Page 1

OWNER’S MANUAL

40” LAWN AERATOR

MODEL:

SAT-40 BH

• Assembly

• Installation

• Operation

• Repair Parts

For the latest product updates & setup tips:

Visit us on the web!

www.brinly.com

Important: This manual contains information for the safety of

persons and property. Read it carefully before assembly and

operation of the equipment!

L-1643BH-D

Page 2

INTRODUCTION

CONGRA TULA TIONS on the purchase o f your new Brinly-Hardy

Lawn Aerator! Your lawn aerator is designed, engineered and

manufactured to give you the best possible dependability and

performance.

CUSTOMER RESPONSIBILITIES

Please read and retain this manual. The instructions enables

you to assemble and maintain your lawn aerator properly. And

please, always observe the “Safety” instructions.

TABLE OF CONTENTS

SAFETY .........................................................................1-2

PARTS REFERENCE .......................................................3

PARTS LIST ......................................................................3

ASSEMBLY.....................................................................4-8

OPERATION ................................................................9-13

MAINTENANCE...............................................................14

SERVICE ........................................................................14

PRODUCT COMPATIBLIITY

This lawn aerator is designed for use with lawn tractors and garden tractors.

RECORD PURCHASE INFORMATION

Record your purchase information in the spaces provided below.

DATE OF PURCHASE: ___________________________

COMPANY NAME: ______________________________

COMPANY PHONE: _____________________________

SERIAL NUMBER: ______________________________

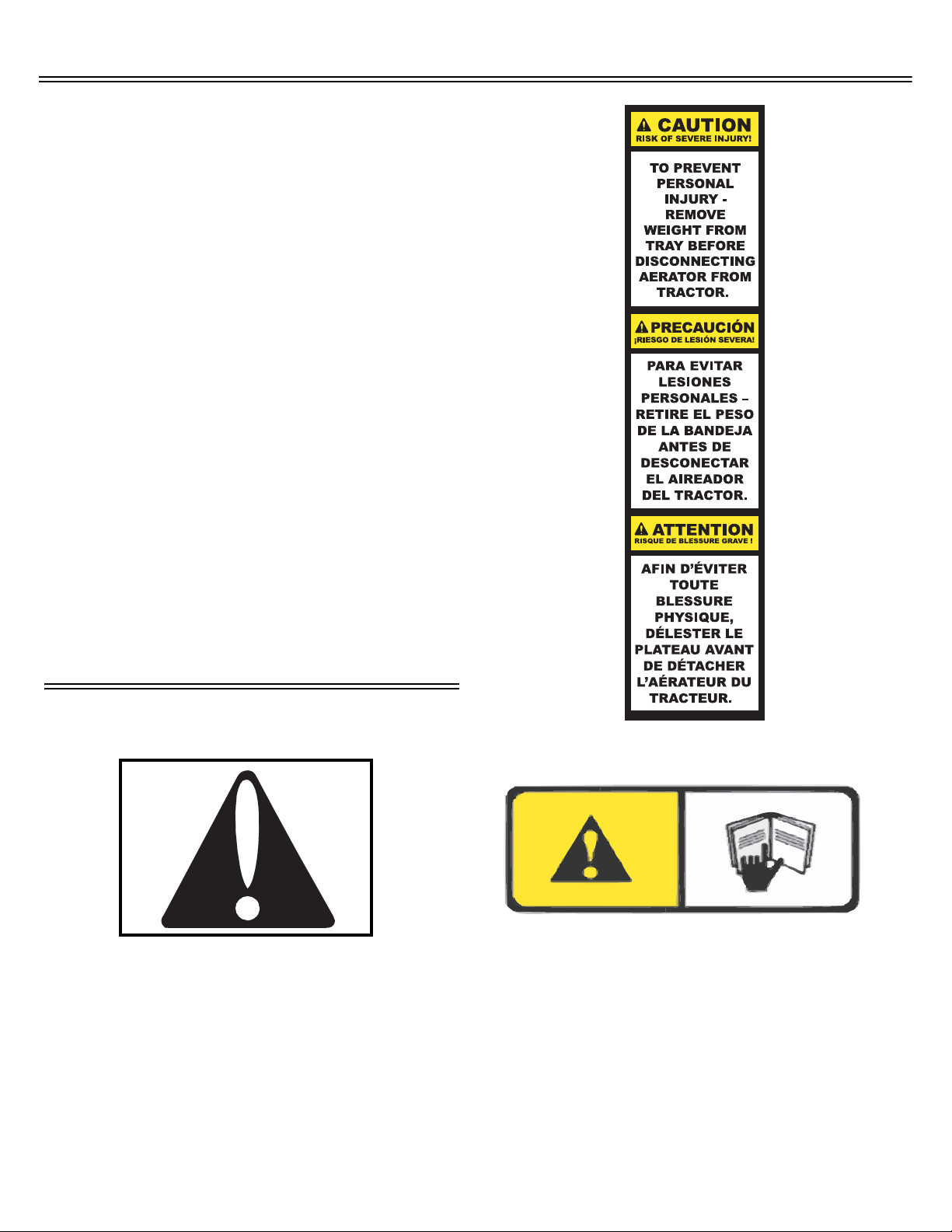

SAFETY LABELS

UNDERSTANDING THE MACHINE SAFETY LABELS

Safety-Alert Symbol

a

The machine safety labels shown in this section are placed in

important areas on your machine to draw attention to potential

safety hazards.

On your machine safety labels, the words DANGER, WARNING,

and CAUTION are used with this safety-alert symbol. DANGER

identifies the most serious hazards.

The operator's manual also explains any potential safety hazards whenever necessary in special safety messages that are

identified with the word, CAUTION, and the safety-alert symbol.

1.

L-1643BH-D

Page 3

SAFETY

TO HELP PREVENT BODILY INJURY DUE TO LOSS OF

STABILITY OR CONTROL:

• Do not exceed maximum towing capacity of towing vehicle

listed in the vehicle operator's manual.

• Do not tow this machine behind a motor vehicle such as a

car, truck or ATV.

• Towing this machine behind a ZTR (Zero Turning Radius)

mower is not recommended due to the sharp turning ability

of the ZTR. Damage to this machine or the ZTR may result.

ZTR’s typically operate at higher speeds. Operating above

5 mph may result in damage to this machine.

SAFETY

Read the general safety operating precautions in your towing

vehicle operator's manual for additional safety information.

OPERATE SAFELY

• Use this machine for intended purpose only.

• This machine is intended for use in lawn care and home

applications. Do not tow behind a vehicle on a highway or

in any high speed applications. Do not tow at speeds

higher than maximum recommended towing speed.

• To wing speed should always be slow enough to maintain

control. Travel slowly over rough ground.

• Do not let children or an untrained person operate

machine.

• Do not let anyone, especially children, ride on this machine

or the towing vehicle. Riders are subject to injury such as

being struck by foreign objects and being thrown off. Riders

may also obstruct the operator's view, resulting in this

machine being operated in an unsafe manner.

• Check towing vehicle brake action before you operate.

Adjust or service brakes as necessary.

• Keep all parts in good condition and properly installed. Fix

damaged parts immediately . Replace worn or broken p arts.

Replace all worn or damaged safety and instruction decals.

• Do not modify the machine or safety devices. Unauthorized

modifications to the towing vehicle or machine may impair

its function and safety, and void the warranty.

• Keep all nuts, bolts and screws tight.

TOWING SAFELY

• Stopping distance increases with speed and weight of

towed load. Travel slowly and allow extra time and distance

to stop.

• Total towed weight must not exceed limits specified in towing vehicle operator's manual.

• Excessive towed load can cause loss of traction and loss of

control on slopes. Reduce towed weight when operating on

slopes.

• Never allow children or others in or on towed equipment.

• Use only approved hitches. Tow only with a machine that

has a hitch designed for towing. Do not attach this machine

except at the approved hitch point.

• Follow the manufacturer's recommendations for weight limits for towed equipment and towing on slopes. Use counterweights or wheel weights as described in the towing

vehicle operator's manual.

• Do not turn sharply. Use additional caution when turning or

operating under adverse surface conditions. Use care

when reversing. To avoid jack-knifing, do not allow towing

vehicle wheels to contact drawbar.

• Do not shift to neutral and coast downhill.

PROTECT BYSTANDERS

• Keep bystanders away when you operate this machine

• Before you back look carefully behind for bystanders.

• Before you operate any feature of this machine, observe

your surroundings and look for bystanders.

KEEP RIDERS OFF TOWED ATTACHMENT

• Keep riders off towed attachment.

• Riders on a towed attachment are subject to injury, such as

being struck by objects and being thrown off the attachment during sudden starts, stops and turns.

• Riders obstruct the operator's view, resulting in the attachment being used in an unsafe manner.

• Keep riders off of hitch bracket.

KEEP BODY PARTS FROM UNDER DRAWBAR

Before disconnecting this machine from towing vehicle hitch

plate:

• Stop on level ground.

• Stop towing vehicle engine.

• Lock towing vehicle park brake.

• Block wheels of the machine.

• Make sure body parts are not under drawbar.

L-1643BH-D 2.

Page 4

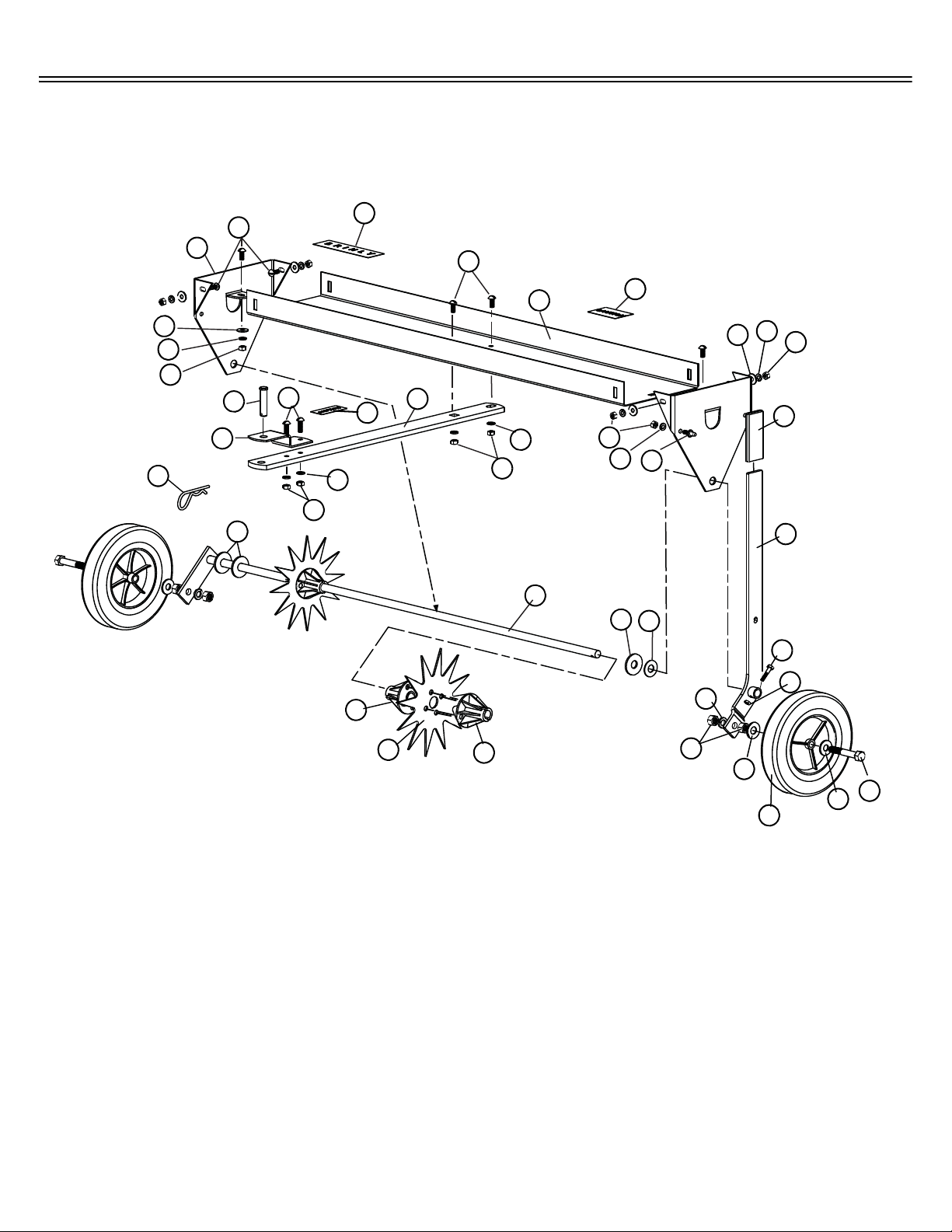

EXPLODED VIEW

1

2

3

4

5

6

7

8

9

11

23

21

23

22

25

26

20

27

27

28

17

17

16

16

16

16

16

12

18

19

15

15

15

15

15

29

29

24

13

13

14

10

TOOLS REQUIRED FOR ASSEMBLY:

• 1 - Pair of work gloves

• 1 - Pair of pliers

• 1 - Screwdriver (flat blade)

• 2 - 7/16” Wrenches

• 1 - 1/2” Wrench

• 2 - 3/4” wrenches

REF PART NO. DESCRIPTION

QTY.

1.

R-821-10 Drawbar Clevis

1

2.

B-5925 Logo Decal

1

3.

B-5453-10 Tray

1

4.

B-3593-10 Drawbar

1

5.

B-3593-10 End Panel

2

6.

B-5832-10 Axle Assembly

1

7.

B-5423-10 Tine

11

8.

B-4888-10 Handle Assembly

1

9.

R-891 Wheel

2

10.

B-4867 Handle Grip

1

11.

R-1946 Caution Decal

1

12.

D-146P Hairpin Cotter

1

13.

20M1012P Round Head Screw, 5/16”x3/4”

8

14.

20M1016P Round Head Screw, 5/16”x1”

2

15.

30M1000P Hex Nut, 5/16”

11

16.

40M1000P Lock Washer, 5/16”

11

17.

B-5456 Flat Washer, 5/8” (think)

5

18.

B-3861 Drawbar Pin

1

19.

B-3922 Caution Decal

1

20.

1M1648P Hex Bolt, 1/2”x3”

2

21.

30M1600P Hex Nut, 1/2”

4

22.

40M1600P Lock Washer, 1/2”

2

23.

45M1717P Flat Washer, 1/2”

4

24.

B-3307-S Transport Lock Pin

1

25.

2M0820P Hex Bolt, 1/4”x1-1/4”

1

26.

B-1673P Hex Lock Nut, 1/4”

1

27.

B-5425 Spacer/Bearing, Tube

22

28.

B-4768 Flat Washer, 5/8” (thin)

2

29.

45M1111P Flat Washer, 5/16”

6

REF PART NO. DESCRIPTION

QTY.

PARTS LIST

PARTS REFERENCE

3.

L-1643BH-D

Page 5

Step 1.

ATTACH END PANELS TO TRAY

2a) Install Drawbar (4) to

Tray (3) using two 5/16” x3/4”

Rd Hd. Screws (13), 5/16”

Lock Washers (16) and 5/16”

Hex Nuts (15), as shown.

2b) Attach Clevis (1) to

Drawbar using two 5/16” x 1”

Rd Hd. Screws(14), 5/16”

Lock Washers (16) and 5/16”

Hex Nuts (15), as shown.

2c) Attach Transport Lock

Pin (24) to End Panel (5)

using one 5/16” Lock Washer

(16) and 5/16” Hex Nut (15),

as shown.

NOTE

: The inside distance

between the two end panels

should be 41 inches to

ensure proper installation.

INSTALL DRAWBAR

Step 2.

1a) Attach the two End Panels (5)

to the Tray (3) using six 5/16” x3/4”

Rd Hd. Screws (13), 5/16” Flat

Washers (29), 5/16” Lock Washers

(16) and 5/16” Hex Nuts (15), as

shown.

16

5/16” Lock Washer

Qty. 6

13

5/16” x 3/4” Rd Hd Screw

Qty. 6

29

5/16” Flat Washer

Qty . 6

15

5/16” Hex Nut

Qty. 6

3

15

13

16

29

5

16

5/16” Lock Washer

Qty. 5

15

5/16” Hex Nut

Qty. 5

13

5/16” x 3/4” Rd Hd Screw

Qty. 2

14

5/16” x 1” Rd Hd Screw

Qty. 2

24

Transport Lock Pin

Qty. 1

4

3

13

15

15

15

5

16

16

16

14

24

1

ASSEMBLY

L-1643BH-D 4.

Page 6

Step 3.

ASSEMBLE TINES TO AXLE

3a) Place a 5/8” Flat Washer, Thick

(17) onto the Axle Assembly (6), then

slide it through the hole in End Panel

(5 right Side) and add another Flat

Washer Thick (17) if needed.

3b) Position the eleven Tines (7) and

twenty-two Spacer/Bearing Tubes

(27) onto the Axle Assembly (6) as

follows:

• Bearing, small end first

• Aerator Tine

• Bearing, large end first

Note: Round projections on Spacer/

Bearing flanges must fit into small

holes in aerator tines and into two

holes of opposite Spacer/Bearing

3c) Position one or two Washers (17

or 28) as needed to eliminate any

side-to-side movement and push

Axle Assembly (6) through hole in

the left End Panel (5) as far as possible. See layout below

28

5/8” Washer (thin)

Qty. 2

17

5/8” Washer (thick)

Qty. 4

WARNING

: Gloves are required when handling

aerator tines. Tines have extremely sharp

points. Use caution when handling.

5

17

17

28

27

7

6

Note: Tines must not move from side to side inside opening of end panels. If looseness exists, use additional 5/8”

Thick or Thin Washers (17 or 28) inside End Panel to eliminate any side movement.

Tine and Spacer/Bearing Tube Layout:

• Spacer/Bearing Tube (small end first)

• Aerator Tine

• Spacer/Bearing Tube (large flange first)

ASSEMBLY

!

5.

L-1643BH-D

Page 7

Step 4.

ATTACH HANDLE ASSEMBLY

25

Hex Bolt, 1/4 x 1-1/4”

Qty . 1

26

Hex Lock Nut, 1/4”

Qty. 1

4a) Attach the Handle Assembly (8) to end the of the Axle

Assembly (6) by inserting one 1/4” x 1-1/4” Hex Bolt (25)

though the hole in the end of the Axle Assembly) and secure

with 1/4” Hex Nut(26), as shown.

Note:

The wheel bar mount on the Axle Assembly must be

positioned downward, as shown, in order to properly attached

the wheels.

4b) Slide the Handle Grip (10) on to the Handle Assembly (8).

8

26

25

10

6

WHEEL BAR MOUNT

ASSEMBLY

L-1643BH-D 6.

Page 8

Step 5.

INSTALL WHEELS

4a) Attach one Wheel (9) to the

Handle Assembly (8) and the other

wheel to the wheel bar mount on

the Axle (6). Secure to each side

using hardware in the following

order:

• 1/2” x 3” Hex Bolt (20)

• 1/2” Flat Washer (23)

• Wheel (9)

• 1/2” Flat Washer (23)

• 1/2” Hex Bolt (21)

• 1/2” Lock Washer (22)

• 1/2” Hex Bolt

Note: Attaching wheel without all of

the proper hardware will cause the

wheel to wobble. Insure all hardware is used, see insets below.

21

Hex Nut, 1/2”

Qty . 4

22

Lock Washer, 1/2”

Qty . 3

23

Flat Washer, 1/2”

Qty. 4

20

Hex Bolt 1/2” x 3”

Qty. 2

21

22

23

21

23

20

9

9

21

21

23

20

22

23

20 23

9

9

23

202323

21

21

21

21

22

22

8

6

6

8

RIGHT

WHEEL

LEFT

WHEEL

RIGHT

WHEEL

LEFT

WHEEL

ASSEMBLY

7.

L-1643BH-D

Page 9

Step 6.

MOUNTING & TRANSPORTING

6a) Attach Aerator to your towing vehicle using Drawbar

Pin (18) and Hairpin Cotter (12) supplied.

6b) To place in Transport Position:

• Pull FORWARD on Handle Assembly (8).

• Pull out slightly and position over Transport Lock

Pin (24). Aerator rests on wheels.

6c) To place in Operating Position:

Pull OUT on Handle Assembly (releasing from Transport

Position) and push Handle BACK.

Aerator should rest on Tines.

CAUTION:

Avoid damage to tines. Engage

the transport wheels when crossing concrete or

asphalt driveways and walkways

8

12

18

24

ASSEMBLY

L-1643BH-D 8.

Page 10

C

A

B

OPERATION

INSTALLING YOUR AERATOR

CAUTION:

hands are clear of Tine T ips.

Avoid injury! Do not operate lift handle unless

attachment is installed to towing vehicle

1. Park machine safely. (See towing vehicle manual).

2. Align aerator clevis (A) with towing machine drawbar.

3. Install drawbar pin (B) through clevis and machine drawbar.

Secure drawbar pin with Hairpin Cotter (C).

Avoid injury! Make sure feet and

REMOVING AERATOR

CAUTION:

from under drawbar. Do not attempt to disconnect aerator from towing vehicle with weight on

the tray.

1. Secure towing vehicle parking brake. (See towing vehicle manual).

2. Place Aerator in the Transport Position

3. Unload aerator tray.

CAUTION:

from under drawbar. Do not attempt to disconnect aerator from towing vehicle with weight on

the tray.

4. Remove cotter pin and drawbar pin.

5. Push aerator away from towing vehicle.

6. Install drawbar pin and cotter pin to towbar for storage.

Avoid injury! Keep body parts away

Avoid injury! Keep body parts away

OPERATING

CAUTION:

Engage the transport wheels when crossing concrete

or asphalt driveways and walkways.

Excessive towed load can cause loss of control on

slopes. Stopping distance increases with speed and

weight of towed load.

Total towed weight must not exceed combined weight

of towing vehicle, ballast and operator.

Avoid injury! Avoid damage to tines.

USING THE WEIGHT TRAY

The following maximum loaded weight capacity is the weight of

the aerator plus the weight loaded in the tray:.

Model Weight Capacity

SA T 40BH 42 lbs. (Empty)

150 lbs (Max Load).

192 lbs Max Towed Weight

.

CAUTION:

from under drawbar. Do not attempt to disconnect aerator from towing vehicle with weight on

the tray.

Avoid injury! Keep body part s away

Towing capacity will vary with weight of towing vehicle and operator. Add the weight of your machine to operator weight to find

the maximum capacity for towing.

DEPTH/PENETRATION

Weight should be added to the tray after installing to the towing

machine. Weight should be secured by rope, straps, or other

suitable means to contain the weight in the tray.

Weight tray maximum capacity = 150 pounds.

Moderate soil moisture is important for proper penetration.

Extremely dry conditions will not permit penetration and may

damage the tines. Extremely wet conditions will cause full penetration to the tine spacers. This condition will cut slots in the turf.

SPEED

The best operating speed is 3 mph or less.

FREQUENCY

Aeration is not accomplished in a single pass. It will normally

take several passes over the lawn. Alternating the direction by

90° will improve the aeration effect.

The aerator may be used in an independent operation or may be

used when mowing your lawn.

9.

L-1643BH-D

Page 11

SERVICE

MAINTENANCE

After the first 30 minutes of use check all fasteners for tightness.

Tines are manufactured with galvanized steel to resist wear of

abrasive soil. Striking objects can cause tines to curl or break.

Contact our Customer Service Department to purchase replacement Tines (Part # B-5423).

Aerator is essentially maintenance free. However as with any

steel product, it can rust. Apply a light coat of oil on tines after

use to prevent rust. For rust appearing on painted surfaces, sand

lightly and coat with enamel.

Periodically remove debris that builds up between tines.

Apply lubricating oil at each tine and bearing before use.

SPECIFICATIONS

Maximum Towing Speed ..................................... ... .... ....... ..5 mph.

Maximum Load.................................................................. 150 lbs.

Empty Weight .......................... ............................................ 42 lbs.

Maximum Towed Weight ................................................... 192 lbs.

GETTING QUALITY SERVICE

Quality Continues with Quality Service

We provide a process to handle your questions or problems.

Follow the steps below to get answers to any questions you may

have about your product:

1. Refer to your attachment and machine operator manuals.

2. In North America or Canada, call 1-877-728-8224 and provide

product serial number (if available) and model number.

L-1643BH-D 10.

Page 12

MANUF ACTURER’S LIMITED WARRANTY

FOR

Pull Behind Accessories

The limited warranty set forth below is given by Brinly-Hardy

Company with respect to new merchandise purchased and

used in the United States, its possessions and territories.

Brinly-Hardy Company warrants the products listed below

against defects in material and workmanship, and will at its

option, repair or replace, free of charge, any part found to be

defective in materials or workmanship. This limited warranty

shall only apply if this product has been assembled, operated,

and maintained in accordance with the Operator’s manual furnished with the product, and has not been subject to misuse,

abuse, commercial use, neglect, accident, improper maintenance, alteration, vandalism, theft, fire, water, or damage

because of other peril or natural disaster.

Normal Wear Parts or components thereof are subject to separate terms as follows: All normal wear parts or component failures will be covered on the product for a period of 90 days.

Parts found to be defective within the warranty period will be

replaced at our expense. Our obligation under this warranty is

expressly limited to the replacement or repair, at our option, of

parts found to be defective in material and workmanship.

HOW TO OBTAIN SERVICE: Warranty parts replacements are

available, ONLY WITH PROOF OF PURCHASE, through our

Pull Behind Accessories Customer Service Department. Call

877-728-8224.

This limited warranty does not provide coverage in the following

cases:

a) Routine maintenance items such as lubricants and filters.

b) Normal deterioration of the exterior finish due to use or expo-

sure.

The provisions as set forth in this warranty provide the sole

and exclusive remedy arising from the sale. Brinly-Hardy Co.

shall not be liable for incidental or consequential loss or damage including, without limitation, expenses incurred for substitute or replacement lawn care services or for rental expenses

to temporarily replace a warranted product.

Some states do not allow the exclusion or limitation of incidental

or consequential damages, or limitations on how long an

implied warranty lasts, so the above exclusions or limitations

may not apply to you.

During the warranty period, the exclusive remedy is replacement of the part. In no event shall recovery of any kind be

greater that the amount of the purchase price of the product

sold. Alteration of safety features of the product shall void this

warranty. You assume the risk and liability for loss, damage, or

injury to you and your property and/or to others and their property arising out of the misuse or inability to use this product.

This limited warranty shall not extend to anyone other than the

original purchaser or to the person for whom it was purchased

as a gift.

HOW STATE LAW RELATES TO THIS WARRANTY: This limited

warranty gives you specific legal rights, and you may also have

other rights which vary from state to state.

IMPORTANT: The Warranty period stated below begins with the

PROOF OF PURCHASE. Without the proof of purchase, the

Warranty period begins from the date of manufacture determined by the serial number manufacturing date.

WARRANTY PERIOD:

The warranty period for this Lawn Aerator is as follows: Steel

Frame Parts - 3 Years, Tires and Tines are normal wear parts 90 days.

c) Transportation and/or labor charges.

d) The warranty does not include commercial and/or rental use.

No implied warranty, including any implied warranty of merchantability of fitness for a particular purpose, applies after

the applicable period of express written warranty above as to

the part as identified below. No other express warranty

whether written or oral, except as mentioned above, given by

any person or entity, including a dealer or retailer , with respect

to any product, shall bind Brinly-Hardy Co. During the period

of the warranty, the exclusive remedy is repair or replacement

of the product as set forth above.

L-1643BH-D

Brinly-Hardy Company, 3230 Industrial Parkway, Jeffersonville, IN 47130 (877) 728-8224

Loading...

Loading...