Page 1

SAFETY PRECAUTIONS

1. Check if an electric leakage occurs in the set.

2. When servicing current applying parts, unplug prior to

servicing.

3. In case of testing with power injecting, wear rubber

gloves to prevent electric shock.

4. If you use any appliances, check regular current, voltage

and capacity.

5. Don't touch metal products in cold freezer room with wet

hand. It may cause frostbite.

SERVICING PRECAUTIONS

6. Prevent water flowing to electric elements in mechanical

parts.

7. When sloping the set, remove any materials on the set,

especially thin plate type(ex,: glass plates or books.).

8. When servicing evaporator part, wear cotton gloves

without fail. It is to prevent wound by sharp fin of

evaporator.

9. Leave a breakage freezing cycle to a heavy service

center. The gas in cycle inside may soil ambient air.

AIR RECHARGING IN COMPRESSOR

Test the refrigeration system by connecting it electrically

before refilling operation. This is necessary to ascertain the

function of the motor-compressor and identify the defects

immediately. If the defects have been found, empty the old

system of eventual R-12 residue by breaking off the end of

the extension piece at its narrow point. (Figure 1)

Replace the filter and any damaged components. Unsolder

and pull off the piece remaining inside the service tube and

then attach an extension completely with male Hansen and

last, solder it to the same tube again. (Figure 2)

POINT TO BE

BROKEN

SERVICE TUBE

EXTENSION

CHARGE TUBE FEMALE

EXTENSION HANSEN

MALE

HANSEN

SOLDERING

POINT

It is necessary to execute the soldering operation with

valve open so that the fumes caused by oil residue can

come out freely without blowholes between two tubes

during heating the point to be soldered.

The extension fitted with the male Hansen is connected to

the female fitting of the vacuum pump tube. (Figure 3)

Air evacuating from the system begins as soon as the

pump starts. The refrigeration system must be kept under

vacuum until the reading on the low-pressure gauge

indicates vacuum (0 absolute, -1 atm., -760 mm Hg) in any

case it is advisable to keep the pump running for about

30 minutes. (Figure 4)

PRESSURE

GAUGE

Figure 1

Figure 2

Figure 3 Figure 4

-3-

Page 2

In case that a considerable leakage occurs and to stop the

vacuum pump will be necessary and add a small quantity

of Freon to the system, if vacuum should not be obtained

(pressure gauge can't fall to 1 atmosphere.), start the

refrigeration unit and find the leakage with the special

leak-finder. When the defective soldering point is visible,

re-do it after opening the extension tube valve and

reestablishing the normal outside pressure inside the

group.

Because the melted alloy is sucked into the tubes and

block them, the pressure must be rebalanced when

vacuum is in the system in soldering. As soon as the

vacuum operation is over, add the quantity in grams of R-

12 to the refrigeration system. Remember that every

system has an exact quantity of R-12 with a tolerance of

+5 grams than can be added. (Figure 5)

Before performing this operation (if the vacuum pump and

refilling cylinder are connected), make sure that the valve

placed between the vacuum pump and refilling tube are

closed to keep the Freon for adding to the system. (Figure 6)

FILLING OR VALVE TO BE

_ CHARGE TUBE OPENED WHEN

TO THE TO THE

REFRIGERATION CHARGE

SYSTEM CYLINDER

TO THE VALVE TO BE

VACUUM CLOSED

PUMP AFTER VACUUM

Figure 6

REFILLING

TO THE

R-12 CYLINDER

__ TO THE

= REFRIGERATION

SYSTEM

Figure 5

In addition, check the graduated scale on the cylinder for

the quantity of R-12 to be added, for example, if we have

750 grams of Freon in the cylinder and must add 165

grams to the group, this amount will be reached when R-12

has dropped to 585 grams, remembering that the indicator

shows a lower limit of meniscus. Do this after choosing the

scale corresponding to the gas pressure different scales

reported as the same gas pressure indicated by the

pressure gauge on the top of the column.

To make R-12 flow into the system, open the valve placed

at the base of the cylinder and connected to the filling tube.

The amount of Freon cannot be added to the system all at

once because it may cause a blocking of motor-compresson

Therefore, proceed by adding original quantity of about

20-30 grams and close the valve immediately.

The pressure rises and the motor-compressor must start,

sucking the gas and making the pressure go down again.

Regulate the valve again, maintaining the same manner

until reaching the quantity of R-12 established for the

system being charged. When the system is running, the

suction pressure must be stabilized from 0.30 to 0.6

atmosphere.

-4-

Page 3

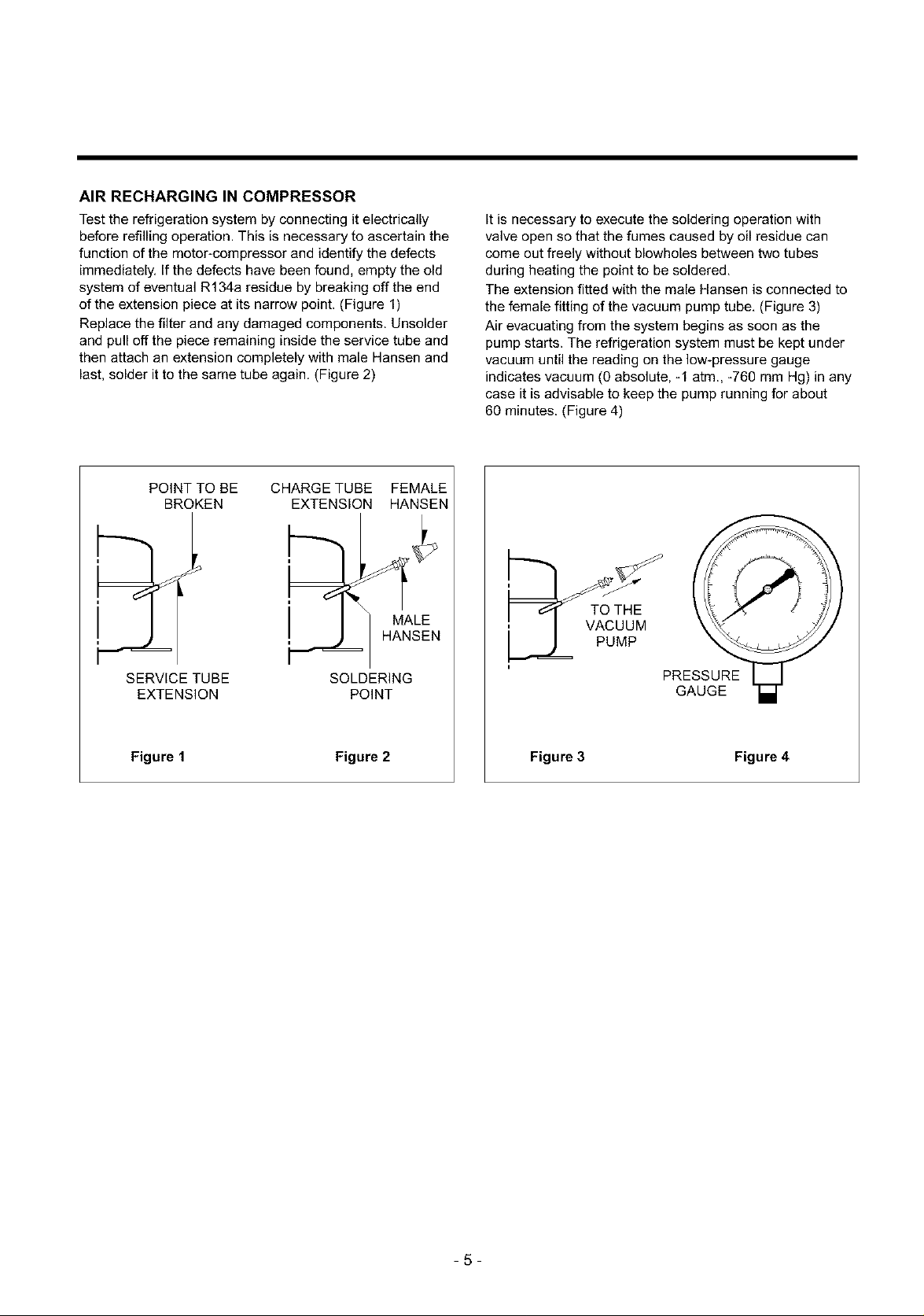

AIR RECHARGING IN COMPRESSOR

Test the refrigeration system by connecting it electrically

before refilling operation. This is necessary to ascertain the

function of the motor-compressor and identify the defects

immediately. If the defects have been found, empty the old

system of eventual R134a residue by breaking off the end

of the extension piece at its narrow point. (Figure 1)

Replace the filter and any damaged components. Unsolder

and pull off the piece remaining inside the service tube and

then attach an extension completely with male Hansen and

last, solder it to the same tube again. (Figure 2)

It is necessary to execute the soldering operation with

valve open so that the fumes caused by oil residue can

come out freely without blowholes between two tubes

during heating the point to be soldered.

The extension fitted with the male Hansen is connected to

the female fitting of the vacuum pump tube. (Figure 3)

Air evacuating from the system begins as soon as the

pump starts. The refrigeration system must be kept under

vacuum until the reading on the low-pressure gauge

indicates vacuum (0 absolute, -1 atm., -760 mm Hg) in any

case it is advisable to keep the pump running for about

60 minutes. (Figure 4)

POINT TO BE

BROKEN

SERVICE TUBE

EXTENSION

Figure 1

CHARGE TUBE FEMALE

EXTENSION HANSEN

MALE

HANSEN

SOLDERING

POINT

Figure 2

MP

PRESSURE

GAUGE

Figure 3 Figure 4

-5-

Page 4

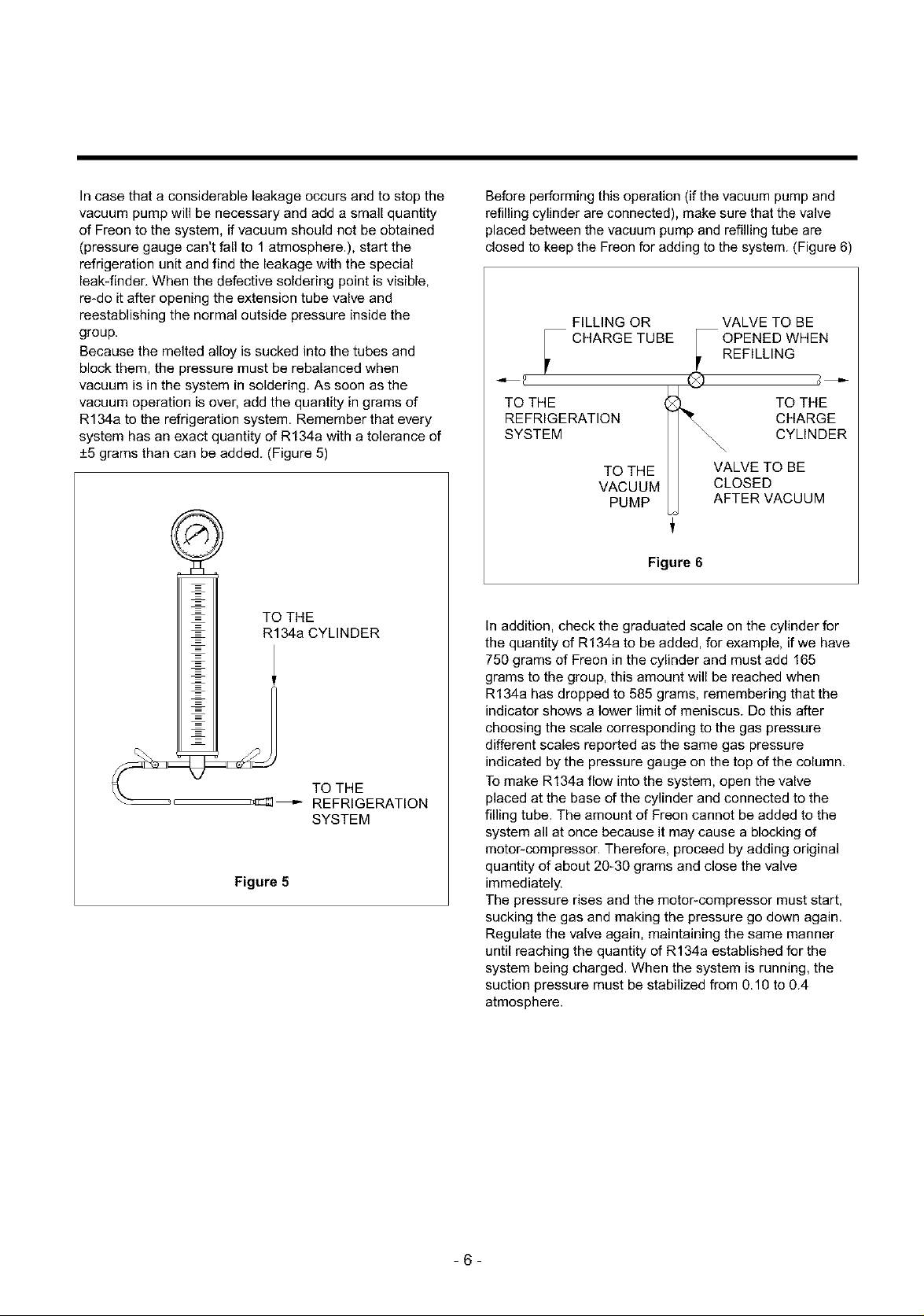

In case that a considerable leakage occurs and to stop the

vacuum pump will be necessary and add a small quantity

of Freon to the system, if vacuum should not be obtained

(pressure gauge can't fall to 1 atmosphere.), start the

refrigeration unit and find the leakage with the special

leak*finder. When the defective soldering point is visible,

re*do it after opening the extension tube valve and

reestablishing the normal outside pressure inside the

group.

Because the melted alloy is sucked into the tubes and

block them, the pressure must be rebalanced when

vacuum is in the system in soldering. As soon as the

vacuum operation is over, add the quantity in grams of

R134a to the refrigeration system. Remember that every

system has an exact quantity of R134a with a tolerance of

+5 grams than can be added. (Figure 5)

Before performing this operation (if the vacuum pump and

refilling cylinder are connected), make sure that the valve

placed between the vacuum pump and refilling tube are

closed to keep the Freon for adding to the system. (Figure 6)

FILLING OR VALVE TO BE

_ CHARGE TUBE OPENED WHEN

TO THE TO THE

REFRIGERATION CHARGE

SYSTEM CYLINDER

TO THE VALVE TO BE

VACUUM CLOSED

PUMP AFTER VACUUM

Figure 6

REFILLING

TO THE

R134a CYLINDER

Figure 5

TO THE

REFRIGERATION

SYSTEM

In addition, check the graduated scale on the cylinder for

the quantity of R134a to be added, for example, if we have

750 grams of Freon in the cylinder and must add 165

grams to the group, this amount will be reached when

R134a has dropped to 585 grams, remembering that the

indicator shows a lower limit of meniscus. Do this after

choosing the scale corresponding to the gas pressure

different scales reported as the same gas pressure

indicated by the pressure gauge on the top of the column.

To make R134a flow into the system, open the valve

placed at the base of the cylinder and connected to the

filling tube. The amount of Freon cannot be added to the

system all at once because it may cause a blocking of

motor*compressor. Therefore, proceed by adding original

quantity of about 20-30 grams and close the valve

immediately.

The pressure rises and the motor*compressor must start,

sucking the gas and making the pressure go down again.

Regulate the valve again, maintaining the same manner

until reaching the quantity of R134a established for the

system being charged. When the system is running, the

suction pressure must be stabilized from 0.10 to 0.4

atmosphere.

-6-

Page 5

SPECIFICATIONS

ITEMS SPECIFICATIONS

DOOR TYPE 1 DOOR

NET CAPACITY 94 l

CONDENSER TYPE WALL CONDENSER

(FLUSH BACK)

DEFROSTING SYSTEM MANUAL

TEMPERATURE CONTROL KNOB DIAL

PARTS IDENTIFICATION

EVAPORATOR(DoorInside)

- The heartof the refrigerator.

- It evaporates the refrigerant

fluid and thereby absorbs

heatfrom the surrounding.

ITEMS

INSULATION DO_OR

_ CABINET

EVAPORATOR

DIMENSION

NET WEIGHT

REFRIGERANT

VS Series

COMPRESSOR

LUBRICANT

NS Series

COMPRESSOR

SPECIFICATIONS

POLYURETHANE

POLYURETHANE

ROLL BOND TYPE

463(W)X830(H)X500(D)mm

22 Kg

R-12(67g) R-134a(60g)

HTS-150 FREOL a 22G

(200cc) (200cc)

HTS-150 FREOL a 22G

(180cc) (180cc)

THERMOSTAT

Regulates the operation of

the motor and controls the

temperature inside the

refrigerator.

ICE CUBETRAY(DoorInside)

Ice cube is easy to remove

from the tray

DRIP TRAY

Catches the water that

drips off the evaporator

when defrosting.

PLASTIC COATED

SHELVES

Have full width and can

slide out.

PVC BAR

Keeps any kinds of fruits

and vegetables.

NOTE : This is a basic model. The shape of refrigerator is subject to change.

SUPPORTER CAN

Keeps any kinds of bottles.

MAGNETIC GASKET

- Tight fitting door seal

keeps all the cooling

power locked inside,

- No hooks or latches.

-7-

Page 6

DISASSEMBLY

A. DOOR

1. Loosen 3 screws holding an upper hinge to separate the

door body. (Figure 7)

Figure 7

B. THERMOSTAT

1. Pull Knob Dial,

2. Loosen 1 screw holding the case and pull it out to

remove the Therme cover. (Figure 8)

C. COMPRESSOR AND PTC

1. Remove Clamp, Protector Cover, Power Cord and Lead

Wire first. (Figure 10)

2. Separate OLR

3. Separate PTC.

4. Remove the Compressor Base by loosening 4 bolts fixed

to base plate of the set. (Figure 11)

-%

Figure 10

5. Remove the Compressor by loosening 2 earth screws

next to Compressor.

NOTE : Replace the Compressor, after peeling off

painted part of earth terminal.

• Compressor inhales the gas evaporated from Evaporator

and condenses this gas and then delivers to Condenser.

• PTC is abbreviation of Positive Temperature Coefficient

and is attatched to the Compressor, and operates motor.

• OLP prevents Motor coil from being started inside

Compressor.

• Do not turn the Adjust Screw of OLP in any way for

normal operation of OLR

Figure 11

Figure 8

3. Pull out thermostat in the theremostat cover, and

disconnect lead wires. (Figure 9)

NOTE : Replace a new thermostat with proper specification.

@

Figure 9

-8-

Page 7

CIRCUIT DIAGRAM

THERMOS'[A'T

4

YL _ BK

GN{GN_L)t <_ BK

s_

YL: YELLOW

BK: BLACK

BL: BLUE

GN:GREEN

it"__FL_REs_oR

P.T.C STARTER

THE PLUG TYPE ON CIRCUIT DIAGRAM IS SUBJECT

TO CHANGE IN DIFFERENT LOCALITIES. J652-00041C

Page 8

TROUBLESHOOTING

DEFECT EFFECT CAUSE REMEDY

GROUP PARTIALLY

OR COMPLETELY

OUT OF

REFRIGERANT

CHARGE

EXCESSIVELY

FULL

HUMIDITY IN THE

SYSTEM

PRESENCE OF AIR

IN THE SYSTEM

Evaporatordose notfrosteven

thoughmotoFcompressorruns

continually.

This defect is indicatedby the

presenced water outside

refrigeratornearthemotor caused

byformationsof ice onthe return

tube.

This defect is indicatedby thepartial

frosting of the evaporatorandby

continualdefrostingcycles

determinedbythe interruptionof the

flow of gas onthe evaporator.The

motorcompressorkeepsrunning.

Poorperformanceofthe refrigerant

systemwhich is indicated:onthe

evaporatorwitha slightfrostwhich

dosenot freezeandanexcessive

overheatingof thecondenserand

motor-compressor.

An emptyrefrigerantsystem

indicatesa leakageof R134a This

lossis generallyto belookedfor at

the soldering pointsconnectingthe

variouscomponentsor in an

eventualholeintheevaporator

madebythe user.

Ifin therefrigerantsystema quantity

of R134aisintroducedwhichis

greaterthan that indicated,the

excessgas dosenot terminateits

expansionin the evaporatorbut

proceedsintothe returntube.

The refrigerantsystemis humid

when there isasmall percentageof

waterpresentwhich,notcompletely

retainedbythe dehydratorfilter,

enters into circulationwiththe Freon

andfreezes atthe capillaryexitin

the evaporator.

There isair in arefrigeratingsystem

when duringthe fillingphase

vacuum isnoteffectedorit is not

adequatelydone.

Leakagemust beeliminatedby

resolderingthe defectivepointor

substitutingthedamaged

evaporator.

Thesystemmustbe emptiedand

subsequentlyrefilledintroducingthe

correctquantityof R134a.

Thesystemmustbe emptiedand

thenrefilledafter eliminatingthe

humidity.

Groupmustbedrainedand

subsequentlyrefilledaftercarefully

creatingvacuum.

BLOCKED

CAPILLARY

MOTOR-

COMPRESSOR

SHORT-CIRCUITED

OR BLOCKED

MOTOR-

COMPRESSOR

DOSE NOT

COMPRESS

NOISY MOTOR-

COMPRESSOR

Becauseof thelackof circulation

Freonin the system,there is no

frosting of the evaporator,whilea

slightoverheatingofthe first spiralof

the condenseris noted.

The systemdose notworkandthe

"clixson" intervenesinterrupting

deliverytothe motorraompressor.

Nofrostformsonthe evaporator

evenifthe motor-compressoris

apparentlyrunning regulary.

Incaseof mechanicalfailureinthe

motor-compressorthere in an

excessivenoisewhenthe systemis

functioning:incasea suspension

spring isunhooked,bangingwill be

heardand therewill be especially

strong vibrationswhen the system

startsup andstops,

Eventualimpuritiescontainedin the

Freonor inthe componentsofthe

refrigerationsystembefore

assemblyandnot retainedbythe

filter can obstruct thecapillary.

Incaseof shortcircuit,the

breakdownis dueto the electric

winding:if blocked,thereis a

mechanicalfailureinthe motor-

compressoE

Inthiscasethere isa mechanical

failurein the diaphramvalveswhich:

remainingcontinuallyopen, do not

permitthepistonto suckand

compressorthe which

consequenteIydosenot circulatein

the system.

The causeof the excessivenoise is

normailytobe soughtfor ina

mechanicalbreakdown,andonly

rarelyinthe unhookingofone of the

suspensionsprings.

Torestore the systemitmust be

emptied,substitutethe capillaryor

the evaporatorentirelyin casethe

capillaryis coaxialwith respectto

the return tube, then refillit.

Themotor-compressormustbe

replacedand thenproceedwith

refilling.

Themotor-comprossormustbe

replacedand thenproceedwith

refilling.

Themotor-comprossormustbe

substitutedand thenproceedwith

the refilling.

-10-

Page 9

NO COOLING

The Compressor

doesn't run,

Check if the current

flows at the contacting

Poor contacting point

Replace the

Thermostat.

Check if the current flows

at the contacting point of

the starting system.

Check if the current

flowing of the sub coil of _ "

Poor contacting point

and broken

Replace the device.

-11-

Page 10

COMPRESSOR AND ANOTHER ELECTRIC COMPONENTS

Check the L

resistance of the

Compressor Motor.

Separate the PTC-STARTER from

the Compressor and measure the

voltage between M and C of the

Compressor.

Equal to the applied _ r_

voltage. (Rating _ 2>

voltage + 10%) I

YES

YES

NO

OLP works within 30 sec.

in forcible OLP operation

by turning instant power on _ NO _

NO

Measure minimum starting voltage

after checking steps 1-3 above.

And measure the pressure balance

of the PTC with the interval of

more than 5 min.

YES

Replace OLR

-12-

Page 11

PTC

Poor starting or no

operating of the

Compressor.

First, separate the PTC from

the Compressor and check the

4D

voltage between NO 5 and 6

in the PTC with a muititester or

Wheatstone Bridge.

F

Separate the OLP from

the Compressor and

check resistance value

4m

between two terminals of

OLP with Tester.

Normal _ Check another

__ Abnormal _ Replace the

_{_ Abnormal _ Replace the

electric

components.

PTC.

PTC.

-13-

Page 12

EXPLODED VIEW

-14-

Page 13

-15-

Page 14

HOME DEPOT(HDP) Electrical Specification

ITEM GR-051SF GR-131SF GR=151SF

BUYER MODEL NAME GR_051SF GR_131SPF GR-151SPF

RATED INPUT(W) 70+15% 70+15% 70+15%

DEFROST INPUT(W)

ENERGY CONSUMPTION(kwh/yr) 288 330 350

AMPERE(Amp) 0.84 1.0 0.7

RATING(V/Hz) 115/60 115/60 115/60

REFRIGERANT R134a R134a R134a

CHARGE(Oz) 1.41 2.12 3.35

COMPRESSOR NS24LBCM NS24LBCG NS30LACM

OLP 4TM232NFB 4TM232NFB 4TM265MFB

PTC P6R8MD P6R8MC P6R8MD

CAPACITOR-R 101JF/250VAC 101JF/250VAC

CAPACITOR-S

Loading...

Loading...