Sears Craftsman 358.356091,Craftsman 358.356101 Important Manual

IMPORTANT MANUAL

__.ARS

operator's

manual

• Assembly

• Operation

• Maintenance

• Repair Parts

MODEL NO.

358.356091-3.7120"

358.356101-3.7118"PS

AWARNING

Thischainsawiscapableof severe

kickbackthatcouldtesultinserious

lr_uryto theuser.Donotoperatethis J

sawunlessyouhaveextraordinary

cuttingneeds,andha_especialized

trainingand experiencefor dealing

with kickback.Chainsawswithslg-

nificantlyreducedkickbackpotential

areavailable.

Do Not Throw Away

_A/RSICRRFTSMRN I

3.7/20" 3.7,/t8"PS

GASOLINE CHAIN SAWS

i1: i,,,ii ii

Record in the space provided below the Model N% and Serial No. of

your saw. These numbers are located on the starting instructions

decal.

M6del No. Serial No.

Retain these numbers for future reference.

,i

530-066648-5-21188

Sears, Roebuck and Cx)., Chicago, Ill. 60684 U.S.A.

.

©Sears, Roebuck and Co., 1988.

FULLONEYEARWARRANTYON GASOLINECHAINSAW

(ExcludingBar_Chain_SparkPlu9, A!rFilterandStarterRope)

Foroneyear fromdateof purchase,whenyou maintain, lubricate, and tune up thisgasoline chain saw according tothe

operating andmaintenanceinstructionsin theowner's manual, Searswillrepair aetectsin mazedal or workmanship inthis

i gasoline chainsawatno charge.

This warranty excludesthe bar, chain, spark plug, air filter, andstarterropewhichare expendable parts andbecomeworn ._

during normaluse. .....

If this gasolinechain,saw is usedforcommercial or rental p_Jrposes, this warranty applies for only 30 days fromdateof ._

purchase.WARRANTYSERVICEISAVAILABLEBYRETURNINGTHE CHAINSAWTOTHE NEARESTSEARSSERVICE

_ CENTER/DEPARTMENTIN THE UNITEDSTATES. '" -.

Thiswarrantygivesyouspecificlegal dghts,andyoumay alsohaveotherrightswhichvaryfromstatetostate. .<

TABLE OFCONTENTS

Specifications ............................... 2

SPECIAL SAFETY SECTION ............... 3, 4 &5

Know Your Chain Saw ........................ 6

Preparing Your Saw For Use-., " 7

A; Getting Ready .................. :.. ...... 7

B. Attaching the Handguard .............. .... 7

C. Attaching the o,_r,.... 7

D. Attaching the Bar and Chain ....... . ........ 8

E. Chain Tension ........................... 9

F. Fueling Your Engine ............... ........ 9

G. Bar and Chain Lubricant. ... 10

Using Your Saw ........................ ".... 11

A. Control Devices " 11

B. Starting Instructions .... -................. 11

Using the Power Sharp" System .............. 12

Types of Cutting ............................ 14

A. Basic Cutting Technique .................. 14

B. Tree Felling Techniques ................... 14

C. Bucking ............................... 16

D. Debranching and Prunin.g ................. 17

Maintenance

A. Guide Bar and Chain ..................... 18

B. Spark Arrestor .......................... 19

C. Starter Rope ............................ 20

D. Carburetor Adjustments ................... 21

E. Clutch and Drum/Sprocket ................. 22

F. Air Filter ............................... 22

G. Storage ................................ 22

H. Maintenance Accessodes ................. 23

L Trouble Shooting Chart ................... 24

J. Maintenance Chart ....................... 25

Repair Parts List ............................ 28

Quick Reference Page ........................ 35

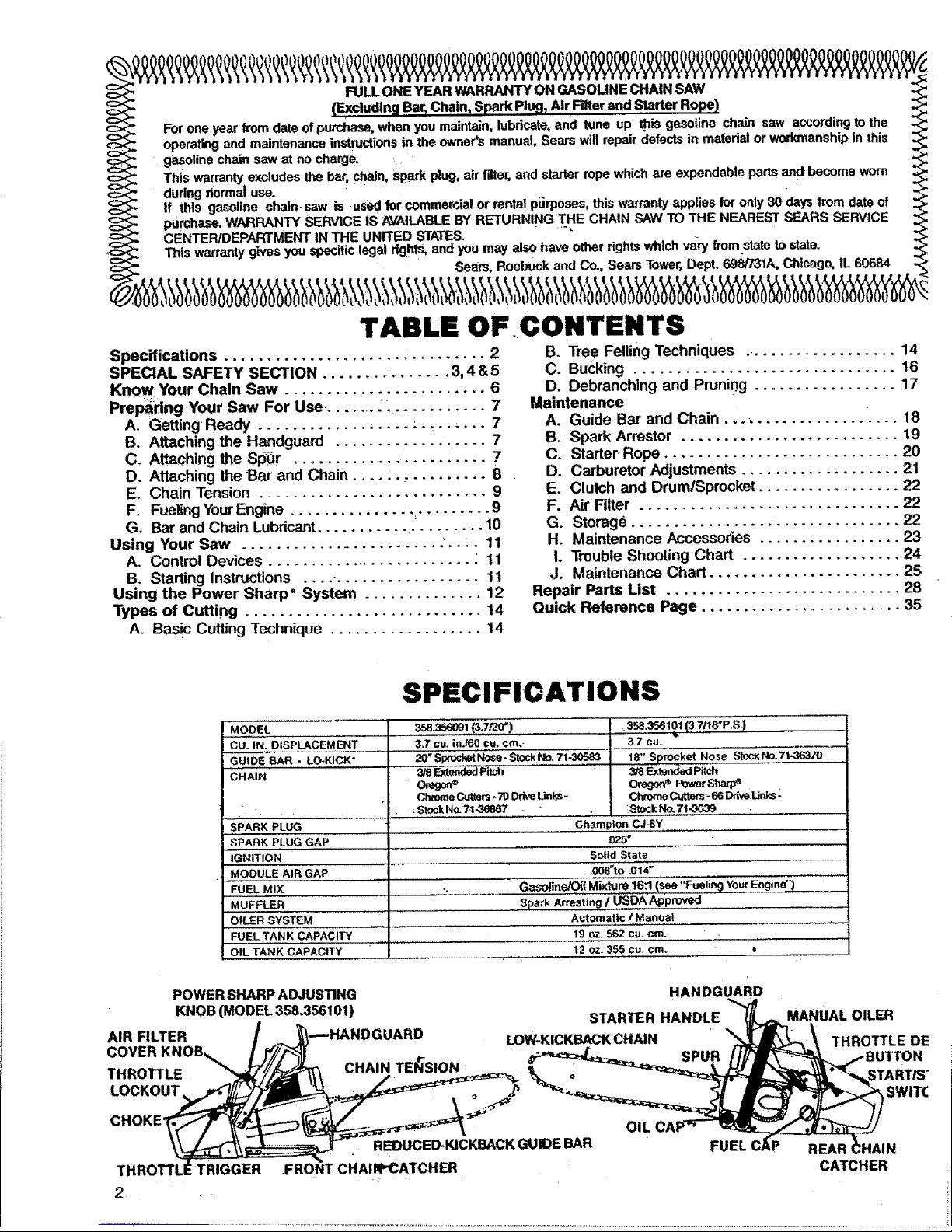

SPECIFICATIONS

MODEL

cu:iN.DISPU_CE.E.Ti

GUIDE BAR - L,O*KICK"

CHAIN

SPARK PLUG' ,,

SPARK PLUG GAP

IGNITION

MODULE AIR GAP

FUEL MIX

MUFFLER

OILER SYSTEM ..........

FUEL TANK CAPACITY

OIL TANK CAPACITY

_r_K6091{3.7/20 _) ,,, ,, , ,358.356101(3.7/t6"1_.S.)

3.7 cu. inJ60 cu. cm. 3.7 cu.

20"SprocketNose-StockNo.7t_ 18" Sprocket Nose StockNo.7t-36370

318Extended 'Pitch 318_' Pitch

" O_,gon® OtegorPPowerSham_

ChromeCutters*70DriveLinks- ChromeCutters'-66 DriveLinks

:Stock No.T1-36867 " _'tock No. 71-3639

Champion cJ-aY , ,

_025"

Solid State'

.008 to .014

.. ' ...... Gasoline/Oi! Mitre 16:1 (_ "FuelingYourEngine';)

Spark Arresting / USDA Approved,,

Automatic / Manual .......

.... 19 oz. 562 cu. cm. ......

12 oz. 355 cu. cm. ,,

POWER SHARP ADJUSTING

KNOB (MODEL 358.356101 )

AIR FILTER

COVER

THROTTLE

LOCKOUT

CHAIN TEI_SION

CHOKE'

HANDGUARD

STARTER HANDLE

LOW-KICKBACK CHAIN

TRIGGER

REDUCED-KICKBACKGUIDE BAR

CHAII_ATCHER

FU

.ER

THROTTLE DE

I SWITC

REAR !HAIN

CATCHER

UL I i I IHIIIIIIIIIIIJlIJl II I II I / . I I roll=l, ,,,,,,H,II

SPECIAL SAFETY SECTION

GUARD AGAINST KICKBACK

Kickback is a dangerous reaction that can lead to

serious injury. Do not rely only on the safety

devices provided with your saw. As a chain saw

user, you must take special safely precautions to help

keep your cutting jobs free from accident or injury.

A KICKBACK WARNING

Kickback can occur when the moving chain contacts

an object atthe upperportionof the tip ofthegulde bar

or when the wood doses inand pinches the saw chain

inthe cut. Contact at the upper portion of the tip of the

guidebarcan causethechaintodig into theobject and

atop the chain for an Instant. The result is a lightning

fast, reverse reaction which kicks the guide bar up and

back toward the operator, ff the saw chain is pinched

along the top of the guide bar, the guide bar can be

driven rapidly back toward the operator. Either of

these re=icti0ns Can Cause io_,sof saw control which

can result in serious injury.

KICKBACK PATH

Figure 1

AVOID

OBSTRUCTIONS

CLEAR

WORKING AREA

Figure2

NEVER I t STAND

REVERSE TO THE

HAND LEFT OF

POSITIONS THE SAW

ELBOW

I_.OCKED

LEFT HANo

Figure 3

f

ON

UNDER SIDE

-" OF HANDLEBAF_

REDUCE THECHANCE OF

KICKBACK

1. ReCognize that kickback can happen. With a

basic understanding of kickback, you can reduce

the element of surprise which contributes to

_ccidents.

2. Never letthe moving chain contact anyobject at the

tip of the guide bar. Figure 1.

3. Keep the working area free from obstructions

such as other trees, branches, rocks, fences,

stumps, etc. Figure 2. Eliminate or avoid any

- obstruction that your saw chain could hit while you

are cutting through a particular log or branch.

4. Keep your saw chain sharp and properly ten-

sioned. Followmanufacturer's chainsharpeningand

maintenance instructions.Check tension at regular

intervalswiththeenginestopped,neverwiththeengine

running.Make sure the bar clamp nuts are securely

tighter,ed after tensioning the chain. A _ or dull

chain can increase the chance of kickback to occur.

5. Begin and continue cutting aitfull throttle. If the

chain is moving at a slower speed, there is greater

chance for kickback to occur.

6. Cut only one log at a time.

7. Use extreme caution when re-entering a previous

cut.

8. Do not attempt plunge cuts.

9. Watch for shifting logs or other forces that could

close a cut and pinch or fall into the chain.

10. Use only the Reduced-Kickback Guide Bar and

Low-Kickback Chain specifiedforyoursaw.

MAINTAIN CONTROL

1. Keep agood firl_ grip on the saw with both hands

when the engine is running and don't let go.

Figure 3. A firm.grip can neutralize kickback and

help you maintain control of the saw. Keep the

• fingers of your left hand encircling and your left

thumb under the front handlebar. Keep your right

hand completely around the rear handle whether

you are right handed or lefthanded. Keep your left

arm straight with the elbow locked.

2. Position your left hand on the front handlebar soit

isIn a straight line with your right hand on the rear

handle when making bucking cuts. Figure 3. Never

reverse right and left hand positions during any lype

ofcutting.

3. Stand with your weight evenly balanced on

both feet.

4. Stand slightly to the left side of the saw, to keep

your body from being in a direct line with the

cutting chain. Figure 3.

5. Do not overreach. You could be drawn or thrown

off balance and lose control of the saw.

6. Do not cut above shoulder height. It isdifficultto

maintain control of the saw above shoulder height.

SPECIAL SAFETY SECTION (continued)

_ i i i iml. ,,,

.............. j i

,i_ WARNING

Because a chain saw isa high-speed wood-cutting tool, special safety precautions must

be observed to re(zuce the risk of accidents, Careless or improper use can cause

.serious injury.

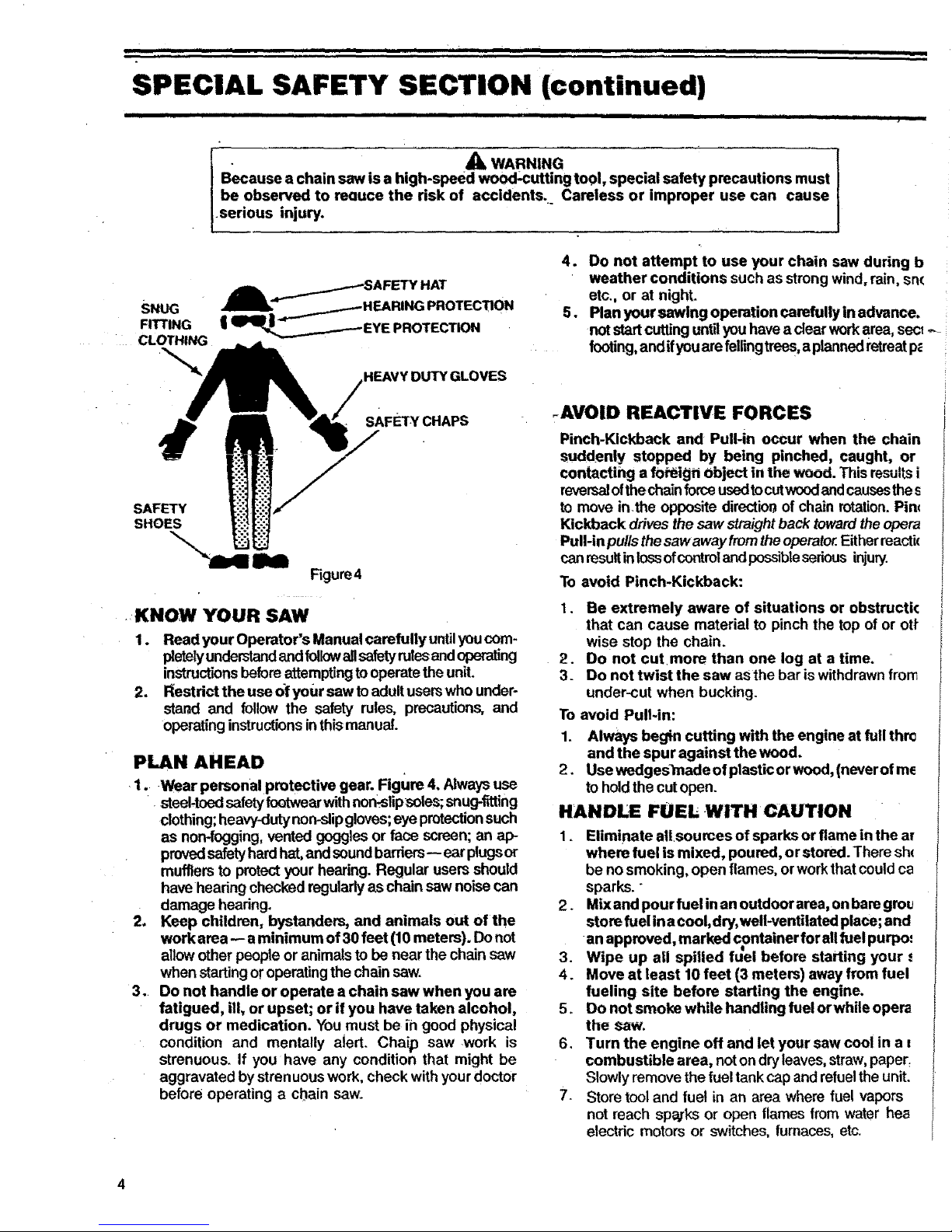

SNUG

FITTING

4. Do not attempt to use your chain saw during b

weather conditions such as strong wind, ralnzsn(

etc., or at night.

5. Plan your sawing operation carefully inadvance.

not startcutting untilyou havea clear workarea, sect ,--

footing,andifyouare fellingtrees,aptanned retreatp_

SAFETY CHAPS

SAFETY

SHOES

Figure4

,KNOW YOUR SAW

1. Read your Operator's Manual carefully untilyou com-

pletelyunderstandandfollowagsafetyrotes andoperating

instructionsbeforeattemptingtooperatethe unit.

2. I_estdct the use o'fyour saw to adult userswho under-

stagd and follow the safety rules, precautions, and

operating instructionsinthismanual.

PLAN AHEAD

1. Wear personal protective gear. Figure 4, Alwaysuse

steel-toedsafetyfoQtwearwithnon,slipsoles;snug-fitting

clothing;heavy-dutynon-slipgloves;eye protectionsuch

as norvfogging, vented goggtes or face screen; an ap-

provedsafetyhardhat,and soundbarriers-- ear plugsor

mufflersto protect your hearing. Regular users should

have headng checked regularlyas chain saw noisecan

damage hearing.

2. Keep children, bystanders, and animals out of the

work area-- aminimum of 30 feet (10 meters). Donot

allowother people or animals to be near the chain saw

when startingor operatingthe chain saw.

3. Do not handle or operate a chain saw when you are

fatigued, ill, or upset; or if you have taken alcohol,

drugs or medication. You must be in good physical

condition and mentally alert. Chaip saw .work is

strenuous. If you have any condition that might be

aggravated by strenuous work, check with your doctor

before operating a chain saw.

_AVOID REACTIVE FORCES

Pinch-Kickback and Pull-in occur when the chain

suddenly stopped by being pinched, caught, or

contacting a foi_ign object in the wood. Thisresultsi

reversalofthechainforceusedtocutwoodand causesthes

to move inthe opposite directior_of chain rotation.Pine

Kickback drives the saw straightback toward the opera

Pull-inpuffs the saw awayfromtheoperator.Eitherreactk

canresult inloss ofcontrol and possible serious inju_.

To avoid Pinch-Kickback:

1, Be extremely aware of situations or obstructk

that can cause material to pinch the top of or otf

wise stop the chain.

2. Do not cutmore than one log at a time.

3. Do not twist the saw asthe bar is withdrawn from

under-cut when bucking.

To avoid Pull-in:

1. Always begin cutting with the engine at full thin

and the spur against the wood.

2. Use wedges_nade ofplastic orwood, (never ofme

toholdthe cut open.

HANDLE FUEL WITH CAUTION

1. Eliminate allsources of sparks or flame in the ar

where fuel is mixed, poured, or stored. There sh(

be no smoking, open flames, orworkthat couldca

sparks."

2. Mix and pour fuelin an outdoor area, on bare grou

store fuel ina cool, dry,well-ventilated place; and

an approved, marked container forall fuel purpo.,

3. Wipe up all spilled f_el before starting your.,

4. Move at least 10 feet (3 meters) away from fuel

fueling site before starting the engine.

5. Oo not smoke while handling fuelor while opera

the saw.

6. Turn the engine off and let your saw cool in a I

combustible area, noton dryleaves,straw,paper:

Slowlyremove thefuel tank cap and refuelthe unit.

7. Store tool and fuel in an area where fuel vapors

not reach sparks or open flames from water hea

electric motors or switches, furnaces, etc.

OPERATE YOUR SAW SAFELY

1. Do not operate a chain saw that is damaged, im-

properly adjusted, or not completely and securely

assembled.

2. Operate the chain saw only in outdoor areas.

3. Do not operate the saw from a ladder or in a tree.

4. Position all parts of your body to the left of cut and

away from the saw chain when the engine is

running.

5. Cut wood only. Do notcutmetal;plastics,masonry,'non-

woodbu,ding materials, etc.Donotuse yoursaw to pryor

shove away limbs,rootsor other objects.

6. Make sure the chain will not makecontact with anyob-

Jectwhile startingthe engine. NeverWto stadthe saw

when the gu'rdebar is in a cutor kerf.

7. Use extreme caution when cutting small size brush

and saplings. Slender material can catchlthe saw

chain and be whipped toward you or pull you off

balance.

8. Be alert for springback when cutting a limb that is

under tension so you will not be struck by the limb or

saw when the tension in the wood fibers is released.

9. Do not put pressure on the saw st the end of a cut.

This can cause you to lose control when the cut is

completed.

10. Stop the engine before setting the saw down.

MAINTAIN YOUR SAW IN GOOD

WORKING ORDER

1. Have all chain saw service performed by your Sears

Service Center withthee00cept_oftheitems listedinthe

maintenance section of this manual. For example, if

improper tools are used to removeor hold the flywheel

when servicing the clutch, structural damage to the

flywheel c_ occur and cause the flywheelto burst.

2. Keep fuel and oil caps, screws and fasteners

securely tightened.

3. Keep the handles dry, clean, and free of oil or fuel

mixture.

4. Make certain the saw chain stops moving when the

throttle trigger is released. Forcorrection,refertopage

24 for carburetor idleadjustmentinstructions.

5. Stop the saw ifthe chain strikes a foreign object. In-

sPect the unitand repair or replace parts as necessary.

6. Disconnect the spark plug before performing any

maintenance except for carburetor adjustments.

7. Never modify your saw in any way. Use only attach-

ments supplied or specifically recommended by the

n_nufacturer.

8. Always replace the handguard immediately if it

becomes damaged, or broken or is otherwise

removed.

9. Keep vibrstion isolators in good condition. Peri,odically

inspectisolatorsfortears,ripsorseparationofthe'rubber

portionfromthe metal mountings. Have your Sears Ser-

vice Center replace the isolatorsif worn or damaged, if

Vibrationincreasesorifmountsdevelopanoutofroundor

swollenshape from exposure to gasolineand/or oil.it is

recommendedthat_ isolatorsbe replaced when a failure

toone occurs.

CARRY AND STORE YOUR SAW SAFELY

1. Handcarry the unit with the engine stopped, the

Muffler away from your body, and the Guide Barand

"Chain to the rear covered preferably with a scabbard.

2. Before transporUng in any vehicle or storing in any

enclosure, allow your saw to cool completely, cover

the bar and chain and properly secure to avoid

turnover, fuel spillage or damage.

3. Empty the fuel tank before storing the tool. Use

up fuel left in the carburetor by starting the eng-

ine and letting the engine run until it stops.

4. Store in a dry area out of the reach of children and

away from where fuel vapors can reach sparks or an

open flame from hotwater heaters,furnaces,etc.

SAVE THESE INSTRUCTIONS

NOTE: Exposure to vibrations through prolonged useof

chain saws may produce Whiteflnger disease

(Raynaud's phenomenon). This phenomenon

reduces the hand's ability to feet and regulate

temperature, produces numbness and burning

sensations and can cause nerve and circulation

damage and tissue necrosis.

An anti-vibration system designed to reduce

engine vibration is recommended for those using

chain saws on a-regular or sustained basis and is

provided on this saw. However, an antivibration

system does not guarantee the avoidance of

•Whitefingerdisease. Continual and regular users

must monitor closely their use of chain saws and

physical condition.

Notice: Refer to the Code of Federal Regulations, Section

1910.266(5); 2.5.1 of American National Standard

Safety Requirements for Pulpwood Logging, ANSI

03.1-1978; and relevant state safety codes when

using a chain saw for logging purposes.

ii ilill ii i ii i i iii

KNOW YOUR CHAIN SAW

i iiiii i i iii

A. INTRODUCTION

• Your saw has been designed with safetyinmind and

includesthefollowing feature_ _sstandardequipment:

- Reduced-Kickback Guide Bar

- Low-Kickback Chain

- Spark Arrestor

-Temperature Limiting Muffler

- Handguards

- Counter-Vibe ® Anti-Vibration System

WARNING

The following features areincluded on your saw to help

reduce the hazard of kickback, however, such features

will not totally eliminate this dangerous reaction. As a

chain saw user, do not rely only on safety devices. You

must follow all safety precautions, instructions and

maintenance in this manual to help avoid kickback and

other forces which can result in serious injury.

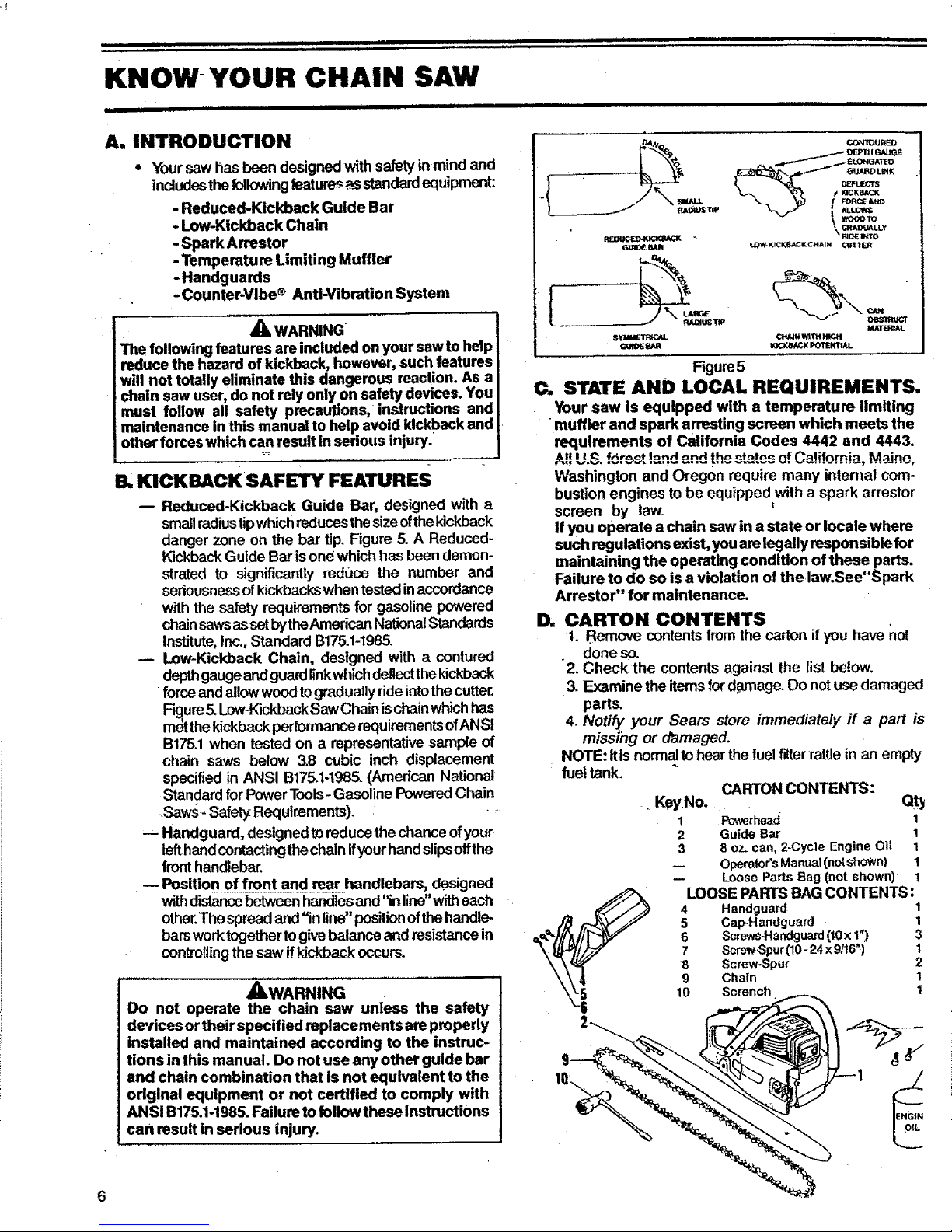

B, KICKBACK SAFETY FEATURES

-- Reduced-Kickback Guide Bar, designed with a

smallradiustipwhichreduces the sizeofthekickback

danger zone on the bar tip. Figure 5. A Reduced-

KickbackGuide Bar isone which has been demon-

strated to significantly redt'Jce the number and

seriousnessofkickbackswhen testedinaccordance

with the safety requirements for gasoline powered

chainsawsassetbythe AmericanNational Standards

Institute,Inc., Standard B175.1-1985.

Low-Kickback Chain, designed with a contured

depthgaugeandguardlinkwhichdeflectthekickback

force and allowwoodto graduallyrideintothecutter.

Figure5.Low-KickbackSaw Chainischainwhichhas

met thekickbackperformancerequirementsofANSI

B175.1when tested on a representative sample of

chain saws below 3.8 cubic inch displacement

specified in ANSI B175.1-1985.(American National

Standard for PowerTools-Gasoline Powered Chain

Saws- Safety Requirements)_

-- Handguard, designed toreduce the chanceof your

tefthandcontactingthechaJnifyourhand slipsoffthe

fronthandlebar.

_-_ PosiUon of f_mntand mar handlebars, designed

withdistancebetweenhandlesand "in line"witheach

other.The spread and "in line" positionofthehandle-

barsworktogethertogivebalanceand resistancein

contmflingthesaw ifkickback occurs.

_,WARNING

Do not operate the chain saw unless the safety

devices or their specified replacements are properly

installed and maintained according to the instruc-

tions in this manual. Do not use any othefguide bar

and chain combination that is not equivalent to the

original equipment or not certified to comply with

ANSI B175.1-1985. Failure tofollow these instructions

can result in serious injury.

OEFTHGAUG_

_ ELONGATED

i [IEFUEC'rs

- I FOR_ _KO

GU_0_ _ R _OW'KICK_ Ken'lAIN _T_rl_*

S_ CHAI_WlTH HIGH

Rgure5

STATE AND LOCAL REQUIREMENTS.

Your saw Is equipped with a temperature limiting

muffler and spark arresting screen which meets the

requirements of California Codes 4442 and 4443.

Aft U.S.forest !and and the s_tes of California, Maine,

Washington and Oregon require many internal com-

bustionengines tobe equipped with a spark arrestor

screen by taw. J

Ifyou operate achain sawin a state or locale where

such regulations exist, you are legally responsible for

maintaining the operatingcondition of these parts.

Failure to do so is a violation of the law.See"_park

Arrestor" for maintenance.

D. CARTON CONTENTS

1. Remove contents fromthe carton ifyou have not

done so.

"2.Check the contents against the list below.

3. Examine the items ford_mage. Do notuse damaged

parts.

4. Notify your Sears store immediately if a part is

missing or damaged.

NOTE: Irisnormalto hearthe fuel filter rattlein an empty

fuel tank.

CARTON CONTENTS:

• Key No. __ Qt_

1 Powerhead 1

2 GuideBar 1

3 8 oz.can,2-Cycle Engine Oil 1

Operator's Manual (not shown) 1

-- LoosePartsBag(notshown) 1

LOOSE PARTSBAG CONTENTS:

4 Handguard 1

5 CapHandguard 1

6 Scmws-Handguard (10x 1") 3

7 Screw-Spur (10- 24x 9/16") 1

8 Screw-Spur 2

9 Chain 1

10 Scrench 1

Ae

S.

GETTING READY

1. READ YOUR OPERATOR'S MANUAL

CAREFULLY.

Your Operator's Manual has been developed to

help you prepare your saw for use and to under-

stand its safe operation, It is important that you

read your manual completely to become familiar

with the unit before you begin assembly.

2. HAVE THE FOLLOWING AVAILABLE:

a. Protective gloves

b. Approved, marked fuel container

c. Onegallon regular unleaded gasoline.

d. 8 oz. (1/2pt.), 2-cycle,engine oil provided with

your unit.

e. Bar and Chain Lubdcant

f. Scrench -- providedwithyouruniLThe longend

ofthetoolcan beused as a slottedscrewdriver.

The small pipe end can be used as a socket

wrench. The larger pipe end can be used to

removethe spark plug.

g. Phillips Screwdriver

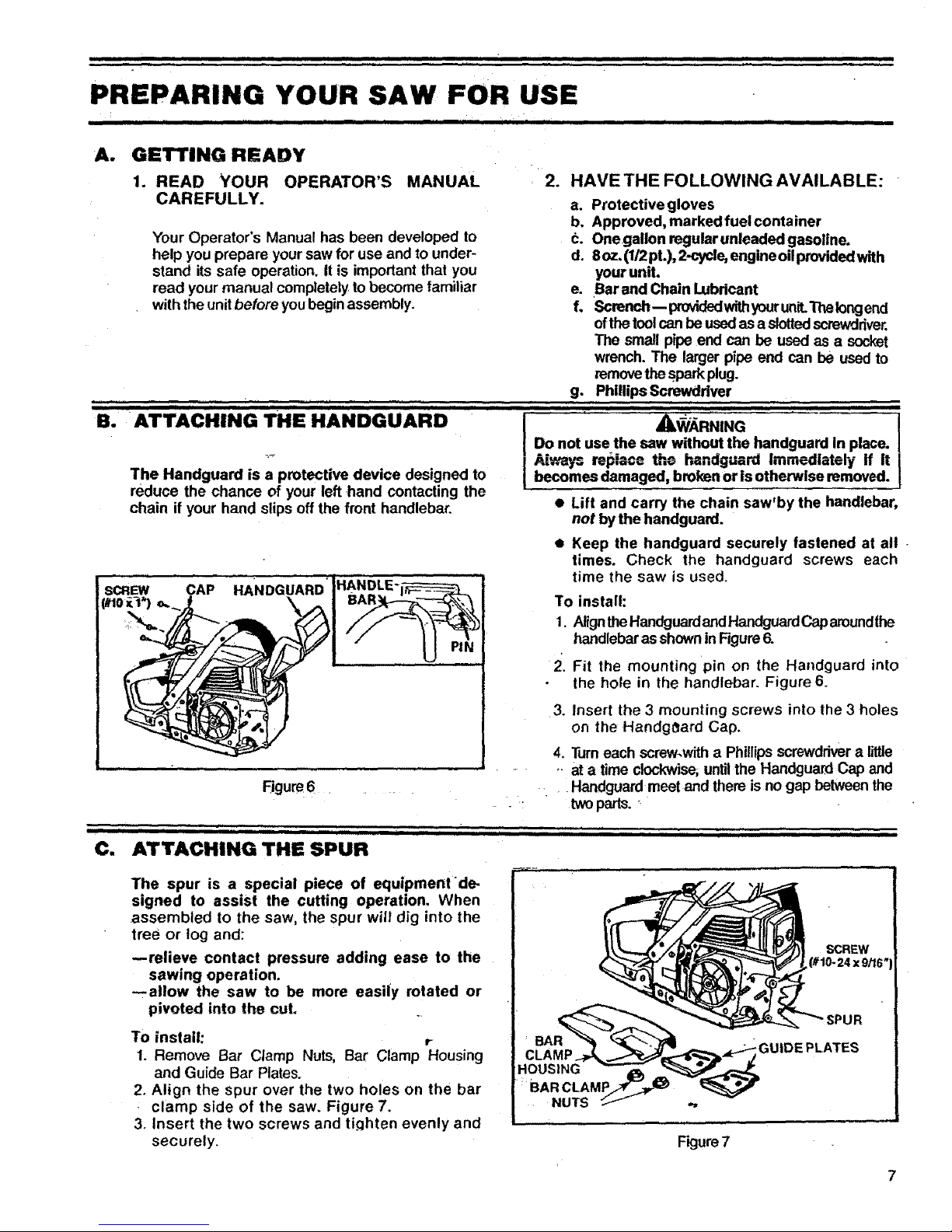

ATTACHING TH'E HANDGUARD ......... [......................Do notuse" the sawA_ti/_RNINGwithoutthe handguard In place. I

Aiways rel_lace the handguard Immediately if itThe Handguard is a protective device designed to becomes damaged, broken or is otherwise removed.

reduce the chance of your left hand contacting the

chain if your hand slips off the front handlebar. • Lift and carry the chain saw'by the handlebar,

not by the handguard.

• Keep the handguard securely fastened at all

limes. Check the handguard screws each

time the saw is used.

SCREW

(//10il *)

To install:

1. Align lhe HandguardandHandguardCap aroundthe

handlebaras shownin Figure 6.

2",Fit the mounting pin on the Handguard into

the hole in the handlebar. Figure 6.

Rgure6 ....

3. Insert the 3 mounting screws into the 3 holes

on the Handg_ard Cap.

4. Turn each screw.with a Phillips screwdrivera little

"- at a time cloclcwise; untilthe HandguaEI Cap and

., Handguard meet and there is no gap between the

two parts.,

C. ATTACHING THE SPUR

,, ,, ,

,, iiiiiii

The spur is a special piece of equipmentde-

signed to assist the cutting operation. When

.assembled to the saw, the spur will dig into the

tree or log and:

--relieve contact pressure adding ease to the

sawing operation.

--allow the saw to be more easi|y rotated or

pivoted into the cut.

To install: r

1. Remove Bar Clamp Nuts, Bar Clamp Housing

and Guide Bar Plates.

2. Align the spur over the two holes on the bar

clamp side of the saw. Figure 7.

3. Insert the two screws and tighten evenly and

securely.

BAR

CLAMP

HOUSING

BAR CLAMP

NUTS

Figure 7

,,,,,,,,,,,,,,,,,, =ll =. ill i ii

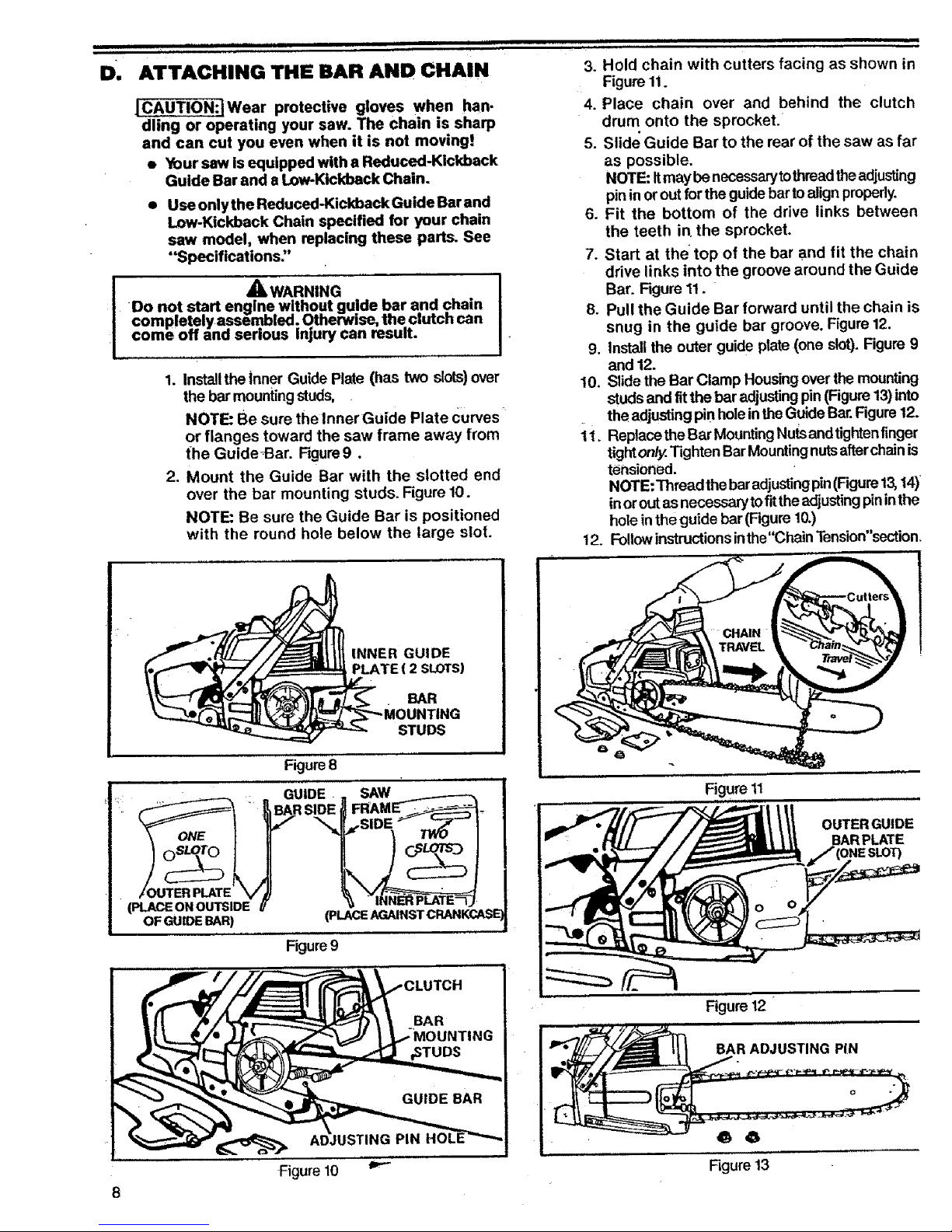

D, ATTACHING THE BAR AND CHAIN

JCAUT!ON:JWear protective gloves when ban.

dling or operating your saw. The chain is sharp

and can cut you even when it is not moving!

• Your saw is equipped with a Reduced-Kickback

Guide Bar and aLow-Kickback Chain.

• Use only the Reduced-Kickback Guide Bar and

Low-Kickback Chain specified for your chain

saw model, when replacing these parts. See

•'Specifications:'

AWARNING

i Do not sta..rt engine without guide bar an.d chain

completely assembled: Otherwise, zne czutcn can

com_ on ano serious injury can result.

1. Installthe inner Guide Plate (has two slots)over

the bar mountingstuds, .

NOTE: Be sure the InnerGuide Plate curves

or flanges toward the saw frame away from

the Guide_Bar. Figure9.

2. Mount the Guide Bar with the slotted end

over the bar mounting studs. Figure 10.

NOTE: Be sure the Guide Bar is positioned

with the round hole below the large slot.

Figure8

j.... _ GUIDE

/ OUTER PLATE

PLACE ON OUTSIDE

OF GUIDE BAR)

INNER GUIDE

PLATE ( 2 SLOTS)

BAR

STUDS

SAW .... !

(PLACE AGAINST CRANKCAS_

Figure9

3. Hold chain with cutters facing as shown in

Figure 11.

4. Place chain over and behind the clutch

drum onto the sprocket.

5. Slide Guide Bar to the rear of the saw as far

as possible,

NOTE; Itmay be necessarytothreadthe adjusting

pinin orout for the guidebarto align properly.

6. Fit the bottom of the drive links between

the teeth in the sprocket.

7. Start at the top of the bar and fit the chain

drive links into the groove around the Guide

Bar. Figure 11.

8. Pull the Guide Bar forward until the chain is

snug in the guide bar groove. Figure 12.

9. Install the outer guide pla_e(one slot). Figure 9

and 12.

10. Slide the Bar Clamp Housing over the mounting

studs and fit the bar adjusting pin (Figure 13)into

the adjusting pin hole in the Guide Bar. Figure12.

11. Replace the Bar Mounting Nuts and tighten finger

tightonly. Tighten Bar Mounting nutsafterchain is

tensioned.

NOTE: Thread the bar adjusting pin(Figure 13,14)

in or out asnecessaryto fit the adjusting pinin the

hole in the guide bar (Figure 10.)

12. Follow instructions inthe"ChainTension"section,

Figure 11

OUTER GUIDE

BAR PLATE

Figure12 "

BAR ADJUSTING PIN

4_ 6

Figure13

, i

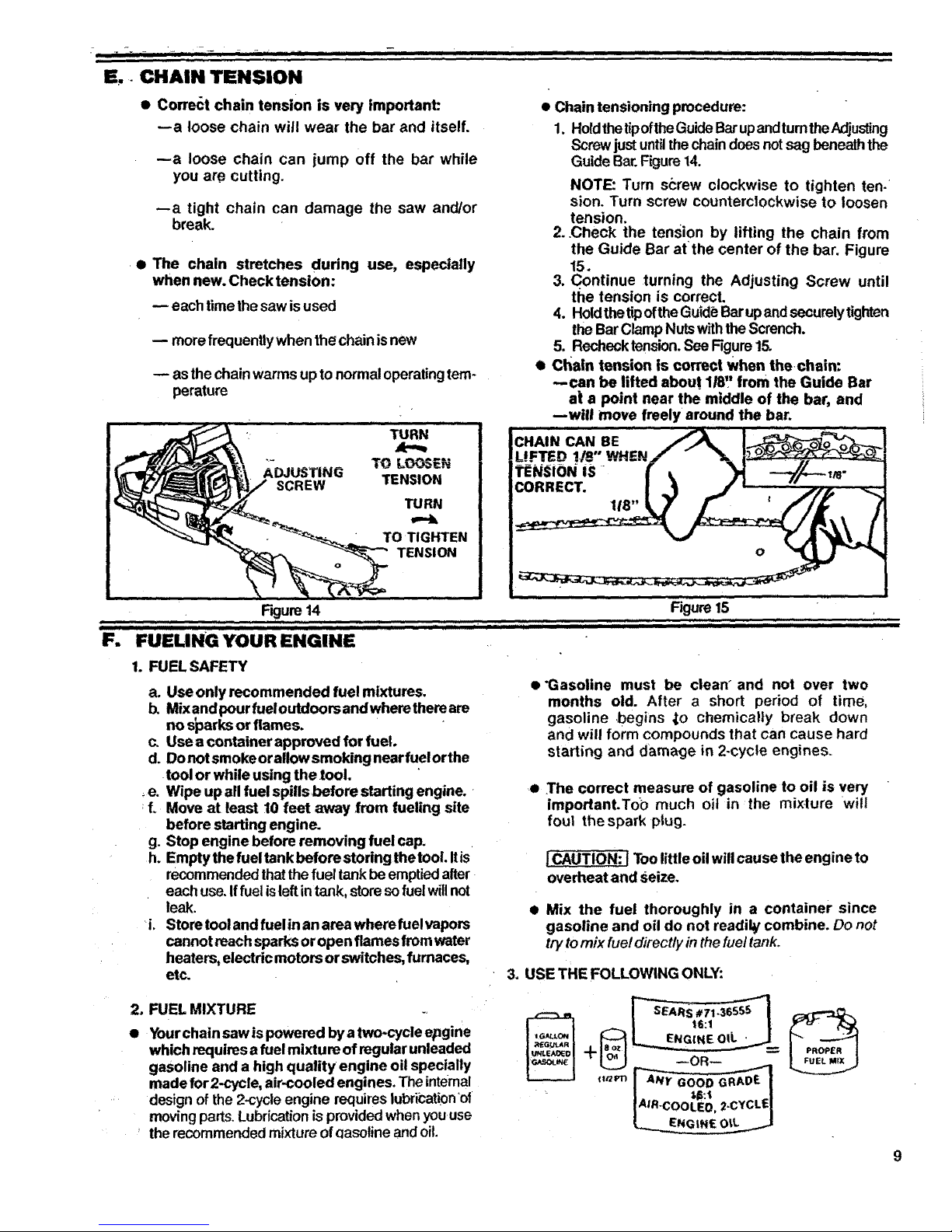

E, - CHAIN TENSION

• Correct chain tension is very important:.

--a loose chain will wear the bar and itself.

--a loose chain can jump off the bar while

you are cutting.

--a tight chain can damage the saw and/or

break.

• The chain stretches during use, especially

when new. Check tension:

each time the saw isused

more frequently when the chainisnew

as the chain warms up to normal operatingtem-

perature

• Chain tensioning procedure:

1. Holdthe t{poftheGuideBarupandturntheAdjusting

Screwjustuntilthe chain does notsag beneath the

Guide Bar.Figure 14.

NOTE: Turn s_:rew clockwise to tighten ten-

sion. Turn screw counterclockwise to loosen

tension.

2..Check the tension by lifting the chain from

the Guide Bar atthe center of the bar. Figure

15.

3. Continue turning the Adjusting Screw until

the tension is correct.

4. Holdthe tipof the Guide Barupand securely tighten

the Bar Clamp Nutswiththe Scrench.

5. Recheck tension.See Figure 15.

• Chain tension is correct When the,chain:

--can be lifted about. 1/8" from the Guide Bar

at a point near the middle of the bar, and

--will move freely around the bar.

Figure14

iiiiiii ii iiii ii i iiiii i

F. FUELING YOUR ENGINE

1. FUEL SAFETY

Figure 15

! _

lift IIIII1[ II I IIIII i IIII IIIIIII IIIIII i iiiii n I iiiiiiiii IIIII I IIIIIIII

a. Use only recommended fuel mixtures.

b. Mix and pour fuel outdoors and where there are

no s_arks or flames.

c. Use a container approved for fuel.

d. Do not smoke or allow smoking near fuel orthe

tool or while using the tool.

e. Wipe upall fuelspillsbeforestarting engine. -

f. Move at least 10 feet away ,from fueling site

before starting engine.

g. Stop engine before removing fuel cap.

h. Emptythefueltankbeforestoringthetool. Iris

recommended thatthe fuel tank beemptiedafter

each use. If fuelisleft intank, storesofuelwill not

leak.

_i. Store tool and fuelin an area where fuelvapors

cannot reach sparks or open flames from water

heaters, electric motors or switches, furnaces,

etc.

• "Gasoline must be clean _and not over two

months old. After a short period of time,

gasoline .begins _to chemically break down

and will form compounds that can cause hard

starting and damage in 2-cycle engines.

• The correct measure of gasoline to oil is very

important.Too much oit in the mixture •will

foul thespark plug.

I_UTION.:_J Too little oil will cause the engine to

overheat and seize.

• Mix the fuel thoroughly in a container since

gasoline and oil do not readily combine. Do not

trytomix fuel directly in the fuel tank°

3, USE THE FOLLOWING ONLY:

2, FUEL MIXTURE

• Yourchainsawispowered byatwo.cycleepgine

which requires afuel mixture of regular unleaded

gasoline and a high quality engine oil specially

made for2-cycle, air-cooled engines. The internal

design of the 2-cycleengine requires lubrication'of

moving parts.Lubrication is provided when youuse

the recommended mixtureof qasoline and oiL

10

4. DO NOT USE:

• BIA C)il (Boating Institute of America)

Doesnothave properadditivesfor_r-cooled,

2-cycleengines and cancausedamage.

• AUTOMOTIVE OIL-

•_ Does not have proper additivesfor 2-cycle

enginesand can cause damage.

c; Covercontainer tighUyand shake forone minute.

d. Slowly remove fuel container cover.

e. Add remainder of gasoline.

f. Cover container tightly and shake again.

g. Slowly remove fuel container cover.

h. Slowly remove fuel cap. See Figure 16for location:

i. Fill the tank using a spout or funnel.

j. Reinstall the fuel cap securely.

5. HOWTO MIX FUELAND RLL TANK

a, Pour 1/2gallonof regular unleaded gasoline

intoanapproved, marked container.Do nottry

tomixoitand gasoline directly in the fuel tank.

b. Add entire measurez)f engine oil.

G, PAR AHD'cHA!" LUBB!¢ANi;

• The guide bar and cutting chain require con-

tinuous lubrication in order to remain in

operating condition. Lubrication is provided

by the automatic oiler system when the oil

tank is kept filled.

-- Lackof lubricant will quickly ruin the bar and

chain.

--Too little lubricant will cause overheating

shown by smoke coming from the chainand/or

discolorationoftheguide bar rails,

Use Sears Bar and Chain Lubricant #71-36554 -

I qt. or #71-36556 - 1 gal. or clean SAE 30W oil.

In f_eezing weather, oil will thicken, making it

necessary to thin bar and chain oil with a small

amount of Diesel Fuel #1 or Kerosene. Barand

chainlubricantmustbefreeflowingfortheoilsystem

topump enough oil for adequatelubrication,

USE:THE FO'LLowING:

30°F or above -- Lubricant.-- undiluted.

30°F - 0°F -- 95% lubricant to 5% Diesel

Fuel # 1 or Kerosene.

Below 0° F -* 90% lubricant to t0%'Diesel

Fuel #t or Kerosene.

FILL THE OIL

TANK EACH'

IS FILLED.

Figure 17

2.

3.

4;

Figure 16

..............."' '

HOW TO FILL THE OIL

a. Stop the engine.

b. Turn saw on its side withoil cap up. Figure 17.

c. Loosen cap slowly and w_litfor pressure in the

tank to bereleased before removing the cap.

d. Fill the oil tank.

e. Replace the oil cap securely.

ADJUSTING THE AUTOMATIC OILER

The adjustlng screw k)catadat the b(_:)m of the

saw on the crankcase next to the bar clamp can

be adjusted with the screwdriver end of the

scronchprovided withyour saw.

a. Toincrease the - oil flow, turn the adjusting

screw counterclockwise 4b,,_,

b. Todecreasa the oil _flow, turn the adjusting

screw clockwise_'-'jk .

NOTE: Theeutomatic oilercan delivermoreoilthan

is requiredduringcertaintypes of cuttingsuchas

pruningordebranchingwhichrequirethesawtobe

operatedata high RPM for a longtime period. To

avoid runningoutofchainoilbefore_runningoutof

'_el, Check the=oil tank:pedodicaUy. Be sure to

readjustthe oiler beforereturning to types of cutting

that requiregreater lubrication.

IMPORTANT POINTS TO REMEM3ER

a. Prime the oil pump on a new saw or a saw that

has been unused for an extended period of

time. Pump the manualoiler slowlyseveraltimes.

Starttheengineandallo_vthechaintorun. Stopthe

engine and check for an even flow Ofoil onthe

chain. Repeat thisprocedureuntiloil is visible on

the chain.

b. Fill the oil tank each time you refill the fuel

tank to ensure there wiltbe stJfficientoilfor the

chainwheneveryou startand runthe saw.

c. The saw will use about 1/2 tank of chain oil for

each tank of fuel mixture. If less oil is used,

checkfor a pluggedoilholeinthe guidebar.

d- it is normal tor a small amount of oil to appear

under the saw after the engine stops. This is

due to oil drainingfrom the bar and chainwhen

not inuse.

!

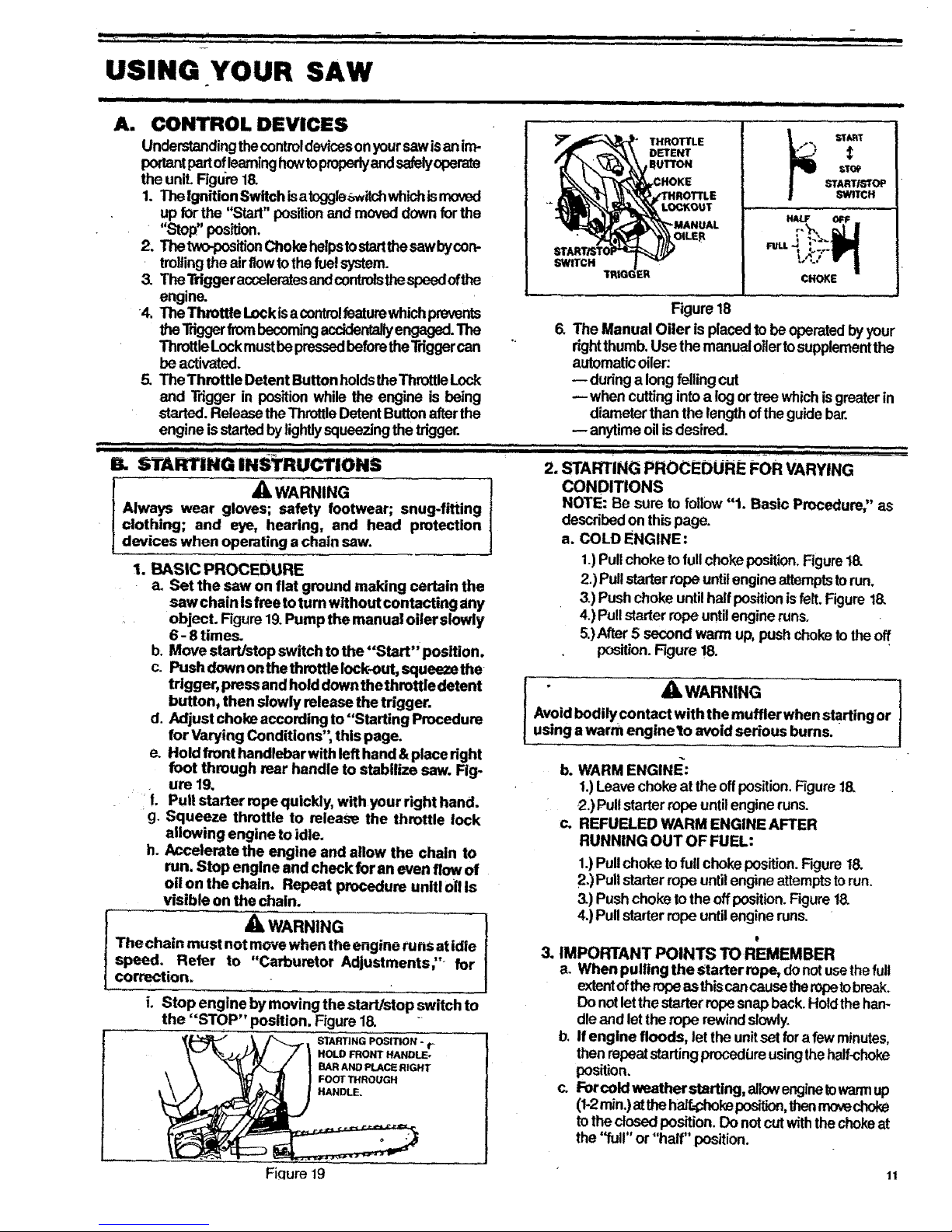

USING YOUR SAW

A! CONTROL DEVICES

Understandingthecontroldevicesonyoursawisanirn-

portantpartoflearninghowtoproperlyandsafelyoperate

the unit. Figu're18.

1. The IgnitionSwitch isatoggle_,witchwhiohismoved

up for the "Start" positionand moved down for the

"Stop" position,

2. Thetwocosition Choke helpstostartthesawbycorv

trollingthe airflow tothe fuel system.

3. TheTdggeracceleratesandcontrolsthespeedofthe

engine.

4. The Throttle Lockisa controlfeaturewhichprevents

theTriggerfrom becomingaccidentallyengaged. The

ThrottleLockmustbe pressedbeforethe Triggercan

beactivated.

5, The Throttle Detent Button holdsthe ThrottleLock

and Trigger in position while the engine is being

started.Release the ThrottleDetentButtonafterthe

engine isstartedbylightlysqueezingthe trigger.

B. STARTING INSTRUCTIONS

_,WARNING

Always wear gloves; safety footwear; snug-fitting

clothing; and eye, hearing, and head protection

devices when operating a chain saw.

1. BASIC PROCEDURE

a. Set the saw on fiat ground making certain the

saw chain is free toturn without contacting any

object. F'igure19.Pump the manual oiler slowly

6- 8 times.

b. Move start/stop switch tothe "Start" position.

c. Push down on the throttle lock.out, squeezethe

trigger, press and hold down thethrottle detent

button, then slowly release the trigger.

d. Adjust choke according to "Starting Procedure

for Varying Conditions" this page.

e. Hold front handlebarwith left hand & place dght

foot through rear handle to stabilize saw. Fig-

ure 19.

f. Pull starter rope quickly, with your right hand.

g. Squeeze throttle to release the throttle lock

allowing engine to idle.

h. Accelerate the engine and allow the chain to

run. Stop engine and check for an even flow of

oil on the chain. Repeat procedure unitl 0il is

visible on the chain.

WARNING

The chain must not move when the engine runs atIdle

speed. Refer to "Carburetor Adjustments;'- for

correction.

i. Stop engine by moving the start/stop switch to

the "STOP" position, Figure 18.

_ ,\ F'-_. STAmlNGPosrnoN-,-

_..>_.v_ / | .OLDmO_.AN.UE.

!

xJ_Y'--Z I _RANO_AC_R_T

_'_\ _ ! FOOTTHROUGH

Figure t9

SWITCH

THROTTLE

DETENT

b"Tt,,_T

_'tOl;'

$TARTISffOP

SWITCH

H&LF OFF _

,.- =t I

t_.., Wl

CHOKE

Figure 18

6. The Manual Oiler is placedtobe operatedby your

rightthumb,Use the manualoiler tosupplementthe

automaticoiler:

duringa longfellingcut

when cutting intoa log ortree which isgreaterin

diameterthan the length oftheguide bar.

-- anytimeoilisdesired,

3. IMPORTANT POINTS TO REMEMBER

a. When pulling the Starter rope, do notusethefull

extentoftheropeasthis cancausetheropetobreak.

Do notletthe starterropesnap back. Holdthe han-

dle and letthe rope rewindslowly.

b. If engine floods, let the unitset fora few minutes,

then repeatstartingprocedbreusingthehalf-choke

position.

c. For cold w_.atherstarting, allowenginetowarmup

(1-2min.)atthehaJf.t::hokeposition, then movechoke

to the dosed position. Do not cutwiththe chokeat

the "full" or "half" position.

11

t¸ }

_kWARNING

Avoidbodily contact with the muffler when starting or

using a warm enginelto avoid serious burns.

b. WARM ENGINE:

1.)Leave choke at the offposition.Figure18.

2.) Pull starterrope untilengine runs.

c. REFUELED WARM ENGINE AFTER

RUNNING OUT OF FUEL:

1.)Pullchoke tofull choke position.Figure 18.

2.)Pullstarter ropeuntilengine attemptsto run.

3.)Pushchoke tothe offposition.Figure18.

4.)Pullstarter rope untilengine runs.

2. STARTING PROCEDURE FOR VARYING

CONDITIONS

NOTE: Be sure to follow "1. Basic Procedure" as

describedon thispage.

a. COLD ENGINE:

1.)Pullchoke tofullchoke position. Figure18.

2.)Pull starterrope until engine attemptstorun.

3.)Push choke untilhalfpositionis felt.Figuret8.

4.)Pullstarterropeuntilengine runs.

5.)After 5 second warm up,push choketo the off

position.Figure !8.

Loading...

Loading...