Page 1

CAUTION:

Read, understand and follow all safety rules and instructions before using this tool.

SOLD BY:

Kmart Corporation Troy, Michigan 48084

Variable Speed

Jig Saw

®

OWNER'S MANUAL

MODEL NO. BT400

Save this manual

for future reference

Form No. 389997-00 Cat. No. BT400 Printed in U.S.A.. SEP 01-2

389997 -00/BT400 Jig Saw 11/3/03 2:48 PM Page 1

Page 2

2

TABLE OF CONTENTS

WARRANTY

INTRODUCTION

FULL 2 YEAR WARRANTY ON

BENCHTOP

® VARIABLE SPEED JIG SAW

If this BENCHTOP

® Jig Saw is found to be defective in

materials or workmanship within 2 years from the date of purchase,

Kmart will replace the tool, free of charge.

WARRANTY REPLACEMENT IS AVAILABLE BY RETURNING

THE TOOL TO THE NEAREST KMART STORE ALONG WITH RECEIPT

SHOWING DATE OF PURCHASE.

This warranty does not include damage/defects caused by or resulting from

abuse, accidents, alterations or commercial use. It also does not cover

accessories. This warranty does give you specific legal rights, and you

may also have other rights which vary from state to state.

Kmart Corporation, 3100 Big Beaver Road, Troy, Michigan 48084

• Warranty / Introduction / Tool Specifications..............................................................................2

• General Safety Rules ..............................................................................................................3-6

• Additional Safety Rules ..............................................................................................................6

• Assembly/Set-Up ........................................................................................................................7

• Operating Instructions ............................................................................................................8-9

• Accessories ................................................................................................................................9

• Maintenance ..............................................................................................................................9

Your Jig Saw has many features that will make your job faster and easier.

Safety, performance and dependability have been given top priority in the

design of this tool, making it easy to maintain and operate.

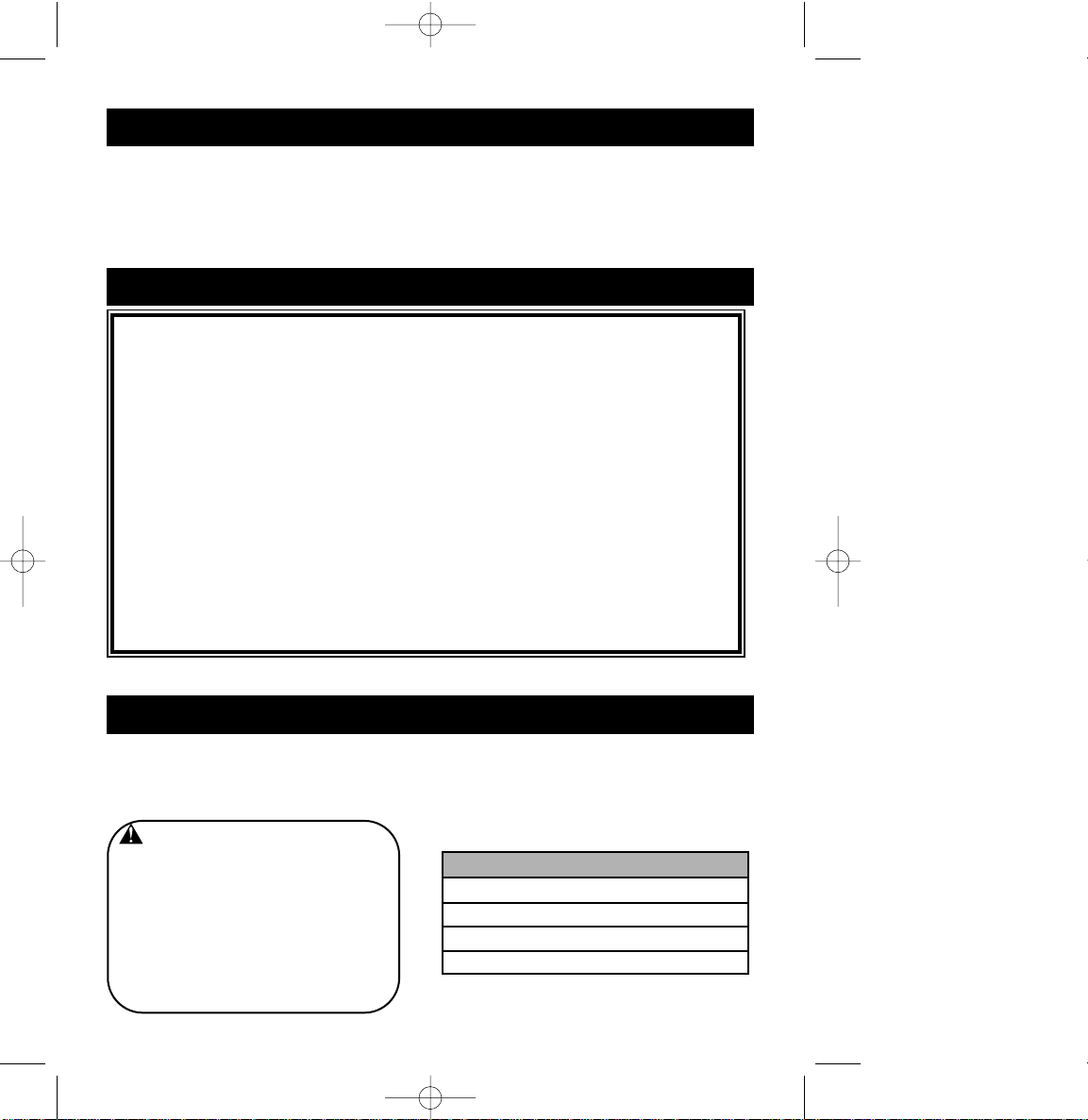

Bevel Capacity 45 degrees

Strokes per Minute 800-3,200 SPM

Voltage 120 Volts

Cutting Stroke 11/16"

SPECIFICATIONS:

For repair / replacement parts after warranty has expired, call: 1-800-544-6986

CAUTION:

Carefully read

through the entire manual before

attempting to use this tool. Be sure to

pay special attention to the Warnings

and Cautions on page 6 in this

manual. If you use the tool properly

and only for the operations for which

it was intended, you can enjoy years

of safe, dependable service from it.

389997 -00/BT400 Jig Saw 11/3/03 2:48 PM Page 2

Page 3

3

GENERAL SAFETY RULES (FOR ALL TOOLS)

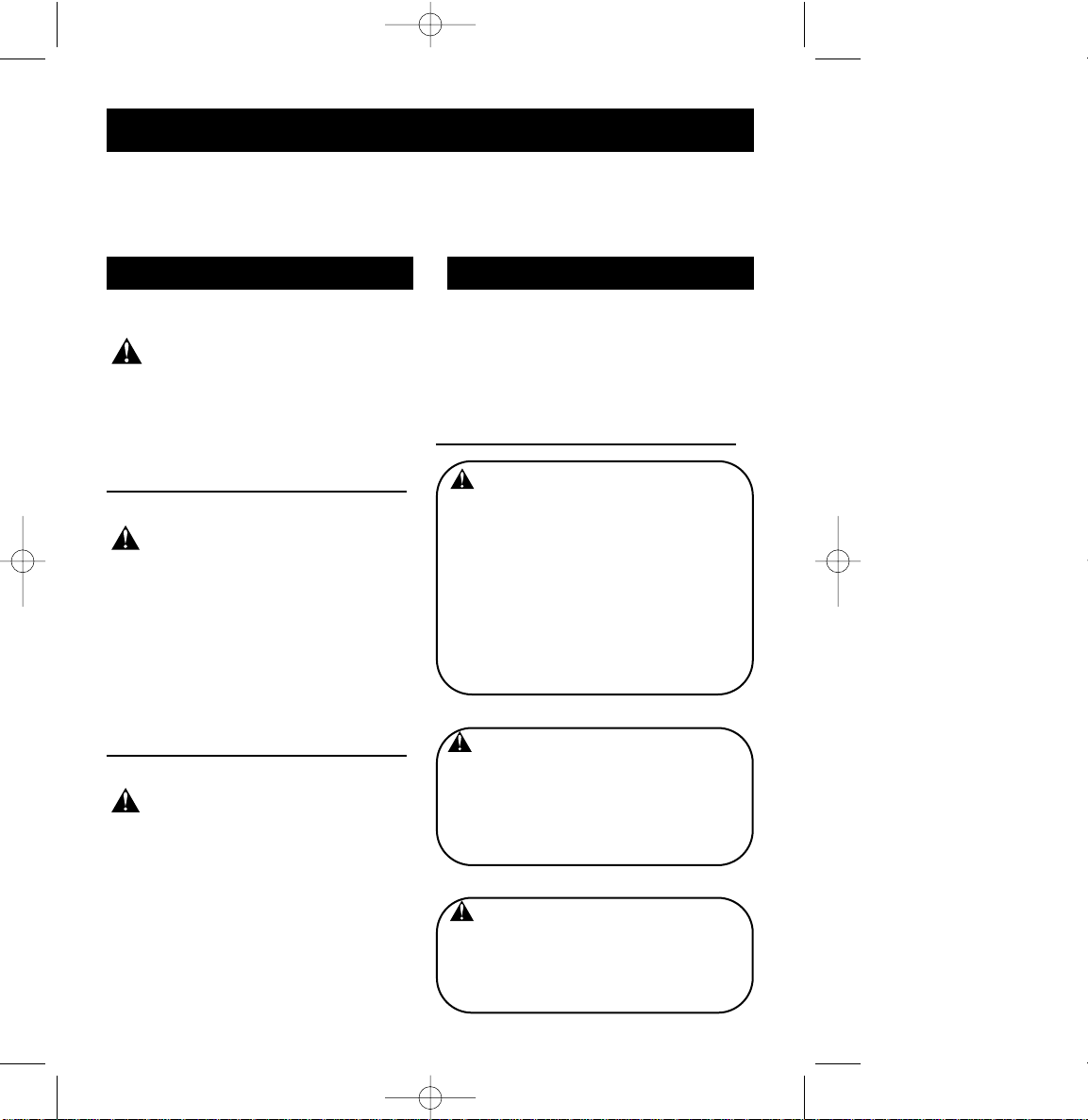

SYMBOL MEANING

The purpose of safety symbols is to immediately attract your attention to the possibility of danger. The following safety symbols and the explanations of them deserve

your careful attention and complete understanding. These safety warnings do not

eliminate any dangers on their own, and the instructions and warnings they give

should not be taken as substitutes for proper accident prevention measures.

SAFETY ALERT

SYMBOL Indicates

caution or warning.

May be used in

conjunction with

other symbols or

pictures/graphs.

WARNING

Failure to heed a

safety WARNING

can result in serious injury to

yourself or to others. Always follow

the safety precautions to reduce the

risk of fire, electric

shock and personal

injury.

CAUTION

Failure to heed a

safety CAUTION

can result in

property damage

or personal injury

to yourself or to

others. Always fol-

low the safety precautions to reduce

the risk of fire,

electric shock and

personal injury.

NOTE

Advises you of

information or

instructions that

are necessary in

the operation and

maintenance of the

tool.

WARNING:Do not attempt to

operate this tool until you have thoroughly

read and fully understand all the Safety

Rules, Rules For Safe Operation, and

Instructions and Information specific to the

safe operation of this tool. Failure to do so

can result in accidents involving serious

personal injury, fire or electric shock. Save

this manual and review it frequently for

safe operation and for instructing others

on the proper use of this tool.

WARNING: Do not attempt to

operate tool if any parts are missing.

Failure to do so could result in possible

serious personal injury. Do not use tool

if trigger switch does not turn it on or

off.

WARNING:

Do not allow familiarity

with the tool to make you careless in its

operation. Remember that it only takes a

careless fraction of a second to inflict

severe injury

.

SYMBOL MEANING

389997 -00/BT400 Jig Saw 11/3/03 2:49 PM Page 3

Page 4

4

WARNING! Read and understand

all instructions. Failure to follow all

instructions listed below may result in

electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

Work Area

✔ Keep your work area clean and well

lit. Cluttered benches and dark areas

invite accidents.

✔ Do not operate power tools in

explosive atmospheres, such as in

the presence of flammable liquids,

gases, or dust. Power tools create

sparks which may ignite the dust or

fumes.

✔ Keep bystanders, children, and visi-

tors away while operating a power

tool. Distractions can cause you to

lose control.

Electrical Safety

✔ Grounded tools must be plugged

into an outlet properly installed and

grounded in accordance with all

codes and ordinances. Never

remove the grounding prong or

modify the plug in any way. Do not

use any adaptor plugs. Check with

a qualified electrician if you are in

doubt as to whether the outlet is

properly grounded. If the tools

should electrically malfunction or

break down, grounding provides a low

resistance path to carry electricity

away from the user. Applicable only to

Class I (Grounded) tools.

✔ Double insulated tools are

equipped with a polarized plug (one

blade is wider than the other.) This

plug will fit in a polarized outlet

only one way. If the plug does not

fit fully in the outlet, reverse the

plug. If it still does not fit, contact a

qualified electrician to install a

polarized outlet. Do not change the

plug in any way. Double Insulation

eliminates the need for the three wire

grounded power cord and grounded

power supply system. Applicable only

to Class ll tools.

✔ Avoid body contact with grounded

surfaces such as pipes, radiators,

ranges and refrigerators. There is an

increased risk of electric shock if your

body is grounded.

✔ Don’t expose power tools to rain or

wet conditions. Water entering a

power tool will increase the risk of

electric shock.

✔ Do not abuse the cord. Never use

the cord to carry the tools or pull

the plug from an outlet. Keep cord

away from heat, oil, sharp edges or

moving parts. Replace damaged

cords immediately. Damaged cords

increase the risk of electric shock.

✔ When operating a power tool out-

side, use an outdoor extension

cord marked “W-A” or “W.” These

cords are rated for outdoor use and

reduce the risk of electric shock.

Personal Safety

✔ Stay alert, watch what you are

doing and use common sense

when operating a power tool. Do

not use tool while tired or under the

influence of drugs, alcohol, or medication. A moment of inattention while

operating power tools may result in

serious personal injury,

✔ Dress properly. Do not wear loose

clothing or jewelry. Contain long

hair. Keep your hair, clothing, and

GENERAL SAFETY RULES

IMPORTANT! READ ALL INSTRUCTIONS!

389997 -00/BT400 Jig Saw 11/3/03 2:49 PM Page 4

Page 5

5

gloves away from moving parts.

Loose clothes, jewelry, or long hair

can be caught in moving parts.

✔ Avoid accidental starting. Be sure

switch is off before plugging in.

Carrying tools with your finger on the

switch or plugging in tools that have

the switch on invites accidents.

✔ Remove adjusting keys or wrench-

es before turning the tool on. A

wrench or a key that is left attached to

a rotating part of the tool may result in

personal injury.

✔ Do not overreach. Keep proper

footing and balance at all times.

Proper footing and balance enables

better control of the tool in unexpected

situations.

✔ Use safety equipment. Always wear

eye protection. Dust mask, non-skid

safety shoes, hard hat, or hearing protection must be used for appropriate

conditions.

Tool Use and Care

✔ Use clamps or other practical way

to secure and support the workpiece to a stable platform. Holding

the work by hand or against your body

is unstable and may lead to loss of

control.

✔ Do not force tool. Use the correct

tool for your application. The correct

tool will do the job better and safer at

the rate for which it is designed.

✔ Do not use tool if switch does not

turn it on or off. Any tool that cannot

be controlled with the switch is dangerous and must be repaired.

✔ Disconnect the plug from the power

source before making any adjustments, changing accessories, or

storing the tool. Such preventive

safety measures reduce the risk of

starting the tool accidentally.

✔ Store idle tools out of reach of chil-

dren and other untrained persons.

Tools are dangerous in the hands of

untrained users.

✔ Maintain tools with care. Keep cut-

ting tools sharp and clean. Properly

maintained tools, with sharp cutting

edges are less likely to bind and are

easier to control.

✔ Check for misalignment or binding

of moving parts, breakage of parts,

and any other condition that may

affect the tools operation. If damaged, have the tool serviced before

using. Many accidents are caused by

poorly maintained tools.

✔ Use only accessories that are rec-

ommended by the manufacturer for

your model. Accessories that may be

suitable for one tool, may become

hazardous when used on another tool.

Service

✔ Tool service must be performed

only by qualified repair personnel.

Service or maintenance performed by

unqualified personnel could result in a

risk of injury.

✔ When servicing a tool, use only

identical replacement parts. Follow

instructions in the Maintenance

section of this manual. Use of unau-

thorized parts or failure to follow

Maintenance Instructions may create

a risk of electric shock or injury.

Specific Safety Rules

✔ Hold tool by insulated gripping sur-

faces when performing an operation where the cutting tool may

contact hidden wiring or its own

cord. Contact with a "live" wire will

make exposed metal parts of the tool

"live" and shock the operator.

GENERAL SAFETY RULES

IMPORTANT! READ ALL INSTRUCTIONS!

389997 -00/BT400 Jig Saw 11/3/03 2:49 PM Page 5

Page 6

6

ADDITIONAL SAFETY RULES: JIG SAWS

IMPORTANT! READ ALL INSTRUCTIONS!

WARNING:To reduce the risk of

serious personal injury, read, understand and follow all important safety

warnings and instructions prior to

using this tool.

The label on your tool may include the following symbols.

V ..............volts

A ..............amperes

Hz ............hertz

W ............watts

min ..........minutes

............alternating current

........direct current

n

o ............no load speed

.............

Class II Construction

.............earthing terminal

............safety alert symbol

.../min ......revolutions or

reciprocations

per minute

GENERAL SAFETY WARNINGS GENERAL SAFETY SYMBOLS

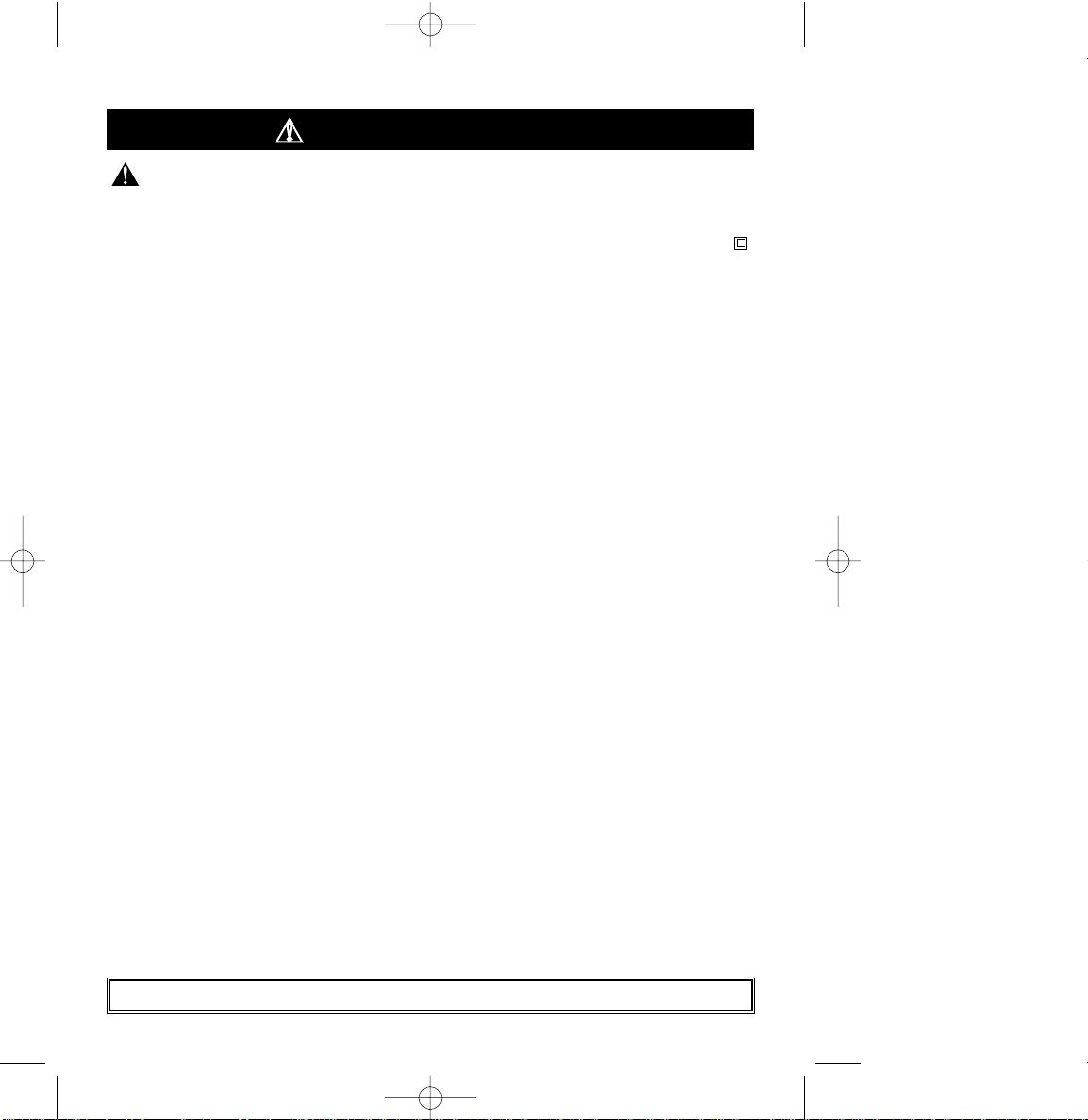

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more AWG

Than Than

0-6 18 16 16 14

6-10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

• KEEP HANDS AWAYfrom cutting

area. Never reach underneath the

material for any reason.

• KEEP BLADES SHARP . Dull blades

may cause the saw to swerve or stall

under pressure.

EXTENSION CORDS

When using an extension cord, be sure

to use one heavy enough to carry the

current your product will draw. An

undersized cord will cause a drop in line

voltage resulting in loss of power and

overheating. The following table shows

the correct size to use depending on

cord length and nameplate ampere

rating. If in doubt, use the next heavier

gauge. The smaller the gauge number,

the heavier the cord

MOTOR

Be sure your power supply agrees with

nameplate marking. 120 Volts AC only

means your drill will operate on standard

60 Hz household power. Do not operate

AC tools on DC. Arating of 120 volts

AC/DC means that your tool will operate

on standard 60 Hz AC or DC power.

This information is printed on the

nameplate. Lower voltage will cause

loss of power and can result in overheating. All BENCHTOP®tools are

factory-tested; if this tool does not

WARNING: Some dust created by power

sanding, sawing, grinding, drilling, and

other construction activities contains

chemicals known to cause cancer, birth

defects or other reproductive harm. Some

examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and

cement and other masonry prod

ucts, and

• arsenic and chromium from

chemically-treated lumber. (CCA)

Your risk from these exposures varies,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals: work in a well ventilated area,

and work with approved safety equipment,

such as those dust masks that are specially

designed to filter out microscopic particles..

389997 -00/BT400 Jig Saw 11/3/03 2:49 PM Page 6

Page 7

7

ASSEMBLY / ADJUSTMENT SET -UP

VARIABLE SPEED SWITCH

Before plugging your jig saw in, ensure

that the trigger switch is in the OFF

position.

To turn the saw on, squeeze the trigger

switch, as shown in Figure 3. The

speed of the saw is determined by how

much the trigger switch is depressed.

To turn the tool off, release the trigger

switch.

The tool can be locked on for

continuous operation by fully squeezing

and holding the trigger switch while you

depress the lock-on button shown in

Fig. 3. With the lock-on button

depressed, release the trigger switch

and the tool will continue to run. To

release from lock position, squeeze and

release the trigger. Always disengage

the lock before disconnecting from the

power supply. Do not overload your jig

saw as this could damage the motor.

Use your saw only for its intended

purpose.

operate, check the power supply.

INSTALLING BLADES

BEFORE INSTALLING BLADES, TURN

OFF AND UNPLUG TOOL.

Your jig saw uses the Quick Clamp™

blade changing system. To install a

blade, lift the Quick Clamp™ lever

(Figure 1). Ensure the blade teeth are

facing forward and insert the saw blade

shank fully into the blade clamp.

Release the lever and the blade will be

Blade Clamp Lever

1

clamped securely in place. To release

the blade, lift the lever.

ROLLER SUPPORT GUIDE

The roller support guide on your jig saw

improves its performance when cutting

tough materials by adding support to the

blade. This support should be adjusted

so that the roller touches the back of the

blade when cutting. Ensure the blade is

aligned with the groove in the roller.

Adjust the support roller by loosening

the screw on the bottom of the shoe

(Fig.2) and moving the shoe so that the

roller touches the back edge of the

blade. Retighten screw. Lubricating the

guide roller from time to time with a drop

of oil will extend the life of the roller.

Roller Support Guide

Screw

Shoe

2

Lock On Button

Trigger Switch

Blade Storage

Dust Blower

3

389997 -00/BT400 Jig Saw 11/3/03 2:49 PM Page 7

Page 8

8

BEVELADJUSTMENT

TURN OFF AND UNPLUG T OOL.

To adjust the bevel angle, loosen the

screw (approximately 3 full turns) on the

bottom of the shoe, as shown in Figure

2. Lift the shoe slightly and pull

backward, then set the shoe at 45° and

retighten screw. To reset the shoe for a

square cut, loosen the screw and move

the shoe until it is approximately 90° to

the blade. Adjust the blade support roller

to the blade and retighten the screw.

GENERAL CUTTING

Be sure board is firmly secured. Hold jig

saw by the handle and operate switch to

turn the unit on. Don’t attempt to turn on

the unit when blade is against material

to be cut. This could stall the motor.

Place front of shoe on material to be cut

and hold jig saw shoe down firmly

against the work surface while cutting.

Don’t force the tool; let the blade cut at

its own speed. Whenever possible,

clamp or support work close to the line

of cut; when the cut is completed, shut

off power and lay the saw aside before

loosening the work.

CUT LINE BLOWER

To aid visibility when cutting, your jig saw

is equipped with a cut line blower (Fig. 3)

which will keep the work area clear of

dust as you saw.

BLADE STORAGE

Aconvenient blade storage

compartment (Fig. 3) is provided at the

rear of the saw.

METAL& PLASTIC CUTTING

In cutting thin gauge sheet metals, it is

best to clamp wood or plywood to the

bottom of the metal sheet; this will

insure a clean cut without the danger of

vibration or tearing of metal. Use a finetooth blade for ferrous metals (for those

that have an iron content); and use a

coarser blade for nonferrous metals

(those that do not have an iron content).

Cutting thin metal will take longer than

cutting relatively thick wood so do not be

tempted to speed up the process by

forcing the saw. Spread a thin film of

cutting lubricant along the cutting line

(any light weight oil).

Use low speeds for cutting metals,

plastics and composition tile. When

cutting laminated plastic, place the

finished side down and use a fine tooth

hollow ground blade.

POCKET CUTTING

• Measure the surface to be cut and

mark clearly with a pencil. Next tip

the saw forward until the front edge

of the shoe sits firmly on the work

surface, but with the blade well clear

of it Figure 4.

•Turn the tool on and allow it to attain

maximum speed by fully depressing

the trigger switch.

• Grip the handle firmly and slowly

lower the back edge of tool until the

blade cuts smoothly into material. Do

not move the jig saw forward along

the cut line until the saw blade has

completely entered the material and

shoe comes to rest flat on its surface.

RIP & CIRCLE CUTTING

Ripping and circle cutting without a

pencil line are easily done with the rip

fence and circle guide (available at extra

cost).

OPERATING INSTRUCTIONS

4

389997 -00/BT400 Jig Saw 11/3/03 2:49 PM Page 8

Page 9

9

OPERATING INSTRUCTIONS

Using the screw supplied with the

accessory guide, position as shown in

Figure 5 and thread the screw into the

shoe to clamp the fence securely.

When circle cutting, adjust rip fence so

that distance from blade to hole in cross

bar is at the desired radius and tighten

screw (use hole which lines up best with

saw blade). Place saw so that hole in

cross bar is over center of circle to be

cut (make pocket cut, drill hole for blade

or cut inward from edge of material to

get blade into position). When saw is

properly positioned, drive a small nail

through hole in cross bar. Using rip

fence as a pivot arm, begin cutting

circle. For circle cutting, the cross bar

should be up, as shown in Figure 5.

When ripping, slide the rip fence under

the screw from either side of the saw.

Set the cross bar at desired distance

from blade and tighten screw. For

ripping, the cross bar should be down

and against the straight edge of the

workpiece.

TMTM

OPERATING INSTRUCTIONS

ACCESSORIES

Use only mild soap and damp cloth to clean the tool. Never let any liquid get inside

the tool; never immerse any part of the tool into a liquid.

MAINTENANCE

Kmart has a large selection of accessories for your Jig Saw for most any job

application around the home or in your

workshop.

CAUTION: Never use acces-

sories in your jig saw that are not

designed for use in your jig saw.

They may be hazardous and may

present a risk of injury to operator.

5

389997 -00/BT400 Jig Saw 11/3/03 2:49 PM Page 9

Page 10

MODELO NO. BT400

Conserve este manual

para referencias futuras

PRECAUCIÓN:

Lea, comprenda y siga todas las reglas e instrucciones de seguridad antes de

usar esta herramienta.

VENDIDO POR

Kmart Corporation Troy, Michigan 48084

Sierra Caladora

Velocidad variable

®

MANUAL DEL PROPIETARIO

389997 -00/BT400 Jig Saw 11/3/03 2:49 PM Page 10

Page 11

• Garantía / Introducción / Especificaciones ................................................................................2

• Reglas generales de seguridad..............................................................................................3-5

• Reglas adicionales de seguridad ..............................................................................................5

• Ensamblaje/Ajustes iniciales......................................................................................................7

• Instrucciones de operación ....................................................................................................8-9

• Accesorios..................................................................................................................................9

• Mantenimiento............................................................................................................................9

CONTENIDO

GARANTÍA

INTRODUCCIÓN

Su lijadora tiene varias características que ayudarán a hacer su trabajo de

manera más rápida y más sencilla. Seguridad, rendimiento y confiabilidad

han sido la máxima prioridad en el diseño de esta herramienta, haciendo de

ella una pieza de fácil mantenimiento y operación.

PRECAUCIÓN:

Lea cuidadosamente el manual

completo antes de intentar usar esta herramienta.

Asegúrese de prestar especial atención a las

“Advertencias y Precauciones” que se encuentran en las

página 6 , y todas las advertencias y avisos precautorios

que se encuentran a lo largo del manual. Si utiliza la

herramienta apropiadamente y solamente para las

operaciones para las que se diseñó, podrá disfrutar de

años de servicio seguro y confiable

.

ESPECIFICACIONES

Capacidad de bisel 45 grados

Golpes por minuto 800-3,200 GPM

Tensión de alimentación 120 V~

Carrera de corte 17,4 mm (11/16")

GARANTÍA COMPLETA POR 2 AÑOS

en la Sierra Caladora de BENCHTOP

®

Si esta sierra caladora BENCHTOP®resultase con defectos en los materiales o

mano de obra dentro de los 2 años siguientes a la fecha de compra, Kmart

reemplazará la herramienta, libre de cargo.

EL CAMBIO EN GARANTÍA ESTÁ DISPONIBLE DEVOLVIENDO

LA HERRAMIENTA A LA TIENDA KMART MÁS CERCANA JUNTO

CON EL RECIBO QUE MUESTRE LA FECHA DE COMPRA.

Esta garantía no cubre daños/defectos causados o resultantes de abuso,

accidentes, alteraciones o uso comercial. Tampoco cubre los accesorios.

Esta garantía le otorga derechos específicos, y usted puede tener

otros derechos que varían de estado a estado.

Kmart Corporation, 3100 Big Beaver Road, Troy, Michigan 48084

Para reparaciones o refacciones después de que la garantía haya expirado,

llame al: 1-800-544-6986

Tension de alimentación: 120V~

Potencia nominal: 357 W

Frecuencia de operación: 60 Hz

Consumo de corriente: 3,2 A

2

389997 -00/BT400 Jig Saw 11/3/03 2:49 PM Page 1

Page 12

3

REGLAS GENERALES DE SEGURIDAD

(PARA TODAS LAS HERRAMIENTAS)

El propósito de los símbolos de seguridad es atraer su atención inmediatamente a los posibles

daños. Los siguientes símbolos de seguridad y sus explicaciones merecen su atención cuidadosa y entendimiento completo. Estas advertencias de seguridad no eliminan ningún peligro

por sí mismas, y las instrucciones y advertencias no deben tomarse como sustitutos de las

medidas de prevención de accidentes apropiadas.

SÍMBOLO SIGNIFICADO

SÍMBOLO DE ALERTA

DE SEGURIDAD

Indica precaución o

advertencia. Puede

utilizarse junto con otros

símbolos o pictogramas.

NOTA

Le avisa de información

o instrucciones que son

necesarias para la

operación y

mantenimiento de la

herramienta.

ADVERTENCIA

Hacer caso omiso de

una ADVERTENCIA de

seguridad puede oca-

sionarle lesiones

graves a usted o a

otras personas. Siga

siempre las precau-

ciones de seguridad

para reducir el riesgo

de incendio, choque

eléctrico y lesiones per-

sonales.

PRECAUCIÓN

Hacer caso omiso de

una PRECAUCIÓN de

seguridad puede

resultar en daños a sus

propiedades o lesiones

personales a usted o a

otras personas. Siga

siempre las precauciones

de seguridad para reducir

el riesgo de incendio,

choque eléctrico y

lesiones personales.

ADVERTENCIA: No intente

operar esta herramienta hasta haber

leído y comprendido completamente

todas las Reglas de seguridad, Reglas

para la operación segura, e

Instrucciones e Información específica

para la operación segura de esta herramienta. No hacerlo puede resultar en

accidentes que involucren lesiones personales graves, incendios o choques

eléctricos. Conserve este manual y

revíselo con frecuencia para operar la

herramienta de manera segura y para

instruir a otras personas en el uso correcto de esta herramienta.

ADVERTENCIA: No intente

operar la herramienta si falta cualquier

parte. Hacerlo podría ocasionar una

lesión personal de gravedad. No use la

herramienta si el interruptor no

enciende y apaga.

ADVERTENCIA: No permita

que el familiarizarse con la herramienta

le haga perder cuidado en la operación.

Recuerde que sólo toma una fracción de

segundo descuidarse y provocar una

lesión grave.

389997 -00/BT400 Jig Saw 11/3/03 2:49 PM Page 2

Page 13

4

¡Importante! ¡Lea todas las instrucciones!

REGLAS GENERALES DE SEGURIDAD

(PARA TODAS LAS HERRAMIENTAS)

✔ CONOZCA SU HERRAMIENTA. Lea

cuidadosamente este manual del propietario. Aprenda las aplicaciones y limitaciones de su herramienta, así como los

peligros relacionados con ella.

✔ CONSERVE LIMPIA EL ÁREA DE TRA-

BAJO. las zonas y los bancos con objetos

acumulados en desorden propician los

accidentes.

✔ DE PRIORIDAD AL ÁREA DE TRABAJO.

• No exponga las herramientas eléctricas

a la lluvia.

• No use herramienta eléctricas en

lugares inundados o mojados.

• Conserve el área de trabajo bien iluminada.

• No se use en presencia de líquidos o

gases inflamables, Los motores de

estas herramientas producen chispas

en condiciones normales, y estas chispas pueden originar la ignición de los

vapores.

✔ PROTÉJASE CONTRA EL CHOQUE

ELÉCTRICO. Evite el contacto corporal

con superficies aterrizadas, por ejemplo:

tuberías radiadores, hornos, gabinetes de

refrigeración, etc. Tenga precaución

extrema cuando taladre, atornille o corte

en muros, pisos, techos u otras áreas en

que pueda hacer contacto con cables

eléctricos vivos, no toque ninguna parte

metálica de la herramienta. Sujete las herramientas únicamente por las

empuñaduras de plástico para evitar el

choque eléctrico.

✔ CONSERVE APARTADOS A LOS NIÑOS.

No permita que niños ni otros visitantes

toquen la herramienta ni los cables de

extensión. Todos los niños y visitantes

deben apartarse del área de trabajo.

✔ GUARDE LAS HERRAMIENTAS QUE

NO EMPLEE. Siempre que no use las he-

rramientas, debe guardarlas en un lugar

seco y elevado o bajo llave, fuera del

alcance de los niños.

✔ NO FUERCE LA HERRAMIENTA. Esta

hará el trabajo mejor y de manera más

segura bajo las especificaciones para las

que se diseñó.

✔ EMPLEE LA HERRAMIENT A

ADECUADA. No fuerce a una herramienta

pequeña o a sus dispositivos en una tarea

destinada a una herramienta de alto

rendimiento. No utilice la herramienta para

tareas para las que no ha sido diseñada.

✔ VÍSTASE DE MANERAADECUADA. No

utilice ropas sueltas ni joyas, pueden

quedar atrapadas en las partes móviles.

Se recomienda el uso de guantes y calzado antiderrapante cuando trabaje a la

intemperie. Cúbrase el cabello si lo tiene

largo.

✔ UTILICE GAFAS Y OTRO EQUIPO DE

SEGURIDAD. Utilice gafas o anteojos de

seguridad con cubiertas laterales, que

cumplan con los estándares de seguridad

aplicables y, cuando se requiera, una

careta. Utilice también una mascarilla contra polvo si la operación lo produce. Esto

se aplica a todas las personas que se

encuentren en el área de trabajo. Utilice

también casco, protección para los oídos,

guantes, calzado de seguridad y sistemas

de recolección de polvo cuando se especifique o así se requiera.

✔ NO MALTRATE EL CABLE. Nunca car-

gue la herramienta por el cable ni tire de

éste para desconectarlo de la toma de

corriente. Aléjelo de calor, aceite y bordes

afilados

389997 -00/BT400 Jig Saw 11/3/03 2:49 PM Page 3

Page 14

5

REGLAS GENERALES DE SEGURIDAD

(PARA TODAS LAS HERRAMIENTAS)

Calibre mínimo para cordones de extensión

Volts Longitud total del cordón en metros

120V 0-7.62 7.63-15.24 15.25-30.48 30.49-45.72

240V 0-15.24 15.25-30.48 30.49-60.96 60.97-91.44

AMPERAJE

Más No más Calbre del cordón

de de

0-6 18 16 16 14

6-1018 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 No Recomendado

✔ ASEGURE LAS PIEZAS DE TRABAJO.

Utilice prensas para sujetar su pieza de

trabajo; es más seguro que usar su mano

y le deja ambas manos libres para operar

la herramienta.

✔ NO SE SOBREEXTIENDA. Apoye bien los

pies y conserve el equilibrio siempre.

✔ CUIDE SUS HERRAMIENTAS. Conserve

sus herramientas limpias y afiladas para

un rendimiento mejor y más seguro. Siga

las instrucciones de lubricación y cambio

de accesorios. Revise los cables de extensión periódicamente y reemplácelos si

están dañados. Conserve las

empuñaduras secas, limpias y libres de

aceite y grasa.

✔ DESCONECTE LAS HERRAMIENTAS.

Desconecte la herramienta cuando no la

utilice, cuando la cambie de lugar, antes

de darle servicio y cuando le cambie accesorios (como brocas, puntas o cortadores)

o hacer ajustes.

✔ QUITE LAS LLAVES DE AJUSTE Y LAS

HERRAMIENTAS DE MANO.

Acostúmbrese a verificar que se hayan

retirado todas las llaves antes de encender la unidad.

✔ EVITE EL ENCENDIDO ACCIDENTAL. No

acarree la herramienta con el dedo en el

interruptor. Asegúrese que el interruptor

esté en posición de apagado antes de

conectar la unidad.

✔ CABLES DE EXTENSIÓN. Asegúrese que

su extensión esté en buenas condiciones.

Cuando utilice una extensión, asegúrese

que tenga el calibre suficiente para conducir la corriente que su herramienta

necesita. Una extensión con calibre menor

al necesario causará una caída en el

voltaje de la línea, resultando en pérdida

de potencia y sobre calentamiento. La

tabla siguiente muestra el calibre correcto

para usarse, de acuerdo con la longitud de

la extensión y el amperaje en la placa de

identificación. Si tiene dudas, utilice el calibre siguiente. Mientras menor sea el

número del calibre, mayor será la capacidad del cable.

✔ CABLES DE EXTENSIÓN PARAINTEM-

PERIE. Cuando utilice la herramienta a la

intemperie, utilice únicamente extensiones

destinadas para este uso y marcadas así.

✔ ESTÉ ALERTA. Concéntrese en lo que

hace. Utilice el sentido común. NO

OPERE LA HERRAMIENTAsi está cansado o discapacitado de alguna manera.

✔ REVISE LAS PARTES DAÑADAS. Antes

de seguir usando la herramienta, debe

revisar las guardas y otras partes para

determinar realizarán su función adecuadamente. Revise la alineación de las

partes móviles, la manera en que están

sujetas, que no haya piezas o soportes

rotos, y cualesquiera otras condiciones

que puedan afectar la operación. Si una

guarda u otra pieza se daña, regrese la

unidad a la tienda Kmart de su localidad

para obtener un reemplazo gratuito (aplica

durante la duración de la garantía, consulte la sección de la GARANTÍA al principio de este manual).

✔ USO DE ACCESORIOS Y DISPOSI-

TIVOS. El uso de accesorios y dispositivos

no recomendados para emplearse con

esta herramienta puede ser peligroso.

Las herramientas con doble aislamiento se

han construido con dos capas separadas de

aislamiento eléctrico o una de espesor doble

entre usted y el sistema eléctrico de la her-

389997 -00/BT400 Jig Saw 11/3/03 2:49 PM Page 4

Page 15

6

ADVERTENCIAS E INSTRUCCIONES DE SEGURIDAD:

DOBLE AISLAMIENTO

ADVERTENCIAS E INSTRUCCIONES DE SEGURIDAD:

CLAVIJAS POLARIZADAS

ADVERTENCIAS E INSTRUCCIONES DE SEGURIDAD:

SIERRAS CALADORAS

PRECAUCIÓN: Cuando corte en

muros, pisos o dondequiera que pudiese encontrar cables eléctricos vivos, NO TOQUE NINGUNA PARTE METÁLICA DE LA HERRA-MIENTA.

Sujete la herramienta únicamente por las superficies de sujeción aislantes para evitar el

choque eléctrico si corta un cable vivo.

PRECAUCIÓN: Algunas maderas con-

tienen conservadores como el arsenato cúprico

de cromo (CCA) que pueden ser tóxicos.

Cuando lije estos materiales, debe tener cuidado

extremo para evitar la inhalación y minimizar el

contacto de estas sustancias con la piel.

ADVERTENCIA: Para reducir el riesgo

de lesiones personales de gravedad, lea, comprenda y siga todas las advertencias e instrucciones importantes de seguridad antes de

emplear esta herramienta.

ramienta. Las herramientas fabricadas con este sistema de aislamiento no están diseñadas

para conectarse a tierra. Como resultado, su herramienta está equipada con una clavija de dos

patas que le permite emplear cables de extensión sin preocuparse por tener una conexión a

tierra.

El doble aislamiento no reemplaza a las precauciones básicas de seguridad al operar esta herramienta. El sistema de aislamiento brinda protección adicional contra las lesiones resultantes

de posibles fallas en el aislamiento eléctrico de la herramienta.

Se emplean clavijas polarizadas (con una pata más ancha que la otra) para reducir el riesgo

de choque eléctrico. Estas clavijas se ajustan a las tomas de corriente de una sola manera. Si

la clavija no se acopla completamente en la toma, inviértala. Si aún así no se ajusta, contacte

a un electricista calificado para que le instale el contacto adecuado. No modifique la clavija en

ninguna manera.

✔ UTILICE SIEMPRE PROTECCIÓN

EN LOS OJOS.

✔ Limpie su herramienta periódica-

mente.

NO SE RECOMIENDA el lijado de pinturas con base de plomo debido a la

dificultad para controlar el polvo contaminado. El mayor peligro de envenenamiento por plomo es para niños y

mujeres embarazadas.

Ya que es difícil identificar si una pintura

contiene plomo o no sin efectuar un

análisis químico, recomendamos tener

en cuenta las siguientes precauciones

cuando lije cualquier tipo de pintura:

NOTA: Sólo deben utilizarse mascaras

adecuadas para trabajo con polvo y

vapores de pintura. las mascaras ordinarias para pintura no ofrecen esta protección. Vea a su distribuidor de herramienta local para conseguir la más-

389997 -00/BT400 Jig Saw 11/3/03 2:49 PM Page 5

Page 16

7

ENSAMBLAJE/AJUSTES INICIALES

INSTALACIÓN DE SEGUETAS

ANTES DE INSTALAR UNASEGUETA,

APAGUE YDESCONECTE LA HERRAMIENTA.

Su sierra caladora utiliza el sistema de cambio de seguetas Quick Clamp™. Para instalar

una segueta, levante la palanca Quick

Clamp™ (Fig. 1). Asegúrese que los dientes

de la segueta apunten hacia adelante e

inserte completamente el vástago en el portaseguetas. Suelte la palanca y la segueta

habrá quedado asegurada en su posición.

Para sacar la segueta, levante la palanca.

GUÍA DE SOPORTE DE RODILLO

La guía de soporte de rodillo mejora el

rendimiento de su sierra al cortar materiales

resistentes al aumentar el apoyo a la segueta. El rodillo debe ajustarse de manera que

haga contacto con la parte posterior de la

segueta durante el corte. Asegúrese que la

segueta esté alineada con el canal del rodillo.

Ajuste el rodillo de soporte aflojando el tornillo de la parte inferior de la zapata, como se

muestra en la Figura 2 y moviendo el rodillo

hasta que casi toque, sin llegar a hacerlo, la

segueta. Apriete el tornillo con firmeza.

Lubricar el rodillo con una gota de aceite de

vez en cuando prolongará su duración.

INTERRUPTOR DE VELOCIDAD VARIABLE

Antes de conectar su sierra caladora,

asegúrese que el gatillo esté en posición de

apagado.

Para encender la sierra, oprima el gatillo

interruptor, como se muestra en la Figura 3.

La velocidad de la sierra está determinada

por qué tanto se oprima el gatillo. Para apagar la sierra, suelte el gatillo.

La herramienta puede asegurarse para

operación continua a cualquier velocidad al

oprimir el gatillo interruptor al mismo tiempo

que el botón de encendido permanente,

como se observa en la Figura 3. Una vez

oprimido el botón de encendido permanente,

podrá soltar el gatillo interruptor y la herramienta seguirá funcionando. Para apagar la

unidad desde esta posición, oprima y suelte

el gatillo interruptor una vez. Siempre desactive el botón de encendido permanente antes

de desconectar la sierra de la toma de corriente. No sobrecargue la sierra ya que esto

puede dañar el motor. Utilice su sierra solamente para lo que está destinada.

ADVERTENCIA: La operación de cualquier herramienta eléctrica

puede ocasionar que objetos extraños salgan despedidos hacia sus ojos, con

el consiguiente riesgo de lesiones oculares graves. Antes de empezar a operar

la herramienta, le recomendamos usar gafas de seguridad o anteojos de

seguridad con cubiertas laterales, y en caso necesario una careta.

GAFAS DE SEGURIDAD

PREVISÓN ES MEJOR

QUE SIN VISIÓN

UTILICE SUS

Palanca del

porta seguetas

Guía del rodillo de soporte

Tornillo

Zapata

1

2

389997 -00/BT400 Jig Saw 11/3/03 2:49 PM Page 6

Page 17

8

INSTRUCCIONES DE OPERACIÓN

AJUSTE DE BISEL

APAGUE Y DESCONECTE LA HERRAMIENTA

Suba o retire la cubierta contra polvo antes

de cortar a bisel.

Para ajustar el ángulo de biselado, afloje el

tornillo de la parte inferior de la zapata

(aproximadamente 3 vueltas completas),

como se observa en la figura 2. Tire de la

zapata ligeramente hacia atrás y colóquela a

45˚ y apriete de nuevo el tornillo. Para ajustar

la zapata de nuevo para corte a escuadra,

afloje el tornillo y mueva la zapata hasta que

quede aproximadamente a 90˚ con respecto

a la segueta. Ajuste el rodillo de soporte y

apriete el tornillo.

CORTE GENERAL

Asegúrese que la tabla esté firme. Sujete la

sierra caladora por el mango y oprima el

gatillo interruptor para encenderla. No intente

encender la unidad cuando la segueta esté

apoyada sobre la superficie de trabajo, esto

podría atascar el motor. Coloque el frente de

la zapata sobre el material que vaya a cortar

y presione la zapata con firmeza contra la

superficie de trabajo durante el corte. No

fuerce la herramienta; permita que la segueta

corte a su propia velocidad. Siempre que sea

posible, prense o apoye la pieza de trabajo

en un sitio cercano a la línea de corte; cuan-

do haya completado el corte, apague la sierra

y colóquela a un lado antes de soltar la pieza

de trabajo.

SOPLADOR EN LA LÍNEA DE CORTE

Su sierra caladora está equipada con un

soplador en la línea de corte (Fig. 3) para

conservar libre de polvo el área de corte

mientras usted trabaja.

COMPARTIMIENTO PARA SEGUETAS

En la parte trasera de la sierra (Fig. 3) hay un

compartimiento para que usted pueda

guardar seguetas adicionales de manera conveniente.

CORTE DE METALES Y PLÁSTICOS

Para cortar láminas metálicas delgadas, es

mejor prensar madera o madera contraplacada a la parte inferior de la lámina; esto asegurará un corte limpio sin el riesgo de que las

vibraciones desgarren el metal. Utilice una

segueta de dientes finos para metales ferrosos (aquellos con contenido de hierro) y

una segueta con dientes más grandes para

los metales no ferrosos (aquellos que no contienen hierro).

Cortar metal delgado llevará más tiempo que

cortar madera relativamente gruesa, de manera que no intente acelerar el proceso forzando la sierra. Distribuya una película delgada

de lubricante para corte a lo largo de la línea

de corte (cualquier aceite ligero) y consulte la

tabla de seguetas en este manual para seleccionar la segueta adecuada para su aplicación.

Utilice velocidades bajas para cortar metales,

plásticos y mosaico. Cuando corte laminados

plásticos, coloque la cara con el acabado

hacia abajo y utilice una segueta con dientes

cóncavos.

¡Importante! ¡Lea todas las instrucciones!

3

Soplador de polvo

Compartimiento para seguetas

Botón de encendido perma-

nente

Gatillo Interruptor

389997 -00/BT400 Jig Saw 11/3/03 2:49 PM Page 7

Page 18

9

INSTRUCCIONES DE OPERACIÓN

CORTE DE BOLSILLO

• Mida la superficie por cortar y márquela

claramente con lápiz. Incline a continuación la sierra hacia adelante hasta que

la parte frontal de la zapata asiente con

firmeza contra la superficie de trabajo

(Figura 4).

• Encienda la sierra y espere a que llegue a

la máxima velocidad oprimiendo a fondo el

gatillo interruptor.

• Sujete firmemente la empuñadura y haga

descender el borde posterior de la herramienta hasta que la segueta corte el

material con suavidad. Asegúrese que la

segueta alcance su profundidad máxima y

que la zapata esté completamente apoyada en la superficie antes de empezar el

corte.

CORTES DE TIRAS Y CIRCULARES

Los cortes al hilo y en círculo sin líneas

trazadas con lápiz se efectúan con facilidad

con el accesorio de corte al hilo y guía para

cortes circulares (disponible con cargo extra)

Utilice el tornillo que se suministra con el

accesorio. Coloque como se muestra en la

figura 5 y enrosque el tornillo lo suficiente

para sostener la guía en posición.

Cuando corte en círculo, ajuste la guía de

manera que la distancia de la segueta al orificio en la barra en cruz sea el radio deseado y

apriete el tornillo (utilice el orificio que se alinee mejor con la segueta). Coloque la sierra

de manera que el centro del agujero de la

barra en cruz quede en el centro del círculo

que desea cortar (haga un corte de bolsillo,

perfore un orificio para la segueta o corte

hacia adentro desde la orilla del material para

colocar en posición a la segueta). Cuando la

sierra este posicionada correctamente,

coloque un clavo delgado a través del agujero de la barra en cruz más cercano al centro del brazo. Utilizando la guía como brazo

de pivote, comience a cortar el círculo.

Para cortes en círculo, la barra en cruz debe

quedar hacia arriba, como se muestra en la

Figura 5. Deslice la guía para corte al hilo

debajo del tornillo desde cualquier lado de la

sierra. Coloque la barra en cruz a la distancia

deseada de la segueta y apriete el tornillo.

ACCESORIOS

Kmart cuenta con una gran selección de

accesorios para su sierra caladora para casi

cualquier aplicación que pueda requerir en su

casa o taller.

MANTENIMIENTO

Utilice únicamente jabón suave y un trapo

húmedo para limpiar la herramienta. Nunca

permita que se introduzca ningún líquido en

la herramienta; nunca sumerja ninguna parte

de la herramienta en un líquido.

TM

4

5

PRECAUCIÓN: Nunca utilice accesorios en su sierra caladora que no

estén diseñados para ella. Pueden ser

peligrosos o presentar riesgos de

lesiones para el operador.

389997 -00/BT400 Jig Saw 11/3/03 2:49 PM Page 8

Page 19

10

389997 -00/BT400 Jig Saw 11/3/03 2:49 PM Page 9

Page 20

PLACE

1ST CLASS

STAMP

HERE

PRODUCT REGISTRATION DEPARTMENT

3100 BIG BEAVER ROAD

TROY, MI 48084-3163

BENCHTOP

®

389997 -00/BT400 Jig Saw 11/3/03 2:49 PM Page 10

Page 21

OWNER REGISTRATION CARD

This is your owner registration card. Proper registration will enable us to contact you in the event any safety notifications are issued for this product.

First Name:

Address: (Number and Street) Apt. No.: City: State/Province CP/Zip

MI: Last Name: Company Purchased For: (Business use only)

Comments:

9) ❒ Router

10) ❒ Sander

Electric outdoor equipment

11) ❒ Edger

12) ❒ String Trimmer

13) ❒ Hedge T rimmer

14) ❒ Cordless shears

15) ❒ Lawn mower

16) ❒ Blower/vacuum

17) ❒ Other:

8. What other

BENCHTOP

products do you own?

1) ❒ Hammers 8) ❒ Screwdrivers

2) ❒ Layout tools 9) ❒ Sockets

3) ❒ Pliers 10) ❒ Wrenches

4) ❒ Leather Workgear 11) ❒ Measuring tools

5) ❒ Cutting tools 12) ❒ Hex keys

6) ❒ Saws 13) ❒ Worklights

7) ❒ Drills

7. Reasons for selecting this tool:

1) ❒ Unique features 5) ❒ Price

2) ❒ Brand name 6) ❒ Warranty

3) ❒ Availability 7) ❒ TV commercial

4) ❒ Quality 8) ❒ Received as a gift

10. Best description of product use:

1) ❒ On the job 2) ❒ Project in or around the home

1. Name: ❒ Mr. ❒ Mrs. ❒ Ms. ❒ Miss.

11. Please describe your level of experience:

1) ❒ Residential contractor/ tradesman

2) ❒ Non-residential contractor/ tradesman

3) ❒ Advanced/serious do-it-yourself projects

4) ❒ Intermediate/medium do-it-yourself projects

5) ❒ Occasional task/ light do-it-yourself projects

12. Education (Highest level attained):

1) ❒ High school 3) ❒ Graduate school

2) ❒ Some college 4) ❒ Completed college

14. Total household income:

1) ❒ Under $19,999

2) ❒ $20,000 - $49,999

3) ❒ $50,000 and over

16. In the last three (3) months have

you or your spouse purchased any

of the following products from Kmart:

1) ❒ KGRO 5) ❒ Kathy Ireland

2) ❒ BBQ Pro 6) ❒ Concourse

3) ❒ Jaclyn Smith 7) ❒ American Fare

4) ❒ Martha Stewart 8) ❒ B.A.S.S.

Kmart greatly values your feedback.

We appreciate and thank you for your

time in filling out this questionnaire.

6. Model #: Type of Power Tool:

Today's Date

2. Your date of Birth

Month Day Year

Month Day Year

4. Date of Purchase:

5. Location of Kmart store where purchased:

3. Phone:

( )

17. ❒ Check here if you do not want to receive

information from

Kmart on new products/

services

or opportunities.

9. Other power tools owned:

1) ❒ Corded drill

Cordless drill

2) ❒ Detachable battery

3) ❒ Built-in battery pack

4) ❒ Hammer drill

5) ❒ Cordless

screwdriver

6) ❒ Circular saw

7) ❒ Jig/sabre saw

8) ❒ Reciprocating saw

15. In the past three (3) months,

have you shopped at:

1) ❒ Kmart

2) ❒ Wal-Mart

3) ❒ Target

Which do you shop more frequently?

4) ❒ Sears

5) ❒ J.C. Penney

13. Excluding yourself, what are the ages

of the other people (in years) in your household?

Age of male(s):

Age of female(s):

BENCHTOP

®

®

389997 -00/BT400 Jig Saw 11/3/03 2:49 PM Page 11

Page 22

®

7) ❒ Taladros

TARGETA DE REGISTRO DEL PROPIETARIO

Esta es la targeta de registro del propietario. Registrarse apropiadamente nos permitirá contactarlo en el caso de algunas notificaciones

de seguridad concernientes a este producto.

Nombre:

Dirección (Número y calle): Apt. No. Ciudad Estado/prov. CP.

Inicial:

Apellido: Compañia para la que se compra (sólo para negocios)

Comentarios:

9) ❒ Rebajadora/fresadora

10) ❒ Lijadora

Equip Eléctrico para exterior

11) ❒ Cortadora/podadora

12) ❒ Recortadora de hilo

13) ❒ Podadora de setos

14) ❒ Tijeras inalámbricas

15) ❒ Cortadora de pasto

16) ❒ Sopladora/aspiradora

17) ❒ Otros:

8. ¿Que' otros productos

BENCHTOP

posee?

1) ❒ Martillos 8) ❒ Desarmadores

2) ❒

Herramientas para diseño

9) ❒ Llaves tipo dado

3) ❒ Alicates 10) ❒ Llaves para tuercas

4) ❒ Herramientas para 11) ❒ Herramientas de

trabajar en cuero medición

5) ❒

Herramientas para cortar

12) ❒ Llaves hexagonales

6) ❒

Sierras/serruchos/seguetas

13) ❒ Luces para trabajo

7. Razones para seleccionar esta herramienta

1) ❒ Características únicas 5) ❒ Precio

2) ❒ Marca 6) ❒ Garantía

3) ❒ Disponibilidad 7) ❒ Propaganda por TV

4) ❒ Calidad 8) ❒ Recibido como un regalo

10. Describir bien el uso que se le va a dar a la herramienta

1) ❒ En el trabajo 2) ❒ En el hogar

1. Nombre: ❒ Sr. ❒ Sra. ❒ Srta.

11. Por favor describir su nivel de experiencia

1) ❒ Contratista residencial/oficio

2) ❒ Contratista no residencial/oficio

3) ❒ Avanzado/proyectos medianos por mi mismo

4) ❒ Intermedio/proyectos medianos por mi mismo

5) ❒

Tareas ocasionales/proyectos sencillos por mi mismo

12. Educación (el nivel meas alto alcanzado)

1) ❒ Secundario 4) ❒ Educación

2) ❒ Algo de educación superior Superior completa

3) ❒ Graduado de la universidad

14. Total del ingreso familiar

1) ❒ Debajo de $19,000

2) ❒ $20,000 - $49,999

3) ❒ $50,000 y más

16. En los tres (3) meses pasados, usted

o su esposa (o) ¿han comprado alguno

de los siguientes productos de Kmart?

1) ❒ KGRO 5) ❒ Kathy Ireland

2) ❒ BBQ Pro 6) ❒ Concourse

3) ❒ Jaclyn Smith 7) ❒

American Fare

4) ❒ Martha Stewart 8) ❒ B.A.S.S.

Kmart valoriza sus comentarios. Nosotros

apreciamos y le agradecemos por su tiempo

en llenar este cuestionario.

6. Modelo #: Tipo de herramienta eléctrica

Fecha de hoy

2. Su fecha de

Nacimiento

Mes Día. Año

Mes Día. Año

4. Fecha de compra

5. Ubicación de la tienda Kmart donde compró

3. Teléfono

( )

17. ❒ Marque aquí si no desea recibir

información de Kmart sobre nuevos productos/

servicios u oportunidades.

9.

Otras herramientas eléctricas que poseen

1) ❒ Taladro con cordón

Taladro inalámbrico

2) ❒

Con batería removible

3) ❒

con batería incorporada

4) ❒

Taladro de percución

5) ❒ Desarmador

inalámbrico

6) ❒ Sierra circular

7) ❒ Caladora

8) ❒ Sierra reciprocante

15. En los tres(3) meses pasados,

ud. ¿Ha comprado en?

1) ❒ Kmart 4) ❒ Sears

2) ❒ Wal-Mart 5) ❒ J.C. Penney

3) ❒ Target

¿Donde compra ud. con más frecuencia?

13. Excluyéndose usted, ¿qué edad tienen las otras

personas (en años) en su hogar?

Edad de el (los) hombre (s)

Edad de la (las) mujer (es)

BENCHTOP

®

389997 -00/BT400 Jig Saw 11/3/03 2:49 PM Page 12

Page 23

PLACE

1ST CLASS

STAMP

HERE

PRODUCT REGISTRATION DEPARTMENT

3100 BIG BEAVER ROAD

TROY, MI 48084-3163

BENCHTOP

®

389997 -00/BT400 Jig Saw 11/3/03 2:49 PM Page 13

Loading...

Loading...