Sears Craftsman 171.25450 Owner's Manual

ModelNo,

171.25450

CRAFT$1VlAK

INDUSTRIAL

DOVETAIL

FIXTURE

• Assembly

• Operation

iMPORTANT;Thefollowingrouterbitsarerequired

for usewiththis fixture:#25414-1/4-in. Straight Router Bitand

#25415-9/16-in. DovetailRouter Bitwhich are used

for THROUGHor OPENJOINTS.

: #25505 or #26318-1/2-in. DovetailRouterBit which

are usedfor a!l HALFBLINDJOINTS.

Readandfollow

all instructions

carefully.

KEEPTHIS

MANUALFOR

' FUTURE

REFERENCE,

# 83463

Sold by Sears,Roebuckand Co,, Hoffman Estates,IL 60179

, i i

FAILURETO HEEDALLSAFETYANDOPERATINGINSTRUCTIONS

ANDWARNINGSREGARDINGUSEOF THISPRODUCTCANRESULT

IN SERIOUSBODILYINJURY

1) KNOWYOURPOWERTOOL

Readtheowner'smanualcarefully.Learnitsapplicationsand

Iimitatlonsaswell asthespecificpotentialhazardsparticularto

thistool.

2) GROUNDALLTOOLS(UNLESSDOUBLEINSULATED)

Iftoolis equippedwithanapproved3-conductorcordanda3-

pronggroundingtypeplug,itshouldbepluggedintoathreehole

electricalreceptaute.It adapteris usedtoaccommodateatwo-

prongreceptacle,theadapterwiremustbeattachedto known

ground,(usuallythescrewsecuringreceptaclecoverplate).

Neverremovethirdprong.Neverconnectgreengroundwireto a

terminal.

3) KEEPGUARDSINPLACE

--in workingorder,andinproperadjustmentandalignment.

4) REMOVEADJUSTINGKEYSANDWRENCHES

Forma habitof checkingtoseethatkeysandadjustingwrenches

areremovedfromtoolbeforeturningit on.

5) KEEPWORKAREACLEAN

Clutteredareasandbenchesinviteaccidents.Floormustnot be

slipperydoeto waxor sawdust.

6} AVOIDDANGEROUSENVIRONMENT

Donot usepowertoolsindamporwetlocationsorexposethornto

rain.KeepworkareawelIlighted.Provideadequatesurrounding

workspace.

7) KEEPCHILDRENAWAY

All visitorsshooktbekeptata safedistancefromworkarea.

B) MAKEWORKSHOPCHILD-PROOF

--with padlocks,masterswitches,or byremovingstarterkeys.

9) DONOTFORCETOOL

It willdothejob betterandsaferatthe rateforwhichitwas

designed.

10)USEAPPROPRIATETOOL

Donotforcetoolor attachmentto doajob forwhichitwasnot

designed.

11)WEARAPPROPRIATEAPPAREL

Donotwearlooseclothing,gloves,necktiesorjewelry(rings,

wristwatches)to getcaughtin movingparts.Nonslipfootwearis

recommended.Wearprotectivehaircoveringtocontainlonghair.

Rolllongsleevesel;Dyetheelbow.

12)USESAFETYGOGGLES(HeadProtection)

WearSafetyGoggles(mustcomptywith ANSIZ87.1) atalltimes.

Also,usefaceordustmaskif cuttingoperationis dusty,andear

protectors(plugsormuffs)duringextendedperiodsofoperation.

13)SECUREWORK

Useclampsora viseto holdworkwhenpractical,it'ssaferthan

usingyourhandandfreesbothhandsto operatetool.

14)DONOTOVERREACH

Keepproperfootingandbalanceatalltimes.

15)MAINTAINTOOLSWITHCARE

Keeptools sharpandc]eanfor bestandsafestperformance.Follow

instructionsfor lubricatingandchangingaccessories.

16)DISCONNECTTOOLSBEFORESERVICING

-when changingaccessoriessuchasblades,bits,cutters,etc.

17)AVOIDACCIDENTALSTARTING

Makesureswitchisin OFFpositionbeforepluggingin.

18)USERECOMMENDEDACCESSORIES

Consulttheowner'smanualfor recommendedaccessories.Follow

theinstructionsthataccompanytheaccessories.Theuseof

improperaccessoriesmaycausehazards.

19)NEVERSTANDONTOOL

Seriousinjurycouldoccur;fthetool Istippedorthecuttingtool is

accidentallycontacted.0o notstorematerialsaboveor nearthetool

thatwouldmakeit necessaryto standon thetoolto reachthem.

20)CHECKDAMAGEDPARTS

BeforefurtheruseofthetooI,aguardor otherpartthatis damaged

shouldbecarefullycheckedto ensurethatitwill operateproperly

andperformitsintendedfunction.Checkfor alignmentof racy(rig

parts,bindingofmovingparts,breakageof parts,mounting,andany

otherconditionsthat mayaffectitsoperation.Aguardorotherpart

thatisdamagedshouldbeproperlyrepairedorreplaced.

21)DIRECTIONOFFEED

Feedworkintoabladeorcutteronlyagainstthedirectionof rotation

ofthe bladeor cutter.

22)NEVERLEAVETOOLRUNNINGUNA'n'ENDED

Turnpoweroff. Donotleavetooluntilit comesto a completestop.

23)KEEPHANDSAWAYFROMCUT(1NGAREA

24)STOREIDLETOOLS

Whennotin use,toolsshouldbestoredindry,highorIocked-up

place---outof reachofchildren.

25)O0HOTABUSECORD

Keepcordawayfrom heat,oil,andsharpedges.

28)OUTDOOREXTENSIONCORDS

Whentoo!isusedoutdoors,useonlyextensioncordssuitablefor

useoutdoors,andso marked.

27)NEVERUSEINANEXPLOSIVEATMOSPHERE

Normalsparkingofthemotorcouldignitefumes,flarnmab;eliquids,

or combustibleitems.

28)DRUGS,ALCOHOL,MEDICATION

Donotoperatetoolwhile undertheinfluenceofdrags,alcohol,or

anymedication.

READANDUNDERSTANDTHISCOMPLETEINSTRUCTIONBOOK

BEFOREUSINGTHISPRODUCT

2

ADDITIONALSAFETYINSTRUCTIONSFORYOUR

INDUSTRIALDOVETAILFIXTURE

1) AlwaysweareyeprotectionthatcomplieswithcurrentANSI

StandardZ78A.

2) Noiselevelsvarywidely.Toavoidpossiblehearingdamage,wear

earpIugsor muffswhenusingtheDovetailFixturefor hoursata

time.

3) Wearadust maskalongwiththesafetygoggles.

4) Donotusethis DovetailFixturewith routerbitsor guide

bushingsotherthanthosespecifiedforthecuts beingmade.

5) FollowtheinstructionsinyourRouterOwnersManual.

6) Vibrationscausedbytherouterduringusecancausefasteners

to becomeloose.Beforeuseandperiodicallyduringusecheckall

fastenerstomakesurethattheyareagtightandsecure.

7) Donotusethis productuntilallassemblyinstallationstepshave

beencompleted,andyouhavereadandunderstandnitsafetyand

operationalinstructionsinthis manual,andtheRouterOwners

ManuaL

8) Makesurethattherouterbitis properlypositionedin therouter

sothatit doesnotcontacttheguidebushingorthetemplatewhen

cutting.

9) TheDovetailFixturemustbesecurelymountedtoaworkbench

or otherstablesurfacewheninuse.Thefrontof thebaseshould

overhangthe frontof theworkbenchbynomerethan1/4"to provide

clearancewhenclampingworkpiecestotheDovetailFixture.

10) DonotusetheDovetailFixtureasaworksurface.Doingsomay

causedamageto theDovetailFixture,whichcancauseitto beunsafe

to use.Aworkbenchshouldbeusedforthispurpose.

11)Thisproductis designedtocutflatworkpieces.Donotcutor

attempttocutworkpiecesthatarenotflat orthatareirregularly

shaped.

12)Thisproductis to beusedforcuttingwoodworkpiecesonly.Do

notusethisproducttocutmetaloranyothernon-woadmaterial.

13)Thisproducthasbeendesignedto cutworkpieceshaving

thicknessesof3/8"to 1".Donotuseforworkpiecesofanyother

thicknesses.

14)DonotclampanyworkpiecestotheDovetailFixtureormakeany

adjustmentsto theDovetailFixtureunlesstherouterhasbeenturned

off,the routerbitisnotturning,andthe Routerhasbeen

disconnectedfromtheelectricaloutlet.

15)Whensetting"lhe-dopth-ot-cut"oftherouterbit,makesurethat

theworkplaceis clampedto theDovetailFixturein sucha.manner

thattherouterbitdoesnotcutinto the Dovetailbasecausing

damagetoit orpassibleseriousinjurytoyou.

16) ALWAYSUNPLUGTHEROUTERFROMTHE

ELECTRICALOUTLETBEFOREINSTALLINGORREMOVINGROUTER

BITSFROMTHEROUTERANDWHENADJUSTINGTHECUTTING

DEPTHOFTHEROUTERBIT;ORWHENINSTALLINGORCHANGING

GUIDEBUSHINGS,

17)NEVERLiFTTHEROUTERUPWARDSWHENTHEROUTERiS

"ON",THEROUTERBITISROTATING,ANDTHEGUIDEBUSHINGiS

NEARORTOUCHINGTHETEMPLATE,BECAUSETHISWILLCAUSE

THEROUTERBITTOCUTINTOTHETEMPLATEANDDAMAGEIT.

INTRODUCTION

o Your Sears/Craftsmanindustrial DovetailFixture is an accessory used with your Routerto allow you to make drawers, chests, and the like

where dovetail joints are used to join the front, back,and sides of the workpiece.

TheDovetail Fixturewig allow you to make1" spaced flush andflush offset and 318"rabbetedhaif-bfind dovetail joints, in addition you can

make1" spaced (or open) dovetail joints.

• Workplace widths up to 16"can beaccommodated.

Workplacethicknesses between318"and1" can beaccommodated,

The Dovetail Basehas six pockets molded into its front which are gauges to aid you in setting the "depth-of-cut" for commonly used

depths: 3/8", 1/2", 5/8", 3/4'1,7/8", and 1".

The Dovetail Fixture comeswith two templates andtwo guide bushings for making bait-blind and through or openjoints.

Sears/Craftsman router bits,#25414 and#25415, WHICH MUST BEPURCHASEDSEPARATELY,are required to makethe THROUGHor

OPENjoints.

Sears/Craftsman router bit, #25505 or #26318, WHICH MUSTBE PURCHASEDSEPARATELY,is required for making the haIf-bIind joints.

• Eachtemplate has a label, describing the joint that can becut, along with set up information, the bit and guide bushing required, and the

stop block setting for a particular joint.

The Dovetail Fixture can be used with al! Sears/Craftsman Routers.

With a separately purchasedSears/Craftsman#25326, Universal Router Adapter,the DovetagFixture can be usedwith many non-

Craftsman Routers, such as, Black & Decker,Makita,and SkiL

UNPACKINGANDCHECKINGCONTENTS

in orderto simplify handIingand to minimize any damagethat may occur during shipping, your Industrial Dovetail Fixtureis packaged

unassembled,

Separateall parts from the packing materials and check eachonewith the igustrations and list of partsat the endof this manuaIto make

sure that ag parts are presentbefore discarding any packaging material.

• Ifany parts aremissing or cannot beaccounted for, do not attemptto assemble,install, or use the industrial DovetailFixture

until the missing parts havebeenobtained and the product has beenassembled correctly.

Contactyour localSearsRetail Outletfor a repIacement product or for the missing parts.

3

ASSEMBLYINSTRUCTIONS

Thefollowingtoolsare requiredforassembly:

1) AmediumsizedPhillipsscrewdriver,

2) Asmallor mediumsizedadjustablewrench.

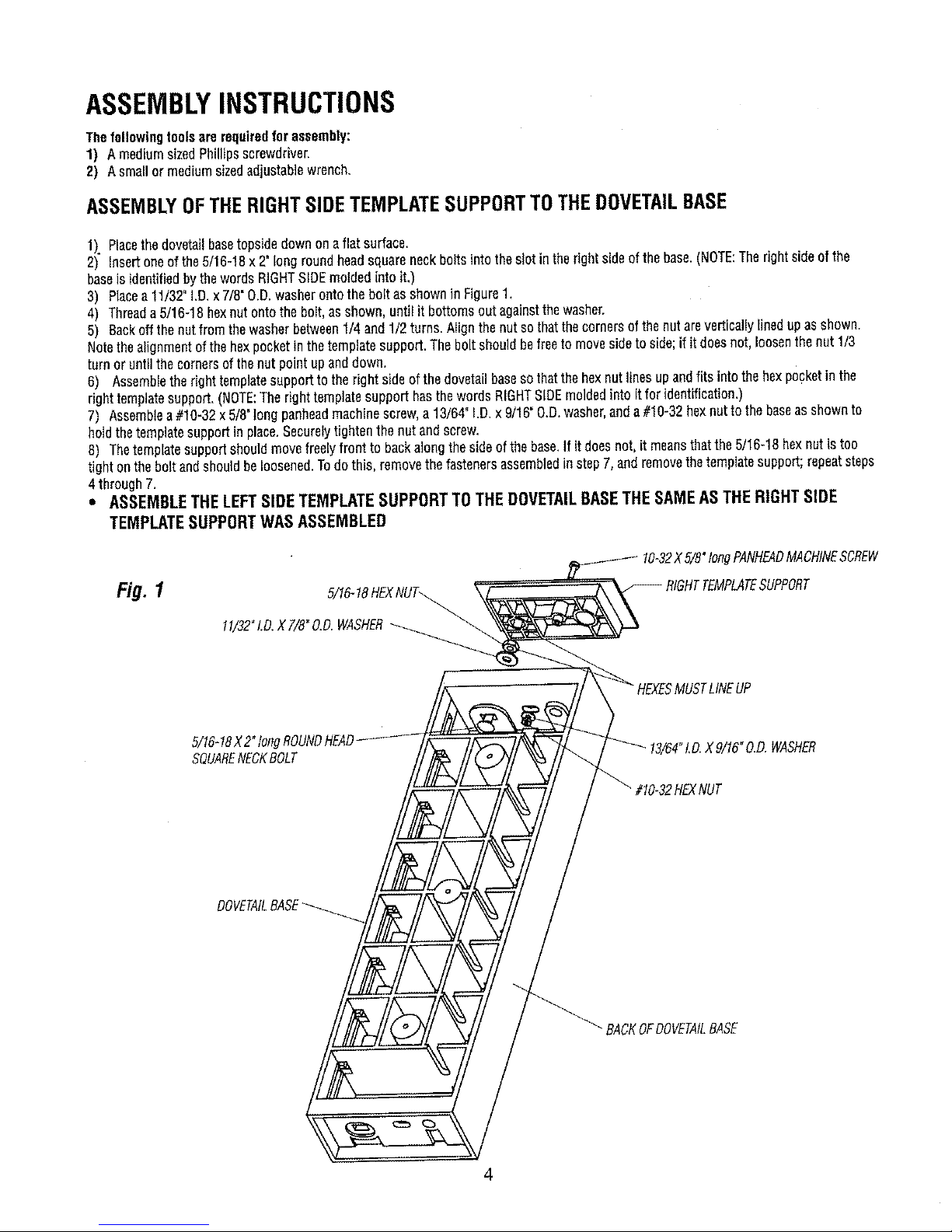

ASSEMBLYOFTHERIGHTSIDETEMPLATESUPPORTTOTHEDOVETAILBASE

1). Placethedovetailbasetopsidedownonaflatsurface.

2) insertoneof the5/16-18x2"longroundheadsquareneckboltsintothes!otintherightsideofthebase.(NOTE:Therightsideof the

baseis identifiedbythewordsRIGHTSIDEmoldedintoit.)

3) Placea11/32"I.D_x 7/8"O.D.washerontothe boltasshownin Figure1,

4) Threada5/16-18hexnutontothebolt,asshown,untilit bottomsoutagainstthe washer,

5) Backoffthenutfromthe washerbetween1/4 and1/2turns.NighthenutsothatthecornersofthenutareverticallYlineduPasshown.

Notethe alignmentofthe hexpocketinthetemplatesupport.Theboltshouldbefreeto movesidetoside;if it doesnot,loosenthenut1/3

turnor untilthe cornersofthenutpointupanddown.

8) Assembletherighttemplatesupportto therightside ofthedovetailbaseso thatthe hexoutlinesupandf ts intothehexpocketinthe

righttemplatesupport,(NOTE:TherighttemplatesupporthasthewordsRIGHTSIDEmoldedintoitfor identification.)

7) Assemblea#10-32x5/8°tongpanheadmachinescrew,a 13/64"!.D.x 9/16"O.D.washer,anda#10"32hexnutt° thebaseassh°wnt°

holdthetemplatesupportin place.Securelytightenthenut andscrew_

8) Thetemplatesupportshouldmovefreelyfrontto backalongthe sideofthe base,If it doesnot,it meansthatthe5/16-18hexnutis too

tight ontheboltandshouldbeloosened.Todothis, removethefastenersassembledinstepT,andremovethetemplatesupport;repeatsteps

4 through7.

• ASSEMBLE THE LEFT SIDE TEMPLATE SUPPORT TO THE DOVETAIL BASETHE SAME AS THE RIGHT SIDE

TEMPLATE SUPPORT WAS ASSEMBLED

Fig. 1

11/32"LO.XT/8"O.D.WASHER

5/16-18X2"tongROUNDHEAD

SQUARENECKBOLT

DOVETAILBASE

"/8"longPANHEADMACHINESCREW

MUSTLINEUP

_.D.WASHER

?HEXNUT

_ BACKOFDOVETAILBASE

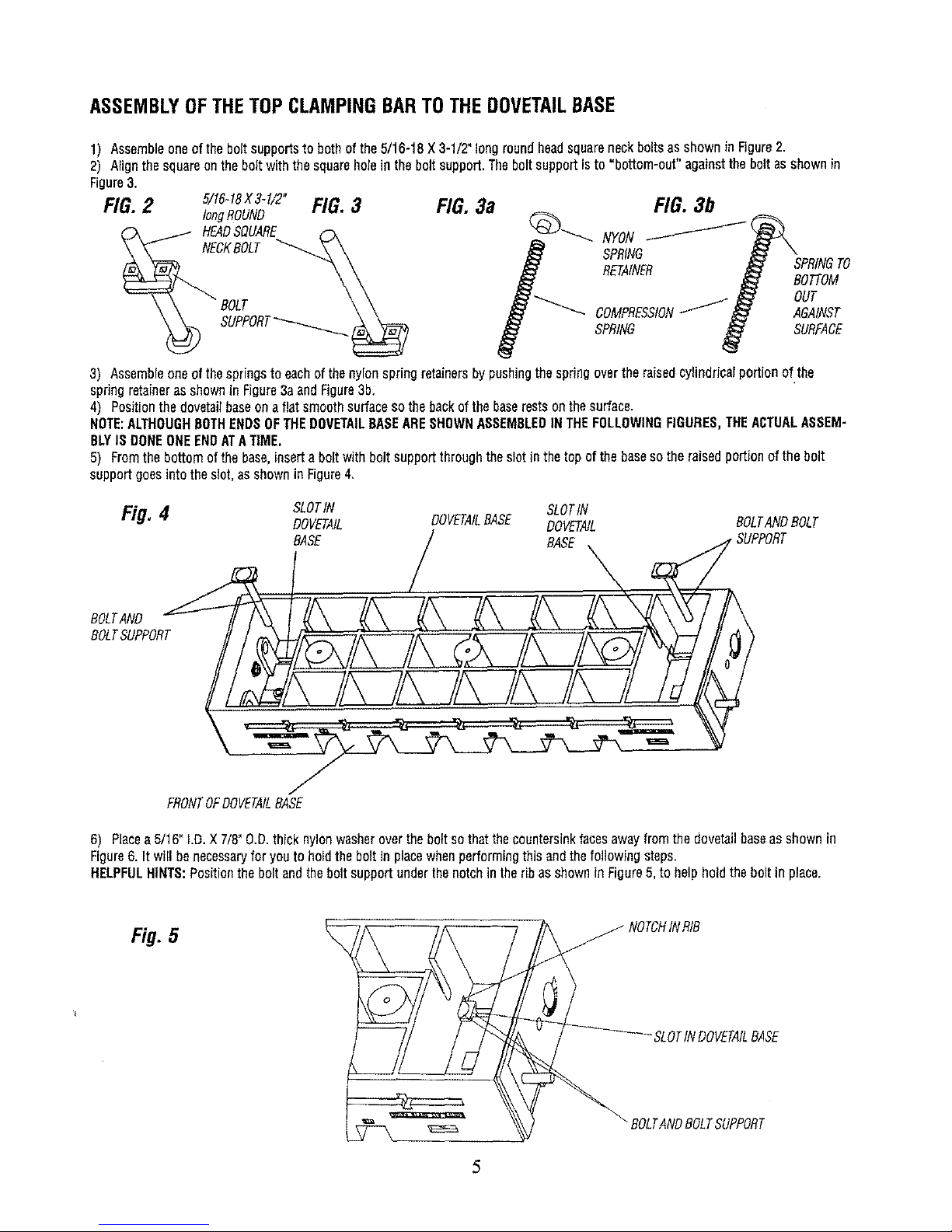

ASSEMBLYOFTHETOPCLAMPINGBARTOTHEDOVETAILBASE

1) Assembleoneoftheboltsupportsto bothofthe 5/16-18X3-1/2"longroundheadsquareneckboltsasshowninFigure2.

2) Alignthesquareontheboltwiththesquareholeinthe boltsupport.Theboltsupportisto =bottom-out"againstthe bolt asshownin

Figure3.

FIG.2 5/16-18X3-1/2"FIG.3

longROUND

HEADSQUARE _-x

,o,,

FIG. 3a

3) Assembleoneofthespringsto eachofthenylonspringretainersbypushingthespringoverthe raisedcylindricalportionof the

springretaineras shownin Figure3aandFigure3b,

4) Positionthedovetailbaseonafiat smoothsurfacesothe backofthebaserestsonthesurface.

NOTE:ALTHOUGHBOTHENDSOFTHEDOVETAILBASEARESHOWNASSEMBLEDINTHEFOLLOWINGFIGURES,THEACTUALASSEM-

BLYIS DONEONEENDATATIME.

5) Fromthebottomofthe base,inserta boltwithboltsupportthroughtheslotin thetop ofthebasesothe raisedportionof thebolt

supportgoesinto theslot,asshowninFigure4,

Fig, 4 SLOTIN SLOTIN

DOVETAIL DOVETAILEASE DOVETAIL BOLTANDBOLT

EASE / BASE

BOLTAND

BOLTSUPPORT

FRONTOFDOVETAILBASE

6) Placea5/16"I.D.X7/8"O.D.thick nylonwasheroverthe boltso thatthecountersinkfacesawayfromthe dovetailbaseasshownin

Figure6. It will benecessaryfor youto holdthe boltin placewhenperformingthis andthefollowingsteps.

HELPFULHINTS:Positionthe boltandtheboltsupportunderthenotchin theribas shownin Figure5, to helpholdtheboltin place,

Fig. 5 _ NOTCHINRIB

SLOTINDOVETAILBASE

BOLTANDBOLTSUPPORT

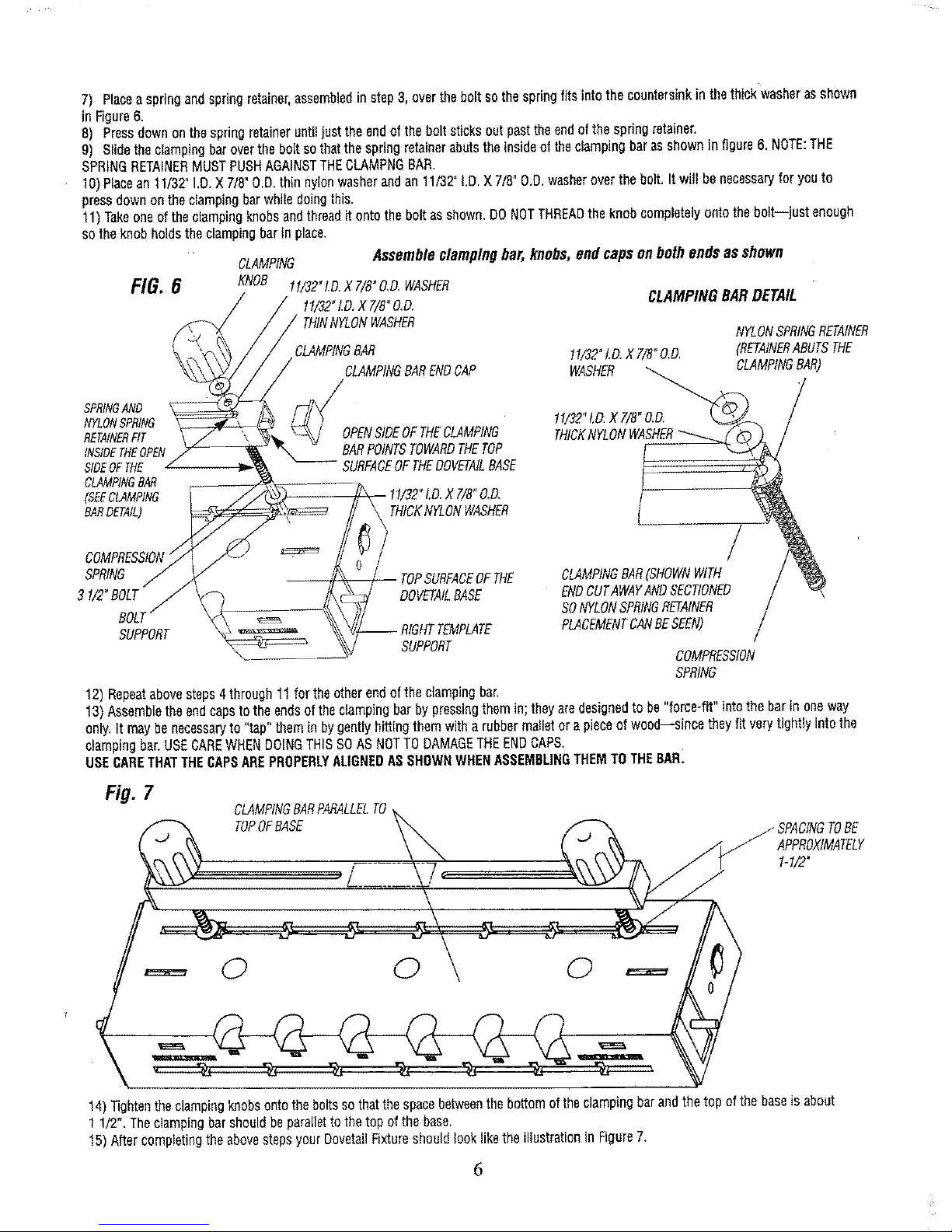

7) Placeaspringandspringretainer,assembledinstep3, overtheboltsothespringfitsintothecountersinkinthethickwasherasshown

InFigure6.

8) Pressdownonthespringretaineruntiljusttheendofthebolt sticksoutpasttheendofthe springretainer.

9) Slidetheclampingbaroverthebolt sothatthespringretainerabutstheinsideoftheclampingbarasshownin figure6.NOTE:THE

SPRINGRETAINERMUSTPUSHAGAINSTTHECLAMPNGBAR.

10)Placean11/32"I.D.X7/8"O.D.thin nylonwasherandan 11/3Z I.D.X7/8"O.D.washeroverthe bolt.It will benecessaryfor youto

pressdownonthe dampingbarwhiledoingthis.

11)Takeoneoftheclampingknobsandthreaditontothe boltasshown.DONOTTHREADtheknobcompletelyontothebolt--just enough

sothe knobholdsthe clampingbarinplace.

CLAMPING

FIG. 6 KNOB

SPRINGAND

NYLONSPRING

RETAINERFIT

INSIDETHEOPEN

SIDEOFTHE

CLAMPINGBAR

(SEECLAMPING

BARDETAIL)

SPRING

31/2"BOLT

BOLl

SUPPORT

12)Repeatabovesteps4through11for theotherendof theclampingbar.

13)Assembletheendcapstotheendsoftheclampingbarby pressingthemin; theyaredesignedto be"force-fit"intothebarin oneway

only.It maybenecessaryto "tap"themin bygentlyhittingthemwitha rubbermatletora pieceofwood--sincetheyfit verytightlyintothe

clampingbar,USECAREWHEN DOINGTHISSOAS NOT TO DAMAGE THEEND CAPS,

USECARETHATTHECAPSAREPROPERLYALIGNEDAS SHOWN WHEN ASSEMBLINGTHEM TO THEBAR.

tf/32"LD.X 7/B"O.D.WASHER

11/32"LD.X T/8"O.D.

THINNYLONWASHER

CLAMPINGBAR

\

Assembleclampingbar,knobs,endcaps on bothends asshown

CLAMPINGBARDETAIL

11/32"LD.X7/8"O.D. (RETAINERABUTSTHE

CLAMPINGBARENDCAP

WASHER LAMPING SAR)

OPENSIDEOFTHECLAMPING

BARPOINTSTOWARDTHETOP

SURFACEOFTHEDOVETAILBASE

11/32"LD.X 7/8"O,D.

t THICKNYLONWASHER

CLAMPINGBAR(SHOWNWITH /

DOVETAILBASE

/ TOPSURFACEOFTHE

-- RIGHTTEMPLATE

SUPPORT

ENDCUTAWAYANDSECT!ONED /

SONYLONSPRINGRETAINER /

PLACEMENTCANBESEEN) /

COMPRESSION

SPRING

NYLONSPRINGRETAINER

/

fig.7

CLAMPINGBARPARALLELTO

TOPOFBASE

0 0 0

14)Tightentheclampingknobsontothe boltssothatthespacebetweenthebottomoftheclampingbarandthetop of thebaseisabout

1 1/2".Theciampingbarshouldbeparallettothe topofthe base.

15)AftercompletingtheabovestepsyourDovetailFixtureshouldlookliketheillustrationin Figure7.

J SPACINGTOBE

APPROXIMATELY

1-1/2"

6

ASSEMBLYOFTHEFRONTCLAMPINGBARTOTHEDOVETAILBASE

1) Assemblethe front clampingbarto the dovetailbasefollowingthesameprocedureusedto assemblethetop clampingbartothedove-

tail baseasshownin Figure8.The5/16-18X4-1/2"longroundheadsquareneckboltsareused,

Fig. 8

BOLT

0

4 I/2" BOLT / ""

11/32"1.D.X7/8"O.D,

THICKNYLONWASHER

COMPRESSIONSPRING

CLAMPINGBAR

ENDCAP

1!/32"LD.X7/B"O.D,

RETAINER THINNYLONWASHER

CLAMPINGBAR

(SHOWNWITH

ENDCUTAWAY

ANDSECTIONED

SONYLONSPRING

RETAINERPLACE-

MENTCANBE

SEEN)

COMPRESSION

SPRING

NYLONSPRING

RETAINER

(RETAINER

ABUTSTHE

CLAMPINGBAR)

11/32"I.D.X 7/8"O.D.WASHER

ASSEMBLYOFTHECAMHANDLESAND PIVOTSHAFTTOTHEDOVETAILBASE

Afterthecamhandlesandpivotshafthavebeenassembledto thebase,it willbepossibleto accuratelypositionthetemplatesfor close

fittingjoints,

Notethattherearesomegraduationsonbothtemplatesupports.

• Rotatingthecamhandlesothat thepointerlinesupwithoneofthegraduationspermitsaccuratefront-to-backpositioningofthe

template.

• Camhandlesaredesignedto provideinfinitetemplateadjustment.

Onegraduationequals1/64"of movementof thetemplate.

• Rotatingthecamhandlesothat thepointerlevermovestowardthefrontof thebase.causesthetemplateto alsomovetowardsthefront

ofthe base.

• Converselyrotatingthecamhandlesothatthepointerlevermovestowardthe backofthe base,causesthetemplateto alsomove

towardsthebackofthe basealso.

1) Assembleoneofthe camhandlestothepivotshaftusinga #10-32x 5/8"longpanheadmachinescrewanda 13/64"I.D.x9/16"LD.

washer,asshownin Figure9,

2) Usecareso thatthe pivotshaftfitsintothehex-shapedholein thecamhandle.Thepivotshaftmayfit tightly intothecamhandle;

this isnormal.

3) Makesurethatthepivotshaftbottoms*outinsidethecamhandle.

Fig. 9

/ CAMHANDLE

13/64"t.D.X9/16°0.O,WASHER--_,,,,_ _ PIVOTSHAFT

7

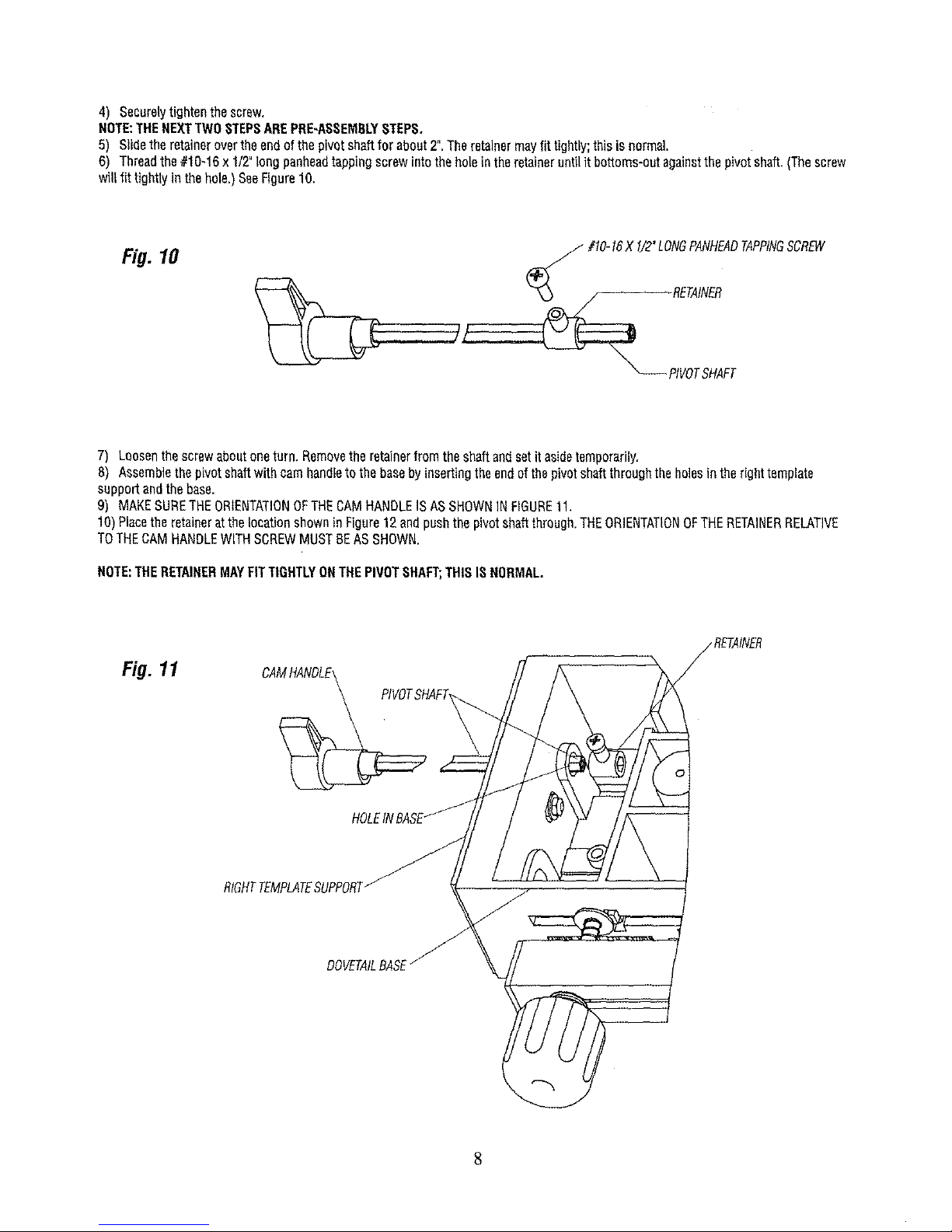

4) Securelytightenthe screw,

NOTE:THENEXTTWOSTEPSAREPRE-ASSEMBLYSTEPS.

5) Sgdetheretainerovertheendof thepivotshaftfor about2".Theretainermayfit tightly;thisis normal

6) Threadthe#1_`16x1/2"_ngpanheadtappingscrewint_theh_eintheretainerunti_itbott_ms-_tagain_tthepiv_tsha_.(Thescrew

willfit tightlyinthehole.)SeeFigure10.

Fig. 10

_ #!0-16X 1/2"LONGPANHEADTAPPINGSCREW

7) Loosenthescrewaboutoneturn.Removethe retainerfromtheshaftandsetit asidetemporarily.

8) Assemblethe pivotshaftwithcamhandleto the basebyinsertingtheendof thepivotshaftthroughthe holestntherighttemplate

supportandthebase.

9) MAKESURETHEORIENTATIONOFTHECAMHANDLEISASSHOWNINFIGURE11.

10)PlacetheretaineratthelocationshowninFigure12endpushthepivotshaftthrough.THEORIENTATIONOFTHERETAINERRELAT]VE

TOTHECAMHANDLEWITHSCREWMUSTBEASSHOWN.

NOTE:THERETAINERMAYFITTIGHTLYONTHEPIVOTSHAFT;THISISNORMAL.

Fig. 11

DOVETAILBASE

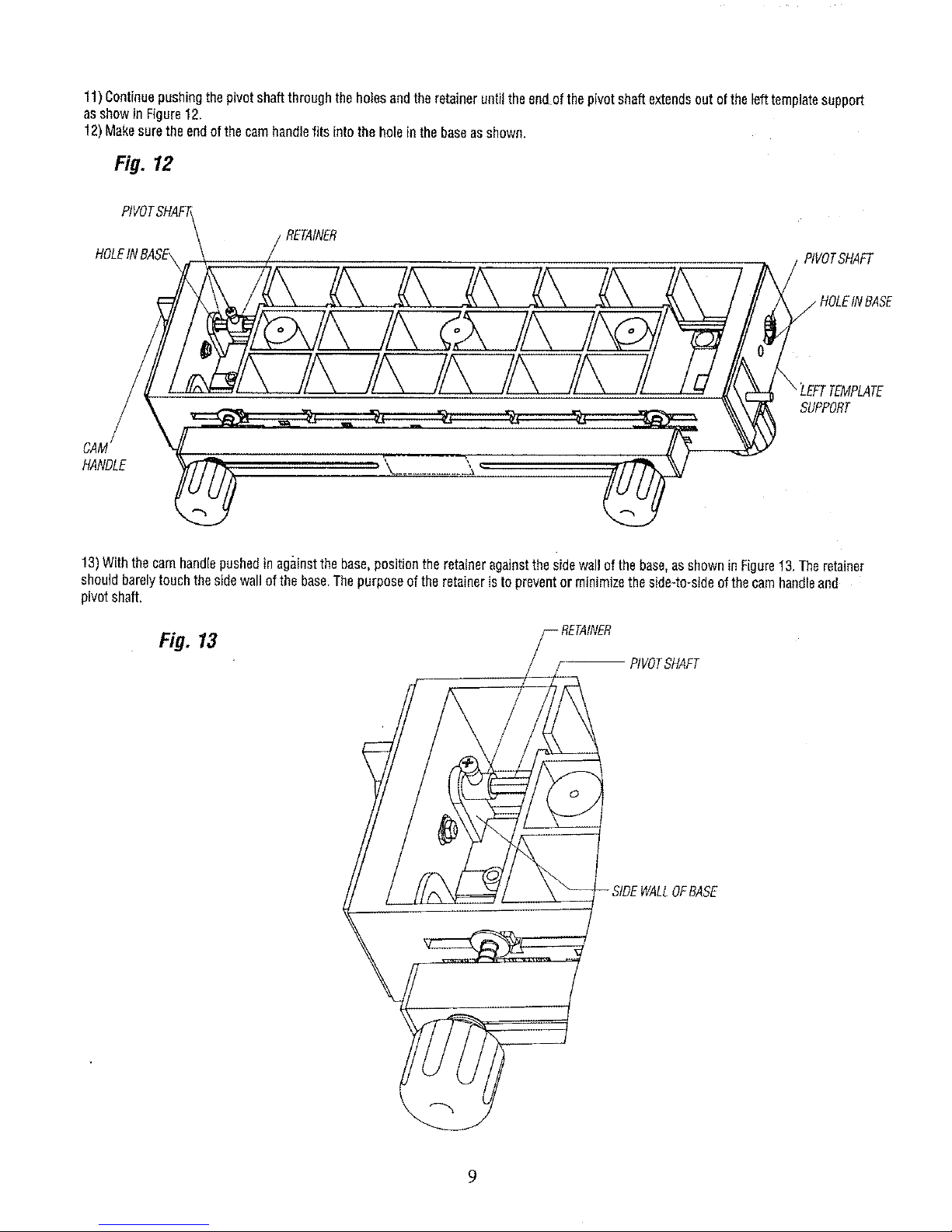

11)Continuepushingthepivotshaftthroughtheholesandtheretaineruntilthe endofthepivotshaftextendsout ofthelefttemplatesupport

asshowin Figure12.

12)Makesuretheendof thecamhandlefits intothe holein thebaseasshown,

Fig. 12

PIVOT,

HOLEINBASE,

CAM

HANDLE _"

13)Withthecamhandlepushedin againstthebase,positionthe retaineragainstthesidewallofthebase,asshownin Figure13.Theretainer

shouldbarelytouchthesidewall ofthe base.Thepurposeof the retaineristopreventor minimizetheside-to-sideofthecamhandleand

pivotshaft.

PtVOTSHAFT

SUPPORT

Fig. 13

RVOTSHAFT

-SIDEWALLOFBASE

9

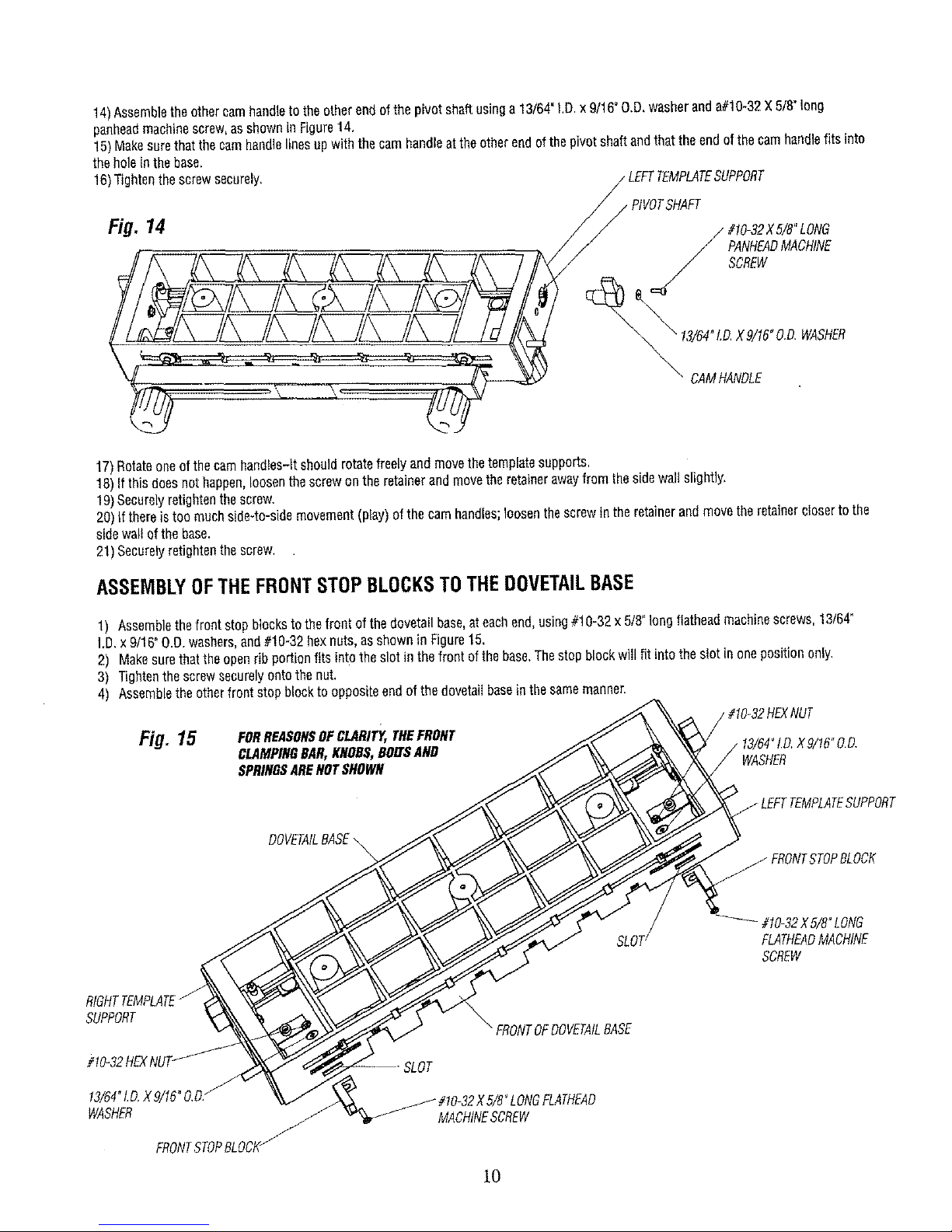

14)Assembletheothercamhandleto theotherendofthepivotshaftusinga13/64"I,D.x 9/16"O.D,washeranda#10-32X 5/8"long

penheadmachinescrew,asshownin Figure14.

15)Makesurethatthecamhandlelinesupwiththecamhandleattheotherendofthe pivotshaftandthattheendofthecamhandlefitsinto

theholein thebase.

16)Tightenthe screwsecurely, LEFTTEMPLATESUPPORT

Fig. 14

/_ #10-32X5/8"LONG

PANHEADMACHINE

SCREW

_" DAMHANDLE

17)Rotateoneofthecamhandtes-ltshoutdrotatefreelyand movethetemplatesupports,

18)Ifthis doesnothappen,loosenthescrewontheretainerandmovetheretainerawayfrom thesidewallslightly,

19)Securelyretightenthescrew.

20)If thereistoomuchside-to-sidemovement(play)ofthecamhandles;loosenthescrewin theretainerandmovetheretainerc/osertothe

sidewaltof thebase.

21)Securelyretightenthescrew,

ASSEMBLYOFTHEFRONTSTOPBLOCKSTOTHEDOVETAILBASE

1) Aseemblethefrontstopblockstothefront ofthedovetailbase,ateachend,using#10-32x 5/8"longflatheadmachinescrews,13/64_

I.D.x 9/16"O.D.washers,and#!0-32 hexnuts,asshownin Figure15.

2) Makesurethattheopenrib portionfits intotheslotin thefrontofthe base.Thestopblockwglfit intotheslotin onepositiononly,

3) Tightenthescrewsecurelyontothenut.

4) Assembletheotherfrontstopblocktooppositeendo1thedovetagbaseinthesamemanner.

Fig. 15

FORREASONSOFCLARITY,THEFRONT

CLAMPINGBAR,KNOBS,BOLTSAND

SPRINGSARENOTSHOWN

WASHER

DOVETAILBASE\

SLOT_

#10_32XB/8OLONG

FLATHEADMACHINE

SCREW

SUPPORT

#10-32HEX

13/64_LD.X9/16°O.D/

WASHER J

FRONTSTOPBLOCI_

_ FRONTOFDOVETAtLBASE

5/8"LONGFLATHEAD

MACHINESCREW

10

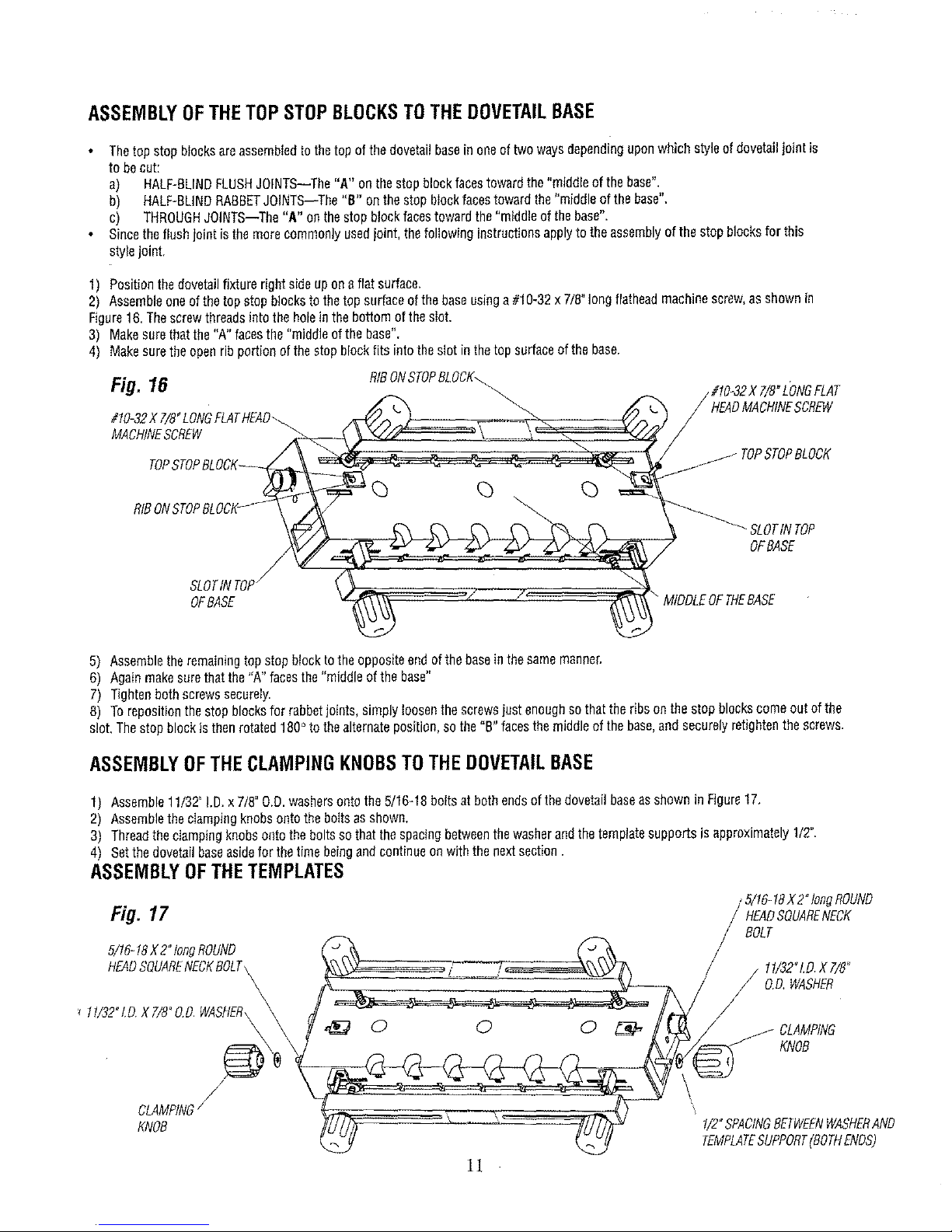

ASSEMBLYOFTHETOPSTOPBLOCKSTOTHEDOVETAILBASE

• Thetopstopblocksareassembledto thetopofthedovetailbasein oneoftwowaysdependinguponwhichstyleofdovetailjointis

to becut:

a) HALF-BLINDFLUSHJOINTS--The"A" onthestopblockfacestowardthe"middleofthebase".

b) HALF-BUNDRABBETJOINTS_The"B"onthestopblockfacestowardthe"middleofthebase".

c) THROUGHJOINTS--The"A" onthestopblockfacestowardthe"middleofthebase".

• Sincetheflushjointis themorecommonlyusedjoint,thefollowinginstructionsapplytotheassemblyofthe stopblocksforthis

stylejoint.

1) Positionthedovetailfixturerightsideuponaflat surface.

2) Assembleoneofthetopstopblockstothetopsurfaceofthe baseusinga#10-32x 7/8"longflatheadmachinescrew,as shownin

Figure16.Thescrewthreadsintotheholeinthe bottomofthesIot.

3) Makesurethatthe "A"facesthe"middleofthebase".

4) Makesuretheopenribportionof thestopblockfits intotheslot in thetopsurfaceofthebase.

Fig. 16 RfBONSTOPBLOCK_

#10_32X 7/8_LONG \

MACHINESCREW

#t0-32X7/8"L'ONGFLAT

HEADMACHINESCREW

TOPSTOPBLOCK

SLOTINTOP/

OFBASE

SLOTINTOP

OFBASE

MIDDLEOFTHEBASE

5) Assembletheremainingtopstopblockto theoppositeendofthebaseinthesamemanner.

6) Againmakesurethatthe"A" facesthe"middleofthebase"

7) Tightenbothscrewssecurely.

8) Torepositionthestopblocksforrabbetjoints,simplyloosenthescrewsjustenoughso thattheribsonthe stopblockscomeoutofthe

slot,Thestopblockisthenrotated180° tothealternateposition,sothe"B"facesthe middleofthebase,andsecurelyretightenthescrews.

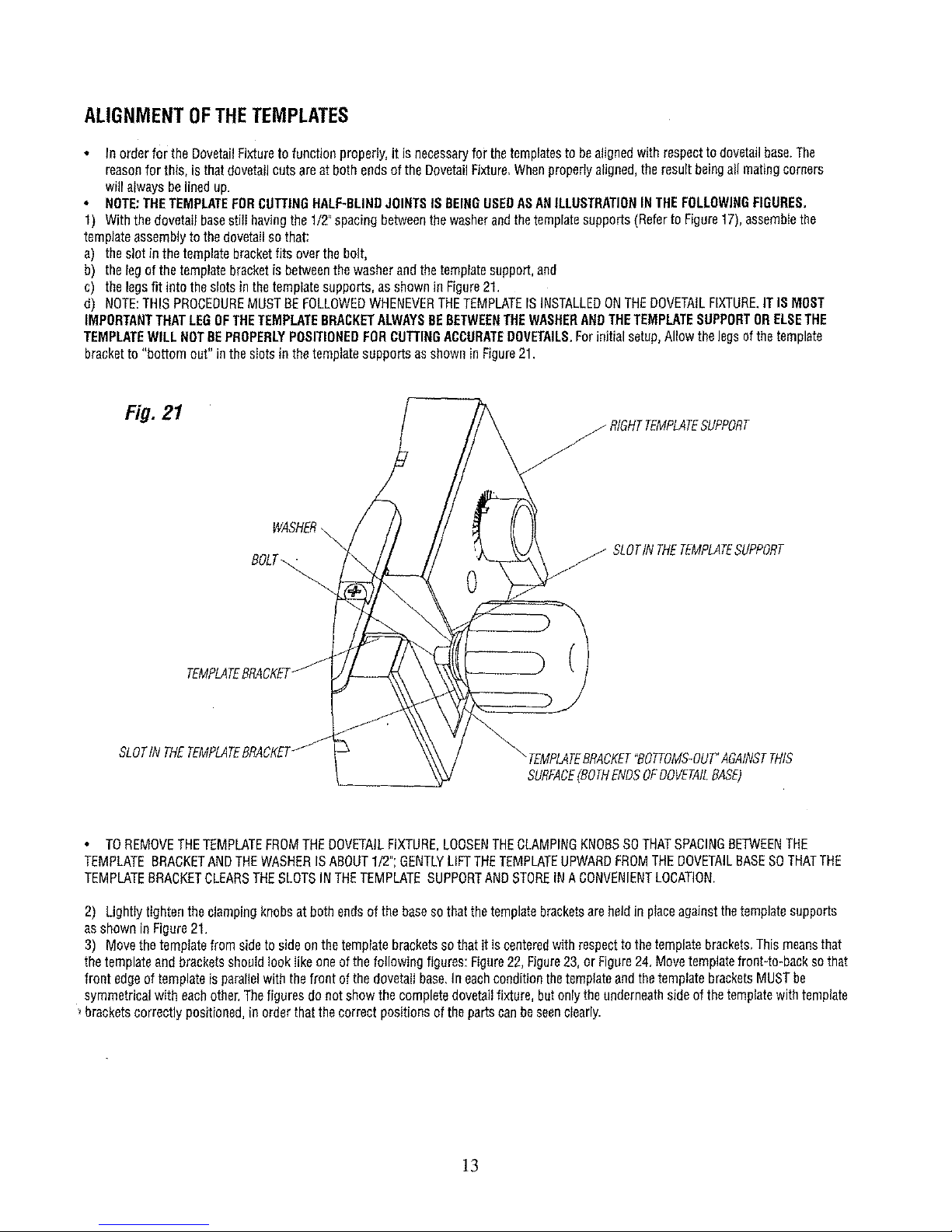

ASSEMBLYOFTHECLAMPINGKNOBSTOTHEDOVETAILBASE

1) Assemb_e1_/32"_D.x 7/8"____was_ers_ntot_e_/1_-18b_itsat b_thends_ft_ed__etai__aseassh__nin Figure17_

2) Assemblethe clampingknobsontothe boItsasshown.

3) Threadtheclampingknobsontotheboltsso thatthespacingbetweenthewasherandthetemplatesupportsisapproximately1/2".

4) Setthe dovetailbaseasideforthetimebeingandcontinueon withthenextsection.

ASSEMBLYOFTHETEMPLATES

/ 5/16-18X2"longROUND

Fig. 17 / HEADSQUARENECK

BOLT

5/t6-t8X2°tongROUND

HEADSQUARENECKBOLT\

\

11/32"I.D.XT/8"

// O.D,WASHER

KNOB

CLAMPING/

KNOB

11

!/2"SPACING8ETWEFNWASHERAND

TEMPLATESUPPORT(BOTHENOS)

•Placethetemplatestiffenerintotherectangularslotin theunderneathsideofthetemplate,asshowninFigure18.

NOTE:THETEMPLATEFORCUTTINGHALF-BLINDJOINTSISBEINGUSEDASANILLUSTRATIONINTHEFOLLOWIHGFIGURES.

1) Threada #8-36x3/16"longpanheadmachinescrewthrougheachofthe fiveholesinthetemplateandintothethreadedholesin the

templatesupport,asshowninFigure24andsecurelytightenallofthescrews.

Fig. 18 _ TEMPLATESTIFFENER

\ _ _ _ J jRECTANGULARSLOT

TEMPLATE

_ _ MACHINESCREwSLOTTEDBINDINGHEAD_ _ MA#&3gX3!!6"t°ngPANHEADcHINESCREW

NOTE:ONSOMEEARLYVERSIONSOFTHISPRODUCT,ASLOTTEDBINDINGHEADMACHINESCREWHASBEENSUBSTITUTEDFORTHE

PANHEADSCREWSPECIFIEDFORASSEMBLINGTHETEMPLATESUPPORTSTOTHETEMPLATES.(SEETHESCREWILLUSTRATIONIN

FIGURE18),

2) Assemblethetemplatebracketsto thetemplateusingfour#10-32x3/8°longpanheadmachinescrews_asshownin Figure19.

3) MAKESURETHATTHETEMPLATEBRACKETSAREASSEMBLEDTOTHEUNDERNEATHSIDEOFTHETEMPLATE,ASSHOWNIN

FIGURE19,ANDTHATTHEAL]GNMENTOFTHEBRACKETSIS ALSOASSHOWNINTHEFIGURE.

4) ITISNOTNECESSARYFORTHESCREWSTOBETIGHTENEDATTHISSTAGE;THETEMPLATEBRACKETSSHOULDBEFREETOMOVE

WITHRESPECTTOTHETEMPLATEORELSEITWILLNOTBEPOSSIBLETOALIGNTHETEMPLATEASDESCRIBEDINTHENEXTSECTION.

5) TheassembledtemplateshouldlookliketheillustrationinFigure20.

Fig. 19

#10-32X3/8"tongPANHEADMACHINESCREW

TEMPLATE

'\

_- TEMPLATEBRACKET....

6) AssemblethetemplatestiffenerandthetemplatebracketstotheTEMPLATEFORCUTTINGTHROUGHJOINTSusingthesamemethod

describedintheprecedingsteps1through5,Referto Figure20.

Fig. 20

lg

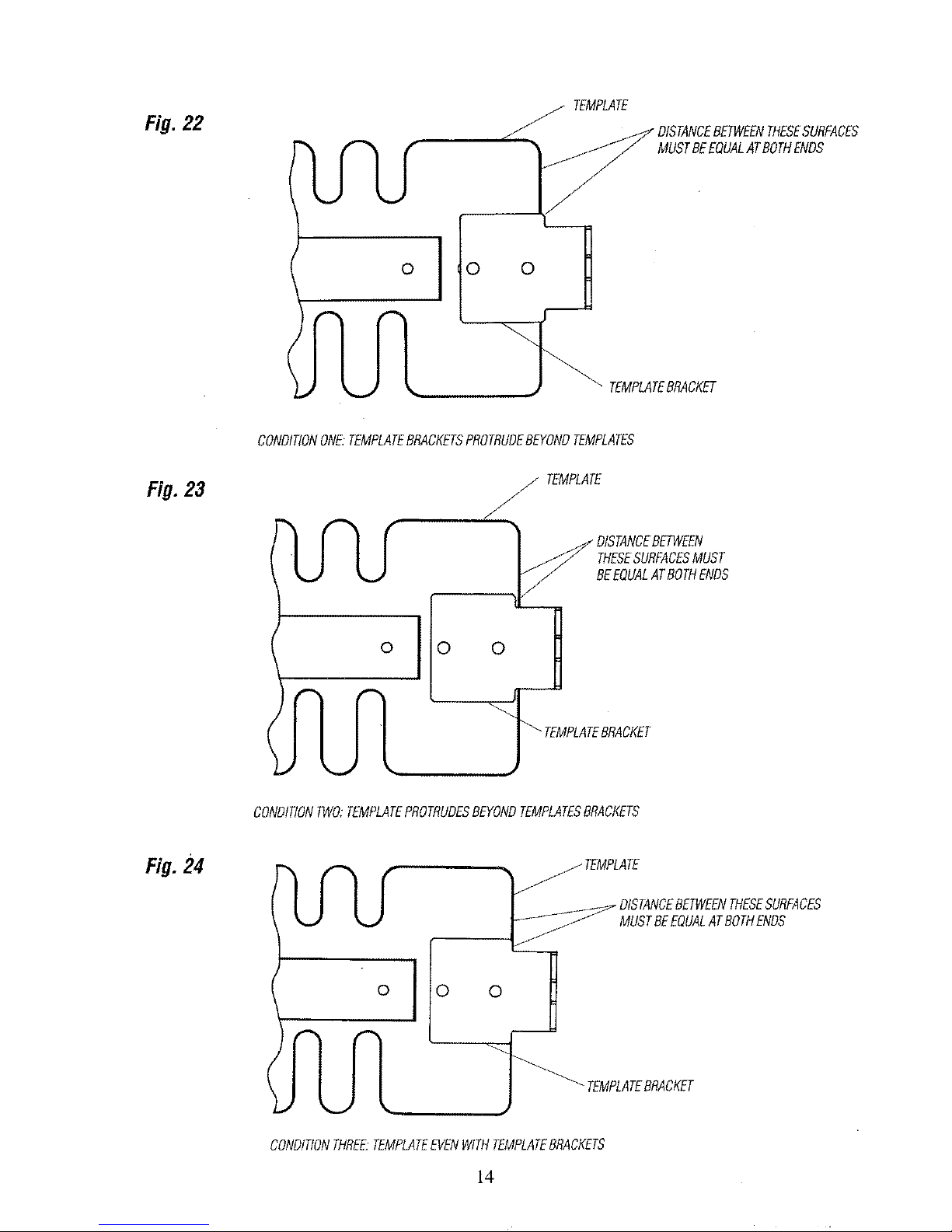

ALIGNMENTOFTHETEMPLATES

Inorderfor the DovetailFixturetofunctionproperly,it isnecessaryfor thetemplatestobealignedwithrespecttodovetailbase.The

reasonforthis, isthatdovetailcutsareat bothendsoftheDovetailFixture.Whenproperlyaligned,theresultbeingall matingcorners

willalwaysbelinedup.

NOTE:THETEMPLATEFORCUTTINGHALF-BLINDJOINTSISBEINGUSEDASANILLUSTRATIONINTHEFOLLOWINGFIGURES,

1) Withthedovetailbasesti!lhavingthe1/2"spacingbetweenthewasherandthetemplatesupports(Referto Figure17),assemblethe

templateassemblyto thedovetailsothat:

a) theslotin thetemplatebracketfitsoverthebolt,

b) thelegofthe templatebracketis betweenthewasherandthetemplatesupport,and

c) thelegsfit intotheslotsinthetemplatesupports,asshownin Figure21.

d) NOTE:THISPROCEDUREMUSTBEFOLLOWEDWHENEVERTHETEMPLATEISINSTALLEDONTHEDOVETAILFIXTURE.ITISMOST

IMPORTANTTHATLEGOFTHETEMPLATEBRACKETALWAYSBEBETWEENTHEWASHERANDTHETEMPLATESUPPORTORELSETHE

TEMPLATEWILLNOTBEPROPERLYPOSITIONEDFORCUTTINGACCURATEDOVETAILS.Forinitialsetup,Allowthelegsofthe template

bracketto "bottomout" intheslotsinthe tempiatesupportsasshownin Figure21.

Fig. 21

WASHER

BOLT_

TEMPLATEBRACKET

SLOTIN THETEMPLATEBRACKET

_ RtGHTTEMPLATESUPPORT

j SLOTINTHETEMPLATESUPPORT

0

"_TEMPLATEBRACKET"BOTTOMS-OUT"AGAINSTTHIS

SURFACE(BOTHENDSOFDOVETAILBASE)

TOREMOVETHETEMPLATEFROMTHEDOVETAILFIXTURE,LOOSENTHECLAMPINGKNOBSSOTHATSPACINGBETWEENTHE

TEMPLATEBRACKETANDTHEWASHERISABOUT1/2";GENTLYLiFTTHETEMPLATEUPWARDFROMTHEDOVETAILBASESOTHATTHE

TEMPLATEBRACKETCLEARSTHESLOTSINTHETEMPLATESUPPORTANDSTOREINACONVENIENTLOCATION,

2) LightIytightentheclampingknobsat bothendsofthebasesothatthetemplatebracketsareheldin placeagainstthetemplatesupports

asshowninFigure21.

3) Movethetemplatefrom sideto sideonthetemplatebracketssothatitis centeredwith respecttothe templatebrackets,Thismeansthat

thetemplateandbracketsshouldlookIikeoneofthefollowingfigures:Figure22,Figure23,or Figure24,Movetemplatefront-to-backsothat

front edgeoftemplateisparallelwith thefrontofthe dovetailbase.IneachconditionthetemplateandthetemplatebracketsMUSTbe

symmetricalwith eachother.Thefiguresdonot showthecompletedovetailfixture,butonlytheunderneathsideofthetemplatewithtemplate

bracketscorrectlypositioned,in orderthatthecorrectpositionsofthe partscanbeseenclearly.

]3

Fig. 22

TEMPLATE

_"DISTANCEBETWEENTHESESURFACES

MUSTBEEQUALATBOTHENDS

I

TEMPLATEBRACKET

CONDITIONONE."TEMPLATEBRACKETSPROTRUDEBEYONDTEMPLATES

Fig. 23

.24

j TEMPLATE

J

F

THESESURFACESMUST

BEEQUALATBOTHENDS

o

_0 0 TEMPLATEBRACKET

CONDITIONTWO;TEMPLATEPROTRUDESBEYONDTEMPLATESBRACKETS

MUSTBEEQUALATBOTHENDS

CONDITIONTHREE.TEMPLATEEVENWITHTEMPLATEBRACKETS

o 0

0

TEMPLATEBRACKET

14

4) Afterthetemplatebracketshavebeencorrectlypositionedonthetemplatesecurelytightenthefourscrewsholdingthetemptatebrackets

to thetemplate.

5) Removethetemplateassemblyfromthebaseandsetit asidefornow.

6) Aligntheothertemplateassemblyin thesamemanner,

ITSHOULDBENOTEDTHATYOUMAYFIND,THATAFTERMAKINGSOMESAMPLECUTS,SLIGHTADJUSTMENTSMAYBEREQUIRED.

HOWTOMAKETHESEADJUSTMENTSIS EXPLAINEDINTWOOFTHEFOLLOWINGSECTIONS:"MAKINGADJUSTMENTSFORHALFBLIND

JOINTS"or "MAKINGADJUSTMENTSFOROPEN(THROUGH)JOINTS".

7) Removethetemplateassemblyfromthebaseandsetit asidefornow.(Figure25 below,isanexampleof INCORRECTLYpositioned

templatebrackets,)

CKET

BEYONDTHETEMPLATE

BRACKET

0

o

!o 0

THETEMPLATEBRACKETEXTENDS

tEMPLATE

CONDITIONFOUR:THISCONDITIONISNOTCORRECT---

TEMPLATEBRACKETEXTENDSBEYONDTHETEMPLATEAND

THETEMPLATEEXTENDSBEYONDTHETEMPLATEBRACKET

• StMPLYMAKESUREBRACKETSAREPOSITIONEDTHESAMEATEACHEND

ASSEMBLYOFA GUIDEBUSHINGTOTHEROUTER

ALWAYSMAKESURETHATTHEROUTERIS "TURNEDOFF"ANDTHATTHEELECTRICALCORDHASBEENUNPLUGGED

FROMTHEELECTRICALOUTLETBEFOREASSEMBLINGAGUIDEBUSHINGTOTHEROUTERORMAKINGANYADJUSTMENTSOR

CHANGINGROUTERBITSINTHEROUTER.

REMOVEANYROUTERBITFROMTHEROUTERBEFOREPROCEEDINGWITHTHEASSEMBLYOFA GUIDEBUSHINGTOTHEROUTER.

Assembly for Sears routers with three hole baseplates:

1) Placethe'routerupsidedawnonaflat surfaceandremoveanyguidebushingthatmaycurrentlybeinthe router,

2) Placetheguidebushingrequiredforthetypeof dovetagjoint to becutundertherouterbaseplateasshownin Figure26.

Fig. 26

10-32X3/8°LONGFLATHEAD

MACHINESCREW

(1/2"DIAMETERSHOWN)

NOTETHEORIENTATIONOF"

THEGUIDEBUSHING

Loading...

Loading...