OVER 150 WOOD TURNING LATHE OPERATIONS DESCRIBED AND ILLUSTRATED

REVISED 1952

Wood

atte

INDEX

| INDEX |

|---|

| GENERAL INFORMATION 2.3 |

| Description Data Manation the Lath |

| Attachments and Assessmine |

| GENERAL OPERATIONS |

| Lathe Safety — Types of Spindles — Position- |

| ing the Tailstock — Adjusting the Tool Rest |

| WORK MOUNTING ATTACHMENTS |

| Two Classes of Wood Turnings Types and |

| Uses of Lathe Centers — Types and Uses of |

| Faceplates — Types and Uses of Chucks |

| CENTERING MOUNTING AND |

| BLANNING WOOD WORK |

| PLANNING WOOD WORK |

| Centering — Locating a Faceplate — Presizing |

| Stock — Mounting Stock — Removing Centers |

|

| WOOD WORKING CHISELS AND |

| HOW TO USE THEM 8-11 |

| Selection of Chisels - Theory of Turning - |

| Using the Gouge, Skew Parting Tool, Chisel |

| Shaper or Molding Knives, a Block Plane, Wood |

| Rasps and Files - Hand Positions |

| VARIOUS WAYS OF MAKING |

| CTANDADD WATS OF MAKING |

| STANDARD WOOD TURNING CUTS 12-14 |

| The Roughing-Off Cut - Rough Cutting to |

| Size — Making Sizing Cuts — Smoothing a |

| Cylinder — Cutting a Shoulder, Beads, Coves |

|

| TO MAKE SPINDLE TURNINGS |

| Plotting the Shape — Duplicate Turnings— |

| Long Spindles — End Turnings |

| TO MAKE FACEPLATE TURNINGS 17 |

| Planning the Work Direct With Col |

| Planning the work — Planning Various Cuts — |

| Deep Recesses - Large Diameter Work Pieces |

| HOW TO MAKE FANCY SPINDLES 18-21 |

| Reduced Squares — Oval Turnings — Inlay |

| Turnings — Club Foot Legs — Combination |

| Turnings — Spiral Turnings — Fluting and |

| Reeding — Split Turnings |

| HOW TO MAKE FANCY FACEPLATE |

| TURNINGS 22-24 |

| Preparing a Plug Chuck - Turning Cylinders |

| Rechucking — Turning a Ring — Turning Balls |

| - Turned Boxes - Segmented, Turnings |

| MISCELLANEOUS LATUE OPERATIONS OF AC |

| MISCELLANGEOUS LATHE OPERATIONS 25-26 |

| Cutting Dowels — Turning Duplicate Pieces |

| - Using a Steady Rest On Square Sections - |

| Guide Blocks for Scraping — Drilling — |

| Inredding — Using Grinding Wheels |

| HOW TO TURN PLASTICS |

| Types of Plastics — Mounting the Work — Use |

| of Wood Turning Chisels — Use of a Slide |

| Rest, Tool Bits and Formed Tools — Turning |

| Balls — Polishing Plastics |

| SANDING, BUFFING AND POLISHING 28-29 |

| Using Lathe to Sand Turnings - Use of Sand |

| ing Discs — Use of Sanding Drums — Use of |

| Wood Chucks for Sanding - Buffing Opera- |

| tions — Polishing Metals |

| WOOD FINISHING 20 |

| Balish Oil Sinish Was hinish - Frictional |

| Polish — Oll Finish — Varnish — French Polish |

| - Shellac Finish |

| The second |

| SHARPENING WOOD TURNING CHISELS31 |

| General Information — The Gouge — The |

|

General Information — The Gouge — The

Skew — Other Chisels — Centers |

|

General Information — The Gouge — The

Skew — Other Chisels — Centers TABLES |

|

General Information — The Gouge — The

Skew — Other Chisels — Centers TABLES |

|

General Information — The Gouge — The

Skew — Other Chisels — Centers TABLES |

Wood Satte

An Illustrated Manual of Operation

HOME CRAFTSMAN SHOP OWNER

BASIC FACTS — SET-UP — ATTACHMENTS CENTERING, PLANNING AND MOUNTING WORK PROPER USE AND HANDLING OF CHISELS MAKING STANDARD CUTS, SPINDLES, FACEPLATE TURNINGS, FANCY TURNINGS TURNING PLASTICS — SANDING — FINISHING SHARPENING CHISELS — TABLES

230 ILLUSTRATIONS

A CRAFTSMAN POWER TOOL HANDBOOK

Copyrighted 1952 SEARS, ROEBUCK and CO. REVISED 1952

Catalog No. 9-2920

THE MOST FASCINATING OF ALL POWER TOOLS

Of all power tools used by home craftsmen, or in industry, the wood lathe is undoubtedly the most fun to operate and the most satisfactory to use. Only on the lathe can the beginner and expert, alike, produce at one time, and all in the same continuous operation, finished masterpieces of intricate and beautiful design. To work with the wood lathe is to know the complete satisfaction of watching ideas take form under the magical touch of the chisel in your hands.

In addition to spinning dreams, the lathe is also a general utility tool. It can be adapted to the boring, routing, sawing, sanding, finishing and buffing of work; and, by varying the spindle speeds, to the turning, spinning, milling, cutting, threading and polishing of metal, plastic and other materials. Though it cannot be made to duplicate performances of the special tools developed for these various functions, it can be used to perform a greater variety of operations than any other single power tool.

SELECTION OF A LATHE AND MOTOR

Any wood lathe consists of four essential parts: the bed, a headstock fixed on the bed, and a tailstock and tool rest, both of which can be

positioned on the bed. In the headstock is a horizontal spindle. On better quality machines, the spindle is hollow with a female taper (usually No. 1 or No. 2 Morse taper) at the work holding end. It is generally threaded at both ends. The tailstock holds a horizontal ram which can be projected out or retracted into the tailstock by turning a handle. This ram, also, usually has a female Morse taper. The perfection in machining the parts, the convenience and accuracy with which the tailstock and tool rest can be positioned, and the use of bearings and other refinements, are the factors which determine the quality of work that can be easily produced on a lathe.

Lathe size is given in terms of the largest diameter workpiece that can be swung between the headstock and tailstock. The larger size lathes generally have longer beds; but this is not necessarily true, and is usually unimportant as lathe bed extensions are nearly always available. Lathes of 6 to 10 inches in size should be powered by a 1/3-hp 1750-rpm motor. Either a split phase or capacitor type can be used. Smaller lathes are made for special purposes and should be powered in accordance with the manufacturer's recommendations. Larger lathes require motors of 1/2-hp and up, depending upon size and usage.

LATHE BED EXTENSION

Bed extensions generally call be purchased for all standard home workshop lathes. One or more can be used to lengthen the lathe for long turnings. Average extensions are 12 to 24 inches long.

SPECIAL TOOL RESTS

Long tool rests are a gro convenience when maki long turnings—can genera be procured in 15- to 20-in

REVERSING SWITCH

Reversal of motor (and spindle direction) is almost a must for grinding, polishing and other special lathe applications. Swithches for use with any type motor, except repulsion-induction type, are generally procurable.

MOUNTING THE LATHE

A lathe can be mounted on the workbench, on bench legs, or on any suitable stand or cabinet that will place the center line of the spindle at the approximate height of your elbows when your arms are at your sides. There does not need to be any standing room behind the lathe

as work is just about always done from the front. Motor can be mounted on bench behind headstock, or on a shelf below headstock—depending upon shape of headstock and convenience. A 3- or 4-step cone pulley, to match pulley on spindle, should be mounted on the motor shaft—and this should provide three or four wood turning speeds (at the spindle) ranging from 875 to 3450 rpm. By adding a jack shaft and two more pulleys (as illustrated) three or four additional speeds, ranging from 875 down to approximately 300 rpm, can be provided for light metal turning and spinning, and other operations.

There should be an "ON-OFF" switch in a convenient location for the left hand.

JACK SHAFT

Additional spindle speed ranges required for special operations and metal turning can be obtained by using a jack shaft, with two cone pulleys, between the motor and headsrock pulleys.

POWR-PANL

A safe, convenient way to hook up your saw, tool light and other accessories. Two plug-in outlets, power-line receptacle and an ON-OFF switch. Fits tool bench.

TOOL LIGHT

Intricate pattern turning requires a good light which can be adjusted to illuminate recesses in the workpiece. A tool light with flexible gooseneck, mounted to back of bench, is excellent.

USE GOOD COMMON SENSE

For safety, as well as convenience, never wear loose, floppy clothing. A work apron is excellent and keeps you clean, too. If working with metals or very hard woods, it is good practice to wear goggles or a face shield (they're very inexpensive) to protect the eyes.

Always check to make certain that work is securely mounted—then spin the set-up by hand before starting the lathe. Stand a little to one side of the cut being made, and hold the chisel so that, if thrust back suddenly, it will not strike your body. Do not reach behind the lathe without shutting it off.

DO NOT BE AFRAID TO WORK CLOSE AND AT HIGHER SPEEDS

Keep the tool rest close to the work, readjusting it often. This is important because the revolving workpiece tends to thrust the chisel point down and seesaw the handle up against the downward thrust of your

chisel there is on your side of the tool rest, the better your leverage, and the more accurate your control over the movements of the chisel point. Keep your chisels sharp. Do not be afraid to use high lathe speeds. Cutting is actually smoother at higher speeds (especially with softer woods) and there is less chance for the workpiece to snag the chisel.

TYPES OF SPINDLES

Spindles are either hollow at both ends, or are solid. Some are also threaded. Hollow spindles usually accommodate Morse taper centers and the threading is useful for mounting threaded chucks and faceplates. Cen-

ters for solid spindles are mounted over the spindle and held with setscrews. On quality

lathes, the outboard end of the spindle is covered for additional safety, and can be uncovered so that it can be used to turn large workpieces. The headstock is not movable.

POSITIONING THE TAILSTOCK

To move the tailstock along the lathe bed, loosen the tailstock locknut. The tailstock is held by a clamp that slides under the bed ways ened by the locknut. To operate the ram (sometimes

called tailstock spindle), loosen the ram clamp handle and turn the ram feed handle. Turning feed handle clockwise extends the ram.

A guide on the underside of the tailstock rides between the two bed ways and keeps the ram in alignment with the spindle, regardless of tailstock position. On some lathes, this guide is mounted on a threaded cross shaft, and it is necessary to adjust the guide position to align the ram and spindle. In such cases, move the

tailstock toward the headstock until ram is practically touching spindle. Use a screwdriver to adjust the threaded cross shaft (sometimes called set-over screw) and align ram and spindle by eye.

ADJUSTING THE TOOL REST

Like the tailstock, the tool rest slide can be moved along the lathe bed. In addition, it is slotted so that it can be moved across the bed or rotated, as desired.

The tool rest is mounted on a post and held in the column of the slide by a thread-

ed lock handle. It can be raised or lowered, and can be rotated 360 degrees, to position it as desired. Various length and shape tool rests can generally be mounted in the same slide. Extra long tool rests require two slides.

INDEXING FEATURE

Headstocks are generally fitted with a springloaded indexing pin. This pin can be set to engage any one of a number of holes in the spindle pulley flange, to hold the spindle in a fixed position. The holes are arranged so that spindle can be set at all commonly used spacings for fluting, reeding and similar operations (page 21).

work mounting attachments

There are more accessories built for the lathe than for any other popular workshop tool. A few of the common work mounting attachments are shown here. Those having shanks are for lathes with hollow taper spindles and tailstock rams; solid spindles and rams take attachments with set screws.

TWO GENERAL CLASSES OF WOOD TURNINGS

A wood workpiece that is mounted between the headstock and tailstock is commonly called a spindle. Two lathe centers are needed to hold a spindle—one in the headstock, the other in the tailstock As the drive is ap-

plied to the headstock, the headstock center must not only hold the spindle on center, but must also engage the end of the spindle to revolve it. The tailstock center simply holds the spindle on center.

A workpiece that is to be made into a disc or

A workprete that is to be in other large circular object having the major portion of the work on the end, instead of around the circumference, is generally mounted on the headstock alone. Such pieces are called faceplate turnings, and are mounted on faceplates which are large

enough in diameter to hold them steady.

TYPES AND USES OF LATHE CENTERS

There are three standard types of headstock centers: the spur center, the screw center, and the combination faceplate, spur and screw center. The spur center, which has sharpened spurs that can be driven into the end of the spindle to firmly engage it, is the most widely used. A screw center is used, as a rule, when a small diameter workpiece is to start out as a spindle, but end up as a faceplate turning. The combination center serves this same purpose. Large diameter workpieces cannot be "faceplate mounted" on the screw center as they will come loose and wobble.

The most commonly used tailstock centers are: the cup center, the ball bearing 60-degree center, and the 60-degree center. Cup centers are the most popular. A sharpened circular rim around the recessed point prevents the point from burning too deeply into the wood and keeps the workpiece properly centered. The more expensive ball bearing center has a point that revolves with the workpiece so that it cannot "burn in." This type of center must be used with some plastics, and is best for all highspeed operations. Simple 60-degree centers are

used in metal turning, and can be used with hardwoods and some plastics for low speed operations.

Drill pads and crotch centers are used in the tailstock for special holding operations. The smoothly polished surface of the drill pad makes it useful for steadying a faceplate turning to temporarily work it as a spindle (page 17) or as a back rest for the workpiece in drilling operations (page 26). A machined V-notch in the crotch center will accurately center round stock for cross drilling (page 26).

The 60-degree center drill is used to end drill workpieces for mounting on the 60-degree centers.

Adapters are needed to mount centers having a different Morse taper from that provided on the spindle and ram.

TYPES AND USES OF FACEPLATES

Faceplates are solidly mounted onto the headstock spindle—either by screwing them on (threaded spindles) or by set screws. A solid mounting is necessary because of the heavy thrust developed when working the edges of the workpiece. For the same reason, the workpiece is screw mounted to the faceplate with three screws through the holes in the plate. The larger size faceplates should be used whenever practical. Faceplates having slots to engage a lathe dog (page 26) are used for turning metal rods and other materials which cannot be conveniently mounted on headstock centers.

TYPES AND USES OF CHUCKS

Three jaw chucks can be used on the headstock spindles to drive drills, reamers and other tools (page 26). For accurate work the self-centering lathe chuck is even better. Lathe chucks can also be used to hold small diameter workpieces for spindle or faceplate turning (page 16).

CENTERING

Accurate centering conserves stock and reduces the amount of work required to turn the workpiece down to a perfect round. If a portion of the workpiece is to be left square, accurate centering is absolutely necessary to keep the square and rounded portions in alignment. Spindle stock is ordinarily sawed square to begin with, but this is not necessary.

Perfectly square or rectangular stock can be quickly centered by means of diagonal lines

drawn across each end. Any stock can be centered by using the combination square to draw lines that are approximately at the center and equally distant from the sides. By placing all the lines—one parallel to each side—close enough together, it is easy to visually select the center point.

Transparent, plastic markers can be obtained and are useful for quick, accurate centering of perfectly square stock.

Perfectly round stock can be centered by drawing two diagonals with the use of the center head on a combination square. If stock is elliptical or slightly out of round, draw a number of diagonals, then visually select the center of these diagonals.

LOCATING FACEPLATE POSITION

A faceplate must be located on the workpiece by matching the faceplate circumference to a circle drawn around the workpiece center. Draw

this circle so that its diameter is approximately 1/8 inch greater than the diameter of the faceplate to be used. The faceplate can then easily be positioned inside the circle.

PRE-SIZING STOCK

Much time can generally be saved by rough sawing the workpiece to size. First, scribe a circle at one end to indicate largest diameter desired for finished work, then saw off corners around outside of circle. Be careful not

to cut too close to circle—at least 1/8 inch is needed for turning and polishing. Also, do not cut away any portion where it is desired to have squares that will be bigger than the largest diameter.

Lopsided pieces should be trimmed at least enough to knock off the heavy side. This balances the workpiece better and prevents the possibility of splitting the wood by gouging too deeply into the heavy side at the start.

Faceplate turnings are nearly always trimmed before starting the work to prevent danger of loosening the work on the faceplate while attempting to knock the large corners off on the lathe with a turning chisel.

MOUNTING SPINDLE STOCK

Spur Centers

The spur center is imbedded into the workpiece end before mounting. First, drill or punch a small hole at workpiece center. This helps to position the center. Place the center on the workpiece, hold it straight, then ham-

mer the end with a rawhide or wooden mallet until the spurs are firmly set into the wood. The center can then be removed for placing it in the lathe—or, to save time, it can be placed in the lathe with the workpiece attached.

It is good practice to drill a small hole at one side of the spur center, and to mark the position of this hole on the workpiece end. The workpiece can then always be remounted to the center in exactly the same position. If workpiece is hardwood or plastic, it is necessary to make two saw cuts in the end to receive the center spurs.

Screw Centers

The end of the workpiece must be sawed flat and square with the sides. Drill a center hole just large enough for the wood to take the screw point without splitting. Turn the screw center down onto the workpiece end until face of center is firmly against end of workpiece. Mount center to lathe with workpiece attached.

Placing Work on Lathe

First secure the work at the headstock end (taper shank centers are thrust firmly into place by hand); then advance the tailstock, with center in it, up to the work. Enter point of tailstock center into work just enough to hold it. Lock tailstock. Advance tailstock ram while slowly rotating work by hand, until it becomes difficult to rotate. The tailstock center will then be properly imbedded in the wood. Back the ram off one-half turn to ease the pressure—and lock the ram.

When using a cup or 60-degree center, apply oil or graphite to tailstock end of work. When using a ball bearing center—especially with batdwood—drill a small hole for the point.

REMOVING TAPER SHANK CENTERS

A center is easily removed ( from the hollow headstock spindle by driving it out with a metal rod inserted through the spindle end. Retracting the ram will automatically eject a tailstock center.

MOUNTING FACEPLATE STOCK

Center the faceplate in the circle drawn on the back of the workpiece, then securely fasten it with three flathead screws, size 10 or 12 gage. A 3/4 inch length screw gives a solid enough

mounting for all but the heaviest types of work. It is good practice to notch the faceplate and mark the workpiece for relocation in the same position. When screws are objectionable, the workpiece can be glued to a mounting block. A piece of paper placed between the glued surfaces will make it easier to later remove workpiece without damage.

CHUCK AND WORK ARBOR MOUNTINGS

Small work can be mounted in the self-centering lathe chuck. If work is long enough to whip as it is revolved, the outer end should be supported by the tailstock, or by a steady rest (page 16). A wood dowel, glued into a hole at the center of the work, makes it possible to mount small faceplate turnings in the chuck. Larger faceplate turnings can be held in a work arbor that is mounted into the head stock spindle, or in a chuck

PLANNING AND MEASURING WORK

Better results can be obtained by planning the work in advance, and by taking constant measurements. This is good practice. Use the measuring tools as illustrated.

The gage block method illustrated will speed up the taking of measure-

up the taking of measurements. Make blocks out of P hardwood. Each acts as a stop for a predetermined setting. Keep the knurled setting nut in the same position. Number the blocks for quick identification.

SELECTION OF CHISELS

The six commonly used chisels shown here are all that are needed for the home workshop. Better chisels have handles approximately 10 inches long, to provide plenty of grip and leverage.

THEORY OF TURNING

The Two Classes of Chisels

There are two classes of chisels: those intended primarily for cutting, and those used only for scraping. The cutting chisels are: the gouge, skew and parting tool. These are the most used. They are commonly sharpened to a razor edge by honing on both sides. The scraping chisels are: the flatnose, round nose and spear point. These are not

honed on the flat sides—the wire edges produced by grinding are left on to aid in the scraping process.

Cutting and Scraping

To cut, the chisel is held so that the sharp edge actually digs into the revolving work to peel off shavings. To scrape, the chisel is held at a right angle to the work surface, and removes fine particles instead of shavings. Many operations require that the cutting chisels be used for scraping; but scraping chisels are practically never used for cutting. Scraping dulls the chisel much faster, especially the razor sharp cutting chisels.

woodworking chisels and how to use them

Cutting is faster than scraping and produces a smoother finish which requires less sanding. However, it is far more difficult to master. Scraping, on the other hand, is far more precise and easier to control.

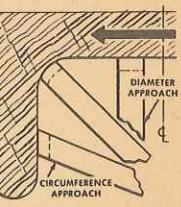

When You Can Cut, and When You Must Scrape

There are two different approaches to the work, when turning. One approach is toward a circumference of the workpiece, for example: turning down the outer surface of a cylinder or the inner wall of a hollow round

box. In this approach, the surface being turned travels under the chisel edge like an endless belt; the chisel can scrape at it, or can dig in and cut off shavings. The second approach is toward the diameter of a workpiece, as when turning the face of a faceplate turning, or the side of a large shoulder on a spindle turning. In this approach the surface being turned rotates like a disc under the chisel edge. Some times the approach will be a combination of both.

Cutting, as well as scraping operations, can be used when the approach is toward a circumference—the shaving is re-

moved like a peeling from a potato. Scraping, only, can be used when the approach is toward a diameter. The reason is obvious when you consider that faceplate turning practically always re-

quires removal of wood across the grain. Wood does not peel easily across the grain, and attempts to use cutting methods will likely result in damage to the work and throwing of the chisel by the work.

For these reasons, cutting methods are used only for circumference turning—that is, for the general run of spindle turning operations. On the other hand, the major part of a faceplate turning is done by the scraping method. When a combination approach is to be used, you will have to judge when to stop cutting and start scraping by the feel of the work. Never try to cut when it becomes difficult to hold the chisel against the roughness of the wood grain.

How to Position Tool Rest For Circumference Cutting

When cutting, the object is to pierce the outer skin of wood to a certain desired depth, then to hold the chisel steady, with the bevel edge parallel to the work circumference, so that it will peel off a shaving at this desired depth. The only sure method of holding the chisel steady is to rest the bevel against the work, as shown in sketch 1. When the 1

shown in sketch 1. When the tool rest is at the proper height (sketch 1), the chisel AT can be held with the bevel pressed against the work, and the tool rest will act as

a fulcrum to support the chisel against the downward force of the revolving work.

If the rest is placed too low, so that the chisel is held with the bevel out from the work (sketch 2), the cutting edge will continue to dig deeper into the work. It will dig in until the "bite" becomes so deep

the "bite" becomes so deep that your hands have difficulty holding the chisel then the improperly supported chisel will begin to so bounce, or chatter, against the workpiece.

If the rest is placed too low, the chisel must be held extremely high to position the bevel against the work (sketch 3). Then the rest loses most of its value as a fulcrum, and the down-

workpiece tends to kick the chisel back out of your hands.

If the rest is placed too high (sketch 4)—then, when the chisel is correctly positioned for cutting, it strikes the workpiece near the top where the direction of force exerted by the workpiece is nearly horizontal—and kickback will again result.

If the rest is placed too far out from the work surface (sketch 5)—then, when correctly held, the chisel is again too high on the work. Also, you have less leverage on your side of the tool rest—and it is even more difficult to hold the chisel.

With large diameter work w/

-9-

can be above the workpiece 6 centerline, and somewhat out from the work surface. With small diameter work (sketch 7), the rest should be lowered almost to the centerline, and should not be far from the work surface. As work grows smaller, the rest should be repositioned.

How to Position Tool Rest for Circumference Scraping

In scraping operations, the tool rest position is not as critical as it is for cutting operations. The chisel is generally held horizontally, though it can be held at an angle to reach into tight places. Considering that the wire edge of the chisel does the scraping, sketches 9 and 10 show the results of too low or too high a position for the rest; and sketch 8 shows the chisel action with the rest correctly positioned. Actual positioning of the rest for best results follows the same rule used for positioning it during cutting operations.

How to Position Chisel and Rest For Diameter Scraping

When scraping on the diameter, that portion of the surface to the right of the upward (sketch 11). If the workpiece center is moving chisel is placed in this area, it will simply be carried up off the rest and out of your hands. All diameter approach operations must be done at the left of center.

Three different chisel contact points are shown in sketch 12. It will be noted that, when chisel is above the workpiece center, or be-

woodworking chisels & how to use them (cont'd)

USING THE GOUGE

Three gouges, the 1/4-, 1/2- and 3/4-inch sizes, are ample for general homeshop turning; but other sizes from 1/8 inch to 2 inches can be purchased. The chief use of the gouge is for rough circumference cutting of raw stock down to a cylinder of working size. It is the best tool to use for rapid cutting away of large areas of the workpiece; but when so used does not produce a smooth surface. With practice, it can be used for cutting coves and the shaping of long cuts is a use or the for scarbing.

When used for cutting, the gouge is always held with the convex side down. It should be rolled approximately 30 to 45 degrees in the direction in which it is being advanced along the rest; and the cutting edge should be a little in advance of the handle.

desired, or all the way through to make a cutoff. It is therefore a very narrow tool-1/8 inch wide—and is shaped to cut its own clearance so that the edge will not be burned. When used for scraping, however, it should be backed off regularly to prevent overheating.

Unlike the gouge and skew, the parting tool is seldom held with the bevel against the work. As the amount of stock removed is small, a support for the bevel is not necessary. The tool is simply fed into the work at an angle (for cutting), or pointed at the workpiece center (for scraping). It can be held easily in one hand.

USING THE SCRAPING CHISELS

A 1/2-inch wide spear point chisel, a 1/2-inch wide round nose chisel, and a 1-inch wide flat-

USING THE SKEW

Two skews, the 1/2- and 1-inch sizes, are all that are needed for general use. Other sizes are available. This tool is nearly always used to make finish cuts, to cut vees and beads, and to square shoulders. Properly used, it produces the best finish that can be obtained with a chisel. It should be used but little for scraping, as this quickly dulls it.

For finish cutting, the skew is held with the cutting edge considerably in advance of the handle, bevel side down. Keep the base of the bevel against the work.

Good practice is to place the skew well over the work, pull it back until the edge begins to cut, then swing the handle into position to advance the cut. Both the toe and the heel of the skew can be used for taking light cuts; but do not penetrate the wood too deeply without cutting clearances, as there is danger of burning the tip of the tool.

EDGE DOES NO SUPPORT

USING THE PARTING TOOL

The parting tool has just one primary purpose: to cut straight into the workpiece as deep as

nose chisel complete the list of tools ordinarily used by home craftsmen. Each of these scraping chisels can be purchased in various other sizes for special purposes. All are very useful for diameter scraping operations and for circumference scraping, when cutting methods cannot be employed.

The spear point is used for fine scraping and delicate operations, such as the forming of beads, parallel grooves and shallow vees. Edges and bowl contours can be rounded with the round nose chisel. Any flat surface can be scraped with the flatnose chisel.

USING SHAPER OR MOULDING KNIVES

An old chisel can be made to serve as a holder for shaper or moulding knives. Such knives make it possible to scrape many interesting shapes in the workpiece surface in one or two operations, instead of the many operations required with

standard chisels. It is generally not practical to use cutting methods with special shape tools; scraping methods should be used.

The holder should provide a shoulder against

which the butt end of the knife can be firmly seated; and the knife must be securely mounted, either by means of a screw threaded into the holder, or by compressing it between one of two prongs and a bolt threaded through the other prong

USING A BLOCK PLANE

Clear, glass-smooth finishes (especially on softwoods) can be obtained by using a block plane set to take a fine shaving. The tool rest should be raised up approximately to the top of the

workpiece—and the plane should be horizontal, but turned slightly in the direction of travel so that it will take a shearing cut. Two tool rests, one in front and the other behind the work, can be used to advantage in positioning the plane so as to exactly limit the depth of cut (and finished size of the workpiece).

USING WOOD RASPS AND FILES

A wood rasp will remove stock quickly when held against the revolving workpiece. Care should be taken to support the rasp firmly against the tool rest, however, as it can tear the hands painfully if caught by a

rough edge of the workpiece and kicked back. The rasp will leave a very rough finish.

Finer finishes (similar to those produced by scraping) can be obtained by using files in the same manner. Various shape files can be used for shaping vees, beads, coves, etc. If pressed into the wood too hard, however, a file can burn the workpiece surface. Keep the file clean to keep it cutting uniformly. Files work best on hardwoods.

HAND POSITIONS

In handling all of the chisels, the handle hand takes a natural position, being nearer or farther from the end depending upon the amount of leverage required. The position of the tool rest hand is a matter of individual liking; but there are three generally accepted positions, each best for certain types of operations.

Roughing-off and other heavy work requires a firm grip and solid positioning of the chisel against the rest. This is best obtained by holding the tool rest hand with the palm down and the fingers wrapped around the chisel blade. The wrist is dropped down so that the heel of

the hand below the little finger acts as a sliding guide against the rest. The handle hand con-

Finish cutting requires more control, with less force—and is better done with the palm of the tool rest hand turned up. The wrist is still held down, and the side of the index finger acts as a guide along the rest. In this position, control of the chisel is shared by both hands, the fingers of the tool rest hand being free to assist in positioning the tool.

Intricate, delicate cutting requires extreme control, with practically no force. This is best accomplished by guiding the chisel with the fingers of the tool rest hand. The hand is held palm up, with the wrist high—with the little finger placed against the rest to steady the hand. The chisel does not touch the rest; and the handle hand is completely secondary to the tool rest hand.

The first and second positions are equally good for scraping operations; but the third position is practically never used for scraping.

Many scraping operations and cutting to depth with the parting tool can be done with one hand. The chisel is grasped firmly, with the index finger on top to press it down against the rest—and is thrust straight into the work. Holding the tool thus leaves the other hand free to hold a pattern, calipers or other measuring device in contact with the revolving workpiece to measure the diameter of the cut being made.

NOTE

Refer to the table on page 32 for proper lathe speeds during various operations.

THE ROUGHING-OFF CUT

Reducing a square or odd shaped workpiece down to a cylinder of approximate size for finish turning is called roughing-off. Faceplate turnings and large diameter spindles should first be partly reduced by sawing (page 6); but small spindles are easily turned down entirely with the large (3/4-inch) gouge.

Start the first cut about two inches from the tailstock end—then run it toward the tailstock and off the end of the workpiece. Then start another cut two inches nearer the headstock and run it, also, toward the tailstock to merge with the first cut. Continue in this manner until two to four inches from the headstock end, then reverse the direction of tool travel and work one or two cuts in succession toward the headstock, and off this end of the workpiece. Never start a cut directly at the end—if the chisel catches the end, it will damage the workpiece. Never take long cuts while corners remain on the work, as this tends to tear long slivers from the corners.

The first series of cuts should not be too deep. It is better to partially reduce the work to a cylinder all along its length; then start a second series of cuts to complete reducing it to a cylinder. Once the cylinder has been formed, step the lathe up to the next faster speed. Fur-

various ways to make standard cuts

ther reductions in size can now be carried out by cutting as deeply as desired at any spot along the work. At this stage, long cuts, from the center off either end, can also be taken. Roughing-off is generally continued until the cylinder is approximately 1/8 inch larger than the desired finish size. Roundness can be tested by laying the gouge on top of the work- it will not ride up and down when cylinder is perfectly round.

ROUGH CUTTING TO SIZE

The roughing-off cut can be made to accurately size the cylinder to a given diameter by using the set-up illustrated. Two gouges are mounted between wood blocks with their cutting edges protruding an exact, pre-determined

Another method is to make a number of sizing cuts (see following) at intervals along the work, then use the gouge to reduce the whole cylinder down to the diameter indicated by these cuts.

MAKING SIZING CUTS

Sizing cuts are useful to establish approximate finish size diameters at various points along a workpiece. The work can then be turned down to the diameters indicated—and be ready for

finishing. Diameters for sizing cuts should be planned to be about 1/8 inch greater than the desired finish diameters

A sizing cut is made with the parting tool. Hold the tool in one hand, and use

the other hand to hold an outside caliper preset to the desired sizing cut diameter. As the cut nears completion, lower the chisel point more and more into a scraping position. When the calipers slip over the workpiece at the cut, the cut is finished.

SMOOTHING A CYLINDER

The final 1/8 inch (from finished rough-cut size down to finish size) can be removed in many ways. Most professionals prefer to use the 1-inch skew as a cutting tool (page 10), working from the center outwards toward both ends of the work, and taking lighter and lighter cuts until finished. However, the block plane method is equally good, if a straight (page 11) or tapered cylinder is being finished. Both methods produce surfaces which require little or no sanding.

Finishes which require sanding, but which are otherwise excellent, can be produced by scraping (page 10), or with rasps and files (page 11).

CUTTING A SHOULDER

A shoulder can be the side of a square portion left in the workpiece, the side of a turned section, or the end of the workpiece. Most shoulders are perpendicular to the work axis; but a

shoulder can be at any angle desired.

First, mark position of the shoulder with a pencil held to the revolving workpiece. Then make a sizing cut with the parting tool, placing this cut about 1/16 inch outside the shoulder position, and cutting to within about 1/8 inch of the depth desired for the area outside of the shoulder. If shoulder is shallow, the toe of the skew can be used to make the sizing cut: but do not go in

deeper than 1/8 inch with the skew unless wider and wider vees are cut to provide clearance for this tool.

Use the gouge to remove any waste stock out-

side the shoulder — and smooth this section, up to within 1/8 inch of the shoulder, in the usual manner. Finishing of the shoulder, unless it is more than 1-inch high, is best done = with the 1/2-inch skew.

First, the toe of the chisel is used to remove thin shavings from the side of the shoulder down to finish size. Hold the skew so that the bottom edge of the bevel next to the shoulder

If the shoulder is at the end of the work, the process is called squaring the end. In

this case, reduce the outer portion to about 1/4inch diameter—then later saw off the waste stock.

CUTTING VEES

Vee grooves can be cut with either the toe or heel of the skew. When the toe is used, the cutting action is exactly the same as in trimming a shoulder—except that the skew is tilted to cut at the required bevel. Light cuts should be taken on first one side then the other, gradually enlarging the vee to the required depth and width.

When the heel is used, the skew is rotated down into the work, using the rest as a pivot. Otherwise, the cut-

As when using the toe, it is important that the cutting be done only by the extreme end of the cutting edge.

If deep vees are planned, it is quicker to start them by making a sizing cut at the center of each vee. Vees can also be scraped with the spear point chisel or a three-sided file.

CUTTING BEADS

It requires considerable practice to cut a uniform series of beads. First, make pencil lines to locate the tops (highest points) of two or more adjoining beads. Then make a vee groove at the exact center between two lines—and down to the desired depth of the separation between the beads. Be careful not to make the groove too wide or you will remove portions of the desired beads. The sides of the two adjoining beads are now ready to be formed.

Actual cutting is done with the heel of the skew—preferably the 1/2-inch size, unless beads are quite large. Place the skew at right angles with the work axis, flat against the surface and well up near the top. The extreme heel should

be just inside the pencil line that marks the top of the bead. Now draw the skew straight back while raising the handle slowly—until the edge of the heel at the pencil line starts to cut. As the edge begins to cut, roll the skew in the direction of the vee—so that the exact portion of the edge which started cutting will travel in a 90-degree arc down to the bottom of the vee. Upon reaching the bottom of the vee, the skew should be on edge. Reverse the movements to cut the side of the adjacent bead.

It is important that only the extreme heel should do the cutting. This means that the bottom edge of the bevel next to the vee must at all times be tangent to the arc of the bead being formed.

Easier beads—separated by sizing cuts and not quite so smooth—can be shaped with the spear point chisel. Penmarks are made to locate the separation points, then sizing cuts to the desired depth are made where the

pencil marks are. The spear point chisel is then pushed straight into each cut and rotated horizontally to round off the adjacent edges. It must be moved slightly in the direction of rotation, at the same time, to keep the point from digging into the adjacent bead.

CUTTING COVES (CONCAVES).

This is the most difficult single cut to masterbut one of the most important in good wood turning. The cove is first laid-out by pencil

marks to indicate the edges. FINCE. It is then roughed out—to within about 1/8 inch of the desired finish surface—by scraping with the gouge or round nose chisel. If the cove is to be very wide, sizing cuts can be made to plot the roughing out. Once it is roughed out, the cove can be finished in two cuts one from each side to the bottom center.

At the start of either cut, the gouge is held with the handle high and the two sides of the blade held between the thumb and forefinger of the tool rest hand, just behind the bevel. Position the fingers ready to roll the blade into the cove.

Hold the blade so that the bevel is at a 90-degree angle to the work axis, with the point touching the pencil line and pointed into the work axis.

From this start, depress the point slightly to start the cut, then continue to move

the point down in an arc toward the bottom center of the cove—at the same time rolling the chisel uniformly so that, at the end of the cut, it will be flat at the bottom of the cove. The object is to keep the extreme point of the chisel doing the cutting from start to finish. Reverse the movements to cut the opposite side.

Coves can also be scraped to a finish, using the round nose chisel or a rattail file—but these methods do not generally produce perfectly curved coves.

MAKING LONG CONVEX CUTS

First turn the work down to

approximate size, using sizing cuts, as required, to determine the various diamters. The finish cut can then be made with either the skew or the gouge. If the skew is used, the principles of the operation are the same as those employed in cutting a beadployed in cutting a beadsccept that the curve is longer and may be irregular. Use the extreme heel throughout-start at the longer end of the curve (if curve is irregular) and progress to-

If the gouge is used, make the cut in the same direction. Start with the handle well back of the point—swinging the handle in the direction of tool travel to overtake the point, if necessary, when the steep part of the curve is reached. The object is to keep the extreme point doing the cutting throughout—with the bevel as nearly tangent to the curve as possible.

MAKING LONG TAPER CUTS

Long taper cuts are made with the skew or gouge, in the same manner as long convex cuts —except that (in each case) the advanced position of the cutting edge with respect to the handle is kept constant during the entire cut. The handle is not swung around. Always cut downhill. Guard against the tendency to cut too deeply at the center of the taper.

Perfect tapers can be cut with a block plane, two tool rests, and two long,

straight-edge boards clamped to the rests. This set-up provides a track—with one board in front, the other in back of the work—down which the plane can travel. The boards must be at equal heights, slanted identically, and long enough for the complete cut.

how to handle spindle turnings

PLOTTING THE SHAPE

Once the basic cuts have been mastered, you are in position to turn out finished work. The first step is to prepare a plan for the proposed turning. This can be layed out on a suitable sheet of paper—and should be to full size. Next, prepare the turning stock by squaring it up to the size of the largest square or round section in your plan. The stock can be cut to the exact length of the proposed turning; but, in most rases, it is best to leave the stock a little long it one or both ends to allow for trimming.

Mount the stock in the lathe, and rough it off to a maximum-size cylinder. Now project your plan on to the turning by marking the various critical dimensions along the length of the spindle in pencil. These dimensions can be layed out with an ordinary ruler—or by using a template. Make the pencil marks about 1/2inch long—they will then be visible when the work is revolved under power, and can be quickly traced around the spindle by touching each line with the pencil.

After marking, use the parting tool to make sizing cuts at all of the important shoulders. When learning, you will find it best to make many sizing cuts to accurately plot the various diameters; but experienced workers can do with a few such cuts at the important shoulders. Plan each sizing cut so that it is in waste stock; and make each deep enough so that there will be just enough wood left under the cut for the finishing process. Once the sizing cuts have been run in, rough-out the excess wood with a gouge—then proceed with the finishing process by making the various types of cuts required.

DUPLICATE TURNINGS

Making identical turnings requires great accuracy when plotting the work and doing the various cuts. Many methods have been devised to aid in perfecting the work.

Use of Patterns

Professional workers generally use a pattern, or

lavout board. This is a thin piece of wood or cardboard on which is drawn a full-size balf section of the turning. The contour of the finished surface is drawn first; then the diameters at various critical points are drawn to scale as vertical lines intersecting the countour line By placing the pattern against the roughed-off cylinder, you can quickly mark the various points of the critical diameters. To make each sizing cut, use outside calipers and set these by actually measuring the length of the vertical line on the pattern which represents the diameter desired. Then make the sizing cut, down to the termine when the cut is finished (page 11). After making the sizing cuts, hang the pattern for completion of the workpiece

Using a Template and a Diameter Board

When many identical turnings are to be produced, it is a convenience to have a prepared template. This can be made of thin wood or cardboard—and is cut on a band saw or scroll saw to have the exact contour of

the finished turning. The number one finished turning can also be used as a template. Attach the template to a board; then mount the board behind the lathe, on hinges, so that the template can be moved down to touch the workpiece and allow you to closely observe progress of your work.

If a great many turnings are being produced, a diameter board will save the time used for resetting calipers. This is simply a thin board along the edge of which a number of semicircular cuts have been prepared to represent all the various caliper settings required for measuring the sizing cuts. Each semicircular cut is held against the workpiece instead of using the calipers.

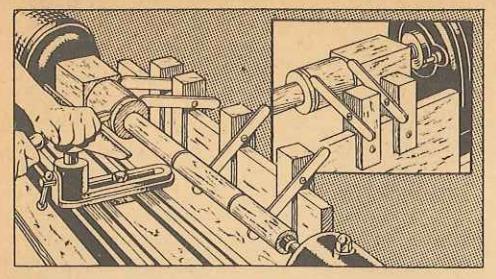

Use of a Semaphore Jig

Production work can be further speeded by the use of a semaphore jig to take the place of caliper measurements. The jig is prepared by erecting a suitable length board on edge in back of the lathe-and by preparing an adequate number of slotted blocks to ride along the top edge of this board. Each block should have a setscrew so that it can be secured at any position along the edge of the board. A thin bar of metal or wood is pinned to one side of each block so that its outer end will rotate down against the workpiece. The positions of the blocks and arms indicate the various sizing cuts to be made-and each arm is of such a length that it will drop all the way down past the back side of the workpiece when the wood under it has been cut out to the desired depth of the sizing cut. If slotted bars-held to the blocks by through bolts-are used, a single jig terns.

Using a Template Semaphore

A template cut from 1/8-inch plywood can be mounted in the same manner as the semaphore arms-and will ride on top of the roughed-off cylinder until the cylinder has been reduced along its entire contour to a series of diameters small enough to allow the semaphore template to drop down behind the workpiece. To mount its straight bottom edge--then support the ends of the dowel between two of the sliding blocks. In use, the template will ride on top of the revolving cylinder and will show a gap between its edge and the cylinder surface until the last diameter of the cylinder has been reduced to the proper size. Reduce the cylinder slowly at each point of contact with the template until all gaps disappear and the template drops off the back edge.

LONG SPINDLES

Turnings that are longer than the normal capacity of the lathe can be accommodated by using a lathe bed extension (page 2). It is also practical to clamp the tailstock to a drill press table—or any adjustable height table that will permit aligning it perfectly with the headstock. Long turnings can also be worked in short sections, with joints arranged to be at shoulders where they will not be noticed.

Long thin work that is likely to whip while turning should be supported at one or two places by a steady rest

or a backstick. The steady rest is secured to the lathe bed and has three jaws that can be adjusted to hold the work. A backstick is simply a V-notched piece of wood mounted in an extra tool rest to support the work from behind. An improved type of backstick can be prepared by substituting, two roller skate wheels for the Vnotch.

Either support is placed

against a pre-turned portion near the center of the spindle, this portion being at least 1/8 inch over finish size to allow for later removal of any marks made upon it. Operate lathe at a slower speed than normal. Lubricate the workpiece at point of contact with the steady rest jaws or backstick, using beeswax (preferably), lard or grease. After completing the turning, move the steady rest or backstick and finish off the original point of contact. Sand off any slight burns remaining on workpiece.

END TURNINGS

Spindles which must be turned at the extreme end can be worked with the aid of the steady rest. When mounting the work between centers for turning, place the large faceplate in position on the headstock. Complete all of the circumference turnings in the usual manner. Then, attach a holding

jig (as shown in the illustration) to the live end of the workpiece to secure it to the faceplate. This jig is simply two V-blocks which are bolted together around the work and which, in turn, can be bolted to the faceplate. After the block is in place, adjust the steady rest to hold the workpiece near the tailstock end, then remove the tailstock. Operate lathe at slow speed to turn down the end.

faceplate and chuck turnings

PLANNING THE WORK

Like spindles, faceplate turnings should be laid out in advance so that you will have a visual pattern to follow while working the turning. Patterns can be laid out in the same manner as spindle patterns—or templates can be made which

can be held against the work for visual comparison. Circles to locate the various critical points (at which the contours of the faceplate take distinct form) can be quickly scribed on the rotating work by using the dividers.

PLANNING VARIOUS CUTS

The circumference of a faceplate turning is roughedoff and finished in the same manner that a spindle is worked. Practically all of the balance of the operations, however, are done by using scraping methods. A few of

the standard contours which must ofen be turned are illustrated in the accompanying sketch which also shows the proper chisels for shaping these contours. Any roughing-out to depth that must be done is generally accomplished with the gouge held in the scraping position.

DEEP RECESSES

The first step is to remove as much wood as possible by boring into the center with the largest wood bit available (page 26).

If a slide rest is available, the remainder of the waste can be quickly roughed-out by boring with a metal boring bar, as shown in the

illustration. If this method cannot be used, remove the waste material by scraping with the round nose chisel or gouge, then smooth the inside circumference by scraping with the spear point chisel or skew. The bottom of the recess can be scraped flat with the flatnose chisel.

Proper support must be provided at all times for the scraping chisels. Several tool rest positions are shown in the accompanying illustra-

tions. Always endeavor to position the part of the rest that supports the tool as close to the working surface as possible.

A right-angle rest will be found to be very advantageous in this type of turning.

The depth and squareness of the sides of the recess can be quickly checked by holding one of the straight sided chisels and a combination square as shown in the illustration.

LARGE DIAMETER WORKPIECES

Large diameter work, too big to swing on the inboard end of the headstock spindle, can be mounted on the outboard end of the spindle. A large faceplate having left-hand threads must be used. For occasional use, the tool rest can be clamped to the table of a floor model drill press. This can be raised or lowered as required to furnish proper support. If much work of this type is to be done, it will be handier to construct an outboard tool rest like that shown in the illustration. This can be made of pipe sections, or entirely of wood—but should provide means of raising or lowering the rest and of turning it to any angle desired.

how to make fancy spindles

less wasteful of stock. First, select stock with a cross section big enough to accommodate the reduced square—then square this accurately. After this, mount blocks of the same wood around the four sides of the stock at the position, or positions, where larger round sections are to be formed. The care with which these blocks are mounted will determine the appearance of the finished turning. Match the grain as closely as possible on all four sides. Also, have the joints as smooth and tight as possible, and use a good grade of glue when assembling the blocks. Allow the assembled pieces to dry, while set in suitable wood clamps, before attempting to turn them down.

Turning of the blocked post is carried out in the same manner as other spindle turning processes. It is good practice, however, to cut away the unneeded corners from the blocked section on a circular saw or band saw before commencing the lathe operation. If this is not done, the first roughing-off cut must be very light, as the strain on the joints during the early stages of turning is considerable.

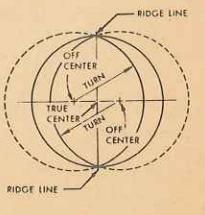

OVAL TURNINGS

Turnings that are oval in cross section, instead of the usual full round, can be made on the lathe by offcentering the workpiece. A hammer handle is a common example of this type of turning.

The true center of the stock is not used at all for mounting the workpiece in the lathe. Instead, two sets of off-centers, plotted to give the desired oval shape, are used. When mounted on one set of off-centers, one half of the workpiece is turned,

REDUCED SQUARES

Some very attractive spindles have square sections which are smaller in cross section than the diameter of the largest round section. In preparing the stock for such turnings, three different methods can be employed. The first two methods consist of using a stock having a sufficient cross section to accommodate the largest di-

The third method of preparing stock is known as "post blocking." With careful workmanship and good glue, the finished product can be made to look almost as good as the solid stock production—and is less expensive, being

while the other half—which rotates out of reach of the chisel—will not be touched. To turn the untouched side, the work is then transferred to the other set of off-centers —and the turning is com-

It is best to prepare for an oval turning by first making a cylinder reduced to the largest required diameter. The true center is used for this portion of the work. When turning the work off-center to produce the two sides of the oval, operate the lathe at the second lowest speed. Cutting in each off-center position is continued until the chisel cuts exactly meet the ridge lines which are at each side of the greatest diameter of the oval. This is easily done without stopping the lathe because the work shows a double image as it revolves—the two ridge lines being the line which appears as the meeting point of these two images.

As the ridge line is approached, very light cuts should be taken. After completing the two sides, the two ridge lines will remain as sharp edges. These can be removed by again mounting the work on the true centers and taking very light cuts. Sanding will further soften the shape to a true oval.

It will be apparent that the original shape of the stock can be rectangular instead of square, as for ordinary spindle work. In such cases, the stock need not be roughed down to a true cylinder at the start—but can immediately be turned on the two off-centers to form the two sides. Careful plotting of the two off-centers is all that is required to produce good oval shapes. Work that is oval at one end and that tapers off to a true round at the other end can be produced by off-setting one end alone from the true center. In this case, the ridgeline image will disappear near the round end, and care must be taken not to cut too deeply into the wood in this area.

INLAY TURNINGS

By using the same technique employed in post blocking, very attractive turnings resembling inlay work can be produced. The wood that is used in the blocking process is not matched; it is selected, instead, to contrast as much as pos-

sible with the adjoining wood. As an example, maple and walnut woods can be arranged to give the desired contrast. Also, instead of just one series of blocks around the workpiece, several layers of blocks can be built up. The arrangement of blocks illustrated was used to produce the inlay turning illustrated at the top of the page.

CLUB FOOT LEGS

The club or Dutch foot on turned spindles also requires off-centering. This type of spindle makes a very attractive leg for chairs and tables.

A paper pattern of the leg is first made, and the shape is then transferred to two adjoining sides of the stock. The true center is carried out to either end of the work; while the off-center is marked only on the club foot end (which will be held by the tailstock). As in oval turning, the off-center is found by experimenting with a compass. It is important that the turning circle around the off-center be plotted to clear the toe of the foot.

After marking the shape, waste stock can be removed by combination sawing on a band saw; or can be turned down by the usual turning methods. All of the leg, except the heel of the club foot, is then finished while on the true centers. At this stage the foot will be of a diameter determined by the length of the toe, and will require off-center reduction for shaping of the heel. To do this, off-center the tailstock end only, then continue turning to remove waste material and shape the heel. During this off-center operation, operate the lathe at second lowest speed. Stop the work frequently for examination, and guard carefully against over cutting (which is an error easily made).

After turning the heel, there will be a sharp ridge line where the two circular arcs come together. Soften this ridge with a few file strokes, then sand the finished piece while turning it on both the true centers and the offcenters. The end of the stock below the club foot is sawed off after the turning operation has been finished.

how to make fancy spindles (cont'd)

COMBINATION TURNINGS

The rear legs of chairs and stools sometimes require a combination turning, the lower part of the leg being a regular turning and the upper part being straight or shaped, and at an angle to the lower part.

The easiest method to produce work of this type is to prepare separate turnings and join them together with a dowel. A stronger leg, however, can be produced if one piece of stock is used to shape both parts. If one portion is to be straight and the other is to be a turning, two methods can be employed. The first method is to prepare a piece of stock which will provide true centers for the turned section-then to complete this section on the lathe, and afterwards cut the straight section on a band saw. The second method requires the use of an auxiliary block glued or clamped to the workpiece so that it can be mounted on true centers in the lathe. In this case, the straight section is sawed first-after which the block is mounted and the turning is completed on the lathe in the usual manner. This second method can be used to turn both sections on the lathe. In this case, one section is turned by securing a block to the other end; then the block is moved to the completed end for turning of the remaining part

When using blocks, or unbalanced stock (as in lead weights at proper points to balance the work so that it will not be thrown out of the lathe when revolving at high speed.

SPIRAL TURNINGS

Spiral turnings are not turned on the lathe in the true sense of the word; the lathe serves only to hold the work while the spiral portion of the turning is worked by hand. Before the spiral is worked, however, the turning is reduced by the usual methods to a cylinder of the desired shape.

To layout a single spiral, first mark the ends of the intended spiral. Select a suitable pitch. This is generally most pleasing if approximately the same dimension, or a little less, than the diameter of the work. That is, a workpiece

1-1/2 inches in diameter should have a spiral pitch of 1-1/4 to 1-1/2 inches.

The exact pitch dimension is somewhat decided by the length of the spiral, since the length must be divided into a number of equal spaces each representing the pitch of the spiral. Mark into four smaller parts. Next, use the center head of a combination square to quarter the end of the stock by drawing two diameters which cross at the center at 90 degrees. With the tool rest as a guide, draw four horizontal lines on the stock to coincide with the four ends of the two diameter lines. The ridge of the spiral can now be sketched by hand by drawing a continuous line that will pass diagonally through one after another of the small quarter spaces. When correctly drawn, the ridge line will advance four small circles (one full pitch line drawn in the first step) for each revolution of the workpiece.

A double spiral is layed out in the same manner-except that each main division (pitch line) is divided into two parts instead of four. One diagonal ridge line is then drawn as before; but will advance the distance of two pitch lines with each revolution of the workpiece. An identical second ridge line is then drawn from the opposite end of the workpiece so that it crosses the first line at a pitch line with each half revolution of the workpiece. Triple spirals can be made in a similar manner by trisecting, instead of quartering the work-

After the ridge line is drawn, another spiral midway between two adjoining turns of the ridge line should be drawn, to mark the bottom of the spiral groove.

Ridge lines can be quickly plotted by wrapping a strip of paper spirally around the turning, leaving a slight space is then traced through the spiral space provided, onto per having parallel sides

Another method of laying out a spiral to almost any desired pitch is to use a marker like the one illustrated. This consists of the "wheel" taken from an ordinary typewriter eraser and

mounted in the end of a dowel rod. This wheel can be inked to trace a line on the workpiece. It is held freehand against the work, which is then rotated slowly by hand. The angle of the wheel with the workpiece will determine the pitch of the spiral produced.

Actual cutting of the spiral is tedious but not

each end of the spiral, this saw cut should be straightened out somewhat so that the cut follows more truly in a circle about the workpiece. The depth of the cut should be approximately 1/4 the diameter of the workpiece. After the saw cut has been made, the hollow of the spiral is worked out with a round file. Next, a flat file is used to dress the round of the spiral. During these operations the work can be revolved by hand in the lathe to permit longer file strokes for smoother results. The penciled ridge line should be preserved throughout this process. After the spiral has been cut in this manner as perfectly as possible, operate the lathe at lowest speed and "chase" the spiral with sandpaper held lightly between both hands. Many light strokes will smooth out all the roughness.

FLUTING AND REEDING

The index pin supplied in most lathe headstocks is used for spacing the various cuts for fluting and reeding operations. The pin provides settings of from 2 to 60 equal spaces, as given in the "Indexing" table on page 32.

A typical jig for making the actual cuts is shown in the illustration. This jig makes use of standard shaper cutters. A cutter is mounted and driven in the jig by means of a flexible shaft. The end of the shaft housing is firmly mounted between two blocks of wood, and is

arranged to slide along a wooden guide bar of sufficient length for making complete cuts. A collar next to the cutter serves to control the denth of cut

If the stock is tapered, the guide bar must be slanted down accordingly at one end. If the operation is reeding, each new cut should be set off by turning the work clockwise (as viewed from the tailstock end) so that the collar will ride solid wood on all but the last cut. Slight burns created by the collar are easily removed by sanding the work after it is finished. This jig can be used on either straight or curved workprieses

SPLIT TURNINGS

Cabinets and furniture are often decorated with pieces of half or quarter-rounds which have been cut from full circle wood turnings.

In preparing the stock for a split turning, two pieces of wood are glued or screwed together to form a square. If the work is glued, a piece of paper should be placed between the two blocks—then, after the work is completed, a knife can be used for easy separation of the turning into halves. Screw fastenings are ideal for all short spindles; but cannot be used on very long spindles as the work will tend to separate in the center.

The assembled square stock is turned or otherwise worked in the usual manner; then separated into halves to form the decorative pieces. If quarter rounds are desired, assemble four pieces of stock, instead of two, into a square.

PREPARING A PLUG CHUCK

A plug chuck is an auxiliary wood chuck mounted onto a faceplate. The chuck can be any size in diameter—should be about 2-1/2 inches thick for stability—and should be provided with a 3/4 or 7/8 inch hole in the center for receiving a tenon turned at the end of the workpiece. Once made, such chucks are permanent useful fixtures for turning balls, goblets, etc. In use, the wood stock for turning is turned between centers to produce a tenon at one end which will be a driving fit in the hole of the chuck. When mounted in the chuck, the workpiece is substantially supported for any faceplate type of turning.

TURNING CYLINDERS

Stock for cylinders should be mounted on the screw center or a small faceplate. The tailstock can be brought up to support the work while the circumference is being turned and finished. Afterwards, the tailstock is backed off and the

how to make fancy faceplate turnings

outer end of the cylinder is recessed, using methods already described for making deep recesses.

After making a recess least 1/2 of the way through the workpiece, and finishing this on the inside, remove the workpiece from the lathe. Now mount a short the screw center and turn this down to form a dowel that will be a tight press (not driving) fit inside the recessed end of the cylinder Mount the cylinder on this wooden chuck, and recess the unworked end deep enough to form a perfect hole through the entire cyl-

RECHUCKING

Rechucking is the general term used to describe any additional work mounting that is necessary to complete a turning project. The method of working cylinders, and the

use of a plug chuck as already described, are typical examples. Another good example is the rechucking of a bowl.

The work is first mounted on a wood backing block secured to the large faceplate, and is turned in the usual manner-all except the back side (which is against the mounting bock). It is then removed' from the mounting block. An auxili ary chuck of softwood i now made in the same manner that the cylinder chuck is made. This chuck must have a turned recess properly sized to accommodate the rim fit. When the bowl is mount ed in this chuck, the bottom can be cleaned off and slightly recessed to complete the desired contours.

TURNING A RING

Another use of rechucking is made in turning

One method of turning a ring requires a spindle chuck. The work stock is first mounted to a backing block held by the large faceplate, and is turned to shape on the outer side. The

inside diameter of the ring is also shaped, all the way through the backing block. The work is then removed from the backing block—or, if no backing block was used, the portion which held the screws is cut off. A spindle chuck is now prepared so that it will be a tight press fit inside the ring, and the ring is reversed and mounted on this chuck. Thus mounted, the remaining contours can be turned to shape.

Another method of turning a ring makes use of a recessed chuck. The work stock is mounted on a screw center and one half of the ring is formed; but the ring is not cut away from its center. The stock is then removed, and a recessed chuck—mounted on the large faceplate —is prepared to receive the ring in a tight press fit. After being chucked, the remaining face of the ring can be turned to the proper

contour, thus cutting away the center portion. In work of this type take constant measurements—or better still, use a template—to guard against over or under cutting.

STEPS IN TURNING A RING

TURNING BALLS

Wooden balls of large size are first roughly turned between centers, using standard procedures. Smaller balls can be mounted as faceplates on the small faceplate or screw center. Lines drawn to indicate the center and ends of the ball shape are helpful in plotting the curve. A template should always be used for accurate visual observation of the work progress.

If the ball is mounted as a faceplate turning, almost the before it becomes necessary to rechuck it Rechucking can the finished portion of the ball in a tight press fit. An other method of rechucking is to use a shallow cup chuck which will not support the in conjunction with the tailstock. When using the shallow chuck, a wood block is fitted to the tailstock so that the ball can revolve upon it. This block should be lubricated with beeswax or chuck method, the ball is constantly shifted - never more than 1/8 turn-and always with a definite system. Since turning between centers makes the work a perfect sphere across the grain. the chuck so that the first scraping cuts will round it

TURNED BOXES

Turned boxes involve deep recessing together with a special system of working the lid and body of the box together as one unit. The inside of the lid is turned first. Next, the inside of the body is turned. A careful check must be made when turning the lip of the body portion so that the lid will be a tight press fit. The lid is then pressed onto the body and the outer circumference and face of the lid, together with the outer circumference of the body, are turned all at one time. This insures accurate matching of the two pieces. After the work is complete, the tight fit of the lid can be relieved by sanding the lip of the body.

SEGMENTED TURNINGS

Segmented bowls and boxes are exceptionally attractive—and this method of preparing wood stock is more economical than the use of large solid pieces. For some types of work, segmenting is the only practical method because a

block (if obtainable) would be so large that it would be very likely to warp.

The bowl illustrated requires 12 segment pieces for the sides. Bowls can be worked with 6 or 8 pieces if desired. To make the 12-piece bowl. a board about 7/8 x 3 x 30 inches is cut into pieces about 2-1/2 inches long, the saw table being tilted 15 degrees and the board being turned alternately face up and face down to make the successive cuts. These 12 pieces are glued together and clamped by wrapping the assembly with wire. When dry, the rim thus formed is glued to a temporary circular backing which is mounted on the large faceplate. A recess of the largest possible diameter, and about 3/4 inch deep, is turned in the open end of the rim. The rim is removed from the lathe, and stock for the bottom is mounted in its place on a second faceplate. This is turned to size—and a rim about 1/8 inch deep is turned to exactly fit the recess prepared in the rim. The rim is then fitted over the bottom and glued, making a drum shape with a faceplate at each end. This drum is cut completely in two at a point about 3/4 inch above the bottom-completing the cut with a hand saw. Both parts of the cut surface are faced off square and smooth -then reglued together, breaking the joints exactly half and half. The cutting and regluing process is repeated with a section about 1-1/4 inch wide. After this, the temporary backing block is cut off, leaving the bowl as shown in the bottom illustration.

From this point on the work is simply a matter of turning down the bowl to any desired shape.

miscellaneous operations

CUTTING DOWELS

Dowels of any size can be turned quickly with one or the other of the two simple jigs illustrated below. If the stock is prepared as a split or quartered turning (page 21), half-rounds and quarter rounds will be produced.

The first jig uses a 1/2-inch gouge as the cutting tool, and will produce dowels up to 7/16-inch diameter. Make the jig from suitable hardwood stock. It should be constructed so that it can be clamped to the lathe bed in the manner shown. The

hole through the jig must be accurately aligned with the headstock spindle. This is done by inserting a 60-degree center in the headstock then advancing the jig to mark the hole position. That half of the hole facing the headstock must be large enough to pass the square stock that will be used; but the remainder of the hole, from the gouge position outward, must be just large enough to hold the finished dowel and give it proper support. This part of the jig can be prepared to receive inserts drilled to pass different sizes of dowels—so that the jig can be used for more than one size of preduct

Clamp the gouge to the block, and secure the block to the lathe bed close to the headstock, as illustrated. Feed the work through the hollow spindle, and through the jaws of a lathe chuck that is adjusted to grip the work just enough to revolve it, but not enough to interfere with the feeding operation. Use a push block to force the work through the jig, and operate the lathe at top speed.

The second jig can be made to take work of any desired size. It is constructed on the same principle as the first jig; but a moulding cutter is used instead of a gouge. This cutter is fastened with a screw.

For workpieces small enough to be passed through the headstock spindle, the jig is mounted in the jaws of a lathe chuck and revolved around the work, which is fed through the jig from front to back of the hollow spindle. For larger work, the jig is placed over one end of the workpiece, which is then mounted between centers on the lathe. The workpiece is revolved—and the jig is hand fed along it from one end to the other.

TURNING DUPLICATE PIECES FROM SMALL DIAMETER STOCK