Sears Craftsman 143.726182 Owner's Manual

Sears

owner's

manual

MODEL

NO.

Se

143.726182

.-

CAUTION:

Read

Safe

and INSTRUCTIONS

RULES for

OPERATION

Carefully

~/D4D

CRAFTSMAN

ENGINE

• Operating

• Maintenance

~

Sold

Printed in

U.S.A.

by

SEARS,

and

SIMPSONS -SEARS

ROEBUCK

AND

LIMITED,

CO., Chicago, IL. 60684 U.S.A.

• Repair Parts

Toronto, Ontario,

Canada

2-1-82

.

181

-383-

11

OIL

FILL

PLUG

AND

DIPSTICK--

CO

OLING

FIN

S

MUFFLER

SYMBOL

THIS

ENDANGER THE PERSONAL SAFETY

A

THE FOLLOWING SYMBOLS

~

FOLLOW

FAST

ALL

INSTRUCTIONS IN THIS

THIS

ENGINE IS USED BEFORE ATTEMPTING TO OPERATE YOUR

POINTS

MAY

.....

SPARK

PLUG

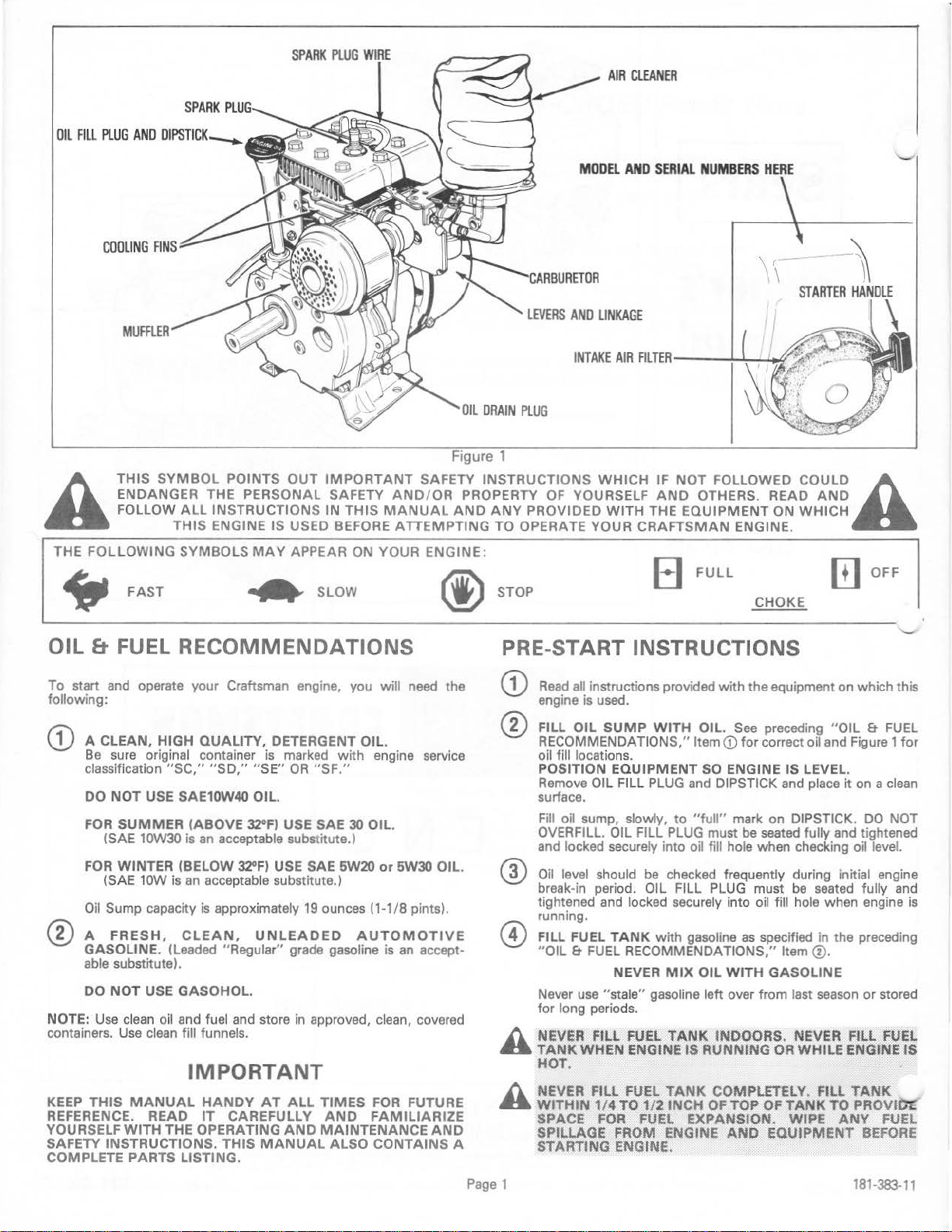

Figure 1

OUT

IMPORTANT

APPEAR ON YOUR ENGINE:

SLOW

SAFETY INSTRUCTIONS

AND/OR

MANUAL

PROPERTY

AND

@STOP

ANY

MODEL

LEVERS

AND

OF

YOURSELF

PROVIDED

AIR

CLEANER

AND

LINKAGE

WHICH

WITH

THE EQUIPMENT ON

CRAFTSMAN

SERIAL

NUMBERS

HERE

\\-

IF NOT FOLLOWED

AND

OTHERS. READ

ENGINE.

...

FULL

1

1

CHOKE

-)

STARTER

COULDA

WHICH

HANDLE

AND

m

OFF

OIL & FUEL RECOMMENDATIONS

To start and operate your Craftsman engine,

following:

A CLEAN, HIGH QUALITY, DETERGENT OIL.

Be

sure original container is marked with engine service

classification

DO NOT USE SAE10W40 OIL.

FOR

SUMMER

ISAE 10W30

FOR WINTER (BELOW

(SAE 10W

Oil

Sump capacity

A

®

NOTE:

containers.

FRESH,

GASOLINE. (Leaded "Regular" grade gasoline is

able substitute).

DO NOT USE GASOHOL.

Use

Use

"SC,"

"SO,"

"SE"

OR

(ABOVE

is

an

is

an

CLEAN,

clean oil and fuel and store in approved, clean, covered

clean fill funnels.

J20F)

acceptable substitute.)

acceptable substitute.)

is

approximately

USE SAE

J20Fl

USE SAE 5W20

UNLEADED

you

will

"SF."

30

OIL.

or

5W30 OIL.

19

ounces (1-1/8 pints).

AUTOMOTIVE

an

IMPORTANT

KEEP

THIS

REFERENCE.

YOURSELF

SAFETY INSTRUCTIONS. THIS

COMPLETE PARTS LISTING.

MANUAL

READ

WITH

HANDY

IT

THE OPERATING

AT

CAREFULLY

MANUAL

ALL

TIMES

AND

AND

MAINTENANCE

ALSO CONTAINS A

FOR

FAMILIARIZE

need

the

accept-

FUTURE

AND

PRE-START INSTRUCTIONS

G)

Read

all

instructions provided with the equipment on which this

SUMP

WITH OIL.

CD

OIL

FILL

PLUG

and DIPSTICK and place it on a clean

oil sump, slowly, to

level

should

FUEL

use

WHEN ENGINE IS RUNNING

1/4

be

OIL

TANK

RECOMMENDATIONS,"

NEVER

"stale" gasoline left over from last

FUEl

TO 1/2 INCH

FOR

FUEL

ENGINE.

"full"

PLUG

must

oil fill hole when checking oil level.

checked frequently during initial engine

FILL

PLUG

with gasoline

MIX

OIL

TANK

TANK

fNDOORS. NEVER FILL

COMPL£T£LY. FILL

OF

EXPANSION. WIPE

Page

engine is used.

FILL OIL

®

RECOMMENDATIONS," Item

oil fill locations.

POSITION EQUIPMENT SO ENGINE IS LEVEL.

Remove

surface.

Fill

OVERFILL. OIL FILL

and locked securely into

Oil

break-in period.

tightened and locked securely into

running.

FILL FUEL

"OIL &

Never

for long periods.

~

NEVER FlU. FUEL

..

TANK

HOT.

~

NEVER FILL

..

WITHJN

SPACE

SPILLAGE FROM ENGINE

STARTING

1

See

preceding "OIL &

for

correct oil and Figure 1 for

mark on DIPSTICK.

be

seated fully and tightened

must

be

oil fill hole when engine is

as

specified in the preceding

WITH

TOP

OF

AND

EQUIPMENT

seated fully and

Item(!).

GASOLINE

season

OR

WHILE ENGINE

TANK TO PROVIOE

ANY

FUEL

DO

NOT

or

stored

FUEL

TANK

FUEL

BEFORE

181-383-11

JS

PRE-START INSTRUCTIONS tcontinuedl

CHECK

®

engine:

A.

"

B.

C.

D.

THE

FOLLOWING before attempting to start your

BE;WRE

.

¢(QTCHIS

{fOLLOW

STRUCTIONS.} THIS

SWITCHES

Be

sure SPARK

(see

Be

sure

RUN

Be

sure

EOUIPMENT

.s,

BELtS

EOUif:iM£Nt ·

IN

SAfE

Figure

any ignition switch on engine

or START position.

FUEL

PLUG

1)

FILL

CAP air vent is open.

~:iS.

.iN:

:Ne·

}

CHAINS,

SHOULD

STARTING POSITION.

WIRE is attached to SPARK PLUG.

urt~AL

··

ere

MANUFACTURER'S IN·

PLACE.

i

:,

blS!NGAGEO

ANV

or

equipment

G~AR

SAFETY

STARTING INSTRUCTIONS

WITH

is

in ON,

WARM

®

running).

NOTE - Warm engine may start without choking.

A. Move remote control on equipment to

,

B.

ENGINE START (Engine still warm from recent

FAST.

START

1.

2.

3.

ENGINE

Grasp

STARTER

out, slowly, until it

sion. Let rope rewind slowly.

Pull rope with a rapid continuous full

rewind

back against starter.

Repeat

If engine falters, move equipment control

engine runs smoothly and then

NOTE: If

of

ENGINE

SLOWLY. Don't let

preceding Instructions 1 and 2 until engine starts.

engine fails to start after a reasonable number

starting attempts, follow preceding "

START" instructions.

HANDLE

pulls harder due to engine compres-

(see

Figure

STARTER

to

arm

FAST.

2)

stroke. Let rope

HANDLE

to

and pull rope

snap

CHOKE

CD

untill

COLD

h NEVER. RUN ENGlNE

..

POOf\tYVEN'f'ILATED

TAINS

DEADLY GAS. . ..

h KEEP

..

AWAY

EQUIPMENT.

h

WARNING

..

BY

AREAs.

G)

COLD ENGINE START (Engine has not

A. Move remote control on equipment to

B.

CARBON

HANDS,

FROM

AREAS

ment manufacturers instructions).

START

1.

Grasp

out, slowly, until

sion. Let rope rewind slowly.

2.

Pull rope with a rapid continuous full arm stroke. Let rope

rewind

back against starter.

3.

Repeat

and when engine starts, move equipment control to

FAST position.

If engine falters, move equipment control

engine runs smoothly and then

NOTE: If

control to

2 until engine starts.

If

engine fires, but fails to start again, repeat preceding In-

structions

FEET,

ANY

- TEMPERATURE

MAY

ENGINE

STARTER

SLOWLY. Don't let

preceding Instructions 1 and 2 until engine fires

engine fires, but fails to start, move equipment

FAST and repeat preceding Instructions 1 and

1,

2 and 3 until engine starts.

lNDOORS

AREAS. ENGINE EXHAUST CON-

MONOXIDE,

HAIR

..

AND

PARTS

OF

1SOOF

(see

MOV!NG

EXCEED

HANDLE

it

pulls harder due to engine compres-

OR

IN

ENCLOSED,

AN

ODORl.ESS

LOOSE CLOTHING

ON

.ENGINE

MUFFlER

(OO'Cl.

Figure

STARTER

to

FAST.

AND

AVOID

.

been

run recently).

CHOKE

2)

and pull rope

HANDLE snap

to

CHOKE

(see

AND

AND

NEAR-

THESE

equip-

untill

TO STOP ENGINE

Move remote control

G)

on engine to

facturer's instructions) .

AFTER

®

h

A.

..

h B. TURN

..

ENGINE IS STOPPED:

DISCONNECT SPARK PLUG WIRE FROM

PLUG

AND

SPARK PLUG. . ·

''

THIS

UNAUTHORIZED STARTING OF ENGINE

EQUIPMENTfS

IGNITION

OFF" POSITION

WILL

h C. NEVER STORE ENGINE WJTH FUEL IN

..

DOORS OR

ENCLOSURES, WHERE

OPEN FLAME,

FURNACE, WATER HEATER. CLOTHES DRYeR, ETC.

on

STOP

PLACE

equipment or any ignition stop switch

or

OFF

position

IT

WHERE

SWITCH KEY

AND

REDUCE

NOT

IN

SPARK

REMOVE KEY FROM SWITCH.

IN

USE.

ENClOSED, POORLY VENTILATED

~UEL

OR

(see

equipment manu-

IT

CAN

If

SO

THE

POSSIBILITY

fUMES

PILOT LIGHT

MAY

NOT

EQUIPPED. TO

SPARK

CONTACT

OF

WHILE

TANK

REACH

AS

IN~

AN

ONA

Page2

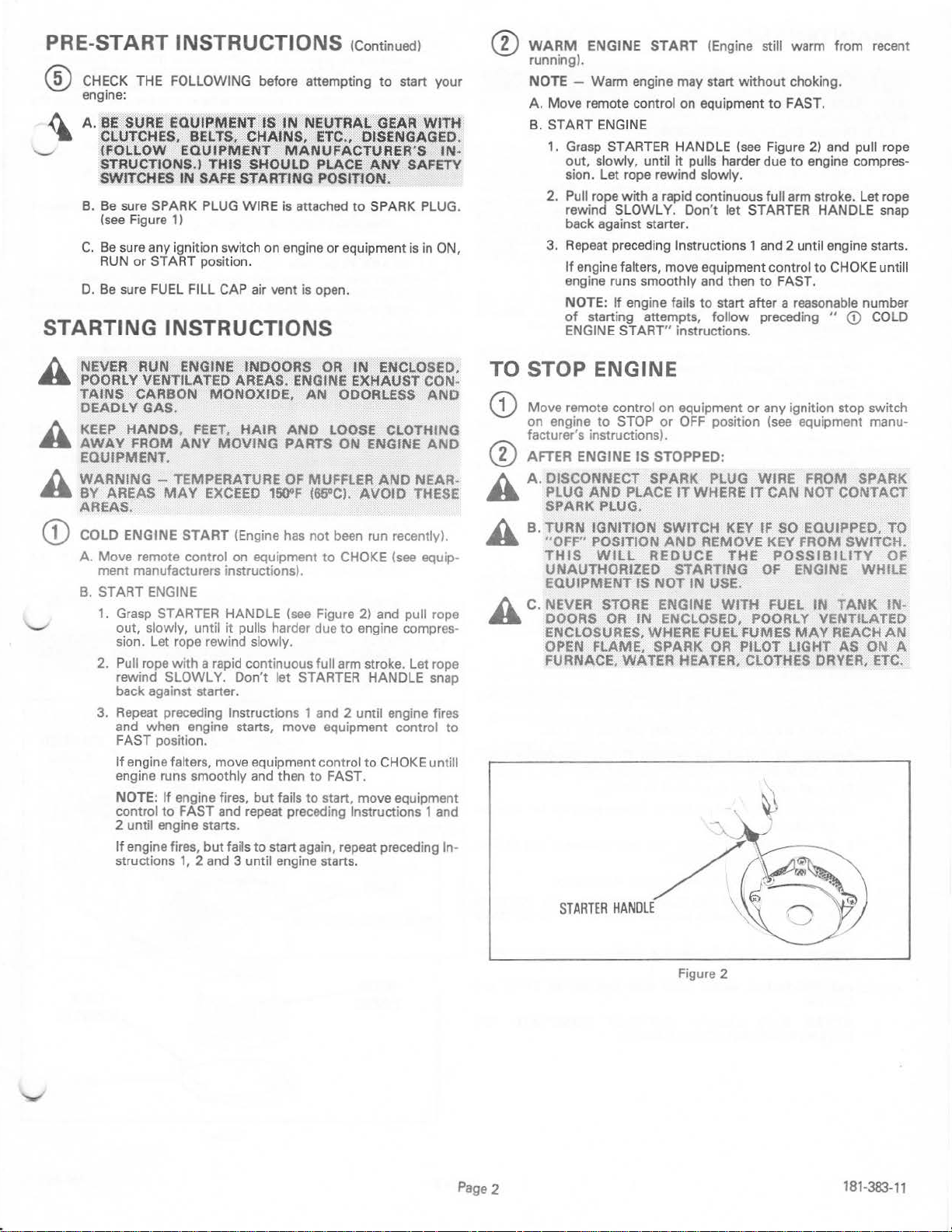

Figure 2

181-383-11

MAINTENANCE

G)

CHECK

POSITION

Check

ment is used. Always

Figure

dirt, grass clippings, etc. Add oil

ENGINE

LEVEL

DIPSTICK.

START INSTRUCTIONS"

CHANGE

®

every twenty-five

operated

DRAIN

PLUG

DRAIN

and

Replace OIL DRAIN

with new

preceding

Replace OIL FILL

®and@

1).

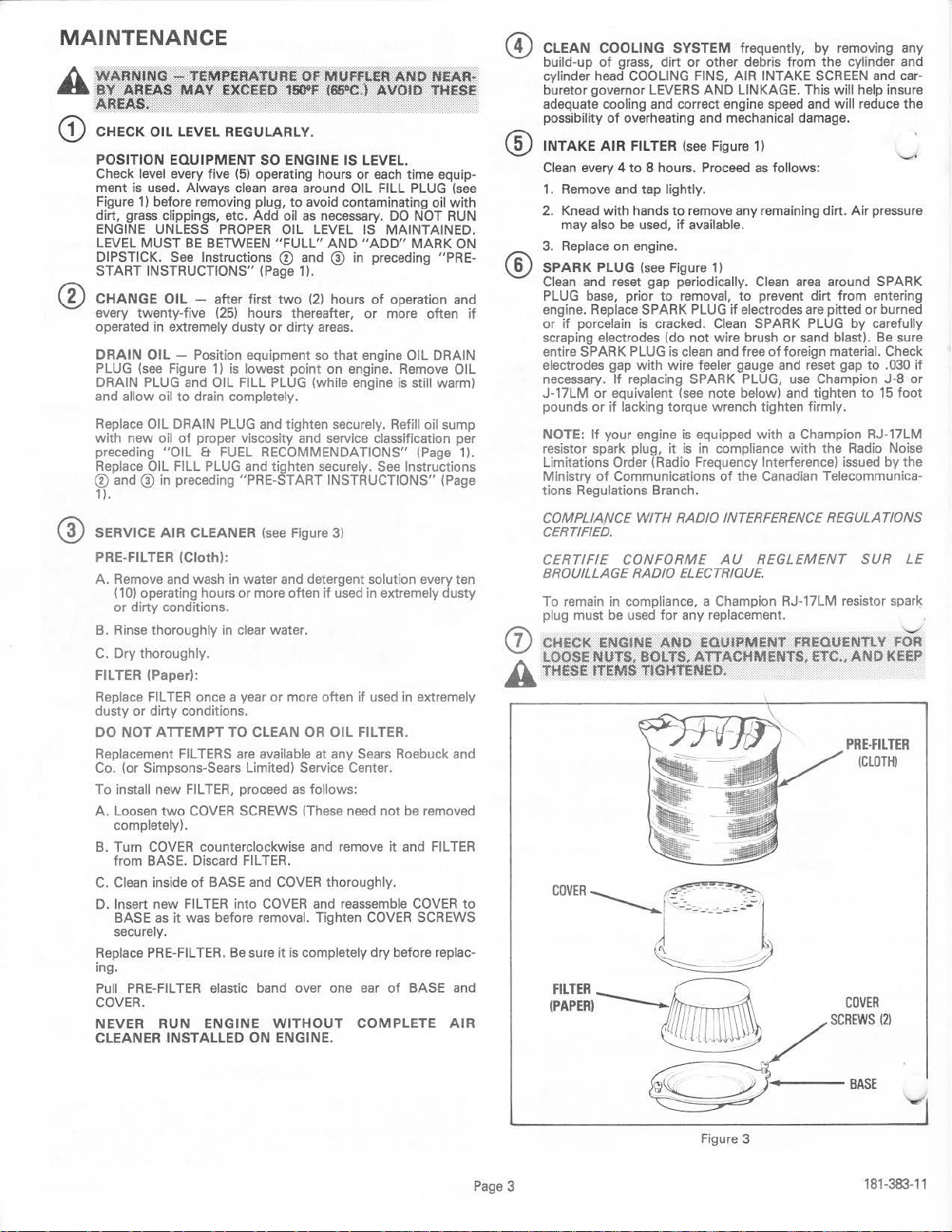

® SERVICE

PRE-FILTER (Cloth):

A. Remove and wash in water and detergent solution every ten

B.

C.

FILTER (Paper):

Replace

dusty or dirty conditions.

DO NOT

Replacement FILTERS

Co. (or Simpsons-Sears Limited) Service Center.

To

A. Loosen

B. Turn

C.

D.

Replace

ing.

Pull

COVER.

NEVER

CLEANER INSTALLED ON ENGINE.

OIL

LEVEL REGULARLY.

EQUIPMENT

level every five

1)

before removing plug,

UNLESS

MUST

BE

BETWEEN

See

Instructions ® and ® in preceding "PRE-

OIL

- after first

in

extremely dusty

OIL - Position equipment

(see

Figure 1 l is lowest point on engine. Remove OIL

PLUG

allow oil

(

10)

or dirty conditions.

Rinse

Dry thoroughly.

install new FILTER, proceed

completely).

from BASE. Discard

Clean

In

sert new

BASE

securely.

PRE-FILTER

and OIL FILL PLUG (while engine

to

drain completely.

oil

of

proper viscosity and service classification per

"OIL & FUEL

PLUG

in preceding "PRE-START INSTRUCTIONS" (Page

AIR

CLEANER

operating hours

thoroughly in clear water.

FILTER

once a

ATTEMPT

two

COVER

COVER

PRE

counterclockwise and remove it and

inside

of

BASE and

FILTER

as

it was before removal. Tighten

-FI

LTER. Be

elastic band over one

RUN

ENGINE

SO ENGINE IS LEVEL.

(5)

operating hours or each time equip-

clean

area

around OIL FILL

to

avoid contaminating oil

as

PROPER

(P

age

(25)

hours thereafter,

or

PLUG

and tighten securely. Refill oil sump

RECOMMENDATIONS"

and tighten securely.

(see

or

more often if used in extremely dusty

year

or

TO CLEAN

are

available at any

SCREWS (These need not be removed

FILTER

into

COVER

sure it

WITHOUT

necessary.

OIL

LEVEL

"FULL"

1).

two

(2)

dirty

so

Figure

more often if used in extremely

OR

as

follows:

.

COVER

and reassemble

is

completely dry before replac-

IS MAINTAINED.

AND

"ADD"

hours

of

or

areas.

that engine OIL DRAIN

3)

OIL

FILTER.

Sears

thoroughly.

COVER

ear

COMPLETE

DO

operation and

more often

See

of

PLUG

(see

with

NOT

RUN

MARK

ON

is

still warm)

(Page

Instructions

Roebuck and

COVER

BASE and

1).

FILTER

to

SCREWS

AIR

if

CLEAN COOLING SYSTEM frequently, by removing any

build-up

cylinder head

buretor governor

adequate

possibility

INTAKE

®

Clean

1.

2.

3. Replace on engine.

SPARK

®

Clean

PLUG

engine. Replace

or

scraping electrodes (do not wire brush

entire

electrodes gap with wire feeler gauge and reset gap

necessary. If replacing SPARK PLUG,

J-17LM or equivalent

pounds

NOTE:

resistor spark

Limitations

Ministry

tions Regulations Branch.

COMPLIANCE WITH RADIO INTERFERENCE REGULATIONS

CERTIFIED.

CERTIFIE

BROUILLAGE RADIO ELECTRIQUE.

To remain in compliance, a Champion RJ-17LM resistor

plug must be used for any replacement. .

(j)

oo~c;t<

J.:Oc:)~e

A

THESE

(PAPER)-------

of

grass, dirt or other debr

COOLING

cooling and correct engine speed and will reduce the

of

overheating and mechanical damage.

AIR

FILTER

every 4

Remove and tap lightly.

Knead with hands

may

if porcelain is cracked.

SPARK PLUG

to

8 hours.

also be used,

PLUG

and reset gap periodically.

base,

or

If

(see

prior

SPARK PLUG

if lacking torque wrench tighten firmly.

your engine is equipped

plug, it

Order (Radio Frequency Interference) issued

of

Communications

CONFORME

ENQit!l~

NU.T~t BQLTSiATfAP.ftMEf!T~~

lTgM~

FILTER

"f*QHT:E~HUik

FINS, AIR INTAKE

LEVERS

AND LINKAGE. This will help insure

(see

Figure 1)

Proceed

to

remove any remaining dirt.

if

available.

Figure

1)

to

removal,

Clean

is

clean and free

(see

note below)

is

in compliance with the

of

AU

A.NP.

EO.Ol~MEN1:

~

-

.i i I

JJ

is

from the cylinder and

SCREEN

as

follows:

Clean

area

to

pre

if electrodes are pitted or burned

vent dirt from entering

SPARK PLUG by carefully

of

with

the Canadian Telecommunica-

REGLEMENT

.,

).

.·······.··············<•·······················. . •.

.·

/SCREWS

around SPARK

or

sand blast).

foreign material. Check

use

Champion J-8

and

tighten

a Champion RJ-17LM

'

~eo~~Nn.v

~'fC.~•

and car-

Air

pressure

Be

sure

to

.030

to

Radio

SUR

or

15

foot

Noise

by

the

LE

spar~

FOA

AND

t(E~f

· . '

...•..

PRE-FILTER

(CLOTH)

CO

VER

I~

if

Page

~

BASE

~

Figure 3

3

181-383-11

Loading...

Loading...