Page 1

WaterWorks TM

Undersink Reverse Osmosis

HOME DRINKING WATER SYSTEM

Model RO 2000

Installation

Operation

Maintenance

Repair Parts

IF YOU HAVE QUESTIONS WHEN

INSTALLING, OPERATING

AND MAINTAINING YOUR REVERSE

OSMOSIS SYSTEM...

CALL TOLL FREE

1-800-86 WATER

System Tested and Certified to

ANSI/NSF Standard 58. See

performance data sheet for details,

Manufactured by EcoWater Systems, Inc, PO BOX 64420, ST. PAUL, MN 55164 Part No. 721 4105 (10/99)

Page 2

- TABLE OF CONTENTS -

Safety Guides ................................................ 2-3

What Your Home Drinking Water System Will Do ..................... 3

Things To Check Before You Start To Install ....................... 4-5

How To Install Your Home Drinking Water System ................. 5-11

How Your Home Drinking Water System Works .................. 11-12

Care Of Your Home Drinking Water System ..................... 13-16

Dimensions And Specifications ................................... 17

Repair Parts ............................................... 18-19

Remote Locations For The RO ..................................... 20

-WARRANTY-

FULL WARRANTY ON DELUXE REVERSE OSMOSIS DRINKING WATER SYSTEM

(except battery, filter, filter cartridge or membrane)

For one year from the date of purchase, when this deluxe reverse osmosis drinking water system

is installed and maintained in accordance with our instructions, Sears will repair, free of charge, de-

fects in material and workmanship, except for disposable battery, filters, cartridges and membranes.

TO OBTAIN WARRANTY SERVICE, SIMPLY CONTACT THE NEAREST SEARS SERVICE

CENTER THROUGHOUT THE UNITED STATES. This warranty applies only while this product

is in use in the United States.

This warranty gives you specific legal rights, and you may have other rights which vary from state

to state.

Sears, Roebuck and Co., D/817 WA, Hoffman Estates, IL 60179

SEARS INSTALLATION POLICY

All installation labor arranged by Sears shall be

performed in a neat, workmanlike manner in

accordance with generally accepted trade prac-

tices. Further, all installations shall comply with all

local laws, codes, regulations, and ordinances.

Customer shall also be protected, during installa-

tion, by insurance relating to Property Damage,

Workman's Compensation and Public Liability.

SEARS INSTALLATION WARRANTY

In addition to any warranty extended to you on

the WaterWorks merchandise involved, which

warranty becomes effective the date the mer-

chandise is installed, should the workmanship of

any Sears arranged installation prove faulty

within one year, Sears will, upon notice from you,

cause such faults to be corrected at no additional

cost to you.

- SAFETY GUIDES -

_' Read all steps, guides and rules carefully

before installing and using your Home Drink-

ing Water System. Follow all steps exactly to

correctly install. Reading this book will also

help you to get all the benefits from your Home

Drinking Water System.

DO NOT ATTEMPT TO USE THIS PROD-

UCT TO MAKE SAFE DRINKING WATER

FROM NON-POTABLE WATER SOURCES.

2

Page 3

- SAFETY GUIDES -

DO NOT USE THE SYSTEM ON

MICROBIOLOGICALLY UNSAFE WATER,

OR WATER OF UNKNOWN QUALITY

WITHOUT ADEQUATE DISINFECTION

BEFORE OR AFTER THE SYSTEM.

Systems certified for cyst reduction may

be used on disinfected water that may

contain filterable cysts.

CHECK WITH YOUR LOCAL PUBLIC

WORKS DEPARTMENT FOR PLUMBING

AND SANITATION CODES. YOU MUST

FOLLOW THEIR GUIDES AS YOU INSTALL

THE SYSTEM. FOLLOW YOUR LOCAL

CODES IF THEY DIFFER WITH GUIDES IN

THIS MANUAL.

house water pressure is over the maximum,

install a pressure reducing valve in the water

supply to the Home Drinking Water System.

Do not install the Home Drinking Water System

outside, or in extreme hot or cold temp-

eratures. Temperature of the water supply to

the Home Drinking Water System must be be-

tween 40OF (minimum) and 100OF (maximum).

See the specification table on page 17. DO

NOT INSTALL ON HOT WATER.

Read the other limits (pH, hardness, etc.) on

page 17 and be sure your water supply con-

forms. Please read WATER SUPPLY, page 4.

The Home Drinking Water System works on

water pressure of 40 psi (minimum) to 125 psi

(maximum). See the table on page 17. If your

- WHAT YOUR HOME DRINKING WATER SYSTEM WILL DO -

Your Home Drinking Water System is a REVERSE

OSMOSIS (RO) water treating unit. It uses

household water pressure to reverse a natural

physical process called osmosis. Water, under

pressure, is forced through a semi-permeable mem-

brane where minerals and impurities are screen-

ed out and sent down the drain with the waste

water. These minerals and impurities are measured

as total dissolved solids (TDS).

The system includes replaceable pre and postfilter

sediment-carbon cartridges. The prefilter removes

sand, dirt, rust particles and other sediments. It also

takes chlorine out of the feed water. The postfilter

removes any remaining tastes and/or odors just

before water is taken from the system faucet. The

storage area holds almost 1 gallon of RO product

water for your needs.

The undersink system connects to a house COLD

water pipe for a water supply. An automatic shutoff

valve prevents water waste when the storage area

is full and the faucet is closed.

The drinking water system gives you a continuous

supply of sparkling clear, delicious water for drink-

ing and cooking. Foods will look better and taste

better too. The system eliminates the need to buy

bottled water. Instead, it puts high quality water right

at your fingertips.

NOTE: A product data sheet is included, and also

available from Sears. The data sheet lists what this

RO system will remove (or reduce) from the water.

ELECTRONIC MONITOR

The electronic model has 2 water quality sensors,

located in the electronic box. Indicator lights on the

faucet base work with the sensors, or probes, to

show you when water quality is good, and when the

system needs servicing.

As you take water from the RO faucet, a flashing

green light means the system is giving you high

quality RO water. Over a period of time, the RO

membrane, prefilter cartridge and postfilter begin

to lose efficiency. Flashing amber lights (see pages

12, 13 and 14) tell you when to service the RO mem-

brane and filters.

3

Page 4

- THINGS TO CHECK BEFORE YOU START TO INSTALL -

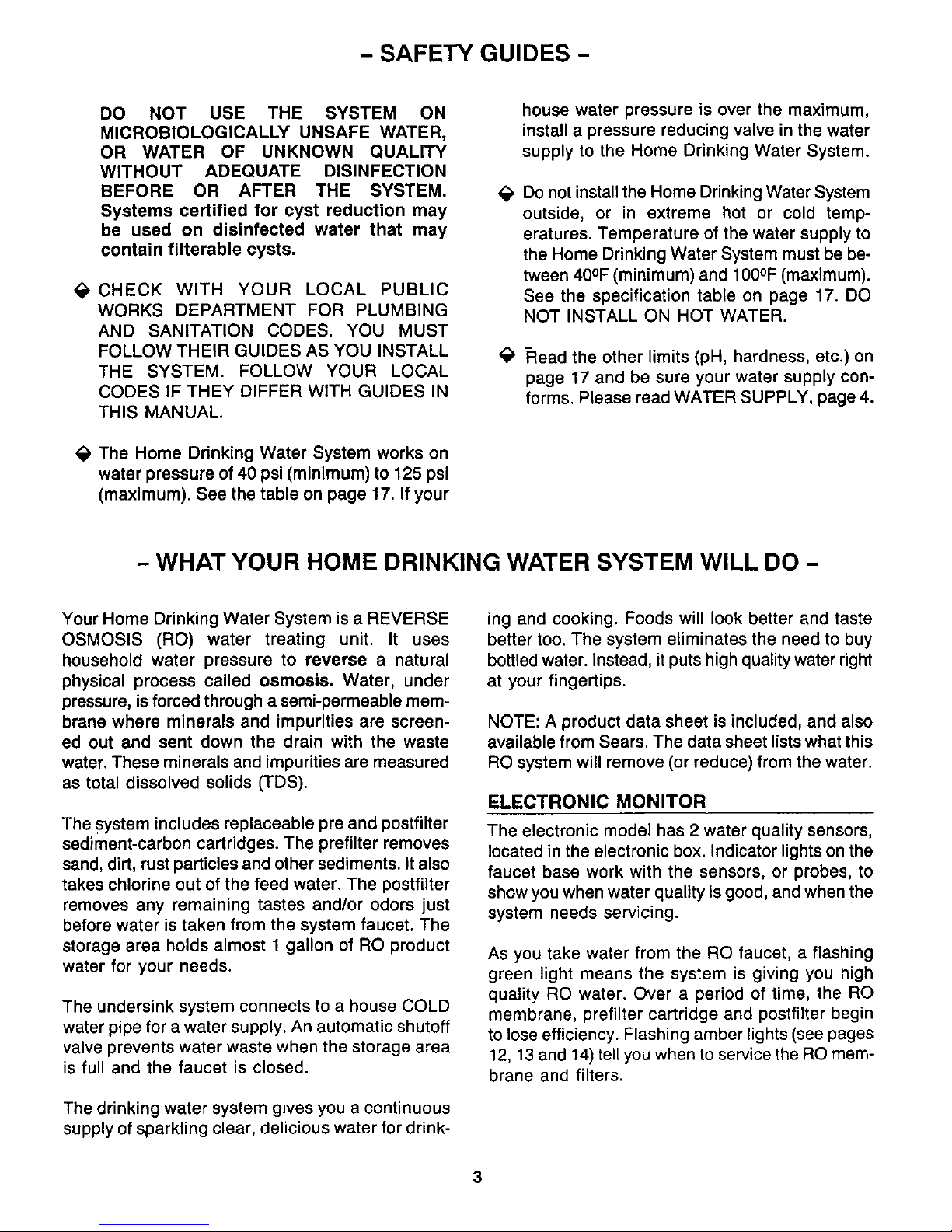

• PARTS IN THE SHIPPING CARTON -- Unpack

the carton carefully so needed parts are not discard-

ed by mistake. Included are:

_ _ WATER

(_ _ _ t SUPPLY

_,/_1 _b')_tl SADDLE

VALVE

_,,_ --.

RO

, I ASSEMBLY _ .t

_ BATTERY

HOLDER

_ WITH

BATTERIES (4)

I

ELECTRONIC

FAUCET

BASE

DRAIN

ADAPTER

£

FAUCET

ASSEMBLY

• WATER SUPPLY -- The cold water supply to

your Home Drinking Water System must be within

certain chemical limits (see page 17). If not, it will

not make product water as it should, and life of the

RO membrane is shortened.

CAUTION: CHLORINE IN WATER SUPPLY. The

RO membrane is destroyed by chlorine. A pre-

filter carbon cartridge removes chlorine from the

water before it enters the RO membrane.

IMPORTANT: TO KEEP CHLORINE FROM

DESTROYING THE RO MEMBRANE, BE SURE

TO REPLACE THIS CHLORINE REMOVAL CAR-

TRIDGE AT LEAST EVERY 6 MONTHS, OR 900

GALLONS. (SEE RO CARE GUIDE, PAGE 16.)

NOTE: Codes in thestate of Massachusetts require installation

by a licensed plumber, and do not permit the use of the saddle

valve. For installation, use plumbing code 248-CMR of the

Commonwea]th of Massachusetts.

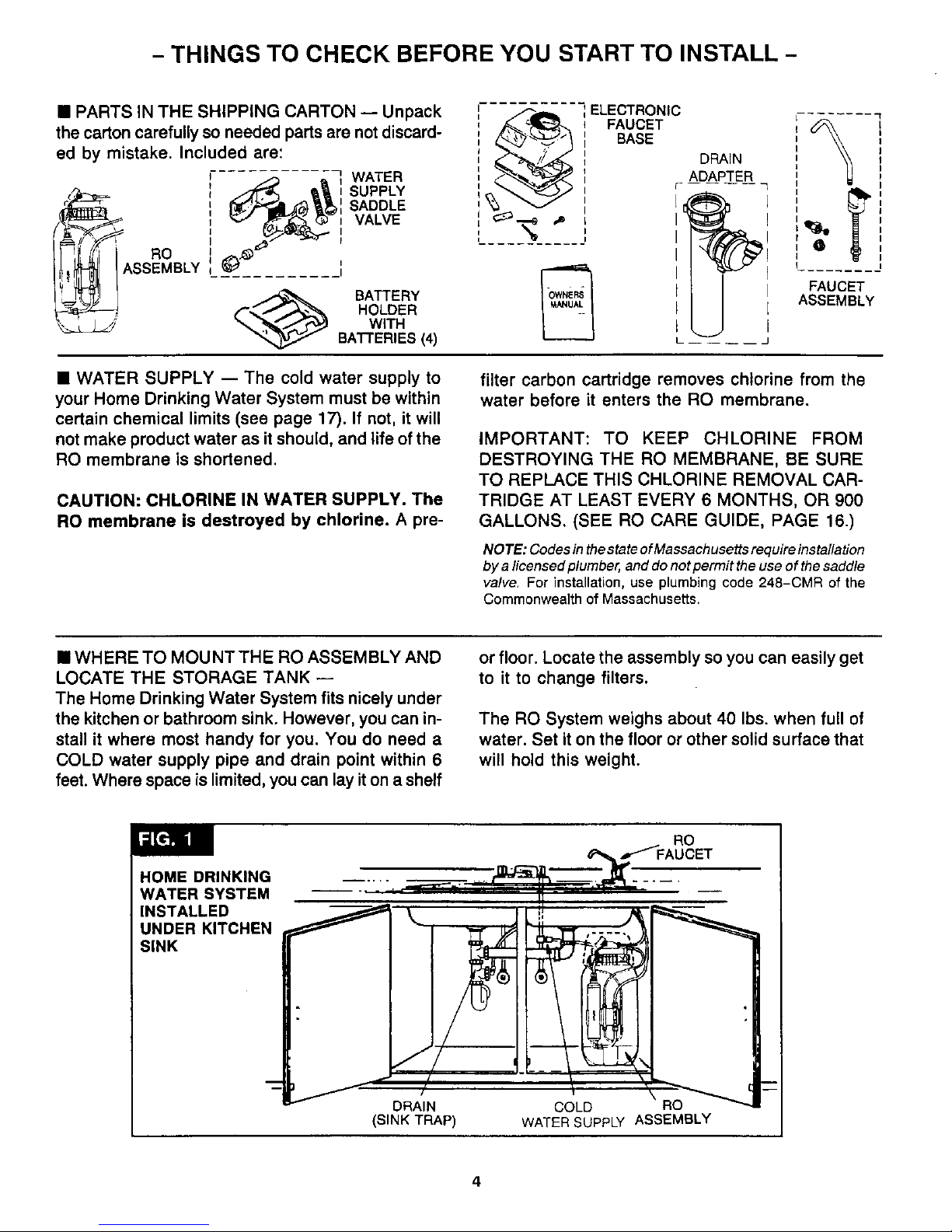

• WHERE TO MOUNT THE RO ASSEMBLY AND

LOCATE THE STORAGE TANK --

The Home Drinking Water System fits nicely under

the kitchen or bathroom sink. However, you can in-

stall it where most handy for you. You do need a

COLD water supply pipe and drain point within 6

feet. Where space is limited, you can lay iton a shelf

or floor. Locate the assembly so you can easily get

to it to change filters.

The RO System weighs about 40 Ibs. when full of

water. Set it on the floor or other solid surface that

will hold this weight.

RO

/FAUCET

HOME DRINKING

WATER SYSTEM

INSTALLED

UNDER KITCHEN

SINK

DRAIN COLD RO

(SINK TRAP) WATER SUPPLY ASSEMBLY

Page 5

- THINGS TO CHECK BEFORE YOU START TO INSTALL -

REMOTE LOCATION -- You can install the RO

assembly or water supply saddle valve in another

place away from the RO faucet (please see page

2O).

• REPLACING ANOTHER RO SYSTEM -- We

suggest you remove all parts of another RO system,

and use everything included with your new RO

system.

- TOOLS AND MATERIALS YOU WILL NEED -

==9/16" open end, or adjustable wrench

• standard pliers, and larger adjustable jaw pliers

or pipe wrench

• slotted and Phillips head screwdrivers

• plumbers putty

• pipe joint compound (thread seal) or Teflon

tape, approved for use on potable water sup-

plies

• hand or battery powered drill with 1/8" bit (if

needed for the cold water supply valve, page 6)

• electric drill and bits, if hole is needed for the

RO faucet, page 7

CAUTION: TO AVOID DAMAGING A SINK

BEYOND REPAIR, CONSULT A QUALIFIED

PLUMBER OR INSTALLER FOR GUIDES

BEFORE DRILLING HOLES IN PORCELAIN OR

STAINLESS STEEL

- 5 STEPS TO INSTALL THE SYSTEM -

STEP 1 - INSTALL THE COLD WATER SUPPLY SADDLE VALVE, PAGE 6.

STEP 2 - INSTALL THE DRAIN ADAPTER, PAGES 6 AND 7.

Note: Running the drain tubing directly to a floor drain, sump, standpipe, laundry tub, etc., as shown on page

20, is preferred. However, ifthat is not possible or practical, the included drain adapter installs in the sink drain

pipe, always above or ahead of the p-trap. Be sure to comply with your local plumbing codes. Other drain

pipe fittings, in addition to the adapter, may be needed.

STEP 3 - INSTALL THE FAUCET, PAGES 7-9,

A - PREPARE MOUNTING HOLE

B - ASSEMBLE FAUCET

C - FASTEN FAUCET IN PLACE

STEP 4 - MAKE ELECTRICAL, AND REMAINING TUBING CONNECTIONS.

STEP 5 - SANITIZING, PRESSURE TESTING, PLACING IN "SERVICE".

5

Page 6

- HOW TO INSTALL YOUR HOME DRINKING WATER SYSTEM -

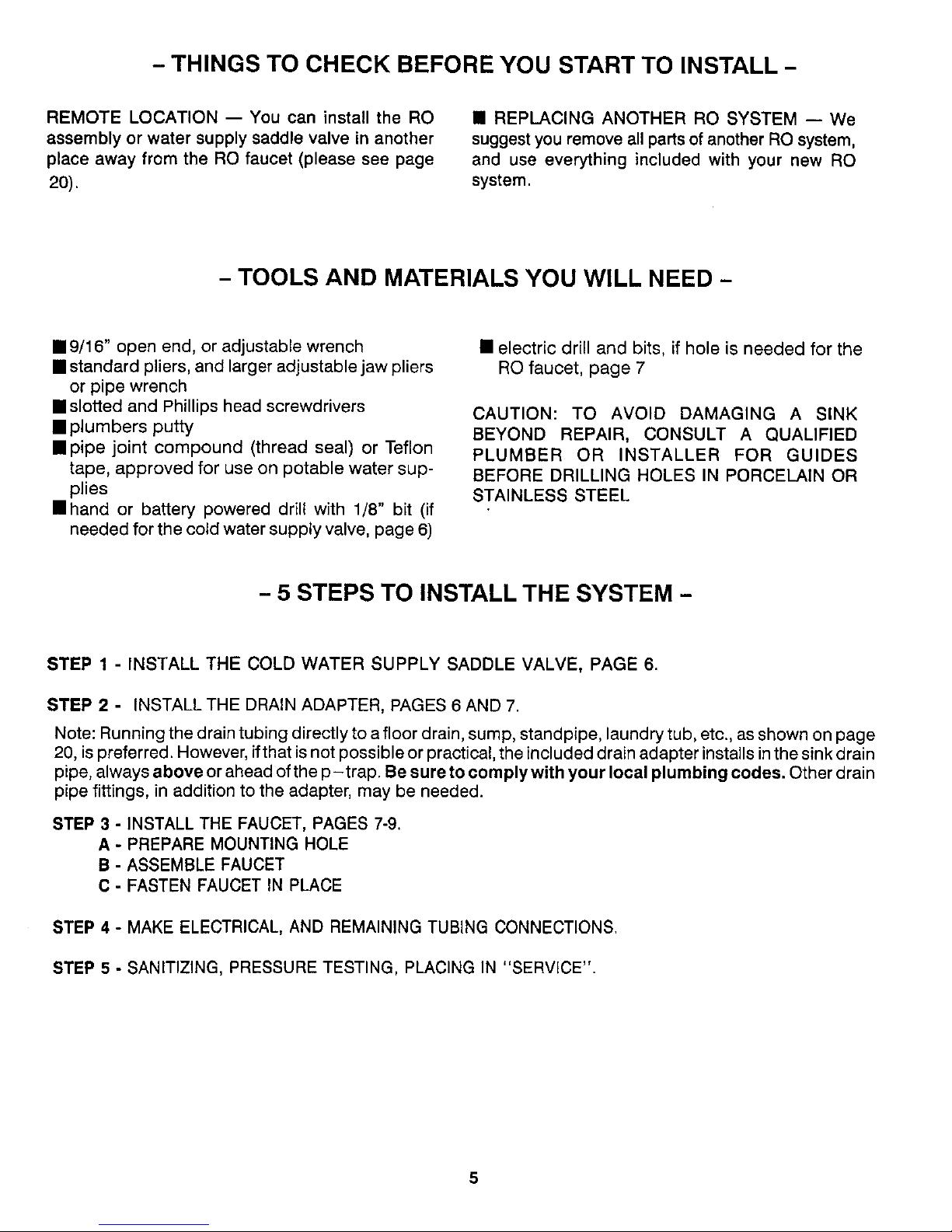

STEP 1 -- INSTALL THE COLD WATER SUPPLY SADDLE VALVE (FIG. 2)

• Install this valve on the COLD water pipe to the

kitchen sink (FIG. 2).

• This valve has a cutting pin and will make its own

hole in copper or plastic pipe. To install on iron pipe,

you have to drill a 1/8" diameter hole for the cut-

ting pin.

DANGER (IF DRILLING PIPE): TO PROTECT

YOURSELF FROM SERIOUS INJURY OR FATAL

SHOCK, USE A HAND OR BATTERY POWERED

DRILL ONLY TO MAKE THE HOLE. DO NOT USE

AN ELECTRIC DRILL.

• USE THE FOLLOWING GUIDES TO INSTALL:

1. Close the house main water supply valve. Open

a high and low faucet in the house to drain water

from the pipes.

2. Looking at FIG. 2, if not already done, turn the

valve into clamp A and tighten. Turn the valve han-

dle all the way out.

NOTE: If you have to drill a 1/8" diameter hole, hold

the valve with clamp A up to the pipe and mark the

spot to drill. BEFORE DRILLING, READ THE

DANGER NOTE ABOVE.

3. Place the seal on the inside of clamp A as shown.

Locate clamp A (turn handle in to align pin if pre-

drilled hole) and clamp B on the pipe. Fasten in

place using 2 screws. Tighten each screw evenly,

WATER SUPPLY SADDLE VALVE

NOTE: In Massachusetts, use

plumb4ng code 248-0MR.

COLD

CHECK LOCAL WATER

CODES FOR PIPE

APPROVAL

CLAMP A

VALVE

CLAMP B

HANDLE

but do not overtighten and crush the pipe.

4. Turn the valve handle inward to make a hole in

the copper or plastic pipe.

DO NOT TURN ON THE WATER SUPPLY AT THIS

TIME.

NOTE: BE SURE THE VALVE HANDLE PACKING

NUT IS TIGHT.

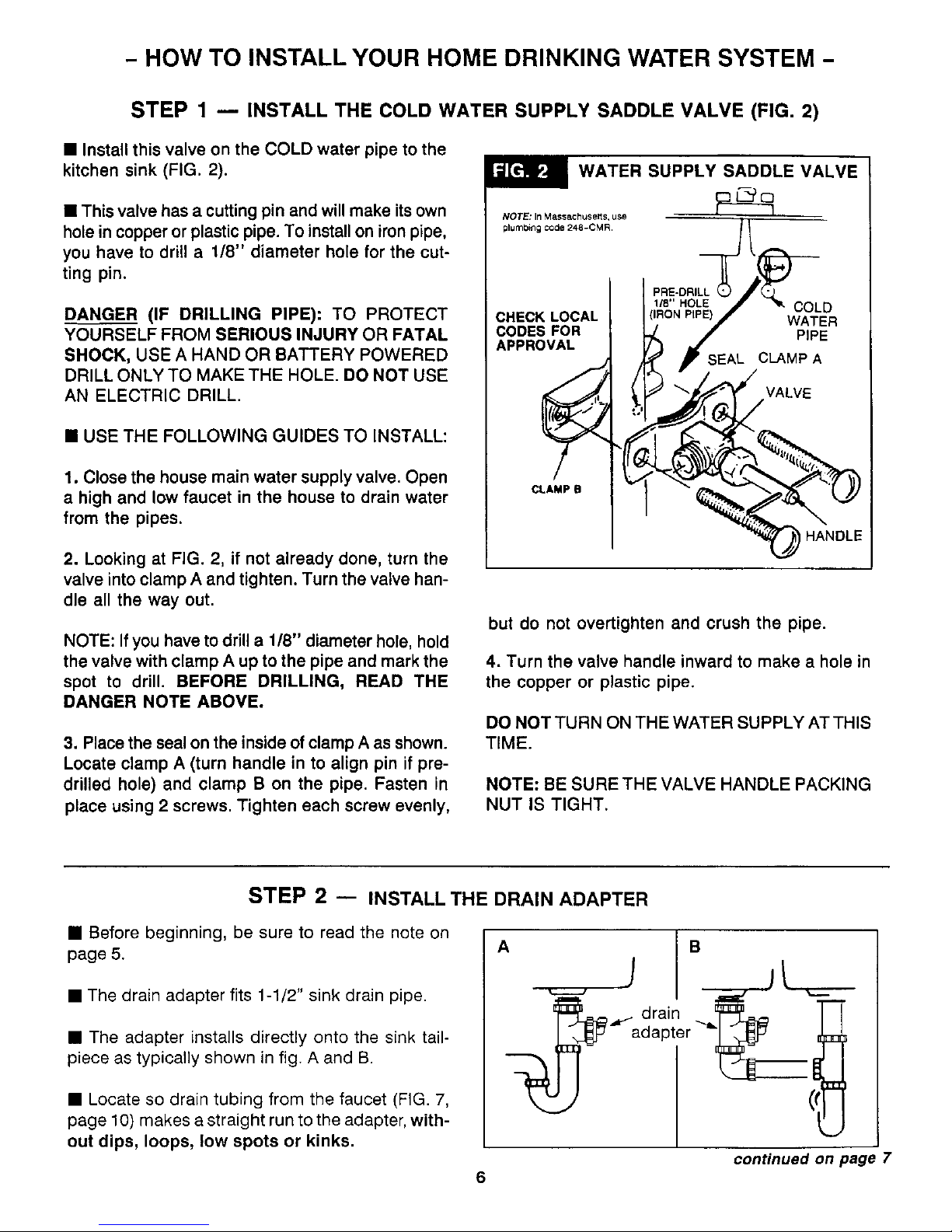

STEP 2 -- INSTALL THE DRAIN ADAPTER

• Before beginning, be sure to read the note on

page 5.

• The drain adapter fits 1-1/2" sink drain pipe.

• The adapter installs directly onto the s(nk tail-

piece as typically shown in fig. A and B.

• Locate so drain tubing from the faucet (FIG. 7,

page 10) makes a straight run to the adapter, with-

out dips, loops, low spots or kinks.

A B

drain

continued on page 7

6

Page 7

- HOW TO INSTALL YOUR HOME DRINKING WATER SYSTEM -

INSTALL THE DRAIN ADAPTER

• Use FIG. 3 and the following guides.

Note: Consult a plumber if you are not familiar with

plumbing procedures•

1. Use a ferrule and nut to assemble the drain

tubing connector to the drain adapter. Turn the

connector to about 45 ° from the 12:00 position,

as shown (to 10:00 or 2:00 position). Tighten the

nut securely.

2. Carefully disassemble the sink drain pipe and

clean the tailpiece to assure a leak-tight fit•

3. Install the drain adapter onto the sink tailpiece,

using a ferrule and nut. Snug the nut, but do not

tighten.

Note: If needed, to make fit, you can cut to shorten

the unthreaded end of the adapter. Do not cut too

short so the adapter will make a leak-tight seal

with the connecting fitting.

4. Assemble the p-trap to the drain adapter, and

other drain pipe fittings as required (check

codes) to complete the drain run.

5. Tighten all connections.

ferrule O

drain adapter

ferrule

cut, if2 t _

needed drain tubing

connector

nut

I

_ o

45 //

STEP 3 u PREPARE MOUNTING HOLE, ASSEMBLE FAUCET AND INSTALL

A. PREPARE MOUNTING HOLE.

1. Pick 1 of the following places for the faucet where

it will fit flat against the surface. Be sure you have

room underneath for the tubing connections (FIG.

7, page 10).

•..in a hole already in the sink (enlarge to 1-1/4"

diameter if needed) to use for an extra faucet

or spray.

...drill a hole (1-1/4" diameter) in the sink top.

BEYOND REPAIR, CONSULT A QUALIFIED

PLUMBER OR INSTALLER FOR GUIDES

BEFORE DRILLING HOLES IN PORCELAIN OR

STAINLESS STEEL.

•.. drill a hole (1-1/4" diameter) in the countertop

next to the sink.

2. Drill the mounting hole.

3. Place plumbers putty around the edge of the hole

to prevent water leakage around the faucet base.

CAUTION: TO AVOID DAMAGING A SINK

7

Page 8

- HOW TO INSTALL YOUR HOME DRINKING WATER SYSTEM -

ASSEMBLE FAUCET AND INSTALL - continued

B. ASSEMBLE FAUCET (FIG. 4)

1. Remove the hex nut, and all other parts shown

in the dotted line box, FIG. 4.

2. Insert the faucet stud through the top gasket and

faucet base. Then, replace the hex nut and tighten.

DO NOT OVERTIGHTEN AND BREAK THE

FAUCET BASE.

NOTE: The faucet may include some small parts

that are not used.

3. Wet the o-rings (2) on the faucet spout. Push the

spout into the faucet body until it bottoms in the

cavity.

C. FASTEN FAUCET IN PLACE

1. Looking at FIG. 5A, locate the faucet support and

gasket over the sink or countertop mounting hole.

NOTE: First, breakout small button and save for use

in step 10.

2. Turn the special nuts (FIG. 5B) a few turns onto

the 1-3/8" long screws.

3. Place a screw into a notch in the faucet support,

with the nut on the underside of the mounting hole

(FIG. 5C). Use a finger to hold the nut and tighten

the screw until snug. In the same manner, install

the second screw and nut. BE SURE THE SUP-

PORT IS POSITIONED CORRECTLY, THEN

TIGHTEN BOTH SCREWS EVENLY UNTIL THE

SUPPORT IS HELD FIRMLY IN PLACE.

4. As shown in FIG. 6, insert the washer into the

tubing adaptor. Turn the adaptor onto the faucet

stud, and tighten.

5. Move the RO assembly into installation position

under the sink, or other desired location. Route the

2 lengths of tubing, marked "FAUCET", and "1/4"

BARB ON FAUCET", from the bottom, upward

through the mounting hole and faucet support (FIG.

6).

6. Using the brass tubing nut, fasten the 3/8"tub-

ing (marked "FAUCET") to the tubing adaptor and

faucet

body

A

gasket

/

plumbers

putty

8

FAUCET AND BASE

ASSEMBLED

faucet

suppod

button

(use in step 10)

screw(2)

nut (2)_,._

mounting

hole

C

TOP VIEW screw (2)

N_1/ mounting

_ hole

_) " nut (underside

"of mounting hole)

faucet support

Page 9

- HOW TO INSTALL YOUR HOME DRINKING WATER SYSTEM -

tighten the nut. NOTE: Cut tubing as needed for

neat appearance, but keep long enough to alllow

easy service of the RO system.

7. If needed, cut the 1/4" tubing (marked "1/4"

BARB ON FAUCET") to length. Then, push the end

all the way onto the 1/4" barb fiting on the faucet.

8. Take the 27" long separate piece of 3/8" tubing

and pass 1 end down through the faucet support.

Push the other end all the way onto the 3/8"barb

fitting on the faucet.

9. Feed the faucet base leadwire down through the

faucet support.

10. Lower the faucet and base down onto the faucet

support, carefully working the tubing and leadwire

through the support. Use the 5/8" long screw to

fasten base and support together. Insert the but-

ton, removed from the support in step 1, into the

hole to cover the screw.

faucet base -_

1/4" barb

fitting

3/8" barb

fitting

washer

tubing

3/8"

faucet su

NOTE:FOREASE

OFSERVIC_AND

MAINTENANCE,KEEP

TUBINGLENGTHSLONG

ENOUGHSOREMOVALOF

THEROSYSTEMFROM

UNDERTNt5SINHIS

POSSIBLE.

1/4" tubing

(1/4" BARB

318" tubing,

27" long

button

faucet base

leadwire

STEP 4 -- MAKE ELECTRICAL, AND REMAINING TUBING CONNECTIONS

A. INSTALL BATTERY PACK iN ELECTRONIC

BOX.

nectors together. Place the battery pack inside the

electronic box and install the back cover.

1. Looking at FiG. 7, page 10, remove the rubber

retainer holding the electronic box and postfilter in

the holder.

2. Pull the electronic box from the holder and

remove the back cover.

4. Reinsert the electronic box and postfilter into the

holder bracket.

5. Replace the rubber retainer around the holder.

3. Fasten the battery pack (BE SURE BATTERIES

ARE INSTALLED CORRECTLY, AS SHOWN ON

THE BATTERY HOLDER) and electronic box con-

continued on next page

9

Page 10

- HOW TO INSTALL YOUR HOME DRINKING WATER SYSTEM -

MAKE REMAINING RO CONNECTIONS - continued

B. CONNECT TUBING, FAUCET TO DRAIN TUB-

ING CONNECTOR

Looking at FIG. 7 and page 16, run the 3/8" x 27"

tubing from the RO faucet, to the connector at the

adapter you installed in the sink drain pipe. Cut this

tubing as needed to route in as straight of a run as

possible without dips, loops, low spots or kinks.

Be sure the end of the tubing is cut square, then

push the end into the connector until itstops (about

11/16"). Pull on the tubing to be sure it is held se-

curely.

C. CONNECT TUBING TO WATER SUPPLY

Use the tubing insert, ferrule and nut, at the water

supply saddle valve, to fasten the remaining 1/4"

tubing (marked "WATER SUPPLY"). Tighten the

nut with a wrench.

D. Fasten the faucet base and electronic box lead-

wire connectors together, routing where dry, and

out of the way.

STEP 5 -- SANITIZING, PRESSURE TESTING, PLACING IN "SERVICE"

A. DO THE SANITIZING PROCEDURES, PAGE

15. THEN, CONTINUE WITH STEP B.

B, Double check all tubing connections to be sure

they are tightened.

C. Open the house main water supply valve and

the supply saddle valve (turn handle fully out). Open

the tank shutoff valve...see below.

D. In about 4 hours, pressure will start to build in

continued on next Daae

FAUCET

3/8" tubing,

27" long (cut to

length needed)

,-faucet base

DRAIN ADAPTER--._

2

HOT WATER

SUPPLY SADDLE VALVE

COLD WATER

1/4" tubing

(WATER SUPPLY)

i

(1/4" see steps 6 & 7,

pages 8 & 9, and

3/8" tubir FIG. 6 to

connect

OPEN

TANK

SHUTOFF VALVE

posffilter

CLOSED

ferrule

nut

NOTE: Codes in tile state of Massaei_usetbs raqutre mstah

/at,on Oy a licensed plumt_er, and do not permit the use of

the saddle valve¸ For insla_lation, use plumbing code

248-CMR of the CommonweaJth of Massachusetts¸

box

RO

ASSEMBLY

leadwire connection

batte_

pack

10

Page 11

- HOW TO INSTALL YOUR HOME DRINKING WATER SYSTEM -

the RO system. At that time, carefully check all fit-

tings and tubing connections for any water leaks.

Correct leaks if any are found.

E. IMPORTANT PURGING INSTRUCTIONS:

The RO cartridge contains a food grade preser-

vative that you should clean from it before using

the system. The preservativewillgive product water

an unpleasant taste and odor.

1. After the storage bladder has filled (takes about

4 hours), open the system faucet until the bladder

is empty.

2. Allow the bladder to fill again for about 4 hours,

then open the faucet and empty. After 4 purgings,

the system is ready to make product water for your

use,

- HOW YOUR HOME DRINKING WATER SYSTEM WORKS -

Water from the cold supply pipe saddle valve is

directed through 1/4" tubing, to the electronic box.

Here, the total dissolved solids (TDS) content, of

the supply water, is measured. Water flow continues

to the RO prefilter.

automati

shutoff

PREFILTER - The prefilter is a replaceable tank

sediment-activated carbon cartridge. It removes shutoff

sand, silt, dirt, other sediments, and up to 2 parts RO water

per million (ppm) chlorine from the supply water, to

CHLORINE WILL DESTROY THE RO MEM- postfilter

and

BRANE... SEE PAGES 4 AND 13. Filtered, clean, faucet

chlorine-free water flows from the prefilter and to

the RO membrane.

RO MEMBRANE CARTRIDGE - The RO car-

tridge, located inside of the prefilter, is a tightly-

wound, semi-permeable membrane. Semi-

permeable means water will work through the mem-

brane, but first, dissolved solids and organic mat-

ter are screened out and flushed to the drain. The

screened, high quality product water goes to the

storage area, or to the postfilter if the RO faucet

is open.

POSTFILTER - After leaving the storage area, but

before going to the faucet, product water goes

through the postfilter. The postfilter is also a

sediment-carbon type filter. It removes any remain-

ing tastes, odors or sediments from the product

continued on next page

supplywater

IN

prefilter

cartridge

RO

membrane

cartridge

RO

housing

check

valve

bladder

11

Page 12

- HOW YOUR HOME DRINKING WATER SYSTEM WORKS -

POSTFILTER - continued

water. High quality drinking water flows from the

postfilter and to the faucet.

NOTE: Before going to the faucet, product water

passes through the electronic box and remaining

TDS is measured by a sensor.

FAUCET - The sinktop or countertop faucet

dispenses the drinking water. It has a hand

operated, spring loaded lever to keep the faucet

closed and to prevent waste. You can keep the

faucet open by pushing upward on the lever and

locking it against the spout. To meet plumbing

codes, an air-gap is built into the faucet drain water

tubes. The air-gap prevents a back siphon of drain

water.

MONITOR - When the faucet is opened, lights on

the faucet base show how the RO system is

working.

• FLASHING GREEN - The RO system is giving you

high quality product water.

NOTE: The green light may stop flashing when the

supply of RO water is nearly gone, and flow from

the faucet decreases. This is a normal condition.

• FLASHING AMBER "FILT" - The prefilter car-

tridge and postfilter need replacing. Also replace

the control box batteries...see page 14. This

light comes on after 6 months, or after 900 gallons

of product water use.

FLASHING AMBER "RO" - The RO membrane

cartridge needs replacing. (BE SURE TO

REPLACE BA-I-FERIES...SEE ABOVE, TO

ASSURE PROPER "RO" LIGHT OPERATION.)

The RO light comes on when the RO membrane

no longer removes at least 75% of the TDS from

the water supply.

NOTE: Disregard the "RO" light when it flashes

for a few seconds at a time.

AUTOMATIC SHUTOFF - When the storage

area has filled with product water, and the RO

faucet is closed, the automatic shutoff is forced clos-

ed. Water flow through the system is stopped before

it can enter the RO module, preventing continued

flow to the drain. The shutoff remains closed, and

water is saved, until the faucet is opened again.

CHECK VALVE - A check valve (FIG. 8) is built

into the product water outlet of the RO housing. The

check valve prevents a backward flow of product

water, from the storage area, to the membrane. A

backward flow could rupture the RO membrane.

FLOW CONTROL - The flow control (FIG. 9)

keeps flow through the RO cartridge at the need-

ed rate for high quality product water. A cone

shaped screen fits over the flow control to help pre-

vent plugging with drain water sediments.

- CARE OF YOUR HOME DRINKING WATER SYSTEM -

To keep your Home Drinking Water System work-

ing and making high quality water, you must make

sure supply water is always within the limits shown

on page 17. This gives you the longest life from the

PREFILTER CARTRIDGE, RO MEMBRANE CAR-

TRIDGE, and POSTFILTER. Each of these will wear

out in time and need replacing.

CAUTION: BEFORE WORKING ON THE

SYSTEM, DO THE FOLLOWING TO

RELIEVE WATER PRESSURE IN THE RO

TANK.

la. Turn off the water supply to the RO (turn the

supply saddle valve all the way inward...FIG. 7).

b. Open the product water faucet and keep open

until water flow stops.

the water, disconnect the posffilter and empty

the storage bladder.

,

Looking at FIG. 9, or page 18, remove the pro-

tective cap and depress the relief valve stem,

allowing air to ENTER the tank (do not block

valve passage). Release the valve stem

AFTER flow from the shutoff valve slows to a

slight drip. Replace the protective cap.

CAUTION: This valve is for vacuum relief only. DO

NOT attempt to pressurize the tank.

3. Reconnect the postfilter.

c. Using a 2 gallon (minimum) container to catch

12

Page 13

- CARE OF YOUR HOME DRINKING WATER SYSTEM -

PREFILTER CARTRIDGE - You must replace

the prefilter cartridge often to protect the RO mem-

brane from being destroyed bychlorine, and/or from

plugging with sediments from the water supply. If

you have chlorine in the water, replace the cartridge

at least every 6 months. If the prefilter cartridge

plugswith sediments, waterflow intothe RO system

drops, slowing the making of qualityRO water. The

RO membrane may also begin to plug with

sediments. If this happens, you maynot get enough

RO water for your needs.

NOTE: The amber "FILT" light on the faucet base

will begin to flash after 6 months or 900 gallons of

product water use to tell you the filter cartridge

needs replacing.

cone screen

RO Cap __

control

_riu:;w_ L_dbg_n e

protective

cap _ o-ring end down

vacuum

relief

prefilter

BOTTOM

END

(2)

--..clamp

section (2)

electronic

box

POSTFILTER - Always replace the postfilter at the

same time you replace the prefilter cartridge. The

postfilter gives the product water a final filtering of

any tastes and/or odors that may remain.

TO REPLACE THE POSTFILTER

CAUTION: BE SURE TO RELIEVE PRESSURE,

STEPS 1, 2 AND 3, Bo'n'OM OF PAGE 12.

1. Disconnect tubing at both ends (Fig. 9).

2. Pull the filter from the holder and remove fittings

from both ends.

3. Observing the flow arrow, on new filter, turn the

fittings (use Teflon tape) into both ends. The

elbow fitting installs at the bottom end, or outlet.

4. Replace filter into the holder and reconnect the

tubing at both ends.

TO REPLACE THE PREFILTER CARTRIDGE

CAUTION: BE SURETO RELIEVE PRESSURE,

STEPS 1, 2 AND 3, BOTTOM OF PAGE 12.

IMPORTANT: BE SURE YOUR HANDS ARE

CLEAN BEFORE WORKING ON RO SYSTEM IN-

TERNAL PARTS.

1. Remove the clamp retainers and clamp sections

(Fig. 9).

2. Separate the cap from the RO housing (no need

to disconnect tubing) and set aside.

NOTE: If the cap o-ring seal remained in the

RO housing, replace it on the cap.

3. Lift the RO cartridge and prefilter cartridge from

the housing, then separate and dispose of the

prefilter cartridge.

4. Dump water remaining in the RO housing.

5. Slide the RO cartridge INTO THE TOP END of

the new prefilter cartridge, as shown in FIG. 9,

then place into the RO housing.

NOTE: Be sure the bottom end of the prefilter is

at the bottom, and the up arrow ( -_ ) on the RO

cartridge points upward (o-ring seal end down-

ward).

6. Be sure the cap o-ring has lubrication (silicone

grease). Then, push into position and install

clamp sections and retainers,

7. Replace the electronic box batteries.., see page

14.

13

Page 14

- CARE OF YOUR HOME DRINKING WATER SYSTEM -

RO MEMBRANE CARTRIDGE - The useful life

of the membrane cartridge depends mostly on the

pH (see page 17) of your supply water. The lower

the pH, the longer the membrane will last. For ex-

ample, if the feed water has a pH of about 7.0, the

cartridge may last for over 1 year; but if the pH is

high, cartridge life may be shortened. The high pH

weakens the membrane and makes pin hole leaks.

NOTE: The amber "RO" light on the faucet base

will begin to flash when RO water quality drops so

less than 75% of the TDS are removed from the

supply water.

This reverse osmosis system contains a

replaceable treatment component critical for

effective removal of total dissolved solids. The

water should be tested periodically to verify

that the system is performing satisfactorily.

TO REPLACE THE RO CARTRIDGE

1. Refer to page 13 and follow instructions under

"To Replace the Prefilter Cartridge".

2. Remove and replace the flow control and screen

(see steps on this page).

3. Turn on the water supply and PURGE THE RO

CARTRIDGE... SEE PAGE 11.

BATTERIES IN ELECTRONIC BOX - Always

replace the batteries (4, "AA" alkaline) in the elec-

tronic control box after installing a new prefilter car-

tridge and postfilter. Good batteries assure proper

operation of the indicator lights. Removing the bat-

teries also resets the 6 month or 900 gallon period

for monitoring the filter cartridges. See FIG. 7 on

page 10.

FLOW CONTROL - A clean flow control is a must

for the RO membrane to make high quality product

water. The flow control keeps water flow through

the membrane at the right rate to get the best quality

product water. If the control becomes plugged, so

water can't get through, it will only take a short time

for the RO membrane to become useless. A small,

cone-shaped screen is positioned over the flow con-

trol (FIG. 9) to help keep the flow control clean.

Every time you work on the RO system, check the

flow control and screen to make sure they are clean.

TO REPLACE FLOW CONTROL AND SCREEN

CAUTIONS: To install the screen, place the cone

end into the RO cap. Then carefully push it in us-

ing 1/4" tubing as a tool. Do not force in farther after

you feel resistance. Visually check to be sure it is

properly positioned.

When installing the flow control, tighten the nut by

hand, then another 1/4 to 1/2 turn with a pliers. DO

NOT OVERTIGHTEN AND DISTORT OR CRUSH

THE TUBING AND FLOW CONTROL.

SERVICING THE BLADDER

If the bladder should require inspection and replace-

ment, use the following guides. Refer to the parts

illustration on page 18.

CAUTION: BE SURE TO RELIEVE PRESSURE,

STEPS 1,2 AND 3, Bo'n'OM OF PAGE 12.

1. Remove the vacuum relief valve (use 7/16"

socket).

2. Rotate the tank shutoff valve 90o and pull from

the RO housing.

3. Apply downward pressure on the RO cap while

rotating counterclockwise 90 o.

NOTE: If the cap turns in the RO housing, first do

steps 1 and 2 under "To Replace the Prefilter Car-

tridge", page 13.

4. Lift the RO housing out of the liner assembly and

PLACE WHERE CLEAN AND SANITARY.

5. Remove the bladder.

NOTE: BE SURE THE INNER SURFACE OF THE

REPLACEMENT BLADDER, AND THE OUTER

SURFACE OF THE RO HOUSING ARE CLEAN.

USE DISH SOAP AND HOT WATER TO CLEAN

AND RINSE.

6. Install the bladder into the liner assembly. Wet

the top bead of the bladder with water, or apply

a light coating of silicone grease.

14

Page 15

- CARE OF YOUR HOME DRINKING WATER SYSTEM -

7. Install the RO housing, push downward and

rotate 900 clockwise to lock in place.

8. Replace the tank shutoff valve and rotate 900 to

lock.

9. Using the o-ring seal, replace the vacuum relief

valve.

10. DO THE SANITIZING AND PURGING PRO-

CEDURES, PAGE 10.

AUTOMATIC SHUTOFF SERVICE

If the shutoff assembly, on the RO cap, requires ser-

vice, reassemble parts exactly as shown in FIG. 10.

Be sure to align indicated marks to properly torque

cap to RO cap.

arrow

align

holes

RO cad

phragm

plunger

support

- plunger

Lphragm

mark

p support

o-ring

WHEN INSTALLING CAP,

TIGHTEN BY HAND.

THEN, USE A PLIERS

TO TIGHTEN AND ALIGN

MARK ON CAP WITH

ARROW ON RO CAP

SANITIZING THE RO SYSTEM

Sanitizing is recommended upon installation of the

RO system, and after servicing inner parts of the

RO housing, and cap. IT IS IMPORTANT FOR THE

SERVICE PERSON TO HAVE CLEAN HANDS

WHILE HANDLING INNER PARTS OF THE

SYSTEM.

1. BE SURE WATER SUPPLY TO THE RO IS

TURNED OFF, AND THE RO FAUCET IS OPEN.

2. Remove the clamp retainers and clamp sections,

Fig, 9, page 13.

3. Lift the cap from the RO housing (no need to

disconnect tubing) and move aside.

NOTE: IF THE CAP O-RING SEAL REMAINED IN

THE RO HOUSING, REPLACE IT ON THE CAP.

4. Remove the RO cartridge and prefilter car-

tridge from the RO housing. If needed, flush hous-

ing with fresh, clean water.

5. Fill the RO housing, with fresh water, to about

1 inch from the top. Add 1.0 oz. of chlorine (ordinary

5,25% household bleach... Hilex, Clerox, etc.) and

mix in the water. DO NOT ADD CHLORINE FIRST.

Concentrated, it will attack plastics,

6. Replace the cap, with o-ring, and install the re-

taining clamps.

7. Connect the RO faucet product water tubing

directly to the tank shutoff valve, isolatinq the car-

bon postfilter.

8. Open the tank shutoff valve, and the water supply

to the RO. Open the RO faucet, locking the lever

upward, against the spout.

9. Allow water to circulate through the system un-

til the bleach odor is gone.

10. Turn off the water supply to the RO. Close the

RO faucet after water flow stops.

11. Reconnect the postfilter (replace used filter) to

the RO system, Fig. 9, page 13.

12a. Do steps 2 and 3.

b. Replace the RO cartridge and prefilter car-

tridge (BE SURE YOUR HANDS ARE

CLEAN).

c. Do step 6.

d. Turn to page 10 and do the pressure testing

and purging steps B through E.

15

Page 16

- CARE OF YOUR HOME DRINKING WATER SYSTEM -

RO CARE GUIDE

MODEL RO 2000 WITH MONITOR

IMPORTANT: BEFORE DOING THE FOLLOWING MAINTENANCE, BE SURETO RELIEVE

PRESSURE AND ALLOW AIR TO ENTER THE TANK, STEPS 1, 2 AND 3, PAGE 12.

t. Replace the prefilter cartridge and postfilter when the amber "FILT" light begins to flash

while taking product water from the RO faucet. Clean or replace the flow control and screen.

and replace the batteries in the electronic control box.

2. Replace the RO membrane cartridge when the amber"RO" light begins to flash while tak-

ing product water from the RO faucet. Clean or replace the flow control and screen.

NOTES: a. If slow making of product water occurs before an amber light begins to flash,

replace the prefilter cartridge. If production rate does not improve, then replace the postfil-

ter and RO membrane, b. If product water flow from the RO faucet is slow, do the steps

referred to in the IMPORTANT note above.

OTHER TROUBLESHOOTING

PROBLEM

Chorine taste and/or odor in

the RO product water

Other taste and/or odor

CAUSE

The ppm of chlorine in your water supply

exceeds maximum limits, and has de-

stroyed the RO membrane.

The prefilter is no longer removing chlo-

rine from the water supply.

Postfilter expended.

RO membrane cartridge expended.

! Contamination in product water storage.

Water supplytothe RO system not within

specifications.

RO membrane cartridge expended.

Indicator lights, on faucet

! base, not working

CORRECTION

Ifthewater supplycontains morethan 2.0 ppmof chlorine, addi-

tional filtering of the water supply to the RO is needed. Correcl

this condition before doing maintenance on the RO system.

Replace the RO membrane cartridge, flow control, screen, pre-

filter, postfilter, and batteries in the electronic box.

Replace the postfilter. Iftaste and odor persists, replace the pre-

filter, RO membrane cartridge, flow control, screen, and batter-

ies in the electronic box.

Use sanitizing procedures. Then replace the postfilter.

High total dissolved solids Increasewaterpressure, preconditionthewater, etc.,aeneeded

(TDS) in product water to conform before doing maintenance on the RO system.

Replace the RO membrane cartridge, flow control, screen, pre-

filter, postfilter, and batteries in the electronic box.

Slow product water flow from Vacuumcreated in storageareeforprod- Open the vacuum relief valve and allow the tank to fill with air.

the RO faucet uct water. See page 12.

Waterleaking from faucet air- Drain side of faucet airgap (3/8" tubing) Inspect and eliminate restriction or plug. Refer to installation

gap hole plugged, restricted, or incorrectly con- instructions for proper drain connection,

nected to drain point.

Faucet base leadwire not connected to

electronic box leadwire.

Batterypacknotconnected to electronic

box.

Connect

Batteries installed incorrectly, or ex- Observeorientationmarkingsontheholderandinstallcorrectly.

_ended. Replace batteries ifold.

Leadwires or connectors damaged. Inspect and repair or replace as needed.

Tubing Connection at Drain Adapter: Cut the end of

the tubing square and push into the fitting as far as

possible (11/16"), Pull on the tubing to be sure it is

held firmly in place.

To Disconnect Tubing: Push the tubing inward to de-

press the fitting collet. Hold the collet in while pulling

the tubing out.

tubing

collet

I

I

I

16

Page 17

- DIMENSIONS / SPECIFICATIONS -

•=-- 8_ 1/8,,--.-_

21"

Supply water pressure limits ...................................... 40-125 PSI

Supply water temperature limits ..................................... 40-100OF

Maximum total dissolved solids (TDS) ............................... 2000 PPM

Maximum water hardness @ 6.9 pH .................................. 10 GPG

Maximum iron, manganese, hyd. sulfide .................................... 0

Chlorine in supply water

(SEE PAGE 4) ......................................... Max. 2.0 PPM 1

Supply water pH limits ................... •.......................... 4-10 pH

Product (quality) water, 24 hrs.* ..................................... 11 gals.

Waste water per gal. product water, 24 hrs.* ............................ 3 gals.

Percent rejection of TDS, minimum (new membrane)*. ..................... 90o/0

Storage capacity .................................................... 1 gal.

Product water vending flow ......................................... 1/2 GPM

METRIC

280-860 kPa

5-40oc

41.6 liters

11.4 liters

3.8 liters

1.9 liters/min.

*Supply water at 55 psi and 770F with 750 parts per million sodium chloride. Quality water production, amount

of waste water and percent rejection all vary with changes in pressure, temperature and total dissolved

solids. See the charts below for additional production and rejection rates.

1 Up to 2,0 ppm removedby the RO prefiltercartridge.

NOTE: This productis testedand complieswith Water QualityAssociation Standards.

You canusethe following chartsto determine ROperformance for your specificwaterpressure and total dissolved

solidscontent. Theresultsarefromtestsconducted onthe ROmembraneusing e9"longflow control ata25%product

water recovery rate.

PRODUCT WATER GALLONS PER DAY PERCENT REJECTION OF TDS

(PRODUCT WATER OUTLET OPEN) (PRODUCT WATER OUTLET CLOSED)

120 39.5 36 33 29

110 36.5 33 30 26

100 33.5 30 27 23

FEED 90 30 27 24 20

WATER 80 27 24 21 17

P_,_URE

23.5 21 18 14

TO R0 --

(PSI) 60 20.5 17.5 15 11

50 16.5 14.5 11.5 8.5

40 13 11 8.5 5.5

24 19

21.5 17

19 14.5

16 12

13,5 9.5

10.5 7

/

/PRESSURES/

/ TOO LO_//,_

/i,)THISDs

120 98.3 97.8

110 98.3 97.7

100 98.2 97.6

90 98.2 97.5

80 98.1 97.4

70 98 97.3

60 97.8 97

50 97.5 97

40 96.7 95.5

97.2 96.4

97.1 96.3

97 96.1

96.8 95.8

96.6 95.5

96.4 95

96 94.3

95.2 93

93.9 90.5

94.8 93,5

94.5 92.8

94.2 92.1

93.8 91.2

93.1 90

92.1 87.9

WATER _"

PRESSURES

TOO LOW/

TOTAL DISSOLVED SOLIDS (TDS)

TOTAL DISSOLVED SOLIDS (TDS)

17

Page 18

- REPAIR PARTS -

WaterWorks _

I 1

I

O I

I

HOME DRINKING WATER SYSTEM Undersink Reverse Osmosis MODEL RO 2000

]

I 36 -----_(_

DRAIN I

ADAPTER I 35 ---'-'-"_(_;J[

I"'---,_ 5 34 "'"""_ _

33 .-.----.-_ "_ 37

32 --"--'-_,_

27

i

TO

7 AIRGAR

i • 1/4" BARB

24 _ 26

\

Z 3 "'\ I / 19

..... _ ....... ""-L I 18 ...,..,_

L_ SADDLE VALVE

NOTE: Codes in the state of Massachu-

setts require installation by _ licensed

plumber, and do not permit the use of the

saddle valve, For installation, use pFumbfng

code 248-CMR of the Commonwealth of

Massachusetts.

38

/

18

46

43

44

Page 19

- REPAIR PARTS -

WaterWorks TM HOME DRINKING WATER SYSTEM Undersink Reverse Osmosis MODEL RO 2000

KEY

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

PART

NUMBER

7205465

1260600

7207734

9043201

7192230

9003204

7131331

7124986

7114509

7116763

7131349

9003203

7011272

7087485

42-34709

9004502

7128702

7118414

0900044

7140869

7109910

7121954

7155018

7176292

7088033

42-34706

DESCRIPTION OF PART

Faucet

Washer

Adaptor (Includes key nos. 2 & 4)

Nut, 3/8" Tubing

Drain Adapter

Nut, 1/4" Tubing (6)

Tubing Insert, 1/4" (5)

Elbow, 1/4" NPTx 1/4" Tubing

Tank Shutoff Valve

O-ring Seal, 7/16" x 5/8" O.D.

Tubing Insert, 3/8" (5)

Nut, 3/8" Tubing (5)

Saddle Valve (water supply)

Connector, 1/4" NPT x 3/8" Tubing

(a) Post Carbon Filter][ replacement

(b) Pre Carbon Filter .jr package1of eachhaS

Elbow, 1/4" NPT x 3/8" Tubing

Filter Holder

Liner Assembly

O-ring Seal, 5/16" x 7/16" O.D.

Vacuum Relief Valve

Bladder

Bali-Check Kit

RO Housing

Clamp Section (2)

Clamp Retainer (2)

RO Membrane Cartridge (Includes

key nos. 27 & 28)

KEY

NO.

27

28

29

3O

31

32

33

34

35

36

37

38

39

4O

41

42

43

44

45

46

47

PART

NUMBER

7167764

709503O

7115610

7110466

7113846

7113838

7124677

7116755

7131721

7125932

42-34704

0900156

7214032

0900713

7115262

7115725

7115822

7170880

7090771

7051206

7126506

7157280

7161823

7214105

DESCRIPTION OF PART

Flow Control

Cone Screen

O-ring Seal, 3-1/8" x 3-3/8" O.D.

RO Cap

Support, Plunger

Plunger

Top Support

O-ring Seal, 1-3/16" x 1-3/8" O.D.

Cap

Diaphragm Kit []

RO Electronics Assembly

Screw, #6-32 x 5/8"

Faucet Base (Includes key nos. 39,

41,42, 43, 46 and 47)

Screw, #6-32 x 1-3/8" (2)

Faucet Support []

Nut (2)

Battery Holder []

Electronic Box

Gasket

Gasket

Cable Extender, 15' - optional (ex-

tends connection between faucet

base and electronic box)

Tubing, 3/8" x 20'

Tubing, 1/4" x 20'

Owner's Manual

[] Place the diaphragm with the small hole into the RO cap first.

Locate the small hole over the vent hole in the cap, at the 12:00

position (see page 13).

[] Includes the button that covers screw, key no, 39.

,_ Purchase batteries locally (4 req'd., "AA" alkaline)

19

Page 20

- REMOTE INSTALLATION LOCATION -

INSTALLING RO ASSEMBLY, AND/OR SUPPLY SADDLE VALVE IN REMOTE LOCATION

Longer lengths of tubing are available from Sears

(see page 19) for installingthe RO assembly, and/or

water supply saddle valve away from the RO faucet.

Examples: In the basement, under the kitchen or

bathroom sink. In a closet or room nearby the kit-

chen or bathroom.

You can run the RO assembly drain tubing direct-

ly to an open drain and bypass the faucet. Suitable

open drains include a laundry tub, floor, sump and

stand pipe drains. It is very important to keep the

end of the RO drain tubing at least 1-1/2" above

the drain point. This provides an air gap to prevent

a back-siphon of sewer water.

Omit the following steps:

- all of step 2, pages 6 and 7.

- steps C7 and C8, page 9.

- step 4B, page 10.

RO WATER

FAUCET

COLD WATER

SOURCE

_airgap

STANDPIPE

RO drain

tubing

OPTIONAL DRAIN

TUBING RUNS

SUMP

airgap

FLOOR DRAIN LAUNDRY TUB

When ordering parts, always provide the following information:

• Product Type: WaterWorks TM Undersink Reverse

Osmosis Drinking Water System

• Model: RO 2000

• Part Number: from page 19

• Part Description: from page 19

For the repair or replacement parts you need

Call 7 am - 7 pm, 7 days a week

1 - 800 - 366 - PART

(1 - 800 - 366 - 7278)

Loading...

Loading...