Sears Gamefisher 298.585130 Owner's Manual

MODELNO.

298.585130

• owner's

responsibility

• maintenance

,_operation

• trouble

shooting

,= replacement

paris

Publication No.

970-35118-203

TABLE OF CONTENTS Pag,,No.

SPECIFICATIONS ......................................... I

OWNER'S RESPONSIBILITY ................................. 2

STEERING HANDLE INSTALLATION 4

MAINTENANCE , ......................................... 4

LUBRIC'_kTION GEAR HOUSING ............... ,............ 4

MUFFLER INSPECTION .......... ........................ 4

PROLONGED STORAGE .................................. 4

'OPERATIONS ............................................ S

BOAT MOUNTING ................ . ..................... 5

STEERING ADJUSTMENT ................................ 5

2-CYCLE ENGINE FUEL MIXTURE ......................... 6

STARTING PROCEDURES - 6

STOPPING PROCEDURES ........... ..................... 6

FLOODING ........................................... 7

CARBURETOR ADJUSTMENTS " 7

PROPELLER SHEAR PIN .......... • ...... . ................ 7

IGNITION SYSTEM ..................................... 8

REMOVING MOTOR FROM BOAT .......................... 8

SALT WATER OPERATIONS .............................. 8

TROUBLE SHOOTING CHECK LIST .......................... 9

_R EPLACEMENT PARTS .................................... I0

• ORDERING PROCEDURES .... ; ................. Outside Back Cover

PRODUCT WARRANTY - Outside Back Cover

SPECIFICATION

Type of Engine ........................... Air Cooled 2-Cycte

Horsepower ........................................ 1.2

Maximum RPM .................................... 7500

Weight . ,................ (6 kg) ........ 13-1/2 Lbs. Approx.

Bore and Stroke ........... (30 mm x 30 mm) .... 1.19" x t.19"

D_splacement ............. (22 cc) ............... 1.39 cu.in.

Fuel Capacity-Engine Tank .... (0.7 liters) .............. 3/4 qt.

Igmtlon .............................. Flywheel Magneto

Spark Plug ................... "_ ........... Champion RCJ-8

Spark Plug Gap Setting ....... (0.6 ram) ................. 025"

Bearings (Engine) .................................... Ball

Bearings (Gear Hsg.) ....................... Ball & Oilite Bronze

Staster Recoil

Propeller Dia. and Pitch ...... (150 mm x 72 ram) 5-29/32" x 2-13/16"

Lub. (Gear Hsg.) ................................. SAE 90

Fuel M_xture . . . 50 to 1 ratio of regular grade gasoline to 2-cycle outboard

lubricant or its equivalent BIA certified TC-W 2-cycte outboard lubricant.

Steering ................................ 130 ° Pivot Steering

IMPORTANT

Owner's Responsibility and Operating Safety Check List

BE SURE TO READ AND DO THE. FOLLOWING BEFORE

OPERATING YOUR OUTBOARD MOTOR

SAFETY CHECK LIST

I. Learn and observe the boating Jaws of the U.S, Coast, Guard, state, local author-

ities.

2. U,S. Coast Guard regulations require the following:

a. Provide an approved life-vest, type 1,2 or 3, Personal Flotation Device for each

person in boat. (Encourage passengers to wear them.)

b, If the boat exceeds 16 feat, also carry e type 4, throwable Personal Flotation

Device.

3. Do not fill fuel tank with motor running or near any flame or lighted smoking

material.

4. When loading boat distribute the load evenly, keep the load low; don't overload;

don't stand in a small boat. Take weather and water conditions into account.

5. Do not permit persons to ride on parts of the boat not designed for such use.

Standing, bow riding and seat back or gunwale riding can be especially dangerous.

OWNER'S RESPONSIBILITY

6. Read owner's manual before running your new outboard motor.

7. Before starting, make sure your motor is securely mounted to boat transom with a

. safety chain. Tighten clamp stud handles securely by hand.

8. Be sure to have pliers, screwdriver, spare spark plugs, wrench, shear pins and cotter

pins in boat whenever leaving shore.

g. Be sure to have an adequate supply of fuel (carry only in an approved container) on

b_ard, Use a good grade of regular gasoline with proper mixture, as cdted in the

SpeciHcations.

10. Occasionally check to be sure clamp stud handles on transom mounting bracket are

tight.

11. IN CASE OF AN EMERGENCY, THE ENGINE CAN BE STOPPED BY DEPRES-

SING THE STOP BUTTON (IF SO EQUIPPED) OR PLACING CHOKE KNOB IN

FULL CHOKE POSITION.

12. Keep an alert lookout. Serious accidents have resulted from failure to u_e eyes,

13. Keep firefighting and lifesaving equipment in good condition and readily accessible

at all t_mes.

14, Good housekeeping is even more important afloat than ashore. Cleanliness dimin-

ishes the probab)tity of fire and tripping hazards,

TIPS FOR TRAILERING OR AUXILIARY USE

15. When launching or loading boat on a trailer, place your outboard motor in the

tilted storage position. Also when trailering your boat and outboard motor, keep

outboard motor in upright (vertical) position on the boat transom. Outboard

motors transported across rough roads in the "tilt" position could cause transom.

damage or mounting brackets to break off, losing your motor. If motor must be

trailered in "tilt" position, a short length of 2 x 4 should be placed between the

motor bracket and the motor leg. The motor leg should then be firmly tied down

against the 2 x 4 to prevent any possible damage, Similar precautions should be

taken if using the motor as an auxiliary power source for a sailboat or power boat.

When using motor as an auxiliary power source, the use of an auxiliary adjustable

position motor bracket is recommended.

2

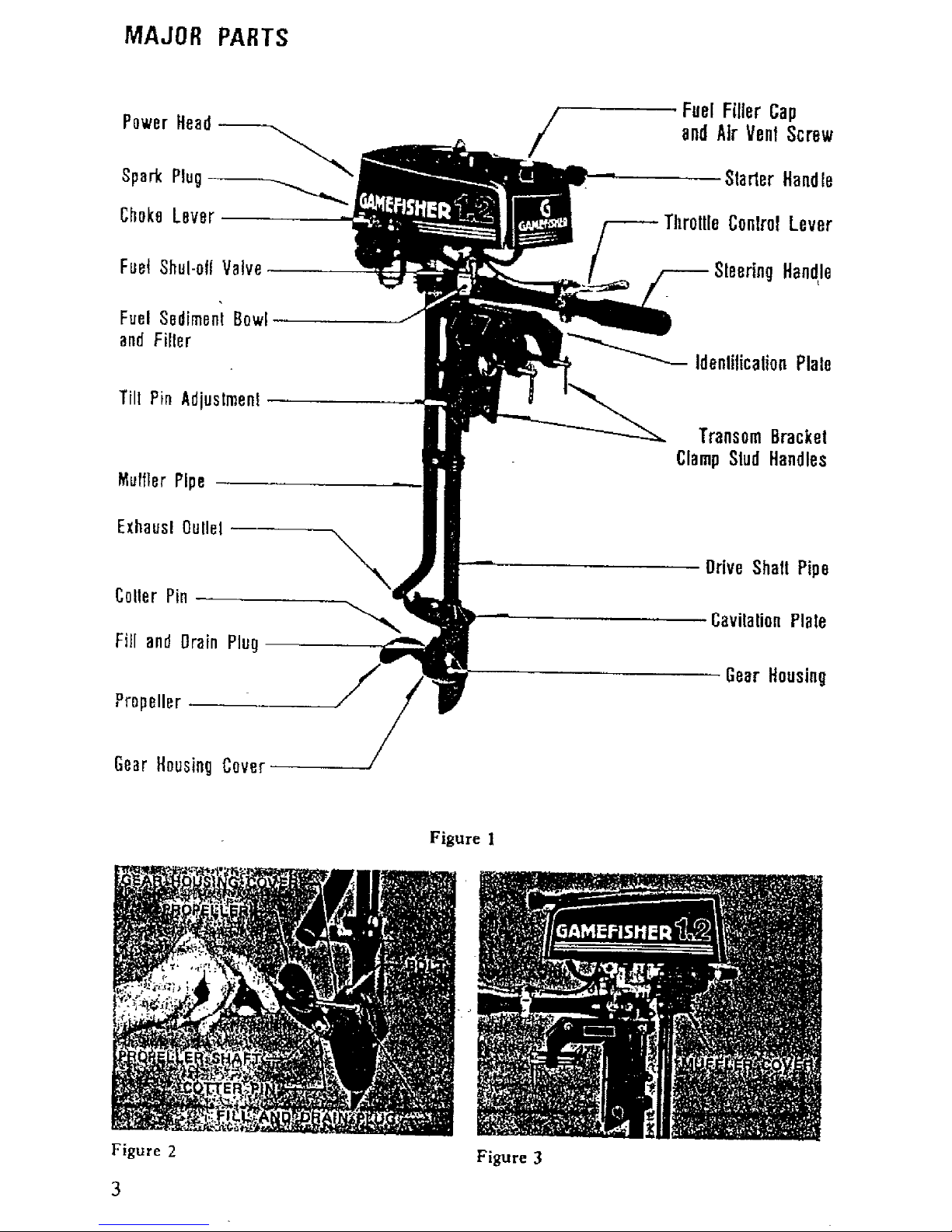

MAJOR PARTS

PowerHeed

SparkPlug

FuelShul-oflVatve

FuelSedimentBow[

andFilter

Tilt Pin Adjustment

MufflerPipe

ExheuslOullel

CoUerPin

Fill andDrainPlug

\

Propeller

/

-Fuel Filler Cap

andAirVenl Screw

Slarter Handle

Throllle ConlrolLever

SleetingHandle

IdenlilicalionPlale

TransomBracket

ClampSludHandles

Drive Shall Pipe

CavilaUonPlate

GearHousing

Figure 2

Figure 1

3

Figure 3

INTENANCE

! FEATURE INFORMATION

This outboard motor has special design

features as shown in Figure 1;

Your selection of our Marine Products will

!provide you with many hours of enjoyable

iboating. To assure your conll01e_te satisfac-

i_ion on the investment you have just made,

iwe ask you to read this manual thoroughly

before going afloat. Acquaint yourself with

]the particular areas of operation on your

ioutboard motor as you read the step-by-step

_procedures. Keep _n"mind maximum per-

formance is achieved only when the owner

or operator is completely familiar with the

operating instructions.

Periodic servicing will be required. It is

recommended that you consult your Sears

Service Center when service is necessary.

We wilt be happy to extend our facilities

and assure prompt service.

STEERING HANDLE INSTALLATION

move snap pin and washer 5 from, .ste.ering

dle, screw handle mounting bolt in joint

e holder and stop steenng handle, Then push

;_ove at tip of steering handle against handle

pper.

it washer 5 in over handle mounting bolt and

iert snap loin.

LUBRICATION--GEAR HOUSING

The Gear Housing has been pre-lubricated at

the factory; however, the grease level should

be checked as follows using SAE 90 out-

board motor grease. (See Figure 2).

(1) Prior to initial operation,

(2) After first four (4) hours of use.

(3) Recheck after every fifty (50) hours

running time.

(4) Replace with new lubricant at the end

of your outboard motor season. This

is =mportant. as it removes any water

from the gear housing and prevents

I

[ possible corrosion to internal parts.

! To Check, Drain or Fill gear housing, follow

these steps:

(1) Position outboard motor upright.

(2) Remove drain plug and washer, then

insert nozzle of gear lubricant tube

into hole.

(3) Squeeze tube untii lubricant is forced

out around tube.

(4) Replace plug and washe(. Be sure piug

is tightened securely.

(5) To achieve complete drainage of-_ubrJ-

cant, remove cotter pin, propeller and

shear pin from propeller shaft, also,

gear housing cover by unscrewing 2

bolts.

C°

(6) When lubricant has completely drained,

reptape parts and refill gear housing

using filling procedure above,

For best results, lubricate propeller shaft

with lithium grease every 30 to 60 days.

4. MUFFLER INSPECTION

a. Perlod_calI¥ remove muffler cover by un-

screwing screws and inspect for carbon

build-up inside the muffler inlet and outlet,

the exhaust port end the combustion

chamber of the cylinder, Excessive carbon

will prevent drawing the maximum power

ou't of the engine. {See Figure 3).

b. Care should be exercised while cleaning

away carbon to prevent scratches to the

surface of the engine components and drop-

ping carbon inside of crankcase.

5. PROLONGED STORAGE

a. To store your outboard motor for pro-

longed storage, prepare outboard as fol-

lows;

(I) See paragraph on stopping procedures.

(2) When removing outboard motor from

boat, allow all water to drain from

unit.

(3) The outboard motor should be

mounled on a stand vertically with

power head up for storage.

(4) Pull starter handle slowly untd resist-

ance is felt due to compression pres-

sure, then stop. Release starter tension

slowly to prevent engine from revers-

ing rotation due to comoression

pressure. This position will close both

the intake and exhaust ports for

storage.

(5) Drain and fill gear housing as outlined

under Lubrication of Gear Housing.

(6) Wipe exterior completely with fresh

water cloth and then apply light coat-

ing of oil.

b. When starting a new season, always use fresh

gasoline. Last year's gasoline may have

varnish deposits that wil} plug the carbu-

retor jets. thus requiring a complete over-

haul.

c. To plan for the coming season, we recom-

mend Vou contact your Sears Service

Center before the new season for any service

repair work required.

JPI'HA[ IL1N

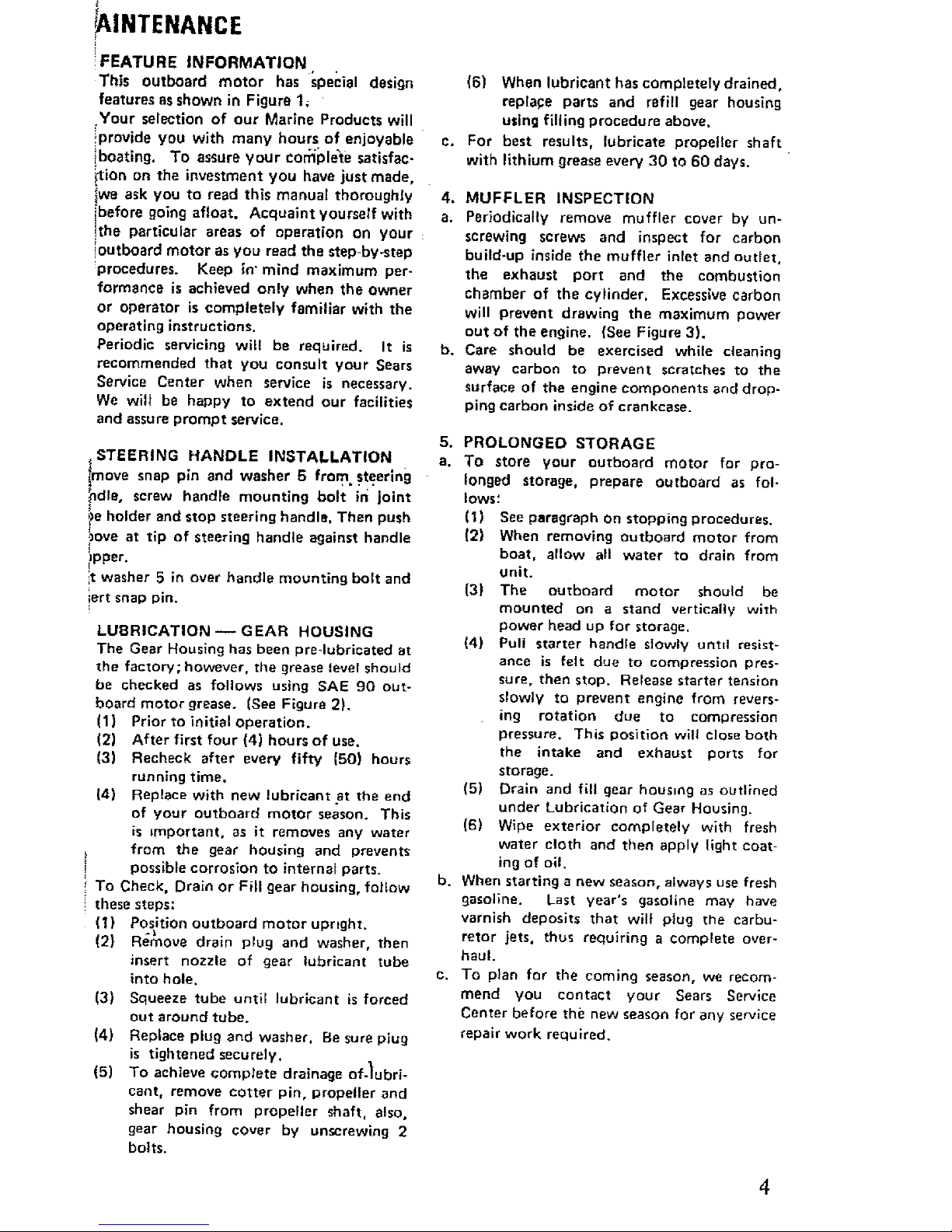

,. BOAT MOUNTING

Mount the motor on the center of the boat

transom (stern). (See Ftgure4).

CAUTION

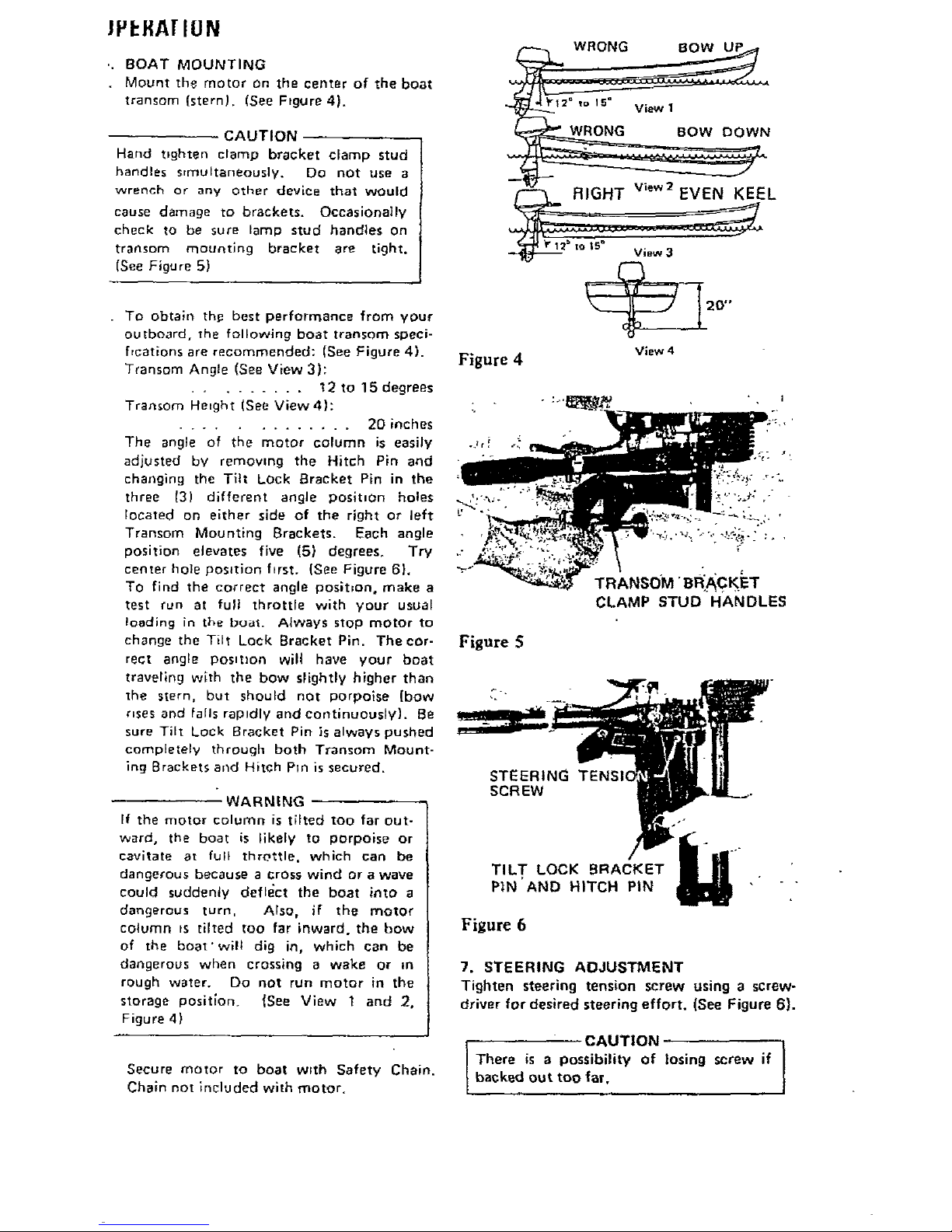

Hand t_ghten clamp bracket clamp stud

handles stmultaneously. Do not use a

wrench or any other device that would

cause damage to brackets. Occasionally

check to be sure lamp stud bandies on

transom mounting bracket are tight.

(See Figure 5)

To obtain thp best performance from your

outboard, the following boat transom speci-

frcations are recommended: (See Figure 4).

Transom Angle (See View 3):

......... t 2 to 15 degrees

Transom Height (See View4):

............. 20 inches

The angle of the motor column is easily

adjusted bv removing the Hitch Pin and

changing the Tilt Lock Bracket Pin in the

three t3) different angle positnOn holes

located on either side of the right or left

Transom Mounting Brackets. Each angle

position elevates five (5) degrees. Try

center hole position f_rst. (See Figure 6},

TO find the correct angle poslt=on, make a

test run at full throttle with your usual

loading in the boat. Always stop motor to

change the Tilt Lock Bracket Pin. The cor-

rect angle Posnt_on wil! have your boat

traveling with the bow slightly higher than

the stern, but should not porpoise [bow

r=ses and falls rapidly and continuously). Be

sure Tilt Lock Bracket Pin is always pushed

completely through both Transom Mount-

ing Brackets and Hitch Pm is secured.

WARNING

If the motor column is tilted too far out-

ward, the boat is likely to porpoise or

eavitate at full throttle, which can be

dangerous because a cross wind or a wave

could suddenly deflect the boat into a

dangerous turn, Also, if the motor

column us tilted too far inward, the bow

of the boat'will dig in, which can be

dangerous when crossing a wake or tn

rough water. Do not run motor in the

storage position. {Sea View 1 and 2,

Figure 4)

Secure motor to boat wrtb Safety Chain.

Chain not included with motor.

Figure 4

.... ! ._

__ 20°"

View 4

Figure 5;

TRANSOM' 13RI._€I_ET

CLAMP STUD HANDLES

STEERING TENSI(

SCREW

TIL T LOCK BRACKET

PIN AND HITCH PIN

Figure 6

7. STEERING ADJUSTMENT

Tighten steering tension screw using a screw-

driver for desired steering effort, (See Figure 6).

I CAUTION

There is a possibility of losing screw if

backed out too far,

OPERATION

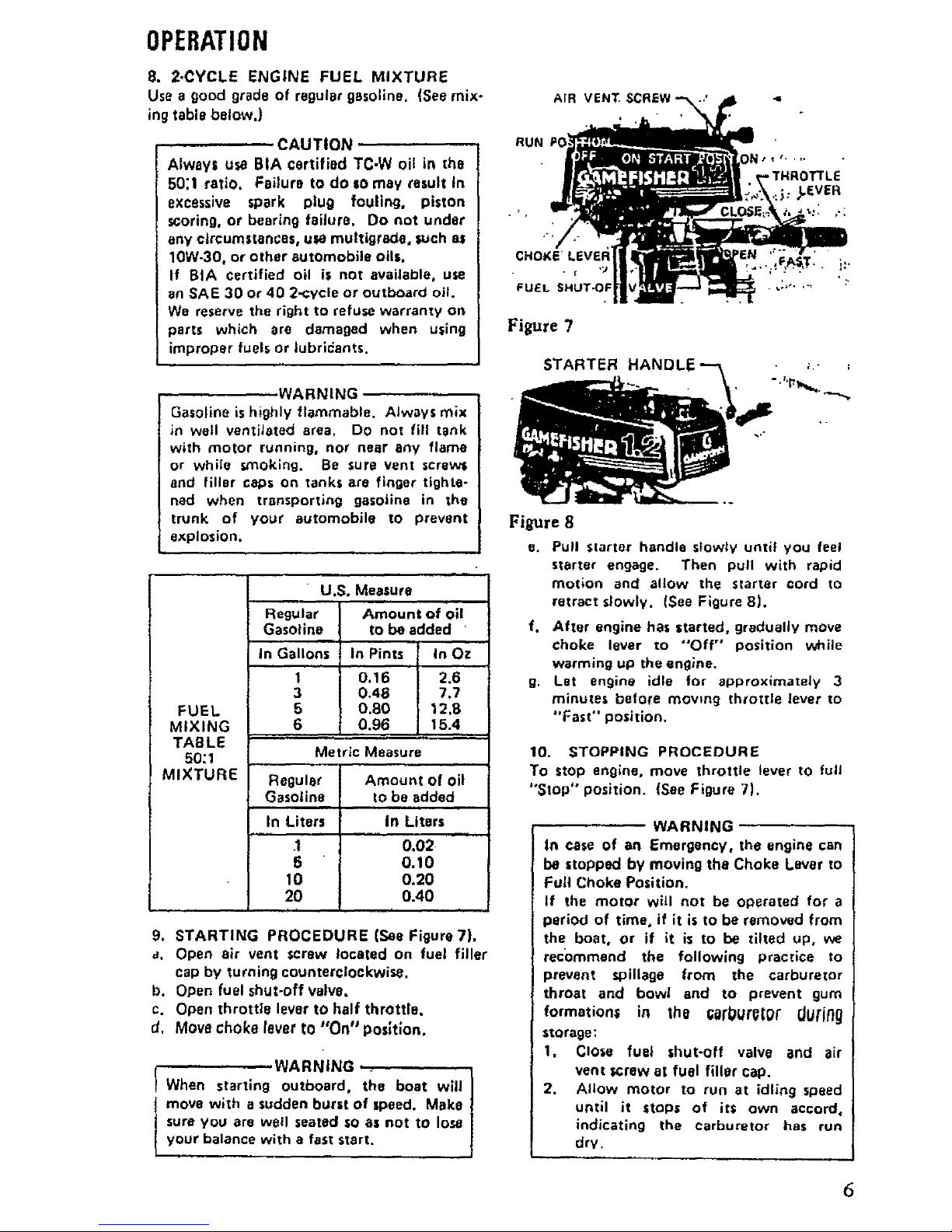

8. 2-CYCLE ENGINE FUEL MIXTURE

Use a good grade of regular gasoline. (See mix-

ing table below,)

CAUTION

Always usa BIA certified TC-W oil in the

50:1 ratio, Failure to do =0 may result tn

excessive spark plug fouling, piston

scoring, or bearing failure. Do not under

any circumstances, ur_ muttigrade, such as

10W-30, or other automobile oils,

If BIA certified oil is not available, use

an SAE 30 or 40 2,<:ycle or outboard oil.

We reserve the right to refuse warranty on

parts which are damaged when using

improper fuels or fubrldants.

WARNING

Gasoline is highly flammable. Always mix

in wefl ventiJated area, Do not fill tank

with motor running, nor near any flame

or while smoking. Be sure vent screWs

and filler caps on tanks are finger tighte-

ned when transporting gasoline in the

trunk of your automobile to prevent

explosion.

FUEL

MIXING

TABLE

50" 1

MIXTURE

U.S. Measure

Regular Amount of 0;I

Gasoline to be added "

in Gallons In Pints In Oz

1 0.16 2.6

3 0.48 7.7

5 0,80 12.8

6 0.96 15.4

Metric Measure

Regular

Gasotina

In Liters

1

5

10

2o

Amount of oil

to be added

In Liters

0.02

0.10

0.20

0.40

9. STARTING PROCEDURE (See Figure 7).

a, Open air vent screw located on fuel filler

cap by turning counterclockwise,

b. Open fuel shut-off valve,

c. Open throttle lever to half throttle.

d, Move choke lever to "On" posfflon.

WARNING ,

When starting outboard, the boat will

move with a sudden burst of speed, Make

sure you are well seated sO as not to lose

your balance with a fast start.

AIR VENT•

RUN P0

Figure 7

STARTER HANDLE

Flsure 8

e. Pull Slartor handle slowly until you feel

starter engage. Then pull with rapid

motion and allow the starter cord to

retract slowly. (See Figure 8).

f. After engine has started, gradually move

choke lever to "Off" position v_,_ile

warming up the engine.

g. Let engine idle for approxlmately 3

minutes before mowng throttle lever to

"Fast" position.

10, STOPPING PROCEDURE

To stop engine, move throttle lever to full

"Stop" position. {See Figure 7).

WARNING

In case of an Emergency, the engine can

be stopped by moving the Choke Laver to

Full Choke Position.

If the motor will not be operated for a

period of time. if it is to be removed from

the boat, or if it is to be tilted up, we

rec'ommend the following practice to

prevent spillage from the carburetor

throat and bowl and to prevent gum

formation= in the =orburQtgrUuring

storage:

I, Close fuel shut-off valve and air

vent _crew at fuel filler cap,

2. Allow motor to run at idling speed

until it stops of its own accord,

indicating the carburetor has run

dry,

Loading...

Loading...