Page 1

Model

Language

Page

Size(W*H)

Designer

Designer

Confirm

Color(cover/body)

Description

Date

No. Date

Chage Record

Change content

ECO No.

1

2

3

4

5

6

7

8

9

Weight 100g

2007.07.30

VTCB423HTU.CLSESRS

English

26

3828FI9002W

1/1

150×220(mm)

Shi Pengfei

Service manual

Material

Part No.

Page 2

DIVISION 20

BASIC FIELD MANUAL

FOR

CANISTER VACUUM CLEANER

MODEL 721.24195S

MODEL 721.24195S

AUGUST, 2007

Page 3

2

FOREWORD

1. SAFETY PRECAUTIONS ................................................................................3

2. CAUTIONS.......................................................................................................3

3. DESCRIPTION/SPECIFICATIONS

3.1 MODEL 721.24195S...................................................................................4

4. DISASSEMBLY.............................................................................................5-8

5. TROUBLE SHOOTING...............................................................................9-11

6. BLOCK DIAGRAM/SCHEMATIC DIAGRAM/CIRCUIT DIAGRAM

6.1 MODEL 721.24195S.................................................................................12

7. POWER AND CONTROL CIRCUIT BOARD

7.1 MODEL 721.24195S.................................................................................13

8. EXPLODED VIEW/REPLACEMENT PARTS LIST

8.1 MODEL 721.24195S...........................................................................14~20

BEFORE SERVICING THE UNIT, READ THE "SAFETY PRECAUTIONS" IN

THIS MANUAL.

MECHANICAL SERVICE INFORMATION

TABLE OF CONTENTS

MODEL 721.24195S

MODEL 721.24195S

Page 4

3

1. SAFETY PRECAUTIONS

2. CAUTIONS

BEFORE OPERATING THIS VACUUM CLEANER, READ THIS SERVICE MANUAL THOROUGHLY, AND

OBSERVE EACH POINT CAREFULLY.

BEFORE ATTEMPTING TO SERVICE OR ADJUST ANY PART OF THE VACUUM CLEANER, DISCONNECT

THE ELECTRICAL POWER SUPPLY CORD FROM THE WALL OUT

1. Motor exchange

1) Separate the Body Cover and Body Base by

unfastening the screws.

2) Disconnect the lead wires.

3) Lift the old motor and replace it with a new one.

2. In case of exchanging other parts, refer to the

exploded view.

1. Change the paper bag in case the

indicatormoves toward red.

1) If the dust bag is full, intake power will be reduced.

2) When the dust bag is full of dust, pull out the dust bag

from the bag mount.

2. Filter

1) The filter is composed of a clean filter, a exhaust filter

and filter bag.

2) Never use the vacuum cleaner without filters.

It may harm to the motor.

NOTE : Re-use of the clean filter.

• Never wash the filter in a washing machine or in a

dishwasher.

• Never use hot water for washing the filter.

• Re-use the filter after drying it completely in the shade.

• Do not dry near fire or direct sun ray.

3. Dust indicator

Dust indicator shows you red color when the filter is full of

dust.

Then, change the bag with new one.

4. Avoid suction such materials as :

1) Liquid or wet dust :

Clog the ventilation holes and reduces the intake

power significantly and harms the motor.

2) Inflammable liquids such as benzene, alcohol or

solvents.

3) Burning objects such as cigarette butts.

4) Bulky objects such as vinyl, paper etc.

5) Sharp objects such as needles, pins, metal or glass

particles etc.

5. Attachments

• Nozzle : for cleaning wooden floor, the room floor and

carpet.

• Brush/Crevice Tool(without brush): for cleaning any

crevice, inside corners of window frames.(However, do

not use the crevice tool more than 20 minutes.)

Brush/Crevice Tool (with brush): for delicate vacuuming

of fabrics on the furniture, curtains, etc.

• Upholstery Nozzle : for vacuuming the dust on the

upholstery.

6. Close supervision is necessary when this

vacuum cleaner is used by or near children.

Children's carelessness may cause damage to

the cleaner or injure persons.

7. Air exhausted from the vacuum cleaner is

normally warm. But if extraordinarily hot air is

exhausted, check if the extension pipe, hose or

dust bag is clogged or not.

8. Electric shock could occur if used outdoors or

on wet surfaces.

MODEL 721.24195S

Page 5

MODEL 721.24195S

4

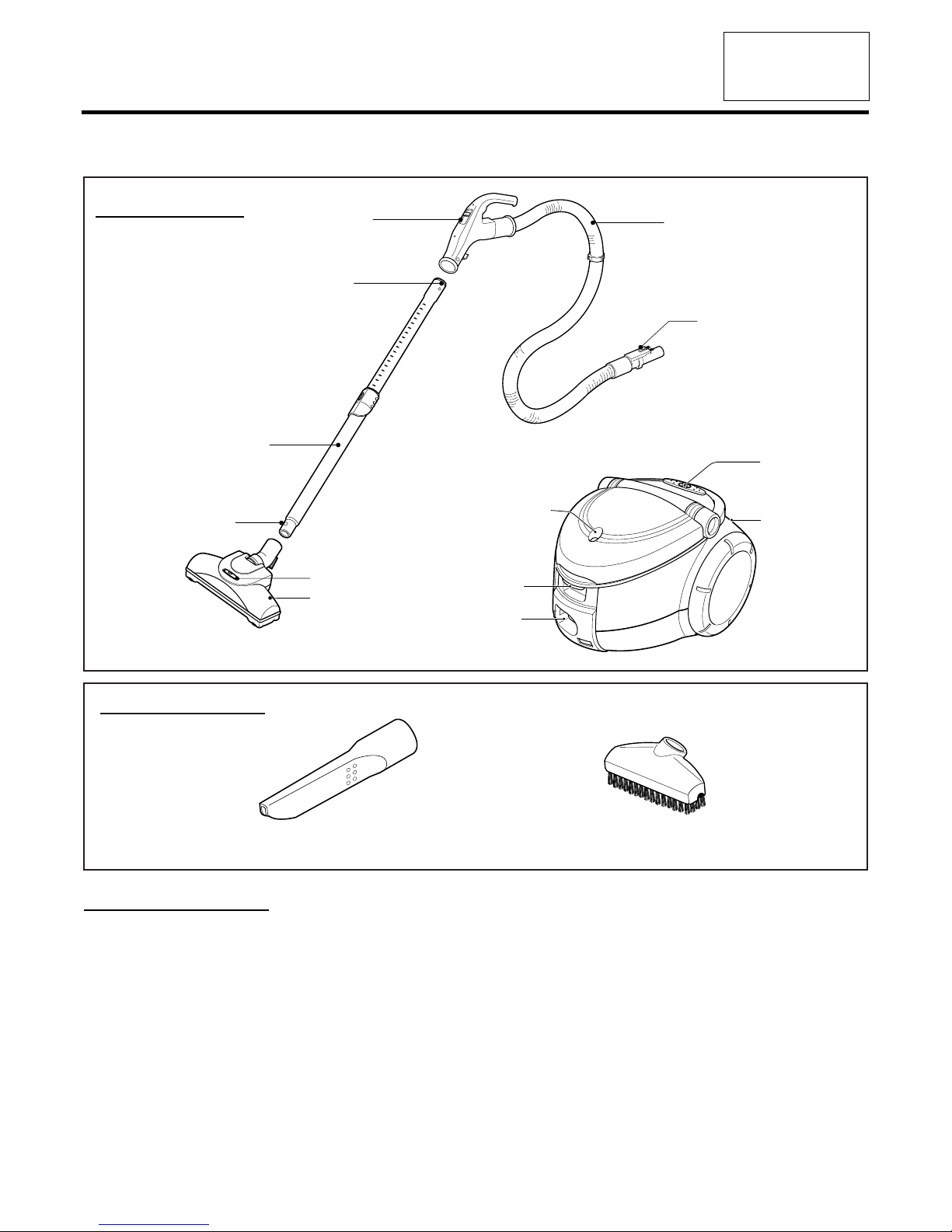

3. DESCRIPTION/SPECIFICATIONS

Slide Switch

Handle Button

Telescopic

Wand

Wand

Button

Hose

Fitting Hook

Power Cord

(Not Shown)

Cord Reel

Button

Suction Inlet

Latch

Performance Indicator

Crevice Tool

Dusting/Upholstery Tool

Air-Turbine

Brush Nozzle

Pile Adjustment

3.1 MODEL 721.24195S

DESCRIPTION

SPECIFICATIONS

• POWER SOURCE: ON RATING PLATE

• POWER CONTROL:

MAIN: SLIDE CONTROL ON HANDLE

• CAPACITY: 2.5

l

• CORD LENGTH: 5.3 m

• HOSE LENGTH: 1.5 m

• NET WEIGHT: 4.7 kg

• PACKING WEIGHT: 9.2 kg

• NET DIMENSION: 296 x 369 x 248 (W x D x H)mm

• PACKING DIMENSION: 330 x 579 x 330(W x D x H)mm

• ATTACHMENTS

FLEXIBLE HOSE ASSY ............................................1EA

TELESCOPIC WAND ................................................1EA

AIR-TURBINE BRUSH NOZZLE ...............................1EA

DUSTING/UPHOLSTERY TOOL ...............................1EA

CREVICE TOOL ........................................................1EA

A

TTACHMENTS

Page 6

• Almost all the parts of this vacuum cleaner can be

assembled with a screw driver and each connecting

component easily fits each other.

Disassemble one by one referring to the exploded view.

• If possible, don’t disassemble except for the necessary

parts. It is not necessary to disassemble the parts that are

not detailed in the exploded view.

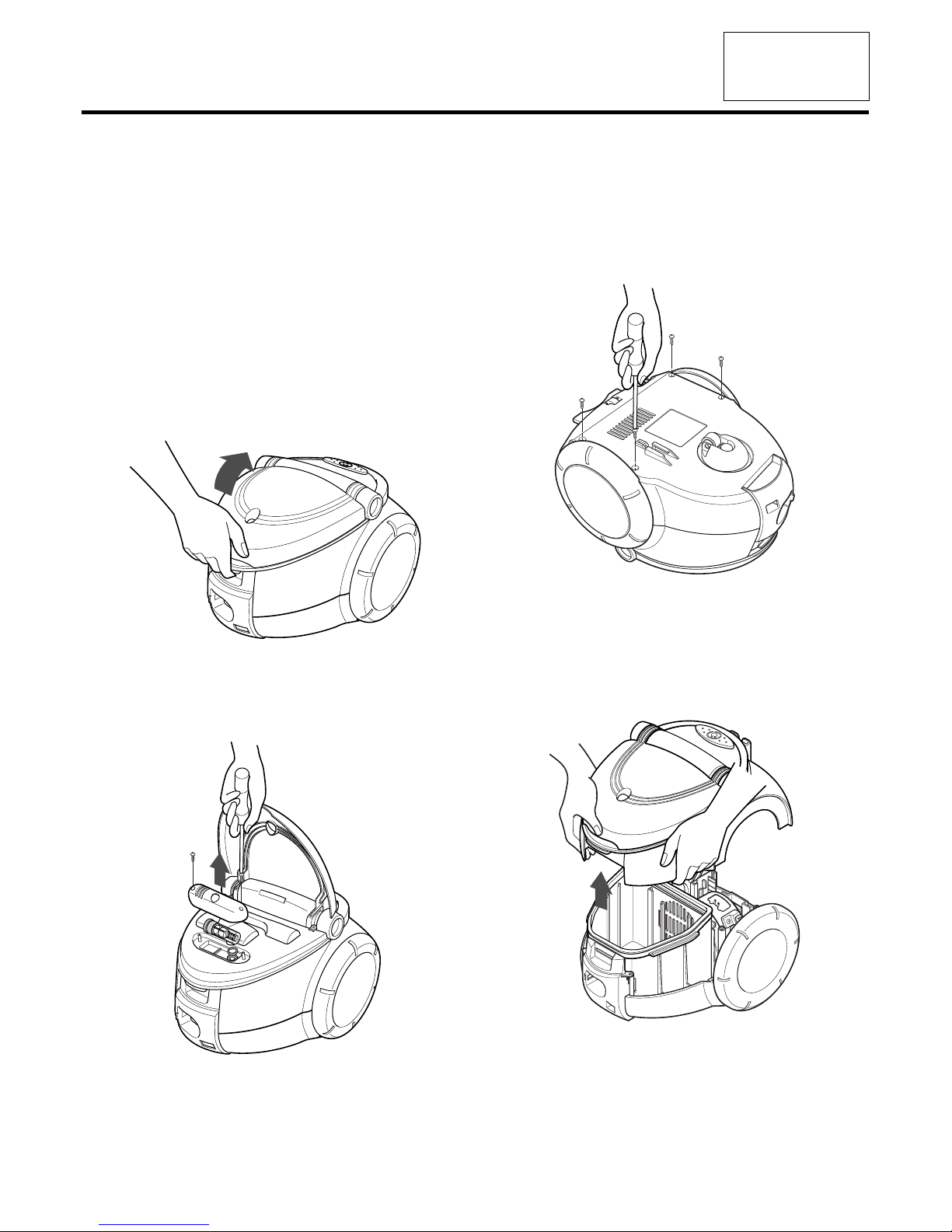

4.1 Filter Cover Assembly Replacement

1) Grasp body base and open filter cover.

4.2 Indicator Assembly Replacement

4.3 Body Cover Assembly Replacement

1) Open the filter cover and remove the two screws and

remove the four screws fastening the body base.

2) Lift body cover in the direction of the arrow.

4. DISASSEMBLY

NOTE: Before attempting to service or adjust any part of the vacuum cleaner, disconnect the electrical power supply cord from

the wall outlet.

5

MODEL 721.24195S

Page 7

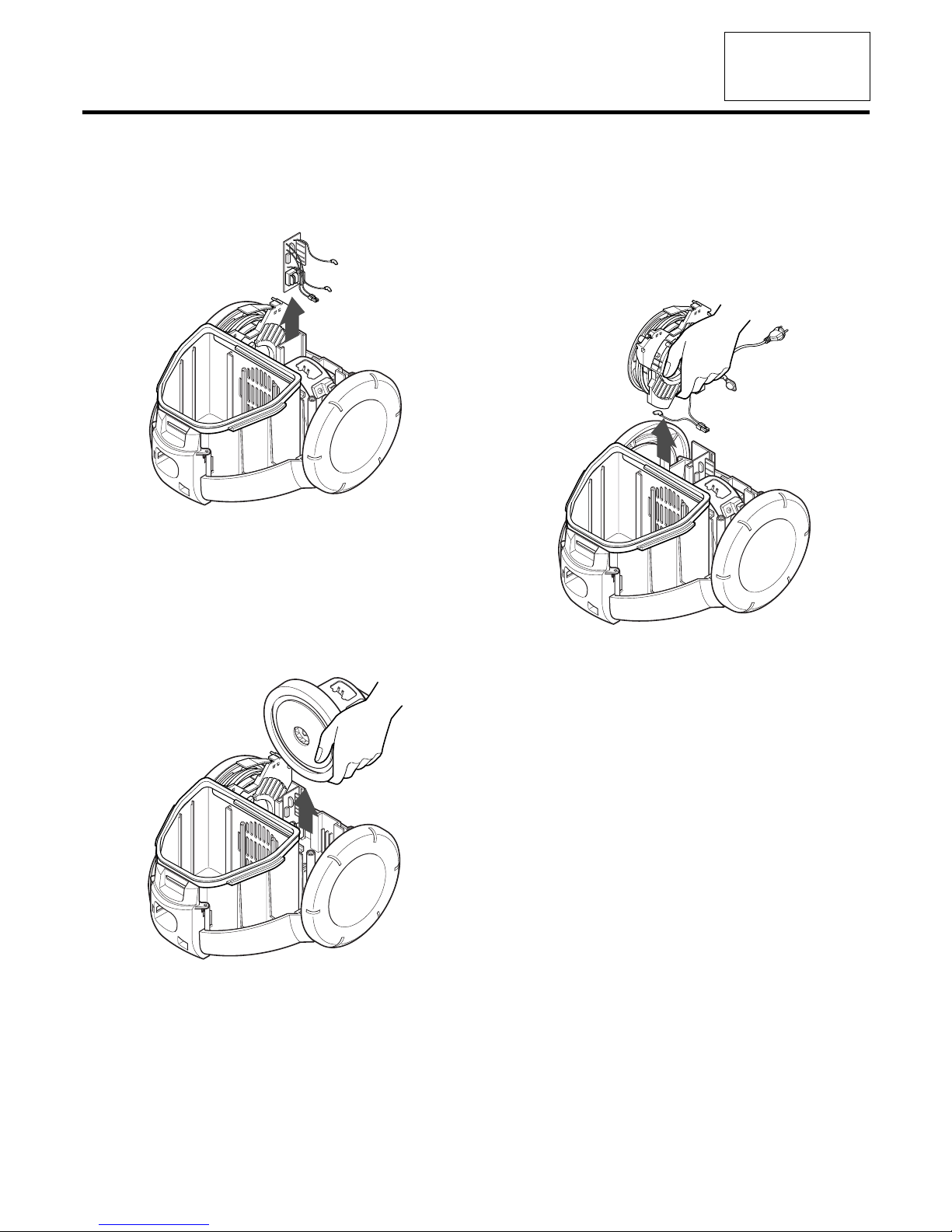

4.4 P.W.B ASS’Y Replacement.

1) Lift the P.W.B ASS’Y in the direction of the arrow.

4.5 Motor Assembly Replacement

• Lift the motor assembly in direction of the arrow after

stripping off the lead wires.

4.6 Cord reel assembly replacement

1) Lift the cord reel assembly from the body base in direction

of the arrow.

2) Strip off the lead wires.

MODEL 721.24195S

6

Page 8

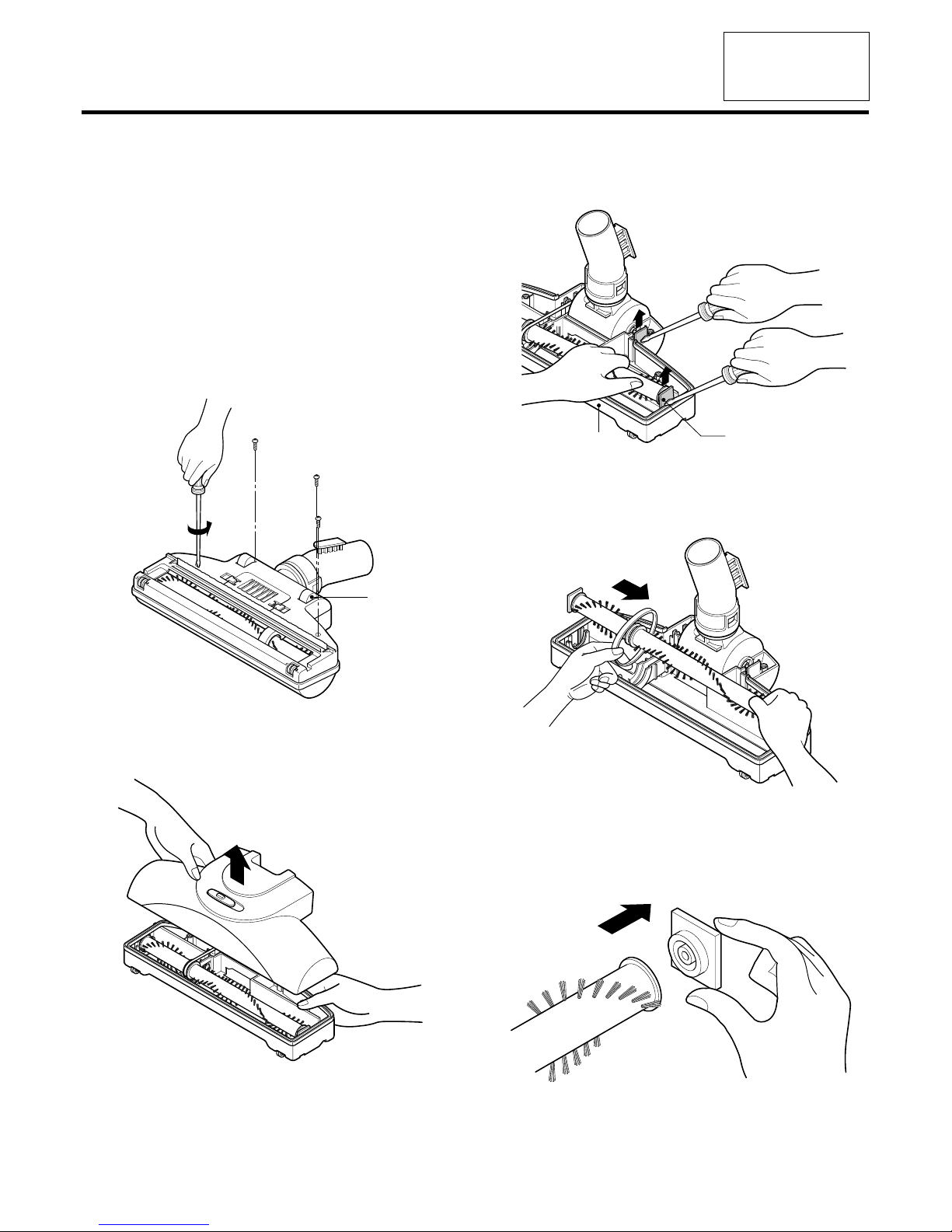

4.7 Belt Changing and Brush Cleaning

• Disconnect cleaner from electrical outlet. Check and

remove hair, string and lint build-up frequently in the AirTubine Brush Nozzle brush and brush support areas. If

build-up becomes emcessive, disconnect Air-Tubine

Brush Nozzle from Telescopic wand.

TO REMOVE BELT

1) Turn Air-Tubine Brush Nozzle upside down.

2) Unscrew the four Air-Tubine Brush Nozzle cover screws.

3) Turn Air-Tubine Brush Nozzle rear side up and tilt cover

forward from back until front snaps free.

4) Carefully insert and lift screwdriver at each brush support

to free brush from base.

5) Remove worn belt.

6) Slide brush supports off to check and clean brush support

areas. See PARTS LIST for picture of complete brush

assembly.

Wheel

Base

Brush Support

MODEL 721.24195S

MODEL 721.24195S

7

Page 9

TO REPLACE BELT:

1) Install brush supports onto brush.

2) Install new belt in belt groove on the brush, then over the

fan shaft. Be sure belt is between the belt guards.

3) Insert each support into its base slot.

4) Push cover and base together.

8

MODEL 721.24195S

Brush

Brush support

Belt

Guard

Belt Groove

Belt

Fan Shaft

Page 10

9

MODEL 721.24195S

5. TROUBLE SHOOTING

SOLUTIONCAUSE

Check the power source

CHECKING

Poor plug insertion

Power cord cut

Interior lead wire cut

Motor(stator armature) coil cut

or damaged

Poor contact carbon brush

defaced

Motor armature cut

Ball bearing defacement

Impeller hindrance

(Caused by foreign matters)

Insert again

Repair or exchange

Exchange the lead wire

Exchange the motor

Exchange or repair

Poor switch contact point Exchange the switch

Exchange the motor

Exchange the motor

Remove the foreign matters

Normal

1) SWITCH ON BUT MOTOR DOSE NOT RUN.

2) SWITCH ON, MOTOR DOES NOT RUN BUT BUZZES.

Page 11

10

MODEL 721.24195S

Poor connection

Poor switch

Carbon brush defaced

Motor armature cut

Foreign matters attached to

the impeller

Low voltage

Hose and extension wands are

clogged with foreign matters

Filter bag or cloth bag is filled

with inhaled foreign matters

Repair

Exchange the switch

Exchange the carbon brush

or the motor

Exchange the motor

Remove the foreign matters

Inquire to the power utility

company

Remove the foreign matters

in the hose or extension wands

Low rotation speed

Motor turns normally,

but suction power is weak

Rotating switch is on low

mode

Rotate it with clock-wise so

power is increasd

Remove the foreign matters

or exchange the filter bag or

clean the cloth bag

3) SWITCH OFF BUT MOTOR RUNS.

4) WEAK SUCTION POWER

Page 12

11

MODEL 721.24195S

Poor cord, lead wire

Poor carbon brush rectified

Poor electric connector

or receiver

Exchange cord, lead wire

Exchange the carbon brush

or the motor

Repair the electric connector

or receiver

Poor capacitor

Exchange the capacitor

Bent connection parts

Poor connection

(Caused by foreign matters)

Exchange the parts

Remove the foreign matters

and reconnect

Loose parts

Unbalanced motor assembly

Foreign matters are attached

to the impeller

Poor carbon brush rectification

Secure firmly

Exchange or repair the motor

Remove the foreign matters

Exchange the carbon brush

or the motor

Armature is cut or foreign

matters attached

Exchange motor

Remove foreign matters

5) VIBRATION NOISES

6) RADIO, TV RECEPTION DISTURBANCE

7) IMPROPER TUBE OR NOZZLE CONNECTION

Page 13

12

MODEL 721.24195S

6.BLOCK DIAGRAM/SCHEMATIC DIAGRAM/CIRCUIT DIAGRAM

6.1 MODEL 721.24195S

WIRING DIA

GRAM

SCHEMATIC DIAGRAM

WH

BL

BL

BK

BL

BR

TS

P.W.B. ASS'Y

MOTOR

C/REEL ASS'Y

BR

BL

SLIDE VOLUME S/W

FLEXIBLE HOSE ASS'Y

M

C5

0.47 F

100V

C1

0.1 F

630V

R2

220

1/2W

R1

100

1/2W

R4

470

1/2W

Transformer

T.S

R12

470K

R12-1

470K

R7

10K

R11

10K

R10

100

R6

22K

IC1

Opto-triac

TLP762

16

4

G

SS

_

+

T1

TRIAC

T2

2

VR1

VR1

20K

Q2

A1015

D5

1N4148

Q1

C3198

BD1

DF01M

R8

1K

R9

100

Page 14

13

7.POWER AND CONTROL CIRCUIT BOARD

7.1 MODEL 721.24195S

COMPONENT SIDE SOLDER SIDE

MODEL 721.24195S

Page 15

14

MODEL 721.24195S

8.EXPLODED VIEW/REPLACEMENT PARTS LIST

1

2

12

3

5

15

17

13

11

10

14

16

4

8

6

7

9

8.1 MODEL 721.24195S

EXPLODES VIEW

MODEL 721.24195S

Page 16

15

MODEL 721.24195S

34 39

40

26

18

31

32

27

29

33

21

30

19

20

22

23

28

25

24

MODEL 721.24195S

35

36

38

37

Page 17

16

MODEL 721.24195S

MODEL 721.24195S

41

Page 18

17

MODEL 721.24195S

MODEL 721.24195S

42

48

49

43

50

52

54

51

44

45

46

47

Page 19

18

MODEL 721.24195S

MODEL 721.24195S

77

60

61

62

63

66

78

65

64

59

56

58

70

75

76

73

74

68

57

67

71

72

69

Page 20

19

MODEL 721.24195S

LOCATION NO.

DESCRIPTIONPART NO. REMARKS

MODEL 721.24195S

REPLACEMENT PARTS LIST

1 3550FI1759K ACCESSORY COVER

2 3550FI1758H FILTER COVER

3 3550FI3868H INDICATOR COVER

4 3I23019L INDICATOR

5 1TPL0302418 SCREW 3*8

6 5203FI2071A DUST BRUSH ASS'Y

7 5058FI3593A CREVICE TOOL

8 4026FI3691G LATCH

9 4970FI4260A LATCH SPRING

10 3650FI2422A HANDLE

11 4370FI3678A HANDLE SHAFT

12 3550FI1757B BODY COVER

13 5020FI3806B CORD WINDING BUTTON

14 4I70024A CORD WINDING SPRING

15 4510FI2441A CORD WINDING LEVER

16 1TPL0402818 SCREW 4*12

17 5230FI3558B EXHAUST FILTER

18 3040FI1525A BODY BASE

19 3920FI1289A DUST SEAL PACKING

20 4661FI1008H WHEEL ASS'Y

21 *5231FI2390J DUST BAG

22 4480FI3752A FILTER SETTING HOOK

23 4I23017A FILTER SETTING HOOK SPRING

24 3550FI1756B FRONT COVER

25 3I23038G TERMINAL PLATE ASS'Y

26 3I23009L TERMINAL SUPPORTER

27 1TPL0402818 SCREW 4*12

28 4036FI3036A TERMINAL PACKING

29 5230FI3248F MOTOR SAFETY FILTER

30 4441FI3608D CASTER ASS'Y

31 4I22017A ROLLER

32 4I22094A ROLLER SHAFT

33 1TPL0403318 SCREW 4*20

34 6871FX2130G PWB ASS'Y

35 3920FI3766A MOTOR MOUNT PACKING

36 4681FI2373Y MOTOR

37 3940FI3646A ABSORBING SPONGE

38 3920FI3859A MOTOR SEAL PACKING

39 5230FI3557C EXHAUST FILTER

40 3940FI3311B EXHAUST SPONGE

Page 21

MODEL 721.24195S

MODEL 721.24195S

REPLACEMENT PARTS LIST

LOCATION NO.

DESCRIPTIONPART NO. REMARKS

41

42

43

44

45

46

47

48

49

50

51

52

53

55

58

57

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

4687FI1468H CORD WINDING ASS'Y

AEM30953708 HOSE ASS’Y

4940FI3431A SLIDE KNOB

3500FI3617B SWITCH BOARD

1TPL0302416 SCREW 3*8

3550FI1511D HANDLE COVER

3650FI1474F GRIP HANDLE

4930FI2360T HOSE

5200FI2357M FITTING PIPE

FITTING HOOK

4I23028A HOOK SPRING

3I23013J

3550FI2358J F/PIPE COVER

5201FI2485A TELESCOPIC WAND

3040FI1502B NOZZLE BASE

5249FI1414E NOZZLE ASSEMBLY, TURBINE

3550FI1637B NOZZLE COVER

4940FI3736A PILE ADJUSTMENT

5200FI2497B SUCTION PIPE

1KZZFI3001B KEY

4930FI2452B SUCTION PIPE HOLDER

5901FI2001A FAN ASSEMBLY

4280FI3003A BEARING BALL

4581FI3001A ROLLER ASSY

4370FI3669A SHAFT

4581FI3002A ROLLER ASSY

4370FI3670A SHAFT

3550FI2540B COVER FLOW

4820FI2399B NOZZLE BUMPER

5882FI2001A SWEEPER

4766FI3709A FELT

3740FI3712A PROTECTOR(MECH)BELT

3740FI3711A PROTECTOR(MECH)BELT

4280FI3004A BEARING BALL

5973FI2001A BRUSH

4400FI3349A BELT

1TPL0403116 SCREW 4*16

20

Page 22

21

MEMO

Page 23

22

MEMO

Page 24

23

MEMO

Page 25

P/No.: 3828FI9002W

Loading...

Loading...