Sears C260-21501 Service Information

7314 Tbronto

T.F.26-22

October

28,

1981

ITII

I

f**

ILT-

Department

fi

srvcsoxs

DCATS

TECHNICAL

FLASH

SERVICE

INFOFIMATION

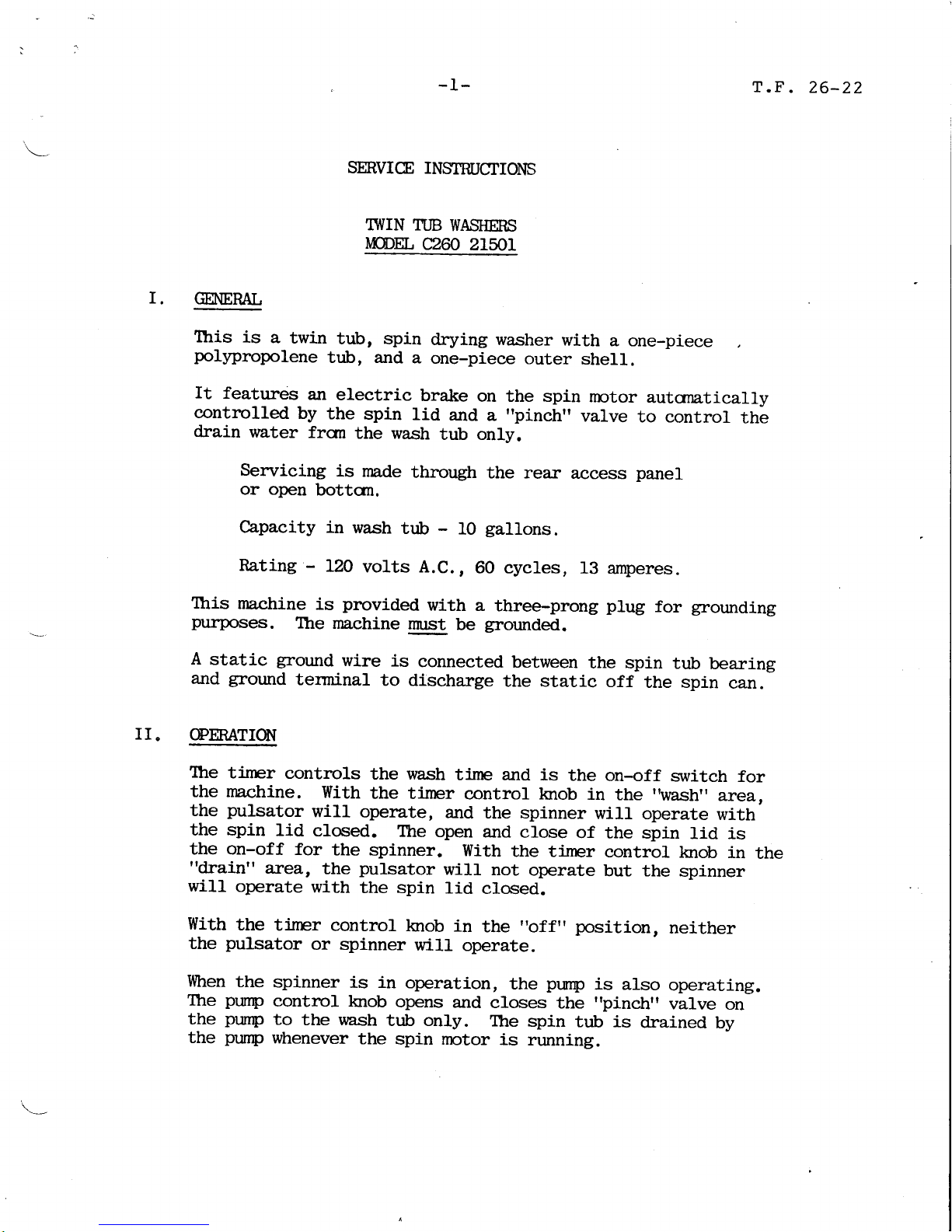

KENMORE

MODEL

C260-21501

i

\

\

-:-

WASHER

SPIN DRYER

-t-

T.F.26-22

SMWcts

INYIAUCf,IOI{S

T'IVIN TIJB

WA,STIER,S

I,rcDEL

effi

zIffiL

I.

@{ENAL

Ttris

is

a

twin

tub, spin

drying washer

with

a one-piece

polypropolene

tub, and

a

one-piece

outer

shell.

rt

features

an

erectric

brake

on the spin

rnctor

autcrnatically

controlled

by

the

spin

lid

and

a

ftpinchrf

valve

to control

th;

drain

water

frcrn

the wash

tub only.

Servicing

is

made

through

the rear

access

panel

or open

bottcn.

Capacity in

wash

trlc

-

10

galIons.

Rating

-

120

volts A.C.,

60 cycles,

13

amperes.

This

ma"chine

is

provided

wi.th

a

three-prong

plug

for

grounding

puposes.

The rnachine

nnrst

be

grounded.

A

static

ground

wire

is

connected

between

the spin

tub

bearing

and

ground

terminal

to

discharge

the static

off

the spin

can.

@MATIOI{

The

tiner

controls

the wash

tirne and

is

the

on-off

switch

for

the machine.

I{ith

the

tinrer

control licrob

in

the

"wash"

area,

the

pulsator

wilr

operate,

and

the spinner

wilr

operate

with

the spin

lid

closed.

The

open

and

close

of

the spin

1id is

the on-off

for

the

spinner.

with

the tiner

control

lmob

in

the

"drain"

a^rea,

the

pulsator

will not

operate

but the

spinner

will

operate

with

the spin

lid

cLosed.

with

the

tinrer

control

lsrob

in

the

"off"

position,

neither

the

pulsator

or spinner

will

operate.

I{hen

the

spinner

is in

operation,

the

ptrnp

is also

operating.

The

purp

control lmob

opens

and

closes

the

"pinch"

valve

on

the

punp

to

the wash

tub on1y.

Ttre

spin

tub is

drained

by

the

pump

whenever

the

spin rnotor

is

running.

II.

-2-

III. TIIIffi

A. Testing

The tiner can be tested

in

the

rnachine.

1. Disconnect

all wires frcm the tirner

terminals.

Refer to the

wiring diagram.

2. With

the timer

control

lorob in

the

rrwash"

area,

test between terminals

A & B

(wash

nrctor

circuit)

and

A

&

C

(spin

nntor circuit). Circuit

should

be cmplete.

3.

With

the timer

control

Imob

in

the

"drain"

area,

test between

terminals

A

& C,

Circuit

should

be

canplete.

4. Ttre

tinrer

nptor

can

be tested

with an

ohm meter

to the

clock terminals.

a.

A resistance reading

would

indicate a

good

timer.

b.

A corplete

circuit or no

circuit would

indicate a

defective

tiner

rnotor.

B.

leplacenent

1. Rernrve all

wiring frcn tiner.

2. Bernrve

retainer

frcrn

control

shaft and slide

enntrol

shaft off.

3.

Rernove four screws securing

timer bracket to

outer

she1l and

remove tiner

and bracket.

4. Renrove

two

screws

securing tirner

bracket

and

skirt to timer.

ry.

SPINNER

LID SI{ITCTI

A.

Creneral

Ttre

lid srpitch

is secured to

the upper

left

hand

corner

of the shelt

and

is operated by

a rod connected

to the

spin

lid hinge.

The

rod actuates the

lid switch

when

the

spin lid

is

closed.

ltris stdtch

also controls the

circuit

for

the electric

brake.

T.F. 26-22

-3-

1. The spin

lid srpitch controls

the

electric

brake

circuit. If

the

electric

brake

of

the

spin

mrtor

does not

operate,

yet

the

spin rnotor

runs,

the

probable

caLLse

is

due to

a

defective

lid switch.

2. The spin

1id

switch

should

always be tested for

correct operation rryhen

a spinner

nptor

is over-

heating.

B. Replacenent

I.

Open

the

spin lid

which

will

nxrve

the

actuator rod

out

of

the

rvay.

2,

Rernove the three screu/s wtrich

secure

the switch

bracket

to the

shell

and lift

out

the

switctr,

bracket,

spring

and

washers.

3. After

the

new switch is

installed, adjust

the bracket

to

close

the

sritch when

the

spin

Iid

is approximately

I"

to close.

V.

PT'I.SATOR

AI\ID. HCI'SING

(REIER

TO

FIG.

1)

A. C'eneral

The hou,sing

contains a bearing

for

the

pulsator

shaft and

a

nilcber

lip seal

to

prevent

water

leakage. A water leak

in

the area of

the

pulsator

will

indicate a worn

bearing

in

the

hou,sing. Always

replace both

the

housing and

pulsator

if

the bearing

is worn as then the

shaft of

the

pulsator

is

also

urcnx.

A scored

or worn

pulsator

shaft

will not hold a new

bearing.

The

pulsator

shaft

is

threaded

(L.H.)

on the end

for

installation

in the

pulley.

The wa.sher between the

pulley

and

housing

prevents

end

p1ay.

The

pulsator

nn:st

be snug

against

the hou,sing. E:<cessive

end

play

will

allottr clothing

to tangle behind the

pulsator.

B.

Replacerrent

1.

Rernove

the

rear

access

panel.

2. Rernove

pulsator

belt.

3.

Grasp

the

pulsator

and

pulley

and

turn

clocktvise

to

rernove

pu1ley.

T.F. 26-22

4-

4. Renrove

the nut

frsn

the hor-using.

If

the housing

turns,

grasp

the

hor.r,sing

with vise

grips

or channel

lock

pliers.

5.

Pull

the

cone

off

the

housing.

6. Rrsh

the

housing

out

into

the

tub.

7. Ctreck the

grrcxnnet

and

replace

if

worn or deteriorated.

8. Do not

overtighten

nut on

housing.

9.

Ctreeh

the disc

for wear

frqn

the

pulsator

and

if

wom,

replace.

lO.

When installing the

pulsator,

apply a

snal1

amount

of

grease

to

the

pulsator

shaft

so a-s

to

prevent

damage to the

lip seal

in the

housing.

VI.

ffIN

PT'LtEY

Ttre spin

pulley

rests

on a

nrbber

nnunt

fastened to the

frane.

A

bearing

is located

inside

the

pulley

and on

the rubber

rnopnt.

Spinner alignment

is adjr:^sted by

rnrving the

rubber

nnunt on

the

frane.

A. Replacenrent

-

Refer to

Fig.

2.

1. Rerncve the

rirn over

spin tub.

2. Bernrve

spin belt

fron

pulley.

The

rubber

rnxnt will

flex to

al1ow slack

in the

belt.

3.

Renrove the

bolt

in

the

spin

pul1ey

wtrich

holds the

spin can

shaft.

4. Slide the

spin can

out

and catch

the

washer

between

resilient

bearing

and

spin

pulley.

d.

Ttre

resilient bearing

is a nrbber

mount with

a bearing

for

the

spin

can

shaft.

T?ris bearing

should

not

be

lubricated.

Ttre

resilient bearing

is secured

in

place

by

a

wire

ring

lock under

the

spin

tub.

A noisy

spinner

can be

caused

by

a

bearing

in the

spin

pulley

or the

resilient

bearing.

T.F. 26-22

-5-

b.

A face

seal

is rncunted

in

the

resilient

bearing and the

courterface

is rmunted

on

the spin

can

shaft.

Ttris seal is

to

prevent

water leakge.

If

the

face

seal

is replaced,

the

c<,unterface

nust be

replaced also.

Rernove

the two bolts which

secure

the

rubber nnunt

to

the

frame

and renpve the spin

pulley

assembly.

To replace

the

rubber nount

assembly,

rennve

the

three

scre$/s fr"qn

the

retaining

ring

and

the

rubber

rnrunt

with

bearing can be

rernoved fron the

pulley.

In replacenent,

the bolt

in

the spin

pulley

which

secures

the

spin

can shaft

nn:st

be tight.

If

not,

the

spin

can

shaft will revolve in the spin

pulley

causing

noise and wear.

wr.

SPINNM ALIANI.,INM

ADruS'IIUEM

1.

Block machine

up

off

the

floor,

V€t

still level.

2. Rernove

the

spin

belt.

3.

Ioosen

the bolts securing the

nrbber

nrcunt

to the

frarne

so the nrbber

mount can be

rxlved

-

yet

snug

enough

so that it will stay

in

the

position placed.

4. Move

the nrbber

rnnrnt so that the top

of

the

spin

can

is

*"

off

center

toward the

rear of the

mactrine.

5.

Tighten

the

bolts to the

frame and

install

the

spin

belt"

Ttre

proper

belt tension

will draw the

spin

can

back to

center.

If

the spin

can

does

not

go

back to

center, the belt

is

too

loose.

If

the

spin

can

goes

too

far out

of center,

the

belt

is too tight.

Adjust spin

rnrtor for

proper

belt

tension

-

Paragraph

VIII.

T.F.26-22

5.

6.

7.

-6-

WII. PIN

Ir,f[OR

(Rffi'ER

TO

FIG. 3

)

A.

C'eneral

The spin nntor drives

the spinner

and

punp.

It

also

is

the

electric brake for

the

spin

can

and operated

thnough the lid

switctt.

The

rnctor

is nnunted in

slotted

holes

in

the

frarne. In

replacenent, slide the rrctor

away from

the

spin

pulley

rlntil spin

belt

is only

snq.

Do

not overtighten the

spin

belt or the spin can

rnay be

throrvn out

of alignment.

Refer

to

Paragraph

VII

on alignment

adjustment.

B. Testing

I.

A

resistance test

throWh

the

rnctor

should

read

6+ ohns.

2.

A

wattage reading of 300

watts with no load

in

the

spin

can

will

indicate

a

good

nntor.

C.

Disassembly

l. Rernove the

rnrtor fran

the

frarne.

2. Rerrcve hood.

3.

Rernove

carbon bnrshes

and check.

4. To rgncve the

armature, remove

the

four screu,s

dlich secure the support

and

end

plate

to the

ca.sing

and lift off the

ea.sing.

5. Grasp

the

arrnature

and

turn

the

pulley

counter-

clockw'ise

off

the

anmature

shaft.

6. Check the

fan

and

lorver bearing"

The

lower bearing

is

part

of the

end

plate

and

nn:st

be

lubricated

with

gnease.

7.

Ttre field coil

ls secured

in the

nrctor ca^sing by

two

scre\[E.

8. Ctreck

the upper

bearing

for wear.

The bearing

is

secured to

the casing

with rivets.

A new

bearing

can

be secured

with

blind

rivets.

T.F.

26-22

Loading...

Loading...