N9MP1 & N9MP2

*9MPD

* Denotes Brands (C, H, T)

FAN ASSISTED, DIRECT

VENT GAS FURNACE

SAFETY REQUIREMENTS

Recognizesafetyinformation. Thisisthesafety--alertsymbol!. When yousee thissymbolon thefurnaceandininstructions manualsbealertto

the potential for personal injury.

Understand the signal words DANGER, WARNING, or CAUTION. Thesewords are used with the safety--alert symbol. DANGER identifies the

most serious hazards, those that will result in severe personal injury or death. WARNING signifies a hazard that could result inpersonalinjuryor

death. CAUTION is used to identify unsafe practices that could result in minor personal injury or product and property damage.

Installing and servicing heating equipment can be hazardous due to gas and electrical components. Only trained and qualified personnel should

install, repair, or service heating equipment.

Untrained service personnel can perform basic maintenance functions such as cleaning and replacing air filters. All other operations must be

performedbytrained servicepersonnel. Whenworkingon heatingequipment,observeprecautionsintheliterature,ontags, andon labelsattached

to or shipped with the unit and other safety precautions that may apply.

Follow all safety codes. In the United States, follow all safety codes including the current edition National Fuel Gas Code (NFGC) ANSI

Z223.1--2002/NFPANo. 54--2002. In Canada,refertothe current editionofthe National StandardofCanada NaturalGasand PropaneInstallation

Code (NSCNGPIC) CSA B149.1--00. Wear safety glasses and work gloves. Have fire extinguisher available during start--up and adjustment

procedures and service calls.

Theseinstructions coverminimumrequirementsandconformtoexistingnationalstandardsandsafetycodes. Insomeinstances,theseinstructions

exceedcertainlocalcodesandordinances,especiallythosethat maynothavekeptup withchangingresidential construction practices. Werequire

these instructions as a minimum for a safe installation.

International Comfort Products Corporation (USA)

Lewisburg, TN 37091 U.S.A.

1. Safe Installation Requirements 3.................

2. Installation 4................................

3. Combustion & Ventilation Air 7..................

4. Vent & Combustion Air Piping 10................

5. Gas Supply and Piping 26......................

6. Electrical Wiring 30...........................

Table of Contents

!

Electric Shock Hazard

Turn Off All Power Before Servicing.

Failure to do so can result in death,

personal injury and/or property

damage.

INSTALLER: Affix these instructions

on or adjacent to the furnace.

CONSUMER: Retain these

instructions for future reference.

7. Ductwork and Filter 30........................

8. Checks and Adjustments 33....................

9. Furnace Maintenance 35.......................

10. Sequence of Operation & Diagnostics 35..........

11.Concentric VentTermination 39.................

TechSupport and Parts 43........................

!

FIRE OR EXPLOSION HAZARD

This furnaceis not designed for use in mobile

homes, trailers or recreational vehicles.

Such use could result in death, bodily injury

and/or property damage.

PrintedinU.S.A. 4/28/2003 440 01 1020 (02)

START--UP CHECK SHEET

For 90+ Furnace

(Keep this page for future reference)

Dealer Name:

Address: Business Card Here

City, State(Province), Zip or Postal Code:

Phone:

Owner Name:

Address:

City, State(Province), Zip or Postal Code:

Model Number:

Serial Number:

Type of Gas: Natural: LP:

Which blower speed tap is used?

(Heating)

Temperature of Supply Air: (°F) or(°C)

(Cooling)

Manual Gas Shut--Off Upstream

of Furnace/Drip--Leg? YES

Condensate Drain Connected? YES NO

Condensate Drain Trapped? YES NO

Transition Pressure switch hose relocated for U/D/H

Application? YES

Blower Speed Checked? YES NO

All Electrical Connections Tight? YES NO

Gas Valve OK? YES NO

Measured Line Pressure When Firing Unit:

Calculated Firing Rate:(See Checks and Adjustments Sec-

tion).

NO

NO

Temperature of Return Air: (°F) or(°C)

Rise (Supply Temp.--Return Temp.): (°F) or(°C)

Filter Type and Size:

Fan “Time ON” Setting:

Fan “Time OFF” Setting:

Dealer Comments:

2

Temperature Rise (supply--return temperature):(°F)

Measured Manifold Gas Pressure:

Static Pressure (Ducts): Supply Air Return

Date of Start--Up:

CO ?

CO2 ?

440 01 1020 02

1. Safe Installation Requirements

!

DEATH, PERSONAL INJURY AND/OR PROPERTY

DAMAGE

Failure to carefully read and follow all instructions

in this manual can result in furnace malfunction,

death, personal injury and/or property damage.

Installation or repairs made by unqualified persons

can result in hazards to you and others. Installation

MUST conform with local codes or, in the absence

of local codes, with codes of all governmental

authorities having jurisdiction.

The information contained in this manual is

intended for use by a qualified service technician

who is experienced in such work, who is familiar

with all precautions and safety proceduresrequired

in such work, and is equipped with the proper tools

and test instruments.

NOTE: This furnace is design--certified by the CSA International

(formerly AGA and CGA) for installation in the United States and

Canada.Refertotheappropriatecodes,alongwiththismanual,for

proper installation.

· Use only the Type of gas approved for this furnace (see

RatingPlateonunit). Overfiringwillresultin failure ofheat

exchanger and cause dangerous operation. (Furnaces

can be converted to L.P. gas with approved kit.)

· Installthisfurnaceonlyinalocationandposition as speci-

fied in “2. Installation” of these instructions.

· Provideadequatecombustion andventilationairto thefur-

naceasspecifiedin“3. Combustion and VentilationAir” of

these instructions.

· Combustionproducts must be discharged outdoors. Con-

nectthisfurnacetoanapprovedventsystemonly, asspecified in “4. Vent and Combustion Air Piping” of these

instructions.

· Never test for gas leaks with an open flame. Use a com-

mercially available soap solution made specifically for the

detection of leaks to check all connections,as specified in

“6. Gas Supply and Piping, Final Check” of these instructions.

· Always install furnace to operate within the furnace’s in-

tended temperature--rise range with a duct system which

hasanexternalstaticpressurewithintheallowablerange,

asspecifiedin“TechnicalSupportManual”oftheseinstructions.

· When a furnace is installed so that supply ducts carry air

circulated by the furnace to areas outside the space containingthefurnace,thereturnairshallalsobehandledbya

duct(s) sealed to the furnace casing and terminating outside the space containing the furnace.

· A gas--fired furnace for installation in a residential garage

mustbe installedass pecified in“2.Installation” ofthesein structions.

· This furnace is not to be used for temporary heating of

buildings or structures under construction.

· Thisfurnaceis NOTapprovedfor installationinmobile

homes, trailers or recreation vehicles.

· Seal around supply and return air ducts.

· Install correct filter type and size.

· Unit MUST be installed so electrical components are pro-

tected from direct contact with water.

Safety Rules

Your unitisbuilttoprovidemanyyearsofsafeanddependableser vice providing it is properly installed and maintained. However,

abuse and/or improper use can shorten the life of the unit and

create hazards for you, the owner.

A. The U.S. Consumer Product Safety Commission recom-

mends that users of gas--burning appliances install carbon

monoxidedetectors. There can be various sources of carbon

monoxidei n abuildingor dwelling.Thesourcescouldbe gas-fired clothes dryers, gas cooking stoves, water heaters, furnaces, gas --fired fireplaces, wood fireplaces, and several

other items.

Carbon monoxide can cause serious bodily injury and/or

death. Carbon monoxide or “CO” is a colorless and odorless

gasproducedwhenfuelis not burned completely or whenthe

flame does not receive sufficient oxygen.

Therefore, to help alert people of potentially dangerous carbon monoxide levels, you should have c arbon monoxide detectors that are listed by a nationallyrecognized agency (e.g.

UnderwritersLaboratoriesorInternationalApprovalServices)

installed and maintained in the building ordwelling (see Note

below).

B. There can be numerous sources of fire or smoke in a building

or dwelling. Fire or smoke can cause serious bodily injury,

death, and/or property damage. Therefore, in order to alert

people of potentially dangerous fire or smoke, you should

have fire extinguisher and smoke detectors listed by UnderwritersLaboratoriesinstalledandmaintainedinthebuildingor

dwelling (see Note below).

Note: The manufacturer of your furnace does not test any detec-

tors and makes no representations regarding any brand or

type of detector.

C. To ensure safeandefficientoperationof your unit,youshould

do the following:

1. Thoroughly read this manual and labels on the unit. This

willhelp you understand how your unit operates and the hazards involved with gas and electricity.

2. Do not use this unit if any part has been under water. Immediatelycalla qualifiedservicetechniciantoinspect theunit

andtoreplace anypartofthecontrolsystemandanygascon trol which has been under water.

3. Never obstruct the vent grilles, or any ducts that provide

air to the unit. Air must be provided for proper combustion

and ventilation of flue gases.

Frozen Water Pipe Hazard

!

FROZEN AND BURST WATER PIPE HAZARD

FaiIure to do so may result in burst water pipes, serious

property damage and/or personal injury.

Furnace may shut down. Do not leave your home

unattended for long periods during freezing weather

without turningoffwater supplyanddraining waterpipes

or otherwise protecting against the risk of frozen pipes.

Your furnace is designed solely to provide a safe and comfortable

living environment. The furnace is NOT designed to ensure that

water pipes will not freeze. It is equipped with several safety devices that are designed to turn the furnace off and prevent it from

restarting in the event of various potentially unsafe conditions.

440 01 1020 02

3

If your furnace remains off for an extended time, the pipes in your

home could freeze and burst, resulting in serious water damage.

Watermaycreateaconditioninwhichmoldcangrowinyourhome.

Certain types of mold have been reported to cause respiratory

problemsorotherserioushealthrisks.Remedialactions,including

immediately drying all wet items, should be taken quickly to help

prevent the development of mold in your home.

If the structure will be unattended during cold weather you should

take these precautions.

1. Turnoff thewatersupplyto thestructureanddrain thewater

lines if possible and add an antifreeze for potable water to

drain traps and toilet tanks. Open faucets in appropriate

areas.

-- o r --

2. Have someone check the structure frequently during cold

weather to make sure it is warm enough to prevent pipes

from freezing. Instruct them on a service agency to call to

provide service, if required.

-- o r --

2. Installation

3. Installareliable remotesensingdevice thatwillnotify somebody of freezing conditions within the home.

Winter Shutdown

Ifyou go away during the winter months and do notleavetheheat

oninyour home,theplastictransition boxandthecondensatetrap

on the furnace must be protected from freeze damage.(See

Figure 8 trough Figure 17)

5

1. Disconnect the

tingthatislocateddownstreamofthecombustionblower.Insert a funnel into the hose and pour four(4) ounces of

sanitary type (RV) antifreeze into the condensate trap. Reconnectthe

fitting. Secure with the hose clamp.

2. Disconnect the

trap. Insert a funnel into the hose and and pour four(4)

ouncesofsanitarytype(RV)antifreezeintotheplastic Transition box. Squeeze the hose together near the end and

quicklyreconnectthe

condensate trap. Secure with the hose clamp.

When you return home, your furnace will be ready to start, as it is

not necessary to drain the antifreeze from the furnace.

/8² OD rubber hose from the vent drain fit-

5

/8² ODrubberhosetothestubonthe ventdrain

3

/4² OD rubber hose from the condensate

3

/4² ODrubber hose tothestubonthe

!

CARBON MONOXIDE POISONING HAZARD

Failure to properly vent this furnace or other appliances

can result in death, personal injury and/or property

damage.

ThisfurnacecanNOTbe common vented orconnectedto

any type B, BW or L vent or vent connector, nor to any

portion of a factory--built or masonry chimney. If this

furnace is replacing a previously common-vented

furnace, it may be necessary to resize the existing vent

andchimneytopreventoversizing problems for theother

remaining appliance(s). See Venting and Combustion Air

Checkin GasVentInstallation section.Thisfurnace MUST

be vented to the outside.

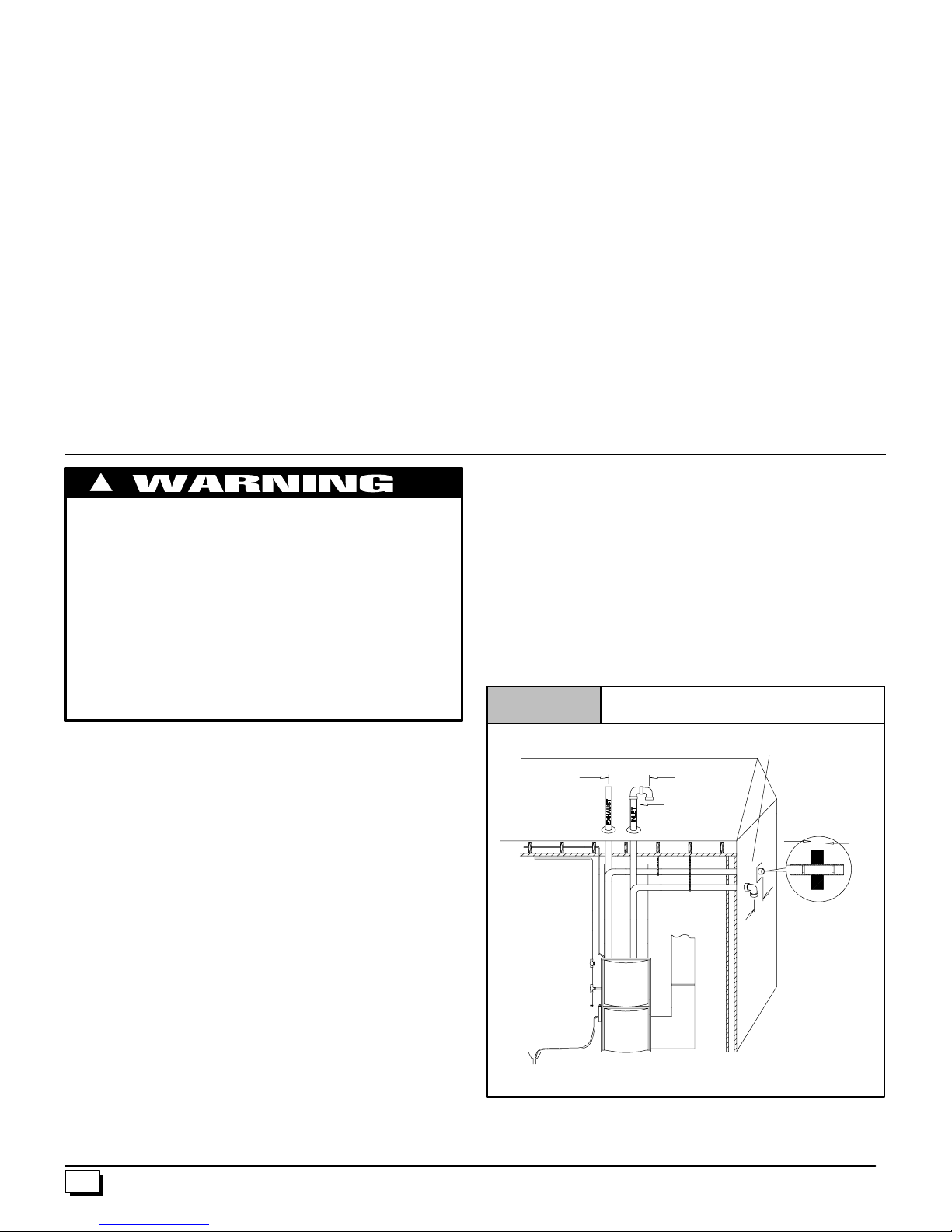

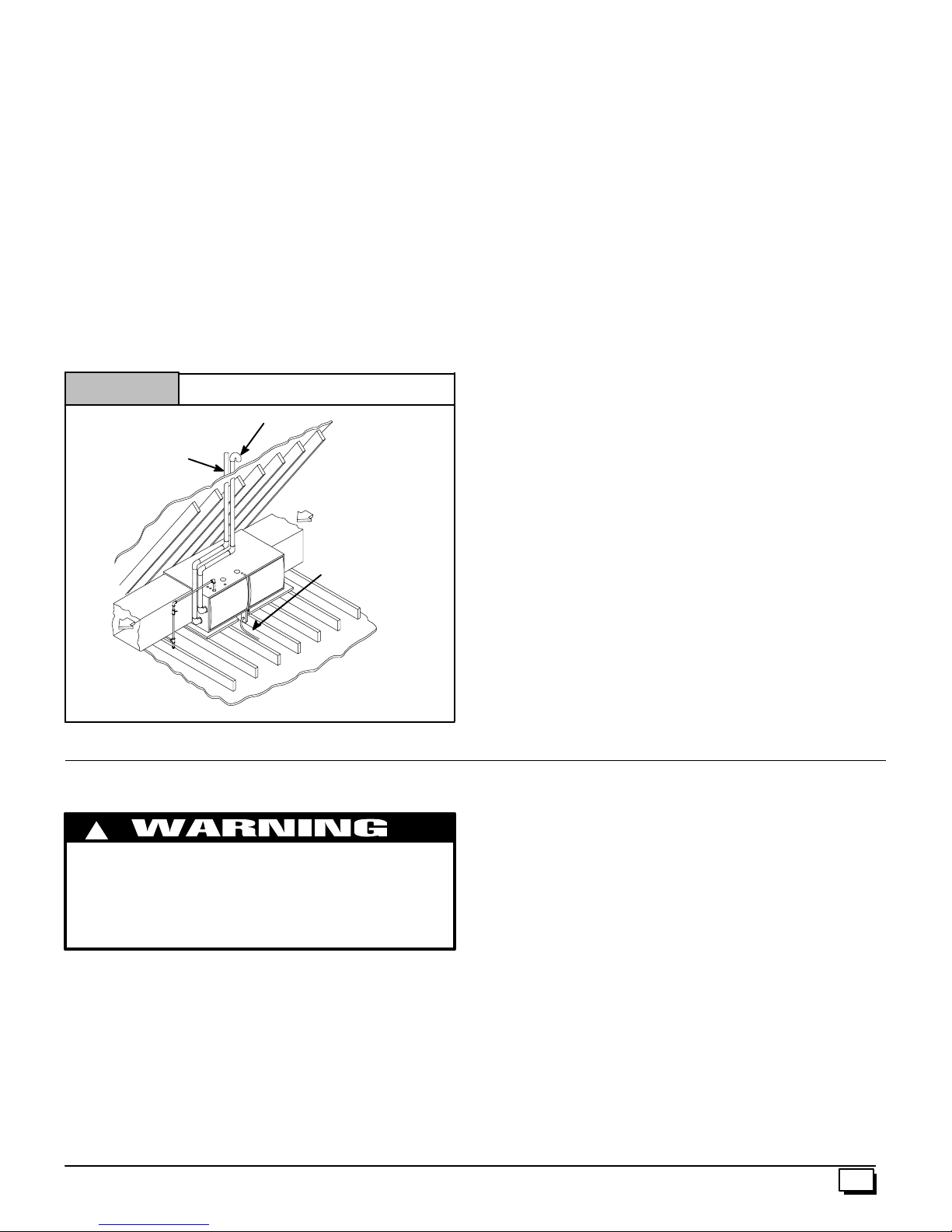

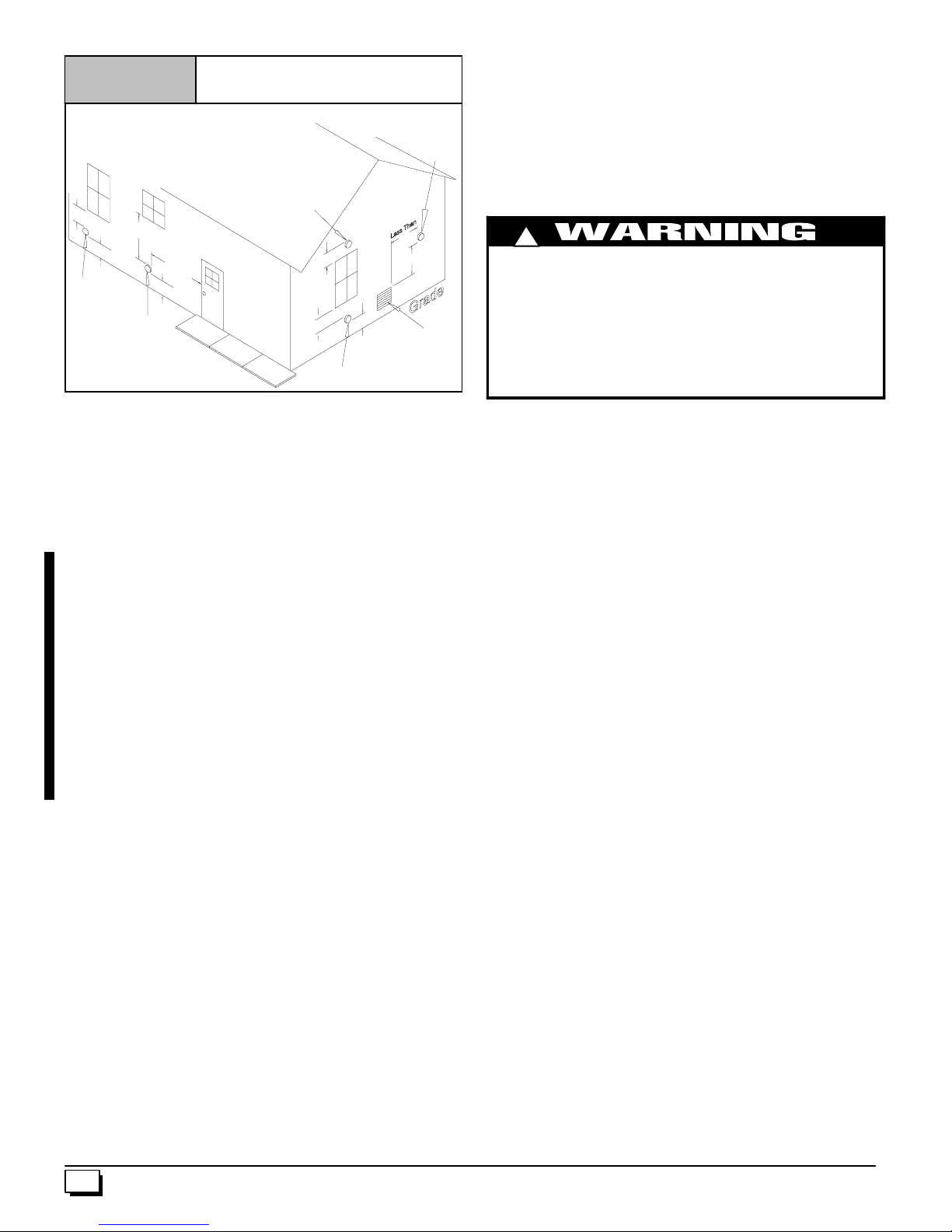

Location and Clearances

4. RefertoFigure 1 orFigure 2 fortypicalinstallationandbasic connecting parts required. Refer to Figure 4 for typical

horizontaldirect ventinstallationandbasicconnectingparts

required. Supply and return air p lenums and duct are also

required.

5. Iffurnaceisa replacement,itisusually besttoinstallthe furnace where the old one was. Choose the location or evaluatethe existinglocationbaseduponthe minimumclearance

and furnace dimensions (Figure 3).

CAUTION

Special precautions MUST be made if installing furnace in an

areawhichmaydropbelow freezing.Thiscancauseimproper

operation or damage to equipment. If furnace environment

hasthepotential of freezing, thedraintrapand drainline must

be protected. The use of electric heat tape or RV antifreeze is

recommendedforthese installations.(See“CondensateTrap

Freeze Protection Section”)

Do NOT operate furnace in a corrosive atmosphere

containing chlorine, fluorine or any other damaging

chemicals. Refer to Combustion & Ventilation Air section,

Contaminated Combustion Air.

Figure 1

*8² Min.

20¢ Max.

in same

atmospheric

zone

VentPipes MUST be

supportedHorizontally

and Vertically

T y pical Upflow Installation

Aluminum ornon-rusting shield recommended.(See

VentTermination Shielding fordimensions).

Couplingonendsof

exhaustpipe.Total

pipe &couplingoutside structure = 8²

*8² Min.

20¢ Max.

in sameatmospheric

zone

DISCHARGEAIR

Inlet Pipe(not

used onSingle

Pipe model)

4

* Increase minimumfrom8² to18² forcoldclimates (sustainedtemperatures below

0 ° F).

25--23--33

440 01 1020 02

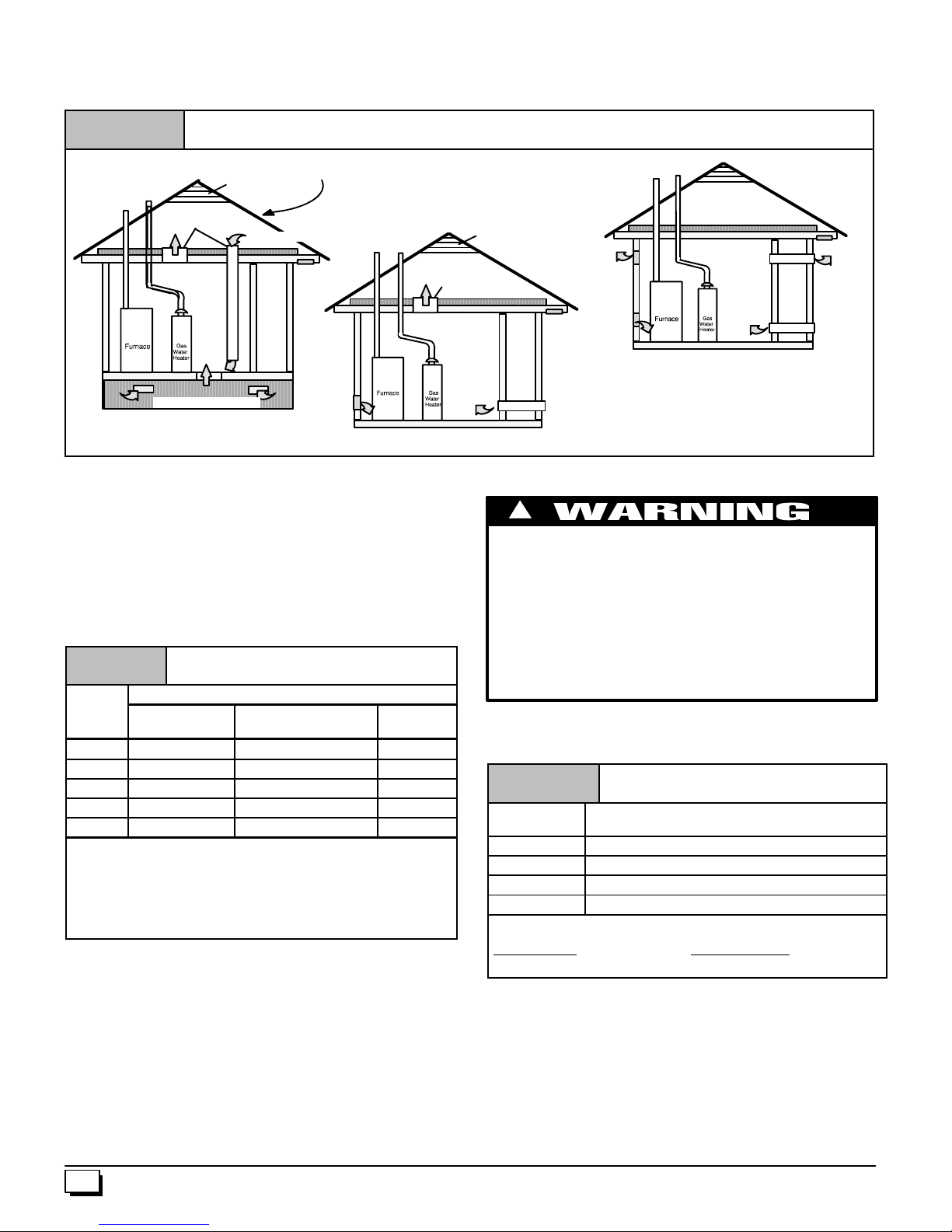

Figure 2 T y pical Downflow Installation

preferred method is to use an angle iron frame bolted to the

rafters or joists.

See VentTermination

Shielding in VentSection.

*8² Min.

Inlet Pipe

(not usedon

Single Pipe

model)

VentPipes MUST be

supportedHorizontally

and Vertically

* Increase minimumfrom8² to 18² forcoldclimates (sustainedtemperatures

below0°F).

20¢ Max.

in same

atmospheric zone

Couplingoninside

and outsideofwall

to restrainvent pipe

8² Min.

*8² Min.

20¢ Max.

in same

atmosphericzone

25--23--33a

!

DEATH, PERSONAL INJURY AND/OR PROPERTY

DAMAGE HAZARD.

Failuretoproperlyinstall this furnacecanresultin death,

personal injury and/or property damage.

Do NOT operate furnace in a corrosive atmosphere

containing chlorine, fluorine or a ny other damaging

chemicals.

Refer to Combustion & Ventilation Air section,

Contaminated Combustion Air for combustion air

evaluation and remedy.

Installation Requirements

1. Install furnace level.

2. ThisfurnaceisNOTtobe usedfortemporaryheatofbuildings

or structures under construction.

3. Install the vent pipes as short as practical. (See Gas Vent

Installation section).

4. DoNOTinstall furnace directlyoncarpeting,tile or othercombustible material other than wood flooring.

5. Maintainclearance for fire safety and servicing. A front clearanceof30² is minimumforaccesstotheburner,controlsand

filter. See clearance requirements in Figure 3 or.

6. Use a raised base if the floor is damp or wet at times.

7. Residential garage installations require:

· Burnersandignitionsourcesinstalledat least 18² (457 mm)

above the floor.

· Furnace must be located or physically protected from pos-

sible damage by a vehicle.

8. Ifthefurnaceistobesuspendedfromthefloorjoistsinabasementora crawl space or the rafters in an attic, it is necessary

tousesteelpipestrapsoranangleiron frametoattachthefurnace. These straps should be attached to the furnace with

sheet metal screws and to the rafters or joists with bolts. The

This furnace may be used for construction heat provided that:

· Thefurnaceispermanentlyinstalledwithallelectricalwiring,

piping, venting and ducting installed according to these

installationinstructions. Areturnairduct isprovided,sealed

tothe furnacecasing,andterminatedoutsidethespace containingthefurnace. This prevents a negative pressure condition as created by the circulating air blower, causing a

flame rollout and/or drawing combustion products into the

structure.

· Thefurnaceiscontrolledbyathermostat. It may not be“hot

wired” to provide heat continuously to the structure without

thermostatic control.

· Cleanoutsideairis provided for combustion. Thisistomini-

mize the corrosive effects of adhesives, sealers and other

construction materials. It also prevents the entrainment of

drywall dust into combustion air, which can cause fouling

and plugging of furnace c omponents.

· The temperature of the return air to the furnace is no less

than55° F,withnoeveningsetback orshutdown. Theuseof

the furnace while the structure is under construction is

deemed to be intermittent operation per our installation instructions.

· Theairtemperatureriseiswithintherated riserange on the

furnace rating plate, and the firing rate has been set to the

rating plate value.

· The filters used to clean the circulating air during the

construction process must be either changed or thoroughly

cleaned prior to occupancy.

· The furnace, ductwork and filters are cleaned as necessary

to remove drywall dust and construction debris from all

HVAC system components after construction is completed.

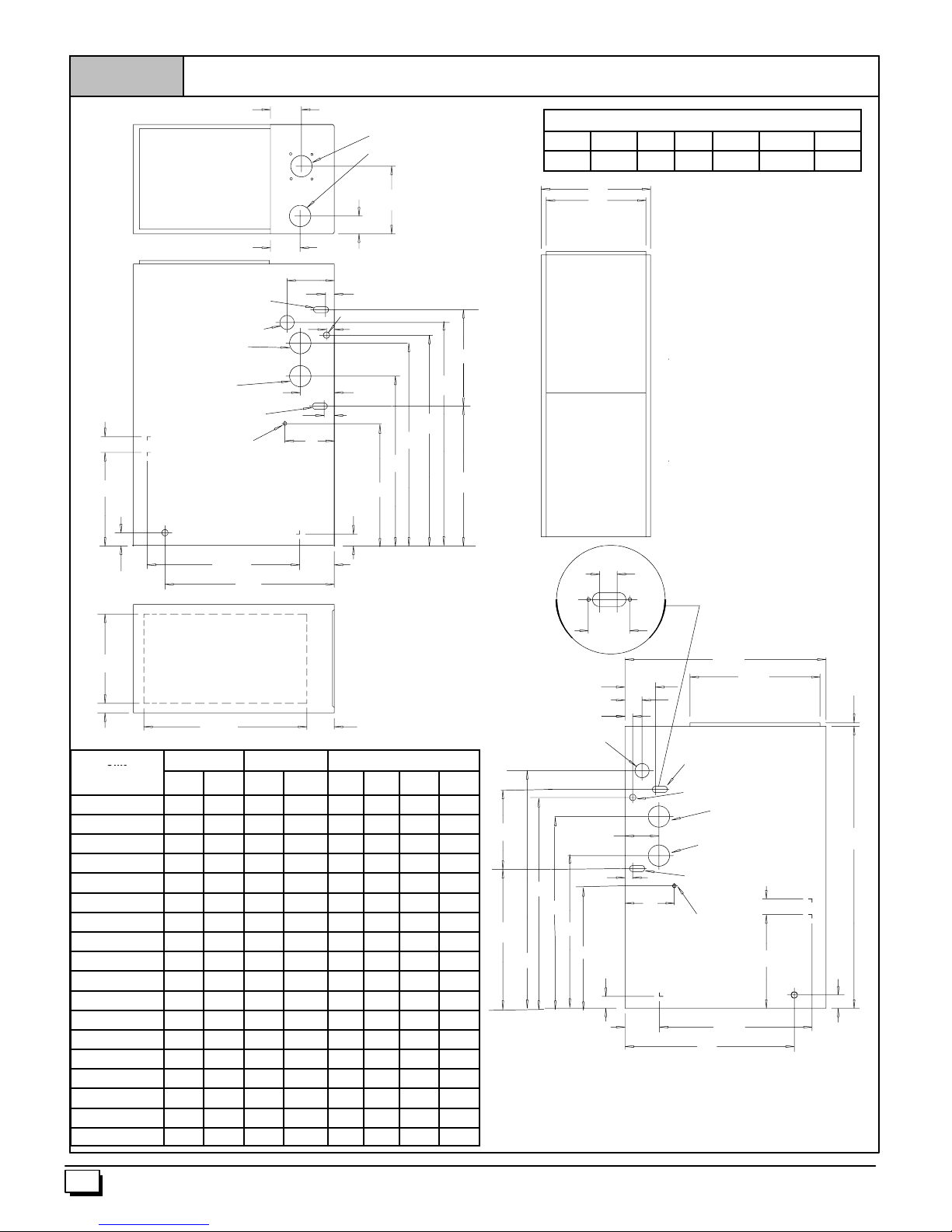

Installation Positions

This furnace can be installed in an upflow, horizontal (either left or

right) or downflow airflow position. DO NOT install this furnace on

itsback.Fortheupflowposition,thereturnairductworkcanbeattached to either the left or right side panel and/or the bottom. For

horizontalanddownflow positions,thereturnair ductworkmustbe

attached to the bottom. The return air ductwork must never beattached to the back of the furnace.

Furnace Installation Considerations

Theinstallation ofthefurnacefora givenapplicationwilldictatethe

positionof thefurnace,theairflow,ductworkconnections,ventand

combustion air piping. Consideration must be given to the following:

CondensateTrapand Drain Lines

Thesupplied condensatetrapmustbeattachedtothefurnaceside

paneloneither theleftorrightside.Forhorizontal installations,the

draintrapisverticallyattachedto thesidepanel belowthefurnace.

A minimum clearance of 6² below the furnace is required for the

condensate trap. Downward slope of the condensate drain line

from the condensate trap to the drain location must be provided.

Adequatefreezeprotectionofthedraintrapand thedrainlinemust

be provided. See “Condensate Drain Trap” section for further de-

tails.

440 01 1020 02

5

Figure 3

Uni

t

Dimensions & Clearances

131/

F

AIR INTAKE

VENT (*9MPD)

TOP

H

Cabinet to Combustible Clearances

TOP BOT. RH LH BACK FRONT FLUE

1² 0² 0² 0² 0² 3² 0²

A

B

G

E

811/

LEFT SIDE

TRAP (COUNTERFLOW)

GAS

VENT

AIR INTAKE

(ALTERNATE)

TRAP

UPFLOW/HORIZONTAL

21/

4

4

17/

8

THERMOSTAT

215/

13

4

8

24

16

11/

4

ELECTRICAL

11/

16

1311/

16

3111/

297/

4

16

8

1913/

16

/

16

13/

8

7

11

1

/

7

4

/

8

283/

241/

16

175/

16

16

FRONT

1

1

/

4

D

C

Unit

Capacity

BOTTOM

231/

8

Cabinet Bottom Top

A B C D E F G H

37/

8

N9MP1050B12A 151/214 13/8125/8-- -- -- -- ---- -- -N9MP1075B12A 151/214 13/8125/8-- -- -- -- ---- -- --

N9MP1080F16A 191/8175/821/8143/4-- -- -- -- ---- -- -N9MP1100F14A 191/8175/821/8143/4-- -- -- -- ---- -- -N9MP1100J20A 223/4211/4115/16183/4-- -- -- -- ---- -- --

N9MP1125J20A 223/4211/4115/16183/4-- -- -- -- ---- -- -N9MP2050B12A 151/214 13/8125/8-- -- 41/2-- -- 73/

N9MP2075B12A 151/214 13/8125/8-- -- 41/2-- -- 73/

N9MP2080F16A 191/8175/821/8143/4-- -- 41/2-- -- 91/

N9MP2100F14A 191/8175/821/8143/4-- -- 41/2-- -- 91/

N9MP2100J20A 223/4211/4115/16183/4-- -- 41/2-- -- 113/

N9MP2125J20A 223/4211/4115/16183/4-- -- 41/2-- -- 113/

*9MPD050F12A 191/8175/821/8143/443/841/221/291/

*9MPD075F12A 191/8175/821/8143/443/841/221/291/

*9MPD080J16A 223/4211/4115/16183/443/841/225/8113/

*9MPD100J14A 223/4211/4115/16183/443/841/225/8113/

*9MPD100J20A 223/4211/4115/16183/443/841/225/8113/

*9MPD125L20A 241/2237/

23 43/841/221/4121/

16

27/

8

281/

11/

GAS

2

181/

5

/

4

23/

16

16

8

2

RIGHT SIDE

1

/

TYP.

2

TRAP (COUNTERFLOW)

ELECTRICAL

AIR INTAKE

(ALTERNATE)

8

273/

16

215/

8

175/

111/

413/

16

111/

16

16

7

16

47/

8

VENT

TRAP

UPFLOW/HORIZONTAL

21/

THERMOSTAT

215/

4

1

/

19

4

8

40

17/

8

24

25--23--36b

13/

16

297/

4

913/

4

2

2

8

8

2

2

8

8

8

4

16

3311/

16

6

440 01 1020 02

Leveling

Proper leveling of the furnace must be provided to insure proper

drainageofthe condensate fromthefurnace. The furnacemustbe

leveltowithin1/4² fromfronttobackandfromsidetosideforupflow

and downflow installations or top to bottom for horizontal installations.

Vent and Combustion Air Connections

On the Dual Certified furnace, the vent and combustion air pipes

attachtothefurnacethroughthetoppanelfor the upflow and horizontal installations. For the downflow installation, the vent and

Horizontal Furnace Installation

This furnace can be installed horizontally in an attic, basement,

crawlspace,alcove,orsuspended from a ceiling inabasementor

utility room . See Figure 4. Do not install furnace on its back or in

thereverseairflowpositions as safety control operation will be adversely affected.

Figure 4

T ypical Horizontal Installation

Inlet Pipe(not used on Single Pipemodel)

Vent

Pipe

combustion air pipes attach to the furnace through the alternate

locations on the furnace side panels.

Note:OntheDirectVent furnace, the vent pipe attaches to thefurnacethroughthesidepanels. The combustion airpipeattachesto

the top panel or to the alternate location on the side panel.

On the Single Pipe furnace, the vent pipe attaches to the furnace

through the furnace side panels.

Note: Repositioning of the combustion blower is required for the

ventpipe connection to the furnace through the “right side”panel.

See “Vent and Combustion Air Piping” section for further details.

If the furnace is to be suspended from the floor joists in a crawl

space or the rafters in an attic, it is necessary to use steel pipe

strapsoranangleironframetorigidly attachthefurnacetoprevent

movement. These straps should be attached to the furnace with

sheet metal screws and to the rafters or joists with bolts. The preferred method is to use an angle iron frame bolted to the rafters or

joists.(Takecautiontoallowdoor panelstoberemovedfor maintenance)

Ifthe furnaceistobeinstalledinacrawlspace,consultlocalcodes.

A suitable concrete pad or blocks are recommended for crawl

space installation on the ground.

NOTE: 6² bottom c learance required for condensate trap.

Thirty (30) inches between the front of the furnace and adjacent

construction or other appliances MUST be maintained for service

clearance.

Condensate

Trap

25--23--34

NOTE: 6²²²² bottomclearance required for condensatetrap.

3. Combustion & Ventilation Air

For Single Pipe Installation

!

CARBON MONOXIDE POISONING HAZARD

Failure to provide adequate combustion and ventilation

air can result in death and/or personal injury.

Use methods described here to provide combustion and

ventilation air.

Furnaces require ventilation openings to provide sufficient air for

proper combustion and ventilation of flue gases. All duct or openingsforsupplying combustionandventilationairmust complywith

National Fuel Gas Code, NFPA54/ANSIZ223.1, 2002 (or current

edition) and applicable provisions of local building codes.

Thisfurnace canNOTbecommonventedorconnectedtoanytype

B, BW or L vent or vent connector,norto any portion of a factory-built or masonry chimney. If this furnace is replacing a previously

common-ventedfurnace,itmaybenecessarytoresizetheexisting

vent and chimney to prevent oversizing problems for the other remainingappliance(s).See“VentingandCombustionAirCheck” in

this section. This furnace MUST be vented to the outside.

Keep all insulating materials clear from louvered door. Insulating

materials may be combustible.

The horizontal furnaces may be installed directly on combustible

wood flooring or supports as long as all required furnace clearances are met. See Figure 4.

Thisfurnace MUSTNOTbe installeddirectlyon carpetingortileor

other combustible material other than wood flooring or supports.

Forhorizontalinstallation overafinishedlivings pace. A fieldfabricatedauxiliary drainpanwithdrainpipeisrequiredtopreventdamage by overflow due to blocked condensate drain.

Air Openings and Connecting Ducts

1. TotalinputratingforallnondirectventgasappliancesMUST

be considered when determining free area of openings.

2. Connect ducts or openings directly to outside.

3. When screens are used to cover openings, they MUST be

no less than

4. The minimum dimension of rectangular air ducts MUST

NOT be less than 3².

5. When sizing grille or louver,use the free area of opening. If

free area is NOT stamped or marked on grill or louver, assume a 20% free area for wood and 60% for metal.

1

/4² mesh.

Confined Space Installation

NOTE: A confined space is defined as an area with less than 50

cubic feet per 1,000 BTUH input rating for all gas appliances

installed in the area.

Requirements

1. Provide confined space with sufficient air for proper combustionandventilationoffluegasesusing horizontalorvertical ducts or openings.

440 01 1020 02

7

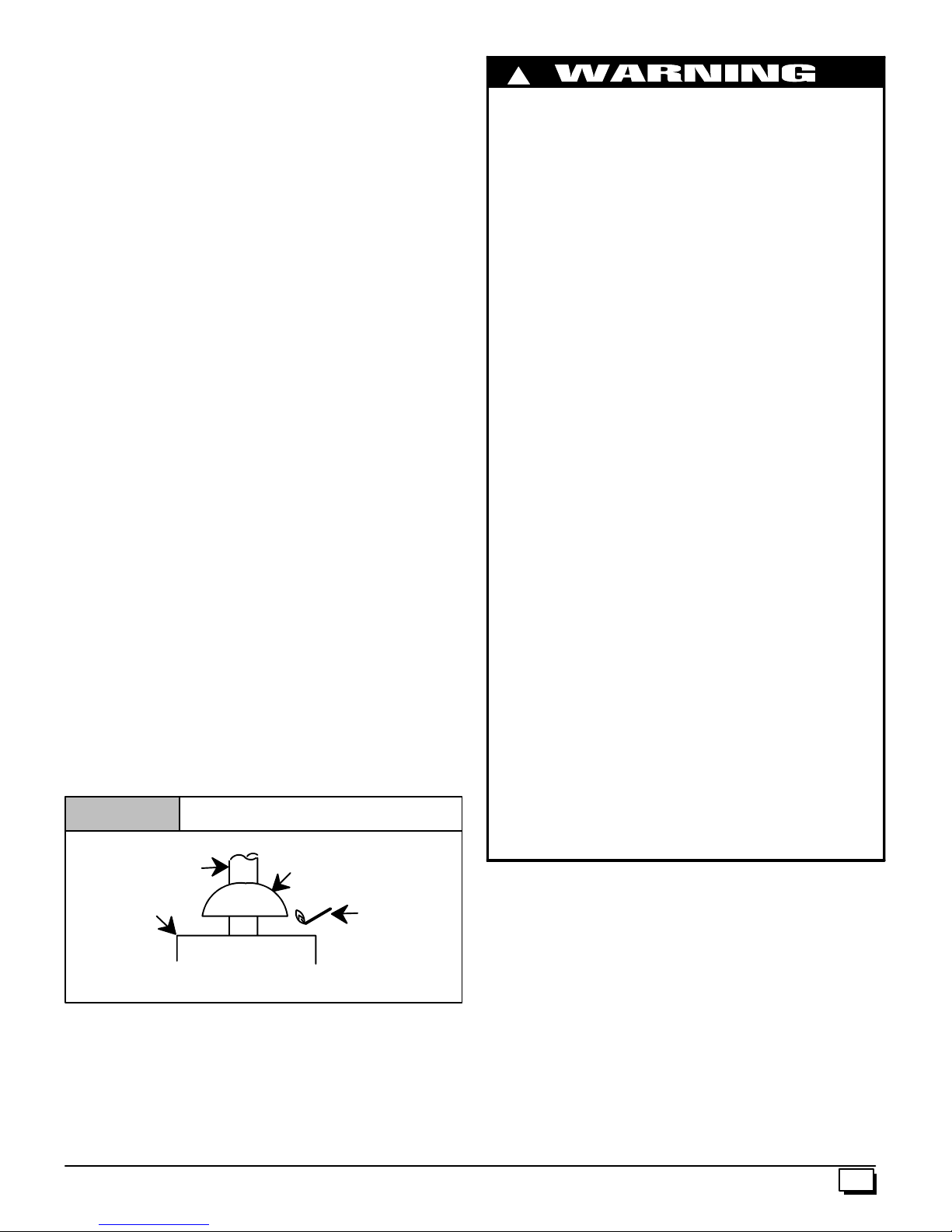

2. Figure 5 illustrate how to provide combustion and ventila-

BTU

H

tion air. A minimum of two permanent openings, one inlet

and one outlet, are required.

3. Oneopening MUSTbewithin12² of thefloorandthesecond

opening within 12 ² of the ceiling.

Figure 5

Outside Air (This is ONLY a guide. Subject to codes of country having jurisdiction.)

This installation NOT approved in Canada

Gable Vent

Gas Vent

VentilatedAttic

TopAbove Insulation

Outlet Air (1)

VentilatedCrawl Space

alternate Inlet Air (1)

alternate Inlet Air (1)

Soffit Vent

Inlet

Air (1)

Gas Vent

VentilatedAttic

TopAbove Insulation

OutletAir (1)

4. Size openings and ducts per Table 1.

5. Horizontal duct openings require 1 square inch of free area

per 2,000 BTUH of combined input for all gas appliances in

area (see Table 1).

6. Vertical duct openings or openings directly to outside require 1 square inch of free area per 4,000 BTUH for combined input of all gas appliances in area (see Table 1).

Table 1 Free Area

BTUH

Input

Rating

50,000 25 sq. in. 12.5 sq. in. 4²

75,000 37.5 sq. in. 18.75 sq. in. 5²

100,000 50 sq. in. 25 sq. in. 6²

125,000 62.5 sq. in. 31.25 sq. in. 7²

150,000 75 sq. in. 37.5 sq. in. 7²

Minimum FreeAreaRequiredfor Each Opening

HorizontalDuct

(2,000 BTUH)

VerticalDuct or openings

to outside(4,000BTUH)

Round Duct

(4,000 BTUH)

EXAMPLE: Determining Free Area

Appliance 1 Appliance 2 Total Input

100,000 + 30,000 = (130,000 ¸ 4,000) = 32.5 Sq. In. Vertical

Appliance 1 Appliance 2 Total Input

100,000 + 30,000 = (130,000 ¸ 2,000) = 65 Sq. In. Horizontal

One permanent opening, commencing within 12² of the top of the

enclosure,shall bepermittedwheretheequipmenthasclearances

of at least 1² from the sides and back and 6² from the front of the

appliance. The opening shall directly communicate with the outdoorsorshallcommunicatethrough a vertical orhorizontalductto

theoutdoors orspaces(crawlorattic)thatfreelycommunicatewith

the outdoors, and shall have a minimum free area of:

· 1 sq. in per 3000 Btu per hr. of the total input rating of all

equipment located in the enclosure, and

· Not less than the sum of the areasofallventconnectorsin

the confined space.

8

Gas Vent

Gable Vent

Soffit Vent

Inlet

Air (2)

Outlet

Air (1)

Inlet

Air (1)

Minimum OneInlet and One OutletAirSupply is Required

May bein any Combination Shown

Inlet Air OpeningMust be Within12² of floor

Outlet AirOpeningMust be Within12² of ceiling

(1) 1 Square Inchper 4000 BTUH

(2) 1 Square Inchper 2000 BTUH

Inlet

Air (2)

Outlet

Air (2)

Unconfined Space Installation

!

CARBON MONOXIDE POISONING HAZARD

Failure to supply additional air by means of ventilation

grilles or ducts could result in death and/or personal

injury.

An unconfined space or homes with tight construction

may not have adequate air infiltration for proper

combustion and ventilation of flue gases.

Most homes will require additional air.

Anunconfinedspaceisdefinedasanareahavingaminimumvolumeof50c ubic feet per 1,000 Btuhtotalinputratingforallgasappliances in area. Refer to Table 2 for minimum area required.

Table 2

BTUH Input

Rating

50,000 312

78,000 490

114,000 712

155,000 968

EXAMPLE: NOTE: Square feet is based on 8 foot ceilings.

28,000 BTUH

1,000 8¢ Ceiling Height

NOTE: Refer to definitions in section titled Unusually Tight

Construction. If any one of the conditions apply,the space MUST

be considered confined space regardless of size.

1. Adjoining rooms can be considered part of an unconfined

area if there are openings without doors between rooms.

2. An attic or crawl space may be considered an unconfined

space provided there are adequate ventilation openings directly to outdoors. Openings MUST remain open and NOT

haveanymeansofbeing closed off.Ventilationopenings to

outdoorsMUST be at least 1² square of free area per 4,000

BTUH of total input rating for all gas appliances in area.

Unconfined Space

Minimum Area in Square Feet

Minimum Area in Square Feet

X 50CubicFt. = 1,400 = 175 Sq. Ft.

440 01 1020 02

3. Install air intake a minimum of 12² above maximum snow

level and clear of any obstruction. Duct or ventilation openingrequiresonesquareinch of freeareaper4,000BTUH of

total input rating for all gas appliances in area.

1

4. Air inlet MUST be screened with not less than

screen.

/4² mesh

Unusually Tight Construction

In unconfined spaces, infiltration may be adequate to provide air

for combustion, ventilation and dilution of flue gases. However, in

buildingswithunusuallytightconstruction, additional air MUSTbe

provided using the methods described in section titled Confined

Space Installation:

Unusually tight construction is defined as: Construction with

1. Walls and ceilings exposed to the outside have a continuous,sealedvaporbarrier. Openings aregasketedorsealed

and

2. Doors and openable windows are weather stripped and

3. Otheropenings are caulked or sealed. These include joints

around window and door frames, between sole plates and

floors, between wall--ceiling joints, between wall panels, at

penetrations for plumbing, electrical and gas lines, etc.

VentilationAir

Someprovincial codes and local municipalities require ventilation

or make--up air be brought into the conditioned space as replacementair.Whichevermethodis used,themixedreturnair temperature across the heat exchanger MUST not fall below 60°Forflue

gaseswill condenseintheheatexchanger.Thiswillshortenthelife

of the heat exchanger and possibly void your warranty.

Venting and Combustion Air Check

NOTE: When an existing Category I furnace is removed or re placed,theoriginalventingsystemmaynolongerbesizedtoproperly vent the attached appliances, and to make sure there is

adequatecombustionairforallappliances,MAKETHEFOLLOW-

ING CHECK.

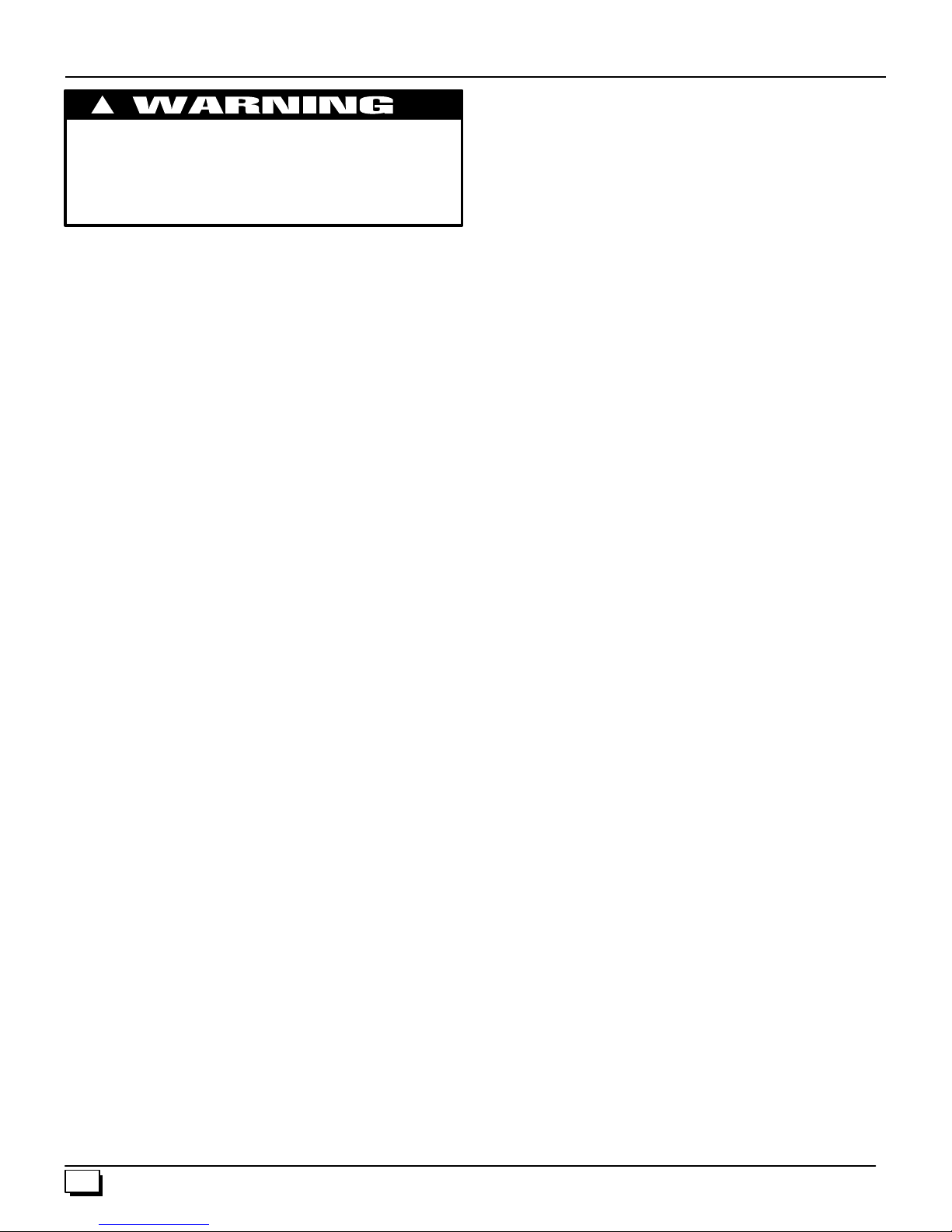

Figure 6

Typical Gas

Water Heater

Ifflamepullstowardsdraft hood, thisindicatessufficient

venting.

Vent Check

Draft HoodVent Pipe

Match

!

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each

applianceconnectedto theventingsystem beingplaced

into operation, while all other appliances connected to

the venting system are not in operation could result in

carbon monoxide poisoning or death.

Thefollowingstepsshallbe followed for each appliance

connected to the venting system being placed into

operation, while all other appliances connected to the

venting system are not in operation:

1. Seal any unused openings in the venting system.

2. Inspecttheventing systemfor propersize and horizontal

pitch, as required in the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 or CSA B149.1, Natural Gas and Pro pane Installation Codes and these instructions. Deter-

minethatthereis no blockage or restriction,leakage,corrosion and other deficiencies which could cause an un safe condition.

3. As far as practical, close all building doors and windows

andalldoorsbetweenthespaceinwhichtheappliance(s)

connected to the venting system are located and other

spaces of the building.

4. Close fireplace dampers.

5. Turnonclothes dryers and any appliance not connected

to the venting system. Turnon any exhaust fans, such as

range hoods and bathroom exhausts, so they will operatingatmaximumspeed.Donotoperatea summerexhaust

fan.

6. Followthelightinginstructions.Placethe appliancebeing

inspected into operation. Adjust thermostat so appliance

is operating continuously.

7. Test for spillage from draft hood equipped appliances at

thedrafthoodreliefopeningafter5minutesofmainburner

operation.Usetheflameofamatchorcandle.(Figure 6)

8. If improper venting is observed, during any of the above

tests, the venting system must be corrected in accordance with the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 and/or CSA B149.1, Natural Gas and

Propane Installation Codes.

9. After it has been determined that each appliance connected to the venting system properly vents when tested

as outlined above, return doors, windows, exhaust fans,

fireplace dampers and any other gas-- fired burning appliance to their previous conditions of use.

For Two Pipe Installation

Thisfurnace canNOTbecommonventedorconnectedtoanytype

B, BW or L vent or vent connector,norto any portion of a factory-built or masonry chimney. If this furnace is replacing a previously

common-ventedfurnace,itmaybenecessarytoresizetheexisting

vent and chimney to prevent oversizing problems for the other remainingappliance(s).See“VentingandCombustionAirCheck” in

this section. ThisfurnaceMUSTbeventedtotheoutside.

440 01 1020 02

9

4. Vent and Combustion Air Piping

!

CARBON MONOXIDE POISONING, FIRE AND EXPLOSION

HAZARD

Failure to properly vent this furnace can result in death,

personal injury and/or property damage.

Read and follow all instructions in this section.

SinglePipe(N9MP1Models)

This furnace is certified as a category IV appliance. This furnace

requires ventilation openings to provide air for proper combustion

and ventilation of flue gases. All duct or openings for supplying

combustion and ventilation air must comply with the gas codes or

in absence of local codes, the applicable national codes.

Whentheinstallation iscomplete,see the“Ventingand Combus-

tion Air Check” in this manual.

Direct Vent (N9MP2 Models)

This furnace is certified as a category IV appliance. This furnace

uses outside air for combustion ONLY, it MUST be taken from the

sameatmosphericpressure zoneastheventpipe. See Confined

SpaceInstallationintheCombustionand VentilationAir inthis

manual.

Dual Certified (*9MPD Models)

This furnace is certified as a category IV appliance. This furnace

can be installed as a direct vent furnaceusingoutsideair forcombustionorthefurnacecanuseairfrominsidethestructure forcombustion. The INLET air pipe is optional. If combustion air comes

frominsidethestructure,adequatemakeupair MUSTbeprovided

tocompensateforoxygen burned. See ConfinedSpaceInstalla-

tion in the Combustion and Ventilation Air chapter.If combustion air is drawn from outside the structure,it MUST be taken from

the same atmospheric pressure zone as the vent pipe.

Contaminated Combustion Air

Installationsincertain areasortypesof structureswillincrease the

exposure to chemicals or halogens that may harm the furnace.

Thefollowingareasortypesofstructuresmaycontainor have exposure to the substances listed below. The installation must be

evaluatedcarefullyasitmaybenecessarytoprovideoutsideairfor

combustion.

· Commercial buildings.

· Buildings with indoor pools.

· Furnaces installed in laundry rooms.

· Furnaces installed in hobby or craft rooms.

· Furnaces installed near chemical storage areas.

· Permanent wave solutions for hair.

· Chlorinated waxes and cleaners.

· Chlorine based swimming pool chemicals.

· Water softening chemicals.

· De--icing salts or chemicals.

· Carbon tetrachloride.

· Halogen type refrigerants.

· Cleaning solvents (such as perchloroethylene).

· Printing inks, paint removers, varnishes, etc.

· Hydrochloric acid.

10

· Sulfuric Acid.

· Solvent cements and glues.

Antistatic fabric softeners for clothes dryers.

·

· Masonry acid washing materials.

Vent and Combustion Air Piping Guidelines

ThisfurnaceisapprovedforventingwithSchedule40PVC,CPVC,

ABS, Cellular Core pipe fittings and SDR--26 PVC.

NOTE: All PVC, CPVC, ABS, and Cellular Core pipe fittings, solventcement,primers and procedures MUST conformtoAmerican

National Standard Institute and American Society for Testing and

Materials (ANSI/ASTM) standards.

· PipeandFittings -- ASTM D1785, D2241, D2466, D2661,

D2665, F--891, F--628

· PVC Primer and Solvent Cement -- ASTM D2564

· Procedure for Cementing Joints -- Ref ASTM D2855

NOTE: All vent piping MUST be installed in compliance with local

codesorordinances, theseinstructions,goodtradepractices,and

codes of country having jurisdiction.

1. Determinethebestroutingand termination fortheventpipe

and air inlet pipe by referring to all of the instructions and

guidelines in this Section.

2. Determine the size required for the vent pipe and air inlet

pipe.

3. Loosely assemble all venting parts without adhesive (pipe

joint cement) for correct fit before final assembly.

4. Use of vertical piping is preferred because there will be

some moisture in the flue gases that may condense as it

leavestheventpipe(See Special Instruction ForHorizontal

Vents).

5. Theverticalventpipe MUST besupportedsothatno weight

is allowed to rest on the combustion blower.

6. Exhaust vent piping or air inlet piping diameter MUST NOT

be reduced.

7. All exhaust vent piping from the furnace to termination

MUST slope upwards. A minimum of

required to properly return condensate to the furnace drain

system.

8. Use DWV type long radius elbows whenever possible, as

they provide for the minimum slope on horizontal runs and

they provide less resistance in the vent system. If DWV elbows cannot be used, use two, 45° elbows when possible.

On horizontal runs the elbows can be slightly misaligned to

provide the correct slope.

9. All horizontal pipe runs MUST be supported at least every

fivefeetwithgalvanizedstraporotherrustresistantmaterial. NO sags or dips are permitted.

10. All vertical pipe runs MUST be supported every six feet

where accessible.

11. The minimum pipe run length is 2¢.

12. The piping can beruninthesamechase or adjacent tosupply or vent pipe for water supply or waste plumbing. It can

also be run in the same chase with a vent from another 90+

furnace.

NOTE:InNO case can the piping be run in a chase where

temperatures can exceed 140° F. or where radiated heat

from adjacent surfaces would exceed 140° F.

13. The vent outlet MUST be installed to terminate in the same

atmospheric pressure zone as the combustion air inlet.

14. Theventsystemcanbeinstalledinanexistingunusedchimney provided that:

1

/4² per foot of run is

440 01 1020 02

· Both the exhaust vent and air intake run the length of the

chimney.

· No other gas fired appliance or fireplace (solid fuel) is

vented into the chimney.

· The top of the chimney MUST be sealed flush or crowned

uptosealagainstrainormeltingsnow so ONLYthepiping

protrudes.

· The termination clearances shown in Figure 7 are main-

tained.

15. Furnaceapplicationswithverticalventsrequiringventdiameter increaser fittings must have increaser fittings installed

in vertical portion of the vent. Condensate will be trapped in

the vent if the vent diameter is increased prior to having an

elbowturnedupward.This could cause nuisancetrippingof

the pressure switch.

Piping Insulation Guidelines

NOTE:Useclosedcell,neopreneinsulation orequivalent.If Fiberglass or equivalent insulation is used it must have a vaporbarrier.

UseRvalues of 7upto10¢,R--11if exposureexceeds10¢.IfFiberglassi nsulation isused,exteriortothestructure,thepipeMUSTbe

boxed in and sealed against moisture.

1. When the vent or combustion air pipe height above theroof

exceeds 30², or if an exterior vertical riser is used on a horizontal vent to get above snow levels, the exterior portion

MUST be insulated.

2. When combustion air inlet piping is installed above a suspended ceiling, the pipe MUST be insulated with moisture

resistant insulation such as Armaflex or other equivalent

type of insulation.

3. Insulatecombustionairinletpipingwhenruninwarm,humid

spaces such as basements.

Sizing Combustion Air and Vent Pipe

Consult Table 3 or Table 4 to s elect the proper diameter exhaust

and combustion air piping. Exhaust and combustion air piping is

sized for each furnace Btuh size based on total lineal vent length

(on inlet or outlet side), and number of 90° elbows required. Two

45° elbows can be substituted for one 90° elbow. The elbow or elbowsusedforventterminationoutsidethestructureAREcounted,

including elbows needed to bring termination above expected

snow levels. The elbow inside the furnace on the *9MPD IS NOT

included in the count.

Table 3

50,000, 75,000 & 80,000 Btuh Furnaces

40¢ & (5) 90° elbows with 2² PVC pipe or

70¢ & (5) 90° elbows with 3² PVC pipe

40¢ & (5) 90° elbows with 3² PVC pipe or

70¢ & (5) 90° elbows with 3² PVC pipe &

Long Vent Kit (See Tech. Manual)

40¢ & (5) 90° elbows with 3² PVC pipe

Elbows are DWV Long Radius Type for 2² and 3² vents.

If more than five elbows are required, reduce the length of

both the inlet and exhaust pipes 5¢ for each additional elbow

used.

Pipe Diameter Table

N9MP1 & *9MPD Models

100,000 Btuh Furnace

125,000 Btuh Furnace

NOTE: It is allowable to use larger diameter pipe and fitting than

shown in the tables but not smaller diameters than shown.

Table 4

50,000 & 80,000 Btuh Furnaces

40¢ & (5) 90° elbows with 2² PVC pipe or

70¢ & (5) 90° elbows with 3² PVC pipe

25¢ & (3) 90° elbows with 2² PVC pipe or

40¢ & (5) 90° elbows with 2² PVC pipe &

Long Vent Kit (See Tech. Manual) or

70¢ & (5) 90° elbows with 3² PVC pipe

40¢ & (5) 90° elbows with 3² PVC pipe or

70¢ & (5) 90° elbows with 3² PVC pipe &

Long Vent Kit (See Tech. Manual)

40¢ & (5) 90° elbows with 3² PVC pipe

Elbows are DWV Long Radius Type for 2² and 3² vents.

If more than five elbows are required, reduce the length of

both the inlet and exhaust pipes 5¢ for each additional elbow

used.

Pipe Diameter Table

N9MP2 Models

75,000 Btuh Furnaces

100,000 Btuh Furnace

125,000 Btuh Furnace

For “Concentric Termination Kit” Venting table, see

“Section 11” in this manual.

VentTerminationClearances

!

CARBON MONOXIDE POISONING, FIRE AND EXPLOSION

HAZARD

Failure to properly vent this furnace can result in death,

personal injury and/or property damage.

Inlet and outlet pipes may NOT be vented directly above

each other.

1. Determine termination locations based on clearances specified in following steps and as shown in Figure 7,

Figure 19, through Figure 27.

For “Concentric Termination Kit” clearances, see Figure 45,

Figure 46, Figure 47, Figure 48 and Figure 49 in “Section 10”

in this manual.

2. The vent termination must be located at least 12² above

ground or normally expected snow accumulation levels.

3. DoNOTterminateoverpublicwalkways.Avoidareaswhere

condensate may cause problems such as above planters,

patios,oradjacent towindowswheresteam maycausefogging.

4. The vent terminationshallbelocatedatleast4¢ horizontally

from any electric meter, gas meter,regulator,andanyrelief

equipment. These distances apply ONLY to U.S. installations.

5. The vent termination is to be located at least 3¢ above any

forced air inlet located within 10¢ ; and at least 10¢ from a

combustionairintake of another appliance, exceptanother

direct vent furnace intake.

6. InCanada,theCanadianFuel Gas Code takesprecedence

over the preceding termination instructions.

440 01 1020 02

11

Figure 7

Vent Termination Clearances

(United States Only)

In Canada See Canadian Fuel Gas Code

Other Than

Direct Vent

Terminal

9²

Direct Vent

Terminal

50,000 Btuh

or less

12²

²

²²

Other Than

Direct Vent

Terminal

4¢

¢

¢¢

12²

²

²²

12²

²

²²

Direct VentTerminal

More Than 50,000 Btuh

12²

4¢

¢

¢¢

²

²²

12²

5

/8² may also be used, as allowed by local codes. Alternate drain

pipes and hoses may be used as allowed by local codes.

1

/4² perfootdownwardslopetoward

1

/4² per foot slope to the conden-

Other Than

Direct Vent

Terminal

Thedrainlinemustmaintain a

thedrain.

1

/4² perfootisrecommended.Installation of an overflow

line is recommended when the

sate drain cannot be maintained. See Figure 1 for proper routing

and installation of the overflow.

DONOTtrapthedrainline inanyotherlocationthanatthecondensate drain trap supplied with the furnace.

10¢

¢

¢¢

3¢

¢

¢¢

!

FROZEN AND BURST WATER PIPE HAZARD

Failure to do so may result in burst water pipes, serious

property damage and/or personal injury.

If a condensate pump is installed, a plugged condensate

Forced Air

²

²²

Inlet

10 -- 11 --3 6

drainorafailedpump maycausethe furnacetoshutdown.

Donotleavethehomeunattendedduringfreezing weather

without turning off water supply and draining water pipes

or otherwise protecting against the risk of frozen pipes.

CondensateDrain Trap

Thisfurnaceremovesbothsensible and latent heatfromtheproducts of combustion. Removal of the latent heat results in condensationofthe watervapor.The condensateisremovedfromthe

furnace through the drains in the plastic transition and the vent fitting. The drains connect to the externally mounted condensate

drain trap on the left or right side of the furnace.

The startup of a new furnace will involve a cycle or two of the furnace to properly prime the condensate trap with water. Until the

trap is fully primed, some condensate will be pulled into the combustionblower. Thefurnacemaycycleonthepressureswitch connected to the plastic transition box due to condensate buildup.

Afterthetrapisprimed,thecondensatewillstartdrainingfromthe

furnace. The combustion blower will clear out any remaining condensateintheblowerhousing through theventfittingdownstream

oftheblower.Notethatthe condensate trap can alsobeprimedby

pouring water into the1/2² drain hose. Remove the1/2² ID drain

hosefromeitherthe gutter orthewhitePVCTeeTrap.Usingafunnelpoureight(8)ounces of waterinto1/2² IDdrainhose.Waterwill

flow through the drain hose and into the condensate drain trap.

Thiswillprimeboththe ventandthe transitionsidesofthetrap.Reconnectthe1/2² IDdrain hosetotheoriginalcomponent, eitherthe

gutter or the PVC Tee Trap.

The condensate drain trap supplied with the furnace MUST be

used. The drain connection on the condensate drain trap is sized

3

for

/4² PVCorCPVCpipe,however alternate1/2² CPVC(nominal

5

/8² O.D.) or vinyl tubing with a minimum inner diameter (I.D.) of

If possible DO NOT route the drain line where it may freeze. The

drain line must terminate at an inside drain to prevent freezing of

the condensate and possible property damage.

1. AcondensatesumppumpMUSTbeusedifrequiredbylocal

codes, or if no indoor floor drain is available. The condensate pump must be approved for use with acidic condensate.

2. A plugged condensate drain line or a failed condensate

pumpwillallow condensatetospill.Ifthefurnaceis installed

where a condensate spill could cause damage, it is recommended that an auxiliary safety switch be installed to preventoperationoftheequipmentinthe event of pump failure

or plugged drain line. If used, an auxiliary safety switch

should be installed in the R circuit (low voltage) ONLY.

3. If the auxiliary switch in the condensate pump is used, the

furnacemayshutdowndue to a blocked condensate line or

failed pump. To prevent frozen water pipes see the “Frozen

Water Pipe Hazard” section on Page 4 of this manual.

Condensate Drain TrapFreeze Protection

SpecialprecautionsMUSTbemadeif installing furnaceinanarea

which may drop below freezing. This can cause improper operation or damage to the equipment. If the the furnace environment

has the potential of freezing, the drain trap and drain line must be

protected.Use3to 6 wattperfootat 115v olt, 40° Fself--regulating

shielded and waterproof heat tape. Wrap the drain trap and drain

linewiththeheattapeandsecurewiththeties.Followtheheattape

manufacturer’s recommendations.

12

440 01 1020 02

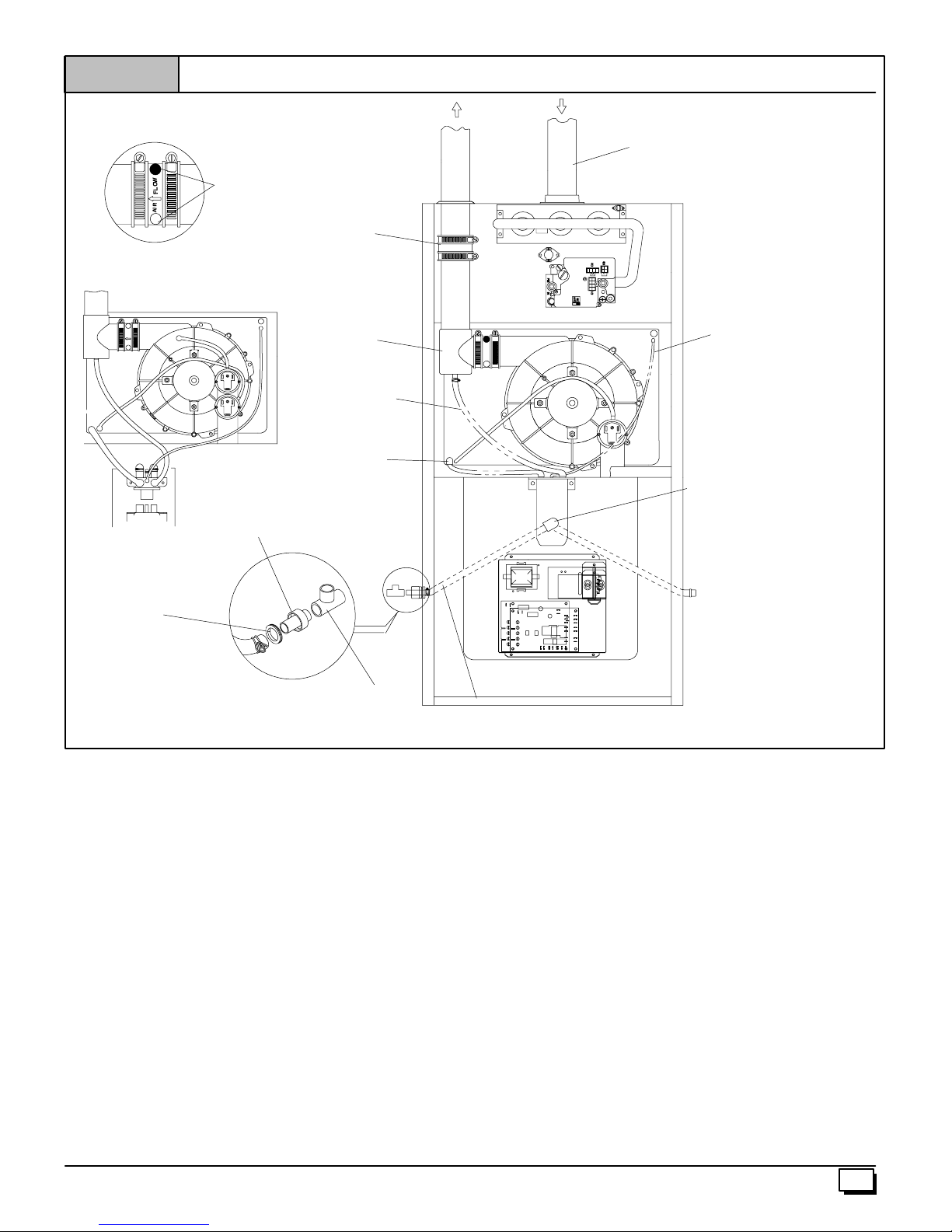

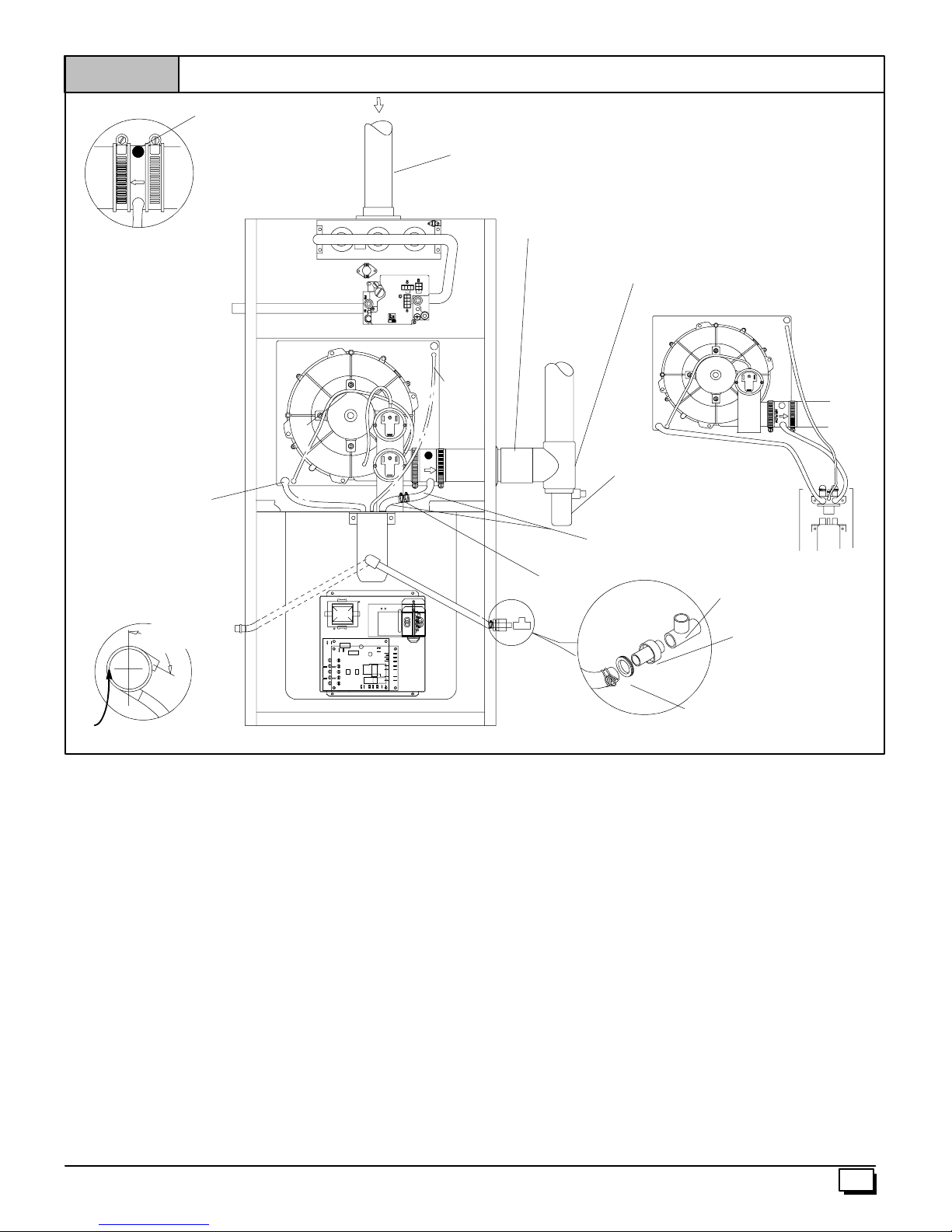

Figure 8

Upflow Installations Top Vent

Vent Drain

&Clamps

Dual Pressure Switch Detail

FLOW

AIR

Casing Grommet

Black Rubber

5

/

²

² ID

²²

8

(Loose partsbag)

Yellowor black Plastic

Caps (2)

Coupling & Clamps

(Optional)

DrainTee

1

/

²

² ID Drain

²²

2

Hose & Clamps

5

/

²

² ID Hose & Clamps

²²

8

Drain ConnectorBlackPVC

3

/

²

² PVC X1/

²²

4

(Loose partsbag)

²

² CPVC

²²

2

EXHAUST

Single Pressure Switch

INLET

On Some Models

ONLY

StreetElbow

1

/

2

(Loose partsbag)

3

/

²

² ID Rubber Tube

²²

16

²

² CPVC

²²

3

/

²

Drain LineVent Tee

1

/

²

² CPVC (Field supplied)

²²

2

² PVC or

²²

4

Upflow Installations Top Vent (See Figure 8)

Removeplug fromtheside ofthefurnacecasingwhereDrainTube

will exit.

5

Install casing grommet (black rubber

parts bag)

1

Install the

/2² CPVC street elbow on discharge of Trap

Install the black PVC tube connector (

loose parts bag) as shown in the illustration above.

5

Cut the black Drain Tube(

/8² ID -- in loose parts bag) to length to

fit between Trap and tube connector through grommet.

Clamp both ends of the Drain Tube using clamps provided.

/8² ID grommet -- in loose

3

/4² PVC x1/2² CPVC from

Drain Tube(& Clamps) Black Rubber5/

Cut lengthtofit(Loose parts bag)

8

²

² ID,

²²

25--24--42

GluetheCPVCstreetelbowtotheTrapusing appropriate cleaner

and solvent cement.

Connect the Tee trap and the main drain line exiting the casing as

shown Figure 17.

Note: It is recommended that all PVC piping and fitting connectionsbefitupand inspected before finalcementing.Trap must be

primed before operation. Verify all condensate drain connections are securely clamped. A coupling and clamps (in loose part

bag)maybe installedasshownfor futureservicingofthevent system.

440 01 1020 02

13

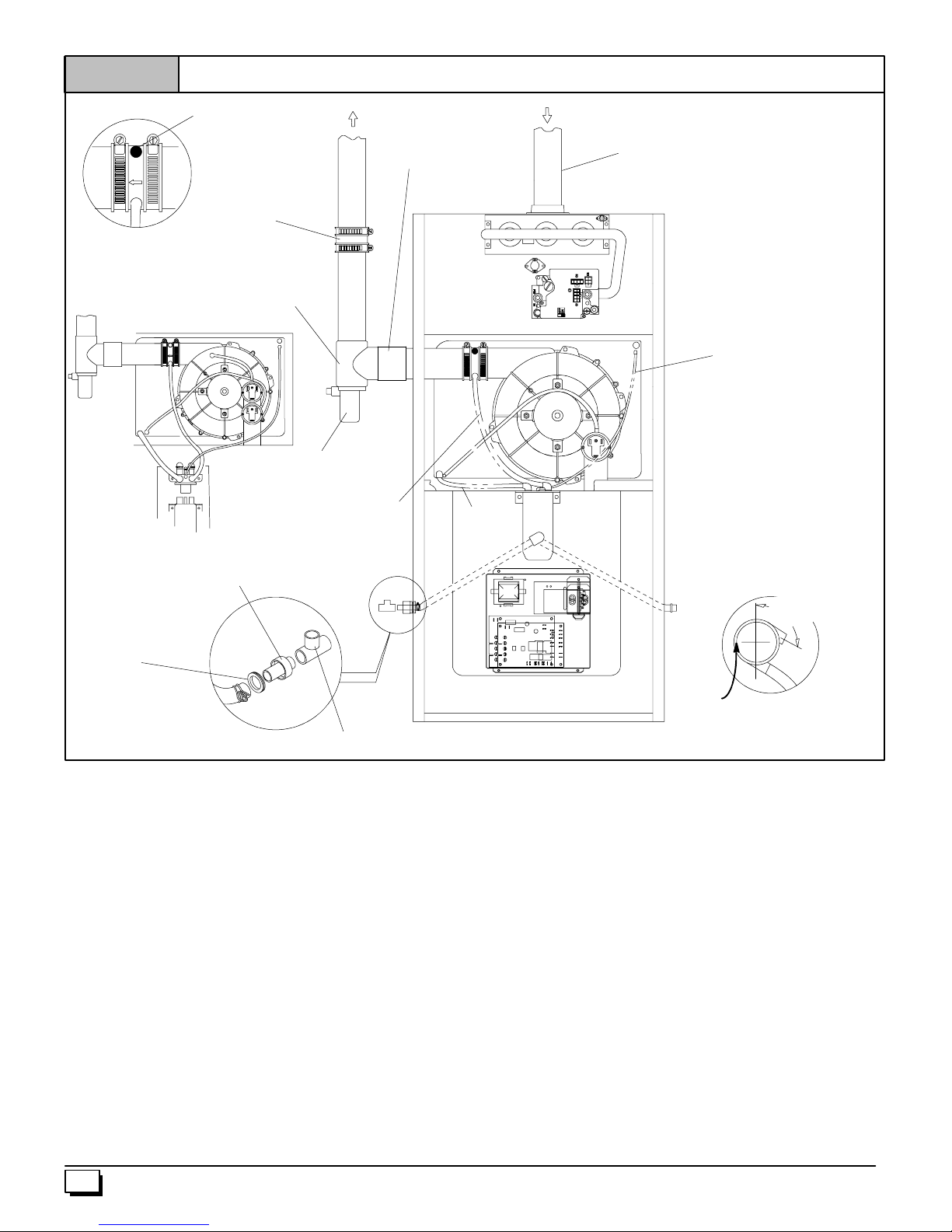

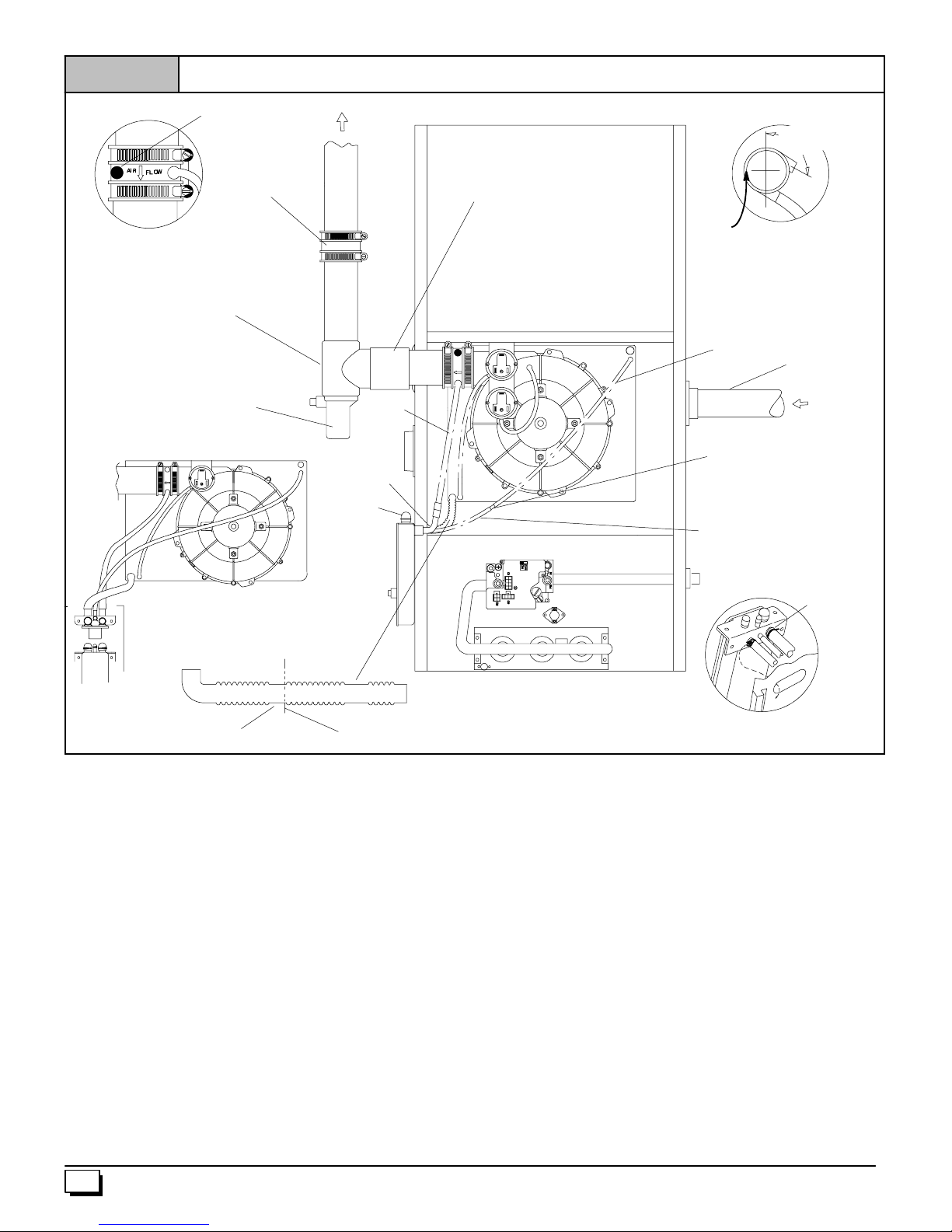

Figure 9

Upflow Installations Vent thru Left Side

Yellowor black Plastic

Cap

2²²²² PVC Coupling

INLET

On Some Models

ONLY

Vent Drain

&Clamps

Dual Pressure Switch Detail

AIR FLOWAIR FLOW

Drain ConnectorBlackPVC

3

/

²

² PVC X1/

²²

4

(Loose partsbag)

Casing Grommet

Black Rubber

5

/

²

² ID

²²

8

(Loose partsbag)

Coupling & Clamps

(Optional)

Either:ThePVC

Drain Teeor a field

supplied 2²²²² PVC Tee

²

² CPVC

²²

2

EXHAUST

TeeTrap White PVC

(loose partsbag)

1

/

²

² ID Drain Tube

²²

2

Black (Move from

bottom of drain tee

if installed)

Single Pressure Switch

5

/

²

² ID Hose

²²

8

&Clamps

3

/

²

² ID Rubber Tube

²²

16

SIDE VIEW

Rotate downward

5°°°° to 10°

NOTE: Built--in channel will

be angled5° to 10° also.

°

°°

Drain LineVentTee

² PVC or1/

²²

4

²

² CPVC (Fieldsupplied)

²²

2

3

/

²

Upflow Installations Vent thru Left Side (See Figure 9)

RemoveDrainTeefrominducerdischargeandremoveblackDrain

Tube (1/2² ID) from bottom of Drain Tee.(*9MPD models only)

Install Vent Pipe grommet in side of casing.

Cut an appropriate length of 2² PVC pipe long enough to exit the

cabinet and connect the vent drain to either:

· A standard field supplied 2² PVC tee (N9MP1 and 2 models),

or

· A2² PVC coupling fastened onto the Drain Tee(*9MPDmod-

els)

Install Tee trap into bottom of tee.

Install the

Install the black PVC drain connector (

1

/2² CPVC street elbow on discharge of Trap

3

/4² PVC x1/2² CPVC from

loose parts bag) as shown in the illustration above.

Cut the black Drain Tube(

fit between Trap and tube connector through grommet.

Clamp both ends of the Drain Tube using clamps provided.

GluetheCPVCstreetelbowtotheTrapusing appropriate cleaner

and solvent cement.

Connect the Tee trap and the main drain line exiting the casing as

shown in Figure 1 7.

Note: It is recommended that all PVC piping and fitting connec-

tions be fit up and inspected before final cementing. Both the in-

ternal Trap and the external Tee Trap must be primed before

operation. Verify all condensate drain connections are securely

clamped. A coupling and clamps (in loose part bag) may be

installed as shown for future servicing of the vent system.

14

25--24--43

5

/8² ID -- in loose parts bag) to length to

440 01 1020 02

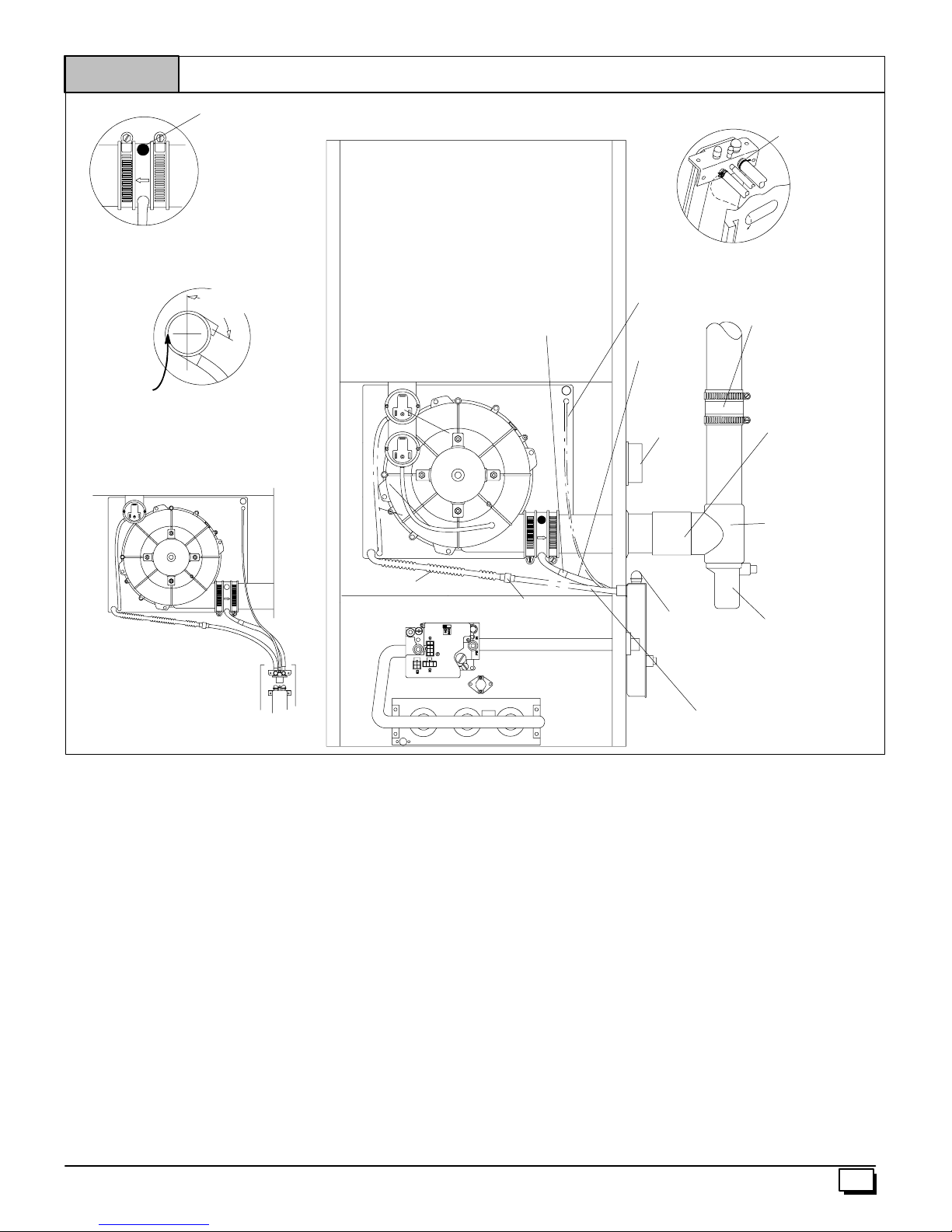

Figure 10

All Models Vent thru Right Side

Yellowor black Plastic

Cap

INLET

On Some Models

ONLY

Vent Drain

&Clamps

5

/

8

&Clamps

SIDE VIEW

Rotate downward

5°°°° to 10°

²

² ID Hose

²²

°

°°

Dual Pressure Switch

AIR FLOW

3

/

²

² ID

²²

16

Rubber

Tube

2²²²² PVC Coupling

Barbed Coupling,1/

(loose partsbag)

Either:ThePVC

Drain Teeor a field

supplied 2²²²² PVC Tee

Single Pressure Switch Detain

TeeTrap White PVC

(loose partsbag)

Elbows Tubes(2) & Clamps Black,

1

/

²

² ID (loose partsbag)

²²

2

²

² OD

²²

2

Drain LineVentTee

1

/

or

2

Drain ConnectorBlackPVC

3

/

4

(Loose partsbag)

3

/

²

² PVC

²²

²

² CPVC

²²

2

4

²

² CPVC (Field supplied)

²²

²

² PVC X1/

²²

NOTE: Built--in channel will

be angled5° to 10° also.

All Models Vent thru Right Side (See Figure 10)

Disconnect the black Drain Tube between the drain vent and the

Trap.

Rotate the inducer 180° for a right side vent after loosening the 4

inducer attachment screws. Reinstall and retighten the inducer

screws to 20² pounds torque.

1

Using the

togetherwiththe2 short

dischargeportoftheventdraintotheTrap. Secureallconnections

with clamps.

Install the vent pipe grommet into the casing

Cut an appropriate length of 2² PVC pipe long enough to exit the

cabinet and connect the vent drain to either:

· A standard field supplied 2² PVC tee (N9MP1 and 2 mod-

· A2² PVC coupling fastened onto the Drain Tee (*9MPD

Install Tee Trap into bottom section of Tee.

Removeplug fromtheside ofthefurnacecasingwhereDrainTube

will exit.

/2² OD barbed coupling in the loose parts bag connect

1

/2² IDelbowtubes andconnectthelower

els), or

models)

Casing Grommet

Black Rubber

(Loose partsbag)

Install casing grommet (black rubber

5

/

²

² CPVC

²²

8

5

/8² ID grommet -- in loose

25--24--44

parts bag)

Install the

Install the black PVC tube connector (

1

/2² CPVC street elbow on discharge of Trap

3

/4² PVC x1/2² CPVC from

loose parts bag) as shown in the illustration above

5

Cut the black Drain Tube(

/8² ID -- in loose parts bag) to length to

fit between Trap and tube connector through grommet.

Clamp both ends of the Drain Tube using clamps provided.

GluetheCPVCstreetelbowtotheTrapusing appropriate cleaner

and solvent cement.

Connect the Tee trap and the main drain line exiting the casing as

shown in Figure 1 7.

Note: It is recommended that all PVC piping and fitting connec-

tions be fit up and inspected before final cementing. Both the in-

ternal Trap and the external Tee Trap must be primed before

operation. Verify all condensate drain connections are securely

clamped. A coupling and clamps (in loose part bag) may be

installed as shown for future servicing of the vent system.

440 01 1020 02

15

Figure 11

Downflow Left Side Vent and Trap

Yellowor black Plastic

Cap

Coupling & Clamps

(Optional)

Vent Drain

&Clamps

Either:ThePVC

Drain Teeor a field

supplied 2²²²² PVC Tee

TeeTrap White PVC

(loose partsbag)

Single Pressure Switch Detail

FLOW

AIR

EXHAUST

Drain

Elbow (1)

WARNING

Move Caps

to top of

trap

1

/

²

² ID

²²

2

Drain

Hose

2²²²² PVC Coupling

Dual Pressure Switch

FLOW

AIR

SIDE VIEW

Rotate downward

5°°°° to 10°

NOTE: Built--in channel will

be angled5° to 10° also.

3

/

²

² ID

²²

16

Rubber Tube

On Some Models

ONLY

INLET

FlexibleTubing Connector,

3

/

²

² OD (loose partsbag)

²²

16

ReliefTube,

Extension Black,

3

/

²

² ID Cut to fit

²²

16

(loose partsbag)

°

°°

5

/

²

Drain TubeBlack,

Cut at straightsection

Leave room forclamp

² ID Corrugated

²²

8

Cut Here

Downflow Left Side Vent and Trap (See Figure 11)

Removetheinducermountingscrews,rotatetheinducer180° and

retighten the inducer screws to 20² pounds torque.

Disconnect the hoses from the Trap assembly, and remove Trap

and Trap mounting bracket from the blower compartment. Using

cover plate and gasket provided in the loose parts bag, cover the

holefromtheburner compartment to the blowercompartmentand

secure with screws.

Movethecapstothe top of theTrapandmount the Trapexternally

to the left side of the unit using the 2 screws provided.

5

Cutthe

bend end to the Trap and fasten the straight end to the transition

drain. Secure both connections with clamps.

Reconnect the

andsecurewithaclamp.. In somecases, additional length will be

required for this hose. Use the Black plastic

plinganda suitablesectionof1/2² IDhose tomakethe connection.

Secure all connections with clamps

Connect the

thetop portofthetransitionasshowninthepicture. Insomecases,

/8² IDcorrugatedhoseasshownaboveandfastenthe90°

1

/2² ID drain hose from the vent drain to the Trap

1

/2² OD barbed cou-

3

/16² ID relief tube from the small port on the Trap to

Trap Connection

Preassemble&

insertinto furnace

additional hose length will be needed. Use the clear plastic

“Clamp ears”

PointedOUT

25--24--45

3

/

16

ODflexibletubingconnectorandasuitablelengthofextra3/16² ID

hose to make this connection.

Install the vent pipe grommet into the casing

Cut an appropriate length of 2² PVC pipe long , enough to exitthe

cabinet and connect the vent drain to either:

· A standard field supplied 2² PVC tee (N9MP1 and 2 models), or

· A2² PVC coupling fastened onto the Drain Tee (*9MPD

models)

Install Tee Trap into bottom section of Tee.

Connect the Tee trap and the main drain line exiting the casing as

shown in Figure 1 7.

Note: It is recommended that all PVC piping and fitting connec-

tions be fit up and inspected before final cementing. Both the ex-

ternal Trap and the external Tee Trap must be primed before

operation. Verify all condensate drain connections are securely

clamped. A coupling and clamps (in loose part bag) may be

installed as shown for future servicing of the vent system.

²

16

440 01 1020 02

Figure 12

Downflow Right Side Vent and Trap

Yellowor black Plastic

Cap

Vent Drain

&Clamps

SIDE VIEW

Rotate downward

5°°°° to 10°

°

°°

NOTE: Built--in channel will

be angled5° to 10° also.

Single Pressure Switch Detail

Dual Pressure Switch

Splice Connector

Barbed

AIR

FLOW

3

/

²

² ID

²²

16

Rubber Tube

1

/

²

² ID

²²

2

DrainHose&

Clamps

On Some

Models ONLY

INLET

Trap Connection

Preassemble&

insertinto furnace

Coupling & Clamps

(Optional)

“Clampears”

PointedOUT

2²²²² PVC Coupling

Either:ThePVC

Drain Teeor a field

supplied 2²²²² PVC Tee

AIR FLOW

Drain TubeBlack,5/

ID Corrugated

²²²²

8

Downflow Right Side Vent and Trap (See Figure 12)

Remove the Drain Tee if installed.

Disconnect the hoses from the Trap assembly, and remove Trap

and Trap mounting bracket from the blower compartment. Using

cover plate and gasket provided in the loose parts bag, cover the

holefromtheburner compartment to the blowercompartmentand

secure with screws.

Movethecapstothe top of theTrapandmount the Trapexternally

to the right side of the unit using the 2 screws provided.

Connect the corrugated Drain Tube from the transition box to the

Trapasshown. Ifanextensionis required,usethe blackPVCtube

connectorandtheblack

Cut tube to length. Secure all connections with clamps.

ConnectthedrainhosefromtheVentDraintothe Trap. If anextension is required, use the black

ablack

1

/2² ID elbow tube and a suitable section of a1/2² ID drain

tubetomakeconnectionfromtheventdraintothetrap.Secureall

connections with clamps.

5

/8² ID Drain Tubeinthelooseparts bag.

1

/2² OD barbed coupling, connect

Drain ConnectorBlack

3

/

²

² PVC X1/

PVC

²²

4

(Loose partsbag)

²

² CPVC

²²

2

WARNING

Move Caps

TeeTrap White PVC

(loose partsbag)

to top of

trap

Drain Tube,(& Clamps)

5

/

²

² ID Cut to fit

Black,

²²

8

(loose partsbag)

25--24--46

Install the vent pipe grommet into the casing

Cut an appropriate length of 2² PVC pipe long , enough to exitthe

cabinet and connect the vent drain to either:

· A standard field supplied 2² PVC tee (N9MP1 and 2 models), or

· A2² PVC coupling fastened onto the Drain Tee (*9MPD

models)

Install Tee Trap into bottom section of Tee.

Connect the Tee trap and the main drain line exiting the casing as

shown in Figure 1 7.

Note: It is recommended that all PVC piping and fitting connec-

tions be fit up and inspected before final cementing. Both the ex-

ternal Trap and the external Tee Trap must be primed before

operation. Verify all condensate drain connections are securely

clamped. A coupling and clamps (in loose part bag) may be

installed as shown for future servicing of the vent system.

440 01 1020 02

17

Loading...

Loading...