Sears Craftsman 113.274600C Owner's Manual

Save

this

manual

fo

r futur

e reference

SEAIRlS

owner's

manual

STOCK NO.

09

27460

MODEL NO.

113.27 4600C

Serial

Number

___

_

Model and seri

al

number may be found

on

th

e motor cover.

You should reco

rd both

model a

nd seri

al numb er

in a safe

pl

ace for

future us

e.

FOR YOUR

SAFETY:

READ

ALL

INSTRUCTIONS

CAREFULLY

S.IEA/RlS

/CIA

FTS

M A

N~o

'

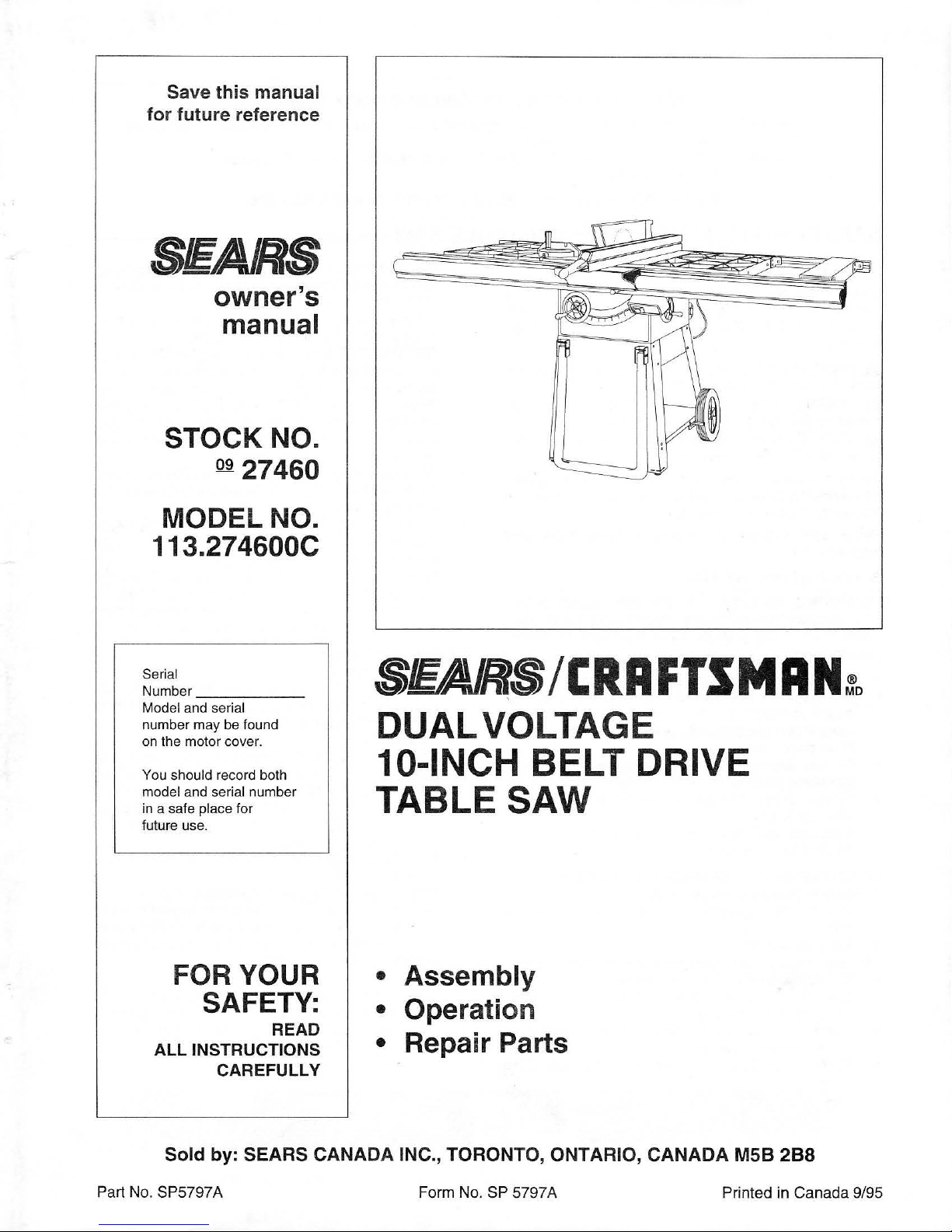

DUAL

VOLTAGE

10-INCH

BELT

DRIVE

TABLE

SAW

•

Assembly

• Operati

on

• Repair Parts

Sold by: SEARS CANADA INC., TORONTO, ONT ARlO, CANADA

M5B

288

Pa

rt

No. SP5797 A Form No. SP 5797A

Printed in Canada 9/95

FULL TWO YEAR WARRANTY ON CRAFTSMAN TOOL

If

this Craftsman Tool fails to operate within two years from date of purchase, retu

(Sears) store and "Sears" will repair it, free ol charge.

If

this tool is used f

This warranty is in addit ion to any statutory warranty.

or

rental purposes this warranty applies for only 90 days from the date of purchase.

SEARS CANADA INC., TORONTO, ONT ARlO, CANADA

rn

it to the nearest Sears Canada Inc.

MSB

2B8

SAFETY INSTRUCTIONS FOR THE TABLE

SAFETY SIGNAL WORDS

Safety signal wor

information in the

signal words, DANGER, WARNING

the level of risk.

~

DANGER:

someone WILL be seriously injured or killed.

~

WARNING: If the safety information is not followed,

someone COULD be seriously injured

~

CAUTION: If the safety information is not followed,

someone MAY be injured.

Safety is a combination of common sense, staying alert

and knowing how your table saw works. Read this

manual to understand this saw.

Read

and

instructions

BEFORE

USING THE SAW:

WARNING:

serious, permanent injury, do not

until the following steps have been satisfactorily

completed.

• Completely assemble and align saw (See pages 12-38)

• Learn the use and function of the ON guard, spreade

table insert and blade elevation and bevel controls.

page 39)

(See

• Review and understand all safety instructions and

operating procedures in

Review

•

(See page 60)

• Find and read all the warning labels found on the

front of saw (shown below).

WHEN INSTALLING OR MOVING THE SAW:

Avoid dangerous environment.

• Use the saw in a dry, indoor place protected from

rain.

• Keep work area well lighted.

To avoid injury from unexpected saw movement:

• Bolt

or

there is plenty of room to handl e and properly

support the workpiece.

• Support the saw so the table is level and the saw

does not rock,

When using a table extension on any side of the

•

ds

are used to draw attention to safety

manual and on the table saw. The

or

CAUTION, tell

If

the safety information is not followed,

or

killed.

follow

all

safety

information

and

To avoid mistakes that could cause

plug the saw

OFF-

r,

anti-kickback device, mitre gauge,

th

is manual.

of

the maintenance methods for this saw.

in

switch,

clamp the saw on a firm level surface where

or

slide.

• Put the saw where neither operators or bystande

• GROUND THE

•

• To avo

• Never stand on tool. Serious injury could occur

BEFORE EACH USE:

Inspect

• To

• Check for alignment of moving parts, binding of

• If any part is missing, bent,

• Replace damaged, miss ing, or failed

• Use the sawblade guard, spreader, and anti-kick-

•

' Ma

SAW----------

saw, bolt the saw to a stat ionary surface or prop up

the outer end of the extension from the floor or bench

top to keep the saw from tipp i

must stand in line with the saw blade.

SAW-

Modei113-274600C has

approved 3-conductor cord and a 3-prong grounding type plug. The plug fits grounding type outlets

designed for 120 volt 15 amp circuits. The green

conductor

in

the cord is the grounding wire. To avoid

electrocution, never connect the green

terminal.

The saw

is

shipped factory wired for 120V operatio

To change the motor to 240V see owners manual for

correct procedure.

id

injury from electrical shock, make sure

your fingers do not touch the plug's metal prongs

plugging in or unp lugging the saw.

when

the to

ol

tips

or

you accidental

Do not store anything above or near the tool where

anyone might stand

on

your saw.

avoid

injury from accidental starti

unp

lug

the saw and

or

removing

ing

the setup or adjusting anyth

remove

the guard, changing the cutting tool,

moving parts, breakage of parts, mounting, and any

other conditions that may affect the way it works.

electrical parts don't work properly, turn the saw

any

off and

usi

back

unplug the saw.

ng

the saw again.

pawls for anythru-sawing (whenever the blade

comes through the top of the workpiece). Make sure

the spreader is in line with the sawblade and the ant

kickback pawls work properly.

Remove adjusting keys and wrenches.

Form habit of checking for

adjusting wrenches from

k€

sure all clamps and locks are tight and no

ha

parts

ve excessive play.

ng.

wi

re

to

ly

hit the cutting too

the tool to reach them.

ng,

turn

switch

the

swi

tch

key

before

raising

chang

ing.

or

broken in any way, or

parts before

an

d removing keys and

tool before turning it on.

an

a live

off

rs

n.

if

l.

,

-

i-

. :

·:

:t

i. . ~ :

······

::

·:;.

::

:' •

,•'

2

To

avoid

injury

(kickback

Use

only recommended accessories.

from

and

throwback):

jams,

slips

or

thrown

pieces

• Follow the instructions that come with the acc esso-

Th

ries.

e use of improper accessories may cause

risk of injury to persons.

• Choose the right bfade or cutting accessory for the

material and the type of cutting you plan to do.

• Never use grinding wheels, abrasive cut-off wheels,

friction wheels (metal slitting blades) wire wheels or

buffingwheel. They can fly apart explosively.

Choose

• To avoid cutting tool failure

and

inspect

your

cutting

tool

and thrown shrapnel

(broken pieces of blade), use only 1

blades

or

other cutting tools marked for speed of

carefully.

0" or smaller

3450 rpm or higher.

• Always use unbroken, balanced blades designed to

fit this saw's

5/8" arbor.

• When thru-sawing, (making cuts where the blade

comes through the workpiece top) always use a

inch diameter blade. This keeps the spreader

10

in

closest to the blade.

•

Do

not overtighten arbor nut. Use arbor wrenches to

"snug"

it

securely.

• Use only sharp blades with properly set teeth. Consult a professional blade sharpener when in doubt.

• Keep blades clean of gum and resin.

• Adjust table inserts flush with the table top. Never

use the saw without the proper insert.

• Make sure all clamps and locks are tight and no

parts have any excessive play.

Inspect

your work

area.

• Keep work area clean.

• Cluttered areas and benches invite accidents. Floor

be

must not

slippery from wax

• To avoid burns or other fi

li

saw near flammable

• To avoid inju

ry,

quids, vapors or gases.

don't

do

work on the table while the blade is spinning.

th

row anything hitting the blade.

work

.

Plan

cut or

your

or

sawdust.

re

damage, never use the

layout, assembly, or setup

It

could

• Plan ahead to protect your eyes, hands, face and

ears.

• Use the right

do a job

for

Dress

•

Do

not wear loose clothing, gloves, neckties or

tool-

Don't force tool or attachment to

it

was not designed for.

safety:

jewelry (rings, wrist watches). They can get caught

and draw you into moving parts.

• Wear nonslip footwear.

• Tie back long hair.

• Roll !ong sleeves above the elbow.

• Noise levels vary widely. To avoid possible hearing

damage, wear ear plugs or muffs when using saw for

long periods of time.

• Any power saw can throw foreign objects into the

eyes. This can cause permanent eye damage. Wear

safety goggles (not

glasses)

that comply with CSA

Z94-3-M88 (shown on package). Everyday eyeglasses have only impact resistant lenses. They are

ai

not safety glasses. Safety goggles are av

lable at

Sears retail catalogue stores. Glasses

in compliance with

CSA Z94-3-M88 could seriously

or

goggles not

hurt you when they break.

WEAR

For dusty operations, wear a dus t mask along with

•

YOU

R

the safety goggles.

Inspect

• Make sure there are no nails

your

workpiece.

or

foreign objects

in

the

part of the workpiece to be cut.

• When cutting irregularly shaped workpieces, pl

your work so it wi

ll

not slip and pinch the blade.

• A piece of molding, for example, must lie flat or

held by a fixture

or jig

that will not let it twist, rock or

an

be

slip while being cut. Use jigs, fixtures where needed

to prevent workpiece shifting.

• Use a different, better suited type of tool for work that

can't be made stable.

your

cut

Plan

.

• Plan your cut to avoid kickbacks and throwbacks when a

and

pa

rt or all of the workpiece binds on the blade

is

thrown violently back toward the front of the

saw:

fr

Never cut

eehand: Always use either a rip

fence, mitre gauge or fixture to position and

guide the wor

so it won't twist, bind

on

the

k,

blade and kickback.

ri

Make sure there's no deb

s between the

workpiece and its supports.

• Use extra caution with large, very small or awkward

workpieces.

• Use extra supports (tables, saw horses, blocks, etc.)

el

for any workpieces large enough to tip when not h

d

down to the table top. Never use anot her person as

a substitute for a table extension, or as additional

support for a workpiece that is longer or wider than

or

the basic saw table,

to help feed, support or pull the

workpiece.

• Never confine the piece being cut off. Tha t

piece not against the fence, mitre gauge

Never hold it, clamp it, touch it,

aga

in

st it. It must

be

free to move. If confined, it could

or

use length stops

get wedged against the blade and cause a k

or

fixture.

ic

is,

the

kback

or throwback.

•

Ne

ver cut more than one workpiece at a time.

•

Ne

ver turn your table saw

"ON"

before clearing

everything except the workpiece and related support

devices off the table.

3

Plan the way you will push the workpiece through.

• NEVER pull the workpiece through. Start and

finish the

cut

from the front of the table saw.

• NEVER put your fingers or hands

in

the path of

the sawblade

or

other cutting tool.

• NEVER reach

in

back of the cutting tool with either

hand to hold down or support the workpiece, remove

wood scraps,

or

for

any other reason.

• Avoid hand positions where a sudden slip could

cause fingers

or

hand to move into a sawblade

or

other cutting tool.

• Don't overreach. Always keep good footing and

balance.

..

Push the workpiece against the rotation

of

the blade.

Never feed material into the cutting tool from the rear

of the saw.

• Always push the workpiece all the

way

past the

sawblade.

• As much as possible, keep your face and body to

one side of the sawblade, out of line with a possible

kickback

or

throwback.

• Set the cutting tool as l

ow

as possible for the cut

you're planning.

• Never turn the saw "ON" before clearing the table of

all tools, wood scraps, etc. except the workpiece

and related feed

or

support devices for the cut

planned.

Avoid accidental starting

• Make sure switch is

"OFF"

before plugging saw

in.

WHENEVER SAWBLADE IS SPINNING

WARNING:

Don't

let

familiarity

(gained from

fre-1

quent use of your table saw) cause a careless

mistake. Always remember that a careless

fraction of a second is enough to cause a severe

injury.

• Before actually cutting with the saw, watch it while it

runs

for

a short while.

If

it makes an unfamiliar noise

or

vibrates a lot, stop immediately. Turn the saw off.

Unplug the saw.

Do

not restart until finding and fixing

the problem.

• Make sure the top of the arbor

or

cutting tool turns

toward the front

of

the saw.

Keep children away.

• Keep all visitors should be kept a safe distance from

the table saw.

• Make sure bystanders are clear of the saw and

workpiece.

Don't force tool.

• Let the blade reach full speed before cutting.

•

It

will do the job better and safer

at

its designed rate.

• Feed the workpiece into the saw only fast enough to

let the blade

cut

without bogging down or binding.

Before freeing any jammed material:

• Turn switch "OFF" .

•

Unplug the saw.

• Wait for all moving parts to stop.

• Check blade, spreader and fence for proper alignment before starting, again.

To avoid throwback of small , cut off pieces:

• Use the guard assembly.

4

To remove pieces beneath or trapped inside the

guard.

• Turn saw off.

• Remove

svvitch

key.

• Unplug saw.

• Wait for blade to stop before lifing the guard.

Before leaving the saw .

• Turn saw off.

• Wait for blade to stop spinning.

• Unplug the saw.

• Make workshop childproof. Lock the shop. Disconnect master switches. Remove the

yellow switch

key.

Store it away from children and others not

qualified to use the tool.

Additional Safety Instructions For:

Rip Type Cuts.

•

•

•

•

•

•

•

•

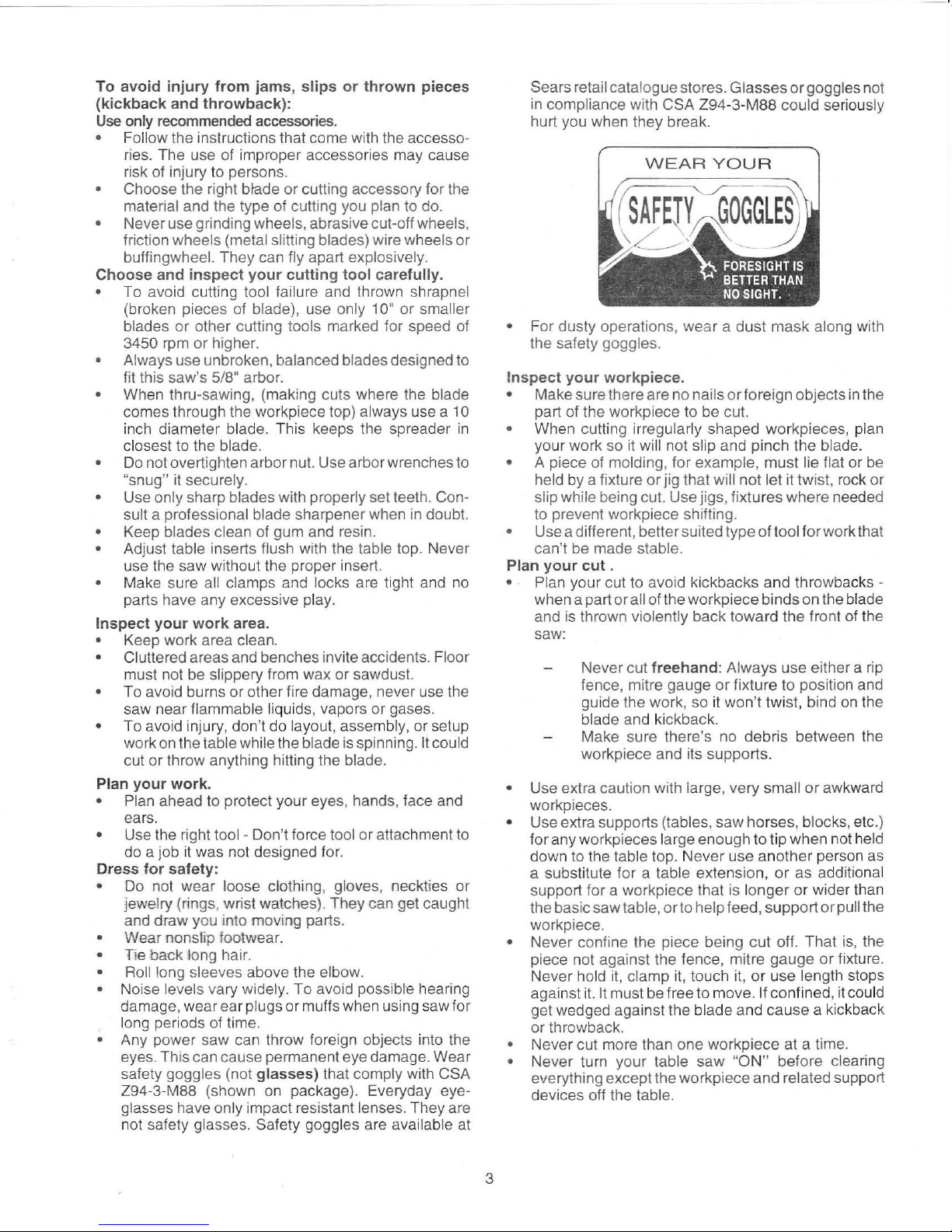

Never use the mitre gauge when ripping .

Use a push stick whenever the fence is 2 or more

inches from the blade.

When thru-sawing, use an auxiliary fence and push

block whenever the fence must be between 1/2 inch

and 2 inches from the blade.

Never thru-saw

rip

cuts narrower than 1/2 inch. (See

"Basic Saw

Operation Using The Rip Fence" section)

Never rip anything shorter than 1

0" long .

When using a push stick or push block the trailing

end of the boa

rd

must be square. A push stick or

block against an uneven end could slip off or push

the work away from the fence.

A featherboard can help guide the workpiece.

See

"Basic Saw Operations - Using the Rip Fence"

section.)

Always use featherboards for any non-thru rip type

cuts.

24

""-

l

~·

4-1/ 2

".l

+-

5"~7----..-J

Before Starting

• To avoid kickbacks and slips into the blade, make

sure the rip fence is parallel to the sawblade.

• Before thru-sawing, check the antikickback pawls

(See "Basic Saw Operations- Using the Rip Fence").

The pawls must stop a kickback once it has started.

Replace or sharpen anti kickback pawls when points

become

dull.

• Plastic

and composition (like hardboard) materials

may be cut

on

your saw. Howeve

r,

since these are

usually quite hard and slippery, the antikickback

pawls may not stop a kickback. Therefore, be especially careful in your set-up and cutting procedures.

While thru-sawing

• To avoid kickbacks and slips into the blade, always

push forward on the section of the workpiece between

the saw blade and the rip fence. Never push forward

on

the piece being cut off.

Anti-Kickback Pawls (AKB)

Device which, when properly maintained, is designed to

stop the workpiece from being kicked back at the operator during ripping operations.

Additional Safety Instructions Fer:

Cross Cut Type Cuts

• Never use the rip fence when crosscutting .

• An auxiliary wood facing attached to the mitre gauge

can help prevent workpiece twisting and throwbacks.

Attach it to the holes provided. Make the facing long

enough and big enough to support your work. Make

sure, however,

guard. (S

Before starting

• Use jigs or fixtures

extend across the

ee

page 40)

it

will not interfere with the sawblade

to

help hold any

full length of the mitre gauge face

p1ece

too small to

t.

during the cu

gauge and workpiece and helps keep your hands

away from the blade .

While cutting

• To avoid blade contact, always hold the mitre gauge

as shown

Mitre

Gauge".

This lets you properly hold the mitre

in

the "Basic Sa w Ope rations - Using the

GLOSSARY

Arbor

The shaft

Bev

An angle cutting operation made through the face of the

workpiece.

Compound Cut

A simultaneous bevel and mitre cutting operation.

Crosscut

A cutting or shaping operation made across the width of

the workpiece.

Da

do

A non-through cut which produces a square sided notch

or trough in the workpiece.

Featherboard

A device which can help guide workpieces during rip

type operations.

Freehand

Performi

fixture, hold down or other proper device to keep the

workpiece from twisting during the cut. Twisting of the

workpiece can cause it to be thrown.

Gum

A sticky, sap based residue from wood products.

Heel

Misalignment of the saw blade such that the blade is not

parallel to the mitre gauge groove.

Ke

rf

The amount of material removed by the blade in a

through cut

through or partial cut.

Ki

ckback

An uncontrolled grabbing and throwing of the workpiece

back toward the front of the saw .

Leading End

q-he

operation,

Mitre Cut

An angle cutting operation made across the width of the

workpiece.

Molding

A non-through cut which produces a special shape

on

el

Cut

ng

end of the workpiece which, during a rip type

is

OF

TERMS FOR WOODWORKING

which a cutting tool is mounted.

a cut without using a fence, mitre gauge,

or

the slot produced

pushed into the cutting tool first.

by

the blade in a non-

in

the

workpiece used for joining

Ploughing

Ploughing

workpiece, using the fence. USE proper holddowns and

feed devices.

Push Stick

A device used to feed the workpiece through the saw

during narrow ripping type operations and help keep the

operator's hands

Push Block

A device used for ripping type operations too narrow to

allow use of a push stick.

Rabbet

A notch

Resin

A sticky, sap base substance that

Revolutions Per Minute (RPM)

The number of turns completed

one minute.

Rip Cut

A cutting operation along the length

Sawblade Path

The area of the workpiece or table top directly in line with

the part of the workpiece which

by the blade.

Set

The distance that the tip of the sawblade tooth is bent (or

set) outward from the face of the blade.

Throw-Back

Throwing of pieces in a manner simila r to a kickback.

Thru-Sawing

Any cutting operation where the blade extends com-

pletely through the thickness of the workpiece.

Trailing End

The workpiece end last cut by the blade in a ripping

operation.

Workpiece

The item on which the cutting operation is being done.

The surfaces of a workpiece are

as faces, ends, and edges.

is

grooving with the grain

well away from the blade.

in

the edge

or

of

a workpiece.

decoration.

the

long way of the

has

hardened.

by

a spinn ing object in

of

the workpiece.

will be,

or

has been, cut

com

mon ly referred to

5

MOTOR SPECIFICATIONS AND ELECTRICAL REQUIREMENTS

----

WARN ING: Do not use blower

or

was

hin

g ma-

chi

ne

motors

or

any

motor with

an

automat

ic

res

et

overl

oad

protecto

r. They

can

start

up

by

th

emselves and you cou

ld

get injured.

POWER SUPPLY- 120 VOL TS/240

VOL

TS

Capacitor Start

Capacitor Run

Motor

Specific

ati

ons

The A-C motor used in this saw is a non-reversible type

having the following specifications:

Voltage ...........................

..

........................... 120/240

Hertz (cycles) .......................................................

60

Phase ............................................................. Single

RPM ......................................

....

....................... 3450

Your

saw

is wired

for

120 volts and is

equipped

with

a 3

conductor

cord

and grounding ty

pe plug

whi

ch

ha

s a grounding

pro

ng

approved by

Unde

rwrit

ers

L

aboratories and

Can

adi

an

Standards Assoc

iation.

See

Fig

. A.

CHANGING MOTO R

VOLT

AGE

1.

Connections

for

120v

AC

Ope

rati

on

a.

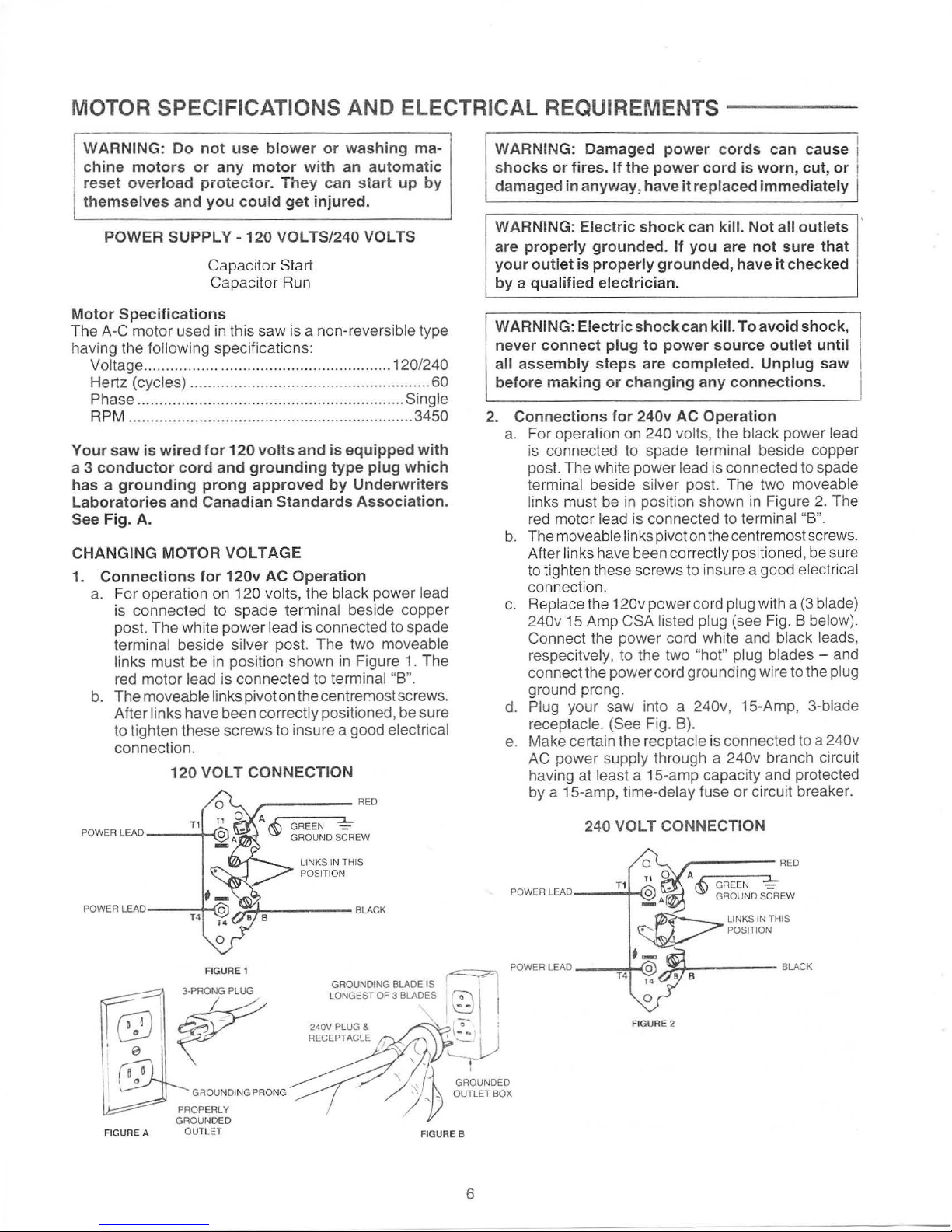

For operation on 120 volts, the black power lead

is

connected to spade terminal beside copper

post. The white power lead is connected to spade

terminal beside silver post. The two moveable

links must be in position shown in Figure 1. The

red motor lead is connected to terminal

"B

".

b.

The moveable links pivot on the

centrer:~ost

sc

rews.

After links have been correctly positioned , be sure

to tighten these screws to insure a good electrical

connection.

1

20

VOLT

CONNECTION

FIGURE 1

3·PRONG PLUG

~

GROUNDING PRONG

PROPERLY

GROUNDED

FIGURE

A OUTLET

J_

GREEN

GROUND SCREW

LI

NKS IN THIS

POSITION

GROUNDING

BLADE IS

LONGEST

OF

3 BLADES

FIGURE B

6

I

WARNING: Damaged

powe

r c

ords

can ca

use

1

sh

ocks

or

fires. If the

power

cord

is

worn, cu

t,

or

!

damaged

in

anyway

, have

it

replaced

immediately

WARNING : Electr

ic

shock

can

kil

l.

Not

all

outlets

are pr

operly

grou

nded. If

you

are

not

sure

that

y

our outl

et

is

properly

grounded, have

it

check

ed

by a

qu

alified ele

ctr

ician.

WARNING:

Electric

shock

can

kill

. To

avoid

shock

,

nev

er

connect pl

ug to p

owe

r so

urce

outlet

until

a

ll ass

embly

steps

are

comple

ted.

Unplug

saw

before

making

or chang

ing a

ny connections.

2. C

onnectio

ns f

or

240v AC

Operation

a. For operation on 240 volts, the black power lead

is connected to spade terminal beside copper

post. The white power lead is connected to spade

terminal beside silver post. The two moveable

links must

be

in

position shown in Figure

2.

The

red motor lead is connected to terminal

"B

".

b.

The moveable links pivot

on

the centremost screws.

A

ft

er links have been correctly positioned, be sure

to tighten these screws to insure a good electrical

connection.

c. Replace the

120v power cord plug with a

(3

blad

e)

240v 15 Amp CSA listed plug (see Fig. B below).

Connect the power cord white and black leads,

respecitvel

y,

to the two "hot" plug bl

ades-

and

connect the power cord grounding wi

re

to the plug

ground prong.

d. Plug your saw into a

240v, 15-Amp, 3-blade

receptacle. (See Fi

g.

B).

e. Make certain the recptacle is connected to a

240v

AC

power supply through a 240v branch circuit

having at least a 15-amp capacity and protected

by a 15-amp, time-delay fuse

or

circuit breaker.

240

VOLT

CONNECTION

FIGURE 2

WARNING:

To

avoid

electrical

shock,

do

not

per-

mit

fingers

to

touch

the

terminals

of

the

plug,

when

installing

or

removing

the

plug

to

or

from

the

outlet.

WARNING:

Failure

to

properly

ground

this

power

tool

can

cause

electrocution

or

serious

shcok,

particularly

when

used

in

damp

locations,

or

near

metal

plumbing.

If

shocked,

your

reaction

could

cause

your

hands

to

hit

the

cutting

tool.

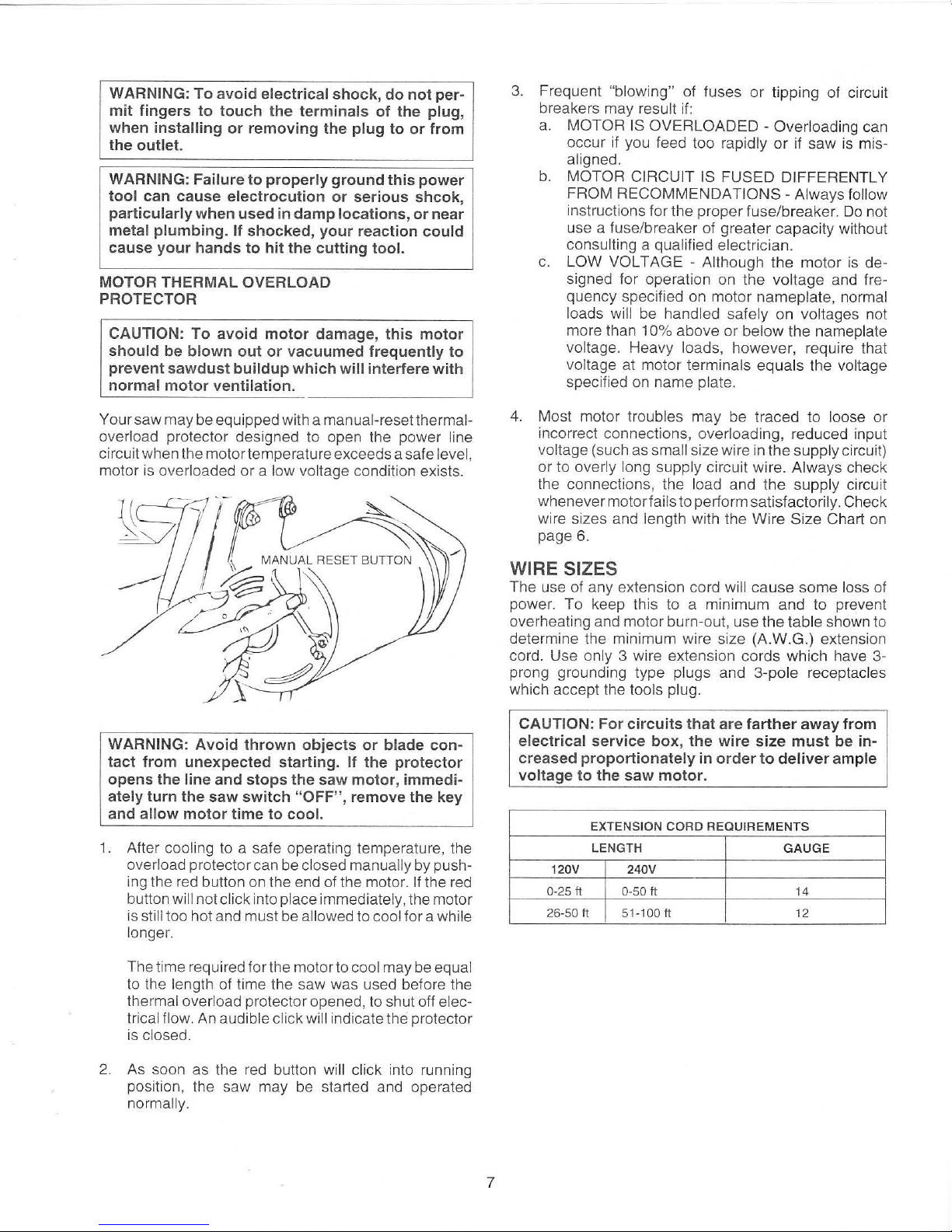

MOTOR

THERMAL

OVERLOAD

PROTECTOR

CAUTION:

To

avoid

motor

damage,

this

motor

should

be

blown

out

or

vacuumed

frequently

to

prevent

sawdust

buildup

which

will

interfere

with

normal

motor

ventilation

.

Your saw may be equipped with a manual-reset thermaloverload protector designed to open the power line

circuit when the motor temperature exceeds a safe level,

motor is overloaded or a low voltage condition exists.

WARNING:

Avoid

thrown

objects

or

blade

con-

tact

from

unexpected

starting

. If

the

protector

opens

the

line

and

stops

the

saw

motor,

immedi-

ately

turn

the

saw

switch

"OFF",

remove

the

key

and

allow

motor

time

to

cool.

1.

After cooling to a safe operating temperature, the

overload protector can be closed

manually by pushing the red button on the end of the motor. If the red

button will not click into place immediately, the motor

is

still too hot and must be allowed to cool for a while

longer.

The time required for the motor to cool may be equal

to the length of time the saw was used before the

thermal overload protector opened, to shut off

electrical flow. An audible click will indicate the protector

is closed.

2.

As soon as the red button will click into running

position, the saw may be started and operated

normally.

7

3.

Frequent "blowing" of fuses or tipping of circuit

breakers may result

if:

a. MOTOR IS OVERLOADED

-Overloading

can

occur if you feed too rapidly

or

if saw is mis-

aligned.

b.

MOTOR CIRCUIT IS FUSED DIFF

ERENTLY

FROM

RECOMMENDATIONS-

Always follow

instructions for the proper fuse/b reaker.

Do

not

use a fuse/breaker

of

greater capacity without

consulting a qualified electrician.

c.

LOW VOLTAGE - Although the

motor

is

designed for operation on the voltage and frequency specified on motor nameplate, normal

loads

will be handled saf

ely

on voltages not

more than 10% above or below the nameplate

voltage. Heavy loads, however, require that

voltage at motor terminals equals the voltage

specified on name plate.

4. Most motor troubles may be traced to loose or

incorrect connections,

ov

erloading, reduced input

voltage (such as

small size wire in the supply circuit)

or to overly long supply circuit wire. Always check

the connections, the load and t

he

supply circuit

whenever motor

fails to perform satisfactorily . Check

wire sizes and length with the Wire Size Chart on

page

6.

WIRE SIZES

The use of any extension cord will cause some loss of

power.

To

keep this to a minimum and to prevent

overheating and motor burn-out, use the table shown to

determine the minimum wire size (A .W.G.) extension

cord. Use only 3 wire extension

co

rds which have 3prong grounding type plugs and 3-pole receptacles

which accept the tools plug.

CAUTION:

For

circuits

that

are

farther

away

from

electrical

service

box, the

wire

size

must

be in-

creased

proportionately

in

order

to

deliver

ample

voltage

to

the

saw

motor.

EXTENSION

CORD

REQUIREMENTS

LENGTH

GAUGE

120V

240V

0-25

tt

0-

50

tt

14

26-50

tt

51-100 tt 12

CONTENTS

WARRANTY ........................................................................ 2

Rip Fence .......

..

............................................................ 40

GENERAL SAFETY INSTRUCTIONS Mitre Gauge .................................................................. 40

FOR

TABLE SAWS ..................................................... 2-5

Blade Guard ............................

...

.................................

.40

GLOSSARY

OF

TERMS FOR

WOODWORK

ING .............. 5

Table Insert ..........

...

.................. .............. ...................... 40

MOTOR SPECIFICATIONS

AND ELECTRICAL

Removing and Installing Saw Blade ........................... .

41

REQUIREMENTS ........................................................... 6

Exact-1-Cut ....................................................................

41

Motor Specifications ..................................

...

................... 6

Micro-Adjust Rip Fence .......................... ......

......

.......... 42

Changing Mot

or

Voltage .................

....

............................ 6

BASIC SAW OPERAT I

ON

................................................ 42

Mot

or

Thermal

Ove

rload ................................................. 7 Work Feed Devices ...................................................... 42

Wire

Sizes ...........................

......

...................................... 7 Push Stick and Push Block .....................

.......

............... 42

UNPACKING

AND

CHECKING CONTENTS ...................... 8 Auxiliary Fence/Work Support ...................................... 43

Tools Needed .................................................................. 8 SAFETY INSTRUCT IONS FOR

List of Loose Parts ................

...................................

..

9-11

BASIC SAW OPERATIO NS ...............

......

..........

...

. .44-55

ASSEMBLY .................................................................. 12-38

Using the Mitre Gauge .................................................. 46

Installing Handwheels ................................................... 12

Crosscutting ......................................

..

.......................... 46

Checking

Table Insert ................................................... 12

Repetitive Crosscutting .........................................

..

...... 47

Checking

Blade Squareness to Table .............

....

......... 13

Mitre Crosscutting .......

..

...............

........

.........................

48

Assembling Steel

Saw

Base Cabinet .........................

..

13 Bevel Crosscutting ... ..................................................... 48

Installing Base Shelf ...................................................

..

14 Compound Mitre Cutting ..................................... .........

.48

Installing Front Panel Handle Brackets ......................... 14

USING THE RIP FENCE .....................................

......

....... .49

Installing Front Panel Levellers ..................................... 15

Ripping

..

.........

....

......................................................

49-51

Installing Rear Axle Brake Bar and Wheels ............. 16-17

Bevel Ripping Narrow Work ......

....

................................

51

Assembling Saw Base Brake System ..................... 17-18

Resawing ...........

..............................................

............. 52

Moun

ti

ng Saw to Saw Base ....... .........

....

...................... 19 Cutting Panels ...

...

..................

...

....................

..............

52

Installing Table Saw Dust Collector ......................... 20-21 Using Featherboards for Thru-Sawing ...................

.......

53

Attaching and Assembling Table Extensions ................ 22 Using Featherboards for Non-Thru Sawing .................. 53

Installing Table Extens ion Brackets ..........................

....

23

Rabbeting .............................................

..

.................... 54

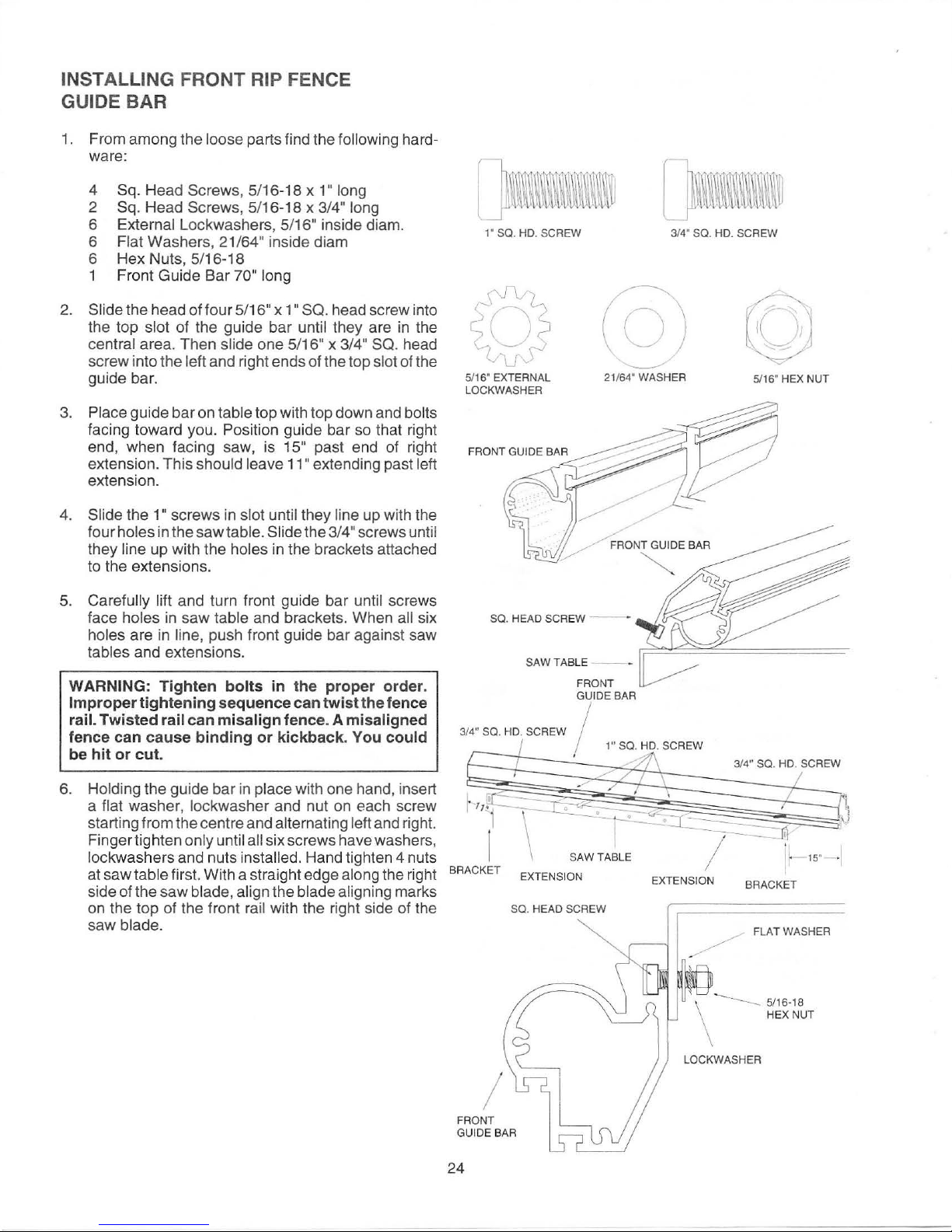

Installing Front Rip Fence Guide Bar ....................... 24-25

Ploughing and Molding ................................................. 54

Installing Rear Fence Guide Bars ................................. 25

Dadoing ..................

....

...................... .................... , .......

55

Adjusting Rip Fence Guide Bars ...............................

....

26

Molding Cutting ....................................... ...................... 55

Installing Separator Channel ................................... 27-28

ADJUSTMENTS ................................................................ 56

Rip Fence

Alignment Adjustment ..................

......

......... 28

Mitre Gauge .......................................

.............

............

..

56

Rip Fence Lock Lever Adjustment ................................ 29 Heeling Adjustment or Parallelism

Assembl i

ng

Micro Adjust and Racks ....................... 29-30

of Sawblade to Mit

re

Gauge Groove ....................... 56-57

Installing Measuring Tapes and Indicat

or

................ 31-32

Installing Blade Guard ............................................. 33-35

Blade Tilt,

or

Squareness of Blade to Table .................

58

90 degree position .........................................

.............

..

58

Positioning Motor on Motor Mounting Base .................. 35

45 degree position .......................

..........

....................... 59

Preparing the Motor Before Mountin g ........................... 36

Tilt Mechanism ............................................................

..

60

Mounting Switch .......................... .......................

........

..

36

MAINTAINING YOUR TABLE SAW ........

......

.................... 60

Mounting Motor .................................. ........................... 37

Maintenance .....................

.....

...

.................................... 60

Installing Belt

Guard ................................................ 37-38

Lubrication

..

..................................................................

61

Securing Motor Wire .......

.......................... .................... 38

TROUBLE

SHOOTING ................................

....

.................. 62

GETTING

TO

KNOW

YOUR SAW ............................... 39-42

General .....

...

......

....

............

......

.................

....

................ 62

On-Off Switch ..............

....

.............................................. 39

Motor ..............................

..

.....................

....

.............. 62-63

Elevation Handwheel ....

...

.............. ...............................

40

REPAIR PARTS ... ..............................................

.......... 64-74

Tilt Handwheel ..............................................................

40

CUSTOMER RESPONSE ................................................. 76

Tilt Lock Handle ...............

............................................

.40

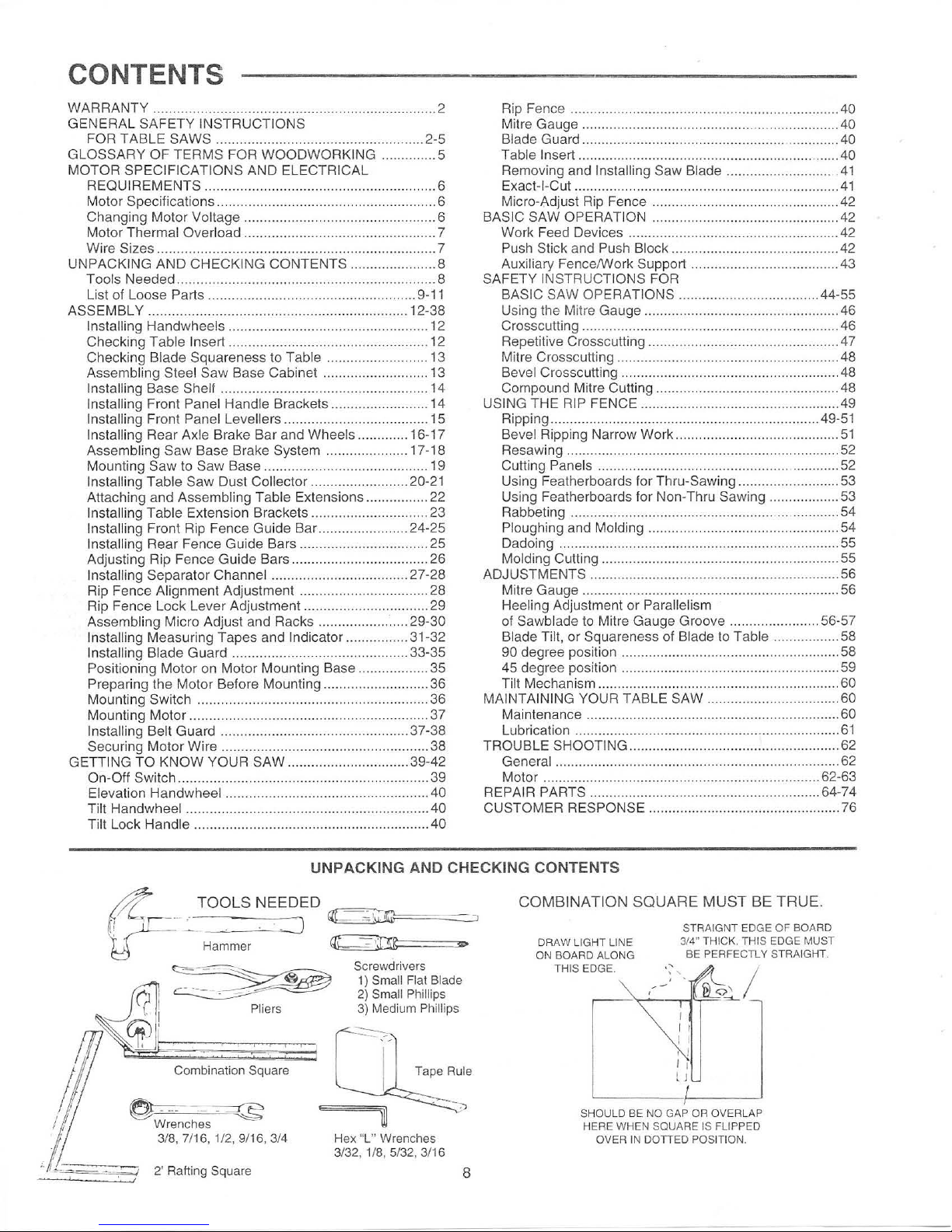

UNPACKING AND CHECKING CONTENTS

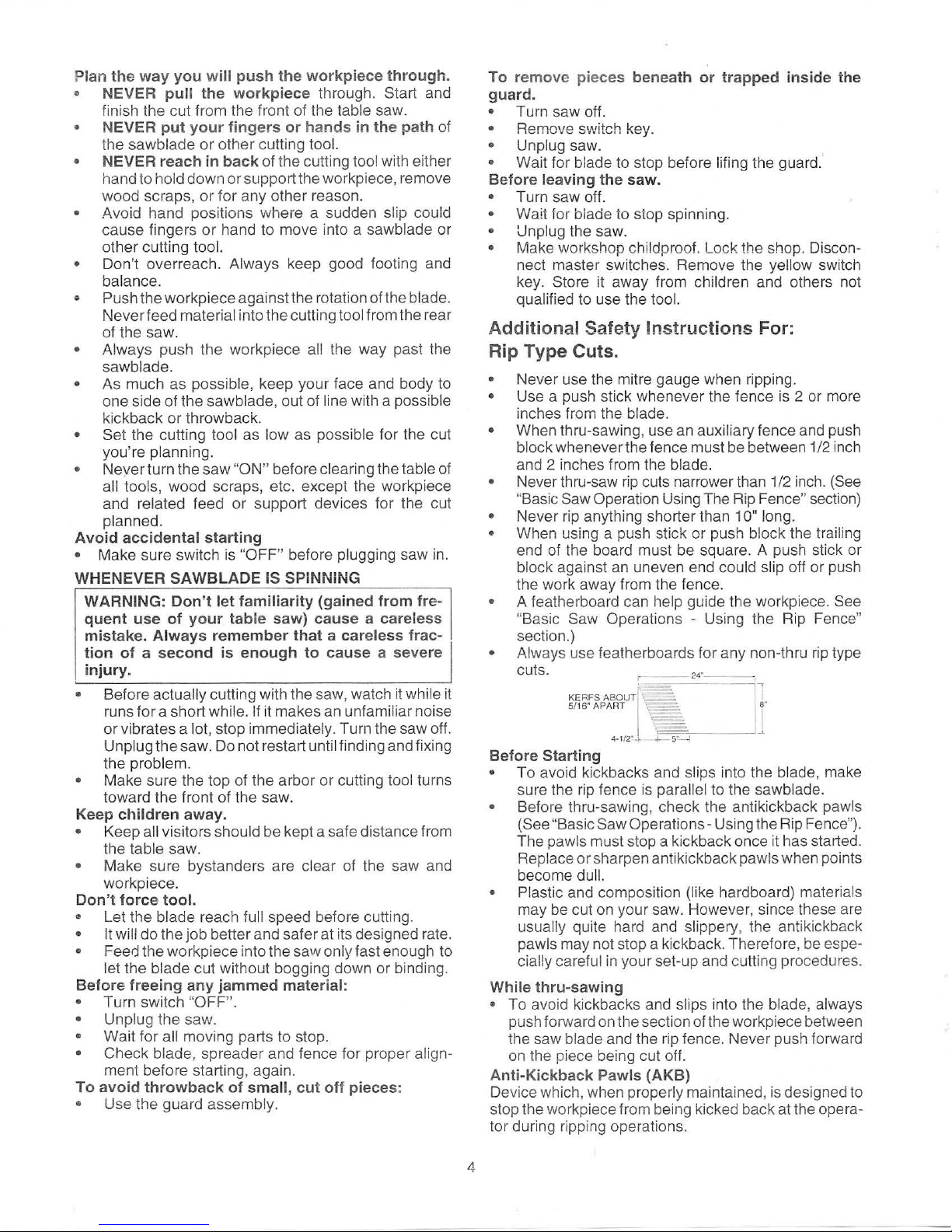

Combination Square

~

--~

Wre

nches

3/8, 7/16, 1/2, 9/

16

, 3/4

Screwdrivers

1)

Small Flat Blade

2)

Small Phillips

3) Medium Phillips

Tape Rule

Hex "L" Wrenches

3/32, 1/8, 5/32, 3/16

8

COMBINATI

ON

SQUARE

MUST

BE TRUE.

STRAIGNT EDGE OF BOARD

DR

AW LIGHT LINE 3/4" THICK. THIS EDGE MUST

ON

BOA

RD

ALONG BE PERFECTLY STRAIGHT.

THIS

EDGE

.

~-~

;~

Jf

5<j

I I

I I

I j

I I

lJ

SHOULD BE NO GAP OR OVERLAP

HERE WHEN SQUARE IS FLIPPED

OVER IN

DOTTED POSITIO

N.

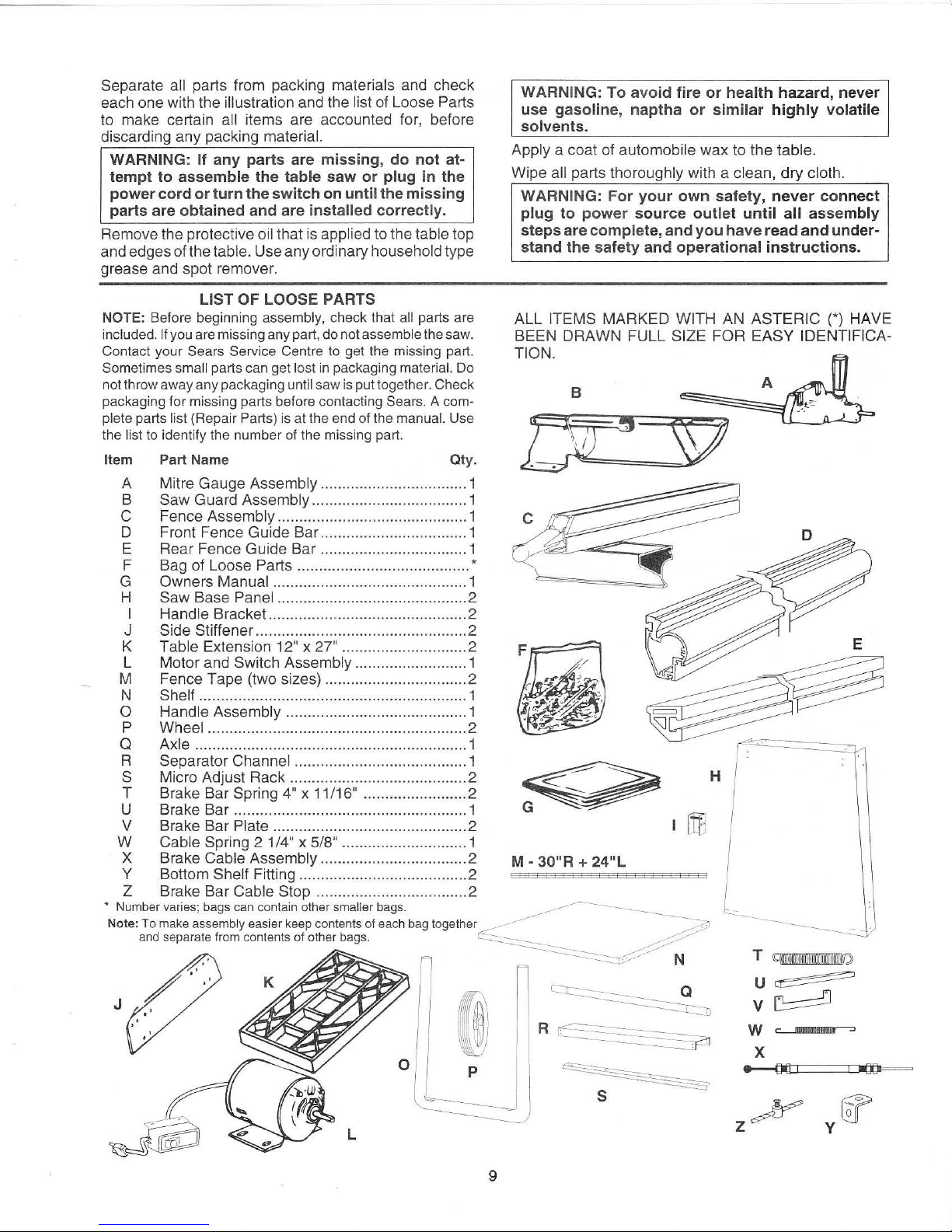

Separate all parts from packing materials and check

each one with the

illustration and the list of Loose Parts

to make certain all items are accounted for, before

discarding any packing

material.

WARNING: If

any

parts are missing, do not at-

tempt to assemble the table saw

or

plug in the

power cord or turn

the

switch on until

the

missing

parts are obtained and are

installed correctly.

Remove the protective oil that is applied to the table top

and edges of the

table. Use any ordinary household type

grease and spot remover.

LIST

OF

LOOSE PARTS

NOTE:

Before beginning assembly, check that all parts are

included.

If

you are missing any part, do not assemble the saw.

Contact your Sears Service Centre to get the missing part.

Sometimes

small parts can get lost in packaging material. Do

not throw away any packaging

until saw is put together. Check

packaging for missing parts before contacting Sears. A complete parts list (Repair Parts) is at the end of the manual. Use

the

list to identify the number of the missing part.

Item Part Name Qty.

A Mitre Gauge Assembly .................................. 1

B

Saw Guard Assembly .................................... 1

C Fence Assembly ............................................ 1

D Front Fence Guide Bar .................................. 1

E Rear Fence Guide Bar ................................

..

1

F Bag of Loose

Parts ........................................ *

G Owners Manual ............................................. 1

H

Saw Base Panel ............................................ 2

I Handle Bracket.. ............................................ 2

J Side Stiffe ner ...............

..

................................ 2

K

Table Extension 12" x 27" ............................. 2

L Motor and Switch Assembly .......................... 1

M Fence Tape (two sizes) ....................

..

........... 2

N

Shelf .............................................................. 1

0 Handle Assembly .......................................... 1

P Wheel ............................................................ 2

Q Axle ..........................................

.....

...

............. 1

R Separator

Channel ........................................ 1

S Micro Adjust Rack ......................................... 2

T Brake Bar Spring 4" x

11

/16" ........................ 2

U Brake Bar ...................................................... 1

V Brake Bar

Plate ............................................. 2

W

Cable Spring 2 1/4" x 5/8" ............................. 1

X Brake

Cable Assembly .................................. 2

Y Bottom Shelf Fitting ....................................... 2

Z Brake Bar Cable Stop ................................... 2

WARNING: To avoid fire

or

health hazard, never

use gasoline, naptha or similar highly

volatile

solvents.

Apply a coat of automobile wax to the table.

Wipe all parts thoroughly with a clean,

dry

cloth.

WARNING: For your own safety,

never

connect

plug

to

power source outlet until all assembly

steps

are

complete, and you

have

read

and

under-

stand the safety and operational instructions.

ALL ITEMS MARKED WITH AN ASTERIC (*) HAVE

BEEN DRAWN FULL

SIZE FOR

EASY

IDE

NTI

FICA-

TION.

B

H

M-

30"R +

24"l

• Number varies; bags can contain other smaller bags.

~--------

Note:

To

make assembly easier keep contents of each bag together

__.-

. ..-----

~

,o,1

·-

J

and separate from contents of other bags.

C::::.:::::::::--...._

~

~

-

~

N

.·

.1·---

-- ·· N

~~

0

p

l

9

R

c=====-=============

~

-----=====::r

-""

~

s

T

<Cilfl

«lll

llllll

llll

lll

lllllillllllllt!fJ

u

~

v

~

w c

MWIH:t~

X

z

~

y

~

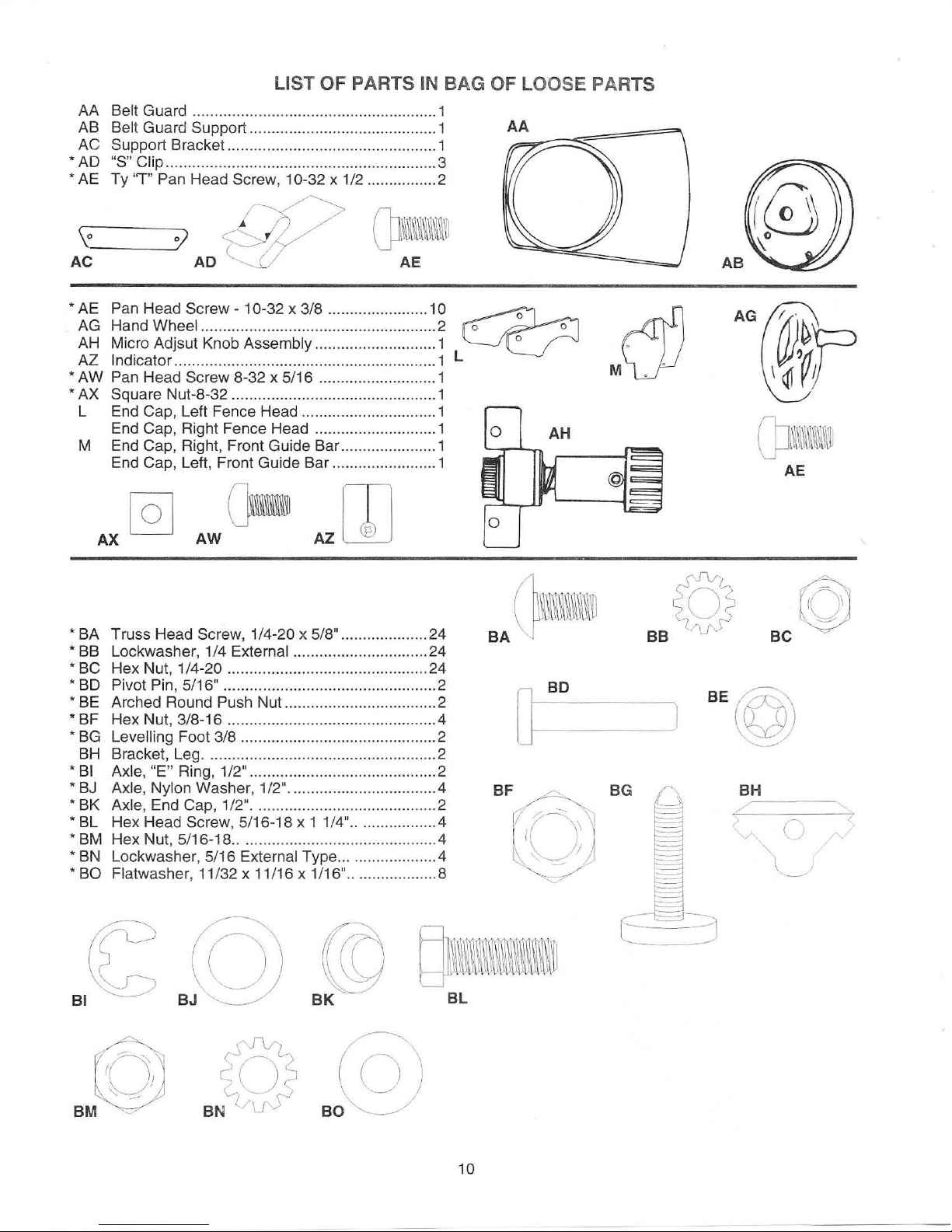

LIST OF PARTS IN BAG OF LOOSE PARTS

AA Belt Guard ........................................................ 1

AB

Be

lt Guard Support ...................

...

..................... 1

A.~A~::=~~==j

AC Support Bracket.. .............................................. 1

:::=

*AD

"S" Clip .................................................... .......... 3

* AE Ty

"T" Pan Head Screw, 1 0-32 x 1/2 ................ 2

\o_~O)

AC

AD

* AE

Pan Head

Screw-

10-32 x 3/8 ....................... 10

~

cj)

AG Hand Wheel ............

...

....................................... 2 o o

AH Micro Adjsut Knob Assembly ............................ 1 ° .

* AZ Indicator ............................................................ 1 L M . .

AW Pan Head Screw 8-32 x 5/16 ........................... 1

*AX

Square Nut-8-32 ............................................... 1

L End Cap, Left Fence Head ............................... 1

End Cap, Right Fence Head .................

...

........ 1

AH

M End Cap, Right, Front Guide Bar ...................... 1

End Cap, Left, Front Guide Bar

..

...................... 1

(JJ

~~~~~~~

~~t

AE

* BA Truss Head Screw, 1/4-20 x 5/8" .................... 24

BA

(}-

BC

©

*

88

Lockwasher, 1/4 External ............................... 24

*

8C

Hex Nut, 1/4-20 .............................................. 24

*

80

Pivot Pin, 5/16"

...

.............................................. 2

*

BE

Arched Round Push Nu

t..

................................. 2

* BF Hex Nut, 3/8-16 ...............................................

.4

*

8G

Levelling Foot 3/8 ............................................. 2

8H Bracket,

Leg ..................................................... 2

*

81

Axle, "E" Ring, 1/2" ........................................... 2

* 8J

Axle, Nylon Washer, 1/2" .................................

.4

BH

* BK Axle, End Cap, 1/2" .......................................... 2

* BL Hex Head Screw, 5/16-18 x 1

1/4" ..................

.4

* BM Hex Nut, 5/16-18

....

.......................................

..

.4

.

--

-

--,

7

<,,._

()

*

8N

Lockwasher, 5/16 External Type .....................

.4

* BO Flatwasher, 11/32 x 11/16 x 1/16" .................... 8

~I

BL

~

BM

~

10

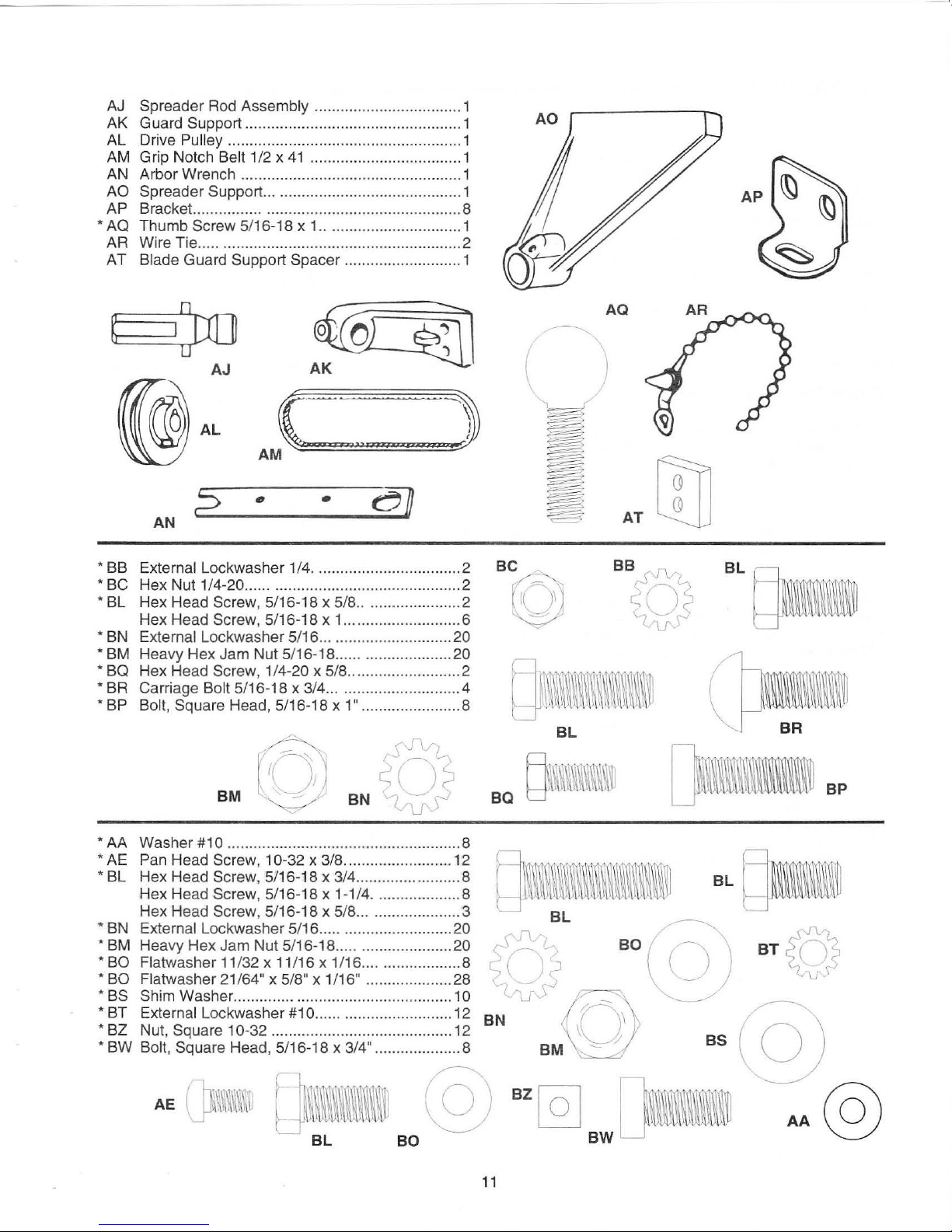

AJ Spreader Rod Assembly ..................

AK Guard Support ..........................

AL Drive

AM Grip Notch

AN Arbor Wrench ......

AO Spreader Support ....................................

AP Bracket. ............... ............................................. 8

* AQ Thumb Screw 5/16-18 x 1 ............

AR Wire Tie ..

AT

Pulley ............................................

Belt 1/2 x

..

......................................................

Blade Guard Support Spacer ........................... 1

41

................................... 1

......

.....................................

................ 1

..

...................... 1

...

....... 1

...

...... 1

..........

..........

..

1

1

..

2

AQ

~

AJ

(@AL

AM

•

AN

*

BB

External Lockwasher 1/4 ........

*

BC

Hex Nut 1/4-20 ...... ........................................... 2

*

BL

He

x Head Screw, 5/16-18 x 5/8

Hex Head

*

BN

External Lockwasher 5/16 ...........................

* BM Heavy Hex Jam Nut 5/16-18 ...... .................... 20

* BQ Hex Head Screw, 1/4-20 x 5/8 .......................... 2

* BR Carriage Bolt 5/16-18 x 3/4 .............. .........

* BP Bolt, Square Head, 5/16-18 x

Screw, 5/16-18 x 1 ...................

~-~

AK

(

.:

'"

eJJ

.:

.:.

:=)

•

...........

1"

....

........... 2

...

....

................ 2

......

...

...

...

....................... 8

.. 6

20

.4

r()l

BM

l~

\

rrn

AT

LzlJ

BL

()IIm

Q\,11~~\\l\11

BL

* AA Washer

* AE Pan Head Screw, 10-32 x 3/8 ....

* BL Hex Head Screw, 5/16-18 x 3/4 ......................

Hex Head

Hex Head Screw, 5/16-18 x 5/8 ....................... 3

* BN E

* BM Heavy Hex Jam Nut 5/16-18 .................

* BO Flatwasher

*

*

* BT External Lockwasher

* BZ Nut, Squa

* BW Bolt, Square Head , 5/16-18 x 3/4" .

xt

BO

Flatwasher

BS

Shim Washer

#1

0 .......................

Screw, 5/16-18 x

ernal Lockwasher 5/16 .............................. 20

11

/32 x 11/16 x 1 /16 ...................... 8

21 /64"

re

x 5/

8"

x 1 /16" .................... 28

.......

........................................... 10

#1

0 ...... ......................... 12

10-32 ........

...

............................... 12

...

.........

1-1

.......

..

.................

/4

...

................. 8

..

................. 8

............ 8

..

12

..

......

... 20

8

11

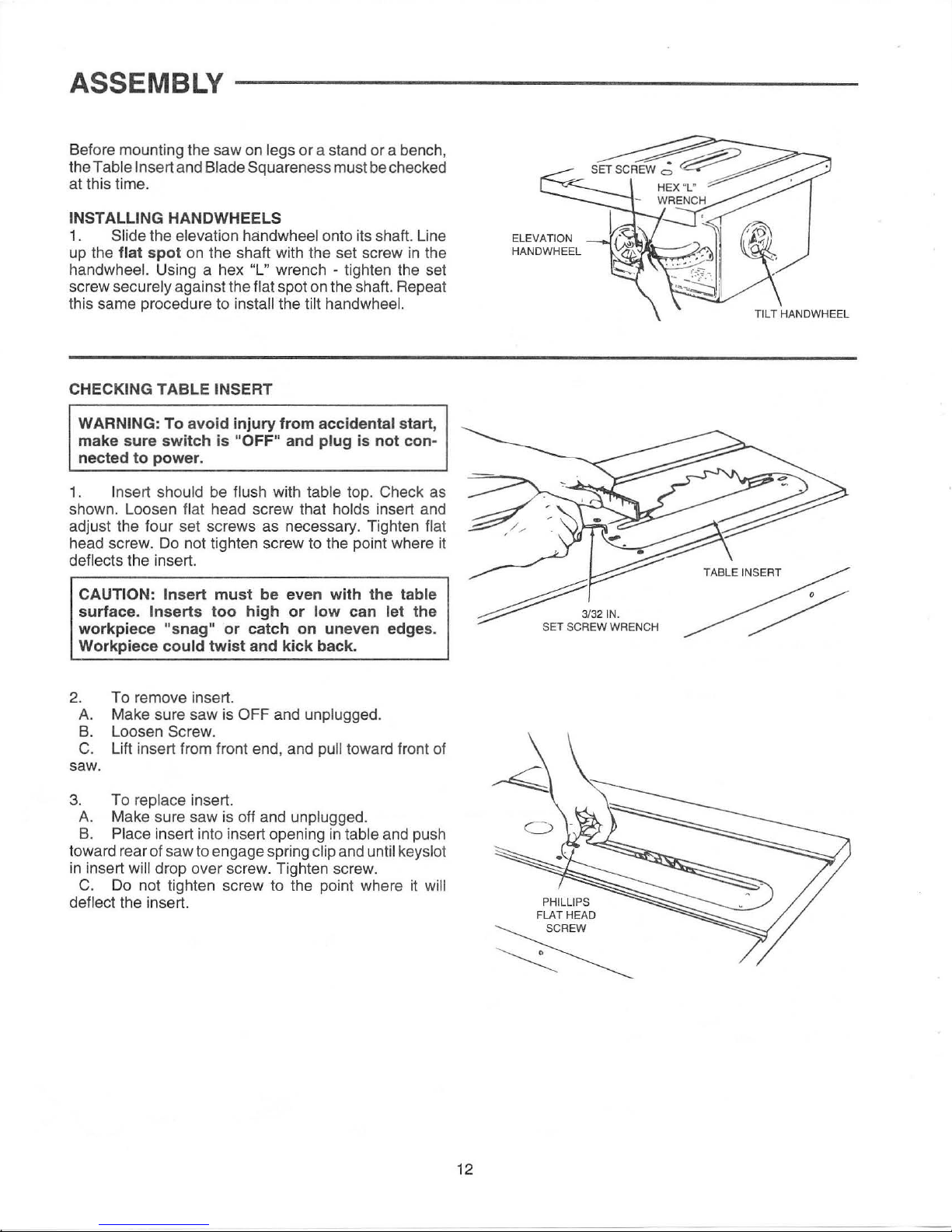

ASSEMBLY

Before mounting the saw on legs

Table Insert and Blade Squareness must be checked

the

at this time.

INSTALLING HANDWHEELS

1.

Slide the elevation handwheel onto its shaft. Line

up the

handwheel. Using a hex "L" wrench - tighten the set

screw

this same procedure to

CHECKING

1.

shown. Loosen

adjust the four set screws as necessary. Tighten

head screw.

deflects the insert.

flat spot

securely against the flat spot on the shaft. Repeat

WARNING:

make sure switch is

nected to power.

Insert should be flush with table top. Check as

CAUTION: Insert must be even with the table

surface. Inserts too high or low can let the

workpiece

Workpiece

on

the shaft with the set screw

install the tilt handwheel.

TABLE INSERT

To avoid injury from accidental start,

"OFF" and plug is not con-

flat head screw that holds insert and

Do

not tighten screw to the point where it

"snag" or catch on uneven edges.

could twist and kick back.

or

a stand or a bench,

in

the

flat

ELEVATION

HANDWHEEL

2. To remove insert.

A.

Make sure saw is OFF and unplugged.

B.

Loosen Screw.

C. Lift insert from front end, and pull toward front of

saw.

3.

To replace insert.

A.

Make sure saw is off and unplugged.

B.

Place insert into insert opening

toward rear of saw to engage spring

in

insert will drop over screw. Tighten screw.

C.

Do

not tighten screw to the point where it will

deflect

the insert.

in

table and push

clip and until keys lot

~

~

PHILLIPS

FLAT HEAD

REW

~

12

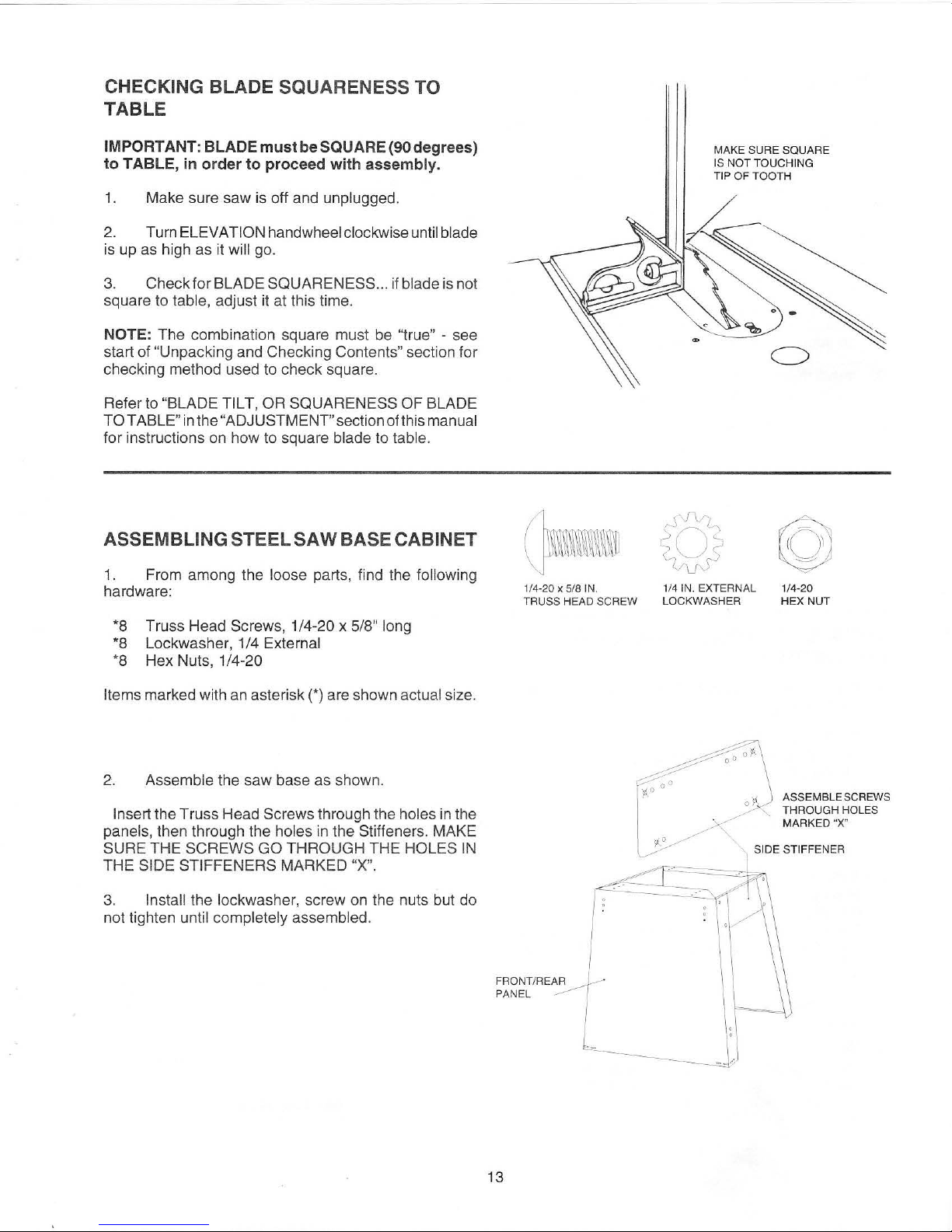

CHECKING BLADE SQUARENESS TO

TABLE

IMPORTANT: BLADEmustbeSQUARE(90degrees)

to TABLE,

in

order to proceed with assembly.

1.

Make sure saw is off and unplugged.

2.

Turn ELEVATI

ON

handwheel clockwise until blade

is

up

as high as it will

go.

3.

Check for BLADE SQUARENESS ... if blade is not

square to

table, adjust it at this time.

NOTE: The combination square must be "t

rue

" - see

start of

"Unpacki

ng

and Checking Contents" section for

checking method used to check square.

Refer to

"BLADE TILT, OR SQUARENESS OF BLADE

TOTABLE"

inthe"

ADJUSTMENT"sectionofthismanual

for instructions

on

how to square blade to table.

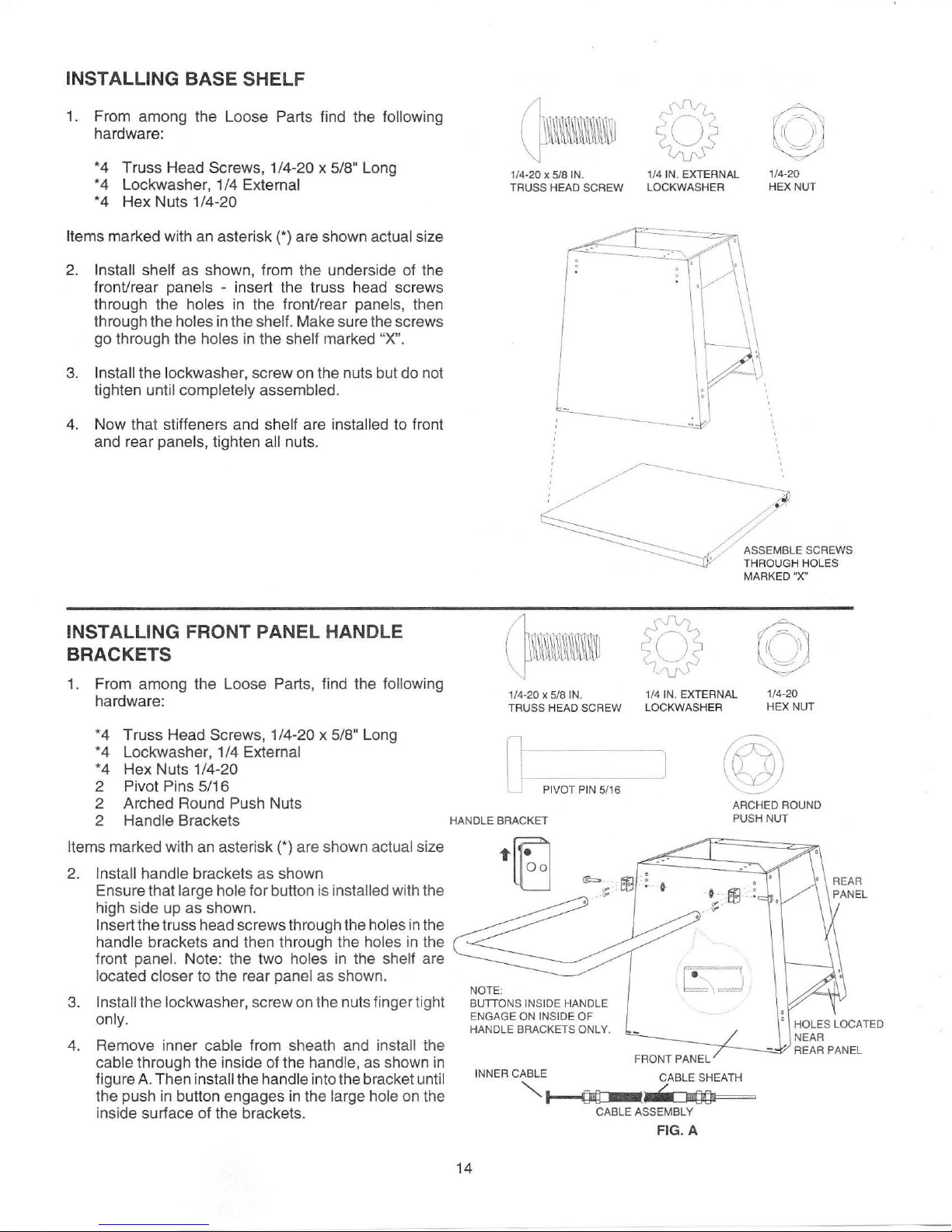

ASSEMBLING STEEL

SAW

BASE CABINET

1. From among the loose parts, find the following

hardware:

*8

Truss Head Screws, 1/4-20 x 5/8" long

*8

Lockwasher, 1/4 External

*8

Hex Nuts, 1/4-20

Items

marked wi

th

an

asterisk(*) are shown actual size.

2.

Assemble the saw base as shown.

Insert the Truss Head Screws through the holes

in

the

panels, then through the holes

in

the Stiffeners. MAKE

SURE THE SCREWS GO THROUGH THE HOLES

IN

THE SIDE STIFFENERS MARKED "X".

3.

In

stall the lockwasher, screw on the nuts but do

not tighten

unt

il

completely assembled.

(]l•m~

1/4·

20

x 5

/8

IN.

TRUSS

HEAD SCREW

MAKE SURE SQUARE

IS

NO

T TOUCHI

NG

TI

P OF TOOTH

r\'J~

~

1

/4

IN. EXTERNAL

LOCKWASHER

©

1/4-20

HEX NUT

ASSEMBLE SCREWS

THROUGH HOLES

MARKED "X"

SIDE STIFFENER

.

.

FRONT/REA1 ·

PANEL

..,____

.

~

-·(

13

INSTALLING BASE SHELF

1. From among the Loose Parts find the following

hardware:

*4 Truss Head Screws,

*4 Lockwasher, 1/4

*4 Hex Nuts 1/4-20

marked with an asterisk (*)are shown actual size

Items

Install shelf as shown, from the underside of the

2.

front/rear

through the

through the

go through the

3. Install the lockwasher, screw on the nuts but do not

tighten

4.

Now that stiffeners and shelf are installed to front

and rear

panels - insert the truss head screws

holes

holes

in

holes

until completely assembled.

panels, tighten all nuts.

1/4-20 x 5/8" Long

External

in

the front/rear panels, then

the shelf. Make sure the screws

in

the shelf marked "X".

/1

@

~--

1/

4-20 x 5/8

TRUSS

IN

.

HEAD SCREW

1/4 IN. EXTERNAL

LOCKWASHER

/

~)

1/4-2 0

HEX NUT

/

INSTALLING FRONT PANEL HANDLE

BRACKETS

1. From among the Loose Parts, find the following

hardware:

*4 Truss Head Screws ,

*4 Lockwasher, 1/4

*4 Hex Nuts 1/4-20

2 Pivot Pins 5/16

2 Arched Round

Handle Brackets

2

Items marked with an asterisk (*) are shown actual size

2.

Install handle brackets as shown

Ensure that

high side up as shown.

In

sert the truss head screws through the holes in the

handle brackets and then through the holes in the

front

located closer

In

sta

3.

4.

ll

on

ly.

Remove inner cable from sheath and install the

cable through the inside of the handle, as shown

figure

the push

inside surface of the

large hole for button is installed with the

panel. Note: the two holes in the shelf are

to

the rear panel as shown.

the lockwasher, screw on the nuts fing

A.

Then insta

in

button engages

1/4-20 x 5/8" Long

External

Push Nuts

er

tight

ll

the handle into the bracket until

in

the large hole on the

br

ackets.

in

1

/4·20 x SIS

TRUSS HEAD SCREW

Q PIVOT PIN-5-/1-6

HANDLE BRACKET

...

~

lLJ

NOTE:

BUTTONS

EN

HANDLE BRACKETS ONL

INNER

INSIDE

GAGE

ON

INSIDE OF

CABLE CABLE SHEATH

"""~

/ ASSEMBLE SCREWS

,;

THROUGH HOLES

MARKED "X"

IN. 1/4 IN. EXTERNAL 1/4-20

HANDLE

CABLE ASSEMBLY

--

Y.

LO

CKWASHER HEX NUT

J

ARCHED

PUSH

FRONT PANEL

< ::J"(}Qi

FIG. A

NUT

ROUND

14

5.

Swing the handle upwards, until the smaller rear

hole

in

the bracket lines up with the hole

handle.

outside of the bracket.

Slide the 5/16" pivot pin through from the

in

the

SAW BASE

6. After both pivot pins are

Push Nuts on the pivot pins. Note both Push Nuts

will be on the inner surface of the bracket. Place the

Push Nuts on the pivot pins. Block the head of the

pivot pin and tap the

7.

Push

in

the lock buttons and lower handle to ensure

Push Nuts are properly engaged.

8.

Tighten nuts at brackets, to front panel.

WARNING: Never operate saw when handle is in

the raised position. Handle is f

and must

operation is perform

be

in the lowered position before any

installed, install the Arched

Push Nut on with a 7/16" socket.

or

moving saw only

ed

on the saw,

of

any kind.

INSTALLING FRONT PANEL LEVELLERS

1.

From among the Loose Parts, find the following

hardware:

4 Hex Nuts 3/8-16

2 Levelling Feet

2 Leveller

Plates

3/8·16

HEX NUT

L . \ J

,

1f~~

HEAD OF HEAD OF

PIVOT PIN

l LOCK PIVOT PIN

'j

J:tf\

'

BUTTON

s~

~

LEVELLER

PLATE

2. Insert leveller plate into bottom corners of front

panel. Ensure that lip on leveller plate faces

plate is too tight for a push fit, tap lightly with a

hammer on the flange of the

tabs extend through the slots of the front pane

3.

Screw on a hex nut to the levelling foot. Turn down

to within a half inch of top of foot to provide enough

in

an

room to fit

4.

Insert foot with nut installed thru underside of level-

ler

plate.

5.

Add nut to leveller. Screw down to plate. Adjust to

suit floor, when unit is

two wrenches.

open end wrench.

leveller plate, until the

fully assembled, tighten with

up.

l.

If

FRO

NT

PANEL

HEX NUT

PLATE

HEXNUT

~

~m)

r ,

~

:_,

"""\..~~

~~

~

15

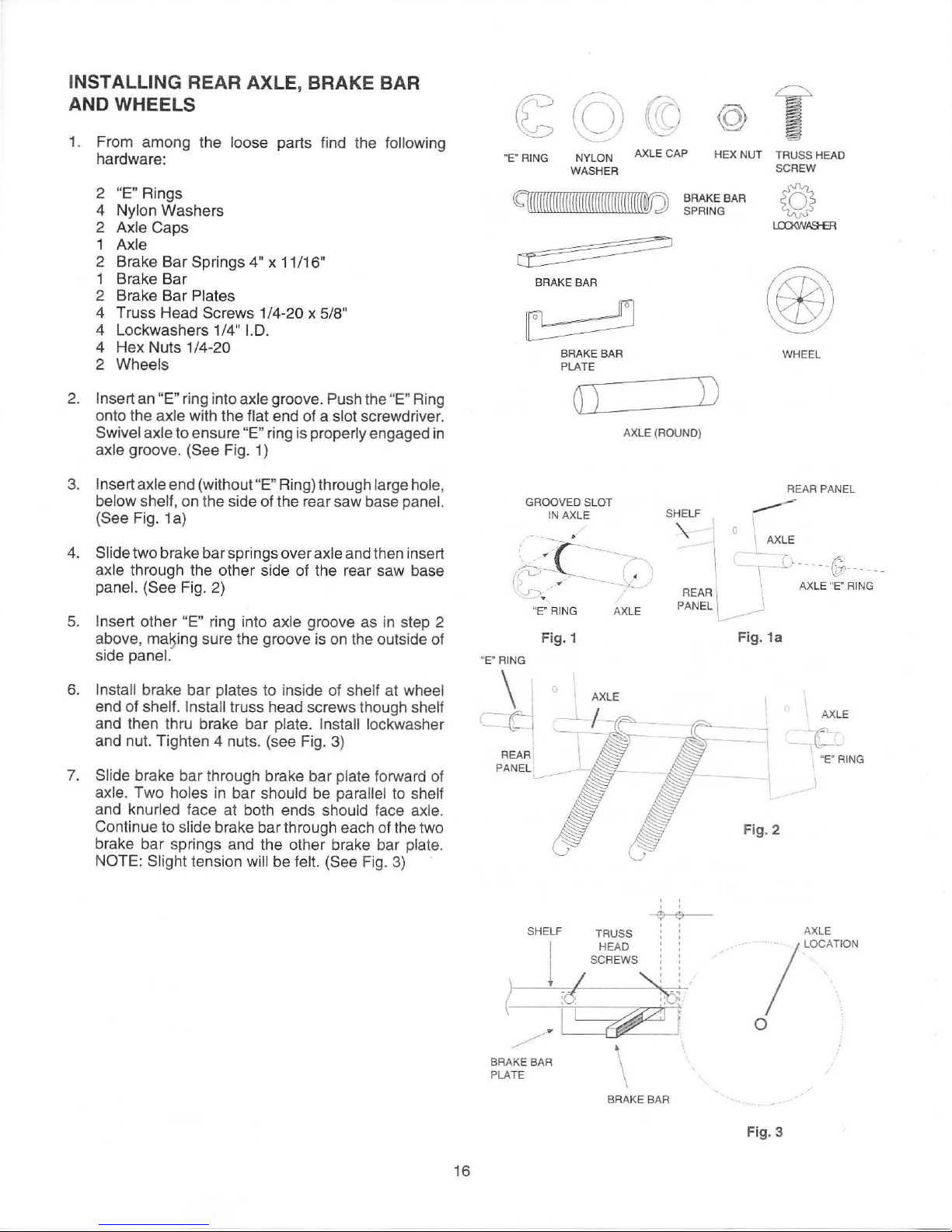

INSTALLING REAR AXLE, BRAKE BAR

AND WHEELS

1. From among the loose parts find the following

hardware:

2

"E" Rings

4

Nylon Washers

2

Axle Caps

1 Axle

2 Brake Bar Springs

4"

x 11/16"

1 Brake Bar

2 Brake Bar

Plates

4 Truss Head Screws 1/4-20 x 5/8"

4 Lockwashers 1/4"

1.0.

4 Hex Nuts 1/4-20

2 Wheels

2. Insert an "E" ring into axle groove. Push the "E" Ring

onto the

axle with the flat end of a slot screwdriver.

Swivel axle to ensure "E" ring is properly engaged

in

axle groove. (See Fig. 1)

3.

Insert axle end (without "E" Ring) through large hole,

below shelf,

on the side of the rear saw base panel.

(See Fig. 1

a)

4.

Slide two brake bar springs over axle and then insert

axle through the other side of the rear saw base

panel. (See Fig. 2)

5.

Insert other "E" ring into axle groove as

in

step 2

above,

ma~ing

sure the groove is

on

the outside of

side

panel.·

6.

Install brake bar plates to inside of shelf at wheel

end of shelf. Install truss head screws though shelf

and then thru brake bar plate. Install lockwasher

and nut. Tighten 4 nuts. (see Fig.

3)

7.

Slide brake bar through brake bar plate forward of

axle. Two holes

in

bar should be parallel to shelf

and knurled face at both ends should face axle.

Continue to slide brake bar through each of the two

brake bar springs and the other brake bar

plate.

NOTE: Slight

tension will be felt. (See Fig.

3)

16

~

©

(((J

@

f

"E" RING NYLON

AXLE CAP

HEX NUT

TRUSS HEAD

WASHER

SCREW

CC(

(((

(((

(((((((((((((((((((((((((((((WJ

@

BRAKE

BAR

SPRING

u::x:»VASHER

~

~

BRAKE BAR

~

BRAKE BAR

WHEEL

PLATE

[)

D

AXLE (ROUND)

REAR PANEL

SHELF

---

GROOVED S

LOT

IN AXLE

'\

I o

I

1

'. AXLE

I

I

\

- -

I:}-

- - -

-~--

----

\

AX

LE

..

~-,

RING

p~

~~~

_J

"E" RING AXLE

"E" RING

REAR'

PANEL

Fig. 1

~--

AXLE

'

e e

'

SHELF TRUSS '

j

HEAD

SC

REWS

~

~

~

BRAKE BAR

PLATE

BRAKE BAR

L -

__.

Fig. 1a

AXLE

"E" RING

AX

LE

/LOC

ATI

ON

0

Fig. 3

8. Position brake bar so an equal amount of each end

extends past bottom shelf and position the springs

between the holes in the brake bar and bottom shelf

outer edge.

9.

Install two nylon washers over axle.

10. With saw base secure so it won't slide, pull the brake

bar back enough to slide wheel onto axle. Release

brake bar.

washers.

11.

Install axle cap over end of axle to secure wheel. Tap

in place with hammer

gaged.

12. Repeat steps 9 -

NOTE: Hub of wheel goes against nylon

to

ensure cap is tightly en-

11

for opposite side.

WHEEL HUB

AGAINST

NY

LO

N WASHER

....

...

....

................

AXLE

HUB

/

~WHEEL

WHEEL -

CABLE

VIEW FRO

STOP _

-

SPRING

-

AXLE

M UNDERSIDE

SHELF

cr

OF

I

I

I

-

I

:>

J

AXLE CAP

-

-co

-

ASSEMBLING

1.

From among the loose parts find the following

hardware:

D Truss Head Screw

E Lockwasher 1/4"

F Hex Nuts

G Cable Spring 2

H Brake

I Bottom Shelf Fitting ..................................... 2

SAW

BASE

1/

4-20

1/4

Cable Sheath .................................... 2

BRAKE

1/4-20 x 5/8" .

1.0

.................................... 2

...... .................................... 2

x 5/8" ............................ 1

SYSTEM

..

......

J Brake Bar Cable Stop ................................. 2

2.

Install 1/2" spacer blocks (not included) between

the brake bar and the wheel to keep tension on

the springs.

Install bottom shelf fittings (2) with 1/4-20 x 5/8" truss

3.

head screws from underside of base shelf as show

Face of fitting with 5/16" dia. hole should face toward

panel. Secure in place with an external

front

lockwasher and

1/4-

20

hex nut.

...

..... 2

n.

D E F

Quam

G c

J

SHELF : BETWEEN BRAKE

@ ©

!llllllllllllllllllllllltlllllllli

@l

--<~~

:'

OJ

~

'

• INSTALL 112·

eer---

': , ON

.. (NOT

l

(~

BRAKEBAR

PLATE

y

~

!

-

BRAKE BAR

I

SPACER BLOCK

BARANDWH

EACH SIDE'

EEL

INCLUDED) -- _

--

17

NUT

\~

u

TRUSS

/

HEAD SCREW WITH 5/16. HOLE

LOCKWASHER

~SHELF

BO

TTOM SI

FITTING

FACING FRONT

DE

OF SHELF

FRONT

PANEL E

(t-c====~

ND

o

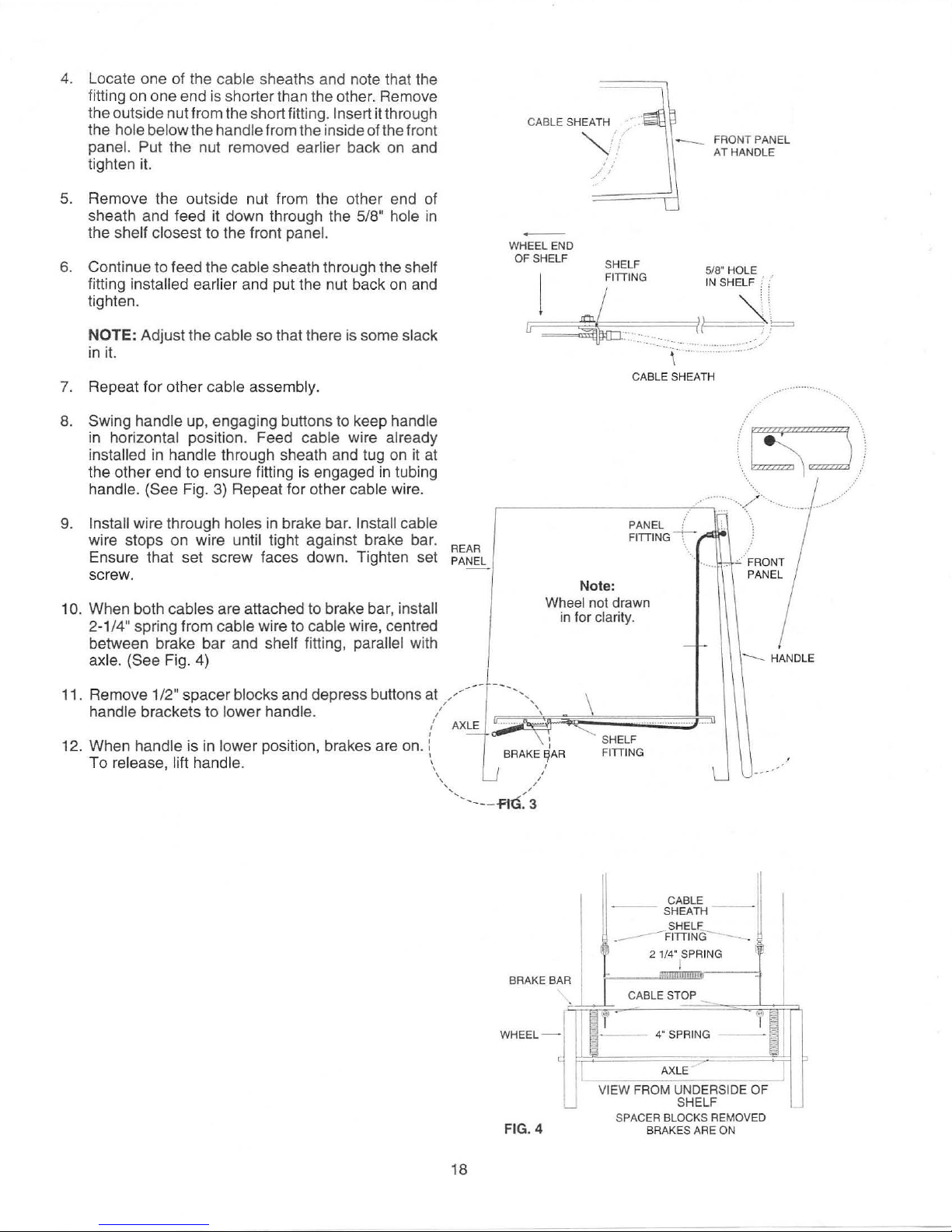

4.

Locate one of the cable sheaths and note that the

fitting on one end is shorter than the other. Remove

the outside nut from the short fitting.

the

hole below the handle from the inside of the front

Insert it through

panel. Put the nut removed earlier back on and

tighten

5.

Remove the outside nut from the other end of

sheath and feed it down through the

it.

5/8" hole

the shelf closest to the front panel.

6.

Continue to feed the cable sheath through the shelf

fitting installed earlier and put the nut back on and

tighten.

in

CABLE SHEATH

WHEEL END

OF SHELF

""'';.'

.

/'/

'

FRONT PANEL

AT HANDLE

HOLE

5/8'

IN

SHELF f

NOTE:

in

7.

Repeat for other cable assembly.

8.

Swing handle up, engaging buttons to keep handle

in

installed

the other end to ensure fitting is engaged

handle. (See Fig.

Install wire through holes in brake bar. Install cable

9.

Adjust the cable so that there is some slack

it.

horizontal position. Feed cable wire already

in

handle through sheath and tug on it

in

tubing

3)

Repeat for other cable wire.

at

wire stops on wire until tight against brake bar.

Ensure that set screw faces down. Tighten set

screw.

10. When both cables are attached to brake bar, install

2-1

/4" spring from cable wire to cable wire, centred

between brake bar and

shelf fitting, parallel with

axle. (See Fig. 4)

11. Remove 1/2" spacer blocks and depress buttons at

handle brackets

12. When handle is

to

lower handle.

in

lower position, brakes are on. i -

To release, lift handle.

---

.-

REAR

PANEL

--

--

/-

,/

AXLE~

\\

' /

'--

....

--,,

u

....

;;;

..

-a-

lJ

BRAK~rR

----FIG: 3

--

--

Note:

Wheel not drawn

in for clarity.

\

~'~,

F~

~::::::;:;:::::::::::::::::;::;J

\ :

...._______

SH

FITIING

CABLE SHEATH

---+--··-.""'"··.,

PANEL ( ..-I

FITTING T ,_ - 1

··

..

--

.

~

.

ELF

··

.......

..

5l

..

u

L

.....

n ·

1.

...

..

__

.....

--

/'·

...

..

..

\

1

~-···

FRONT

PANEL

-....__

HANDLE

U------'

····

..

..-··

18

BRAKE

WHEEL-

FIG. 4

BA

( ,

-_

I 2 1/4' SPRING @

-

R

;-..

'--+--

'-

If

~-

I

VIEW FROM UNDERSIDE

L

SPAC

SHEATH - -

_____

CABLE STOP

4' SPRING

AXLE

ER

BLOCKS REMOVED

BRAKES

~~'

SHELF

FITTIN

I

SHELF

G-

-

-·

ARE

~

~

T

- - -

OF

ON

p

MOUNTING

SAW

TO

SAW BASE

1.

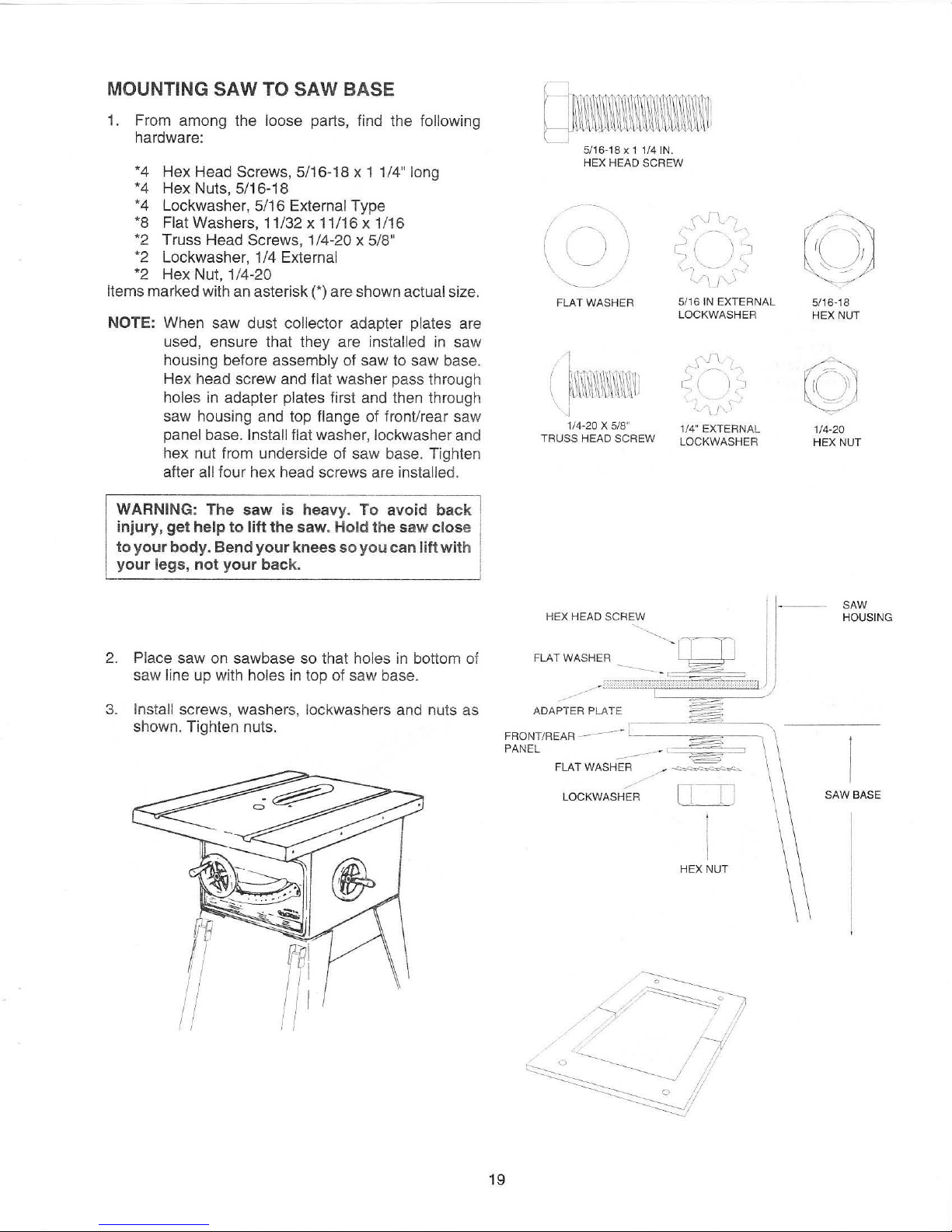

From among the loose parts, find the following

hardware:

*4 Hex Head Screws, 5/16-18 x 1 1/4" long

*4

Hex Nuts, 5/16-18

*4 Lockwasher, 5/16

External Type

*8

Flat Washers, 11/32 x 11/16 x 1/16

*2

Truss Head Screws, 1/4-20 x 5/8"

*2

Lockwasher, 1/4 External

*2

Hex Nut, 1/4-20

Items

marked with an asterisk (*) are shown actual size.

NOTE: When saw dust collector adapter plates are

used, ensure that they are

installed

in

saw

housing before

assembly of saw to saw base.

Hex head screw and

flat washer pass through

holes

in

adapter plates first and then through

saw housing and top

flange of front/rear saw

panel base. Install flat washer, lockwasher and

hex nut from underside of saw base. Tighten

after

all four hex head screws are installed.

WARNING: The saw is heavy. To avoid back

injury, get help to lift the saw. Hold the saw close

to your body. Bend your knees so you can lift with

your legs, not your back.

2.

Place saw on sawbase so that holes

in

bottom of

saw

line up with holes

in

top of saw base.

3.

Install screws, washers, lockwashers and nuts as

shown. Tighten nuts.

19

QDBmm~~

5/

16-1

8X11/41N.

HEX HEAD

SCREW

f

~~

\

('0lj

--

~

·~\

(U)

[~

( )

~

'

/'

'\-~,

.__

' >

~

/

V\j)

FLAT WASHER

5/

16

IN

EXTERNAL

LOCKWASHER

I

,S'!_:

l,

(

f\~m\~~)\~~Wil

~~

)

~J

j

i>\r,\-

1/4-20 X 5/8"

1/4" EXTERNAL

TRUSS HEAD SCREW

LOCKWASHER

FRONT/REAR

--

-~----==""?'

-~

PANEL

--

-=~~=

FLAT WASHER

/

/

LOCKWASHER

ll

J J

HEX NUT

CQJ

5/16 -18

HEX

NUT

©

1/4-20

HEX

NUT

SAW

HOUSING

SAW BASE

IN

STALLING TABLE SAW DUST

COLLECTOR

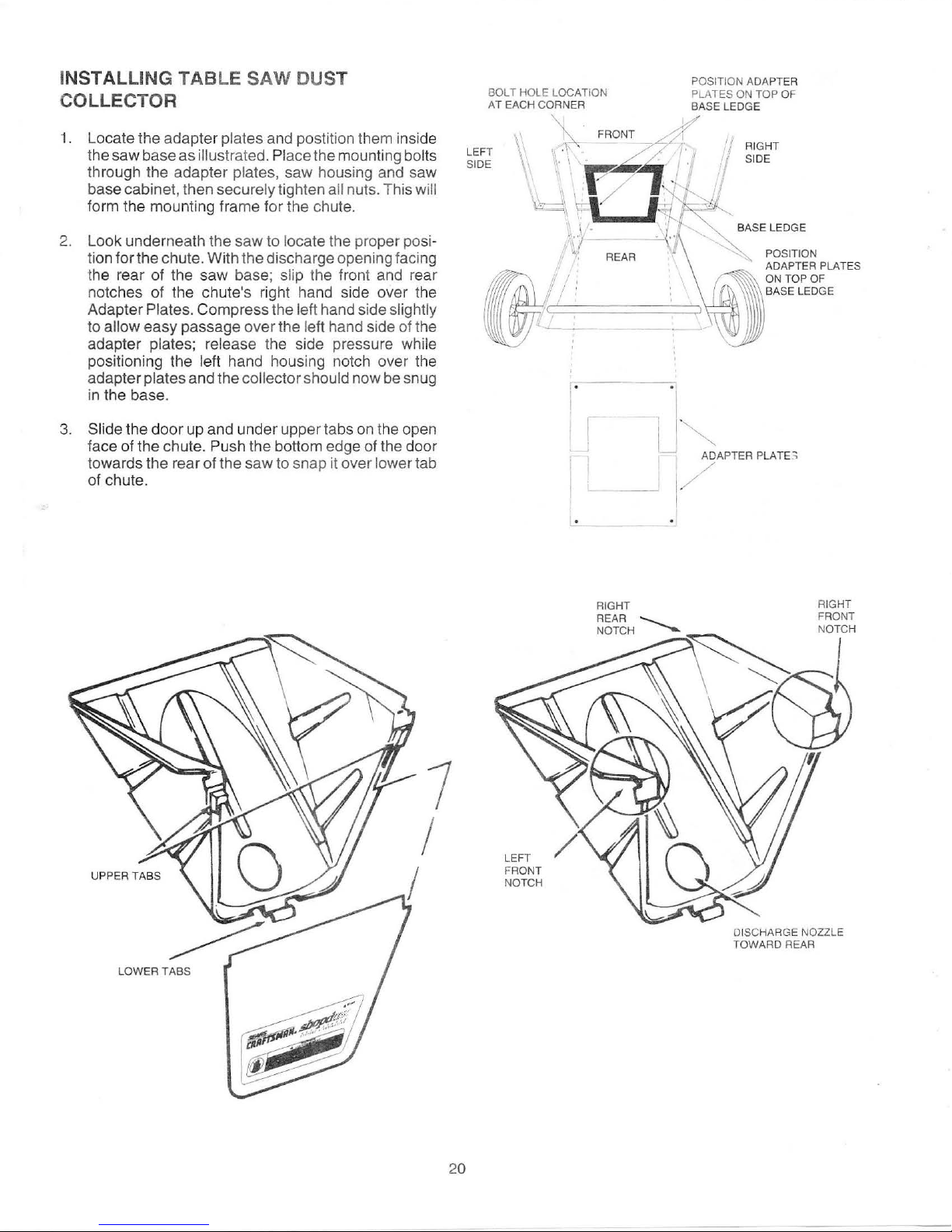

1.

Locate the adapter plates and postition them inside

the saw base as

through the adapter plates, saw housing and saw

base cabinet, then

form the mounting frame for the chute.

illustrated. Place the mounting bolts

securely tighten all nuts. This will

BOLT HOLE LOCATION

AT EACH CORNER

LEFT

SIDE

1

'

RIGHT

SIDE

2. Look underneath the saw to

tion for the chute. With the discharge open ing facing

the rear of the saw base;

notches of the chute's right hand side over the

Adapter

to allow easy passage

adapter

positioning the left hand housing notch over the

adapter

in the base.

3.

Slide the door up and under upper tabs

face of the chute.

towards the

of chute.

Plates. Compress the left hand side slightly

plates; release the side pressure while

plates and the collector should now

Push the bottom edge of the door

re

ar

of the saw to snap it over lower tab

locate the proper posi-

slip the front and rear

over

the left hand side of the

on

be

snug

the open

i•

II

' - J

r

1/

ADAPTER

/

POSITION

ADAPTER PLATES

ON TOP OF

LEDGE

BASE

PLATE~

RIGHT

FRONT

NOTCH

LOW

ER

TABS

7

I

I

20

LEFT

FRONT

NOTCH

DISCHARGE NOZZLE

TOWAR D

REAR

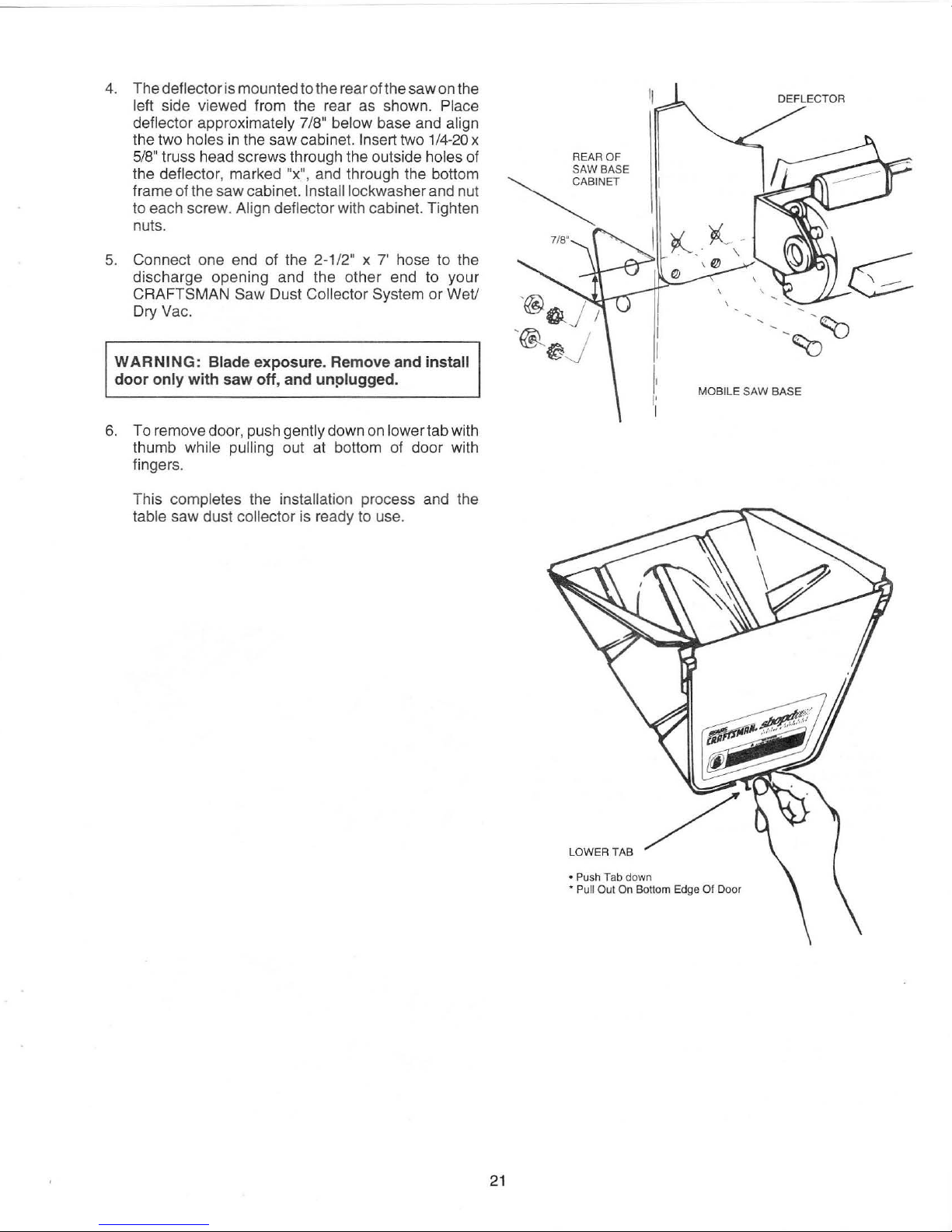

4. The deflector is mounted to the rear of the saw on the

left side viewed from the rear as shown. Place

deflector

the two holes

5/8" truss head screws through th e outside holes of

the

frame of the saw cabinet.

to each screw.

approximately 7/8" below base and align

in

the saw cabinet. Inse

rt

two 1/4

-20

deflector, marked "x", and through the bottom

lnstalllockwasher and nut

Align deflector with cabinet. Tighten

nuts.

x

~INET

REAR OF

SAW

BASE

DEFLECTOR

5. Connect one end of the

discharge opening and the ot

CRAFTSMAN

Saw Dust Collector System or Wet/

2-1

/2" x 7' hose to the

her

end to your

Dry Vac.

WARNING:

Blade exposure. Remove and install

door only with saw off , and unplugged.

6.

To remove door, push gently down on lower tab with

thumb

while pulling out

at

bottom of doo r with

fingers.

completes the installation process and the

This

table saw dust collector is ready to use.

MOBILE

SAW

BASE

21

LOWER TAB

• Push Tab

• Pu

ll

Out

On Bottom Edge

down

Of

Door

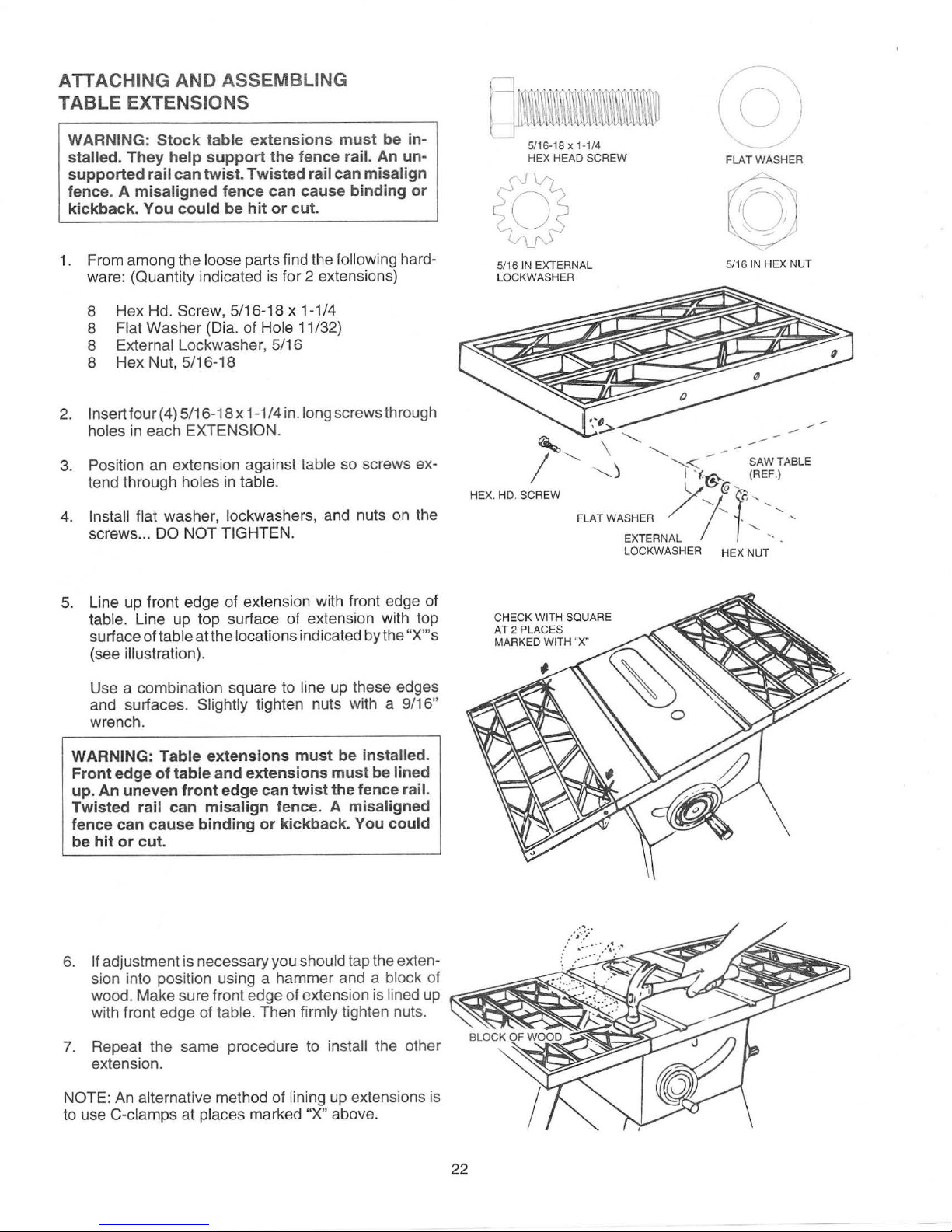

ATTACHING AND ASSEMBLING

TABLE EXTENSIONS

WARNING: Stock table extensions must be installed.

supported rail can twist. Twisted rail can misalign

fence. A misaligned fence can cause binding or

kickback. You

They help support the fence rail.

could be hit or cut.

An

un-

/-

(cJ)

FLAT WASHER

1. From among the loose parts find the following hardware: (Quantity indicated is for 2 extensions)

8 Hex Hd. Screw, 5/16-18 x 1-1/4

8 Flat Washer (Dia. of Hole 11/32}

8 External Lockwasher, 5/16

8 Hex Nut, 5/16-18

2.

lnsertfour(4) 5/16-18 x 1-1/4 in.long screws through

holes

in

each EXTENSION.

3.

Position an extension against table so screws ex-

tend through holes

4.

Install flat washer, lockwashers, and nuts

screws ...

5.

Line

table. Line up top surface of extension with t

surface of table at the locations indicated by the "X"'s

(see illustration).

Use a combination square to line

and surfaces. Slightly tighten nuts with a 9/16"

wrench.

DO

up

front edge of extension with front edge of

in

table.

NOT TIGHTEN.

up

these edges

on

the

op

5/16

IN

EXTERNAL

LOCKWASHER

' \

I

HEX. HD. SCREW

CHECK WITH SQUA

AT 2 PLACES

MARKED

WITH "X"

·:~

'-....

---.........

) I

FLATWASHER

RE

IN

5/16

..........

..........

"-..,<_

'

(.€~

y (if'

/7

EXTERNAL

LOCKWASHER HEX NUT

--

-

SAW TABLE

(REF.)

c:

-...

' • '--....

HEX NUT

....

.._

'.

WARNING: Table extensions must be installed.

Front edge of table and extensions must be lined

up. An uneven front edge can twist the fence rail.