Sears Craftsman 917.251561 Owner's Manual

CRIIFTSMnN+

MODEL NUMBER 917.251561 OWNER'SMANUAL

• Assembly

• Operation

" Customer Responsibilities

• Service and Adjustments

• Repair Parts

CAUTION: Read and follow all safety rules and instructions before operating this equipment.

FOR CONSUMER ASSrSTANCE HOT LINE, CALL TH_S TOLL FREE NUMBER: 1-B00-659-5917

................... II IIIII I I

im

SAFETY RULES

Safe OperatiOn?ractices-for Ride-On Mowers

IMPORTANT: THIS CUTTING MACHINE IS CAPABLE OF AMPUTATING HANDS AND FEET AND THROWING OBJECTS.,

FAILURE TO OBSERVE THE FOLLOWING SAFETY INSTRUCTIONS COULD RESULT IN SERIOUS iNJURY OR DEATH,

L GENERAL OPERATION iii. CHILDREN

Reed, understand, and to_low a_linstructions In the manual Tragic accidents can occur it the operator is not alert to Ihe

and on the machine before slatting presence of chlIdren Children are often attracted to the

Only allow responsible adul[s, who are familiar with the machine and the mowing actMty Never assume that

instructions, to operate the machine

children wH! remain where you last saw them.

C{ear the area of ob ects such as rocks, toys wire, etc,

which could be pcked up and {1rowe by the b ads Keep children Out of the mowing area and under the watchful

Be sure the area Is clear of other people before mowing Slop

machine if anyone enters the area

• Never carry passengers

• Do not mow tn reverse unless absolutely necessary Nways

look down and behind balers end while becking

Be aware of the mower discharge direction and do not point

it at anyone Do not operate the mower without either the

entire grass catcher or lhe guard in place

. Stow down before tumlng

• Never leave a running maohtne unattended, Always tu re elf

blades, sat parking brake, stop engine, and remove keys

before dlsmountlng,

• Turn off blades when not mowing

• Stop engine before removing grass calcher or unclogging

chute

Mow only in daylight or good artificial light

• Do not operate Iha machine while under the influence of

alcohol or drugs.

• Watch for Iraflte when operating near or crossing roadways

Use extra care when loading or unloading the machine into

a trailer or Iruck

IL SLOPE OPERATION

Slopes are a major factor related Io loss-of-control and

tipover accidents, whlch can result in save re Injury or deafh

All slopes require extra caution, ff yotJ cannot back up the

slope or if you feel uneasy on It, do nol mow it

DO.

" Mow up and down slopes, not across

,, Remove obstacles such as rocks, tree limbs, ate

• Watch lot holes, ruts, or bumps. Uneven terrain could

overturn the machine Tallgrasscanhideobstscfes

• Use slow speed Choose a low gear so lhat you will not have

to stop or shill while on the slope.

Follow the manufacturer's recommendations for whee!

weights or counterweights to Improve slabiltty

. USa extra care wt[h grass catchers or other at.tachments

These can change the stability of the machine

, Kaepalimevamantonthesfopeestowandgraduaf, Donut

make sadden changes In speed or direction

Avoid staffing Dr stopping on a slope. It tires lose traction,

disengage the blades and proceed slowly straight down the

slope,

DO NOT:

. Do not turn on slopes unless necessary, and then, turn slowly

and gradually downhill, if possible

• Do not mew near drop-otis, ditches, or embankments The

mower could suddenly turn over if a wheel Is over the edge

o! a cltlf or ditch, or il an edge caves in

Do not mow on wel grass. Reduced traction could cause

eliding

• Do not hy to stabilize the machine by putting your loot on the

ground

• Do not use grass catcher on steep slopes,

t,

=,

e

care of another responsible adult

• Be alert and turn machir_e og tf children enter the ares

Before and when backing, took behind and down for small

children

• Never carry children They may fall off and be seriously

injured or interfere with sale machine operation

• Never allow children to operate the machine

• Use extra care when approaching blindcornea shrubs,

trees, or other objects thai may obscure vision

IV. SERVICE

Use extra care in handling gasoiine and otherfuels, They ara

flammable and vapors are explosive

Use only an approved container,

Never remove gas cap or add fuel wtlh the engine

running Allow engine to cool belora refueling Do not

smoke,

- Never refuel the machine indoors

Never store the machine or fuel conlatner inside where

there ls an open flame, such as a water heater

Never run a machine inside a closed area.

Keep nuts and bolts, especially blade attachment bolts, tight

and keep equipment in good condition

Never leaper wilh safely devices Check their proper

operation regularly.

Keep machfne free el grass leaves, orother debris build-up.

C san oil or fuel spillage Allow machine to coot before

alodng

Stop end inspect the equipment if you strike an obiect

Repair, il necessan/, before restarting,

Never make adjustments or repairs with tire engine running,

Graescatcher components are sub eel to wear damage, and

deterioration, whfeh could expose moving parts or allow

objects to be throwm Frequently check components and

replace with manuiacturer's recommended pads, when nec-

essary

Mower blades are sharp and can cut Wrap the b}ade s) or

wear gloves, and use extra caution when servicing them

Check brake operation frequently Adjust and service as

required,

Look for IhI8 symbol to point out Impor-

tant safety precautions. It means

CAUTION|If BECOME ALERTIII YOUR

SAFETY IS INVOLVED.

CAUTION: Always disconnect spark plug

wire end place wtre where It cannot contact

spark plug in order to prevent eccldentsl

starting when setting up, transpodlng_

adjustEng or making repair s.

WARNING &

The engine exhaust from this product con-

tains chemicals known to the State of Califor-

nia to cause cancer, birth defects, or other

reproductive harm.

rr

LU

I.g

14.

n-

O

LI.

O3

UJ

O

...J

O3

(5

Z

m

I--

-!-

(5

m

or)

u=

ILl

!:3

I-,

o9

uJ

(5

(5

o3

CONGRATULATIONS on your purchase of a Sears

Tractor tt has been designed, englheered and manufac..

tured to give you the best possible dependability and

pefformance_

Should you experience any problem you cannot easily

remedy, please contac! your nearest Sears Authorized

Service centedDepadment Department. We have com-

petent, welt-trained technicians and the.proper tools to

service 0_"repair thts tractor.

Please read and retain this manual The inskuctions will

enable you to assemble and maintain your tractorproperly]

Always observe the "SAFETY RULES"

MODEL

NUMBER 917 25t 56t

SERIAL

NUMBER

DATEOFPURCHASE

THE MODELAND SERIAL NUMBERS WILL BE FOUND

ON A pLATE UNDER THE SEAT

YOU SHOULD RECORD BOTH SERIAL NUMBER AND

DATE OF PURCHASE AND KEEP IN A SAFE PLACE

FOR FUTURE REFERENCE..

MAINTENANCE AGREEMENT

.ASears Maintenance Agreement ls available on _hisprod_

uct ContacJ your nearest Sears store for de|&its

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules

• Fol!ow a regutar schedule in maintaining caring ferand

using your tractor '

- Foitow the instruct_onsunder "Customer Responsibili-

ties" and "Storage'* sections of this owner's manual

PRODUCT SPECIFICATIONS

HORSEPOWER: 22 5

GASOLINE CAPACITY 3 5 GALLONS

AND TYPE: UNLEADED REGULAR

OIL TYPE (API_SF/SG): SAE toW30'(above 32"F)

SAE 5W-30 (batew 32_F)

O_LCAPACITY: W!FILTER: 42 PINTS

W/O FILTER: 3 7 PINTS

SPARK PLUG: CHAMPION RC12YC

(GAP- .030")

VALVE CLEARANCE: NOT ADJUSTABLE

GROUND SPEED (MPH): FORWARD; 0 - 56

REVERSE; 0-25

TIRE PRESSURE: FRONT: 14 PSi

REAR: I0 PSI

CHARGING SYSTEM: 15 AMPS @ 3600 RPM

BATTERY'. AMP/HR: 35

MfN CCA; 280

CASE SIZE: UtR

BLADE BOLT TORQUE: 30.-35 FT LBS.

WARNING: This Iractor is equipped with an internal

combustion engine and should not be'used on or near any

unimproved torest-.covered, brush-covered or grass-cov-

ered land unless the engine's exhaust system is equipped

wilh a spark attester meeting applicable local or state taws

(if any) If a spark arrestor isused, tt should be maintained

in effective working order by lhe operatOr.r

in the state of California the above Is required by law

(Section 4442 ol the California Public Resources Code).

Other states may have similar taws Federal iaws apply on

federal lands A spark arrestor for the muffler is available

through youi" nearest Sears Aulhorized Service Center/

Department (See REPAIR PARTS section ol this manua )

, H,,,i i

LIMITED TWO YEAR WARRANTY ON CRAFTSMAN RIDING EQUIPMENT

For two (2) years from Ihedate of purchase if thisCraftsman R_dtngEquipment telmainla ned, ubficated and laned up according

to fhe instructions in the ewnePs manuaF_Sears wll!repair or replace, tree of charge, any partsfound to be detective in maledal

or Workmanship '

This Warranty does natcover.

Expendable ilems which become worn dadng normal use such as blades, spark plugs• air cleaners, bells, elc

" Tirereplacementor repair caused by puncturesfrom outside objecls, such asnails, thorns, stumps, or gtass

• Repa|ts neeesse_ because ofoperator abuse, negligence, improperstorage or accident or 4hafailure to maintain the

equipment according to thelnstruction_ containedtn the owner's manual

Riding equipmenlused for commercialor _nlal purposes.

LIMITED 90 DAY WARRANTY ON BATTERY

For ninety (90) days from date of purchase, if any batlen/]ncruded with ths rid ng equipment proves defecllve in matedal or

workmanship and ourtesting determines thebalten/will not hold a charge, Searswt_ireplacethe bat ery a! no charge

IN-HOME WARRANTY SERVICE ON YOUR CRAFTSMAN RIDING EQUIPMENT IS AVAILABLE AT NO-CHARGE FOR 30

DAYS FROM THE DATE OF PURCHASE PLEASE CONTACT YOUR NEAREST SERVICE CENTER. AFTER 30 DAYS

FROM THE DATE OF PURCHASE, WARRANTY'SERVICE IS AVAILABLE BY TAKING YOUR CRAFTSMAN RIDING EQUIP-

MENT TO YOUR NEAREST SEARS SERVICE CENTER, (IN-HOME WARRANTY SERVICE WILL STILL BE AVAILABLE

AFTER 30 DAYS FROM THE DATE OF' PURCHASE BUT A STANDARD TRIP CHARGE WiLL APPLY ) THIS WARRANTY

APPLIES ONLY WHILE THIS PRODUCT IS IN THE UNITED STATES

This _/artanty gives you specIflc legal rights, end you may also have otherrightswhich may van/from state to stale

SEARS, ROEBUCK AND CO, Dt817 WA, HOFFMAN ESTATES, iL 60179

! , t ,1 = ,,,,i HH I

3

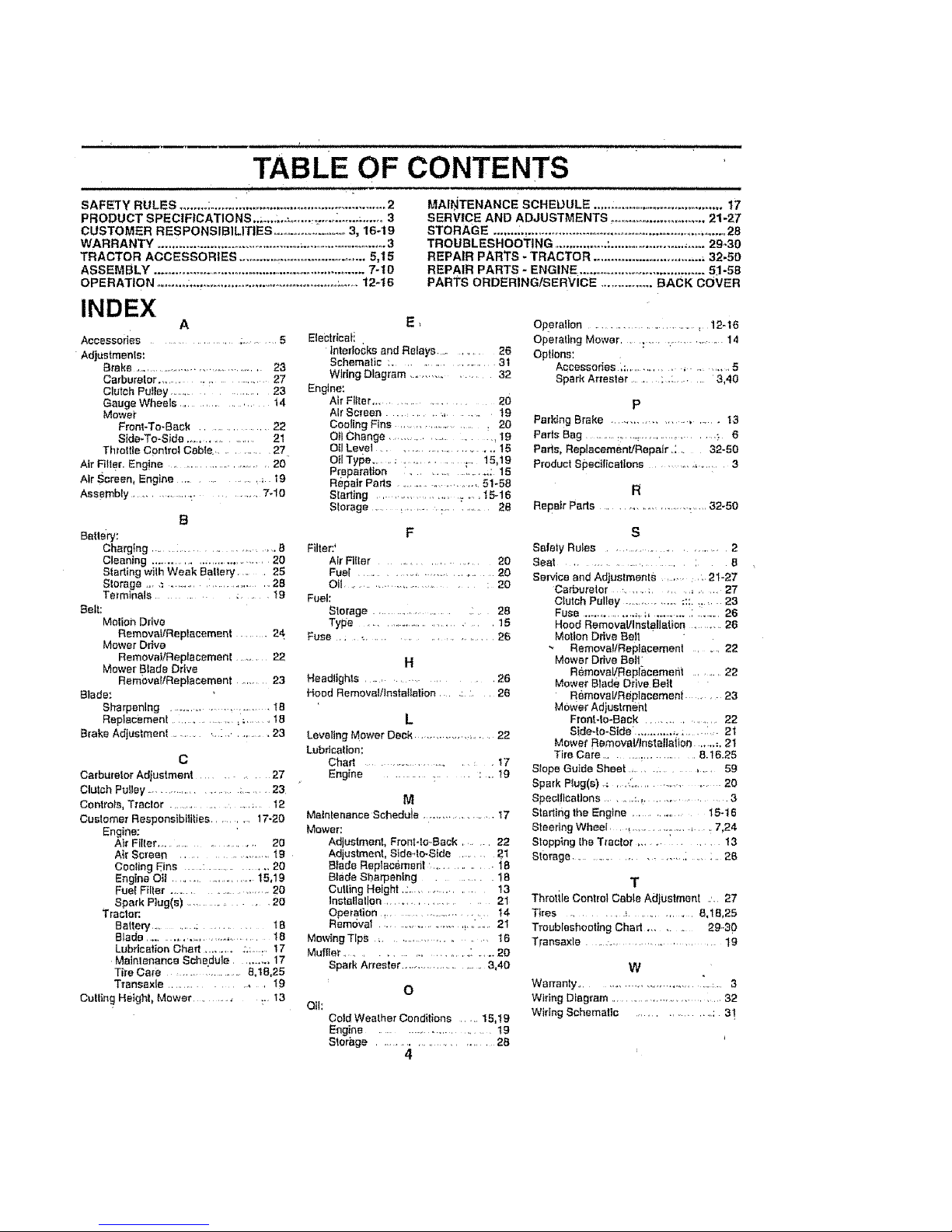

SAFETY RULES ........ ;....... _............................................. 2

PRODUCT SPECtFtCATIONS.....,:._ ....... _...._..o...; ...... 3

CUSTOMER RESPONSIBILITIES .......................... 3, 16-19

WARRANT'Y _...: .................................... _............................. 3

TRACTOR ACCESSORIES ....................................... 5,15

ASSEMBLY" ..................................... i.......................... 7-t0

OPERATION ......... ,:............................................... _....... t2-16

TABLE OF CONTENTS

MAINTENANCE SCHEDULE ..o: .................................. 17

SERVICE AND ADJUSTMENTS ............................. 21-27

STORAGE ....... _._................................................................ 28

TROUBLESHOOTING ............... :..................... ,..... 29-30

REPAIR PARTS - TRACTOR .............................. _ 32-50

REPAIR PARTS- ENGINE ........................................ 51-58

PARTS ORDERING/SERVICE ............... BACK COVER

INDEX

A

Accessories ....................... ;......... 5

Adjustments;

Brake ........................................ 23

Carbu_'eter .......................... 27

Clutch Putley ........................... 23

Gauge Wheels ............. t 4

Mower

Front*To-Back .................. 22

Side-To-Side ................... 21

Threltle Control Cable. .......... 27

Air Filler. Eng!ee ............................ 20

Air Screen, Engine .......... ; 19

Assembly ............................... 7.10

B

Battery:

Charging .............................. 8

Cleaning ................................. 20

Starting wilh Weak Bailer,/ ..... 25

Storage., .= .......... : ................ 28

Terminals ........ :..... t9

Belt:

Motieh Ddve

RemovaL/Replacement ........ 24

Mower Drive

Remeva_Replecemenl ......... 22

Mower Blade Drive

RemovaltReplsoement ........ 23

Blade:

Sharpening ........................... 18

Replacement ............... _ m ....... 18

Brake Adjustment ............. : ............ 23

C

Carburetor Adjustment .......... 27

Clutch Pulley ................... :...... 23

Conlrola, Tractor .................. :. 12

Cuslomer Responsibilities ........ 17-20

Engine:

Air Filter........................ 20

Air Screen ........................ 19

CscItng Eins ..... : ............. 20

Engine OII ...................... t5,19

Fuel Filter ......................... 20

Spark Ping(s) ............ 20

Tractor:.

BatterY ........... : ...... tB

Blade ....... .................. 18

Lubrication Chad .......... ;:,:...... 17

Maintenance Schedule ....... _., 17

Tire Care ......................&tB,25

Trsnssxle ................... 19

Culling Height, Mower ............... 13

E_

Etectrtcati

Interlocks and Relays .......... 26

Schematic ;........................ 3t

Wiring Diagram .................. 32

Engine:

Air Filler .................... 20

Atr Screen .......................... t9

Cooling Fins .................................20

OIl Change ...................... 19

Oil Level ............................. 15

Oil Type ...... ; ................. 15,19

Preparation .......... ',..... : 15

Repair Pads ...................... 51-58

Starting ................ _ ,, ,15-16

Storage ..... _......... : ........... 28

F

Filter:'

Air Filler .......................... 20

Fuel ................................... 20

Oil.........................................20

Fuel:

Storage ......................... 28

Type ............................ , 15

Fuse , ,........................ 26

H

Headlights ............................. 26

Hood Removal/lnstaliation ..... : :, , 26

L

Leveling Mower Deck .................... 22

Lubdcalion:

Chan ..................................... 17

Engine ........................... t9

M

Matnlenanee Scheduie ..................... I7

Mower:

Adjustment, Front4e..Back. ..... 22

Adjustment, Side-4o-Side ...... 2.1

Blade Replacement .............. 18

Blade Sharpening ..... 18

Cutting Height ..:................. !3

installation ...................... 21

Operatisn _...................... t4

Remdval ............... _... .. 2t

Mowing TIps _................... 16

Muffler ..................... : ..... 20

Spark Arrestor ...................... 3,40

Oil:

O

Cold Weather Conditions ..... 15,19

Engine ......................... 19

Storage .............................. 2B

4

Operallsn ............................. , 12-16

Operating Mower . : .... ............ 14

Options:

Accessories ,: ................. , ...........5

Spark Arrestor ..........:.: ........ 3,40

P

Paddng Brake .................... , .... 13

Paris Bag ........ _,, .,,: .................... :* 6

Pads, ReplacemenVRepair.:. 32-50

Product Specifications ................. 3

R

Repair Parts ............................. 32-50

s

Safely Rules ........................ 2

Seat ............... , .... : B

Service end Adjuslment8 ..... , 21-27

Carburetor :...... ...... _ , 27

Clutch Pulley ................ ;::. _..... 23

FUSe .............. ;_,;, .......... : ........ 26

Hood Remova!/Inst@llatien ........... 26

Motion Ddve Belt

'_ Removal/Replacement .... 22

Mower Drive Belt"

Removal/Reprasemeni ...... 22

Mower Blade Drive Belt

Removal/Replacement • . 23

Mower Adjustmef_t

Froat-lo-Bsck ........... ......... 22

Side-to-Side' ................... :, 21

Mower RemovaVtnstallaiFon ....... ;. 21

Tire Care ........... _.............. 8.16.25

Slope Guide Sheet ................... 59

Spark Plug(s) ,; r ,_ ................. 20

Specifications ....... :................. 3

Starting the Engine .......... 15-16

SteedngWheel ,, ........... 1..., ,7,24

Stopping the Tractor ........... 13

Storage ........................................ 26

T

Throtile Control Cable AdjUstment ', 27

Tires .................................... 8,1B,25

TroubleshootingChart ...... 29..30

Transaxle ..... ............. ..... 19

W

Warranty ............................. : . 3

Wiring Diagram ................................... 32

Wiring Schematic ................. : 3!

ACCESSORIES AND ATTACHMENTS

111 ,111 1 i1 , i • :L

These accessories end attachme n!s we re r_vailable through most .Seam retail outlets and ae trice centers when the tractor was purchased;

Most Sears stores can order these Items for you when you provide the model number el your tractor

ENGINE MAINTENANCE

BLADES BELTS

PERFORMANCE

FUEL STABILIZER AtR FILTER

Sesrs offers'awida varietyofsttachments thatflt your traetor Many of these are lisled betoww_thbriefexplanattons ef how theycanhelp

you; This tlstwas currentat the timeof pobflcalion; however, it may changeinfuIure years - more attachments may be added, changes

they be made In theseattachments, or somemay no longer be available or tit yourmodet Contact your nearest Sears store for the

accessories and attachments that are available for your tractor.

Most of these altachments do not requl_eadditionalhitchesor conversionkits (those that do are indicated)and ere designed for easy

attaching and detaching

AERATOR promotes deep reel growth for e healtr_y la_n. Tapered

2 54nch sleet spikes mounted on 104nob diameter discs punciure

holes insoit st dose Inlervais to tel moisture soak tn Stselweighttray

fortrnCreaaedpenetration

BUMPER protects front end of tractor from damage

CARTS make hautfng easy Vadety of sizes avallab!e, pius accesso-

ries such as side panel kits, foolcaddy, cart cover, proteclJve mat and

doily

CORING AERATOR takes smaii plugs out of soilto allow moisture

and nuidenls to reach grsss roots, 36-inch swath 24 hardened steel

codng tips 150 lb. capacity weight trsy

DISC HARROW has 2 gangs of 4 steel blades that angle from 10 to

20 degrees, 40 _nches wide Can hook 2 units in tandem (Requires

sleey_h_ch )

DOZER BLADE removes snow; grades dirt, sand sod gravel 48

Inches wtde, 17Inches high, clears 44-inch path whe_ angled, Master

i_ftcontrol lever Ior operefer ease Spring frtp for snow remover on

uneven I_avement; buiiNn float for blade to foliow ground contour,

Reversible, replaceable scraper bar (Use with tire chains and wheet

we!g_ts'lsn_or rear drawbat welght_)

EASY OIL DRAIN VALVE makes ell changes easier, faster

FRONT NOSE ROLLER canters In trent of mower deck to reduce

chances o! "scslptng" on uneven lerraln_

GANG HITCH lets you tow 2 or 3 pull-behind attachments at

once, such as sweepers, delhatchers, aerators (not Ior use with

rollers ca_e or other heavy attachmenls)

MULCH RAKFJDETHATCHER loosens eoif end Itips thalch and

matted {saves to lawn surface lot easy pickup Twenty spdng tine

teelh Useful to prepare bare areas for seeding, Available for tronl or

rear mounting, HIGH PERFORMANCE REEL-ACTION SPRING

TINE DETHATCHER covers 36qnch wlde path end losses thatch Into

large hopper Mounts behind tractor

PLOW turns soil 6 inches deep, cuts t 0-Inch farrow Crank adjust-

meet controls deplh_ 3-position yoke sets width. Hea'Jy sleeHendside

lot slralght furrowing (Requires sleeve hllch }

RAMP TOPS AND FEET let you 10ad and unlcad Itactm" from a

pickup truck Use with 2 x 8 or 2 x 10 lumber

REAR GRADER B LAD E is 42 Inches wlde and operated from ddve r's

seat Reversible steel blade can be angled at 30 degrees for g_adtng

Reverses for pushing Snow backwards (Requires sleeve hitch )

ROLLER [or smoother t'_,v,,'neudar._, 36_Inch wlde, 1Soinch diameter

water-tight drum he{de up to 390 }bs of weight. Rounded edges

prevent harm to tuff Adjustable scraper automatically cleans drum

SLEEVE CULTIVATOR Is 43 inches wide, Prepares ground for

seeding, helps weed control Sloe! frame holds 5 edtuslsble sweeps,

Adjusts vertically, horizontally (Requires sleeve hitch ) Optional

accessory: steel furrow opener tot wider openings for potaloes,

cam, and other deep-seeded crops

SLEEVE HITC H for use wiih master till system Stngts pin couples/

uncauptss

SNOWTHROWER has 42-inch swath Drum-type auger h_ndles

powdery and welrneavy snow Mounts esstlywtlh simpie pin srrsnge-

ment. Discharge chute adjusts Irom tractor s._st E-inch diameter

spout dtscharges snow to to 50 feet Lift controlled at tractor sest

(Use with chains and who et weights end/or rear drawbar welghl )

SPRAYERS use 12-volt DC electdc meier thai connects 1othe tractor

battery or other 12welt source Includes booms for automatic

spraying and hand held wand ior spotspraytng Wend has adjustable

spray pattern, For applying herbicides. Insecticides, fungicides and

tiqutd fedilizers

SPREADERISEEDERS make seeding, fertilizing, and weed killing

BaBy Ercado_stspresdarsarsatsouselultorgrenularde-icersand

sand•

SWEEPERS let you collect grass cIipplhgs and {eave s

TILLER has 8 hpengtne topmpsre seed beds, cullivste, and compost

garden residue. Chain-drive transmission. Six I t ,inch dtameler one

piece heat-trsaled steel tines,, Tills 304nch path, (Requires sleeve

h_{ch ) Or use 5 hp to',;v-behtndTILLER with 36qnsh swath to prepare

seed beds, cultFvatesod compost garden residue. Tiller has its own

built-to Jill and depth oontroI system and does NOT require e sleeve

hIlch, Fits any lawn, yard or garden tractor, Simply hook up 1othe

tractor drswbar end gel Optional accessories for 5 hp tilter convert

unit lor dethstching, aerating, hiUing Without toots

TIRE CHAINS are heavy duty; closely spaced exlra.iarge cross links

give smooth ride, oulstandtng tracfton

TRACTOR CA B has heavy duty vinyl fabric overtubular steel frame.

ABe ptasfic top; clear plastic windshield offers 380 degree vlsibility

Hinged metal doors with cstch, Keeps operator warm and dry.

Remove vinyl sides and windshields'for use o's sun prolecter in

summer, Optional accessories Include: lintedltempered solid

sorely glass windshield wilh hand operated wiper; ?2-vstt amber

caulionlightfsr mounting on cab fop

VACS for powerful collection of heavy grass clippings end teaves

Opt lonst wand attachment to pick up dab rJsin hard-!o-roach pl&ees

VAO/CHIPPER includes s chipper-shredder.

WEIGHT BRACKET lor drawber for snow remqve/appl_catlona, Can

be mounted on f reel el tractor {orplowing applications Uses (1) 55

Ib weight

WHEEL WEIGHTS for tear wheels provide needed traction Tot snow

removal or dozing heavy ma_etists

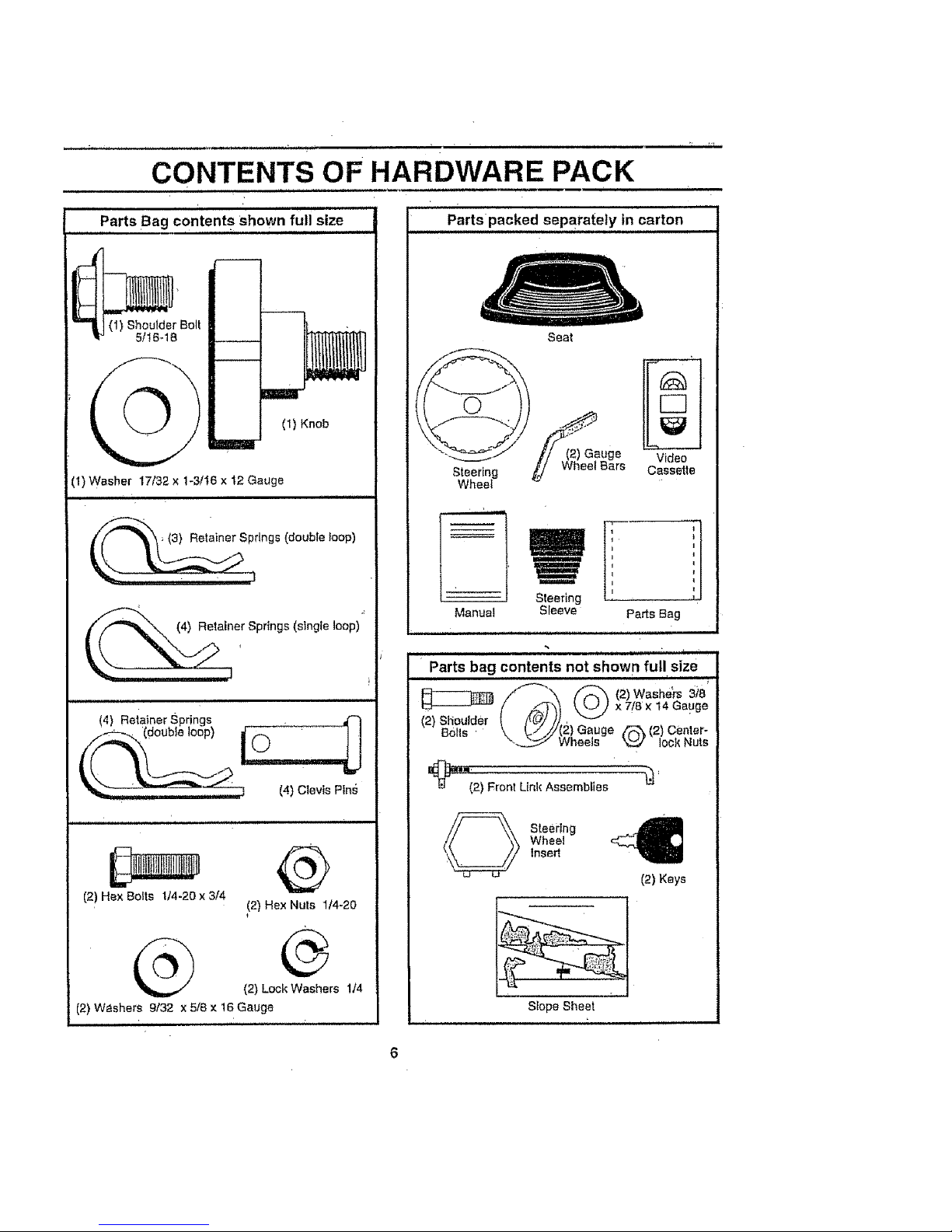

CONTENTS OF HARDWARE PACK

Parts Bag contents Shown full size

(1) Knob

(1) Shoulder Bolt

5/!6qB

(1) Washer 17/32 x 1-3/t6 x 12 Gauge

/(_ (3) Re,ainer Springs (doub|e ,oop)

4) Retainer Springs (single loop) _'

(_etoiner Springs .

io" l!

(4) Clovis P_n_

J. t i

(2) Hex Bolts 1t4-20 x 3/4

(2) Hex Nuts 114-20

@ ®

(2) Lock Washers 1,/4

(2) W_shers 9/32 x 5/8 x 16 Gauge

Parts packed separately in carton

Steering

Wheel

Manual

Seat

Video

Cassetle

J,,

Steering

Sleeve Parts Bag

*" t , ,

Parts bag contents not shown full size

_ /"¢""-'_ _ (2)Washers 3;'a

_i;) Fron,t,n,,Assemb,,es_'

Steering C

Wheel

Insert

(2) Keys

Slope Sheet

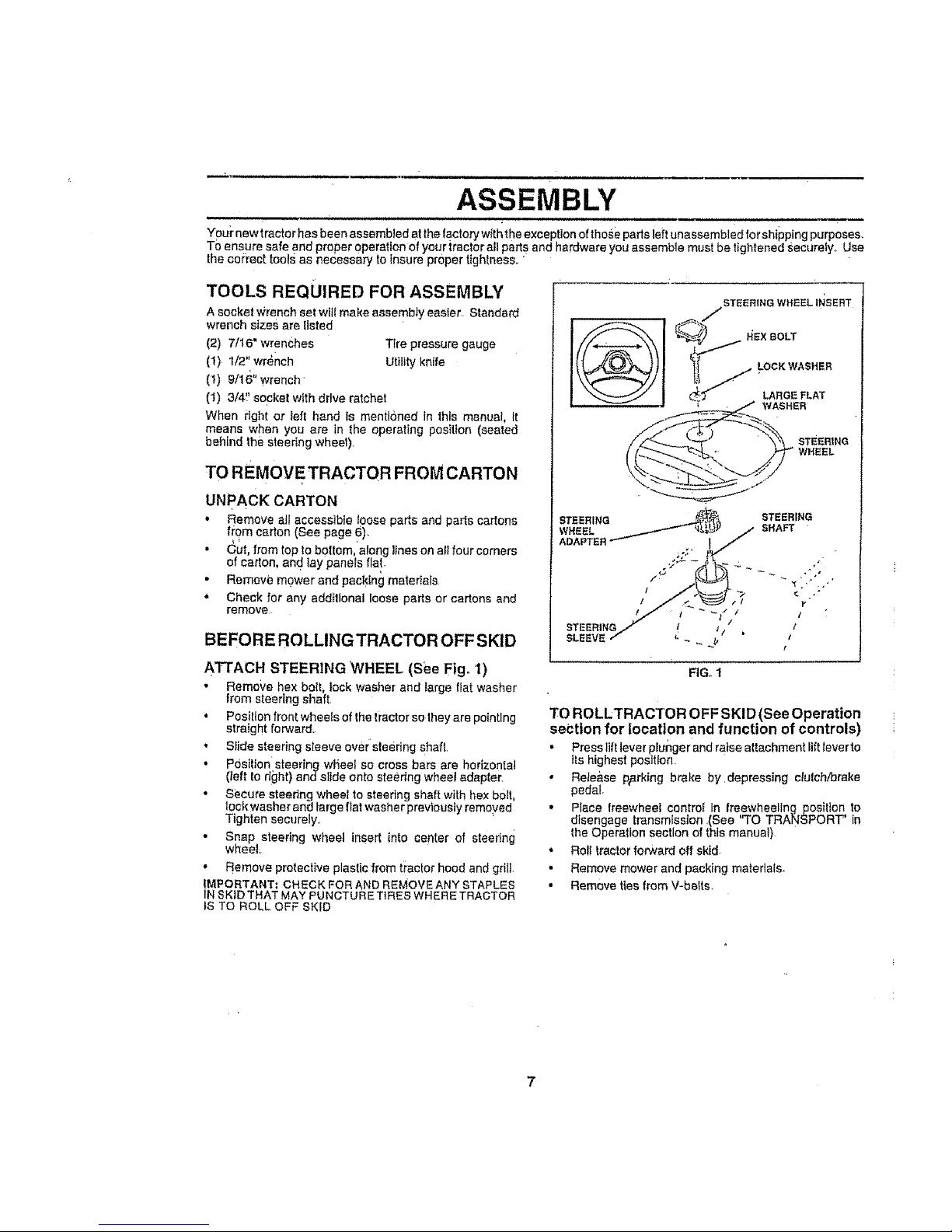

ASSEMBLY

YOU_"new tractor has been assembled at the factory wit" the exception ofthOSeparis le_ssembled for shipping purp0ses_.

To ensure safe and proper operation of your tractor all paris and hardware you assemble must be tightened Securefy.. Use

the cor'rect tools as necessary to insure proper tightness. '

TOOLS REQUIRED FOR ASSEMBLY

A socket Wrench set wilt make assembly easier Standard

wrench sizes are listed

(2) 7/16" wrenches Tire pressure gauge

(1) 1/2" wrench Utflity knife

(1) 9/16" wrench

(t) 3/4_' socket with drive ratchet

When i'ight or left hand Is mentioned in fhls manual, it

means when you are in the operating position (seated

behind the steering wheel)

TO REMOVETRACTOR FROM CARTON

UNPACK CARTON

• Remove atl accessible loose parts and parts cartons

from carton (See page 6)

,' Cut, from top Io bottom, along lines on all four corners

of carton, and toy panels fla!.

" Remove mower and packing materials

• Check for any additional loose parts or cartons and

remove

BEFORE ROLLING TRACTOR OFF SKID

ATTACH STEERING WHEEL (See Fig. 'I)

• Remove hex bolt, lock washer and large fiat washer

from steering shaft

, PosiIIon front wheels of the tractor so they are pointing

straight forward.

,, Slide steering sleeve over sfeedng shaft.

• Posilion sl;eerfng whee! so cross bars are horizontal

(_eft to right) andsiide onto steertng wheel adapter

• Secure steering wheel to steering shaft with hex boil,

lock washer and large fiat washer previously removed

Tighten securely..

• Snap steering wheat insert into center of steeffng

wheel

• Remove protective plastic from tractor hood and grill

IMPORTANT; CHECK FOR AND REMOVE ANY STAPLES

IN SKID THAT MAY PU NCTUR ETIRES WHERE TRACTOR

tS TO ROLL OFF SKID

FIG. 1

TO ROLLTRACTOR OFF SKID (See Operation

section for location and function of controls)

• Press lift tever ptunger and ratse altachment ltfHever to

Its highest position

,' Rete&se p_.rking bt'ake by.depressing clutch/brake

pedal

,, Place freewheel control In freewheeling posilten to

disengage transmission .(See "TO TRANSPORT" In

the Operation section of this manuat)

• Roll tractor forward off skid

. Remove mower and packing materials

• Remove ties from V-belts

ASSEMBLY

;ONNECT BATTERY (See Fig,2)

iii ,nuHu nm ,m,U,l

CAU_rlON: Do not short battery termi-

nals., Before connecting battery, re-

move metal bracelets, wristwatch

bands, rings, etco

Positive terminal must be Connected

first to prevent sparking from acciden-

tal grounding.

i _ 11 1..1 , J,,,,

• Lilt hood to raised position

• Open terminar access doors, remove terminal protec-

• tire caps and discard..

If this battery is put into service alter month and year

indicated on label (iabel located between terminals)

charge battery for minimum of one hour at 6=10 amps.

• First connect RED battery cable to posi{ive (+) battery

terminal with hex bolt, fiat washer, lock washer and hex

nut as shown, Tighten'secUre{y

• Connect BLACK grounding cable to negative (-) bat-

tery terminal with remaining hex boEt,flat washer, lock

washer and hex nut. Tighlen securely

• Close terminal access doors

Use terminal access doors for:

• _hspectton for secure conneclions (to tighten hard-

ware),

• inspec(ion for cbr_osion

• Tesling battery

• Jumping (if required)

Periodic charging

DISCARD HEX NUT LOCK FLAT

WASHER WASHER

TERMINAL

PROTECTIVE HEX

CAPS BOLT

TERMINAL :"

ACCESS

DOOR ,-"

°':_ .

POSITIVE

(RED)

CABLE

NEGATIVE

(BLACK)

CAeLE "

INSTALL SEAT (See Fig. 3)

Adjust seat before tightening adjustment knob,

• Remove cardboard packing on seat pan.

• Place seat on seat pan and assemble shoulder bdtt.,

• • Assemble adjustment knob and flat washer _oosely.-

DO not tighten,,

• Tighten shoulder bolt securely

,, Lower seat inlo operating position and sl! on seat

• Slide seat untila comfodable position is reached which

allows you to press clutch/brake pedal all the way

down

• Get off seat wilhout moving its adjusted positton.

• Raise seat and tighten adjustmenl knob securely,

. SEAT

W.SnER

ADJUSTMENT

KNOB

FIG'. 3

CHECK TIRE PRESSURE

The fires on your tractor were overinflated at the faclory for

shipping purposes. Correct tire pressure is important for

best culting performance.

,. Reduce tire pressure to PSi shown in "PRODUCT

SPECIFICATIONS on page 3 of this manual

CHECK BRAKE SYSTEM

After you learn how to operate your tractor, check to see

that the brake is prqperty adjusted See "TO ADJUST

BRAKE" !n the Service and Adiustments seclion of this

manual

'FIG. 2

8

ASSEMBLY

INSTALl. MOWER AND DRIVE BELT

(See Figs, 4 and 7)

Be sui'a tractor ts on leve! surface and mower suspension

al'ms are raised with attachment llft control. Engage park-

ing brake.

,, Cut and remove ties securing anti-sway bar and belts

Swing sntFsway bar to Jeffside of mower deck_

" Stlde mower under tractor with discharge guard toright

side of tractor,

iMPORTANT; CHECK BELT FOR PROPER ROUTING iN

ALL MOWER PULLEY GROOVES, INSTALL BELT1NTO

ELECTRIC CLUTCH PULLEY GROOVE

h

• lnstatl one front link in top hole of the LH, front mower

bracket and L H front susper_ston bracket. Retain with

two singte loop retainer spdngs as shown

• InstallsecondfronttinkinR.H frontsuspensionbracket

only and retain with singte loop retainer spring as

shown.

" Stide right side of mower back and Install linkin top hole

of R,H, front mower bracket Relain with single loop

retainer spring as shown.,

Turn height adjusfment knob c:ountercfockwise unt[t it

stops.

• Lower mower ltr_kage with attachment lift control,

• Place the suspension arms on inward pointtng deck

pins, If necessary rock and raise front of mower to

alton deck pins with the holes in suspension arms.

SHOULDER

CHASSIS

DOUBLELOOP

RETAINER

ANTI-SWAY

Retain wllh double loop retainer springs with ioops

down as shown

• Connect anti-sway bar to chasss bracket under left

footrest and retain with double loop relainer spring

• Turn height adjustment knob clockwise to remove

slack from mower suspension

° Raise deck to highest pos!tion_

• Assemble gauge wheel bars to brackets using clevis

pihs and doubie toop retainer springs,

, Assemble gaugewhee[s asshown us_nglongshoutder

bolts, 3/8 washers, and 3/8-16 canto rlOcknuts. Tighten

securely.

• Adjust gauge wheels before operating mower as shown

in the Operalton section of this manual,

CHECK MOWER LEVELNESS

For best cutting results mower shouldbe properly eveled

See."TO LEVEL MOWER HOUSING in the Serv ce and

Adjustments section oI this mantJal

CHECK' FOR PROPER POSITION OF ALL

BELTS

See the ftgures Ihat are shown for replacing motion, mower

drive, and mower blade drive beets In the Service and

Adjustments section of thts manuaL Verify that the belts are

routed correctly

FRONT

FRONT

LINKS BRACKETS

L,H. GAUGE

GAUGE

WHEEL

3_

WASHER

USE PLIERS FOR

RETAINER SPRINGS

31S-16

CENTER

LOCKNUT

SINGLE

LOOP RETAINER

SPRINGS

MOWER

BRACKET

DISCHARGE

GUARD

PULLEY

LOOP

RETAINER

SPRINGS

FIG_4

9

i_,,,,u,i, i i , i,i

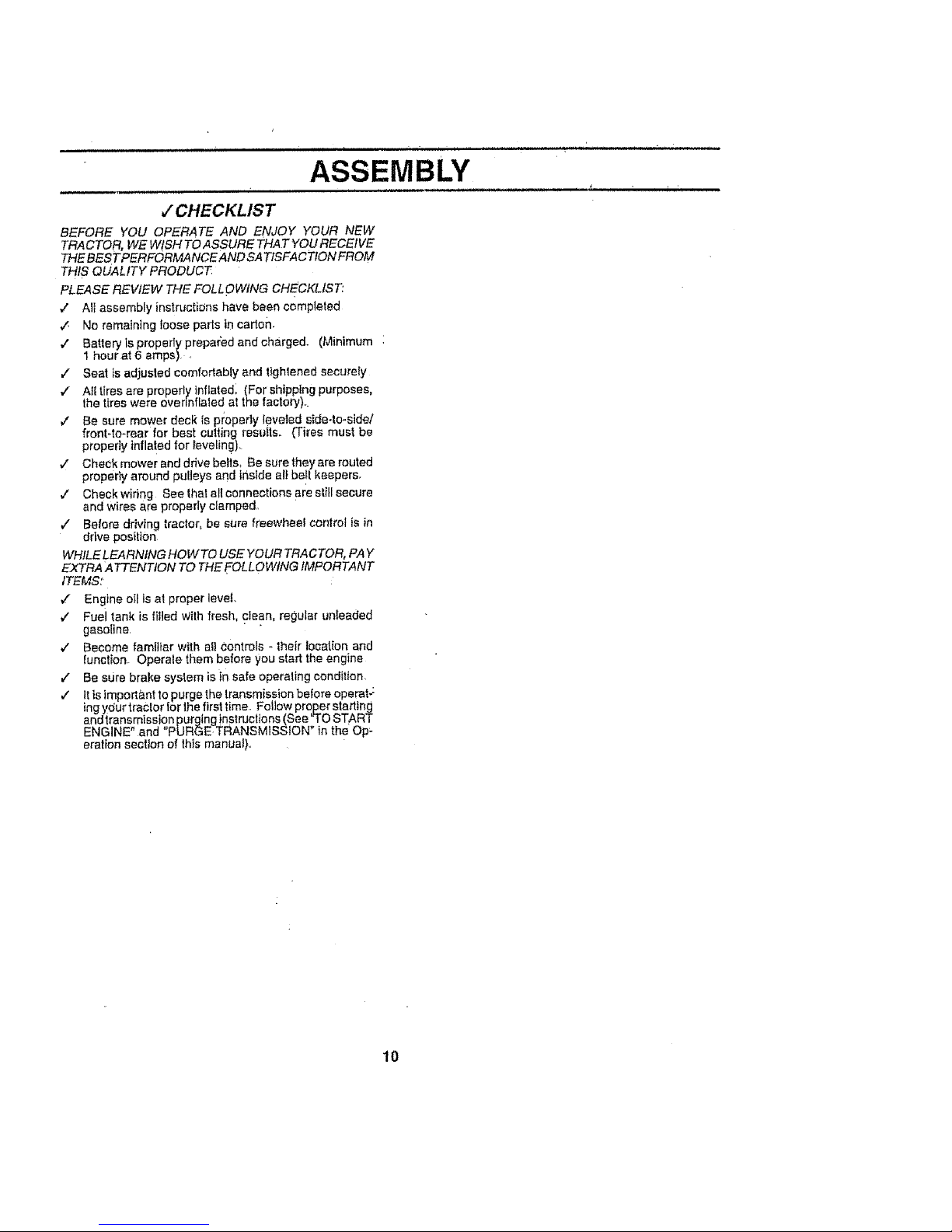

,/CHECKLIST

BEFORE YOU OPERATE AND ENJOY YOUR NEW

TRA CTOR, WE WISH TO ASSURE THAT YOU RECEtVE

THE BEST PERFORMANCE AND SA TISFA C TION FROM

THIS QUALITY PRODUCT

PLEASE REVIEW THE FOLLOWING CHECKLIST:

,/ All assembly instructions have been completed

.,,z No remaining loose parts in carton.

,/ Battery Is properly prepared and charged. (Minimum .

1 hour at 6 crops)

,/ Seat is adjusted comfortably and tightened securely

,/ AI{ tires ere properly lnflated_ (For shipping purposes,

the tires were overmflated at the factory).

v" Be sure mower deck _spz:operty leveled s_de4o-sidei

front4o-rear for best cutting rest._tts° (Tires must be

properly infla!ed for leveling)..

J Check mower and drive belts, Be sure they are routed

properly around pulleys and inside all bell keepers,

,/ Check wiring See thai all connections are still secure

and wires are properly clamped

,/ Before driving tractor, be sure freewhee! control is in

drive position

WHILE LEARNING HOWTO USE YOUR TRACTOR, PAY

EXTRA A TTENTtON TO THE FOLLOWING IMPORTANT

ITEMS:

v" Engine oil ts at proper level.

v' Fuel tank is filled With fresh, clean, regular unleaded

gasoline

•/ Become familiar with all controls - their location and

function. Operate them before you start the engine

,/ Be sure brake system is tn safe operating cond[tIen

,/ It is important to purge the transmission before operat-:

ing ydur tractor Ior the first time. Foflow proper starting

and transmission purging )nstnlcltons (See '%0 START

ENGINE" and "PURGE.TRANSMISSION" in the Op_-

eration section of this man'Jal).,

" i i ii ,i,,nnlnlnl,i ,I lu,,i III I , _ t • ,

ASSEMBLY

n i ,, i , i , ,

10

OPERATION

m

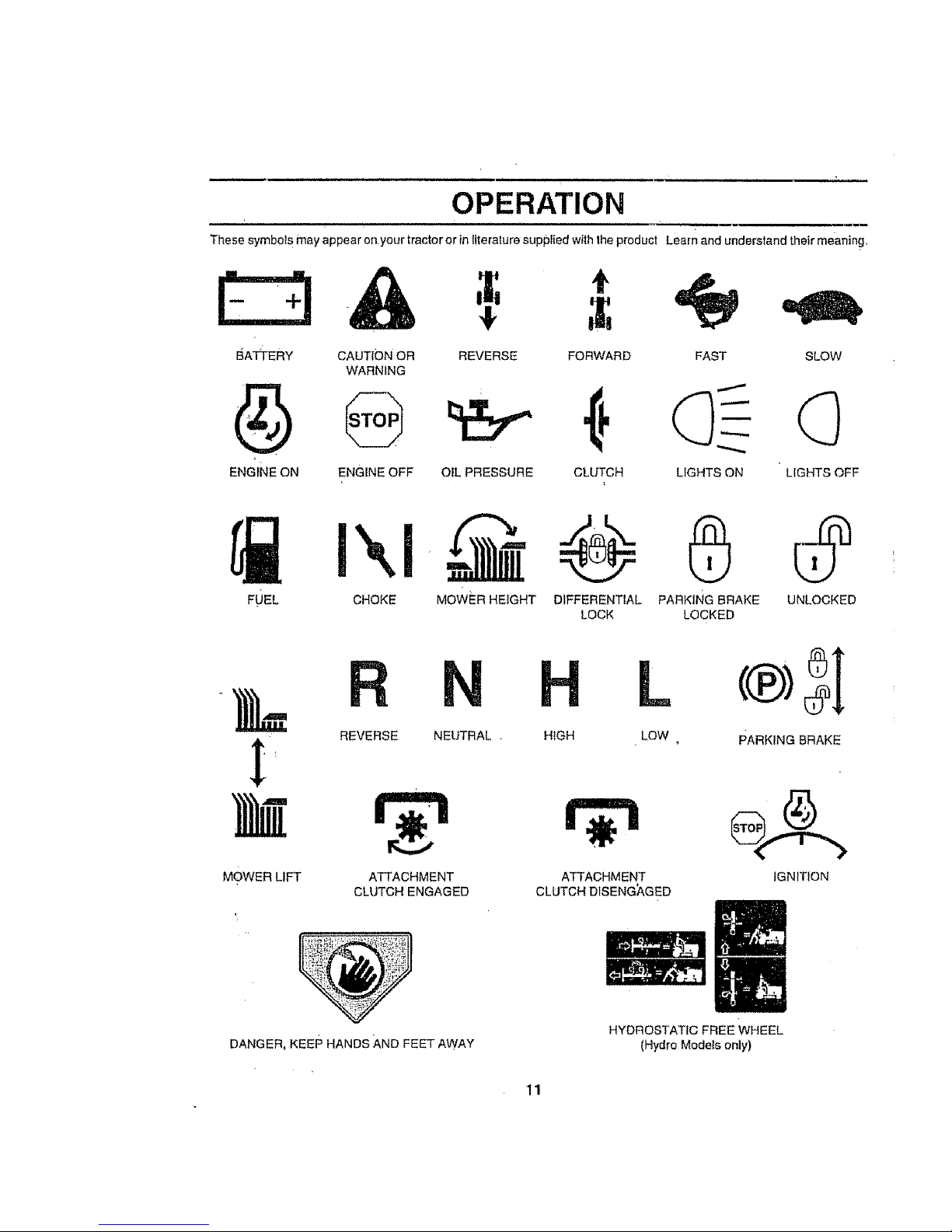

These symbols may appear on.your tractor or in literature suppFied with Ihe product Learn and understand their meaning..

E:3&

BATTEFIY CAUTfON OR

WARNING

@

ENGINE OFF

4!,

t

REVERSE FORWARD SLOW

ENGINE ON OIL PRESSURE CLUTCH LIGHTS OFF

FAST

LIGHTS ON

FUEL CHOKE

MOWER HEIGHT DIFFERENTIAL PARKING BRAKE UNLOCKED

LOCK LOCKED

REVERSE NEUTRAL.

MOWER LIFT

ATTACHMENT

CLUTCH ENGAGED

L

HIGH LOW

ATTACHMENT

CLUTCH DISENG_GED

®SI

PARKING BRAKE

_':'_r,_,_ ' i-'_ _:

DANGER, KEEP HANDS AND FEET AWAY

HYDROSTATIC FREE WHEEL

(Hydro Models only)

OPERATION

• • ...... ,,,,,,, ,,,,,i, , ,, , ,,,,,,,,,,,,,,_, i, ,

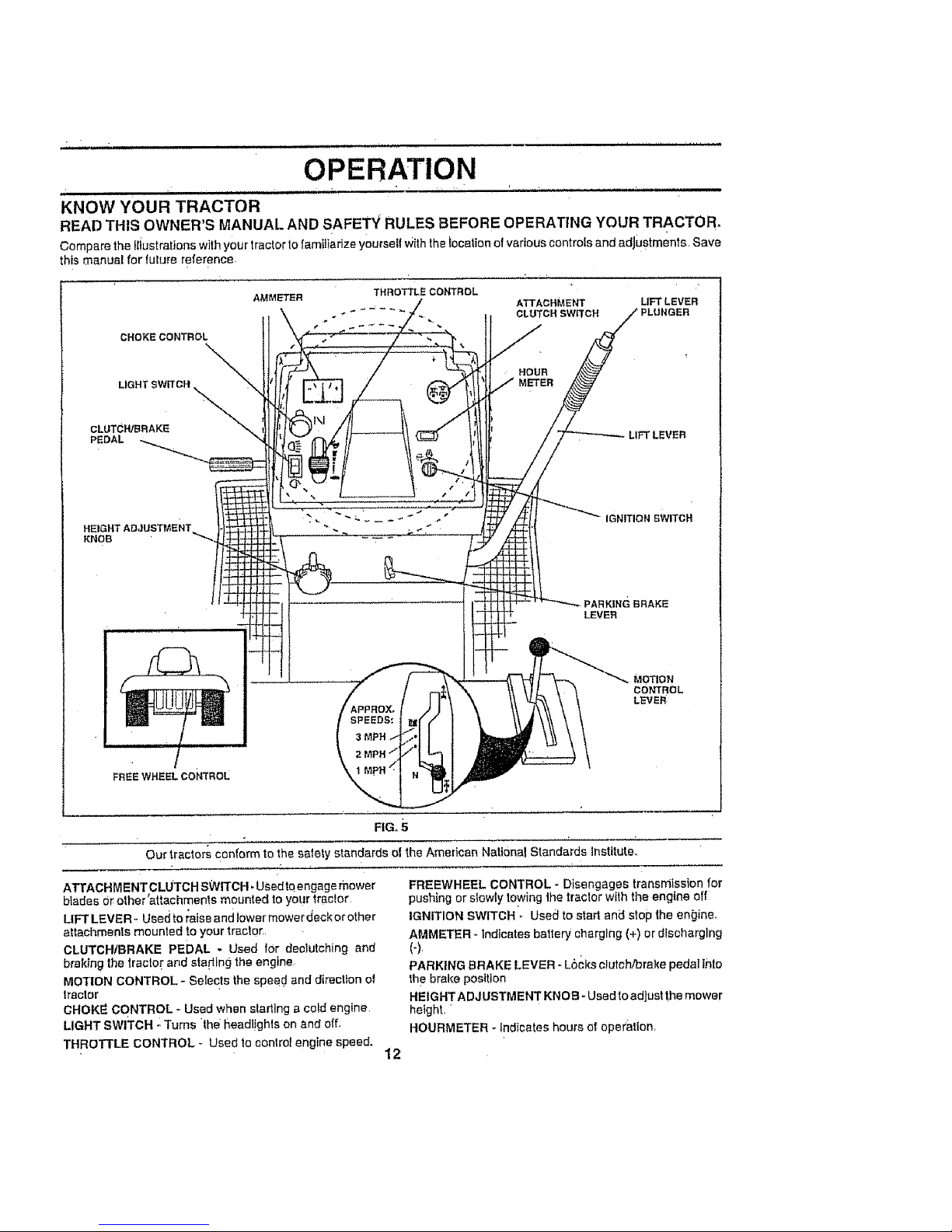

KNOW YOUR TRACTOR

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TRACTOR,

Compare the I{iustrations with your tractor to familiarize yourseif Withthe focalion of various controls and adjustments. Save

this manual for future reference

CROKECONTROL

CLUTCH/BRAKE

PEDAL

HEIGHTADJUSTMENT

KNOB

AMME'TSR

THROTTLE COHTRDL

ATTACHMENT UFTLEVER

. ÷ " " .... CLUTCH SWITCH PLUNGER

HOUR

METER

LIFT LEVER

IGNITION SWITCH

PARKING BRAKE

LEVER

MOTION

CONTROL

LEVER

FREE WHEEL CON"i'ROL

FIG,, 5

Our tractors conform to the salary standards of

ATTACHMENTCLUTCH SWITCH, Usedto engage mower

btades Orether'attachments mounted to your tractor

LIFT LEVER- Used to raise and tower mower deck or other

attachments mounted to your tractor.

Ct.UTCHtBRAKE PEDAL - Used for dectutching and

braking the lractor and sta ding the engine

MOTION CONTROL - Selects the speed and direction of

tractor

CHOKE CONTROL - Used when starting a cold engine,

LIGHT SWITCH - Turns the headt!ghls on _nd off_

THROTTLE cONTROL - Used to controt engine speed.

12

the American National Standards institute°

FREEWHEEL CONTROL * Disengages transmission for

pushing or stowly towing the tractor with the engine off

IGNITION SWITCH - Used to start and stop the en_jine_

AMMETER - indicates battery charging (+) or dfscharglng

(-),

PARKING BRAKE LEVER - Locks c)utch/brake pedal Into

the brake position

HEIGHTADJUSTMENT KNOB - Used to adjust the mower

heighL •

HOURMETER - indicates hours of ope_'atlon_

i i

HOW TO USE YOUR TRACTOR

OPERATION

.u, i iii iiiii ,11,,,11iiiii ii i

The operation of any tractor can result in foreign objects thrown into the eyes, which can resu t l

in severe eye damage. Always wear Safety glasses or aye shields while operating your tractor

f

or performing any adjustments or repairs. We recommend a wide vision safety mask over the

spectacles or standard safety glasses,

.,,HHH

TO SET PARKING BRAKE (See Fig. 6)

Your tracfor isequipped with an opera!or presence sensing

switch. When engine is running, any atlempt by the

operator to leave the seat Without first setting the parking

brake Will shut off the engine.

• Depress clutch/brake pedat into full "BRAKE" position

and hotd

• Place parking brake tever In"ENGAGED" position and

releasepressurefromc}utch/brakepedal Pedalshould

remain in "BRAKE" posi!tOnoMak_ sure parking brake

wiil hold tract6r secure

PUSHiN TO ATTACHMENTCt.UTCH

THROTTLE "DISENGAGE" SWITCHPULLOUTTO

NOTE: Undercedaln conditions when unJtis standing idle

with the engine running, hot engine exhaust gases may

cause "browning" of grass To eliminate this possibility,

always stop engine when stopping tractor on grass areas

'_ CAUTION: Always stop tractor corn:

pletely, a s described above, before leav-

ing the operator's position; to empty

grass catcher, etc..

TO USE CHOKE CONTROL (See Fig. 6)

Use choke €ontrol whenever you are stading a coldengine.

Do not use to slart a warm engine

• To engage choke conlroL pull knob out. Slowly push

knob in to disengage

CONTROL LEVER _,---=--,_. "ENGAGE'_

##

o.o,o,o2%,

PEDAL"BRAKE" \ \ _ i _'_ \\-_'-'_ ./

_-_ I / _'-_. \ CONTROL

t .EI . " "X

POSITION KNOB BRAKE

"DIS ENGAGJSD'" "ENGAGED"

POSITION. POSFION

FIG: 6

STOPPING (See Fig, 6)

MOWER BLADES o

TO USE THROTTLE CONTROL (See Fig. 6}

Always operate engin_ at ful] throttle

• Operallng engine at tess than full throttle reduces the

baltery charging rate

• Full Ihrattle offers the best baggirlg and mower perfor-

mance

TO MOVE FORWARD AND BACKWARD

(See Fig, 6)

The direction and speed o_movement is controlled by lhe

motion control lever

• Start tractor wilh motion Controllever in neutral (N)

position

• Release parking brake and clutch/brake peda!.

• Slowly move molion control lever todesired position,

TO ADJUST MOWER CUTTING HEIGHT

(See Fig_ 6)

Thecuttingheight iscontrolled byturninglhe heightadiusl-

ment knob in desired direction

• Turn knob clockwise ((-_1)to raise cutting height,

• Move attachment clutch switch to "DISENGAGED"

posilton

GROUND DRIVE -

• Depress clutch/brake pedal into lull "BRAKE" position.

• Move motion control lever to neutral (N) poe!lion

IMPORTANT: THE MOTION CONTROL LEVER DOES

NOT..RETURN TO NEUTRAL (N) POSIT!ON WHEN THE

CLUTCHtBRAKE PEDAL IS DEPRESSED

ENGINE -

• Move throttle control tO slow (.,=_) position.

NOTE: Failure to move throttle control to stow (,,a_)

position and allowing engine to idle before stopping may

cause engine to "backfire"

• Turn ignition l<ey to "OFF" position and remove key.

Always remove key when leaving tractor to prevent

unalJthorlzed use.

• Never use choke tO slop engine..

• Turn knob counterclockwise ()¢%} to lower'cutilng

height

The culling height range is approximately 1-1/4" Io 4-1/2"

The heights are measured from the ground to the blade tip

with the engine not running These heights are approxi;

mate and may vary depending upon soil csndittohs, height

_?lgrass and types of grass being mowed.

• The average lawn should be cut toapproximately 2-I12

inches during the cool season and to over 3 inches

during hot months For healthier and better looking

lawns, mow often and after moderate growth°

, For best culling performance, grass over 6 inches in

heighl should be mowed Iwice Make the flrsl cut

relatively high; !he second to desired height

13

OPERATION

,, ,, ,,,,,,,,,,,, i,,,11,

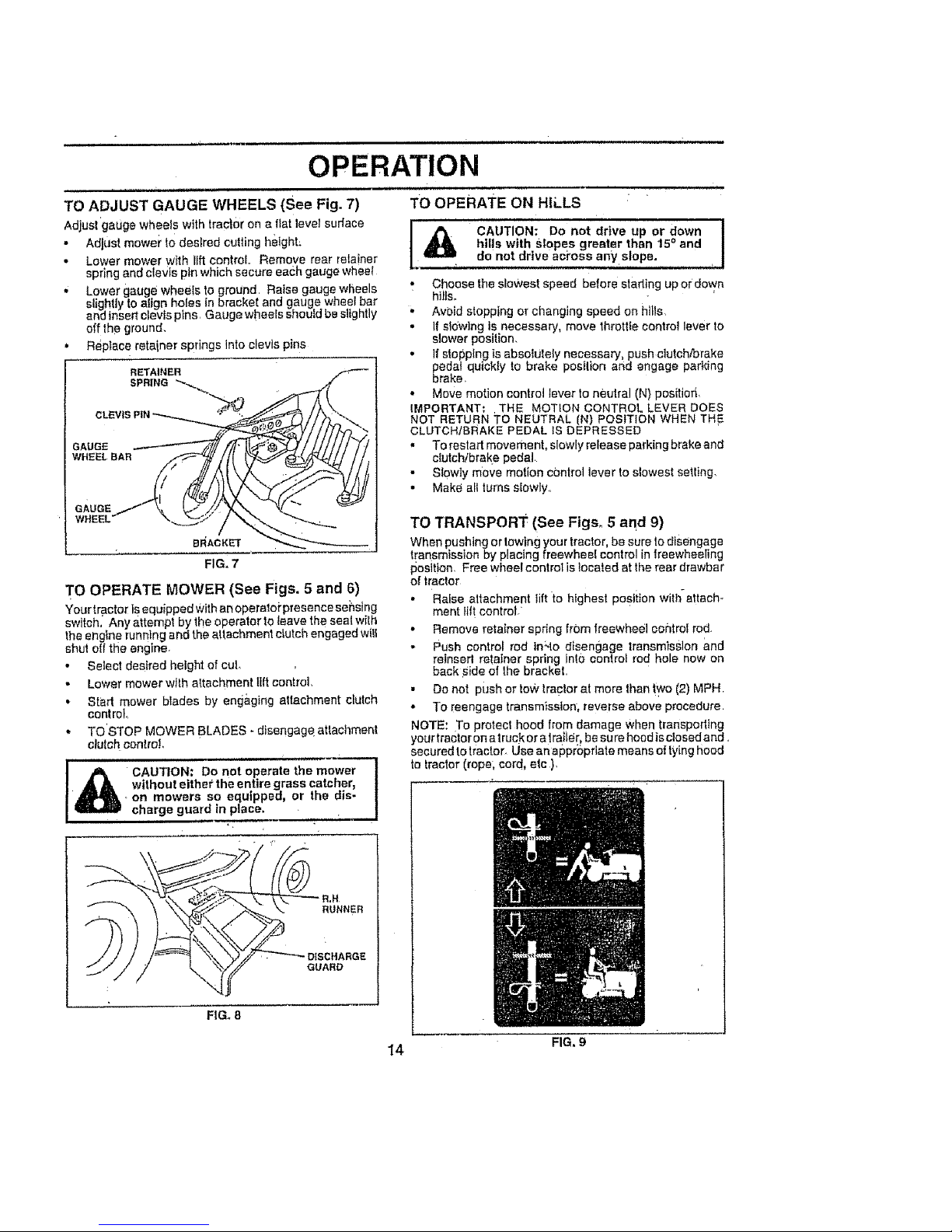

TO ADJUST GAUGE WHEELS (See Fig. 7)

Adjust gauge wheels with trac|or on a flat level suriace

• Adjust mower to desired cutting height:

• Lower mower w_th lift control Remove rear relainer

spring and clevts pin which secure eac:h gauge wheet

. Lower gauge wheels to ground Raise gauge wheels

slightly to align holes in bracket and gauge wheel bar

and insert clevis pins Gauge wheels should be slightly

off the ground_

• Repiace retainer springs lnto clevis pins

RETAINER

SPRING _,_

GAUGE

WHEEL BAR

GAUGE

WHEEL

FIG. 7

TO OPERATE MOWER (See Figs. 5 and 6)

Your tractor is equipped With an operaloi'presence sensing

sw teh. Any attempt by the operator to leave the seal wilh

the engine running and the attachment cLutc _engaged w II

shut elf the engine,

• Select desired height of cuL

• Lower mower with altachment lift control,

• Start mower blades by eng&ging altachment clutch

control

,. TO STOP MOWER BLADES - disengageaftachment

clutch control,

l _ CAUTION: Do'not operate the m_wer_

without either the entire grass catcher, !

. on mowers so equipped, or the dis- !

charge guard in place. . . I

. m _ m " =J

RUNNER

GUARD

FIGo 8

TO OPERATE ON HILLS

I CAUTION: Do not drive up or down !

hills with SlOpes greater than 15 ° and

I

do not drive aci'oss any slope. •

,_ Choose the slowest speed before stading up or down

hi_ls°

• Avoid stopping or changing speed on httls,

• if sldw]ng is necessary, move throttle control lever to

slower position.

• If stopping is absolutely necessary, push clutch/brake

pedal quickly to brake posilion and engage parking

brake

• Move motion control lever to neutral (N) pos_tiorl,

IMPORTANT: THE MOTION CONTROL LEVER DOES

NOT RETURN TO NEUTRAL IN) POSITION WHEN TH 5

CLUTCHtBRAKE PEDAL iS DEPRESSED

" To restart movement, slowly release parking brake and

clutch!brake pedal

• Slewty m0ve motion control lever to slowest setting.

• Make all turns slowly

TO TRANSPORT (See Figs, 5 and 9)

When pushing or lowing your tractor, be sure 1o disengage

t[ar_smisslon by placing freewhee! control in treewheeling

posltion_ Free wheel conlrot is tocaled at the rear drawbar

of traclor

• Raise altachment tilt to highest PoStiion with-attach-

ment lift control/

• Remove retainer spring from freewheel cohlroI rod.

• Push control rod tn'.to disengage transmission and

retnsert retainer spring inl0 control rod hole now on

back Side of lhe bracket

• Do not push or low tractor at more than ly¢o (2) MPH

• To reengage transmission, reverse above procedure

NOTE: To protect hood from damage when transpodtng

your tractor on a truck or atra_ie[_be su re hocd is clese dand.

secured to tractor_ Use an eppropriate means of tying hood

to lractor (rope; cord, etc ),

14 FIG, g

OPERATION

BEFORE STARTING THE ENGINE

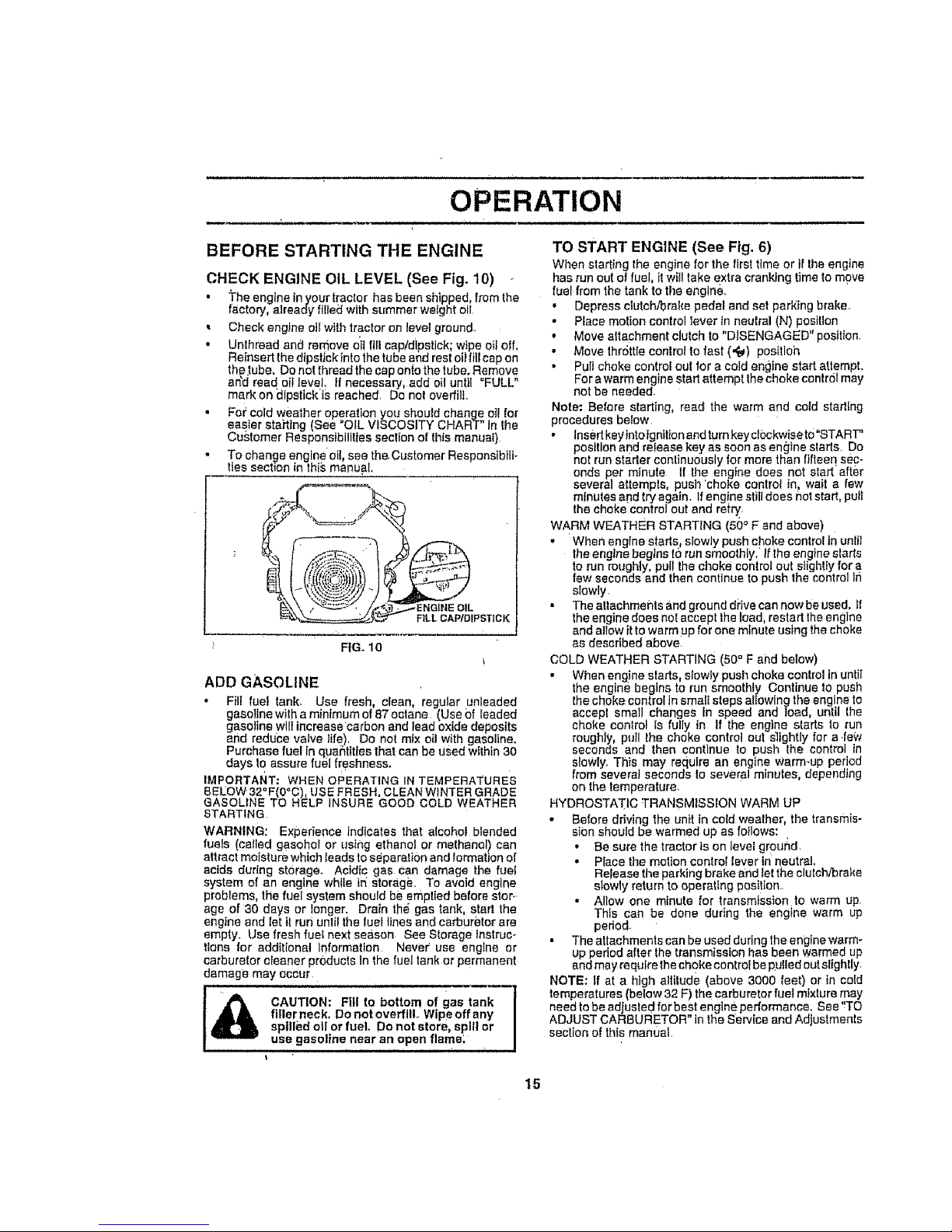

CHECK ENGINE OIL LEVEL (See Fig, 10)

• The engine tn your tractor has been shipped, from the

factory, already filled with summer weight oil

Check engine oil with tractor on level ground,

• Unlhread and remove oit fill cap/dipstick; wipe oil off,

Reinsert the dlpslick Into the tube and rest oii fill cap on

the tube. De not thread the cap onto the tube. Remove

arid read oil level, it necessary, add oi! until "FULL"

mark on _Ipstick ISreached, Do not overfitL

, Fo='cold weather operation you shoutd change oil for

easier stait}ng (See "OiL VISCOSITY CHART" tn the

Customer Responsibilities section of this manual)

• To change engine oil, see the.Customer Responsibili-

ties section in this manual.

i

FILLCAP/DIPSTICK

FIG. 10

ADD GASOLINE

• Filt fuel tank, Use fresh, clean, regular unleaded

gasoline with a minimum of 87 octane (Use Of leaded

gasoline will increase'carbon and lead oxide deposits

afld reduce valve life), Do nol mix oil with gasoline,

Purchase fuel In quar_ttttes that can be Used within 30

days to assure fuel f(eshnesso

IMPORTANT; WHEN OPERATING IN TEMPERATURES

BELOW 32"F(0°C), USE FRESH. CLEAN WINTER GRADE

GASOLINE TO HELP INSURE GOOD COLD WEATHER

STARTING

WARNING: Experience indicates that alcohof blended

fuels (called gasohot or using ethanol or methanol) can

attract moisture which Ieads to se_paralien and formation of

acids during storage. Acidic gas Can damage the fuel

system of an engine while tn storage To avoid engine

problems, the fuel system should be emptied before stor-

age of 30 days or longer. Drain the gas tank, start Ihe

engine and let tt run until the fuel lines and carburetor are

empty_ Use fresh rue! next season See Storage instruc-

tions for additional Ir}format_on Never use engine or

carburetor cleaner products In the fueJ tank or permanent

damage may occur

CAUTION: FIll to bottom of gas tank-_l

filler neck. Do not overfilL Wipeoffany I

spilledo orfueL Do not store, splllor I

use gasoline near an open flame. /

TO START ENGINE (See Fig. 6)

When starting the engine for the firs_ time or if Ihe engine

has run out of fuel, II wiil take extra cranking time to move

fuel from the tank to the engine

• Depress clutch/brake pedal and set parking brake,

• Place motion control lever tn neutral (N) position

• Move attachment clutch to "DISENGAGED" position,

• Move Ihr6ttle control to fast (,f_) pos[tloh

• Pull choke control out for a cold engine start attempL

For a warm engine start attempt the choke control may

not be needed,

Note: Before starting, read the warm and cold starting

procedures below

• Insert key Intotgnllionand rum key clockwise to°START"

position and release key as soon as engine alerts Do

not run Starter continuously for more than fifteen sec-

onds per minute If Ihe engine does not alert after

several attempts, push 'choke control In, wait a few

minutes and try again, tf engine still does not start, pull

the choke control out end re|_

WARM WEATHER STARTING (50 ° F and above)

• When engine starts, slowly push choke control in unlt]

the engine begins t0 run smoothly, if ihe engine sfarts

to run roughly, pull Ihe choke control out s}ightly for a

few seconds and then continue to push the control In

slowly

• The altechmeflls and ground drive can now be used. _1

%heengine does not accept the lea& restart the engine

and allow i_to warm up for one m_nute using the choke

as described above,

COLD WEATHER STARTING (50 ° F and below)

• When engine starts, slowty push choke control in unti!

lhe engine begins to run smoothly Continue to push

the choke control in smalt steps at_owing the engine to

accept small changes in speed and toad, until the

choke control Is fully in If the engine starts to run

roughly pull the choke control out s_ightly for a few

seconds and then continue to push the control in

sloWly, This may require an englne warm-up period

from several seconds to severe! minutes, depending

on the temperature,

HYDROSTATIC TRANSMISSION WARM UP

- Before driving the unit in cold wealher, the transmis-

slon should be warmed up as foIIows:

• Be sure the tractor Is on level ground,

• Place the motion control lever in neutral,

Release the parking brake and let the clutch/brake

slowly return to operating posi!ion.

• Allow one minute for transmission to warm up,

This can be done during the engine warm up

pedod.

• The attachments can be used during the engine warm-

up period after the transmission has been warmed up

and may requlrethe choke control be puffed out siighIly

NOTE: if at a high altitude (above 3000 feet) or in cold

temperatures (below 32 F) the carburetor rue! mixture may

need to be adjusted for best engine performance, See 'rTO

ADJUST CARBURETOR" in the service and Adjustments

section of this mant_al

15

uiH illll

OPERATION

PURGE TRANSMISSION

CAUTION; Neverengageordisengage

freewheel lever while the engine isrun-

ning_

To ensure proper operation and performance, it is recom-

mended thai the transmission be purged before operating

tractor for the first time. This procedure wi!t remove any

trapped air inside the transmission which may have devel-

oped dudng shipping of your traclor

IMPORTANT; SHOULD YOLtR TRANSMiSSiON REQUIRE

REMOVAL FOR SERVICE OR REPLACEMENT, tT

SHOULD BE PURGED AFTER REINSTALLATtON

BEFORE OPERATING THE TRACTOR

• Piace tractorsafety on level surface with engine off and

parking brake set

Disengage tran'smtsslon by placing freewheel control

[n freewheeling position (See "TO TRANSPORT" in

this sectbr_ of manual)

- SIttingtnthetractorseat,stadengine Afterfheengine

ts running, move throttle control to stow (.gh) position

W th Got on control lever inneutral (N) position, slowty

disengage clutch/brake _0edal

• Move motion control lever to full forward position and

hold for five (5} seconds. Move Iever to full reverse

position and hold lot five (5) seconds° Repeat this

• procedure three (3) times,

NOTE; During th_sprocedure ther_ wilI be no movement of

drive wheels. The air is being removed from hydratJtlc drive

system.

• Move motion controileverto neulral (N) position. ShuF

off engine and set parking brake-

. Engage transmission by placing freewheel control in

driving position (See "TO TRANSPORT" inthis section

o4manua!).

• Sitting tn the tractor seat, start engine. After the engine

is.running move lhrottte control to half (1t2) speed.

With metbn control lever tnneutral (N) pos I on, s ow y

disengage clutch/brake pedal

• Slowly move motion control lever forward, alter the

tractor moves approximately live (5) feet, sIewly move

motion control lever to reverse posltton. After the

tractor moves approximately five(5)feet return the

motion control lever to the neutral (N) position. Repeat

this procedure with the moti0fl conlrol lever three (3)

times_

• Your tractor is now purged and now ready for normal

operation.

MOWING TIPS

• Tire chains cannot be used when the mower housing

isattached to tractor.

• Mower should be propedy leveled for best mowing

performance. Sea'TO LEVEL MOWER HOUSING" in

the Service and Adjuslments section of this manual.

• Use the runner on the right hand side of mower as a

guide The blade cuts approximately an inch outside

the runner (See Fig 8)

• The left hand side el mower should be used for trim-

ming

• Drive so tha.t clippings are discharged onto the area

that has been cut. Have the cut area to the right of the

traclor. This will result in a more even distribution of

Clippings and more _intfoim cutting.

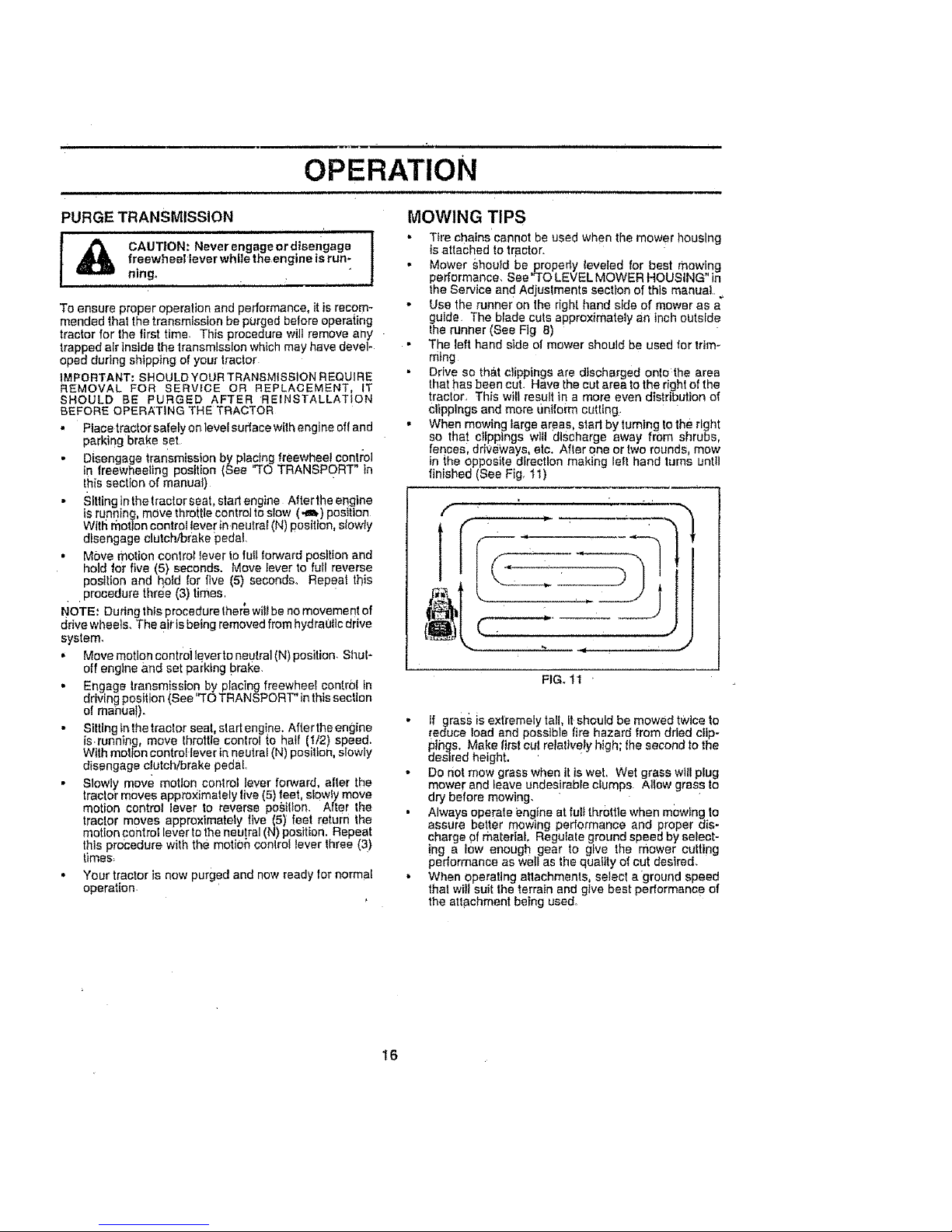

• When mowing Iarge areas, starl by turning to the right

so that cFIpptngs will discharge away from shrubs,

fences, driveways, etc. After one ortwo rounds mow

in _,heopposile direction making left hand turns until

finished (See Fig. tl)

[;

f

FIG. 11 '

• ff grass is extremely tall, it should be mowed twice to

[educe Ioad and possible fire hazard from dried cllp-

pings. Make first cu_ relatively high; the second to the

desired height.

• Do not mow grass when tt is wet, Wet grass will plug

mower and leave undes!rable clumps AIIow grass to

dry before mowing,

• Always operate engine at ful_throttle when mowing to

assure better mowing performance and proper dis-

charge f_f material, Regulate ground speed by seFect-

!ng a low enough gear to give the mower culling

performance as well as the quaitty of cut desired.

• When operating attachments, select a ground speed

thai will suit the terrain and give best performance of

the att#chment being used.

16

, ,,, .,,...Hi, ,

CUSTOMER RESPONSIBILITIES

,,u,, Jl ,,,,, ,1111, ,,,, , m .........J,u,,,,,,,,,,,,,,,,u

......... _ _ ..........._ ......

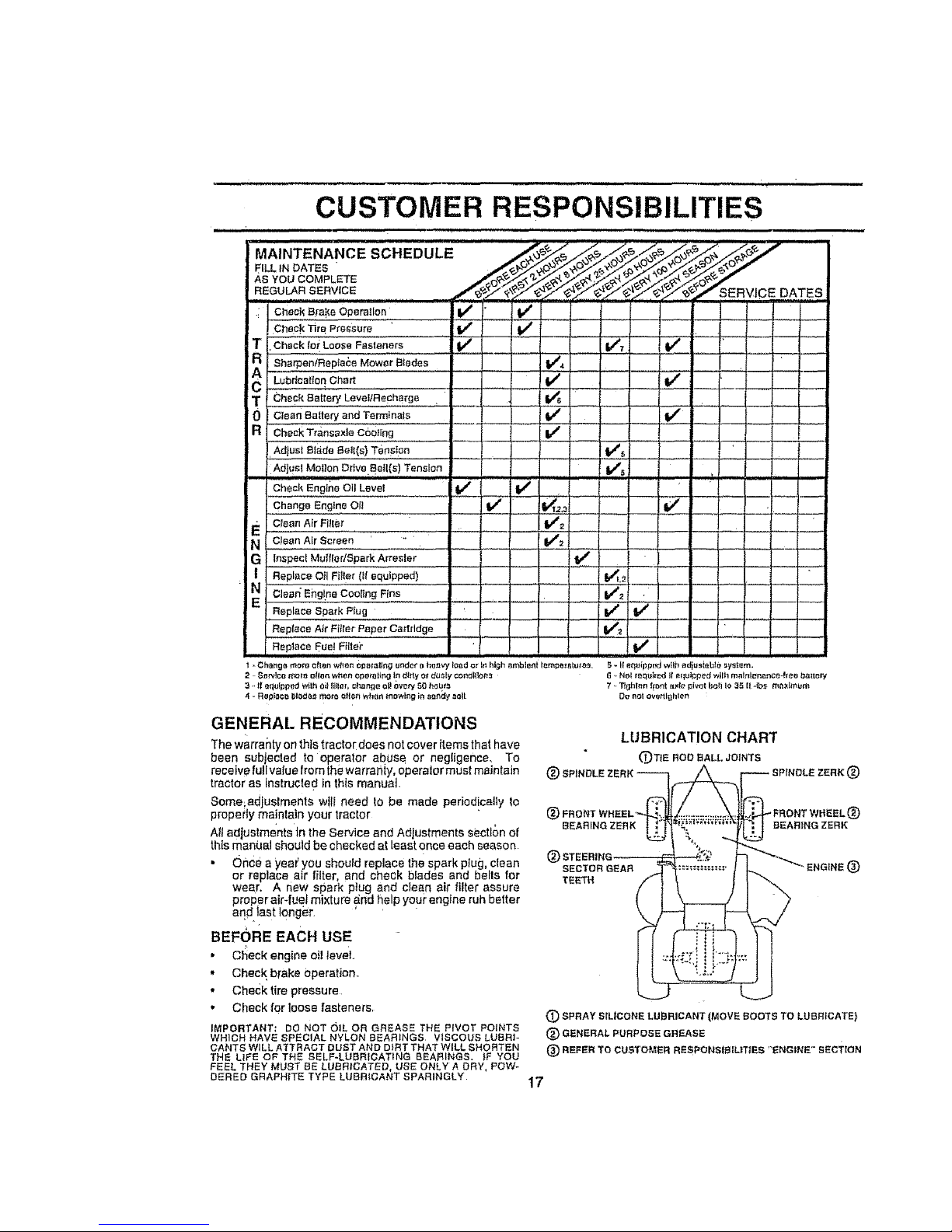

'MAINTENANCE SCHEDULE _.,_ ._,_/_'_,,_, o_'_,_X_' '''"

AS YOU COMPLETE

REGULAR SERVICE ,##-,_o_ _',_7 _'_ _,.._" _'_,.._/_.,-" _.T/" '_,Y'_,,,,'_SERVICE DATES

Check _rB Pressure i tf t,/

i T Check lo_ LOOSe Fasteners If ......1 #m##_' if - --

c Sho eo,Ra,lo oMow ,;,,'0,ee,""';;;;;..... V', -- .__Lubrication Chart ! If

T Check earlap/LeveIIRechsrge

0 Ctean_a_ta_aedTe_._a!e ---_ _ iV' V"

a Check Tr_nsa×le c6oting if

Adjust Blade Bell(e} Tension V"s ,,

Ad_,etMe,.:.T....,vo._.a,(e)._.no Tenancy, v', : ......

Ch_o_E_g!_,ao,Lena,............_ _ I { "

,,Change Englne OI! ...... . • , I #/ t_.z.= { lt_

E CIean Air Filler V_

N C!a_,n,AIrScreen,, I V'= .........

G Inspect Mu{fler/gpark Arresler J 1_ ......

Replece 011 FHIer (Ifequipped) I."_,_

Replace Spark Plug V _ If

Replace Air Fi_ler Paper Cartridge ...... _ __ _ .... _

R_p_aeaFuel_I!!,£.................. V'

1 ..Ch_,ngt_more oft_r_ wM_n 0_e_ling _zl_of t_hn_tv_{o_d .o_I_ high _bi_t _mpe_BlU/_ S - II eq_ipped wilh ad_tlsiabl_* uy_im.

2 Se_lco n_olo o[I_n wt_en Operating I_1ditty ot d_ly ¢o_lt_or_ r 6 _NOI _r_qt_red I1equipped wilh m_l_l_na_ce-hee battery

3 ,,I__qulpp._t't.,l_t_oillille,+change oI_ow_ 50 t_u_ 7 ,.TJEii_I_n(_o_n[it._iepivotb_IIIo35 {I_tbs_Imitm

4 ..RepF_cr_t_lado,_morn ellen wf_en mowh_g in s_nd_ soil Co r_otov_ttlghlen

GENERAL RECOMMENDATIONS

Thewarrantyonthlstractordoesnotcoveritemsthathave

been subjected to operator at_use or negIigenee, To

receive fu!lvatue from the warra}ity operator must maintain

tractor as Instructed in this manuat

Some;adjustments willneed to be made periodicallyto

propeily maintain your tractor

All adjustments tn the Service and Adjustments sectlc)n of

this manL_at should be checked at least once each season

• Once a yea€ you should replace the spark plug, clean

or replace air filter, and check blades and bells for

wear, A new spark plug and clean air filter assure

proper air-fueJ mixture ,and help your engine ruh better

andlast longer

BEFORE EACH USE

• C_eek engine oil level°

• Check brake Operation.

• Checktire pressure

• Check for loose fasteners,

IMPORTANT: DO NOT OIL OR GREASE THE PIVOT POINTS

WHICH HAVE SPECIAL NYLON BEARINGS VISCOUS LUBRI-

CANTS WILL ATTRACT BUST AND DIRT THAT WILL SHORTEN

THE L_FE OF THE SELF-LUBRICATING BEARINGS. _F YOU

FEEL THEY MUST BE LUBRICATED, USE ONLY A DRY, POW-

DERED GRAPHITE TYPE LUBEIICANT SPARINGLY

LUBRICATION CHART

(_TtB ROD BALL JOINTS

®

®FRONT _FRONT WHEEL_[)

BEARING ZERK BEARING ZERK

®

SECTOR GEAR ®

TEETH

(_) SPRAY SILICONE LUBRICANT (MOVE SOOTS TO LUBRICATE}

(_ GENERAL PURPOSE GREASE

® REFER TO CUSTOMER REBPONSIBtLITIES "ENGINE" SECTiON

17

CUSTOMER RESPONSIBILITIES

TRACTOR

Always observe safety rules when performing any mainte-

narcs

BRAKE OPERATION

If tractor requires more than six (6) feet stopping distance

a{ high speed fn highest gear, Ihen brake must be adjusted.

(See "TO ADJUST BRAKE" In the Service and Adjust-

ments section of this manual)

TIRES

• Maintain proper airpressure in all tires (See "PROD-

UCT SPECIFICATIONS" on page 3 of this manual):

• Keep tires free ol gasot(ne, oil, or insect control chemi-

cals which can harm rubber,

• Aveid.slumps, slones, deep ruts, sharp objects and

other hazard s that may cause tire damage.

BLADE CARE

For best results mower blades must be kept sharp, Re-

place bent or damaged blades,

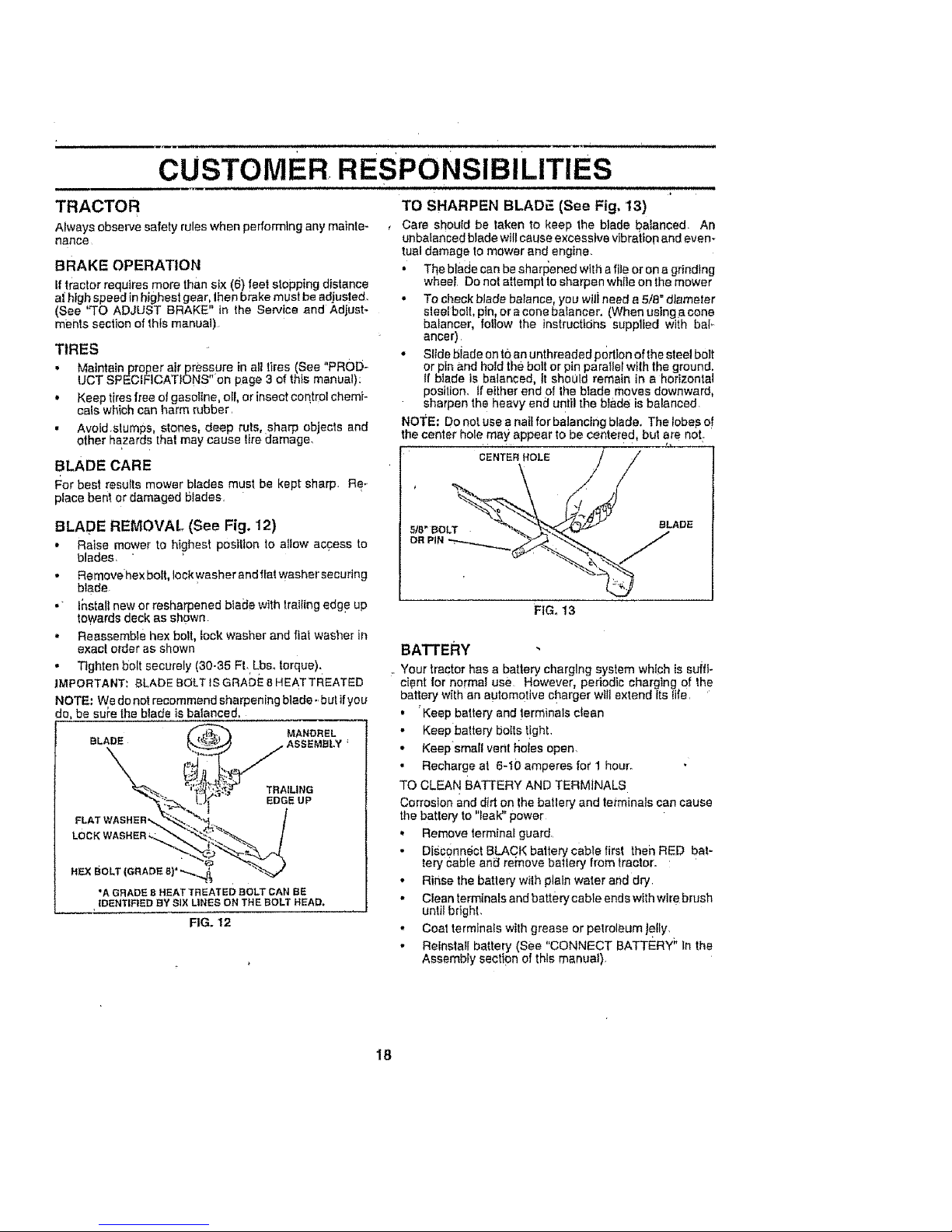

BLADE REMOVAL, (See Fig, 12)

• Raise mower to highest position to allow access to

blades, "

• Remove hexboit, lock washer and flat washer securing

blade

• tnstall new or resharpened blade with trailing edge up

towards deck as shown

,, Reassemble hex bolt, tock washer and fiat washer in

exact order as shown

,, Tighten bolt securely (30-35 FI. Lbso torque).

iMPORTANT: BLADE BOLTISGRADEBHEATTREATED

NOTE: We do net recommend sharpening blade -,bul ifyou

do, be su_'ethe blade is balanced,

a.... _ MANDREL

_,_u_ t",__-_.._.*,_ ASSEMBLY

J

REX BOLT (GRADE 81 "--_.' "_

'AGRADE aHEAT TREATED BOLT CAN BE

IDENTIFIEDBY SIXLINESON THE BOLT HEAD.

FIG. 12

TO SHARPEN BLADF_(See Fig, 13)

, Care should be taken to keep the blade balanced. An

unbaianced btade will cause excessive vibration and even*

tuB! damage to mower and engine.

• The blade can be sharFJened with a file or on a grinding

wheel Do not attempt to sharpen while on the mower

• To check blade balance, you will need a 5/8" diameter

ales{bolt pin, or a cone ba_ancer, (When using a cone

balancer, follow the instructtdhs supplied with bal*

anger)

• Slide biade on to an unthreaded portion of the steel bolt

or pin and hold the bolt or pin parallel wilh the ground.

If btade is balanced, it shoLJld remain in a horizontal

position, tf either end of the biade moves downward,

sharpen the heavy end until the blade is balanced

NOTE; Do not use a nail for balancing blade. The lobes o!

the center hole may appear to be centered, but are not.

NTE"HOLE/ /

FIG, 13

BATTERY

Your tractor has a battery charging system which is suffi-

cient for normal use However, periodic charging of the

battery with an automotive charger will extend Its {ire, '

• "Keep battery and !erminals ctsan

• Keep battery botts t!ght,

• Keepsmall vent tlo_esopen.

• Recharge at 6-!O amperes for I hour,

TO CLEAN BATTERY AND TERMINALS

Corrosion and dirt on the batlery and tei_minalscan cause

the batte_ to "Ieal¢' power

• Remove termina_ guard

Digc0nn6ct BLACK battery cabte first then RED bat-

tery Cable ani_ rei'nove batlery from tractor.

• Rinse the battery with plain water and dry,

• Clean terminals and batterycable ends with wire brush

unlit bright.

• Coat terminals with grease or petroleum Jetly.

• Reinstall battery (See "CONNECT BATTERY _'In the

Assembly section of this manuaI).

18

Loading...

Loading...