-cut, 7" set - will even cut veneers and plywoods with practically no splintering. Dadoes to 1-1/4" deep. No. 2 is 8" heavyduty set for extra tough jobs. Dadoes, to 1-3/4" deep. Both are Kromedge quality.

2 1/8" outside cutters, 4 1/8" chippers and 1 1/16" chipper. Assembles to 13/16" width.

2 1/8" outside cutters, and 6 1/8" chippers Assembles to 1" width.

Tungsten-carbide is one of man's That's why this hardest metals. carbide-tipped, Kromedge blade cuts so fast - stays sharp so long. Blade cuts smoother, feeds more evenly and takes less power than regular blades. Cuts all woods, most plastics, wallboard, thin brass or aluminum. Outlasts an ordinary blade 20 to 1.

MOLDING HEADS AND CUTTERS

1-Cutter Head, with 5-5/8" cutting dia., is excellent for 71/2 and 10-in. bench saws. Set includes 18 different shape bits to mold various trim, edging and joint designs, with unlimited variations if bits are used in combinations.

3-Cutter Head, available in 4-3/4-in. and 7in. cutting dia. - either in sets with an assortment of most popular bits, or heads only and 18 separate cutter patterns.

ADJUSTAB

width from 1/4" to 13/16" from the saw. Calibration depth of cut is 2". Tool precision-ground, carbide-tig any type of required dado cu and fast. Excellent for p Sears bench saw.

Clamps to auxiliary fench steel fingers to hold work against the fence.

BENCH-HEIGH

A rigid, substantial venient operation no provides maximum must frequently be

Rigid angleavailable in

nished unassembled. Speciper set) can be added for ease

SAW BLADES

an-carbide is one of man's metals. That's why this -tipped, Kromedge blade cuts - stays sharp so long. Blade noother, feeds more evenly and ess power than regular blades. I woods, most plastics, wallthin brass or aluminum. Outl ordinary blade 20 to 1.

DING HEADS

with 5-5/8" cutting dia., is 2 and 10-in. bench saws. Set different shape bits to mold dging and joint designs, with ations if bits are used in

available in 4-3/4-in. and 7-. — either in sets with an asost popular bits, or heads only e cutter patterns.

Precision cut, adjustable hub permits dialing any width from 1/4" to 13/16" without removing blade from the saw. Calibrations are in 1/16". Max. depth of cut is 2". Tool steel, 7" blade has 8 precision-ground, carbide-tipped teeth – will make any type of required dado cut, smoothly, accurately and fast. Excellent for plywoods. Use on any Sears bench saw.

HOLD-DOWN ATTACHMENT

Clamps to auxiliary fench. Provides 4 adjustable steel fingers to hold work safely down and in against the fence.

Mounted at each side of a saw blade these 4" dia. stabilizers impart the extreme rigidity required to completely abolish blade tremor and produce the ultimate in smooth, true cutting as required for top-quality cabinetwork joints. For use with any flat-ground blade of 7" or greater size.

A very accurate, easy-to-use, all-aluminum jig for easy plotting and sawing of single or double tapers. Also useful for molding or dado cuts on tapered pieces.

BENCH-HEIGHT MOUNTS FOR 8- AND 10-IN. BENCH SAWS

A rigid, substantial mount to place your saw table at proper height for convenient operation not only adds to the ease and pleasure of your work, but also provides maximum safety. A movable mount is desirable where saw position must frequently be shifted to accommodate various sizes and shapes of work.

INTRODUCTION

SANDING WHEELS FOR BENCH SAWS

Mounted in place of blade, a sanding wheel converts your Bench Saw into a firstrate disc sander – for edge (square or bevel) or limited surface sanding. Karbo-Grit Wheels (at left) are long-lasting metal discs with abrasive grains permanently wheels (at ref) are inigrating metal offices with advance grains permanently bonded on — coarse grit on edge and one side, med. grit on second side. The wheel at right is a heavy steel disc to which replaceable sandpapers in grits as desired can be cemented. These wheels are furnished with coarse and med. grits desired can be cemented. on them, and replacement sandpaper discs come in pkgs. of 6 containing 2 each: coarse, med. and fine grits.

Hardened, ground 50-MM lenses; adjustable plastic frames; side shields.

plastic lens in a plastic frame to fit over spectacles.

CRAFTSMAN HOME-N-SHOP VAC

FOR USE WITH 12-IN. BENCH SAW

This Home-N-Shop Vac is a special shop vacuum that collects sawdust as it is made, before it falls to the floor. Can be directly attached to the fully-enclosed body of the 12-in. model saw . or can be used with other model saws if bench space below saw body is fully enclosed and fitted to receive vac-hose end. Also excellent for cleaning litter from shop floor, workbench top, etc.

band.

SELECTING A BEN

The principal consider lecting a bench saw i cut needed for the typ done. On a construct possibly, for production it generally is nece through 2-in. lumber casionally, through 4 On the other hand, seldom requires sawin thing larger than a 2x of the wood used do 1-in. thickness.

A bench saw is rate the maximum diamete take. Remember, how arbor occupies a porti (the max. cut of an only 2-1/2 in.). Re: that tilting the blade ting will further redu thickness through whi

A-4

al shop vacuum that colore it falls to the floor. Illy-enclosed body of the e used with other model ody is fully enclosed and so excellent for cleaning op. etc.

CHAPTER 1 JOB-FITTING A BENCH SAW

TO YOUR REQUIREMENTS

SELECTING A BENCH SAW

The principal consideration when selecting a bench saw is the depth of cut needed for the type of work to be done. On a construction job — and, possibly, for production-line work it generally is necessary to saw through 2-in. lumber . and, occasionally, through 4x4-in. pieces. On the other hand, homeshop use seldom requires sawing through anything larger than a 2x4, and the bulk of the wood used does not exceed 1-in. thickness.

A bench saw is rated according to the maximum diameter blade it will take. Remember, however, that the arbor occupies a portion of the blade (the max. cut of an 8-in. blade is only 2-1/2 in.). Remember, also, that tilting the blade for bevel cutting will further reduce the vertical thickness through which it can cut.

Furthermore, a blade cuts faster and easier when a greater amount of the blade is projecting above the top of the work being cut. Therefore, even though a bench saw is capable of square-cutting through a certain maximum thickness workpiece, it will not (in one pass) cut a 45o bevel through this same thickness workpiece . nor will it continuously sever workpieces of this maximum thickness with the speed and ease to be expected from a larger size bench saw.

If you will do hobby work, taking two passes for a cut through and/or sawing occasional large pieces more slowly may not greatly inconvenience you . but if the bench saw will contribute toward your income, it is far better to purchase the largest size saw you are likely to need. Each larger size Craftsman saw also offers other advantages: A larger worktable: easier handling blade ele-

SQUARE-CUT DEPTHS

45° BEVEL-ANGLE CUT DEPTHS

MAXIMUM CUTTING DEPTHS FOR 8-, 10- AND 12-IN. SAWS

vation and tilt controls; a more accurately aligning and positive locking fence; superior ruggedness and stability - and, in the case of the 12-in. saw, an integral motor and stand and built-in provision for sawdust collection. All Craftsman bench saws are designed and built for accurate, dependable sawing.

POWERING A BENCH SAW

Motor Selection

The 7-1/2- and 12-in. Craftsman saws have built-in, direct-drive motors that develop all the power needed for the work intended. Motors are not furnished with the 8-in. and 10-in. saws. The 8-in. saw should have at least a 3/4 hp motor; the 10-in. at least a 1 hp motor. In each case use a 3450 rpm capacitor-start motor. preferably with a built-in overload protector. Also, use the size motor pulley recommended in the instruction sheet furnished with your tool. Never underpower your saw if you expect it to do excellent work.

Proper Wiring

Make certain that your power supply is the same rated voltage and current (AC or DC) specified on your tool motor nameplate ... and, if AC, that the phase and cycle are the same. Moreover, if there is any doubt, check (or have the power company check) to make certain that the voltage being

delivered to your motor does not drop more than 10% below the rated amount. An excessive voltage drop can occur, for instance, in an old building not originally wired for all the electricity being consumed by the many modern electrical appliances now in use ... or in a farm barn to which the wiring is undersized or poorly insulated. Any drop in voltage has the same effect on your tool motor as overloading it . can, if consistently extreme. damage the motor and will, in any event, make it run less efficiently.

For the above reason, also make certain that any extension cord you use for connecting the motor to the power supply is of sufficient size.

RECOMMENDED WIRE SIZES

| LENGTH | WIRE | SIZE |

|---|---|---|

| OF RUN | For 115V | For 230V |

| Up to 100 ft. | No. 10 | No. 12 |

| 100 to 150 ft. | No. 8 | No. 10 |

| 150 to 200 ft. | No. 6 | No. 8 |

| 200 to 400 ft. | No. 4 | No. 6 |

Even a thermal overload protector does not protect a motor from line voltage surges due to short circuits or other causes. For maximum protection, fuse the circuit to your motor with a time-lag fuse rated the same as the running amps specified on the motor nameplate. Also, for your own safety, properly ground the adapter plug furnished with your motor.

PROPER GROUNDING ADAPTOR

GROUNDIN

MOUNTING A BE

For sawing ease an cutting, the saw mu it will remain sta table top reasonab height convenient t at your waistline above). Work can straight on a tilted a saw that "walks" duction-type workth in a substantial ben is flush with the s extended at each provide ample worl space is limited, ho steel bench or ped A3) (or, for the 12 integral stand), will versatile arrangeme ing permits the s about as required different shapes of or to be stored aga not in use.

Ample light is essen tool operation prope

SO BEVEL-ANGLE CUT DEPTHS

IN SAWS

motor does not drop low the rated amount. age drop can occur an old building not for all the electricity by the many modern nces now in use ... to which the wiring r poorly insulated. ore has the same efmotor as overloading onsistently extreme or and will, in any run less efficiently.

reason, also make extension cord you ng the motor to the of sufficient size.

DED WIRE SIZES

|

WIRE

or 115V |

SIZE |

|---|---|

| No. 10 | No. 12 |

| No. 8 | No. 10 |

| No. 6 | No. 8 |

| No. 4 | No. 6 |

overload protector t a motor from line lue to short circuits For maximum procircuit to your motor fuse rated the same mps specified on the . Also, for your own ground the adapter ith your motor.

MOUNTING A BENCH SAW

For sawing ease and for accuracy in cutting, the saw must be mounted so it will remain stationary, with the table top reasonably level and at a height convenient to you (generally, at your waistline or a few inches above). Work cannot be fed truly straight on a tilted table top, nor to a saw that "walks" about. For production-type work the best mounting is in a substantial bench the top of which is flush with the saw table top and extended at each side and back to provide ample work area. Wherever space is limited, however, either the steel bench or pedestal stand (page A3) (or, for the 12-in, saw, its own integral stand), will provide a more versatile arrangement. Such a mounting permits the saw to be moved about as required to accommodate different shapes of workpieces . or to be stored against a wall when not in use.

Ample light is essential for doing any tool operation properly — and safely.

Light source preferably should be directly above the table top to avoid casting shadows. It isn't feasible to mount a worklight directly on a bench saw table edge . but provision should be made, wherever necessary, for a worklight (bage A4) or an overhead fixture that can be directed down at the table ton

ADJUSTING A BENCH SAW

Accuracy Is Important

Accurate adjustments are necessary not only to produce good work, but also for safety. A saw that is not trued cannot be expected to make straight, clean cuts . moreover. if fence and blade are not parallel the work can become wedged between them and be kicked back with considerable force. On the other hand. even an inexpensive tool can be made to produce excellent work, if properly adjusted. Checkyour saw adjustments frequently.

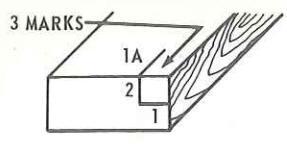

1. Paralleling Blade With Grooves

Set the blade at its highest. Mark the tooth that is just above the table at the front edge of the blade. Measure the distance from the outer edge of this tooth to the nearest edge of the right-hand table groove. Now rotate the blade slowly by hand to place this same tooth just above the table top at the rear edge of the blade. Again measure the distance between this tooth and the same groove. The two measurements should be identical.

If necessary shift the table or trunnions on the base until the measurements are equal. This usually can be done by loosening the bolts that secure the table or trunnions to the base, there being enough play at the bolt holes to permit adjustment when the table edge is tapped lightly with a wooden mallet.

2. Paralleling Fence With Blade

Refer to the instructions packaged with your bench saw. In general, the fence — at any setting — must be parallel to the table grooves. You can check this by measuring the dis-

tances (which must be equal) between each end of the fence and one of the grooves . and by hand setting the fence, as you lock it at a position, if necessary. However, a good fence should be self-aligning if in proper adjustment as explained in the instructions for your model saw.

3. Adjusting Tilt Scale

Using an accurate square, set the blade at an exact right angle to the table top. Now adjust the pointer on the tilt scale to read "O". Also, if there is a stop nut (or nuts) to restrict movement below "O" (or above "45"), make these adjustments also.

4. Adjusting Miter-Gauge Scale

Engage the locating pin in its 00 detent, then adjust (and tighten) the pointer at the 0 mark on the scale. If there is no locating pin, use an accurate square to set and lock the gauge head at 900 to the gauge blade. In each case, make a trial cut, check the cut with a square . and readjust as necessary.

5. Adjusting the F

If there is a scale the fence exactly as measured with tighten the fence p scale. Do this at a

6. Adjusting the St

The splitter serve (saw cut in workpic the cut from spring the blade sides, an complish this the perfectly aligned Shims are furnishe this purpose. Refer packaged with your

SAW MAINTENA

Keep your saw as and lubricated in ac instructions furnis particular, keep th the blade elevating clean and dry to pro of sawdust that will erations. Keep tab guide bar and miter a rust inhibitor Above all, keep the and sharp.

SELECTING THE SAW BLADE

Your Craftsman E fitted with a Cra Blade selected for is an excellent all-----------------------------------

All toothed blades

FOR B

st be equal) between fence and one of the d by hand setting the ck it at a position, if wever, a good fence ligning if in proper xplained in the inur model saw.

Scale

ate square, set the at right angle to the adjust the pointer on read "O". Also, if nut (or nuts) to rebelow "O" (or above e adjustments also.

er-Gauge Scale

ting pin in its 00 dest (and tighten) the mark on the scale. locating pin, use an to set and lock the 0 to the gauge blade. ke a trial cut, check square . and reary.

5. Adjusting the Fence Scale

If there is a scale, position and lock the fence exactly 1 in. from blade as measured with a ruler. Set and tighten the fence pointer at 1 on the scale. Do this at each side of blade.

6. Adjusting the Splitter

The splitter serves to keep the kerf (saw cut in workpiece) open to prevent the cut from springing closed against the blade sides, and binding. To accomplish this the splitter must be perfectly aligned with the blade. Shims are furnished with the tool for this purpose. Refer to the instructions packaged with your saw for their use.

SAW MAINTENANCE

Keep your saw as clean as possible, and lubricated in accordance with the instructions furnished with it. In particular, keep the Acme threads of the blade elevating and tilting screws clean and dry to prevent accumulation of sawdust that will hamper their operations. Keep table top, fence, fence guide bar and miter gauge coated with a rust inhibitor or preservative. Above all, keep the blade rust free and sharp.

SELECTING THE PROPER SAW BLADE

Your Craftsman Bench Saw comes fitted with a Craftsman Kromedge Blade selected for general use. This is an excellent all-purpose blade, but will not do special cutting with the ease, precision and smoothness to be obtained by using a blade especially designed for the purpose. It will greatly improve the quality of any specialized cutting you do — such as tenoning, plywood or hardboard sawing. etc. — to use the proper blade.

All toothed blades belong in one of

three classes, depending upon how the blade is designed to provide its own clearance so as not to bind in the kerf.

SWAGED-TOOTH CLASS. The teeth of this type blade are wider than the rest of the blade. There may be only 8 or as many as 40 teeth. Carbidetipped blades belong in this class ... the (wider) carbide tips are brazed onto the outer edges of the teeth.

HOLLOW-GROUND CLASS. This type of blade is relatively thick at the edge and progressively thinner toward the hub due to tapering of the sides. Full hollow-ground blades are thus tapered from rim to center, and the teeth do not require setting. There is, however, a new class of "Free-Cut" blades which have a thick, wobblefree, flat-ground center hub surrounded by a taper-ground, "working-area" rim — and the teeth of this type may be slightly set. All smooth- and thincutting blades are fully or partially tapered, some without and some with set teeth.

SET-TOOTH CLASS. A blade of this type is uniform in thickness throughout, but the teeth are set (bent) outward at the edge according to a predetermined pattern so that the cutting edge is effectually wider. The general-purpose chisel-tooth and faster, rougher-cutting blades are mostly of this type.

FOR BEST PERFORMANCE ALWAYS KEEP YOUR SAW IN ADJUSTMENT - AND YOUR SAW BLADES SHARP

Fast-Cutting Shop and Contractors' Blades

CHISEL-TOOTH COMBINATION. All-purpose, sturdy blade for ripping, crosscutting or mitering of any wood. Is an excellent contractor's framing blade. Set-tooth.

CABINET COMBINATION. For general cabinetwork. Rips, crosscuts or miters in hard or soft woods. An excellent contractor's trim and finish blade. Settooth.

PLYTOOTH BLADE. For general purpose sawing of plywood in any direction without splintering - or crosscutting and mitering on hard or soft wood. Excellent for sawing Celotex and other wood-fiber materials. Set-tooth.

MASONITE SIDING BLADE. Designed especially for fast, continuous sawing of Masonite siding, decorative hardboards and waterproof plywoods. Set-tooth.

NAIL-CUTTING BLADE. The only blade for sawing through salvaged lumber or rough timber that may contain an occasional nail or wire. Made of extrahard alloy steel to withstand such usage. Will rip, crosscut or miter cut. Set-tooth.

Heavy-Duty, Production-Type Blades

SAFE-SAW CARBIDE-TIPPED BLADE. Has 8 or 12 teeth (depending upon size). Rips, crosscuts or miters with exceptional smoothness and freedom through any wood - even the hardest. Willoutlast other types many times. Is not, however, intended for nail cutting. Swaged-tooth.

MASONITE CARBIDE-TIPPED BLADE. An industrialquality, alternate top-bevel ground blade designed for continuous sawing through Masonite and similar abrasive materials. Excellent for crosscutting or mitering of all woods, plywoods, veneers, Celotex, plastics, Formica and plastic laminates. Swaged-tooth.

A SHARP BLADE IS THE SAFEST

6

Professional, Cab

FREECUTTING R

for clean, fast saw

Extra deep gullets

eliminate binding. tion and wobble. A

and set for cross

soft or hard woo minimizes vibratio and more accurate

SMOOTH FREEC

Sears finest comb joint cuts, leaving

cuts or miter cut and wobble; expa

true, quiet operati

THIN-RIM SATIN best blade for pr and similar mate

mitering and cutti

rim produces an e

TENONING BLAI average blade that with precision crosscuts or mit Taper-ground.

Dado Heads and

(See pages A2 and 1 The conventional is for heavy-duty the adjustable da extra long serv type dadoing. Bot

All-nurnose sturdy or mitering of any r's framing blade.

meral cabinetwork. ard or soft woods. finish blade. Set-

t splintering - or or soft wood. Exper wood-fiber ma-

gned especially for e siding decorative ds. Set-tooth.

gh timber that may e. Made of extra-

crosscuts or miters freedom through outlast other types tended for nail cut-

ADE. An industrialblade designed for e and similar abrasscutting or miters, Celotex, plastics, vaged-tooth.

l purpose sawing of

ly blade for sawing h usage. Will rip,

LADE. Has 8 or 12

Professional Cabinetmakers' Blades

FREECUTTING RIP BLADE. Taper ground and set for clean, fast sawing of all solid woods with the grain. Extra deep gullets sweep out all sawdust to practically eliminate binding. Extra heavy hub minimizes vibration and wobble. Also excellent for resawing

FREECUTTING COMBINATION BLADE, Taper ground and set for crosscutting, ripping or miter cutting of soft or hard woods - without hinding Heavy hub minimizes vibrations and wobble. Cuts cleaner faster and more accurately than ordinary flat-ground blades.

SMOOTH FREECUTTING COMBINATION BLADE. Sears finest combination blade. Makes precision gluejoint cuts, leaving a smooth, square cut, Rips, crosscuts or miter cuts. Heavy hub minimizes vibration and wobble: expansion holes and slots ensure free true, quiet operation. Taper ground and set.

THIN-RIM SATIN-CUT VENEER BLADE. Sears best blade for precision cutting of plywood, veneers and similar materials. without splintering. Also for mitering and cutting of laminates and plastics. Thinned rim produces an extra fine cut. Taper-ground.

THIN-RIM SATIN-CUT COMBINATION BLADE. Sears best all-purpose cabinetmaker's blade for use on solid woods - all fine trim and finish work, Rips. crosscuts or miters. Extra heavy body provides stability: thinned rim produces an extra fine, smooth cut. Taper-ground.

TENONING BLADE (8-IN. ONLY). A thicker than average blade that cuts square-bottom 1/8-in, grooves with precision - to assure hairline joints. Rips. crosscuts or miter cuts through any type of wood. Taper-ground.

Dado Heads and Adjustable Dado -

(See pages A2 and A3 for illustrations.) The conventional flat-ground dado is for heavy-duty dadoing . and the adjustable dado blade will give extra long service for production type dadoing. Both produce clean-cut

grooves in solid woods. However, for clean, smooth, splinter-free dadoing of plywood, veneer, laminate, mosaic and furniture wood we strongly recommend use of the thin-rim, satincut dado made especially for such work.

Metal-Cutting Blades

STEEL SLICER. A special design blade that quickly slices through sheet iron or steel by "burning" a kerf. Sparks are produced and Safety Glasses (page A4) should be worn. Not recommended for sawing aluminum, brass or other non-ferrous metals; but will saw cleanly through Plexiglas, Lucite and similar plastics if work is fed steadily (without stopping) so that no one spot becomes over-heated.

NON-FERROUS METAL BLADE. Designed for sawing aluminum, brass, bronze, copper, zinc and other non-ferrous metals. A professional-quality, extra durable blade. Safety Glasses (page A4) should be worn . and best results will be obtained by using a lubricant (such as a tallow candle) on blade teeth, and a moderate rate of feed.

USE OF SAW-BLADE STABILIZERS

Tapered steel Blade Stabilizers (page A3) clamp blade rigidly to reduce

blade wobble. Produce truer, smoother cuts and result in longer blade life. Recommended for all flat-ground blades, but not for hollow-ground or thickened-hub (thin-rim) blades.

KEEP YOUR BLADE RUST FREE AND SHARP FOR SMOOTH, ACCURATE CUTTING

For sharpening and/or reconditioning see any Sears Retail or Mail Order Store . or refer to Sears Do-It-Yourself Booklet, "How to Sharpen", Cat. No. 9-2924.

Floppy sleeves, loose-end of appa tion to danger as to being caught by (or even by an ung to pull you into con should either be fa or be tightly rolle ones); you should ... or loose shirt apron, tied in b Also - and very glasses or some face shield (page eyes from sawdust - particularly if v tle plastic or meta

Never Stop Bein

One moment of i you a painful inj operations are so done that some op come careless a not fall into this

n blade that quickly by "burning" a kerf. Glasses (page A4) ed for sawing alubus metals; but will aucite and similar vithout stopping) so ted.

Designed for sawper, zinc and other mal-quality, extra age A4 ) should be e obtained by using dle) on blade teeth,

duce truer, smoothin longer blade life. or all flat-ground or hollow-ground or n-rim) blades.

P rs Retail Yourself

CHAPTER 2 STANDARD SAWING OPERATIONS

--------------------------------------

Dress Properly

Floppy sleeves, a necktie or any loose-end of apparel are an invitation to danger as these are subject to being caught by the whirling blade (or even by an unguarded motor shaft) to pull you into contact with the blade (or wrap you around the shaft). Sleeves should either be fastened at the cuffs. or be tightly rolled up (or be short ones); you should not wear a necktie . or loose shirt tails. etc. A work apron, tied in back, is excellent. Also - and very important - wear glasses or some type of goggles or face shield (page A4) to protect your eves from sawdust or flying splinters - particularly if working with a brittle plastic or metal.

Never Stop Being Careful

One moment of inattention can cost you a painful injury. Most sawing operations are so quickly and easily done that some operators tend to become careless and inattentive. Do not fall into this unsafe habit .

and don't permit anyone else to distract you. Always be alert!

A Low Blade Is Safest

When the blade is elevated just enough to clear the top of the workpiece there is, obviously, less exposed blade to cause possible injury than when a large amount of blade projects above the workpiece. Also, in most cases, there will be less of the blade inside of the kerf — and, therefore, less likelihood of kickback should you accidentally twist the workpiece.

These factors make it generally more desirable to operate with a "low" blade, even though a low blade — due to the longer angle of blade inside the workpiece — consumes a little more power and requires a little more feed pressure than a high blade. A properly powered saw will produce just as excellent work with the blade low.

Avoid Kickbacks

Anything that will cause the blade to bind in the work will cause a kickback (a thrusting of the workpiece backwards, toward the operator). Most common causes of kickbacks are: 1) Twisting the workpiece out of line when freehand feeding. 2) Misalignment of fence and blade so that work becomes wedged between them when feeding. 3) Failure to use the splitter (or to otherwise hold the kerf open) so that a long kerf closes around the saw blade. 4) Feeding too rapidly especially if wood is resinous, damp or knotty. 5) A dull or rusty blade. 6) Holding the work too loosely or carelessly.

Under certain circumstances kickback can occur with sufficient violence to cause injury. On the other hand, if you will use the splitter (or wedge the kerf open when necessary), use a clean, sharp blade, and feed the work carefully, there is little chance for a severe kickback to occur. And if you hold the workpiece firmly down on the table at all times, any slight kickback tendency that might develop will cause no problem. Use of a Hold-Down (page A4) is recommended for all workpieces too large or small for your hands to hold firmly down.

Warped or crooked workpieces also can cause kickback, especially if placed on the table or against the fence in a manner that permits rocking or twisting while feeding. Always make certain that the work will slide on the table or along the fence without tendency to bind the saw blade.

Keep Hands Clea

Never put your h allowing them to g or in line with the work. One mista to allow a thumb over in front of th ing, with the inter hand into a safe the cut is nearly tracted you could hand to safety so your hand could the blade. Anoth is to squeeze the and blade to push workpiece. If w hand should slip trouble.

Best practice is hand in such a pos chance, it should suddenly forward by one side of t toward the blade blade and fence least as much a flattened hand), a hand to push wor ... then hook t over the fence steady, and tuck in under your pal the workpiece en space is too narr push stick (page to back of saw through.

In General

Ripping is the saw with the grain. with the fence as and maintain the width for the cut. can be ripped s with a sharp blade impossible to hol cut without using reason the work

10

Keen Hands Clear of the Blade

Never put your hands in jeopardy by allowing them to get close to the blade or in line with the blade when feeding work One mistake easy to make is to allow a thumb or finger to hang over in front of the blade while feeding with the intention of sliding your hand into a safe position later when the cut is nearly finished. If distracted you could forget to slide your hand to safety soon enough . or your hand could slip and carry on to the blade. Another common mistake is to squeeze the hand between fence and blade to push through a narrow workpiece. If work should bind or hand should slip you might be in trouble

Best practice is to always keep each hand in such a position that if, by any chance, it should be pushed or carried suddenly forward it will pass safely by one side of the blade instead of toward the blade. If space between blade and fence is amply wide (at least as much as the width of vour flattened hand), and you do use your hand to push work through this space then hook the two outer fingers over the fence to hold your hand steady, and tuck your thumb safely in under your palm to hook it against the workpiece end (for pushing). If space is too narrow for safety. use a push stick (page 13) - or walk around to back of saw and pull the work through.

In General

Ripping is the sawing through of wood with the grain. It generally is done with the fence as a guide to position and maintain the work at the correct width for the cut. In fact, most woods can be ripped so freely and easily with a sharp blade that it is practically impossible to hold to a true, straight cut without using the fence. For this reason the work must be held firmly

Two Obvious Don'ts

Don't reach up to the saw blade to grab a piece of free wood — until the blade has stopped. Don't let the floor become littered so that your footing is uncertain. Also, sawdust is a definate fire hazard, especially after having been damp, and should never be allowed to accumulate.

--------------------------------------

against the fence (as well as firmly down on the table) while feeding it. Hence, the workpiece edge against the fence must be straight, if cut is to be straight.

NOTE

If there is no straight edge to slide along the fence refer to page 10 , or to page 29 for use of cut-off board.

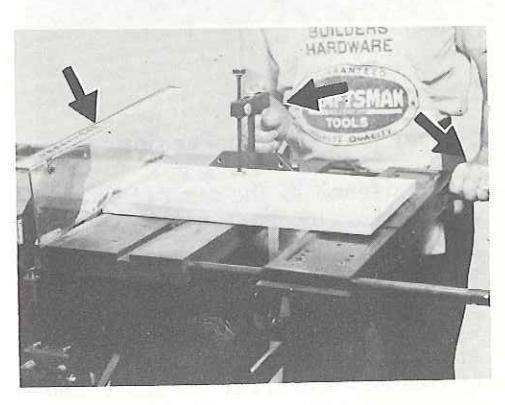

Proper Set-Up and Feeding

Set the fence to the desired width of cut, either by using a mark on the workpiece, the fence guide-bar scale, or a ruler. Plan so that the kerf will be in the scrap side, which can be the portion of workpiece between the blade and fence or the portion at other side of blade, whichever is most convenient. Make certain (if there is any cause for doubt) that fence is aligned parallel to the blade, then lock it in position. Turn motor on.

Use of the saw guard is recommended; the splitter should always be used when making any rip cut longer than three times the saw blade diameter especially if wood is green or damp. Should the splitter not be used, then work should be stopped, after ripping a 12- to 18-in. kerf, and a wedge should be inserted to hold the kerf open, before finishing the cut. The longer the cut you make without having the splitter or a wedge to hold the kerf open, the more likely will be the chance of binding the blade to cause kickback and spoil the cut.

If the fence scale or a ruler is used the setting will be distance A – and the distance B will be workpiece width minus A plus thickness of the blade.

SETTING THE FENCE

Place work flat on table, holding it down and against the fence, and feed it to the blade about as fast as the blade can take it without noticeable overloading of the motor. Try to keepfeeding at a uniform rate throughout, changing the pace only if knots, etc. make this necessary. A uniform feed produces a smoother cut. Stopping at any point may leave a saw mark or discoloration on the cut edge. However, if for any reason you have to walk around to the back of the saw (to insert a wedge or to finish by pulling through), back the work up an inch or two and continue to hold it firmly down and against the fence while walking around. Preferably, do not stop the blade; but if you should, be certain it is again running at full speed before resuming the operation.

Never reach o part of the w through it. Ho most practical, side of the sa and grasp the front edges to h the fence while tion to feed it t

If necessary, ripping operati to the rear of t work through. keep your hand while walking not in use be squeeze the ke the work thro avoid pulling sible . it i work against straight cut.

Handling Narr

It is difficult against the fem – and often the feed it all the For holding we the fence the down (page A4 best is the us down and hold a wood block held in one h work during the (when end is push stick.

12

ruard is recommended: ould always be used ny rip cut longer than saw blade diameter ood is green or damp. tter not be used, then stopped, after ripping n. kerf. and a wedge rted to hold the kerf nishing the cut. The you make without havr or a wedge to hold the more likely will of binding the blade to and spoil the cut.

ruler is used the setting will be stance B will be workniece width

THE FENCE

on table holding it st the fence, and feed about as fast as the it without noticeable the motor. Try to uniform rate throughe pace only if knots, ecessary. A uniform smoother cut. Stopint may leave a saw ration on the cut edge. any reason you have o the back of the saw dge or to finish by back the work up an l continue to hold it d against the fence ound. Preferably, do le; but if you should, again running at full uming the operation.

Never reach over the blade to that part of the work that has passed through it. However, if this seems most practical, you can stand at the side of the saw opposite the fence. and grasp the work at its back and front edges to hold it down and against the fence while using a sidewise motion to feed it through the blade.

If necessary, you can complete a ripping operation by walking around to the rear of the saw and pulling the work through. Hold the work - but keep your hands clear of the blade while walking around. If splitter is not in use be very careful not to squeeze the kerf closed while pulling the work through. On the whole. avoid pulling through if at all possible . it is difficult to keep the work against the fence for a true, straight cut.

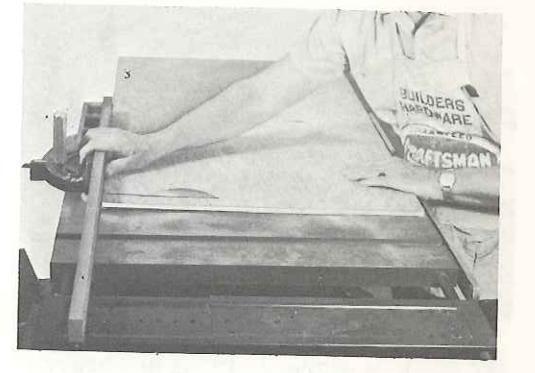

Handling Narrow Work

It is difficult to hold narrow work against the fence with your hands alone - and often too risky to attempt to feed it all the way through the blade. For holding work down and against the fence the best device is a holddown (page A4) used as shown. Next best is the use of a homemade holddown and hold-in . or you can use a wood block fashioned as shown and held in one hand. For feeding the work during the last part of the cut (when end is on table top), use a push stick.

Handling Long Work

Work that is so long that it hangs over the back of the saw table for more than half its length toward the end of a ripping operation is likely to start springing up and down — and to thus shift its position and spoil the cut. To avoid such occurrence, provide a support to catch and support the work behind the saw table. An ordinary wooden horse of proper height, or a homemade roller support will serve this purpose.

When starting to feed such a workpiece also be careful to hold it up exactly level. Again, a sawhorse or roller support may prove helpful.

- RESAWING

Resawing is the rip sawing of a thick board through its edge to produce two thinner boards. For instance, a 2x4 can be resawed to make two 1x4s. The only difference between this operation and ordinary ripping is that the work is on edge — it stands higher above the table and has a relatively narrower (and more wobbly) edge on which to rest. Also, if the workpiece is too wide (high), the blade — even at its highest elevation cannot penetrate it, and two cuts (one from each edge) are needed to slice the work in two.

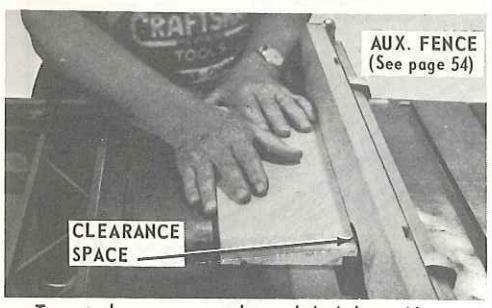

To assure a true, straight cut both a hold-down and a hold-in should be used. When the on-edge workpiece is lower than the fence, preferably use the Hold-Down Attachment ( page A4 ). If work stands higher than the fence, use an extra-high auxiliary fence with the attachment ... or you can clamp a wood block to it to serve as a hold-down (as shown), and clamp a wood spring to the table to serve as a hold-in. Both pieces should be positioned to allow the workpiece to slide without binding.

When two cuts from opposite edges

are required, these should be made to overlap about 1/2 in. at the approximate center of the workpiece. If the first cut is too deep, the kerf may warp closed and bind the blade while making the second cut. Therefore, try to make the first cut only to the work center . then elevate the blade 1/2 in. more to make the second cut.

In General

Crosscutting is the wood across the g has the grain runn each board, a cro made to divide a bo length pieces . lies crossways on the operation. T cannot be used to which must either or with the help Whichever way yo reference point fi sure the piece to must be guided drawn on the work

start and c tion using same side is less accu

A crosscut is unde 900 to the long of (other angles are if fore, the miter gas It may be used in two table grooves erators prefer the In such case the hold the work in gauge and to simu gauge to feed the hand is free to a the right-hand ta the hand positions

Nork

b long that it hangs of the saw table for its length toward the c operation is likely g up and down — and position and spoil id such occurrence, t to catch and support the saw table. An horse of proper made roller support urpose.

feed such a workareful to hold it up gain, a sawhorse or by prove helpful.

e should be made to in. at the approxie workpiece. If the leep, the kerf may bind the blade while d cut. Therefore, irst cut only to the . then elevate the hore to make the

Ē

In General

Crosscutting is the sawing through of wood across the grain. Since lumber has the grain running the long way of each board, a crosscut generally is made to divide a board into two shorter length pieces . and the workpiece lies crossways on the saw table during the operation. The fence ordinarily cannot be used to guide the work which must either be guided freehand or with the help of the miter gauge. Whichever way you do it there is no reference point from which to measure the piece to be cut off: the cut must be guided by a mark or line drawn on the workpiece.

If workpiece is long and heavy start and complete the operation using both hands at the same side of the blade. This is less accurate but a lot safer.

A crosscut is understood to be one at 90° to the long edges of the board (other angles are miter cuts). Therefore, the miter gauge is set at "0". It may be used in either one of the two table grooves, though most operators prefer the left-hand groove. In such case the left hand is used to hold the work in contact with the gauge and to simultaneously push the gauge to feed the work ... the right hand is free to assist as needed. If the right-hand table groove is used the hand positions are reversed.

Freehand Crosscutting

If accuracy is unimportant this is a practical quick and simple operation. Align your mark with the blade by eye and hold the workpiece with both hands at points equally distant from, and at each side of, the mark. Using uniform pressure with each hand, and watching carefully to keep the blade on your mark and (at same time) the workpiece moving squarely with the blade, push the workpiece through the blade. However, you cannot make the entire cutoff using both hands. If you should, when the blade has cut deeply enough into the work, the force of your pushing will tend to pinch the kerf around the blade - and the blade will kick the work back toward you with some force, breaking (instead of sawing) the two pieces apart. Therefore when there still is about 1/3 of the wood remaining to be cut, remove one hand entirely - and complete the cut using one hand only. This allows the unheld end to fall free when cut.

Miter-Gauge Crosscutting

Long Workpieces

The accuracy with which you can crosscut on a straight line depends entirely upon how well you keep the work from sliding or wobbling on the gauge while feeding it. If work is long this is difficult to do with your hands alone. For this reason it is advisable to use a Miter-Gauge Hold-Down Clamp and/or an auxiliary mitergauge extension. The extension is a straightedge board screwed to the miter-gauge face, and long enough to serve your purpose. If it extends beyond the blade it will become slotted in use as shown. A strip of electric tape stuck to the board face will help further to prevent side slipping of the work. And side extensions on the saw table also will help to support and guide extra long workpieces.

Extra Wide Workpieces

When the work is so wide (approx. 15 in. or more) that it completely covers the table in front of the blade, the miter gauge, if placed behind the work, would be off of the table. In such case reverse the gauge to place it ahead of the work for the start of the cut — then stop and relocate the gauge in normal position to finish the cut.

BEVEL-ANGLE CUTTING

With all Craftsman saws bevels – at angles from 1° to 45° – are cut by tilting the arbor and blade. Both rip cuts and crosscuts are made (with the blade tilted) in the same ways previously explained for straight ripping and crosscutting. Since the blade tilts counterclockwise, any bevel cut by the blade will slope downward and toward the right, starting at the top side of the workpiece. Hence, if it is desired to have the finished bevel slope downward and toward the left, the workpiece must be placed on the table upside down.

If you know the b simply tilt the saw Keep in mind that on the scale is the vertical blade posi blade position; t between the slopin piece and the botto at the left of the complementary an angle . and i between the slopin side of the wood blade will be th plus 90°. For th of the blade the co is at top and the bottom.

A miter is a diagon a straight crossc complished freehan not important) or wi The saw blade is n

with which you can straight line depends w well you keep the ng or wobbling on the ing it. If work is long to do with your hands reason it is advisable r-Gauge Hold-Down an auxiliary miter-The extension is a ard screwed to the e, and long enough to pose. If it extends it will become slotted . A strip of electric board face will help it side slipping of the e extensions on the will help to support ong workpieces.

aan saws bevels to 450 - are cut or and blade. Both cosscuts are made tilted) in the same xplained for straight cutting. Since the terclockwise, any ade will slope downthe right, starting of the workpiece. tesired to have the be downward and toworkpiece must be upside down.

If you know the bevel angle desired. simply tilt the saw blade to this angle. Keep in mind that the angle indicated on the scale is the angle between the vertical blade position and the sloping blade position; the angle produced between the sloping side of the workpiece and the bottom side of the wood at the left of the blade will be the complementary angle of the indicated angle . and the angle produced between the sloping side and the top side of the wood at the left of the blade will be the indicated angle plus 90°. For the wood at the right of the blade the complementary angle is at top and the other angle is at bottom.

A = Indicated Angle (for instance 30°)

B = Complementary Angle (for instance 30°) C = Indicated Angle + 90° (for instance 120°)

Max. A value = 45°; Min. B value = 45°

A complementary angle is 90° minus the indicated angle.

To bevel an angle greater than 45° set the blade at 45° and elevate the fence edge of the workpiece 1/45th of the workpiece width for each degree over 45°. Example: To cut a 55° bevel on a 1-1/2-in. wide board, elevate the fence edge (secure a strip of wood under this edge) by 1/45th of 1-1/2 x 10 = 1/3 in.

If you want to create a bevel "by eye", draw the cut-off line on top surface of workpiece, then draw a line down the forward workpiece edge from the top line, to represent the desired slope. With the workpiece on the table stand behind the table and, with right hand, tilt the blade until its slope matches the slope of the latter line.

MITER-ANGLE CUTTING -

A miter is a diagonal crosscut. Like a straight crosscut it can be accomplished freehand (if accuracy is not important) or with the miter gauge. The saw blade is not tilted; whatever

miter angle is desired is obtained by positioning the leading edge of the workpiece at some angle other than 900 to the blade, and holding it thus while feeding.

A = Indicated Angle (for instance 35°) B = Complementary Angle (for instance 55°) C = Indicated Angle + 90° (for instance 145°)

For a straight crosscut A = 0°. Max. value at which A can be set is 60°, to right or left. If indicated angle is read at right side of "0" on miter gauge, angle B will be at left-rear and at right-front on workpiece; but if indicated angle is read at left side of "0", angle B will be at right-rear and left-front on workpiece.

If you have a miter gauge that indicates ''90'' when at the straight crosscut position, then angle B is the indicated angle (instead of being the complementary anale).

To freehand miter simply draw a line on workpiece top where cut is desired, then proceed as for a freehand crosscut. More care will be required to align the blade for the start of the cut, and to keep the blade following along your line. With practice, however, you can learn to miter narrow pieces (like 2 x 4s) well enough for rough carpentry work.

For cutting cabinetwork miters - or any miter requiring accuracy - use the miter gauge. You can draw a line, as above, then set the gauge with the work in place to align this line with the blade. Or, if angle is known, simply set the gauge to this angle, then position the work against the gauge with a starting mark aligned with the blade. Since it is difficult to hold work of any length against the gauge face for mitering, without having it wobble or side slip enough to make the cut slightly imperfect, best use the Miter-Gauge Hold-Down Clamp or, at least, an auxiliary extension. If work width requires the gauge to be placed in front of the work (page 16) this does not alter the angle setting.

If you simultaneou angle and a miter a cut is at a compo pound angles are polygons (three "boxes" that taper and also when cu hip-jack and valley

4

As with other an pound-angle cut ca hand. To do so draw both the ba workpiece leading angle on the workp tilt the blade and so the workpiece to blade with these lin

nstance 35°) (for instance 55°) (for instance 145°)

A = 0°. Max. value at which A sht or left. If indicated angle "0" on miter gauge, angle B I at right-front on workpiece; read at left side of "0", angle I left-front on workpiece.

e that indicates ''90'' when at stition, then angle B is the of being the complementary

etwork miters - or ng accuracy - use You can draw a hen set the gauge place to align this e. Or, if angle is the gauge to this on the work against arting mark aligned ince it is difficult length against the ide slip enough to tly imperfect, best Gauge Hold-Down width requires the d in front of the is does not alter

or use v a nge nis is nis is nis ted ult he vto est wn xhe

If you simultaneously saw at a bevel angle and a miter angle, the resulting cut is at a compound angle. Compound angles are used in producing polygons (three or more sided "boxes" that taper like a cone) ... and also when cutting the ends of hip-jack and valley rafters.

COMPOUND-ANGLE CUTTING

B1 = Bevel Complementary Angle C1 = Bevel Indicated Angle + 90° B2 = Miter Complementary Angle C2 = Miter Indicated Angle + 90°

For Workpiece A, B1 and B2 comprise the compound angle; for Workpiece B, use C1 and C2, instead.

As with other angled cuts, a compound-angle cut can be sawed freehand. To do so it is necessary to draw both the bevel angle on the workpiece leading edge, and the miter angle on the workpiece top — then to tilt the blade and simultaneously slant the workpiece to visually align the blade with these lines.

However, the purpose of sawing a compound angle generally is to produce some certain result (a box of so-many sides, for instance). In such case both the bevel and miter angles have known degree values ( page 47 ) . and each can be preset by tilting the blade (for bevel angle) and angling the gauge (for miter angle).

CHAPTER 3 DADO SAWING OPERATIONS

Dado sawing is the removal of wood, using a special dado head or blade, to leave a groove in the workpiece surface or to leave a chamfered or rabbeted workpiece edge. Tenons, which are cut by making 1 to 4 rabbets, can also be quickly and easily made by dado sawing.

USES OF DADO HEADS

A dado head (page A2) is a set of fitted blades designed for cutting kerfs of various widths. The Satin-Cut dado head shown here has two 1/8-in. thick outside cutters, four 1/8-in. thick chippers, and one 1/16in. thick chipper. With it you can cut kerfs in widths of 1/8, 1/4, 5/16, 3/8, 7/16, 1/2, 9/16, 5/8, 11/16, 3/4 or 13/16 in. - and by using paper shims between blades can obtain hairline variations. With all seven blades and a 1/32-in. shim between each pair the max. expanded width is 1 in. Recommended for most joint-making operations (page 46) this satin-cut head makes an exceptionally smooth splinter-free cut, even in plywoods and veneers. The outside cutters cut 1/64th in. deeper than the chippers to provide glue-relief channels for cabinetwork jointing.

The Standard dado head has six 1/8-in. chippers with an assembled width of 1 in. or an expanded (shimmed) width of 1-7/32 in. It is excellent for fast, square-bottom cutting of tenons and decorative grooves.

USES OF ADJUST

The new Adjustable it possible to quick sired kerf width fr in., without removin from the saw arbor the arbor nut, and width by rotating th half of the blade h calibrated in increm but settings between be made (variatio rather than in steps) ing carbide tips ma smooth cuts (up t depth) in all solid plastics, Formica, e

SETTING-UP FOR

The regular table in placed by a Dado In. slot wide enough to largest Craftsman max. expanded widt dado head (or blad the same manner as with this exception wide for the arbor 75% threaded on the collar is used, omit Also, since the split and the guard is no blade will never p work when dadoing removed.

GENERAL RULES

All operations as ex dard sawing (Chapter for dado sawing wir variations.

A dado should never ting through a workp the wider the kerf shallower a cut shou and deep a cut, due wood being remove undue strain on the and the operator.

the removal of wood, dado head or blade, ove in the workpiece eave a chamfered or niece edge. Tenons, by making 1 to 4 rabbe quickly and easily awing.

21

dard dado head has in. chippers with an d width of 1 in. or an (shimmed) width of I. It is excellent for are-bottom cutting of d decorative grooves.

USES OF ADJUSTABLE DADO

The new Adjustable Dado Blade makes it possible to quickly obtain any desired kerf width from 1/4 to 13/16 in., without removing the single blade from the saw arbor. Simply loosen the arbor nut, and dial the desired width by rotating the accentric outer half of the blade hub. The dial is calibrated in increments of 1/16 in. but settings between marks also can be made (variation is continuous rather than in steps). The long-lasting carbide tips make exceptionally smooth cuts (up to max. of 2-in. depth) in all solid woods, plywood, plastics. Formica. etc.

Use a fingernail file (or similar) to brighten tops of dial numbers for easier reading against black backaround.

BUDRS NOCHARE DADO INSERT

ADJUSTABLE DADO CUTS

IF DEEP TAKE SEVERAL PASSES

wood the more this is so. Therefore, to make deep cuts easily and cleanly best do them in several passes at progressively increased depths.

Since a dado takes a bigger bite than a regular blade the likelihood of kickback is increased. The workpiece should be held down very firmly by hand or by use of a hold-down.

SETTING-UP FOR DADOING

The regular table insert must be replaced by a Dado Insert , which has a slot wide enough to accommodate the largest Craftsman dado head at its max. expanded width (or setting). A dado head (or blade) is mounted in the same manner as a standard blade. with this exception: If dado is too wide for the arbor nut to be at least 75% threaded on the arbor when outer collar is used, omit the outer collar. Also, since the splitter cannot be used and the guard is not necessary (the blade will never project above the work when dadoing) these must be removed.

GENERAL RULES FOR DADOING

All operations as explained for standard sawing ( Chapter 2 ) are the same for dado sawing with the following variations.

A dado should never be used for cutting through a workpiece. Moreover, the wider the kerf being cut is the shallower a cut should be. Too wide and deep a cut, due to the amount of wood being removed, will place an undue strain on the tool, the motor and the operator. The harder the

The pointer cannot be properly zeroed on the fence scale for a blade over companying illustration.

WITH HOLD-DOWN

WORKPIECE TOOTH NEAREST FENCE WORKPIECE

GROOVE LINES directly above saw arbor. Do TOOTH NEAREST FENCE,

GROOVE

GROOVE

LINES

LINES

FENCE

ALIGNING A DADO HEAD

Since dadoing is done "blind" (on underside of workpiece) it is almost impossible to feed a workpiece freehand for cutting a straight groove longer than a couple of inches. A guide must be used. The best guide for most operations is your fence, but the miter gauge also can be used, with or without the fence. Measured blade alignment, when using miter gauge alone, can be accomplished as shown in adjoining illustration. Always hold work securely against the gauge while dadoing, either by using a miter-gauge hold-down clamp or stop rod . with an auxiliary extension, if needed.

1/8 in, thick. Therefore this scale cannot be used when dadoing unless you set the pointer to some other starting number, then make the proper allowance when positioning the fence. However, any width dado head (Satin-Cut or Standard) can easily be aligned by eye with marks on your workpiece . or you can measure from either side of the head to position the fence for accurate placement of a dado cut. On the other hand, at any setting wider than 1/4 in. the Adi. Dado Blade creates the groove width by a wobble motion - and you cannot easily align this blade by eye. In fact, accurate alignment requires careful measurement as shown by ac-

EXTRA WIDE DA

When a cut wider needed it must be more passes. Kee left edge of the da the left edge of the right edge will estal edge. When cut i require three or n accurate set-ups t two outside cuts fin guide the work free many more passes a out the center portion spacing refer to foll

TOOTH NEAREST LINE DADO BLADE GROOVE

ANY

CONVENIENT

DISTANCE

MARK (X)

BLADE ALIGNING FOR MITER CUT

cannot be properly zeronce scale for a blade over k Therefore this scale sed when dadoing unless nointer to some other ber then make the proper hen positioning the fence. w width dado head (Satinlard) can easily be aligned marks on your workor vou can measure from of the head to position accurate placement of a On the other hand, at any r than 1/4 in the Adi creates the groove width motion - and you cannot this blade by eve. In ate alignment requires surement as shown by acillustration.

ADECTIM

GROOVE

ANY

DISTANCE

NING FOR MITER CUT

CONVENIENT

MARK (X)

EXTRA WIDE DADO CUTS

When a cut wider than the dado is needed it must be made in two or more passes. Keep in mind that the left edge of the dado will establish the left edge of the cut, and the dado right edge will establish the cut right edge. When cut is wide enough to require three or more passes, use accurate set-ups to accomplish the two outside cuts first, then you can guide the work freehand to make as many more passes as needed to clean out the center portion. For accurate spacing refer to following.

Make cuts 1 and 2 accurately; freehand cut number 3.

ACCURATELY SPACED CUTS

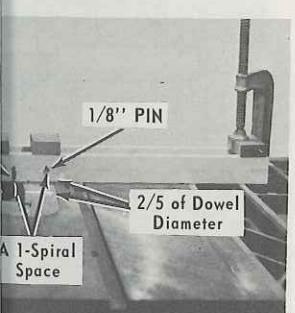

To space ripping operation cuts — or crosscuts made by using the fence and miter gauge together — use the fence scale to reposition the fence for each successive cut. There are several methods of spacing cuts made with the miter gauge alone:

1) Make a series of marks ("MARK X" in illus. "BLADE ALIGNING FOR MITER CUT, page 22) to represent desired spacings — then align each in turn with line on table top, or with a ruler fastened to the miter-gauge extension, as shown.

2) If equal spacings are desired, set the miter-gauge stop rod to catch in the last cut made to position work for the next cut.

3) If producing a number of pieces with identically spaced grooves, use a stepped stop-block for positioning workpiece against miter gauge before starting each successive cut. Clamp this to the table so that first step is flush with the table line used for aligning the first cut.

VEE CUTS-

Vee-shaped cuts can be made by bevel-angling the dado. An equilateral V is cut at a 45o bevel angle with blade lowered so that its top-left edge is at or below table-top level. If blade is raised higher it will cut a 45o bevel-sided groove, instead. When tilted to any other bevel angle it will cut a long-and-short sided V, or a groove with beveled sides at the indicated angle. A truncated V can be formed by making one vee or groove

WORKPIECE

-TABLE TOP

cut to form one side and a second like cut — after rotating workpiece 180° — to form the second side and by then returning the dado to 0° angle to clean out the center of the cut. When straightened, the blade will not cut quite as deeply as when angled . . therefore, to square off the center it must be elevated a little. To this end make a vee cut in some scrap so you can test for the exact amount of elevation required.

After making cut 1 revolve workpiece 180° for remaining cuts. After making cut 2 straighten dado and elevate it as required to make cuts 3, 4 and those needed to clean out area 5.

DADO-HEAD CUTS AT VARIOUS ANGLES

SIDED V

CAUTION

When making bevel dado cuts make certain to check two things: 1) Whether or not the dado will clear the opening in the dado insert...and 2) Whether or not the miter gauge can be used in the right-hand groove without striking the dado. If the dado width (or adj. dado setting) exceeds 1/4 in. and the angle is too great (approx. more than 150), the dado-insert opening is not wide enough to accommodate it — and the operation must be performed without an insert. Similarly, the miter gauge will not clear the dado if used in the righthand groove . . must be used in the left-hand groove instead.

INTO-END RIPPI OR DADOING

This is similar to r but the workpiece narrower and high cut in two. A hol needed — in fact, ually can be ac readily by your ha hold-in is needed: spring (as illustrat be very deep, clan to the table to lead tween it and fence in. If work is ext use an auxiliary fe "snap-on" (page 54)

interfere — or can be bolted and nuts through holes alread

CUTTING A RAB

Except in cases along narrow edge (so that miter gau help guide the work is used as a guide.

m one side and a second - after rotating workpiece ) form the second side n returning the dado to 00 lean out the center of the straightened, the blade will uite as deeply as when . therefore, to square off it must be elevated a little. d make a vee cut in some rou can test for the exact elevation required.

cut 1 revolve workpiece 180° for re-After making cut 2 straighten dado t as required to make cuts 3, 4 and to clean out area 5.

NGLES

certain to not the dado sert ... and n be used in the dado. If exceeds 1/4 c. more than wide enough ion must be y, the miter in the righthe left-hand

CHAPTER 4 PROBLEM SAWING OPERATIONS

INTO-END RIPPING OR DADOING

This is similar to resawing (page 14), but the workpiece generally is much narrower and higher — and is not cut in two. A hold-down is seldom needed — in fact, this function usually can be accomplished more readily by your hands, as shown. A hold-in is needed: use either a wood spring (as illustrated) or, if cut is to be very deep, clamp a straightedge to the table to leave a channel (between it and fence) for work to slide in. If work is extremely high, also use an auxiliary fence — either the "snap-on" (page 54) or as infollowing.

Aux. fence can be clamped to fence, if clamps won't interfere — or can be bolted with flush-head screws and nuts through holes already in the fence.

CUTTING A RABBET

Except in cases where rabbet is along narrow edge of a long board (so that miter gauge is needed to help guide the work), the fence alone is used as a guide.

INTO-EDGE RIPPING OR DADOING

This is even more difficult than the preceding, especially if work is narrow. A very high auxiliary fence generally is needed — one fastened securely to the fence — and one hand should be used to hold work in sliding contact with the top of this auxiliary. Use a push stick in the other hand to simultaneously hold in the work at bottom and feed it to the blade (or provide a channel as preceding).

A RABBET

A Rabbet — With a Saw Blade

Marks 1 and 2 are for the fence settings. 1A makes it easier to set blade height for the first cut.

Two cuts are required — an into-edge cut (made first), then an into-face cut deep enough to remove the edge strip. Mark one end of board to show the rabbet cross-section and use marks for blade elevation and fence

To cut clearance space lower dado below table top and position fence so that aux. fence is about half way over dado. With tool running slowly elevate dado to height desired.

CUTTING A CHAMFER

A simple chamfer is most easily cut with a saw blade tilted to the bevel angle required. When cutting stepped, chamfered edges, however, a dado requires fewer cuts. Stepped, chamfered edges are used to produce raised panels and to decorate table edges.

Cutting must be done along the edge opposite the fence . or the miter gauge must be used, instead. If fence and work are at left side of

settings. Make first (into-edge) cut to exact depth of mark, but when making second (into-face) cut set blade about 1/16 in. below the depth mark so as to remove the edge strip without touching the main workpiece.

A Rabbet With a Dado

Just one — preferably, into face cut is required. Always use a dado wide enough to (or plan last cut of an overlapping series so dado will) overlap the outer edge . and produce a smoother edge. Unless work is too wide always do cutting on workpiece edge opposite the fence. If cut must be made along the edge against the fence, an auxiliary fence must be used — and must be cut out to provide a clearance for the overlapping edge of the dado.

dado it is the top of the edge that is chamfered; if at right side, then the bottom of the edge is chamfered. Use any bevel angle desired. Preferably plan into-face cuts; however, intoedge cuts can be made if more convenient, or if you desire an angle that cannot be cut into-face.

CUTTING A TEN

Tenons having an can be most quick with a dado. Howe fect cabinetmaker with a Tenoning B preferably, using (pages A4 and 51).

With a Dado

Whether tenon has each side is like that a tenon gene that several side-t be needed. Alwa pass of several or accurately as pos

HOW SA

e first (into-edge) cut h of mark, but when d (into-face) cut set '16 in. below the depth remove the edge strip og the main workpiece.

h a Dado

referably, into face d. Always use a dado o (or plan last cut of g series so dado will) ter edge . and proer edge. Unless work always do cutting on e opposite the fence. made along the edge uce, an auxiliary fence — and must be cut out learance for the overthe dado.

top of the edge that is at right side, then the dge is chamfered. Use e desired. Preferably cuts; however, intobe made if more conyou desire an angle cut into-face.

CUTTING A TENON

Tenons having any number of sides can be most quickly and easily made with a dado. However, the most perfect cabinetmaker's tenons are made with a Tenoning Blade ( page 7 ) and, preferably, using a Universal Jig ( pages A4 and 51 ).

With a Dado

Whether tenon has one to four sides, each side is like a rabbet — except that a tenon generally is wider so that several side-by-side passes may be needed. Always make the first pass of several on the inside, and as accurately as possible — then clean

off the outer portion with subsequent passes (which can be done freehand). Preferably produce a tenon with intoface cuts, though on-edge cuts can be used. Note that a Satin-Cut Dado Head can, in some cases, create an undesirable profile unless glue-relief channel(s) is (are) eliminated. To eliminate channels advance successive passes less than 1/8 in.

HOW SATIN-CUT DADO TENONS CAN BE MADE TO APPEAR Unless side(s) of tenon are exposed, as illustrated, Into-the-Face glue-relief channels cannot be seen after assembly. An On-Edge channel will show.

Tenons - With a Saw Blade

For clean, square appearing shoulders always make the shoulder cuts first - to exact depths required - then make the cheek and/or edge cuts, setting the blade about 1/16 in. below exact depth, as for a rabbet second cut ( page 25 ). If you do not have a Universal Jig, use both the miter gauge and the fence ( page 22 ) when making shoulder cuts - and use intoend ripping method ( page 25 ) for the cheek and edge cuts. Or, you can make a tenoning jig ( page 56 ) to hold work for the cheek and edge cuts.

When using a jig (Universal or homemade) there are two methods of assuring accuracy: 1) Clamp the work directly to the jig, then position the jig so as to cut the cheek (or edge) on the side away from the jig. After cutting the first cheek (or edge) turn the work around to cut the opposite one with same jig setting as the first. This method will center the tenon accurately, but the tenon width will be subject to the accuracy of your measurements and the jig setting.

2) When making the first cut use a backing block between the jig and the work and position the jig to cut the cheek (or edge) on the same side as the jig. Have the backing block the exact width of the desired tenon plus the saw-blade width (1/8 in. for a tenoning blade). To make the second cut remove the backing block — with-out turning work or altering the setting. This method will assure a tenon of the exact width desired, but centering of the tenon will depend upon the accuracy of your measurements and the jig setting.

NOTE

If you use two outside dado blades (or a pair of tenoning blades) accurately centered, exact width tenons (up to about 3/4-in. max. width) can be cut as shown. Exact spacing between blades is obtained by using a collar and paper shims.

DADO GAINS A STOPPED GRO SIMILAR SAW

To cut a gain m show end of gain desired depth of with back edge where it rises a Holding workpied block to table against rear edg or, if workpied aligning marks

HANDLING OD

It is sometimes a straight cut cannot be guided gauge (like half such jobs a home ( page 54 ) is ve guide strip at b along the miterthe two parts an top) it can be or be used freeh

between the jig and the ition the jig to cut the ge) on the same side as the backing block the f the desired tenon plus the width (1/8 in. for a the backing block — withork or altering the setthod will assure a tenon width desired, but centenon will depend upon of your measurements ting.

two outside dado a pair of tenoning curately centered, tenons (up to about x. width) can be wn. Exact spacing des is obtained by ar and paper shims.

DADO GAINS AND STOPPED GROOVES OR SIMILAR SAW-BLADE CUTS

To cut a gain mark the workpiece to show end of gain. Elevate dado for desired depth of cut, then align mark with back edge of dado (at the point where it rises above the table top). Holding workpiece thus, clamp a stop block to table or fence butted up against rear edge of workpiece ... or, if workpiece is too long, draw aligning marks on workpiece edge

HANDLING ODD-SHAPED WORK

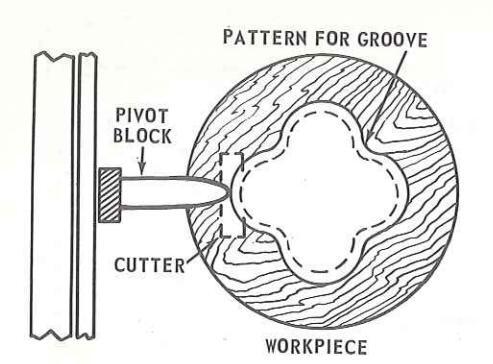

It is sometimes necessary to make a straight cut on a workpiece that cannot be guided by the fence or miter gauge (like halving a circle). For such jobs a homemade Cut-Off Board ( page 54 ) is very useful. With the guide strip at bottom this jig slides along the miter-gauge groove; when the two parts are reversed (strip at top) it can be guided by the fence, or be used freehand.

and table top at a convenient location. Make the cut as usual, feeding the workpiece until it is stopped by the stop block (or marks are aligned). Stop the dado, then lift work off of it.

To cut a stopped groove arrange a rear stop block (or aligning marks) as above. Similarly arrange a front (starting) block (or marks). Start the tool. Butt front edge of workpiece against starting block (or hold workpiece above dado with starting marks in alignment), then lower workpiece onto the dado. Complete the cut as above.