Page 1

,^

ti

=t'

SEARS

DEPT.731A

TECHNICAL

FLASH

DISTRICT

MANAGER

CENTRAL

MANAGER

BRANCH

MANAGER

CALL

CENTRE

MANAGER

PARTS

MANAGER

T. F. 46-93

ocToBER

2001

L.DIVELL

-

DBPARTMBNT

731A

DTVISION

46

SOTJRCE

C978 G.E.

ERVICE

INFORMATIO

Arctica/Prof

i le/G

E Side-by-Side

Refrigerators

with Electronic

Touch

Controls

MODEL

SERIES:

PSS

and GSS

23, 25,

27

and

29 inch

NOTE:

n

FOR PARTS ORDERING

USE

DIVISION 46

SOURCE

C978

Page 2

IMPORTANT

SAFETY

NONCE

The information in

this

service

guide

is intended

for

use by

individuals

possessing

adequate

backgrounds

of electrical,

electronic,

and

mechanical

experience.

Any attempt to

repair

a

major appliance

may result

in

personal

injury

and

property

damage. The

manufacturer

or seller cannot

be responsible

br the

interpretation

of this

information,

nor

can

it

assurne

any liabilig

in

connection witr

its use.

WARNING

To

avoid

personal

iniury

disconnest

power

bebre

servicing

this

product.

lf

electrical

power

is required

for

diagnosis

or test

purposes,

disconnec.t the

power

immediately

after

performing

the

necessary

checks.

RECONNECT

ALL GROUNDING

DEVICES

lf

grounding

wires, screws, sffiaps,

clips, nuts,

or washers

used

to

complete

a

path

to

ground

are removed

for

seMce,

they

must

be retumed

to

their original

position

and

properly

fastened.

GE Consumer

Hone

Serulbes

Training

Technial

Servie Guide

Copyright@ 2001

All rights reserved.

This service

guide

may not

be reproduced

in whole or in

part

in

any

form without written

permission

from the

Genenl Electric

Comparry.

(-

Page 3

Table of Gontents

\J

o

63

Page 4

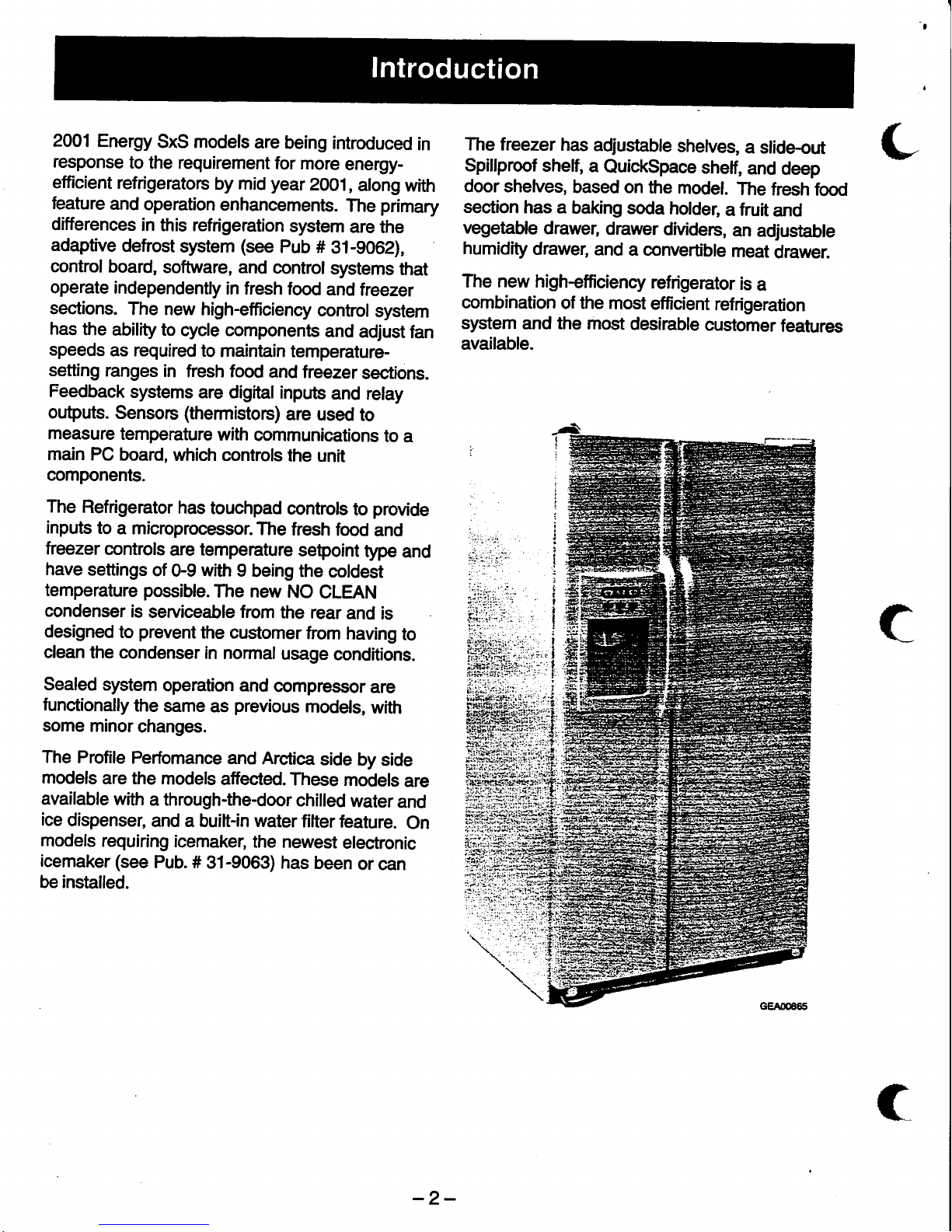

2001 Energy

SxS models

are

being

introduced

in

response

to the

requirement

for

more

energy-

efficient

refrigerators

by

mid

year

2001,

along

with

feature

and

operation

enhancements.

The

primary

differences

in

this refrigeration

system

are

the

adaptive

defrost

system

(see

Pub #

gt-9062),

control

board,

software,

and control

systems

that

operate

independently

in fresh

food

and

freezer

sections.

The

new high-efficiency

control

system

has

the

ability to

cycle components

and

adjust

fan

speeds

as required

to

maintain

temperature-

setting

ranges

in

fresh food

and

treezer

sections.

Feedback

systems

are digital

inputs

and

relay

ouputs.

Sensors

(thermistors)

are used

to

measure

temperature

with

communications

to

a

main

PC

board,

which controls

the unit

components.

The

Refrigerator

has

touchpad

controls

to

provide

inputs

to

a microprocessor.

The

fresh

food

and

treezer

controls

are

temperature

sepoint

type

and

have

settings

of

G9

with

9

being the

coldest

temperature

possible.The

new

NO

CLEAN

condenser

is

serviceable from

the

rear

and

is

designed

to

prevent

the customer

from

having

to

clean

the

condenser

in normal

usage

conditions.

Sealed

system

operation

and

compressor

are

functionally

the

same

as

previous

models,

with

some

minor

changes.

The

Profile

Perfomance

and

Arctica

side

by

side

models

are the

models

affected.

These

models

are

available

with

a through-thedoor

chilled

water

and

ice

dispenser,

and a buift-in water

filter

feature.

On

models

requiring

icemaker,

the

newest

electronic

icemaker (see

Pub. #

31-9063) has

been

or can

be installed.

The

freezer

has

adjustable

shelves,

a slide.out

Spillproof

shelf,

a

QuickSpace

shelf,

and

deep

door shelves,

based on

the

model.

The

fresh

food

sestion

has

a baking

soda

holder,

a

fruit

and

vegetable

drawer,

drawer

dividers,

an

adjustable

humidity

drawer,

and

a convertible

meat

drawer.

The new high-efficiency

refrigerator

is

a

combination

of the

most

efficient

refrigeration

system

and the most

desirable

customer

features

available.

-2-

Page 5

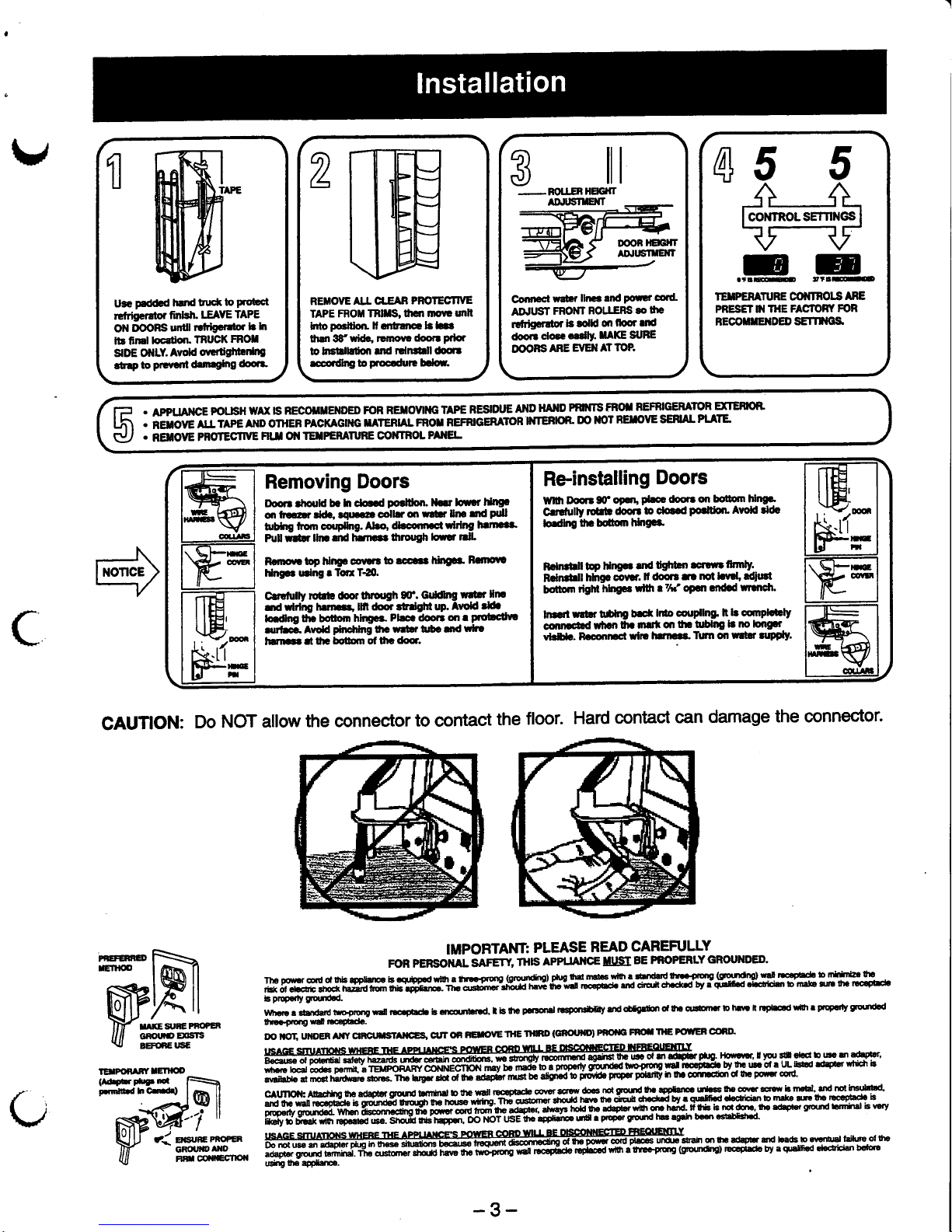

RETIOVE

AIJ. CT.EAB

PFOTEfiIVE

TAPE

FROil TRllls,hc||

mfl!

unlt

hopcnolt.

f ailtmc.bL.a

rhJ|3f

wid., rlmout

rfooc

ptbi

to hfilEdo,r

Jd

rdnsrll dodt

rcconthg

to

ploccdut!

bdo|.

TEXPERATURE @I{IROIS

ARE

PRESET N I}IE

FASTOFI

FOR

REOOTTETDED

SETTIIGS

L

ill

FOU.EN

HEGFT

AD'ITsTE{T

CoilEcl

rsEr

lltElnd

Poutrcord

AqTUST

FROIIT

BOLTERS

3o

$e

rutrigeretu

le rlld

m

fioorra

dooildec.dlY.

SAXESUFE

DOORS

ARE

EVEI{ AT

TOP.

1

u3G

p€dd.d

hJld

tud(

fo

Prot?ct

rGfrtsprator

finteh"

IEIYE

TAPE

ON

oOORS

ulill

rrfrignrelor

b h

llr linel

locdron.

TRUCK

FFOI

gDE

OilLY.

Avold

ot,ltdg|hbdtl3

.urpto

pr€atnt d.t||.g[ng

dootr

rF

.

APPTJA'IGE

PIoIJS}I

wAx IS

RECOTilEIIDED

FOR

RETOYII{G TAPE

RSSIDIE

AT{D

HAND

PRfffS

FROI

REIR]CERAIOR

EXTEHON.

Ui\

.;EirovElrrepernoonrenpAcKAGll{crlrERlAtFRorREFRrcERAroRll{TERloRDollorRErovESEHALPLATE

C-/

.

aqOve

PFOrEsrm

HIJ

0t{

TilPERAnnE

CONTRoL

P ilEL

Re-installing

Doors

Wnh

Ddr

S

o9.tt,

dre

tloo?. on

betn hhg!'

C.rttully

rctrb

d@tt

b do..d

pclti(tn"

Avoid i&

lodlngt|f,benhhgL.

F.ln$rll

bP

hltE

. .nd

tgftbn

srm

fmly.

Rdndrlt

hln$

covtt

It tloq3

f|

nol Lvtl, ldilaf

botlom

tigm

hhgGs

rlll r

7f,' oFl

qldd

uillCl.

ln

.d

rltlr talt|g

b.d(

ltio coudlng lt

Ir

cmplctrly

connoadficn

thr nrtton

tlr tDlng

b no bngpt

vb5aa. R.cootEtwl]t

lrnaaa.I||'|l

olt

wtE tupPly.

Removing

Doors

Door|.hould

b. h dot

d

p6ltlon.

]bt lou.t

lt&|gp

qr

frEr dd., t|lrrc

cdk

on

rlbt Un

r|d

Polt

trbhg

fton coup[ng.

Abo'.tbcontLct

rlrlng

hl||..r

Pu[ '|F

llna md

hlac$ tfuottgh

lorrr nlt

Rqnovr

top hlttgt coF'l

to scc..a

l*|grj

F.r|oUt

Hngr. lCng

rlcrT{0.

Crrdully

rdil! tfoorfttot8h

3C.

Gufhg

r|llrlfir

nd

;irlrU lurnc* m.bo?

ldgftl

W.

Atold

3i.l.

-

ld|f,ng O|. botorn

hirEGa.

Pbca.looc

ofi a

Ptollcltv!

an'f€. ArroS

phchhg

!r

r|t r tfr. f|d

rttt

tura|.

tt 0E

botbm of 0|.

do6.

CAUTION:

Do

NOT

ailow

the connector

to contact

the

floor.

Hard

contact

can

damage

the connector.

ffim

IEIFONABYIEfiOO

(Adrprl[Nlnc

Frrndhffi)

IMPOFTANT:

PLEASE

READ

CAREFULLY

FOR PERSOIIAL

516NY

g$

APFUAilCEIIISI

BE PROPERLY

GROUNDED'

the

Fomr

@r,

.a

thb

appfi.r

b .$bp.d

rfi I tn

.Fso

Gmntng)llug

td Jtdc

$h ! drn

htd lrlflltrg

Gtgftdfto)

m!

tE

Pldl

b n*irilt

lhc

,i*

ot

.t

Gric

!ho.k

tiazrd r- 113 .iffi]ii-i3,ii}

:fria

rni'rip-ml

ocrpoar

lrro doit

dr.dad

by i

q!tr

d ddiiln

lo trta 3n

lh'

E€pE

ir

propody

!|grrxt

a

rin[r ! srerrrsrd

trpmg

tEI rlc.pEdr b

m,ni.rtd,

r b

lhc

Flctd

rsB.tTdy.nd

oDagdon

ol t! ollom.r

to

hm n r.P6

ul'| r

pcFdy

rrqt|dd

tE

ft!.fg

rd nca06d..

DOilgT.UilOEnAt|tf

c|nctffif

llccs,cuTonBETVETHEflInD(GnouD)PnoiacFMnGPOITEFOOnD'

rrsAGE smrrfloils

wHEnE

rHE

lPP|xr|cErs

FglvEn

conD

x4+P!]06coinEcffiD

rfif,qguErtra.Y

Bacals

of

po!3rilu

etsty

rrarus rnoer]m-conotc,

m *onOv

mrmmo

agsi6qt

ut

of ]raah9bcprro-

Hffi. !w sil €Lctb

B D

dhprtr'

yr€ctocd@(bspom{,lTEtpcrFAF.

@NNECTIONrrraytcnader.rprcffifinbcuro+onop4ircda&Uytrcu-otaut-tiur@awtruti

iyrnruearndh.rdm.l",*.rn"iidiiiiJfr"-;d;&t;b";l6ri'tiilrpwriranvhfT

of,itcibnc't!Pont€od

caunoil:AltrrhholhaadapLrgrurdunrinerbthet,|dttoc4tadaco\,arrctwdcnotgufdttt|peLtEultsth3ffis€wbm'bl'JdnotlB'8

4

lrd nr

r.r lgc.Fiad€

ts

g".d"d

!d;'ii;;;"ffi;.-1#

c$sromt

dro,Jd

mn

rr &an

areorJ by. gglfi.d

d.6icitn D

mtla ,n

lh. Gc.gtacr

b

pteervgdrd.d

rna ccom*nfddi;

dnrocrun-tE

aqqebr

dqs-trolctte

ro*ttdth

drhdrd.

tit& b

mrdm,lho

arhprsg[urd

bn*ts|bnry

[i& ri riJr

kr roparC

,rs". Srr.ni-ffffi',

OO-NOTGE]|

qttrtr

urr

.

pFD.r gistd ]E

agth

ban

6ffi.

usecs

snumons

wnene

nre epn l^nces

Pq|En

colD

lu!!+EDFFdilRr:

T?Sry_.f-Y. - -

DonotHa.rt

pilrpl6inte@AGpurm-ptesunlrrfah6ltr.dobrtndLa&ba[rtnlhilwd$a

adaprergro'rd

bmrn1.rn"

or.1*rfiiiliffiffi;&;6;i

Hrir*,-'+Ircd*,thitncpmg

(gdndtd Eog*c ov

aqnrfi.d d€clidm

bsH€

|AhgtF

applJr..

@

r{ erwn:rnorcn

GROI,ID

AI{D

FilOomGcnoil

-3-

Page 6

DISCONNECT

POWER CORD

BEFORE

SERVICING

IMPORTANT-RECONNECT ALL

GROUNDING DEVICES

All

parts

of this

appliance

capable

of conducting

electrical

current are

grounded.

lf

grounding

wires,

screvys,

straps,

clips,

nuts

or washers used to complete

a

path

to

ground

are

removed

for service, they must

be returned

to

their original

position

and

properly

fastened.

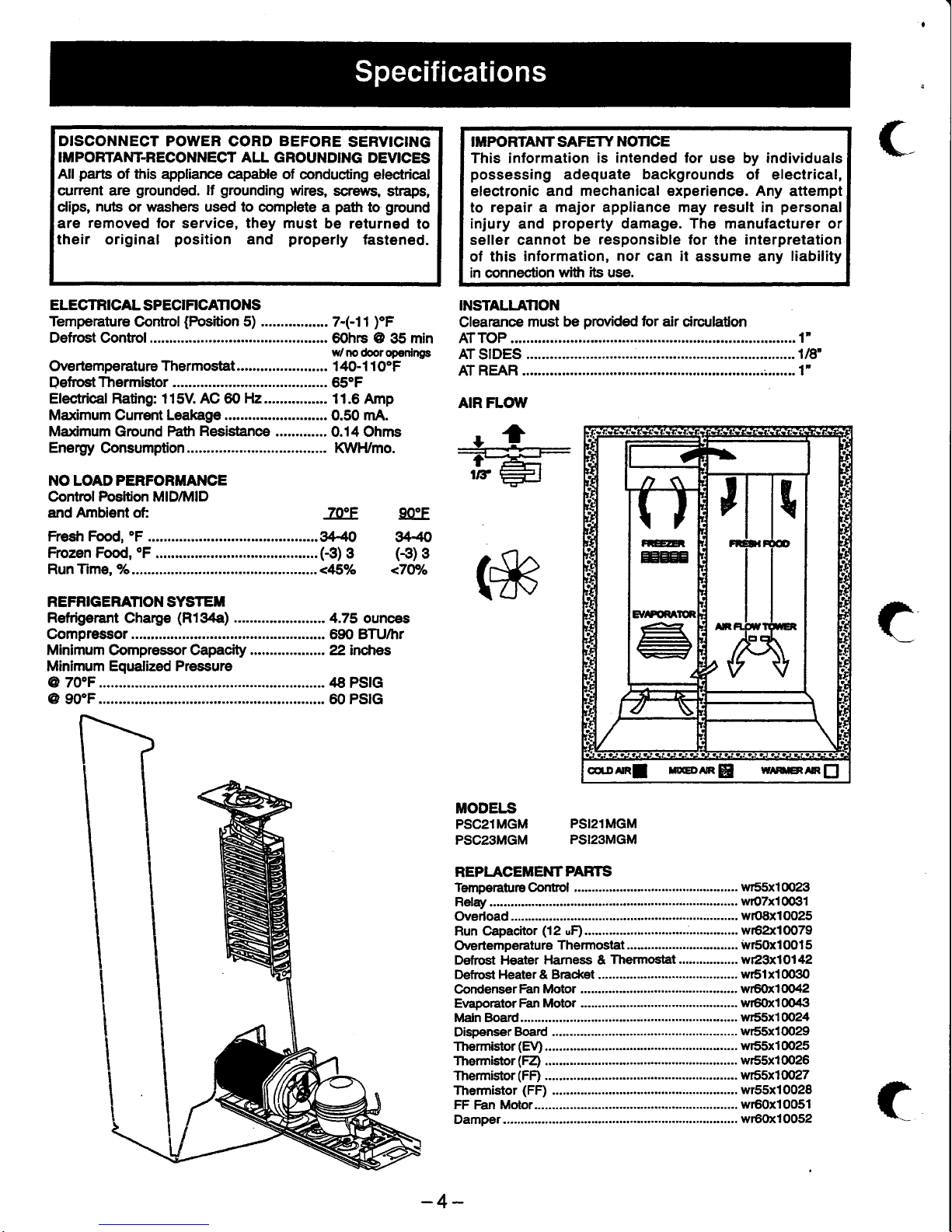

ELECTRICAL

SPECIF|CANONS

Temperature

Control

{Position

5) .................

7-(-11

fF

Defrost Control.

IMFORTAI{T SAFETY

NOTICE

This information

is intended for

use by

individuals

possessing

adequate

backgrounds

of electrical,

electronic and

mechanical experience. Any

attempt

to

repair a major appliance may result in

personal

injury

and

property

damage. The manufacturer or

seller cannot

be responsible for

the

interpretation

of this

information, nor can it

assume any

liability

in connection

with

its

use.

INSTALLATION

Clearance

must be

ptwided

br air

circulaton

tirToP

.........1"

...1t8'

(#

MODELIS

PSC21MGM

PSI21MGM

PSCzSMGM

PSI23MGM

REPI.ACEMENTPARTS

Temperatur€

Control

....-................

... wr55x1@23

(,

60hrs @

35 min

w/no

(borop€nlrigs

Overtemperalure Thermostat .. 140-1 10"F

ATSIDES

Defrost

Thermistor .....

65"F

AT REAR

AIR FLOI'V

ElectricalRating: 115V. AC 6O

H2................

11.6 Amp

Marcimum Cunent Leakage .....

0.50 mA.

Ma<imum

Ground

Path

Resistanoe

.............0.14

Ohms

Energy Consumption

l(/Vl'Umo.

1"

NO LOAD PERFORMANCE

Control Posltion MID/MID

and Ambient oft

TocF

Fresh Food,

oF.,..............

...^M

900F

w

G3)

3

<7Wo

Frozen Food,

oF

......... ..G3)

3

RunTime,

a/o.........,.......

.........<45Uo

REFRIGERATIONSYSTEil

Refrigerant Charge

(R134a)

...4.75

ounoes

Gompressor .......690 BTU/hr

Minimum Compressor Capacity 22 inches

Minimum Equalized Pressure

@ 70"F 48

PS|G

60 PSIG

@

90"F.............

t

....... w()TxlOotll

Overload.....

wo8x10025

Run Capacitor

(12

uD............................................

w62xl0079

Overtemperature

Thermostat

......... iryrsoxloOls

Defrost

HEater

Harness & Thermostat

............-....

wr23xl 0l

42

Defrost Heater & Bracket

wr51x10030

CondenserFan

Motor

......................

wr6uloolt2

E\aporatorFan Motor

.........-..

..........

wr6(Xl004ll

Main Boad.........

....................

wr55x1@24

Thermistor

(EV)

wr55x10025

Thermistor(FZ)

.........

wr55x10026

Thermistor(FF)

......... wr55x10027

Thermistor

(FF)

.....-.....-.

wr55x10028

FF

Fan

Motor.............

w60x1OO51

Damper................

(

cq-oaR!

reen$| wenmenE]

-4-

wr6fi10052

Page 7

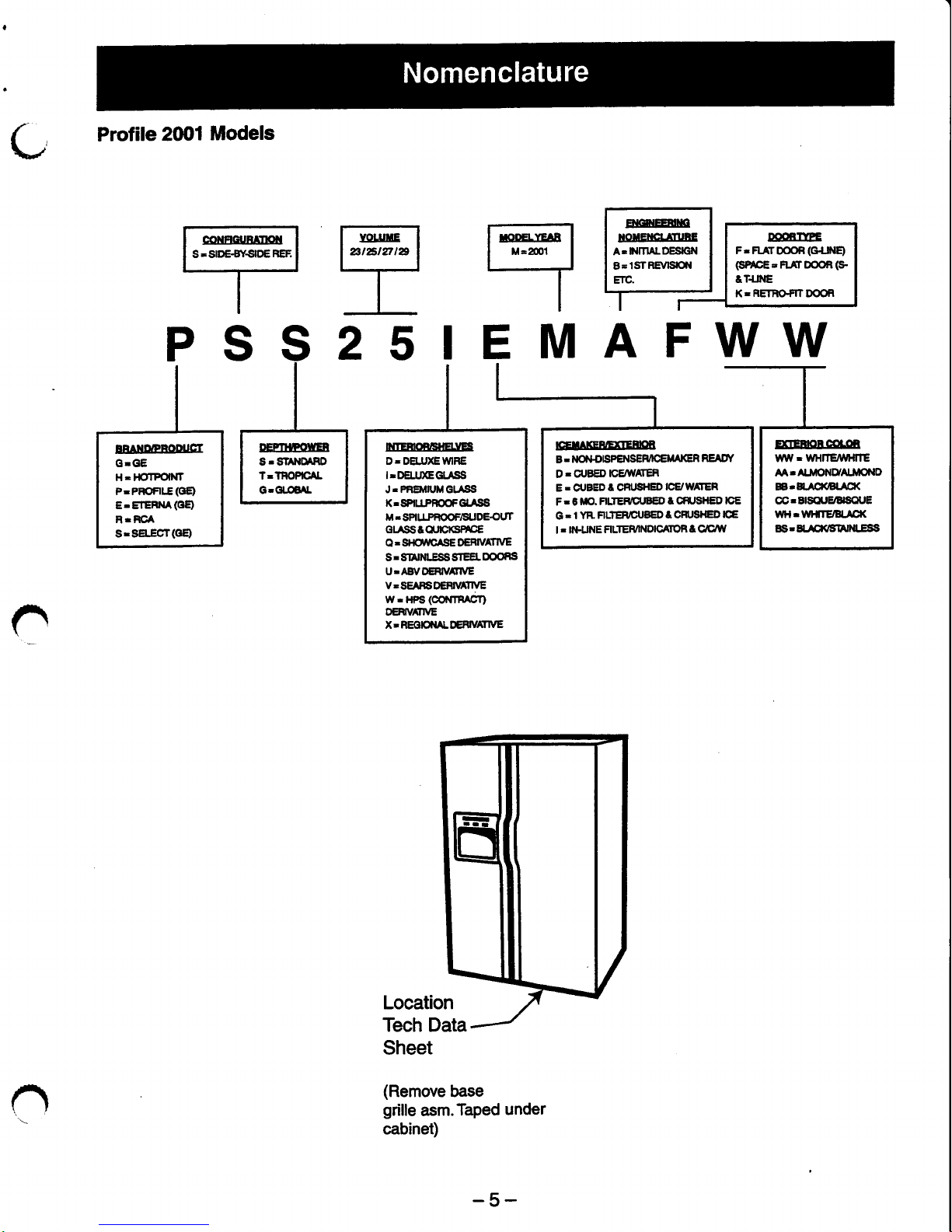

Profile

20/Jl

Models

C

-.

t

"**t"

t:-:

lrcoervrenl lnouerrcrrrune ll

po.nrYDE

I

I

M=2m1

| lA'NrnALDEscN llF-nxrDooR(c+lt{9 1

l--J

l8-lsrREvtstcftt I I

€mcE'FL{rDooR(9

I

I

ril

,,ll:@l

r

I;-

PSS2sIEMAFWW

n

o

Location

Tech Data

Sheet

(Remove

base

grille

asm.Taped

under

cabinet)

-5-

IBAtrENOIUCI

GrGE

H- HOTFOINT

P-PFOFI-E(OE)

E.ETERM(oE)

BT

RCA

S:SEECT(GB

ICETIICEET]EENE

B- Mll+otSPEilSEMCEM

IGR READf

D. CUBED

ICEAYAT€R

E. drBED

t CBUSIIED

ICE/W tER

F- G

ftlO. FILIER

CUBED

t CR SI{ED ICE

G

.

1 YR

FILTERDUBED

t CFT SHED

ICE

| . ll&UNE

FILTEMNDICAIOf,

t Clc/W

ItrIEEOEEUE.IES

D-DEIJ)GWRE

ITDELIJGGI.ASS

J.PBEMIUMGlrSS

K.SP|ITPFC,OFGLTSS

M:SPl1gr6g9P6119g6g1

Grrss&orrcKsnc€

O - SIIO,UCASE DEFIVATIVE

S r SitrlNLESS SIEEL

OOORS

U-AErVOlgl||VAIfVE

v.SE

FSDERI\AIIVE

W

r

HPS

(CO0{TFAGT}

DEHVtrryE

X.REOIOMLDEHVAnVE

EGEOECOIOB

UVW. WHlTElfllfTE

AATA.IIONUAIIOND

EBrE.A€l(BrlCl(

@rEISQUE/BISCUE

WHrlYl{TE/tslliq(

SSrH-SXlSlAllt[-ESSI

Page 8

Sales

slip or canoel,ed

check

is rquird

as

prcd

of

ortginal

purchase

date to obhin *ruioe

under

waffanty.

Allwananty seruice

is

provided

by our Fadory

Seruie

Centers

or

an authorized Customer Care@

technician.

(

c

Any

part

of the refrigerator

(excluding

water filter cartridge) which fails

due to a defect in materials

or workmanship.

During this full on*year

warranty,

GE

will

also

provide,

fre of

chatge,

all labor

and

in-home

servioe

to replace the

defective

part.

Any

part

of the

seated

refrigerating

system

(the

compressor,

condenser, evapoftltor,

and all

connecting

tubing) which f,ails

due to

a

defect in materials

or workmanship.

During

this fiveyear wananty,

GE

wiff

afso

provide,

free

of charge, all

labor and

in-home

service to replace

the defective

part.

Any

s*through

pan

or drawerturnished

with the

refrigerator

if

the

pan

or drawer breaks

during normal household

use.

Drawer covers

are not

included.

Any

part

of the water filter

cartridge

which

fiails due to a defect in

materials

or workmanship.

During

this

fuIt

thirty4ay waftanty, we will

afso

provide,

tree of

charge, all

labor and

in-home service

to

replace

the

defective

part.

.

Service trips

to

your

home

to teach

you

how to use

the

producl

.

lmproPerinstallation.

.

Failure of

the

product

if it is

abused or

used

for other

than

the

intended

purpose

or used commercially.

.

Loss of

food

due

to

spoilage.

.

Replacement

of

the water filter cartridge

due

to water

ptessure

that is

outside the

specified

operating

tange or due to

exces-

sive

sediment

in the water supply.

.

Replacement

of

water filter cartridge

after

its expected

useful

life,30 days.

e

Damage

to

the

product

caused by accident,

fire,

floods, or

acts of God.

'

Feplacement

of

house fuses or resetting

of

.

tncidentat

or

consequential damage caused

circuit breakers'

by

possible

defects

with

this

apptianoe.

This

wananty is ertended

to

the

original

purchaser

and any succeeding

ovvner

for

products purchased

for home

use within

the USA.

ln

Alaska, the wananty

excludes

the crist

of

shipping or seruice

alls

to

your

home.

Some sfafes

do

not allow

the

exclusion or

limiktion

of incidental

or

@nsequential

damages.This

war-

ranty

gives

you

specific

legal ights, and

you

may

also have

other

rights

which vary

from

state to state.

To

know what

your

legal

rights are, consult

your

local

or

state @nsumer

afkirs

office or

your

sfafe's

Attomey

General.

Warrantor: Genenl Eledric

Company.

Louisville,

l<Y

tt025

c

-6-

Page 9

Table

of

Contents

Fresh

Food/Freezer

lndependent Operation..

....

-..

8

Normat

Operating

Characteristics,

but Different

from

Prcvious

Models

.... ... I

Abnormal

Operating Characteristics

(lnconect Operation)....

. -.....

8

Adaptive

Defrost.

.-.---

8

GoolingOperation(AdaptiveDefrost)

.--- 9

Pre-Chilt

Operation

(Adaptive

[lefrost)

.....

. . . 9

Defrost

Heater

Operation

(Adaptive

Defrost)

... 9

Dwell

Period

(Adaptlve

Defrost)

....

9

Post

[)ryvell

(Adaptive

Defros0.

..

... 9

Liner

Protection

Mode

..... -.

9

Electrpnlc

lcemaker

...

-....10

Dispensing

Functlons

..

.....

Qulck

lce

..

Door

Alarm

Dispenserlight

.-..--

10

10

10

10

Dispenser

Lock

Filters

Hinge

System

and

Door Closure

Airflow

(Cabinet

lnterior)

"Jelly

Roll"

Condenser

....

Main Control

Board

10

11

11

11

12

13

-7-

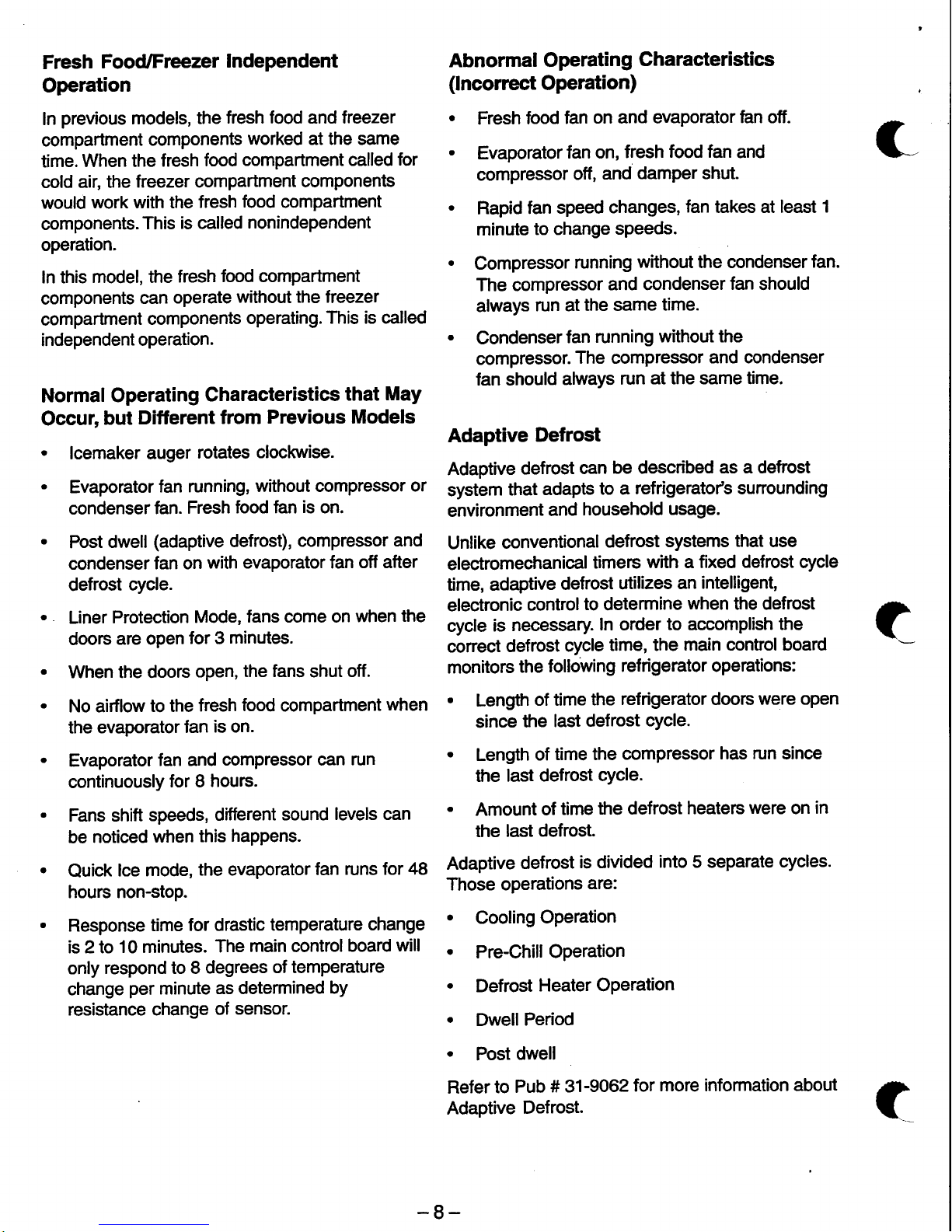

Page 10

Fresh

Food/Freezer

Independent

Operation

fn

previous

models, the

fresh food and treezer

compartment

components

worked at the same

time.

When the

fresh

food

compartment called

for

cold

air, the

freezer compartment

components

would

work with the

fresh

food

compartment

components.

This

is

called

nonindependent

operation.

In this

model, the

fresh

food compartment

components

can

operate

without the freezer

compartment

components

operating.

This is called

independent

operation.

Normal

Operating

Characteristics

that

May

Occur,

but

Different

from

Previous Models

.

lcemaker auger

rotates

clockwise.

.

Evaporator

fan running,

without compressor

or

condenser

fan.

Fresh

food fan

is

on.

.

Post

dwell

(adaptive

defrost),

compressor

and

condenser

fan on

with evaporator fan

off after

defrost

cycle.

.

Liner

Protection

Mode,

fans come on

when

the

doors

are open

for 3 minutes.

.

When the doors

open,

the fans

shut

off.

.

No airflow

to the

fresh

food

compartment

when

the evaporator

fan

is on.

.

Evaporator

fan and

compressor can run

continuously

for 8

hours.

.

Fans shift

speeds,

different

sound

levels can

be

noticed

when

this

haPPens.

.

Quick

lce mode,

the evaporator

fan runs

for 48

hours non-stop.

.

Response

time

for drastic

temperature

change

is 2 to

10 minutes.

The

main control

board

will

only

respond to 8

degrees

of temperature

change

per

minute

as determined

bY

resistance change

of

sensor.

Abnormal Operating

Characteristies

(lncorrect

Operation)

.

Fresh

food

fan

on and evaporator

fan off.

.

Evaporator

fan on,

fresh

food fan

and

compressor

off,

and

damper shut.

.

Rapid

fan

speed

changes,

fan

takes at least

1

minute

to change

sPeeds.

.

Compressor

running

without the condenser

fan.

The compressor

and condenser

fan

should

always

run at

the same

time.

.

Condenser

fan running

without the

compressor.

The compressor

and condenser

fan should

always

run

at the same time.

Adaptive

Defrost

Adaptive

defrost

can

be described

as a defrost

system

that

adapts

to a

refrigerato/s sunounding

environment

and

household

usage.

Unlike

conventional

defrost

systems

that

use

electromechanical

timers

with a fixed defrost cycle

time, adaptive

defrost

utilizes

an

intelligent,

electronic

controlto

determine

when

the defrost

cycle

is

necessary.

In order

to accornplish the

corect

defrost

cycle

time, the

main control board

mon

itors

the f ollowi

n g ref rigerator operations

:

.

Lengft

of time

the

refrigerator doors

were open

since

the

last

defrost

cycle.

.

Length

of

time the

compressor

has run since

the last

defrost

cycle.

.

Amount

of

time

the defrost

heaters

were

on

in

the

last

defrost.

Adaptive

defrost

is divided

into 5 separate

cycles.

Those operations

are:

.

Cooling

Operation

.

Pre-Chill

Operation

.

Defrost

Heater Operation

.

Dwell

Period

.

Post

dwell

Refer

to

Pub

# 31-9062

for

more information about

Adaptive

Defrost.

c

t

-8-

Page 11

r\

Cooling

Operation

(Adaptive

Defrost)

During

the cooling operation, the

main

control

board monitors door opening

(fresh

food

and

treezer

doors)

and compressor

run times.

The

length

of time between consecutive

defrosts

is

reduced

by each

door

opening.

lf the

doors

are not

opened, the compressor

will

run

up to

60 hours

between defrosts.

lf the

doors

are

opened

frequently

and/or

for

long

periods

of time,

the

compressor run

time

between

defrosts

will

be

reduced

to as

little as I hours.

Pre-Chill

Operation

(Adaptive

Defrost)

When the

main

control board determines

that

defrost is necessary

the main

control

board

will

force

the refrigerator

into

a cpntinuous

cool

mode

(pre-chill).

During

pre-chill,

the freezer

temperature

may

be

driven below

the temperature

cpntrol

panel

display setpoint.

However,

the fresh food

temperature will be regulated

by the

damper.

Pre-

chill will last

for 2 hours if it is not

intemlpted

by

any door openings.

lf,

after I hours,

the

unit

has

been

unable

to complete

an uninterrupted

pre-chill,

it

will

proceed

to the

defrost

rycle.

Defrost Heater Operation

(Adaptive

Defrost)

After 2 hours of

pre-chill

operation

or

8 hours

of

intemlpted

pre-chill

attempts, the

main control

board turns the

compressor,

condenser

hn,

and

evaporator

fan off. The main

control

board then

energizes the defrost relay, which

completes

the

defrost circuit.

During

defrost

operation, the main

control

board

monitors the

evaporator

temperature

using

evaporator thermistor inputs. The

thermistor

will

terminate

defrost

heater operation

usually in

less

than 20 minutes.

Typicaldefrost

time

is 20-30

minutes.

The

defrost system is

protected

by a defrost

thermostiat

(srlitch).

The

thermostat

opens when

the evaporator temperature

raises

to

140"

Fahrenheit

and closes

when

the evaporator

temperature

lowers

to 110

degrees Fahrenheit.

Dwell Period

(Adaptive

Defrost)

After defrost heater

operation

has

been terminated

by

the main

control board,

a S-minute

dwell

period

occurs.

During

this

period,

the

compressor,

the

condenser

fan,

and the

evaporator fan

remain

off.

The remaining frost melting

from

the

evaporator

will continue to

drip and drain

so the

evaporator

will

be

totally

clear of

any moisture

prior

to the

cooling

operation.

Afterthe

5 minute

dwellperiod,

the unit

goes

into

post

dwell.

Post Dwell

(Adaptive

Defrost)

The

post

dwell

period

is

designed

to

coolthe

evaporator before circulating

air within

the

refrigerator.

This

prevents

any

residual

heat

on

the evaporatorfrom

being

distributed

in the

treezer.

During

this

period,

the

compressor

and

condenser

fan are

on, but

all interior

fans

are off

and the

damper is

closed.

Post

dwelltimes

vary

with different models.

However,

there is

a

5-

minute maximum

post

dwelltime.

Liner Protection

Mode

The

liner

protection

mode

will

activate if

either of

the doors have been

open for

3 minutes.

This

mode willstart

the

fans

and

close the

damper.

This mode is controlled

by 2 timers.

Timer #1

monitors

door-open

time.

A

3-minute door-open

count begins

when

the

door is opened.

lf

3

minutes elapse before

the

door

is

closed,

the liner

protection

mode will

become

active.

Once

the

door

is

closed, timer #1 resets

and liner

protection

mode

goes

into

standby.

In

standby,

normalfan

and

damper

operations

resume

and

timer

#2

begins a 3-minute

door-

closed count. lf 3 minutes

elapse without

a

door

opening,

liner

protection

mode will

completely

deactivate. lf a door is

opened within

the timer #2

door-closed

count, the remaining

time in the

door-

closed count will be

deducted from

the timer #1

door-open

count.

n

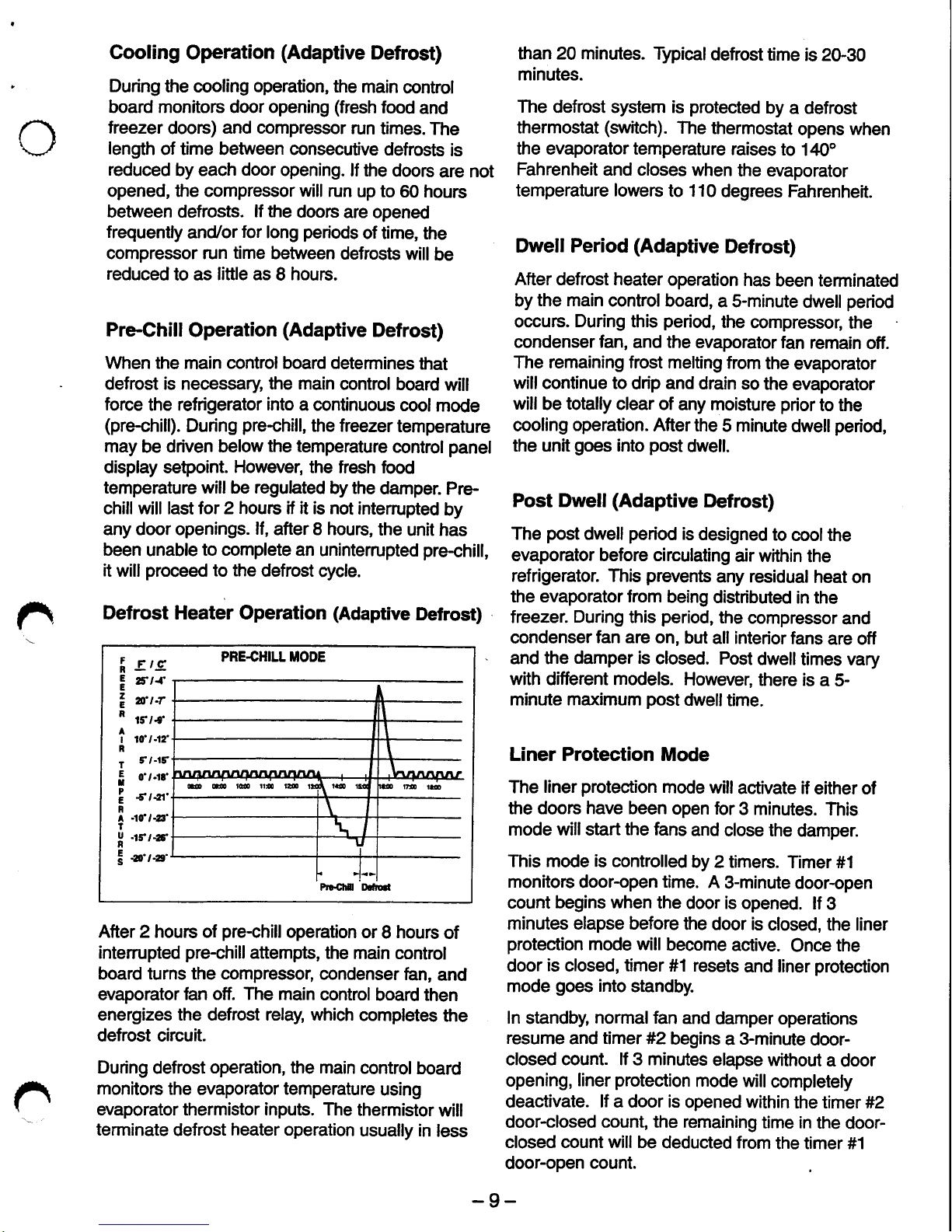

PRE4HILL TIODE

I

erc

I

stt

I

a.rt

"

rtl.f

?

tar"t

T

'r-tt

I

o'r.rr

2

st,ar'

F

A 40!l-,3'

T

X

-rfr-zr

!

eo'rar'

@ml@trsta

-9-

Page 12

Electronic

lcemaker

This

refrigerator is equipped

with

an

Electronic

lcemaker.

Refer to

Pub # 31-9063lor more

information.

Dispensing

Functions

The

water, crushed

ice, and cubed ice functions

are controlled

by the

main

control

board.To select

a function,

press

the

appropriate

pad

on the

dispenser.The LED

will

light to identify

the

selection.

To dispense

the selected

item,

depress

the

dispenser cradle

located

in the

dispenser

re@ss.

The solenoid and

linkage

assembly will open the

ice

chute door

to dispense

the ice. lf

cubed

ice is

selected, the

crushed

ice

bypass solenoid will

allow cubed

ice to bypass

he

ice

crusher.

The

ice

chute door

must remain

open for 5 seconds after

dispensing

ceases.

After

this

S-second

delay, the

solenoid

and

linkage assembly

will

shut

the icp

chute door.

The

dispenser

light

will come on automatically

when the dispenser

cradle

is

depressed and

will

fade out 5 seconds

after

it is released.

The dispenser

selection

is recorded in the main

control board.

ln the event

of a

powerfailure,

the

last selected function

will be

restored.

Quick

lce

The

quick

ice

feature is available

on

some

models.

This feature causes

the evaporator fan to operate

non-stop tor 48

hours

(fan

may operate in high or

low

speed).

This enables

madmum icemaker

ouFut

The

QUICK

ICE

pad

initiates

the

quick

ice mode

in the refrigerator.

Pressing

the

QUICK

ICE

pad

lights the LED and sets

the

evaporator fan to

run

at medium

speed

(unless

the main controlboard

selects

high speed)

for a

48-hour

period.The

evaporator

fan is

terminated during defrost, dwell,

post

dwell,

and door

openings.

The

quick

ice

selection

is stored

in

the main

control board.

The

function

will

be restored

in

the

event of

a

power

failure.

Door Alarm

The DOOR AIARM

pad

is used

to tum on and

tum off

the door

alarm feature.

lf

the

feature

is on,

the DOOR

ALARM LED

willflash

when the

door

is

opened.

lf the door

is

open

for more than 2

minutes,

the door

alarm

will sound.

The

alarm can

be stopped

by

pressing

the DOOR

ALARM

pad

or

by shutting

the door.

lf

the

DOOR

ALARM

pad

is

pushed

while

the door

is open, the alarm willstop

but the

led

will continue

to flash untilthe

door is

closed.

When

the door

is closed it will reset

the

audible

alarm.

This feature

will

be retained in the

event of a

power

failure.

Dispenser

Light

The LIGHT

pad

tums the

dispenser light

on and

off.

When

the light

is

tumed

otf,

it

will

fiade

out. The

dispenser

light

will come on automatically when

the

dispenser

cradle

is

depressed

and willfade out

5 seconds

after

it

is released.

The

LIGHT

pad

will

not tum off

the light during

dispense.

Dispenser

Lock

When

the

dispenser

system is

locked, no

dispenser

command

will be

accepted.

This

includes

the dispenser

cradle

and will

prevent

accidental

dispensing

that

may

be caused by

children or

pets.

lf a

pad

is

pressed

with

the

system

locked,

it will be acknowledged with

3

pulses

of

the LOCK

LED accompanied by an

audibletone.

To lock

or

unlock communication between

the

dispenser

and the

main

control

board,

press

the

LOCK

pad

and

hold it for 3 seconds. The

LOCK

LED

willflash

while the LOCK

pad

is

pressed.

\Afhen

the

communication

is locked,

the LOCK

LED

will be

illuminated.

The status

of other

functions, selected

prior

to the

initiation

of

the

lock

feature, will be

displayed. lf the

lock is engaged

while a

mode is

active,

the LED

will remain

on untilthat

mode times

out.

lf the

lock

is engaged

when the

filter

timer

expires,

the LED

willcome

on

but

cannot be reset untilthe

lock is tumed

off.

The lock

feature

will be retained

through a

power

outage.

r

-

10-

Page 13

o

Filters

The

FreshSaver

filter is located

on the

FRESH

PRODUCE drawer

and will last for 1

year.

Some

models

are equipped

with a FreshSaver

FILTER

LED. After

1

year

of

refrigerator

operating time,

the FreshSaver

FILTER LED will illuminate

as

a

reminder to

the

ownerto change the filter.The

LED

can

be

reset

by

pressing

and

holding

the HOLD

3

SECS

pad

for 3

seconds. The LED will flash

while

the

pad

is

pressed,

remain illuminated

for

3

seconds after

the

pad

is released,

and

tum off.

Some

models

are

equipped with a water

filter that

is located in

the upper

right-hand

comer

of

the

fresh food

compartment.

Filters

are designed to be

used

for up

to

18 hours of

open

valve

time

or 1

year

of

clock

time.

When 90%

of

filter time has elapsed

(open

valve

time or

clock

time,

whichever

@mes

first),

the

main controlboard

willilluminate

the filter

reminder

LED

(amber).

When

10O/" of the filter time

has

elapsed,

the

main control board

will

illuminate the

filter

reminder

LED

(red).

Hinge System

and Door

Closure

The

hinge

brackets are

not

adjustable

on the

cabinet. The

fresh

food

door can be

adjusted up

and

down

by

using

the hinge

adjustment

pin

(located

on

the fresh

food lower

door hinge).

This refrigerator

is equipped

with

a

door opening/

closing

feature.

This

feature

consists

of a

spring-

loaded

arm

located

at

the

bottom of the

cabinet for

each

door.

The

arm

provides

a stop for

the door

when the door

is

partially

open and automatically

closes

the door

when the door is almost

closed.

IMPORTANT:

The

refrigerator rollers must

be

adjusted

correctly

for

proper

door closure. When

the rollers are

adjusted

correctly,

the

door should

close easily

when open approximately

45

degrees

(haltway).

Airflow

(Cabinet

Interior)

The freezer cabinet

is designed so that air is

drawn

into the bottom

of the airtunnel and through

the evaporator

when the evaporator fan is

operating.The

chilled air

is then

pushed

out

into

the top of the

treezer.

The fresh

food compartment

receives chilled air

via

an electronic

damper that is

positioned

at the

top

rear

of the refrigerator between the

freezer

cabinet

and

the fresh

food

cabinet.

The

damper

is

controlled

by the

main control

board and

when

open,

allows

chilled air

from the freezer

air

tunnel

to

move

into

the fresh food air tower. The fresh

food air

tower contains

a fresh food fan which

draws

chilled

air

from the freezer

(through

the

damper)

into

the

air

tower.

The

air tower directs

chilled

air across

the top of the

fresh

food cabinet

to

two

outlets. The

air tower also directs

chilled

air

down

the

back

wall of the

fresh

food cabinet.

The

chilled

air exits

the air tower

through vents in the

tower.

Air

retums from the

fresh food

cabinet

to the

treezer cabinet

via a

mullion located to the left of

the

FRESH

PRODUCE drawer.

AIR FLOW

+,

i,

H

ilr -l

\Er'-

lt..u/

lr

-!

UI\/

1LJ"

o

n

aoenl reenfil

-11-

Page 14

"Jelly

Roll"

Condenser

The

"jelly

roll"

condenser

is a new

type

of

condenser.

The condenser

fian is

located

at one

end

of

the

"jelly

roll" condenser

and

a

solid

plate

is

located

at the other

end. Air

is

drawn

in

through

the

outside

diameter

of

the

condenser

and

pulled

out

by

the condenser

fan.

The

condenser

is

located

in the

machine

compartment

which

can

be

accessed

from

the back

of the

unit

at the

bottom.

(

-12-

Page 15

Main Control

Board

INPUTS

ACCUMUI-ATED

FF

AND FRZ

DOOR OPENTNGS

(MINUTES)

COMPRESSOR

RUNNilE

(MTNUTES)

DEFROST

HEATER

OI{ TIIIE

(MTNUTES)

->

.|>

->

I

oUTPUTS

i

COOUNG

PRE-CHILL

DEFROST

<.

+

<-

n

i------lr-

----'t----,

ico||xt[rcattoil

ll ourpen

|

:ncooen

ll

THEhrstoa

i

roDEL

:

|

!'o'tfio{rrpur

tl

@[s

I rwuts

11

NRfGi

i

*

;

!!!s3

tlo

o o o

oliilo

o

o oio

rt:_-_---_e1t

rt_

r----,'

'=

n

---i--,t----l.?

oooo:oooooo

-13-

Page 16

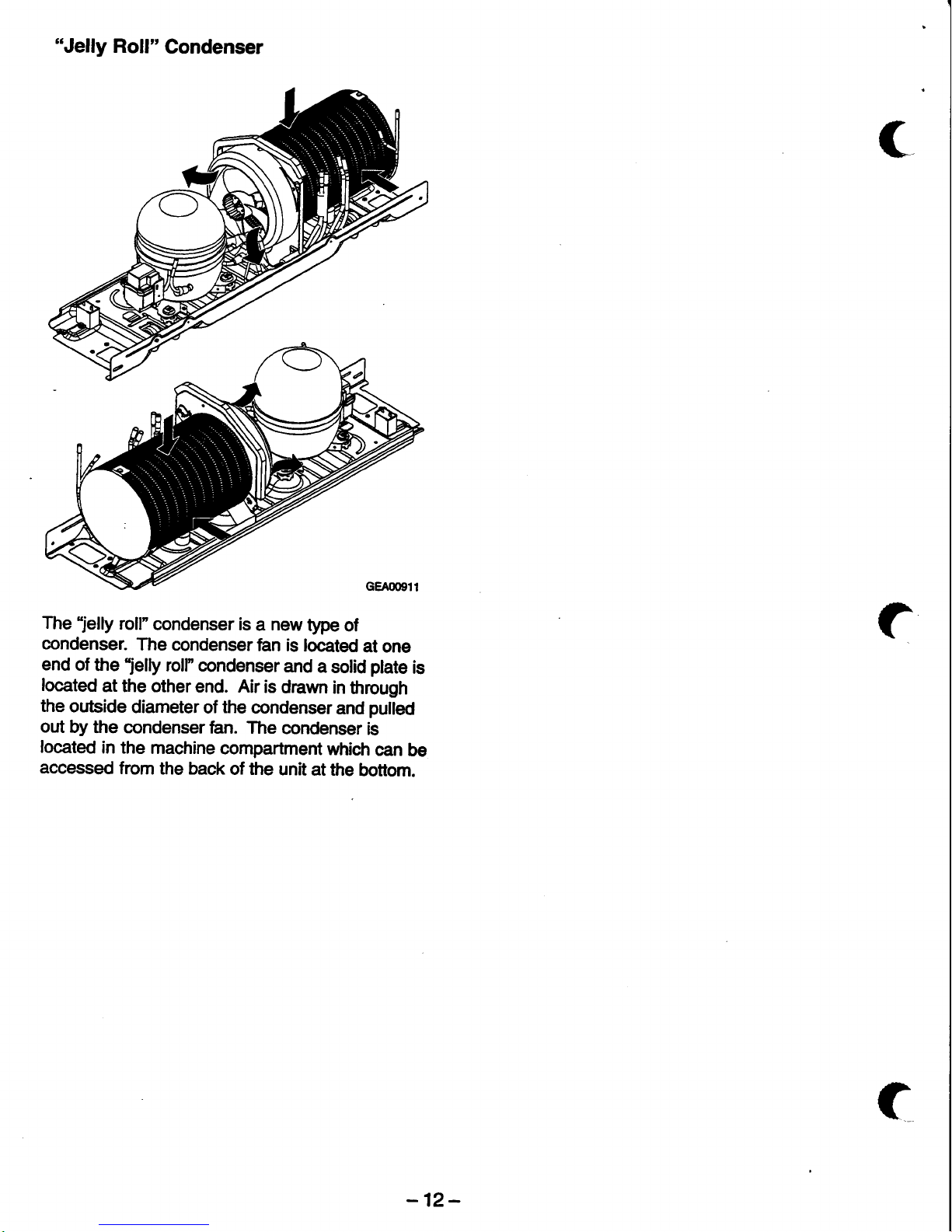

Temperature

Controls

Frcezer Light

Switch

Evaporator

Fan

Evaporator

Freezer

Thermistor

Evaporator

Thermistor

Fresh Food

Thermistor

Fresh

Food

Light

Switch

c

-14-

Page 17

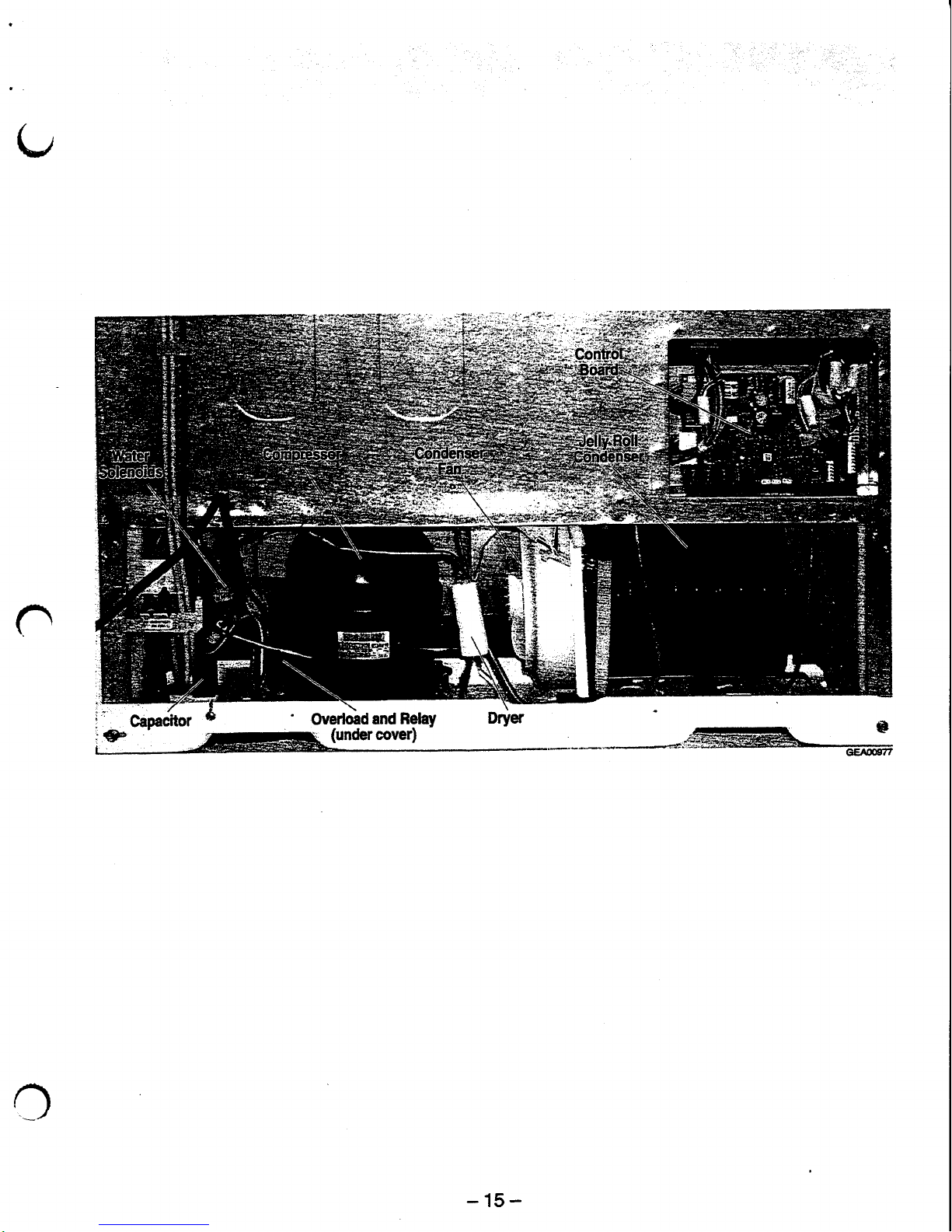

o

o

"

gapacfior

-

vvt,rKras

dlls nElay

etra

o

ie"

'

.-ruF-'', (::dercove0

_.

_**

-

,,o.

==, =*,

GEA(E,''

-15-

Page 18

Table

of

Gontents

Door

Handle

18

Door Gasket

18

.

.:

Fresh Food Compartment Quick

Access Door

.

Fresh

Food Door

Light

Switch

19

Fresh Food Gompartment

Door Shelves

Fresh

Food Compartment

Shelves

. ..

19

Fresh

Food Compartment

Drawerls ... ....:.,:

....

19

Fresh Food Compartment

Ughts

Water Filter

20

Fresh Food

Fan and

Mullion Damper.

....,...

20

D,eli

Fresh Damper

FreshFoodThermistors..

r.!i,

21

Temperature

Gontrol

Panel

n

Freezer Door

Bins

.

22

Doors and

Door

Hinges

Uz

Fresh Food

Door Adjustment.

..

23

Rollers

23

Roller Adjustment

..

24

Freezer Compartment

Shelves

and Bins.

24

Freezer

Door Light

Switch

24

lce Dispenser

.

24

lce

Dispenser

Auger Drive and Cube Solenoid

lcennaker

25

?s

-16-

Page 19

Frcezer

Light

..........

.,.,.

26

Evaporator

Fan

. '... -

26

Evaporator

Thermistor...

.....,

27

Defrost

Thermostat

27

Defrost

Heater.

27

EvaporatorDriPPan.

"""

28

Evaporator...

.

Freezer

Thermistor....

.. '..

Condenser

Fan.

.....,..r.

Main

Processor

Gard

r.........

Water

Solenoids

...

-,.....

28

a

n

n

C

-17

-

Page 20

Door Handle

The door handles

allow

access into

the

fresh food

and freezer compartments. They

are front

mounted with 1 Ton

head

screw.

With a small flat-blade screwdriver,

slide the

handle trim down and

pull

it

out.

Remove the lower Torx head

screw.

Lift

the

handle in and upward motion

until

it

disengages the

locking tabs.

Pullthe

handle

outward to

remove

it.

Door

Gasket

The

door

gasket

is

a

molded

gasket

set into

a

channel located

in

the

door

liner.

1.

Open

the

door.

2. Grasp the

gasket

and

pull

in an

outward

motion untilthe molded

gasket

separates

from

the door liner.

Fresh

Food

Compartment

Quick

Access

Door

The fresh icod

compartment allows access

to the

fresh

food

compartment

without opening

the

fresh

food

door.

1.

Open

the

quick

access door

and remove

the

hinge

Tox head screws

(2),

located

on

each

side of the door.

With a small

flat-blade screwdriver, remove

the

door

frame and

door

frame assembly.

Remove the

gasket

and

slide

the door

out of

the frame.

The

quick

access door also

has

an

interlock

switch

located

at

the top

right-hand

side

of the

interior frame. Remove

the

Phillips

screw

and

slide the switch assembly

down and out.

Disconnect

the

wires

to the switch and remove

it.

C

1.

2.

3.

Rir'.

ffi.'

te

16:

*,r:

u.

k.

i:;

t

x

N:.

i.

I

t'

i.

f:-"--

t

i'

t.

:'

;.

!1'l

l:

'

i:::

't

GEA00922

-18-

Page 21

Fresh

Food

Door

Light Switch

In

addition

to

the

quick

access

door

light swttch,

the fresh food

compartrnent

has

a door

light

sntitch

located in the

lower

right comer

for the

compartment.

1.

Use a

small flat-blade

screwdriver

to

unlock

the locking

tab tabs

and

pullthe

switch out until

the

wire connector

is

visible.

2. Disconnect

the connector

and

remove the

switch.

Fresh Food

Compartmenl

Door

Shelves

The

door shelves

allow storage

of

perishable

items.

1. Tilt the shelf

up

and slide

it out.

Fresh Food

Compartment

Shelves

These shelves

allow

the storage

of

larger

items

and

pull

out

for easy

access.

1. Pull the

shelf

out

until

the shelf stop

tab meets

the compartment

stoP.

2.

Push the

shelf

stop

tab

down and

pullthe

shelf out

until

it is

removed.

Fresh

Food

Compartment

Drawers

Fresh

irod compartment

drawers

are designed

for

storage

of

fruils,

vegetables, and deli

items.The

drawers

are

located

in

the lower

portion

of

the

fresh

frood

compartment.

Pull

out

the drawer until

the rollers meet

the

mechanical

stoP.'u''

Tilt the

drawer

up

and

pull

it out

until

it is

removed.

Fresh

Food Compartment

Lights

The fresh

food

compartment

lights are

located

in

the upper

and

lower

portion

of

the fresh

food

compartment.

1.

To access

the

upper

lights,

remove the upper

opaque

cover

by unlocking

the tabs and

pulling

the cover

down.

1.

n

GEAfiIg28

GgA0@9

GEAOGIT'

-19-

Page 22

GEA{'GfiI

GEAOoSTO

2.

3."

To

access the

lower lights,

pullthe

delifresh

damper

adjusting

knob off.

Lift the

opaque

cover off the

tabs.

,

Water Filter

The waterfilter is

located

in the

upper right-hand

portion

of the fresh food compartrnent.

The

water

filter, filters uater for the

ice

maker

and the

water

dispenser. An LED

on

the

temperature

control

panelwill

illuminate when the filter

needs

to be

changed.

1. Turn the water filter 112 turn counterclochryise

and

pull

it

down.

2. To installthe

filtet

push

it up

while

turning 1/2

turn clockwise. Do not

force

the

filter.

Fresh

Food Fan and Mullion

Damper

The

fresh food

compartnent fian is located

under

the upper dustwork in the fresh

frcod

compartnent.

This fan

distributes

cold

airfrom the

lreezer

via

the

mullion

damper.The

mullion damper

is

located

in

the

same assembly as

the fan.

Both

are

controlled

by the

prccessor.

1.

Remove

the

delifresh adjusting

knob

and

light

cover.

2.

Unlock

the upper

and

lower

locking

tabs

for

the

center ductwork and

remove.

The

ductwork

is

also

fastened

with double-sided

tape

at

the

upper and

lower

portions.

GEA0oSI

GEA@982

-20-

Page 23

3.

Remove

the

upper

water

filter cover.

4.

Unlock

the

upper

opaque

light

cover tabs and

remove

the

cover.

5. Unlock

the

upper

ductwork

tabs

and remove it.

9.

Lay the fan

and damper

assembly

against

the

compartment

and

open the

back cover.

10. Disconnect

the

wire connections

and

remove

the damper

or

fan.

6. Remove

the

Phillips

head

screws

(8)

for

the

upper

light

assembly

plastic

bracket-

Pullthe

stainless

steel

light

bracket

down until

the

wires

are exposed

and

disconnect

them.

Remove

the

Phillips

head

screws

(2)

for the

fresh food

fan

and damper

cover

and

remove

the cover.

Deli

Fresh

Damper

The

delifresh

damper

is

located

at the bottom

of

the

cold

air ductwork.

lt allows

the

flow

of cold

air

to be

adjusted

to the

delifresh

drawer.

1.

Remove

the

delifresh

damper

adjusting

knob

and

the

lower

light cover.

2.

Remove

the

center

ductwork

by

unlocking

upper

and

lower tabs.

Double-sided

tape

is

applied

to upper

and

lower

areas.

3.

Remove

the

damper

Phillips

head mounting

screws

(3)

and

remove

the damPer.

Fresh

Food

Thermistors

The

fresh

food thermistors

are

located at

the

upper

and

lower

portions

of the

fresh

food

compartment.

They send

temperature

signals

to

the

processor.

7.

n

oEAOO$4

GEAO09I5

GEA00938

GEAO09S6

-21

-

Page 24

1. \Mrth

a small flat{lade

screwdriver,

unlock

the

tabs

and

remove

the

assembfy.

Remove the

thermistor from the

cover

and

disconnect the wire

connector.

Temperature

Contnol Panel

The

temperature

control

panelis

located

in

the

fresh food

comparFnent and mounted

atthe

upper

front.

This

panel

allows

temperature

control for

the

fresh

food

and freezer

compar[nents.

Eacfr

comparfrnent

has an LED readout

of

the

temperature

setting.

In

addition

the

panelhas

an

LED

readout for

water filter

change.

1. Remove

the control

panel

Phillips

head

mounting

screws

(3).

2. Pullthe

paneldown

untilthe

wire

connections

are exposed.

G€ m.F

Disc-onnect

the

panel

wire connector.

Disconnect

the circuit card ribbon.

Unlock

the

cad

locking tabs

located

at the

lower

lefi-

and

right-hand

oomers

of

the

card.

Remove

the

card.

Frcerer

Door Bins

The

freezer

door bins are located

on

the

inside

of

the freezer

door and tilt

out

to

allow

easy

access

of frozen items.

1. Tilt

the

bin

up and slide it

out

of

the

door.

Doors and Door

Hinges

IMPOffiANT:

The freezer

door

is

not

adjustrable.

The

fresh food door can

be adjusted

up

and down

to match

the

height

of

the

freezer

door.

Adiust

the

fresh

food door up or down using

the

hinge

adjustrnent

pin

(located

on the fresh

food

door

lower

hinge).

IMPORTANT:

The refrigerator rollers

must

be

adjusted

conecdy

to

ensure

proper

door

closure.

Refer to

the

Roller Adjusffnent

section

in

this

.

chapter for

more information.

1. Remove the base

grille.

2. Wih

the

door in

the closed

position,

disconnect the wiring harness

connector.

3. Disconnect the water

supply tube. To

disconnect

the tube,

push

the

white

collar

on

the

quick

connector

in

and

pullthe

tube

out.

4.

5.

6.

7.

GEAdXX]9

GEAO094e

GEAO@41

GEAOogrfi'

-22-

Page 25

4. Witr a

small

flat-blade screwdriver, disengage

the

locking

tabs of

the upper hinge cover

and

remove

it.

Remove

the

Tox head

hinge

scre\,\fs

(2)

and

lift

the upper

hinge

off the unit.

CAUTION:

Do

not side-load

hinges.

CAUTION:

Freclzer

door only

-

Do not

allow the

connrtor

to

contact

the

floor. Hard

contact may

damage

the

connector.

NOTE:

Guide

the

waterline and wiring

harness

through

hinge

while lifting the

door from hinge.

6. Open

the

door

90o and

lift

door straight up and

off

the

lower

hinge.

Thlmbb

Hlnge Pln

Torx Scrprv

6EAOO90I

Lower

Hinge, Freezer Side

7.

Remove

the

Tox screws

(3)

and

the lower

hinge

from

the

cabinet.

Thimbb

Hinge

\--Torrscre*

Lower

Hinge, Fresh Food Side

Fresh

Food

Door Adjustment

IMPORTANT:

The freezer door is not adjustable.

The

fresh

food door can be adjusted to

match the

height of

the

freezer door.

IMPORTANT:

The refrigerator rollers must be

adjusted

conectly

to ensure

proper

door closure.

Refer

to the

Roller Adjustment

section in this

chapter

for more information.

1. Remove

the

base

grille.

2.

Turn

the

hinge adjustment

pin

(located

on the

fresh food

lower

hinge)

clockwise

to raise

the

door

level and

counterclockwise

to

lower the

door.

Rollers

This unit

has

4 rollers

for

easy

movement

of the

refrigerator.There

are

2 rollers

located in the

front

and

2

rollers

located

in the rear of the unit.

IMPORTAM:

The reftigerator

rollers must be

adjusted

properly

to

ensure

proper

door closure.

Refer

to

Roller Adjustment.

1.

To

remove

the front

rollers, back the level

adjusting

screw all

the

way

out.

2.

Remove

the

1/4-in. roller

mounting screws

and

remove

the caster.

To

remove

the

rear rollers,

remove 114-in.

mounting

screws

(2).

Tilt

the

roller

down and slide

it out.

Hlngc

ffJ"*".".

GEqOOtXa

GEA0G'15

-23

-

Page 26

1.

2.

Roller Adjustment

The

front

(2)

rollerc are adjustable.

Adjust

them

so

that the refrigerator

is solid and the

doors close

easily.

Remove the base

grille.

With

a flat-blade screwdrivel

tum

the

adjusting

screw clockwise to raise

the roller

and

counterclockwise

to lower

the roller.

Freezer

Compartment Shelves and

Bins

The

shelves

and bins slide

out

for easy access for

frozen items.

1.

Slide

the

shetfibin out

until

it

reaches

its stop.

2. Tilt the

shelfibin up and slide it

out

of the

compartment.

Freezer

Door Light Switch

This

switch is located in

the

left-hand

portion

of

the freezer

compartment and sends

a signalto

the

processor.

1.

With

a

small flat-blade screwdriver,

unlock

the

locking

tabs and

pullthe

switch

out

untilthe

wire

connector

is

visible.

2. Disconnect

the wire connector and remove the

switch.

lce

Dispenser

The ice

dispenser

is located in the

upper

portion

of

the freezer

comparhnent.

This

assembly stores

ice

made by the

icemaker

and dispenses

ic€

on

demand from the door dispensertarget

switch.

1.

Remove the

upper

ice bucket tray.

2. Slide out the

ice

dispenser assembly.

Remove the

ice

cube solenoid linkage Phillips

head

screw

and slide the linkage

back.

Remove the

ice

crusher cover Phillips head

screws

(2)

and

remove

the

cover.

With a

pair

of

pliers,

twist off the

backing

plate

tabs located

on either side of the

crusher.

c

GEAO€46

GEA00947

GEAO€5o

Page 27

7.

With 2

smallflat-blade

screwdrivers,

unlock

the

ice

crusher

locking

tabs

located

at either

side

of

the

ice

crusher-

Lift the

ice

crusher

out

of

the

bucket.

8.

Remove

the

ice crusher

bac*

cover.

9.

Remove

the

locking

ring

from

the

ice crusher

auger.

10.

Remove

the

plastic

nut

with

a

pair

of

pliers

by

tuming

it

clockwise.

11.

Remove

the

spacers

and

blades.

The blades

are

numbered

for

reassemblY.

lce

Dispenser

Auger

Drive

and

Cube

Solenoid

The

ice

dispenser

drive

motor

and

cube

solenoid

are

located

in

the

upper

rear

of

the

freezer

compartment.The

drive

motor

rnoves

the auger

via a

fork

located

on

the

drive

motor.The

cube

solenoid

allows

cube

or crushed

ice to

be

dispensed

on

demand-

1.

Remove

114'in.

housing

mounting

screws

(4)

located

at

the

four comers

of

the

housing.

2. Slide

the

housing

forward

untilthe

connector

is

visible,

disconnect

the connector,

and

remove

the unil

from

the

housing.

Note:

Drive

fork

has

reverse

threads;

tum

clockwise

to

remove.

3.

Remove

the

fork

from

the

drive

motor

by

tuming

it clockwise.

4.

Disconnect

the

motor

connectors

and

remove

the

ground wire.

5.

Remove

1l4-|in.

mounting

screws

(3)

and

remove

the

motor.

6.

Dismnnect

the

cube

solenoid

wires.

7.

Remove

cube

solenoid

1/4-in.

mounting

screws

(2)

and

remove

the cube

solenoid.

lcemaker

The

icemaker

is

located

in the upper

rear

of

the

trwzer

compartment

and

supplies

ice to

the

dispenser

tub.

1.

Disconnect

the

icemaker

cable

connector.

2.

Remove

1l&in"

icemaker

mounting

screws

and

slide

out

the

icemaker.

This

relrigerator

is equipped

with an

Electronic

lcemaker.

Refer

to Pub

# 31-9063

for more

information.

-25-

Page 28

Freezer

Light

The

freezer

light is

located

in the upper rear

of

the

freezer

bompartment

The

light is

covered by an

opaque

cover.

1.

Unlock the

locking tabs and remove

the cover.

2.

Replace the

appliance

light

Evaporator

Fan

The

evaporator

fan

is located

in

the

upper rear

portion

of the

treezer compartment.

This

fan

supplies

cold air

to the freezer

and fresh

food

compartments. The evaporator

thermistor

must

be

replaced

when replacing

the fan.

1.

Remove 1lSin. icemaker

bracket screws

(4)

located at the four comers

of

the bracket.

2. Remove 1l&in.

ice dispenser

drive mounting

bracket screws

(2)

and remove

the brackets.

Remove 1lSin. upper

evaporator fan

duslwork

screws

(2).

Unlock the

tabs and

remove

the

lower

evaporator

fan ductrrvork.

Remove 1l#in, evaporator cover screws

(4)

and

remove the oover.

Remove

1l$in. upper

evaporator fan

duct work

screws

(2),

located at the

lower

portion

of

the

ductwork.

\ffith

a smallflat-blade

screwdriver,

unlock the

tabs for

the

icemaker and dispenser

cables.

Slide

the upper

fan ductwork out.

Disconnect the

evaporator

fan

wiring hamess.

4.

c

6.

7.

8.

9.

G8400855

GE400058

-26-

Page 29

10. Remove

the

1/4-in.

screw

for the evaporator

fan

ground

wire.

11. Remove

the

1/4-in.

evaporator

fan

bracket

mounting

screws

(2),

located at

either side

of

the bracket.

12.

Remwe

the evaporator

fan assembly.

Evaporator

Thermistor

The evaporator

thermistor

is

snapped

on to the top

portion

of the

evaporator.

This

thermistor

sends

evaporator

temperature

signals

to

the

processor.

The thermistor

must

be

replaced

when replacing

the evaporator

fan.

1. Complete

evaporator

fan

procedure.

2. Unsnap

the

evaporator

thermistor

from the

evaporator

and

remove

it.

Ilefrost

Thermostat

The

defrost

thermostat

is snapped

onto the

top

portion

of

the evaporator.The

thermostat

sends

temperature

information

to the

processor.The

detrost

heater

must

be replaced

when

replacing

the

thermostat.

1.

Remove

the

lower fan duct

work

from the

evaporator

cover.

2

Remove

the

1/4-in.

evaporator

cover screws

and

remove

the evaPorator

cover.

3.

Disconnect

the

defrost

thermostat

wiring

connector.

4. Remove

the

defrost

thermostat

from

the

evaporator.

Defrost

Heater

The

defrost

heater

is located

at the bottom

of the

evaporator.The

defrost

heater

heats the

evaporator

in

the defros{

mode of operation.The

thermostat

must be

replaced when replacing

the

defrost

heater.

1.

Complete

defrost

thermostat

procedure.

2.

Remove

Phillips

head defrost

heater

mounting

screws

(2).

3.

Remove

the

defrost

heater.

GEAOMG2

GEAO@63

-27

-

Page 30

n

Condenser

Fan

The condenser

fan

is located in the rear of the

unit.

It

provides

forced-draft

cooling

for the condenser

coil.

1. Remdve

the

1i4-in. back

panel

access screws

(5)

and

remove

the

back

Panel.

2. Remove

the

1/4-in.

condenserfan

mounting

screw and

slide

the

lan out untilthe

wire is

exposed.

3. Disconnect

the supply

wire connector.

Main Processor

Card

The main

processor

card

is located in

the

back of

the

unit.

This card

controls the operation of

the

unit. lf a fan short

has

occurred,

replace the

fan

prior

to

the card

or the card

will be destroyed.

1.

Secure

power

to the unit.

2. Remove

the

1/4-in.

processor

card

panel

screws

(10)

and

rernove

the

panel.

Disconnect

the

processor

cable

connectors.

Remove the

card by

unlocking

plastic

locks

located

at

the comerc

of

the card.

Water Solenoids

When

the solenoids

receive a signalfrom

the

processor,

they route

water to the filter, cooler, and

icemaker.

1. Remove

the 1/4-in.

rear

panel

screws

(10)

and

remove

the

rear

panel.

2. Remove

the

1/4-in.

bracket screw.

3.

Slide

the

solenoid

assembly out.

4.

Disconnect

the

cable assembly.

5. Disconnest

the

water

tube.

To disconnect

the

quick

connect,

push

the black collar

in and

pull

the

tube

out.

6.

Remove

the solenoid.

3.

4.

o

-29-

Page 31

r

-30-

Page 32

/t\

o

-31

-

Page 33

Table

of

Contents

Efficient

Use

of Diagnostics

...

g2

Failure

Gauses

(table

1)

...

......

3il

Self Diagnostics

......

3lt

Diagnostic

Tests

ftable

2)

.

. .

35

Communication

Tests

(0

2,

0 3, or

0 4)

. . .

35

Temperature

Control

Panel

Self-Test

(0

6)

.

gs

_

Dispenser

Board.

36

Control

and

Sensor System

Self-Test

pn.

r o i '

36

Main

Control

Board

(Low-Voltage

Side)

......

97

Main

Control

Board

(120-VAC

Side)

38

Main

Control

Board Locator

Table

(Low-Voltage

Side)

gg

Main

Control

Board LocatorTable (l2GVAC

Side)

40

Unit Dead,

No