Page 1

II

fl

srurcoxs

DCATS

rl

De,partment

731.4.

Tbronto

TECHNICAL

FLASH

T.F.

26-23

ApriL

7, 1983

SEF?VICE

INFORMATINN

*^

CGNMPACT

P(}&TAtsLE

I}RYffiffi

c26(}-

6@g(}(}

'.*

Page 2

T.F.

26-23

INDEX

PAGE

I General

. . . .

. . . . . . .

. .

. . .

. .

.

. . ' . . . . .l

II

Specifications...............

.....2

III Basic Operation....o...o..........3

IV

Disassembly.

.

. . . . . . . . . . .

. . . . . . . .

.

.4

V Trouble

Shooting..................18

Page 3

-1-

T.F.

26-23

SERVICE

INSTRUCTIONS

COMPACT

PORTABLE

DRYER

I.

GENERAL

This

is

a

portable

electric

dryer

designed to oPerate

efficiently

on

I20

volts,

60

hertz.

It

is equipped

with a

Ehree-wire

cord

for use

in a

grounded

receptacle.

THE UNTT

MUST BE

GROUNDED!

Although

noE

necessary

for operation,

it

would

be advantageous,

as with

any

dryer,

to

vent

this unit

to

the

outside

whenever

and

wherever

possible for maximum

efficiency.

(See

specification

section).

The

reset

button

must

be

pushed

to re-start

the

dryer

each

time the

door

is opened

and closed.

The rear

panel

must

be rercved

for urost

servicing

except

to re-position

a

displaced

drive

belt,

or

idler

pulley

and

spring.

The

timer

controls

drying time.

Ttte

brown

area

of

the

dial

is

heat,

except

the

last

7 minutes of

the cycle,

which

is a cool-down

period.

The orange

area of

the

dial is air

(no

heat) only.

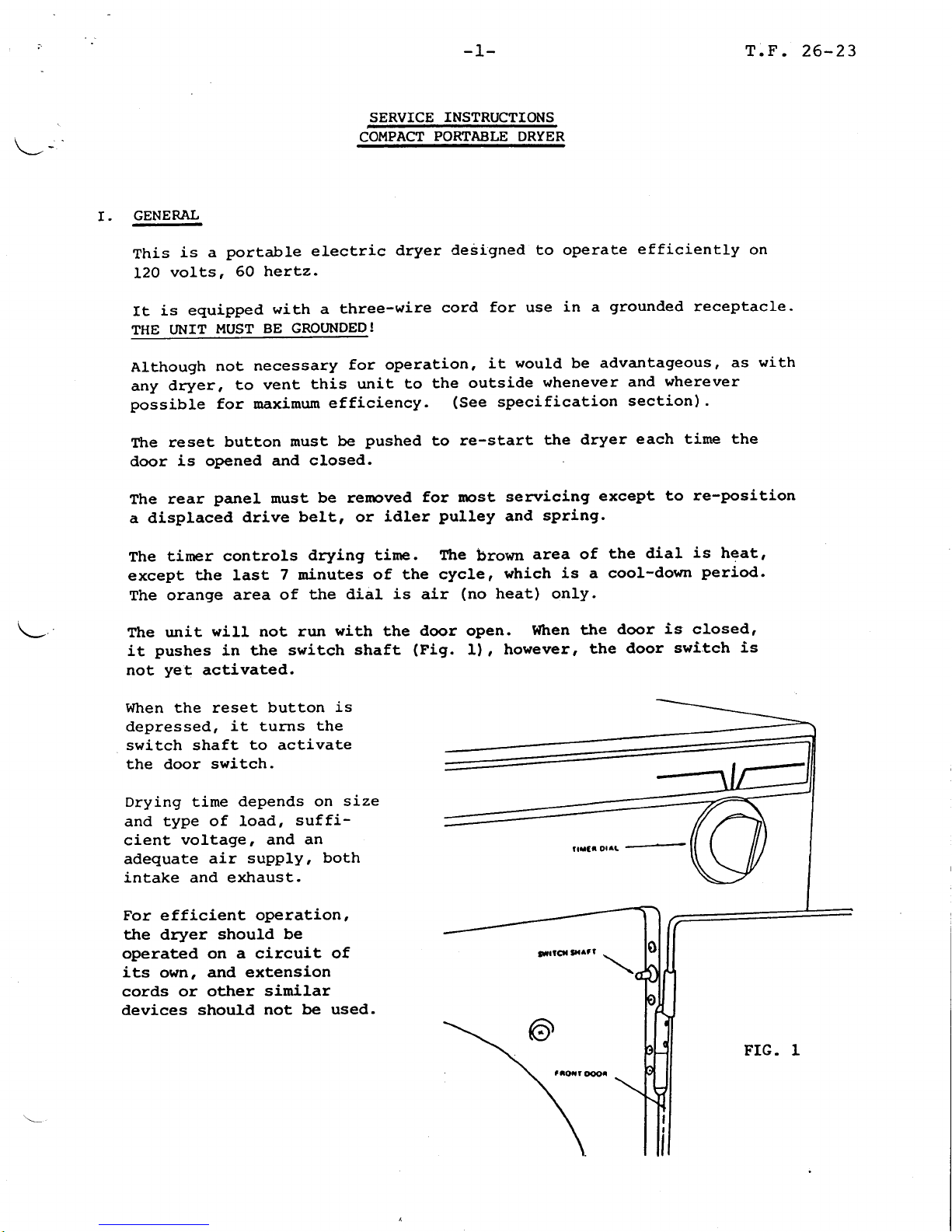

the unit

will not run

with

the

door oPen.

l{hen the

door

is

closed,

it

pushes

in the

switch

shaft

(Pig.

I),

however,

the

door

switch

is

not

yet

activated.

When the reset

button

is

depressed,

it turns

the

switch shaft

to

activate

the door

switch.

Drying tsime

depends on

size

and

type of load,

suffi-

cient

voltage, and

an

adequate

air supply,

both

intake and exhaust.

For

efficient

operation,

the dryer

should be

operated on a circuit

of

its own,

and extension

cords or

other

similar

devices

should

not be used.

Page 4

rr.

SPECIqrgaT-IoNS.

Size

Weight

Drum

Diameter

Drum

DePth

Drum

Speed

Element

Motor

Rating

Drum

Drive

Blower

Drive

-2-

T.F.

26-23

31" high, 16"

deep,

24" wide

84 Ibs.

zL-I/2"

12-3/8"

56-58

R.P.M.

12OO

Watt

(17

Gauge

Nichrome

Wire)

4

Anps

Poly-vee

belt

off of

motor

Direct

off of

motor

Horsepower

I/6

"\--

Hi-Limit

Thermostat

2000

Cycling

Thermostat

L250

External

Venting

(te

Used)

S"

pipe,

12'

maximun length:

2-9Oo

elbows

maximum

Lint

Filter Location

fnside

drum--rear

centre

Page 5

-3-

T.F.

26-23

\

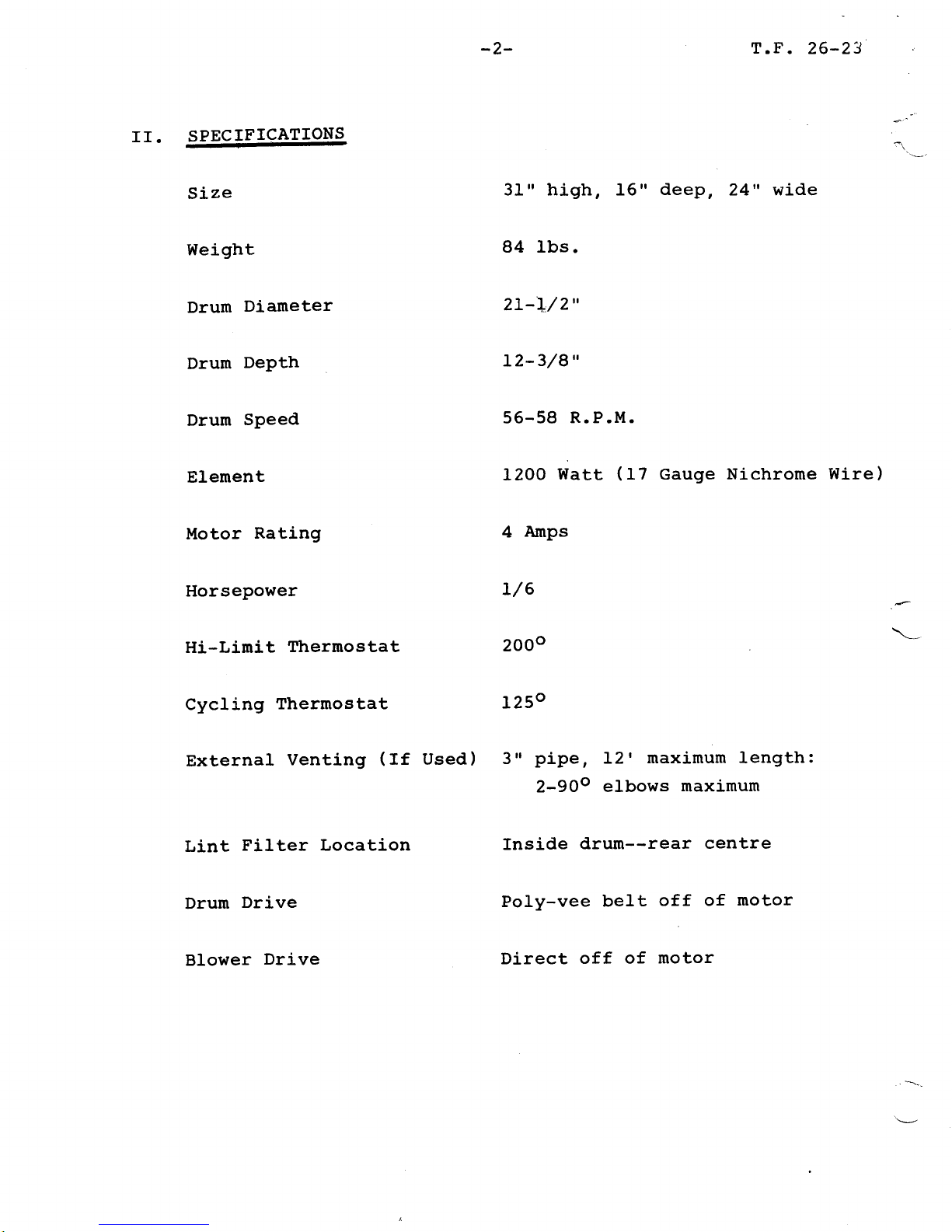

III. BASIC

OPERATTON

CUT.tsffiY

UIEH

(,FHtl(lUER

DffYEN

stx E

stc

g,fttrfis

T}€RilOStAI

lHr

rjflrTl

HE Tilt8

AIHAfi

rpoR

ffilrsrAT

lcofinuj

mr nile

tntfl

l

illsrm

rx,cT

TXHAUST

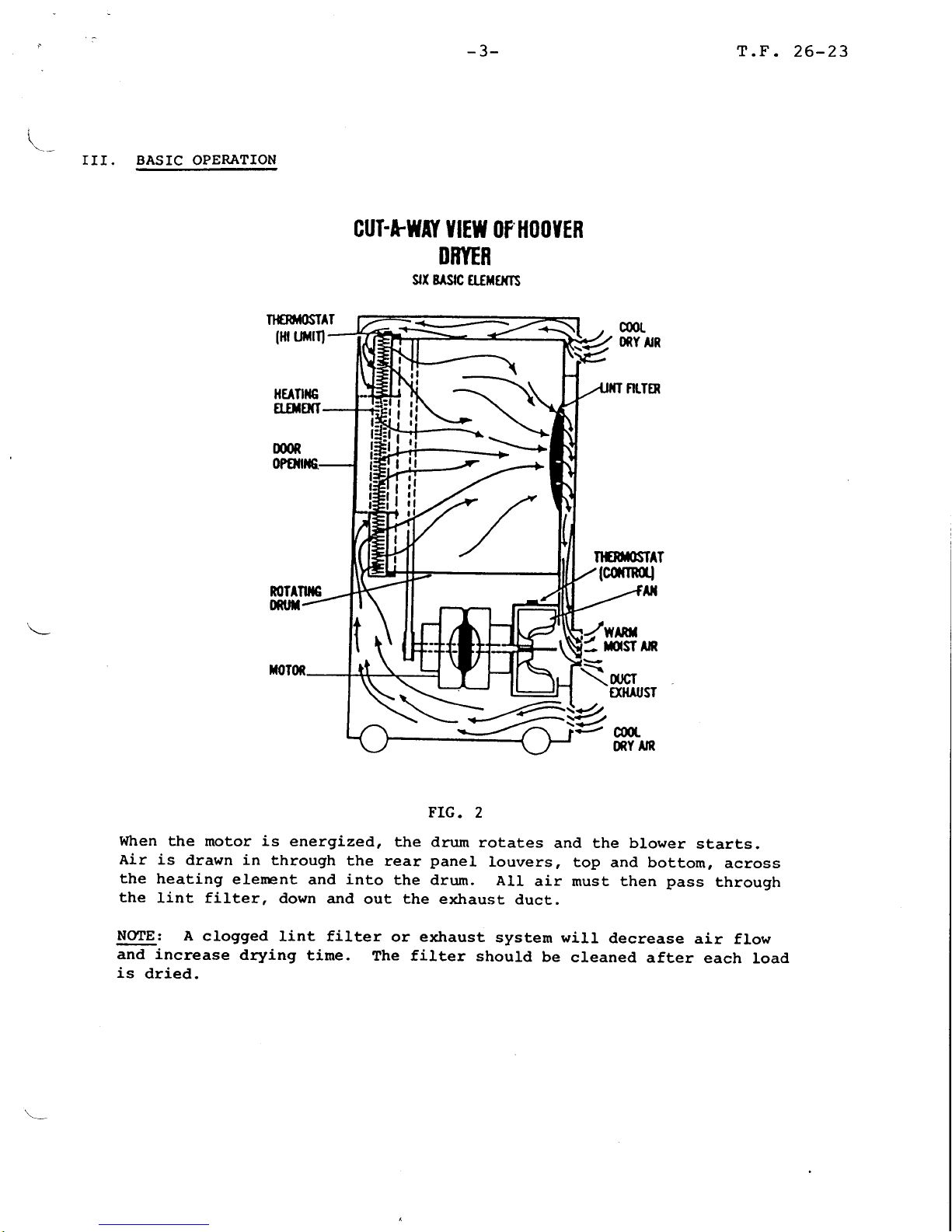

FIG.

2

When

the

motor is energized,

the drum

rotaCes

and the blower

starts.

Air is

drawn in

through

the

rear

panel

rouvers,

top

and bottom,

across

the

heating

elerent

and

into

the drum.

All

air must then

pass

through

the

lint filter,

down

and

out

the

exhaust

duct.

NCIE:

A clogged

lint filter

or exhaust

system will

decrease

air flow

and increase

drying

time.

The filter

should

be

cleaned

after

each

load

is

dried.

al

f,

rl

,1,

-\

=-\

7

:?

Page 6

-4-

DISASSEMBLY

BE

SURE

THE

UNIT

IS

UNPLUGGED

A.

Rear

Panel

Assembly

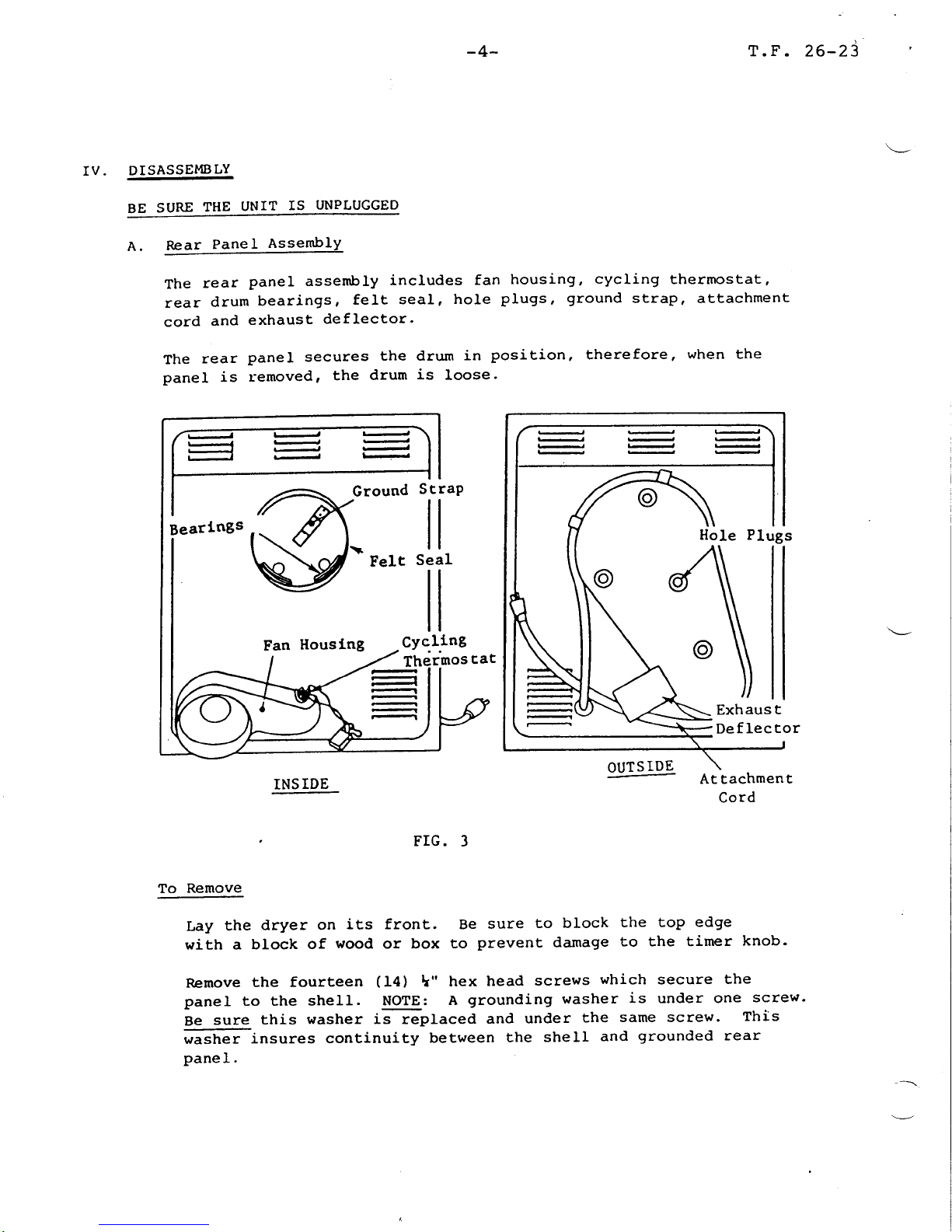

The

rear

panel assembly

includes

fan

housing,

cycling

thermostat,

rear

drum

bearings,

felt

seal, hole

plugs,

ground

strap, attachment

cord

and

exhaust

deflector'

The

rear

panel secures

the drum

in

position,

therefore,

when

the

panel is

removed,

the

drum

is

loose.

Hole Plugs

Exhaus

t

De

f Iec

tor

OUTS

IDE

-

At Eachmen

t

Cord

TNS

IDE

FIG.

3

To

Remove

Lay

the

dryer on

its front. Be

sure

to block

the top

edge

with a

block

of

wood

or box

to

prevent

damage

to the timer

knob.

Remove

the fourbeen

(f4)

L"

hex

head

screws

which

secure

the

panel to the

shell.

NOTE:

A

grounding

washer

is under one

screr".

Be

sure

this

washer is

replaced

and

under

the

same

screw.

This

washer

insures continuity

between

the

sheII

and

grounded

rear

panel.

T.F.

26-23

IV.

Beartngs

Fan

Houslng

Felt

Seal

Cyc.1.1ng

Thermos

cat

Page 7

-5-

Lift

the

rear

panel

up only

clear of

FIG. 4

T.F.26-23

the drum

and

Rear

Panel

I

I

fan

(Fig.4l

Reach

in and

seParate

the

The

rear

panel

can

now be

wiring harness

renroved.

aE the

multiple connector.

REC€PTACL€

HOUSING

TA8

ITOUSING

MULTIPLE

CONNECTOR

Mulciple

ConnecEor

FIG.5

Page 8

-6-

Ground

StraP

The

Ground

strap

is located

in

the

rear duct. It

bleeds off any

static

charge

in

the drum.

If the

spring tension

is

gone

or

the

blade

is worn,

replace

the

ground

strap using

blind

rivets.

Lr:bricate

the

strap

with a light coat of

specified

silicone

grease

prior

to

re-assenbly.

Attachment

Cord

If the cord

must

be

replaced, the multiple

connector

will have to

be removed

and

the

ground

wire disconnected

frorn

inside of

the

rear

panel.

The cord

wires

lock

into the multiple

connector

and

if

forced

out,

destroy

the

lock,

creating

an

electrical

hazard.

Therefore,

when

replacing

wires

in the

multiple

connector,

cut

the connector

at

every wire

to free

the terminals.

Use a

nehr

connector.

Use

a

good

crimp

on any

terminal

replaced.

Push

the

terminal

into the

connector and

it will

lock

into

position.

Felt Heat

Seal

Grasp at

any

point

and

work

seal off.

The

seal

is held by an

adhesive

around

the

entire mounting

surface.

Wtren replacing

seal,

clean

off all

old

adhesive

and then attach

new seal

with

3M-1300.

Therrnostat

This section

covers

both the control

thermostat

located

in

the

fan housing

and

hi-limit thermostat

located

on

top of

the

heat

shroud.

The

hi-Iimit

thermostat

is rated

at

2000. The

cycling

thermostat

is rated at 1250. The

rating

is

stanped

on

the

thermostat

for

indentification.

ftre

hi-Iimit

thermostat

will

open

with the

failure of

the cycling

thermostat or any

interruption of air

flow

such

as

a lint

clog'

broken

fan or

worn

felt seals.

lltre cycling

thermostat

controls

the

drying

temperature

in the drun.

Testing

The thermostats

cannot

be electrically

tested

with the unit

running. If

the heat cycle

will

not

operate'

a

test can

be

taken with an ohm

meter across

the

terminals.

A complete

T.F.

26-23

1.

2.

3.

4.

Page 9

-7-

T.F.

26-23

circuit

tends to indicate

a

good thermostat

electrically.

Hovtever, after

attaching

ohm

meter

leads

to the

thermostat

terminals, the terminaLs

should

be moved to

check

for inter-

mittent

contact. If the

condition

of

the thermostat

is

questionable,

after

testing,

it

should be

replaced.

In addition to a

continuity

test,

the

operating

temperature

may have

to be checked.

A temperature test

can be

made

i.lith a stem thermometer

in

the

lower

plug

hole or an

oven

thermometer

in the rear exhaust

duct. The temperature

will

vary

from l5Oo

to

ltOo

on

cycles.

This

would

verify the

cycling

thermostat.

After

the cycling therrostat is

verified, the

hi-linit

thermostat

can

be

checked

in the

same method

by

jumping

the cycling therrnstat.

Another test

of the hi-Iimit therrnostat

is to

run the

unit

with

the door

open and the door

switch

depressed. If the

hi-Iimit thermostat

cuts out

the

heat

circuit,

it is

serving

its

purpose.

Thermostats are subject to temperature

variance, therefore,

a temperature test

rnay be

required

to

verify normal operation.

5. Molded Fan Housing

Secured

by eight

5,/L6"

hex

head screws

located

on

the

outside

of

the rear

panel.

NOTE:

One

hole

plug will

have to

be removed

from the

rear

ducF6 make

one

screvt

accessible.

6. Drum

Bearings

This

section

covers replacement of

both

front

and

rear

drum

bearings

located

in the heat shroud

and rear

duct,

respectively.

NOTE: Lubrication for drum

bearings

is

applied

to the drum

G-nges

before

re-installing it into the

unit.

1. Clean aII

existing

grease

from

the

front

and rear drum

flanges.

2.

Clean

flanges with

fine

grade

(250-400)

emery cloth

or

sandpaper

to

insure

they

are

free

of foreign

matter,

then

wipe clean.

3.

Be sure

inside

of drum is

clean.

4. Apply a

thin

coat of Silicone Grease

(GE

G-34I-M)

to

each drum

flange.

Page 10

T. F .

26-23'

-8-

To replace

bearings:

I.

Remove

the

bearing(s)

to be

replaced

from the

flange.

2. Remove all old adhesive

and felt

from

the flange

with

a

non-flammable

solvent.

Be sure the

flange surface

is

clean and

drv.

3.

Use

3I"t

#847

Adhesive to attach new

bearing blocks

to the

flanges.

4.

Apply

a thin coat

of adhesive

to

the entire

felt surface

of the bearing

where

it

contacts

the flange.

Rear:

Install blocks

on

flange

of

the rear

panel,

flush

dff,-

tne

inside

edge. A

4"

wide

putty

knife

or

metal

lrlate

can

be

used as a

guide

to

assure that

the

bearing blocks

are

motrnted flush.

Bearing

Block

Felt

SeaI

FTG.

6

Position

one block

in

upper

centre^of rear duct, and

two

(2')

blocks

in

lower half

on centre,

45" off of

bottom centre.

To

determine

this,

place

one block

(no

adhesive)

on

bottom centre,

then

mark the

flange approximately

l"

from

each end of this

block.

These

marks

are the

position

of

the

bottom edges of

the two

(2)

lower

blocks

when installed.

Bearing

Flange

t

Page 11

-9-

T.F.

26-23

tdler RoIler

rnst.arr the new bearing

and

clarnp*

securely in

the

centre.

Allow

a minimum

of 30

min,rrefE

dry@

installing

the drum.

Do

not.

st@

eight

(B)

hours.

NOTE:

IDL BINDER

CLIP*

p3-2O-2O.

is one

suggested

c)-amp.

ores.

Front:

Refer

blocks

to

the

front

panel.

Posit,ion

one

three

blocks;

bolt;

and

one

above).

BeIt

to

preceding

steps

I-4, then:

Install

bearing

flange

of

the

heat

shroud

with

edge against

t.he

Refer

t.o Fig.

15.

(I)

block

in

upper

cent,re

of heat

shroud

and

one in

lower

half;

one

centred

over each

shroud

on

bottom

centre.

(Adhesive

setting

time:

see

B.

l.2.If off

of

the

idler pulley.

it

can

be

re-positioned

by

removing

the

access panel

rocated

on the

bottom

of the

unit.

Viewing

the

dryer

from

the

front,

lay it

on

its

reft

side -

Remove

tne

uoGilnel

and

work

t.hrough

che

opening-

(Fig.

7

shows

bert

position

after instarlation).

ff

broken,

the

rear

panel

wilt

have to

be removed.

See

Section

Iv, A,

for

panel

removal.

Be

sure idler

spring

is

hooked

into

the

shell

near

the

access

panel.

To

install:

a. Place

belt

over

drum with

ribbed

portion

of belt

next

to

drum,

and

hold

belt

taut.

b.

Place

belt

over

motor

pulley

white

stitl

holding

taut

to

keep

it

on

the

drum-

c. Lift

the

idler

roller

up

past

the

belt,

putting

tension

on

the

spring,

and

place

the

belt

over

the

roller

and

release

the

roller

slowly

so

that

tension

will

be

maintained

on

the

beIt.

(See

rig.

71.

This

is

the

position

of

the

belt

and

idler

after

assembly.

PuIley

Belc

er

Sg

DrrJm

Spring

Outer

Shell

Idler

FIG.7

Page 12

-10-

T.F.

26-23

Drum

Remove the rear

panel

and drive belt,

then

lift the

drum

straiqht

out

from the

shelI.

Filter Guard

Assembly

The filter

guard,

inside

the

drum,

rear centre,

is

removed

by

grasping in the finger holes

provided

and

pulling

straight

out.

NOTE:

A bead around that

portion

of the

fiLter guard

which

?iE

into

the drum

and

four

(4)

dimples

in

the

rear

portion

of

the drum keep

the

guard

from falling

out. When

installing,

the

guard

should snap

into

place

with a positive

click.

Lint Filter

The filter itself is inside

the

filEer guard.

With

the

filter

guard

in

one

hand,

screen

mesh

portion

facing you,

notice

a

"handle"

on

the filter

itself.

Grasp

handle

and

rotate

filter so

that it is

adjacent

to

any one

of four

(4)

securing

Eabs

of the filter

guard.

pull

the

',handIe,,

away

from the tab

and

straight

out.

To

replace,

place

filter

in

guard

and

push

into

place

around

the entire

3600

circumference

or until

the filter

"cricks"

past

arl four

tabs.

FTG.

8

D.

Outer Shell Assembly

The shell

assembly includes:

(f)

Motor

Assembly,

(2)

Idler

Assenbly,

(3)

Bottom Access

panel,

(41

Clips

which

secure

wiring,

and

(5)

wheels.

The

rear

panel

must be removed

to

service all but

the

wheels

and

the boEtom

access

panel

I.

2.

Page 13

-11-

T.F.26-23

l.

Motor

Assembly

General:

It. is not

necessary

to remove

t.he

motor

assembly

to change,

t,ighten,

or

re-position blower

fan

or

drive

pulley.

The motor

is

equipped

with

a

thermar-overload

procector

that

wirl

shut off

the motor

if it

gets

too

hot.

The

overroad

will

reset

when

the

motor

cools

sufficienely.

Therefore,

before

replacins

a rptor,

check

to

see

if it

is

not,

brocked

by

lint,

reducing

air

flow,

thus

causing

overheating.

'NOTE:

The nptor

should

be

vacuumed

free

of

all

lint

any

EGe

the rear

panel

is

renpved,

for whatever

reason.

Ttre

heating

circuit

is

inoperative

unress the

sptor

is running.

This

is

controlled

by

the external

switch rrcunted

on the

mtor.

rtre switch

has

a back

contact

operated

by urotor

current

and

acts as

a safety

device.

FIG.

9

Replacement

-

Assenrbly

complete

Disconnect

the

wiring

harness

from the

switch.

Rercve.the.

3,/8"

bolt

securing

the

nrornting

bracket

to

the

shell.

slide

motor

assembry

for*rard

and

out as it

is

herd

in

the

shell

by

a tab

on the

opposite

end

of the

moturting

bracket.

NCIE:

The

pad

under

tshe

mounting bracket

is

to danpen

rctor

to

shell

vibration

and should be

in

place

when

replacing

motor.

Page 14

-r2-

Blower

Fan

-

Remove

fan

to

the

PuIleY

end of

the

councer-clockwise.

The

t'lotor

Mounting

ClamPs

-

with

straight

blade

screw driver,

pressure down and

PrY

out to

the

clamp

from the mounting

bracket.

by

attaching a

pair

of

vice

grips

motor

shaft and

turn

the fan

fan housing

has

a

right-hand

thread.

secured

by

to the

area

toctite should

CIamP

a large

APPIY

free

FIG.

TO

rrcroR

sYvrtcH

Erci I'AO

\-

*'

T.F.

26-23

a.

b.

b.

d.

Drive

Putley

-

Remove

l,/8" set

screw,

which

is

Loctite.

If

difficult

to

remove, heat applied

of

the

set

screw

helps

to

loosen

the

loctite.

be

added

if new

pulley

or

set screw is used.

Fan

Housing

gqeling. Plate

-

Secured

by

four

3,/8"

nuts.

c.

d.

e.

Motor

Switch

-

External

-

Available

ffi

Testing

a.

The

notor

can

be tested

in the

shell

with harness

wiring removed.

c.

Connect

a test

jumPer

cord

to

terminals

4 arld 5 of

the

motor

switch

(riS.

I1).

A

wattage reading

should

be 140

watts

at 120

volts

-

no load.

(200

watts

with empty

drum load)

tilith motor

running,

test

for

voltage

between

I and

5

or

between

1 and

4.

This

will

test the

back contact

switch.

If

this contact

does

not close

with motor

running,

the

heat circuit

will

not

operate.

To bypass switch, connect one

leg

or test cord

to

orange

motor

lead

wire

and other

leg

of test

cord

to blue and

black rptor leads.

ttouncing

Bracket

wra

aiofr

t

a(uc

rctot

taao

oi0cc

rctoi tcao

rIG.

II

d\

o€t3

o@o

e.

Page 15

Ttmer

-13-

T.F.

26-23

2. Idler

Assembly

-

(Refer

to

Fig.

7)

Release

the split

ring which

holds

the

idler

arm

to

the

bott.om

of the

sherr.

This

is

a friction

fit

and the

arm

has

no groove.

Ring can

be

released

with

speciar

"tru-arm"

priers

or

the

arm

can

simpry

be

pushed,

from

its srot,

towards

the

front

paner-

ReLease the

idler

spring

from

its

groove

in

the

bottom

of

the shell.

a.

RoIIer

off

of

b.

Spring

rol

Ier.

-

Remove

split

ring

and

washer,

then

slip

roller

idler

arm.

-

Remove

roller

and additional

split

ring

behind

E. Front Panel

Assembly

components of

the

front

panel

incruding

door,

door

switch,

timer,

heat shroud

and door

latch

can be

changed without

removing

entire

front

panel.

The

main

purpose

for removing

the

front

panel

would

be for

damage to

the

paner

itself

or the sherl

to

which

it is

attached.

Side

View

--rn

\../

o

I

I

I

I

t""1.

But

ton

Tiner

t\

Ca

Door

Door

Switch

Gaske

t

Front

Vies

FTG.

L2

Page 16

-I4-

T.F.

26-23

t.

Door Assembly

-

@en

the

door

stightly

past

half-qrayr

then

lift

up and straight

off

of its

hinges.

2.

Door Gasket

-

Held with

return

tabs.

Lift tab and remove

door

gasket.

3. Tiurer

a. General

The timer controls

the

drying time.

The

brown

area

of the

dial is heat,

except

for

the last 7

minutes

of the

cycle.

The orange area

of the dial is

air only.

b. Testing

(1)

The

timer

can be tested in

the

unit.

(2)

Disconnect

harness wiring

to the

timer.

(3)

Turn

timer

dial

past

60 minutes.

Circuit

should

be

complete

between OR - BK

-

BU.

(.41

Turn

timer

dial back to

cool-dolrn

period

(last

7

minutes).

A

click

in

the timer is

audible.

Circuit

should

be conplete

bethreen

OR

-

BK

and

open between

OR

-

BU.

(5)

Turn timer

dial

into

orange

area. Circuit

should

be

\-

complete

between

OR

-

BK, and

open between

OR

-

BU.

c.

Replacement

(f)

Pull

timer knob

off.

(21

Remove

two

screws securing timer

to

front

panel.

(3)

Turn

nehr

timer so that the

cam

is

located

in the

shortest

arc between two

audible

clicks.

(4)

Install

timer

with

flat

of

shaft in

the three

o'clock

position.

4. Door

Switch_as:enb_ly.

Rernove

the

wires

from

the

switch

itself,

then

remove

the mounting

screhrs

from

the front,

inside

the door

opening.

The switch itself

can be

removed from the bracket

by

removing

@crevrs

The switch

can

be tested in

the

unit

with

a voM.

Page 17

-15-

T.F.

26-23

5.

DOOR

SI.TITCH

ASSEMBLY

FIG.

13

Reset

Bushing-Button-Spring

If

the bushing

is

or has

to be

removed,

it

with

a ne'i,

one.

Install

by

pushing

in

the

front.

panel.

should

be

replaced

opening

in

the

Bushing

iJuLCon

Sprin

g

RESET

BUTTON-BUSHING-SPRING

FIG.

L4

To

reprace

button

or

spring

only,

push

old buttons

and

spring

out

from

inside

the

sherl,

then

insert,

new

components

in

the

bushing

from

the' front.

Heat

Shroud

Assembly

Renove

the

brue

wire

from

the safety

thermostat

and

the

orange

wire

from

its

attachment

at the heating

element.

Remove

the

four rounting

bolts

and

nuts.

Bolts

are

located

on

front

panel

around

the

outer edge

of

the

drum

opening;

nuts

are inside

heat

shroud.

Door

Swlcch

6.

Page 18

-16-

T.F.

26-23

safety

thermos

tat

clip &

insu

lacor

t

sh

roud

felt

seal

porce

1

ain

insu Ia Cors

hea

t ing

element

a.

h

FIG. 15

Safety

Thermostat

Remove

wires

and

two

(2)

mounting

screws.

Ref. A,

#4

for

testing

procedure.

Felt Heat

Seal

Ref.

A,

fl3.

Heating

Element

The element can

be replaced

by

disconnecting the old

element

from the

terminals and

sliding

out

through

the

insulators

(Fig-

f5).

The

new element

is not stretched

to

length and

must be evenly

stretched taut around

the

shroud.

After

the o1d element

is

removed,

stretch

the new element

to the

same length

by

puJ-ling

on both

ends.

Slide

the

new element

in through

the

insulators.

c.

flange

ar

oc

I

I

I

I

shroud assembly

Page 19

-17-

If

the

insulators

are

broken, the heat

shroud must be

removed.

The

insulator retainers

are

then snapped

out

of the

shroud

and

a new

insulator

used.

The

male

element

terminal-

insulator is

located

on

the

element

side

of

the

heat

shroud. The element

must

not

touch any

metal

parts

or

have

any space which

could

cause

a

short

due to vibration.

Door

Catch

T.F.26-23

7.

Reltpve

heat shroud,

depress

molded ears

the

opening

in the front

panel.

InstaII

into the opening

until

it

"clicks"

into

and

push

out

through

new

catch

by

pushing

place.

au

at:u

oa

oiaxol

at

xori

trtti tattci

rrxutaita

-f,rra""u.rau"

|

|

oa aottE

I

ooor

J

lwltcx

^ttltNAi:

tNtlix^t xotoa

tEurxr!

ao^io

scx6ml

oE MoNTAcE

WIRINC

DIAGRAil

tta'Latl

tr - ttrcaut

aouot

ti - ti^caui

xott

iOtl: ll lt iaO

li^Cai

at tt ltact tiacai

a(lic

ti

_

Htllllo tllrtil

rirtl Itlata^wol

aleraltcx^uttlxl

vttror il

(.ra

afot

J^Uia

li

I

o

a

a

o

t

3

o

o

I

2

a

rrie xaiittt

coxxacloi

cYcttio

txciroalar

rxtiroar^l

cfero0l

tcivlc:

coio

t.to

awot

coi&x oa atryEa

EI,ECTRIC

WIRING

z

o

o

C

o

]

a

0

3

k-?Fi

:

a

s---l

1..-f:::

litra

it(ata

awol lt^ic

ti

Frc.

15

Page 20

-18-

T.F.

26-23

V. TROUBLE SHOO{TING

This

section

is

a

guide

outlining

possible

failures and their

causes.

GENERAL

The following

procedure

is suggested as

a

good

service

practice

and

prevention

maintenance

fF THE DRYER IS DISASSEMBLED

FOR

ANY REASON:

I. Unplug

the unit.

2. Remove the rear

panel,

drive belt

and

drum.

3. Clean

all existing

grease

from

block

drum bearings

unless

they

are to be replaced.

4.

Clean

the

lubricant

from

the

ground

strap.

5. Replace the felt heat seals, front and

rear.

6.

Clean all lubricant

from the drum

flanges, front

and

rear.

7.

Clean drum

flanges

lightly

with

fine

grade

(250-4o0)

sand-paper

or

emery

cloth

and

wipe

clean.

8. Be sure the inside

of

the

drum is clean.

9.

Apply

a thin

coat of

silicone

grease

to

the

drum flanges,

front

and rear,

and

the

ground

strap.

10.

Vaculm

the

inside

of

the unit,

including motor, before

re-assembling.

I1.

With clean hands, re-assemble

the unit.

L2.

Run

the unit to

be

sure

the customer is satisfied

(when-

ever

possible)

before

leaving.

A.

l.totor Does Not Run

t. No

power

applied.

Be sure the

unit

was

plugged

in.

2.

Blown

Fuse/Tripped

Breaj<er

Short in Dryer. Circuit

over-

Ioaded. The dryer should

be on

a 15 amp rated circuit

by

itself

|

.-

No other appliance or

lighting

should be operated off of

the

dryer circuit.

Correct

cause

before

replacing fuse.

AL!{AYS REPLACE FUSE

WITH

ONE OF

Page 21

-19-

5. Bad

Motor

or

Motor

Switch

Ref.

Section IV,

D,

#f

T.F.26-23

6.

Bad

Door

Switch

Ref.

Section IV. D,

*f

7. Lint

In

llotor

This

could

cause the

therrrc

overload

protector,

Iocated

inside

the

motor, to

cut out,

making

the motor inoperative.

B.

No Heat

NOTE:

Verify this complaint

before

changing

any components. The

real complaint

rnay be

"too

long of

drying time".

Run unit at

mid-point

in

brown

portion

of Timer

Dial for

approximately two

minutes,

then feel the

air coming out

of

the

exhaust

duct. If

the unit

is heating,

refer to

C,

this

section.

If

the unit is

not

heating,

check

the following:

l. Bad

Tirpr Ref.

Section fV, E,

*4

2. O5ren or Intermittent

Thermostat

(s)

Ref.

Section IV,

A,

*4

3.

Open

in

Heating Element

4.

Open

in Wiring

5. Bad

Motor Switch

Motor

and Switch

replaced

as

an

assembly.

C.

Too Long to

Dry

Clothes

I. Clogged Lint

Filter

Filter

must be kept

clean

maximum

drying efficiency.

Clean

after each load

is

dried.

2. Poor Air Supply Unit should be

kept

at

a

ninimum

of 8"

from

a

waII and

out of

closets

and

other

small

area when

running. Operating

close to

walls

or in small

areas allows the dryer

to cycle

its

own moisture-laden,

exhausted

air stream.

Page 22

-20-

T.F.

26-23

4.

Load

Too Large

This

unit

is not

designed to

handle

a large

load

such as

washed in a full-sized

auto-

matic

washer.

5.

Too

Much

water

Retained

in

Spun,/!{rung

load

to

be

dried.

Compact

Dryer is

an

excellent

companion

to Hoover IUin-Tub

Washer

or

similar

type.

Other

types

may leave

501 to

60t more

lrater

in the clothes than these,

making

drying

time

considerably

Ionger.

6. customer

Orientation

Customer

may be expecting

entirely too much from a lI0volt

compact,

especially if

results of a

22O-volt full-

sized dryer such as at laundro-

mats

has been

experienced.

7.

Iow Operating

Voltage

The

wattage output of

the

heating

elenent is closely

related

to the supplied voltage.

8.

Intermittent

Q>eration

Check

motor to be sure

it is

completely

free of lint.

vacuun

if necessary.

o

Clogged

or

Obstructed

Blower

or

Vent Pipe

10.

Ioose

Blower

Fan

Re-position

flush

with

the

end

of

the

motor shaft, add Loctite

and

re-tighten.

NOTE:

If

this

condition

does

not

exist,

the complaint

will

probably

ber

"Noisy".

I1.

Eratic

Thermostats

Ref. Section

Iv,

A,

*4

for

testing.

Drum Does

Not

Rotate

1.

Broken or

Displaced

Belt

Ref.

Section

IV, B

D.

2.

Add Ioctite and

re-tighten.

Loose

Motor Drive

Pulley

Page 23

-2L-

T.F.

26-23

3.

Frozen

Idler

Roller

4. Drum Binding

Check

Drum

Bearings for

both

wear

and

adequate

lubrication.

Replace and lubricate

worn

bearings.

Ref. Section IV,

A,

*6.

E.

Noisy Dryer

1.

Worn Drum Bearings

Ref.

Section

Iv, A,

#6

for

replacement.

2.

Bearings

Dry Clean,

then

re-Iube

with

GE G-34I-M

Silicone Grease

only.

3. Loose Blower

Fan Re-position

flush with end of

the rnotor shaft, add Loctite,

and re-tighten.

4. Binding

or

Dry Idler

Roller

5. Flat

on

Drun

Flange

This usually

produces

a

regular

thuq)ing

sound.

5. Distorted

Front

or

Rear Panel

(See

Note*)

7.

Loose or

Worn Ground

Strap

Rep1ace.

8. Skewed Drum

(See

Note*).

9. Door Gasket If bearings

show

considerable

wear, the

drun may drop

enough

to

rub

the

gasket,

sometimes

displacing

it. A squeaking

sound

is usually

produced

when

this condition

first

develops.

10.

No Damper Pad

Under

Motor Mount

This

will soretines

result

in

motor

to shell vibration.

NO|[E* A skewed

(distorted)

drum

or

distorted

front or

rear

panel

can

usually be recognized

by vibration

and

pulsating

of the shell and/or

panels.

Once

during each revolution, the

panel

would be

pushed

outward.

DEPARTMENT

731A

-

J.

CUNNINGHAM

Loading...

Loading...