Sears 987.889,Craftsman 987.889000 Owner's Manual

I , r_ --.

OWNER'S

MANUAL

MODEL NO.

987.889000

,_ Caution:

Read and Follow

All Safety Rules

and Instructions

Before Operating

This Equipment,

CRAFTSMAN°

8 HORSEPOWER

33-INCH MOWER

• Assembly

• Operation

• Customer Responsibilities

• Service and Adjustments

• Repair Parts

Sears, Roebuck and Co., Hoffman Estates, Illinois 60179 U.S.A.

.FORM 1905122 (3/98)

SAFETY RULES

A AUTION: ALWAYS DISCONNECT SPARK PLUG WIRE AND PLACE WIRE WHERE IT

CANNOT CONTACT SPARK PLUG TO PREVENT ACCIDENTAL STARTING WHEN SET-

TING UP, TRANSPORTING, ADJUSTING OR MAKING REPAIRS,

IMPORTANT

Safe Operation Practices for Walk-Behind Mowers

This curing machine is capable of amputating hands and feet and tl_rowing objects. Fail-

ura to observe the following safety instructions could result in serious injury or death.

8,

WARNING:

The engine exhaust from this product

containschemicalsknownto the State of

Californiatocausecancer,birthdefects,or

otherreproductiveharm.

I. GENERALOPERATION

1.

Read, understand, and follow all instructions on the

machine and in the manuals. Be thoroughly familiar

with the controls and the proper use of the mower

before starting.

2. Do not put hands or feet near or under rotatingparts.

Keep clear of the mower blade and discharge open-

ing at all times.

3.' Only allow responsible individuals, who are familiar

with the instructions, to operate the mower.

4. Clear the area of objects such as rocks, _oys, wire,

bones, sticks, etc., which could be picked up and

thrown by the blade.

5. Be sure the area is clear of other people before

mowing. Stop mower if anyone enters the area.

Keep bystanders at least 25 feet away from the area

of operation.

6.

7.

Do not operate the mower when barefoot or wearing

open sandals. Always wear substantial foot wear.

Do not pull mower backwards unless absolutely nec-

essary. Look down and behind before and while

moving backwards.

.

10.

11.

Do not operate the mower without proper guards,

plates, grass catcher or other safety protective de-

vices in place.

Refer to provided instructionsfor proper operation

and installation of accessories. Only use acces-

sories approved by Sears, Roebuck and Co.

Stop the blade when crossing gravel drives, walks,

or roads.

Stop the engine and disconnect the spark plug wire

from the spark plug whenever you leave the unit, be-

fore cleaning the mower or unclogging the chute.

12. Shut the engine off, wait until the blade comes to a

complete stop, and disconnect the spark plug wire

before installing or removing the mulcher cover or

the optional grass catcher. Make certain that the

grass catcher is securely attached before operating

the mower. Empty the grass catcher after each use-

decomposing debris could generate enough heat to

catch fire.

13. Mow in daylight or good artificial light.

14. Do not operate the mower while under the influence

of alcohol or drugs.

15. Never operate mower in wet grass. Always be sure of

your footing; keep a firm hold on the handle and walk;

never run.

16. Disengage the Wheel Drive Lever on self-propelled

models before starting the engine.

17. If the unitshould start to vibrate abnormally, stop the

engine and disconnect the spark plug wire. Then

check immediately for the cause. Vibration is gener-

ally a warning of trouble.

I

,_ LOOK FOR THIS SYMBOL TO POINT OUT IMPORTANT SAFETY PRECAUTIONS. I

IT MEANS- ATTENTION!!! BECOME ALERT!I! YOUR SAFETY IS INVOLVED.

I

SAFETY RULES

18. Always wear safety goggles or safety glasses with

side shields when operating mower.

19. Watch for traffic when operating near, or when cross-

ing roadways.

20. Never attempt to carry children or other passengers

on the mower. They could fail off and be seriously in-

jured, or they could interfere with the safe operation

of the mower.

21.

Check the operation of the Operator Presence Con-

trol before each use. See the Customer Responsibili-

ties Section of this manual for instructions. Ifthe

mower blades rotate longer than three seconds after

the Operator Presence Control is released, the sys-

tem is not working properly. Immediately contact

your local Sears Service Center/Department for in-

structions. Do not use the mower until the mecha-

nism is repaired.

22.

The mower is equipped with a safety discharge

chute, comes with a special mulcher cover and offers

an optional grass catcher. The safety discharge

chute must be working properly at all times. Never

attempt to disconnect or otherwise cause this dis-

charge chute to cease working. If used, mulcher

cover or grass catcher attachment must be installed

properly and function correctly. Do not use your

equipment otherwise.

23.

Never runthe engine in an enclosed area. Engine ex-

haust contains carbon monoxide, a deadly gas that is

ododess, colodess, and tasteless. Always run the en-

gine outdoors and make sure there is adequate

ventilation.

II. SLOPEOPERATION

Slopes are a major factor related to slip and fall acci-

dents which can result in severe injury. All slopes

require extra caution. If you feel uneasy on a slope,

do not mow it.

DO:

Mow across the face of slopes; never up and down.

Exercise extreme caution when changing direction on

slopes. Avoid slopes greater than 15o.

Remove objects such as recks, tree limbs, etc.

Watch for holes, ruts, orbumps. Tall grass can hide

obstacles.

DO NOT:

Do not mow near drop-offs, ditches, or embankments.

The operator could loose footing or balance.

Do not mow excessively steep slopes.

Do not mow on wet grass. Reduced footing could

cause slipping.

III. CHILDREN

Tragic accidents can occur if the operator is not alert

to the presence of children. Children are often at-

tracted to the mower and to the mowing activity.

Never assume that children will remain where you

last saw them.

1. Keep children out of the mowing area and under the

watchful care of a responsible adult.

2. Be alert and turn mower off ifchildren enter the area.

3. Before and while moving backwards, look behind

and down for small children.

4. Never allow children to operate the mower.

5. Use extra care when approaching blind comers,

shrubs, trees, or other objects that may obscure

vision.

IV.SERVICE

.

2.

3

.

5.

Use extra care in handling gasoline and other fuels.

They are flammable and their vapors are explosive.

a) Use only an approved container.

b) Never remove gas cap or add fuel when the en-

gine is-running.Allow engine to cool before refu-

eling. Do not smoke.

c) Never refuel the machine indoors.

d) Never store the machine or fuel container inside

where there is an open flame, such as a water

heater, etc.

e) Move mower away from any gasoline fumes be-

fore starting the engine.

Never run an engine inside a closed area.

Never make adjustments or repairs with the engine

running. Disconnect the spark plug wire and keep

the wire away from the plug to prevent accidental

starting.

Keep all nuts and bolts, especially the blade attach-

ment bolts, tight and keep equipment in good condi-

tion.

Never tamper with safety device s. Check their opera-

tion regulady.

SAFETY RULES

6. Keep mower free of grass, leaves or other debds

build-up. Clean up oil or fuel spillage. Allow mower to

cool before storing.

7. After stdking an object, stop the engine and discon-

nect the spark plug wire. Inspect the mower and re-

pair, if necessary, before restarting.

8. Never attempt to mal_e mower cutting height adjust-

ments while the engine is running.

9. Grass catcher components are subject to wear, dam-

age and deterioration, which could expose moving

parts or allow objects to be thrown. Frequently check

components and replace with Sears recommended

parts, when necessary.

10. Mower blades are sha_rpand can cut. Wrap the blade

or wear gloves, and use extra caution when servicing

them.

11. Do notchange the engine govemor setting or over-

speed the engine.

12. Do nottouch engine parts which may be hot from

operation. Allow parts to cool completely before in-

specting, cleaning or repairing the mower.

13. To access the underside of the mower, tip the mower

rearward. Do not tip the mower forward or on either

of its sides, unless specifically advised to do so in

this manual.

14. Maintain or replace safety and instructional decals.

Refer to the Repair Parts Section for replacement

decal information.

4

CONGRATULATIONS on your purchase of a Craftsman

33-Inch Mower. It has been designed, engineered and

manufactured to give you the best possible dependability

and performance.

Should you experience any problems you cannot easily

remedy, please contact your nearest Sears Service

Center/Department. We have competent, well-trained

technicians and the proper tools to service or repair this

machine.

Please read and retain this manual. The instructions will

help you assemble and maintain your machine properly.

Always observe the "SAFETY RULES."

PRODUCT SPECIFICATIONS

HORSEPOWER: 8 HP

DISPLACEMENT: 19.43 CU. IN.

FUEL CAPACITY: 3 Quarts

SPARK PLUG (GAP .030-in.): Champion RJ-17LM

or equivalent

IGNITION "Electronic

NET ENGINE WEIGHT 57 LBS.

*InCanada,replacesparkplugwitharesistorplug.

MODEL NUMBER: 987.889000

SERIAL

NUMBER:

DATE OF

PURCHASE:.

THE MODELAND SERIAL NUMBERS WILL BE

FOUND ON A DECAL LOCATED RIGHT SIDE OF

THE MOWER DECK.

YOU SHOULD RECORD BOTH THE SERIAL NUM-

BER AND DATE OF PURCHASE AND KEEP IN A

SAFE PLACE FOR FUTURE REFERENCE.

MAINTENANCE AGREEMENT

A Sears maintenance agreement is available on this

product. Contact your nearest Sears store for details.

WARNING: This machine is equipped with an internal

combustion engine and should not be used on or near

any unimproved forest-covered, brush-covered or

grass-covered land unlessthe engine's exhaust system

is equipped with a spark arrester meeting applicable lo-

cal or state laws (if any). If a spark arrester is used, it

should be maintained in effective working order by the

operator.

In the state of California the above is required by law

(Section 4442 of the California Public Resources Code).

Other states may have similar laws. Federal laws apply

on federal lands. This engine is not equipped with a

spark arrestor for the muffler. A spark arrester for the

muffler is available through your nearest Sears autho-

rized service center. See the REPAIR PARTS section of

this manual.

CUSTOMER RESPONSIBILITIES

D Read and observe the safety rules.

O Follow a regular schedule in maintaining, caring for

and usingthis product.

O Follow the instructionsunder "CUSTOMER

RESPONSIBILITIES" and "STORAGE" sections of

this manual.

LIMITED TWO-YEAR WARRANTY ON CRAFTSMAN® POWER MOWER

Fortwo yearsfrom dateof purchase,whenthis Craftsman® Lawn Mowerismaintained,lubricated,andtuned upaccordingto the

operatingand maintenanceinstructions in the owner's manual,Searswill repairfree of chargeanydefectin material orworkmanship.

If this Craftsman® LawnMower is usedfor commercialor rentalpurposes,this warrantyappliesfor only 90 days from the date of

purchase.

THISWARRANTYDOESNOTCOVER:

• Expendableitemswhichbecome worn during normaluse,such asrotary mowerblades,bladeadanters,belts,air cleanersand

• Repairsnecessary becauseof ooeratorabuseor negligence,includingbentcrankshaftsandthefailureto maintainthe eouiDment

according to the instructionscontainedinthe owner's manual.

WARRANTYSERVICEISAVAILABLEBYRETURNINGTHE'CRAFTSMAN®MOWERTOTHENEARESTSEARSSERVICECENTER]DE-

PARTMENTINTHE UNITEDSTATES.THISWARRANTYAPPLIESONLYWHILETHISPRODUCTIS INUSEIN THEUNITEDSTATES.

This warrantygivesyou specificlegalrights,andyou may also haveotherrightswhichvaryfrom stateto state.

Oneyearwarranty on the following: #38700, #38607, #38712, #38720, #38721, #38725

TABLE OF CONTENTS

SAFETY RULES ................................................... 2

CUSTOMER RESPONSIBILITIES ................. 5, 23

PRODUCT SPECIFICATIONS .............................. 5

WARRANTY .......................................................... 5

-ACCESSORIES AND ATTACHMENTS ................ 7

ASSEMBLY ........................................................... 8

OPERATION ....................................................... 13

CUSTOMER RESPONSIBILITIES ................. 5, 23

SERVICE AND ADJUSTMENTS ........................ 26

STORAGE ........................................................... 34

TROUBLESHOOTING ........................................ 35

DECALS ................... ,.................... ;..................... 36

REPAIR PARTS - MOWER ................................. 37

REPAIR PARTS - ENGINE ................................. 46

PARTS ORDERING/SERVICE ........... Back Cover

INDEX

A

Accessories and Attachments .... 7

Adjustments:

Height of Cut .............. 15

Air Cleaner .................. 25

Assembly .................... 8

B

Blade:

Replacement ............. 32

Sharpening ................ 32

Blade Drive Control ........... 14

C

Carburetor .................. 26

Controls:

Blade Drive Control ......... 14

Cutting Height Lever ......... 15

Engine Throttle Control....... 16

Gear Select Lever........... 14

Operator Presence Control.... 13

Wheel Drive Control ......... 15

Customer Responsibilities:

Air Filter .................. 25

Blade Care/Replacement ..... 32

Engine ................. 24-25

Lubrication ................ 23

Spark Plug ................ 26

I}

Decals ..................... 36

E

Engine:

Air Filter .................. 25

Cleaning ................. 24

Oil ...................... 24

Operation ................. 13

Recoil Start Rope .......... 16

Spark Plug ................ 26

Storage .................. 34

F

Features/Controls ............ 13

Fuel Storage ............. 17, 34

Fuel Type ................... 17

G

Gear Select Lever ............ 14

!1

Handlebar:

Assembly .................. 9

I.

Lubrication:

Engine ................ 17, 23

Mower ................... 23

M

Maintenance:

Agreement .................. 5

Schedule ................. 23

Mowing Tips ................. 21

Mulching Cover ........... 15, 18

0

Off-Season Storage ........... 34

Oil ................... 17,23

Operation ................... 13

Operator Presence Control ..... 13

Op_ons ..................... 7

P

Parts List ................ 21-27

Product Specifications .......... 4

R

Recoil Start Rope ............ 16

Repair Parts ................. 37

Responsibilities, Customer ...5, 23

$

Safety Decals ............... 36

Safety Rules ................. 2

Service and Adjustments ....... 26

Spark Plug .................. 26

Specifications ................ 5

Starting/Stopping Engine ....... 19

Storage. ................... 34

T

Troubleshooting .............. 35

g

Unpacking ................... 8

W

Warranty .................... 5

Wheel Drive Control .......... 15

OPERATOR'S POSITION

All references in this Manual

to LEFT and RIGHT sides of

the mower are given from the

operator's position behind the

handlebars (unless specified

: otherwise).

6

ACCESSORIES AND AI IACHMENTS

These accessories and attachments were available when the mower was purchased. They are also available at most

Sears retail outlets, catalog and service centers. Most Sears stores can order repair parts for you when you provide

the model number of your unit.

ENGINE

Spark Plug

J

GasCan FuelStabilizer

Motor Oil

MOWER

GrassCatcher

Belt

Blade

7

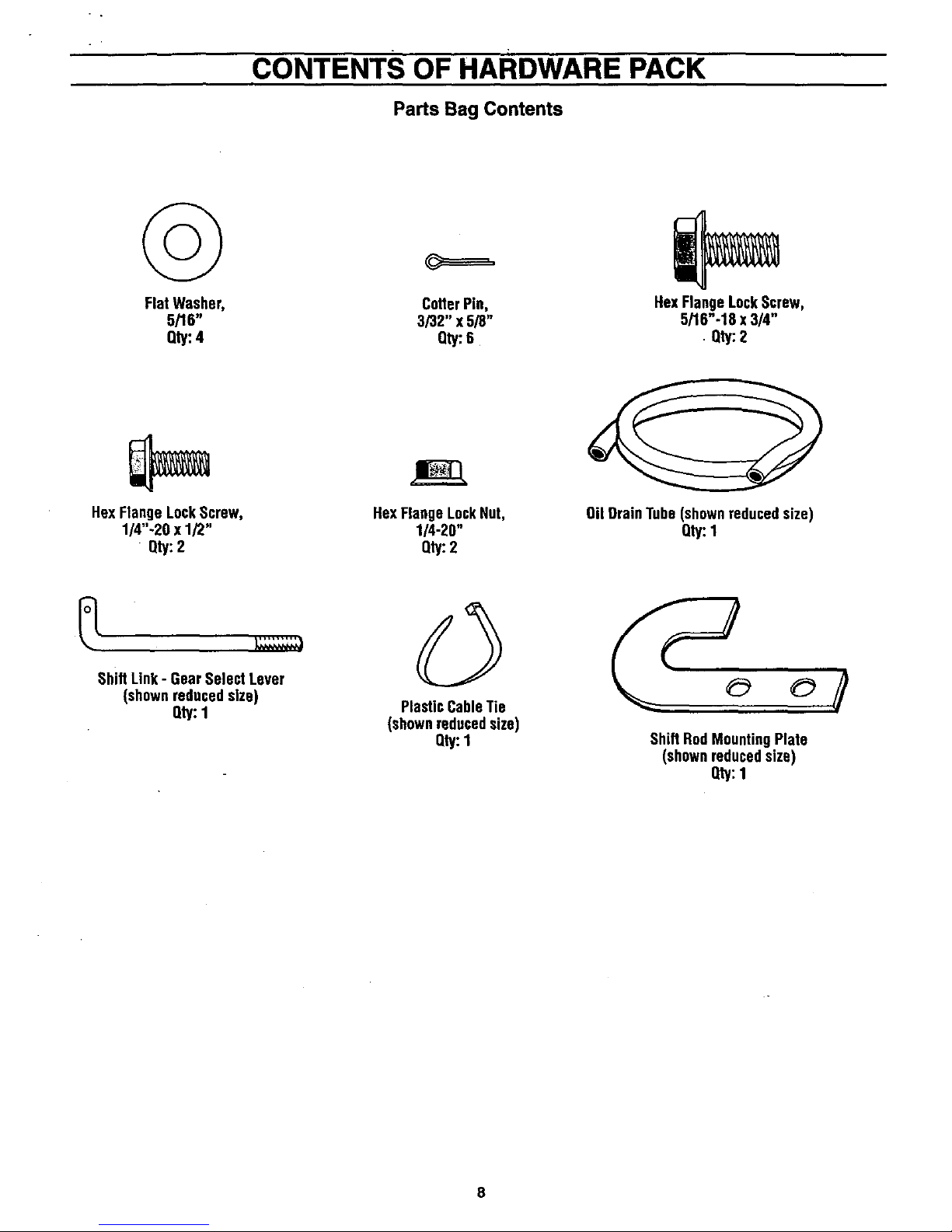

CONTENTS OF HARDWARE PACK

Parts Bag Contents

©

Flat Washer,

5/16"

Qty:4

CotterPin,

3/32" x 5/8"

Oty:6

HexFlangeLockScrew,

5/16"-18 x 3/4"

. Qty:2

HexFlangeLockScrew,

1/4"-20 x 1/2"

Qty:2

HexFlange LockNut,

1/4-20"

Qty:2

Oil DrainTube (shownreducedsize)

Qty:1

ShiftLink- GearSelectLever

(shownreducedsize)

Qty:1

PlasticCableTie

(shownreducedsize)

Qty:1 Shift RodMountingPlate

(shownreducedsize)

Qty:1

ASSEMBLY

Read these instructionsin their en-

tirety before you attempt to assem-

ble or operate your new equipment.

Your new equipment has been as-

sembled at the factory with the ex-

ception of those parts left unassem-

bled for shippingpurposes. To en-

sure safe and proper operation of

your machine, all parts and hard-

ware you install or adjust must be

tightened according to the assem-

bly instructions. Use the correct

tools as necessary to ensure proper

tightness..

ToolsNeededForAssembly:

• (1) 7/16" Wrench

• (1) 3/8" Wrench

• (2) 1/2" Wrenches

• (1) Needle-nose Pliers

• (1) Wire Cutter Pliers

• (1) Tire.Gauge

• (1) Scissors or Pen Knife

UNPACKING

INSTRUCTIONS

• Inspect your machine immediate-

ly. Be sure neither the carton nor

contents have been damaged. If

you find or have reason to sus-

pect damage, contact your near-

est Sears Service Center/Depart-

ment for assistance.

• Cut plastic banding with scissors.

Open box flaps and remove any

packing material from around the

machine. Remove any staples

securing bottom of carton to wood

pallet. Lift off carton. Cut metal

straps secudng unitto base.

Leave unit on base of pallet dur-

ing assembly steps (to safely re-

move unit from base, wait until

you have completed assembly

steps 1-2). Before disposing of

the carton or any of the packing

materials, be sure to check them

thoroughly for any small parts.

• Cut plastic tie straps holding three

long control rods to handlebars.

Also remove any packaging

around the handlebars.

• Perform the assembly on a clean,

level surface. If you need to

move the machine, be careful not

to severely bend any of the con-

trol cables on the equipment.

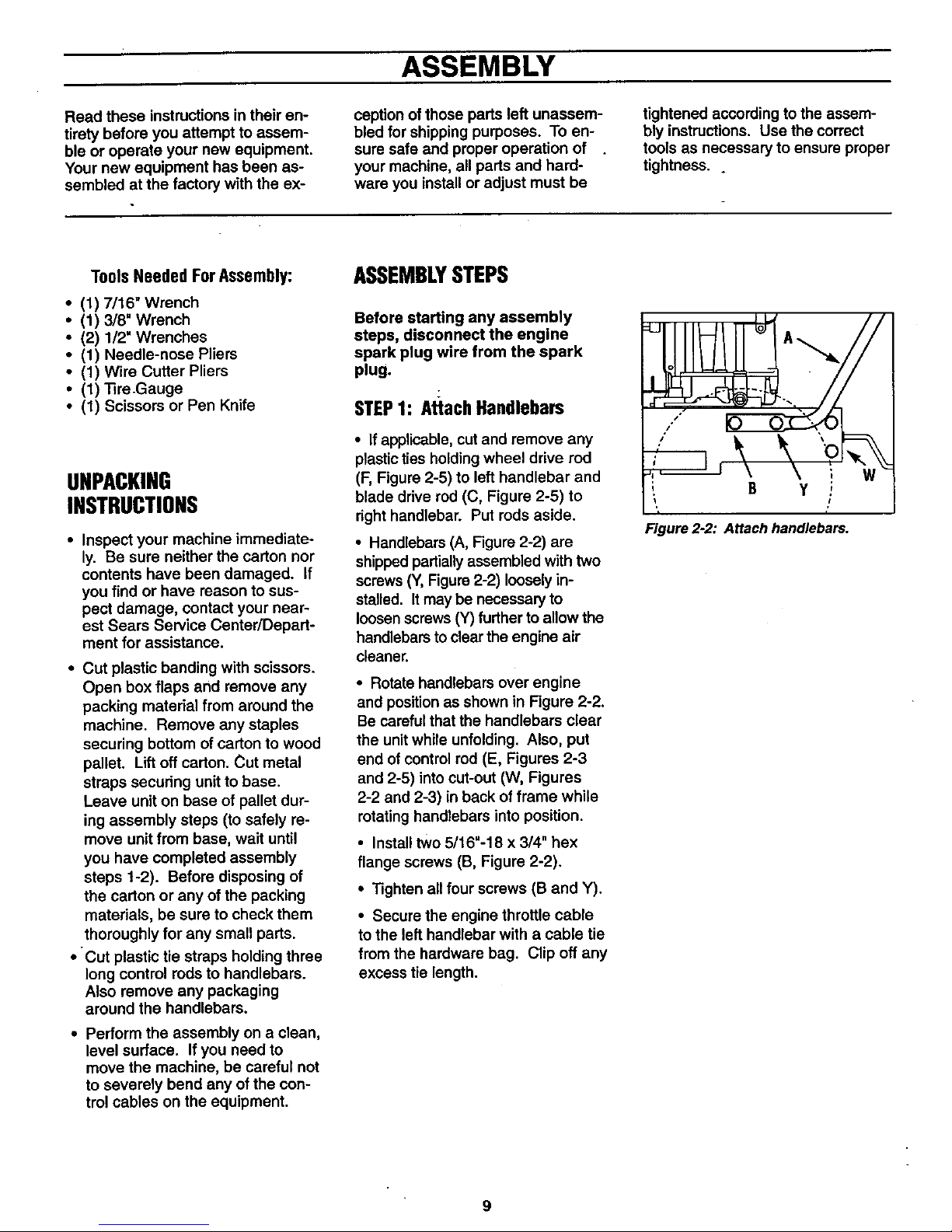

ASSEMBLYSTEPS

Before starting any assembly

steps, disconnect the engine

spark plug wire from the spark

plug.

STEP1: AttachHandlebars

• If applicable, cut and remove any

plastic ties holdingwheel drive rod

(F, Figure 2-5) to left handlebar and

blade ddve rod (C, Figure 2-5) to

right handlebar. Put rods aside.

• Handlebars (A, Figure 2-2) are

shippedpartially assembled with two

screws (Y,Figure2-2) loosely in-

stalled. It may be necessary to

loosen screws (Y) further to allow the

handlebars to clear the engine air

cleaner.

• Rotate handlebars over engine

and position as shown in Figure 2-2.

Be careful that the handlebars clear

the unit while unfolding. Also, put

end of control rod (E, Figures 2-3

and 2-5) into cut-out (W, Figures

2-2 and 2-3) in back offrame while

rotatinghandlebars into position.

• Install two 5/16"-18 x 3/4" hex

flange screws (B, Figure 2-2).

• Tighten all four screws (B and Y).

• Secure the engine throttle cable

tothe left handlebar with a cable tie

from the hardware bag. Clip off any

excess tie length.

, B Y ,

Figure 2-2: Attach handlebars.

9

ASSEMBLY

STEP2: AttachControlRods

WARNING

The controlrodsare adjusted

at the factory and should not

require additional adjustment

during assembly. After as-

sembling unit, controlrodad-

justment should be checked

(and re-adjusted, if neces-

sary) accordingto information

in "Customer Responsibili-

ties" Section. Severe person-

a] injury or property

damage could result from

not following this

instruction.

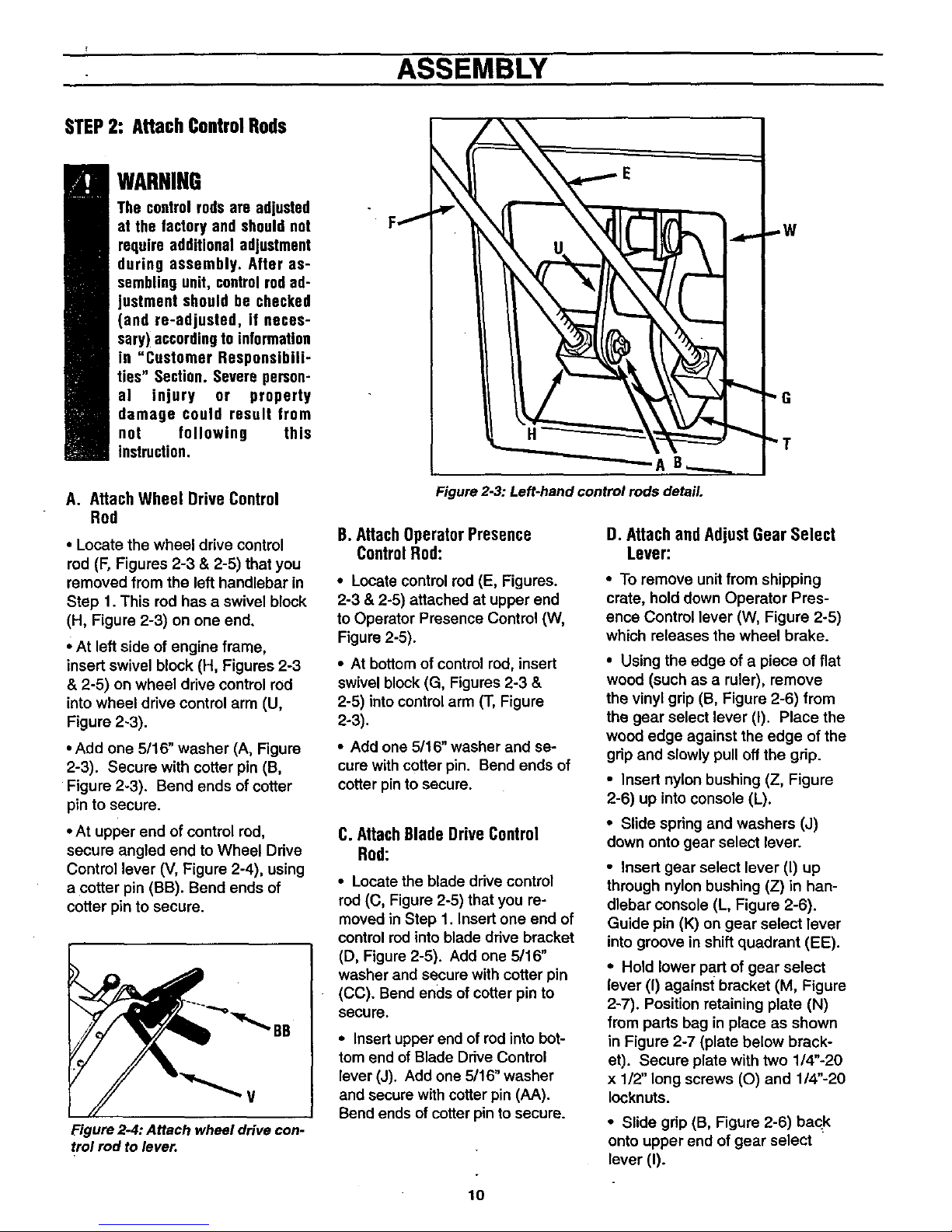

A. AttachWheel DriveControl

Rod

• Locate the wheel drive control

rod (F, Figures 2-3 & 2-5) that you

removed from the left handlebar in

Step 1. This rod has a swivel block

(H, Figure 2-3) on one end.

• At left side of engine frame,

insert swivel block (H, Figures 2-3

& 2-5) on wheel drive control rod

intowheel drive control arm (U,

Figure 2-3).

• Add one 5/16" washer (A, Figure

2-3). Secure with cotter pin (B,

Figure 2-3). Bend ends of cotter

pin to secure.

• At upper end of control rod,

secure angled end to Wheel Drive

Control lever (V, Figure 2-4), using

a cotter pin (BB). Bend ends of

cotter pin to secure.

B

V

Figure 2-4: Attach wheeldrive con-

trolrod to lever.

AB

Figure2-3: Left-handcontrol rods detail.

B. AttachOperatorPresence

ControlRod:

• Locate control rod (E, Figures.

2-3 & 2-5) attached at upper end

to Operator Presence Control (W,

Figure 2-5).

• At bottom of control rod, insert

swivel block (G, Figures 2-3 &

2-5) into control arm (T, Figure

2-3).

• Add one 5/16" washer and se-

cure with cotter pin. Bend ends of

cotter pinto secure.

C.AttachBladeDriveControl

Rod:

• Locate the blade drive control

rod (C, Figure 2-5) that you re-

moved in Step 1. Insert one end of

control red intoblade drive bracket

(D, Figure 2-5). Add one 5/16"

washer and secure with cotter pin

(CC). Bend ends ofcotter pin to

secure.

• Insert upper end of rod into bot-

tom end of Blade Drive Control

lever (J). Add one 5/16" washer

and secure with cotter pin (AA).

Bend ends of cotter pin to secure.

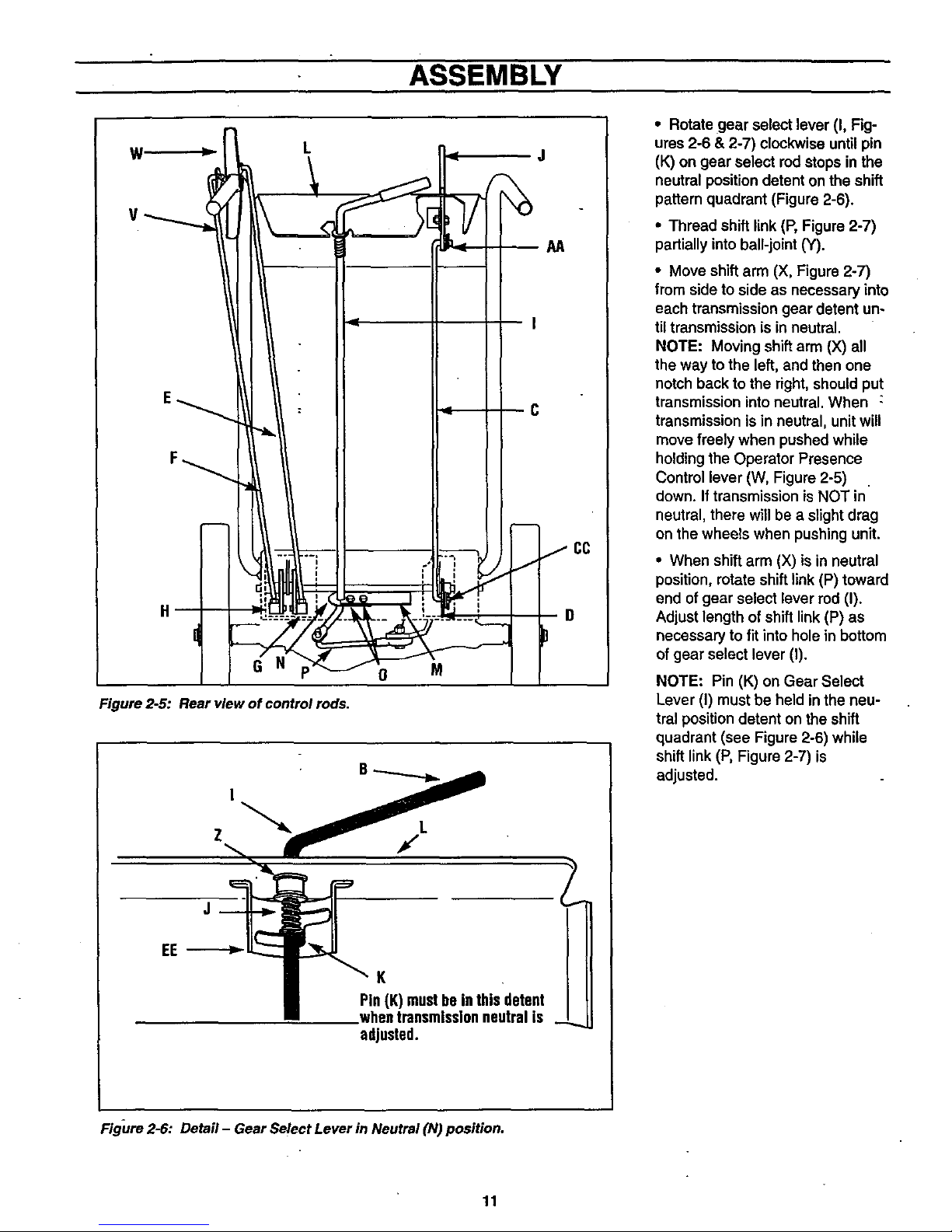

D. AttachandAdjustGear Select

Lever:

• To remove unit from shipping

crate, hold down Operator Pres-

ence Control lever (W, Figure 2-5)

which releases the wheel brake.

• Using the edge of a piece of flat

wood (such as a ruler), remove

the vinyl grip (B, Figure 2-6) from

the gear select lever (I). Place the

wood edge against the edge of the

grip and slowly pull off the grip.

• Insert nylon bushing (Z, Figure

2-6) up into console (L).

• Slide spring and washers (J)

down onto gear select lever.

• Insert gear select lever (I) up

through nylon bushing (Z) in han-

dlebar console (L, Figure 2-6).

Guide pin (K) ongear select lever

intogroove inshift quadrant (EE).

• Hold lower part of gear select

lever (I) against bracket (M, Figure

2-7). Position retaining plate (N)

from parts bag in place as shown

in Figure 2-7 (plate below brack-

et). Secure plate with two 1/4"-20

x 1/2" long screws (O) and 1/4"-20

Iocknuts.

• Slide grip (B, Figure 2-6) back

onto upper end of gear select

lever (I).

10

ASSEMBLY

Figure 2-5: Rear view of control rods.

0 M

D

P

Pin(K) mustbe in this detent

whentransmissionneutral is _

adjusted.

• Rotate gear select lever (I, Fig-

ures 2-6 & 2-7) clockwise until pin

(K) on gear select rod stops in the

neutral position detent on the shift

pattern quadrant (Figure 2-6).

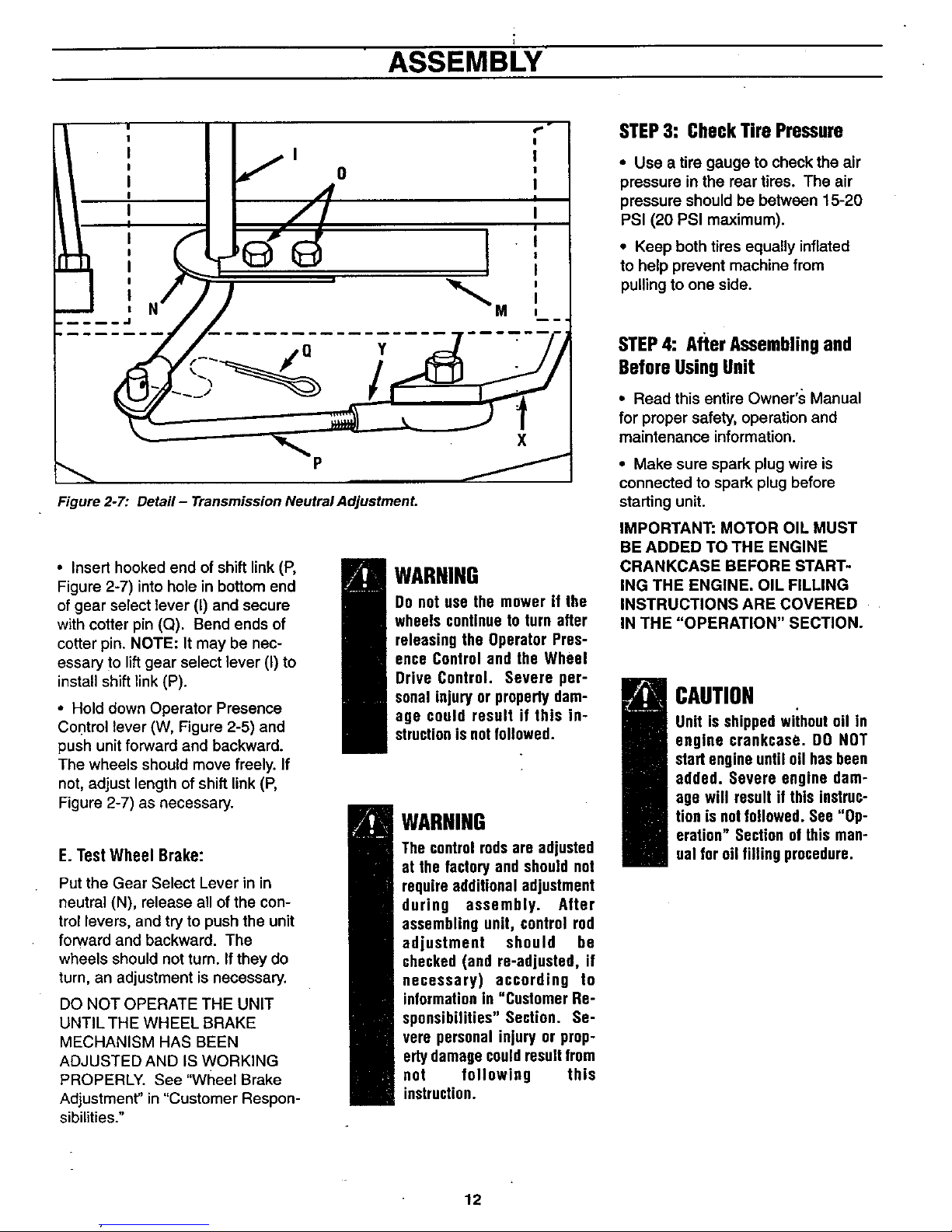

• Thread shift link (P, Figure 2-7)

partiallyinto ball-joint (Y).

• Move shift arm (X, Figure 2-7)

from side to side as necessary into

each transmissiongear detent un-

tiltransmission is in neutral.

NOTE: Moving shift arm (X) all

the way to the left, and then one

notch back to the right, shouldput

transmission into neutral. When :

transmission is inneutral, unit will

move freelywhen pushed while

holdingthe Operator Presence

Control lever (W, Figure 2-5)

down. If transmission is NOT in

neutral, there will be a slight drag

on the wheels when pushingunit.

• When shift arm (X) is in neutral

position, rotate shift link (P) toward

end of gear select lever rod (I).

Adjust length of shift link (P) as

necessary to fit into hole in bottom

of gear select lever (I).

NOTE: Pin (K) on Gear Select

Lever (I) must be held in the neu-

tral positiondetent on the shift

quadrant (see Figure 2-6) while

shift link(P, Figure 2-7) is

adjusted.

Figure2-6: Detail - Gear SelectLever in Neutral (N) position.

11

ASSEMBLY

I

I

I

!

I

I

I

I

I

I

I

I

I

!

!

I

!

I

I

!

I

P

Figure 2-7: Detail- TransmissionNeutralAdjustment.

• Insert hooked end of shift link (P,

Figure 2-7) into hole in bottom end

of gear select lever (I) and secure

with cotter pin (Q). Bend ends of

cotter pin. NOTE: It may be nec-

essary to lift gear select lever (I) to

install shift link (P).

* Hold down Operator Presence

Control lever (W, Figure 2-5) and

push unit forward and backward.

The wheels should move freely. If

not, adjust length of shift link (P,

Figure 2-7) as necessary.

E.TestWheel Brake:

Put the Gear Select Lever in in

neutral (N), release all of the con-

trol levers, and try to push the unit

forward and backward. The

wheels should not turn. if they do

turn, an adjustment is necessary.

DO NOT OPERATE THE UNIT

UNTIL THE WHEEL BRAKE

MECHANISM HAS BEEN

ADJUSTED AND IS WORKING

PROPERLY. See "Wtleel Brake

Adjustment" in "Customer Respon-

sibilities."

WARNING

Do not use the mower if the

wheels continueto turn after

releasing the Operator Pres-

ence Control and the Wheel

Drive Control. Severe per-

sonal injury or property dam-

age could result if this in-

structionis notfollowed.

WARNING

The controlrodsare adjusted

at the factoryand shouldnot

requireadditionaladjustment

during assembly. After

assembling unit, control rod

adjustment should be

checked (and re-adjusted, if

necessary) according to

informationin "Customer Re-

sponsibilities" Section. Se-

vere personal injury or prop-

ertydamagecouldresultfrom

not following this

instruction.

STEP3: CheckTire Pressure

• Use a tire gauge to check the air

pressure in the rear tires. The air

pressure should be between 15-20

PSI (20 PSI maximum).

• Keep both tires equally inflated

to help prevent machine from

pullingto one side.

STEP4: After Assemblingand

BeforeUsingUnit

• Read this entire Owner's Manual

for proper safety, operation and

maintenance information.

• Make sure spark plug wire is

connected to spark plug before

starting unit.

IMPORTANT: MOTOR OIL MUST

BE ADDED TO THE ENGINE

CRANKCASE BEFORE START-

ING THE ENGINE. OIL FILLING

INSTRUCTIONS ARE COVERED

IN THE "OPERATION" SECTION.

CAUTION

Unit is shippedwiihoutoil in

engine crankcase. DO NOT

startengineuntil oil hasbeen

added. Severe engine dam-

age will result if this instruc-

tion isnot followed. See"Op-

eration" Sectionof this man-

ual for oil filling procedure.

12

OPERATION

KNOWYOUREQUIPMENT

READ THIS OWNER'S MANUALAND ALL SAFETY RULES BEFORE OPERATING YOUR EQUIPMENT. Know the

location and function of all features and controls on the equipment. Save this manual for future reference.

MEETS ANSI B71.1 - 1996

SAFETY STANDARD

This machine meets voluntary

safety standard B71.1 - 1996,

which is sponsored by the Outdoor

Power Equipment Institute, Inc.,

and is published by the American

National Standards Institute, Inc.

Operating Symbols

Various symbolsare used on the

mower to indicate control settings

(yourmodel may not have all of the

symbols). These symbols are

shown below with a description of

theirmeaning.

FAST SLOW CHOKE

ENGINE ENGINE ENGINE

STOP START RUN

ENGAGE DISENGAGE

IMPORTANT: The mower is

equipped with a blade-brake-clutch

controlsystem which is designed

to stopthe mower blades within

three (3) seconds after release of

the Operator Presence Control.

This system will stop the blades

but not the engine. Therefore, you

can disengage the blade drive at

anytime without having to stop and

restart the engine. This feature is

particularly useful when you need

to crossgravel drives or rough ter-

rain and you do not want the spin-

ning blades to strike stones or hid-

den obstacles.

WARNING

The blade-brake-clutch con-

trol system should stop the

mowerbladeswithinthree(3)

secondsafter release of the

OperatorPresenceControl.If

the bladesdo notstopwithin

three-(3) seconds,potthe En-

gine Throttle Control in the

STOP position. Disconnect

thesparkplugwire anddonot

operate the mower until the

blade-brake-clutch control

systemhasbeenrepaired_

LOCATIONANDUSEOF

CONTROLS

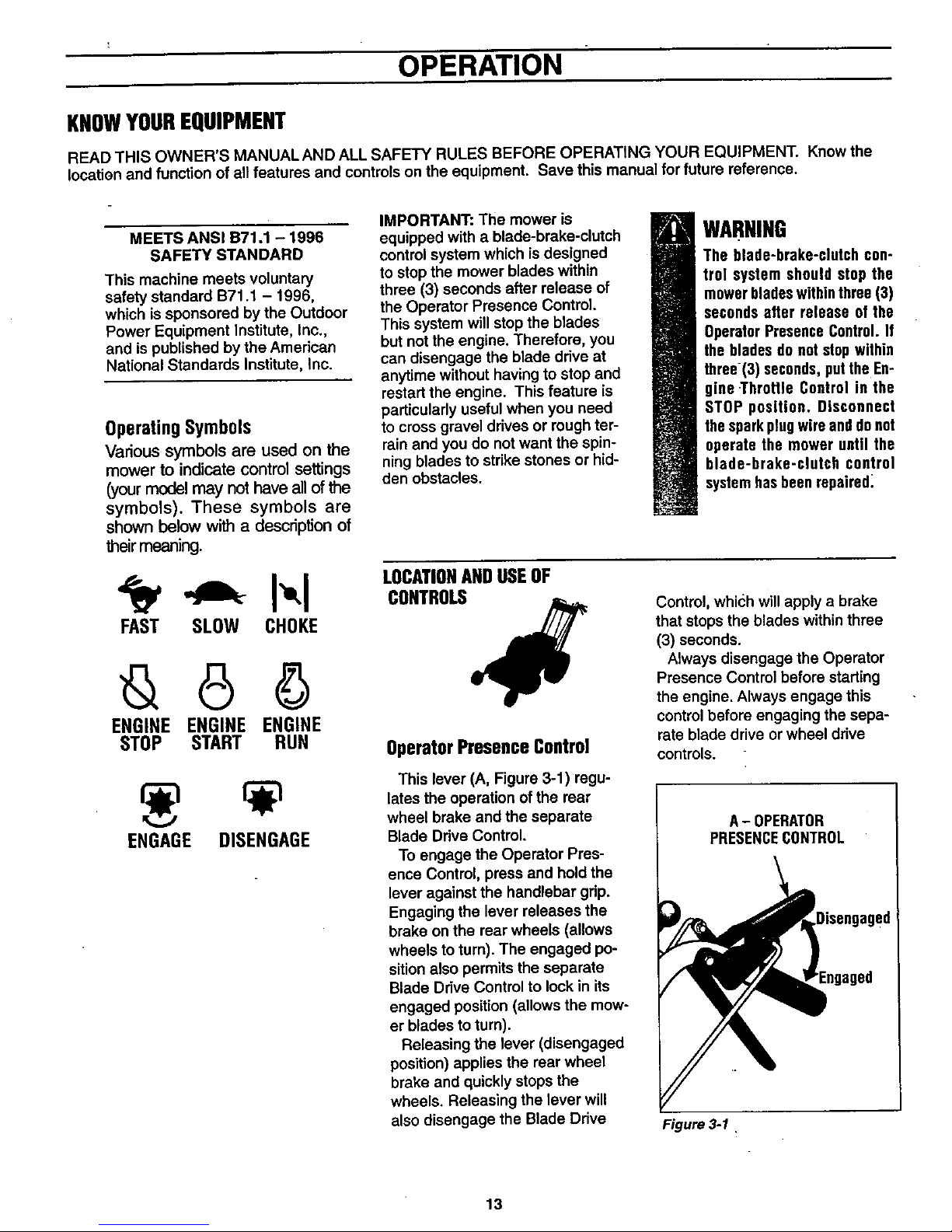

OperatorPresenceControl

This lever (A, Figure 3-1) regu-

lates the operation ofthe rear

wheel brake and the separate

Blade Drive Control.

To engage the Operator Pres-

ence Control, press and hold the

lever against the handlebar grip.

Engaging the lever releases the

brake on the rear wheels (allows

wheels to turn). The engaged po-

sitionalso permits the separate

Blade Drive Control to lock in its

engaged position (allows the mow-

er blades to turn).

Releasing the lever (disengaged

position) applies the rear wheel

brake and quickly stops the

wheels. Releasing the lever will

also disengage the Blade Drive

Control, which will apply a brake

that stops the blades within three

(3) seconds.

Always disengage the Operator

Presence Control before starting

the engine. Always engage this

controlbefore engaging the sepa-

rate blade drive or wheel drive

controls.

A- OPERATOR

PRESENCECONTROL

ed

Figure 3-1 ,

13

OPERATION

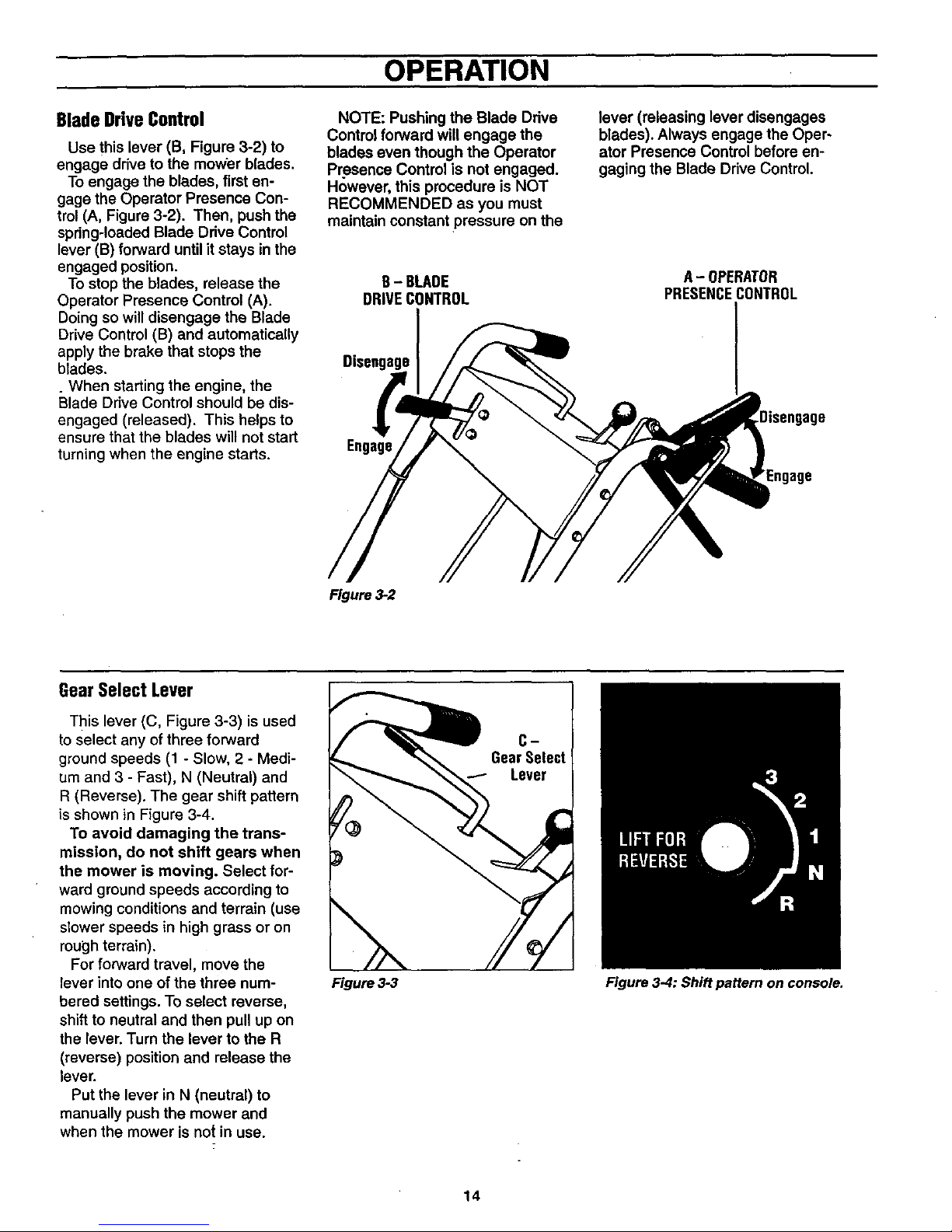

BladeDriveControl

Use this lever (B, Figure 3-2) to

engage drive to the mower blades.

To engage the blades, first en-

gage the Operator Presence Con-

trol (A, Figure 3-2). Then, push the

spring-loaded Blade Drive Control

lever (B) forward until it stays in the

engaged position.

To stop the blades, release the

Operator Presence Control (A).

Doing so will disengage the Blade

Drive Control (B) and automatically

apply the brake that stops the

blades.

_When starting the engine, the

Blade Drive Control should be dis-

engaged (released). This helps to

ensure that the blades will not start

turning when the engine starts.

NOTE: Pushing the Blade Ddve

Control forward will engage the

blades even though the Operator

Presence Control is not engaged.

However, this procedure is NOT

RECOMMENDED as you must

maintain constant pressure on the

B- BLADE

DRIVECONTROL

Disengage

Engage

lever (releasing lever disengages

blades). Always engage the Oper-

ator Presence Control before en-

gaging the Blade Drive Control.

A-OPERATOR

PRESENCECONTROL

Engage

Figure 3-2

GearSelectLever

This lever (C, Figure 3-3) is used

toselect any of three forward

ground speeds (1 - Slow, 2 - Medi-

um and 3 - Fast), N (Neutral) and

R (Reverse). The gear shift pattern

is shown in Figure 3-4.

To avoid damaging the trans-

mission, do not shift gears when

the mower is moving. Select for-

ward ground speeds according to

mowing conditions and terrain (use

slower speeds in high grass or on

rough terrain).

Forforward travel, move the

lever into one of the three num-

bered settings. To select reverse,

shift to neutral and then pull up on

the lever. Turn the lever to the R

(reverse) position and release the

lever.

Put the lever in N (neutral) to

manually push the mower and

when the mower is not in use.

CD

GearSelect

Lever

Figure 3-3 Figure 3-4: Shift pattern on console.

14

OPERATION

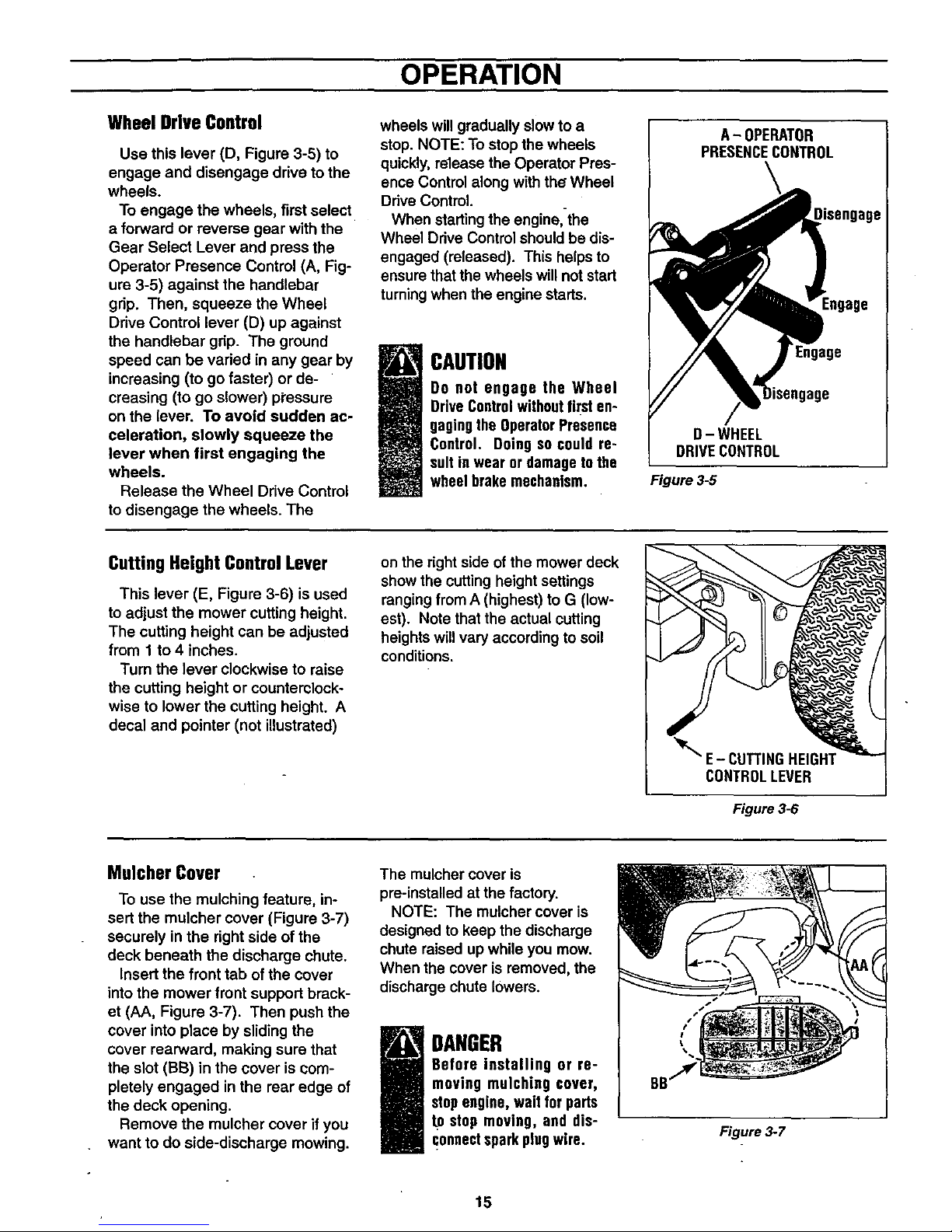

WheelDriveControl

Use this lever (D, Figure 3-6) to

engage and disengage drive to the

wheels.

To engage the wheels, first select

a forward or reverse gear with the

Gear Select Lever and press the

Operator Presence Control (A, Fig-

ure 3-5) against the handlebar

grip. Then, squeeze the Wheel

Drive Control lever (D) up against

the handlebar grip. The ground

speed can be varied in any gear by

increasing (to go faster) or de-

creasing (to go slower) pi'essure

on the lever. To avoid sudden ac-

celeration, slowly squeeze the

lever when first engaging the

wheels.

Release the Wheel Drive Control

to disengage the wheels. The

wheels will gradually slowto a

stop. NOTE: To stopthe wheels

quickly, release the Operator Pres-

ence Control along withthe Wheel

Drive Control.

When startingthe engine,-the

Wheel Drive Control should be dis-

engaged (released). This helps to

ensure thatthe wheels willnotstart

turningwhen the engine starts.

CAUTION

Do not engage the Wheel

DriveControlwithoutfirst en-

gagingthe OperatorPresence

Control. Doingso could re-

sult inwear or damageto the

wheelbrakemechanism.

I A- OPERATOR

PRESENCECONTROL

!isengage

Engage

D- WHEEL

DRIVECONTROL

Figure 3-5

CuttingHeight ControlLever

This lever (E, Figure 3-6) is used

to adjust the mower cutting height.

The cutting height can be adjusted

from 1 to 4 inches.

Turn the lever clockwise to raise

the cutting height or counterclock-

wise to lower the cutting height. A

decal and pointer (not illustrated)

on the rightside of the mower deck

show the cuttingheight settings

ranging from A (highest) to G (low-

est). Note that the actual cutting

heights willvary according to soil

conditions.

MulcherCover

To use the mulching feature, in-

sert the mulcher cover (Figure 3-7)

securely in the right side of the

deck beneath the discharge chute.

Insert the front tab of the cover

into the mower front support brack-

et (AA, Figure 3-7). Then push the

cover intoplace by slidingthe

cover rearward, making sure that

the slot (BB) in the cover is com-

pletely engaged in the rear edge of

the deck opening.

Remove the mulcher cover if you

want to do side-discharge mowing.

The mulcher cover is

pre-installed at the factory.

NOTE: The mulcher cover is

designed to keep the discharge

chute raised up while you mow.

When the cover is removed, the

discharge chute lowers.

i DANGER

Before installing or re-

moving mulching cover,

stopengine,wait for parts

tD stop moving, and dis-

connectsparkplugwire.

Figure 3-7

15

OPERATION

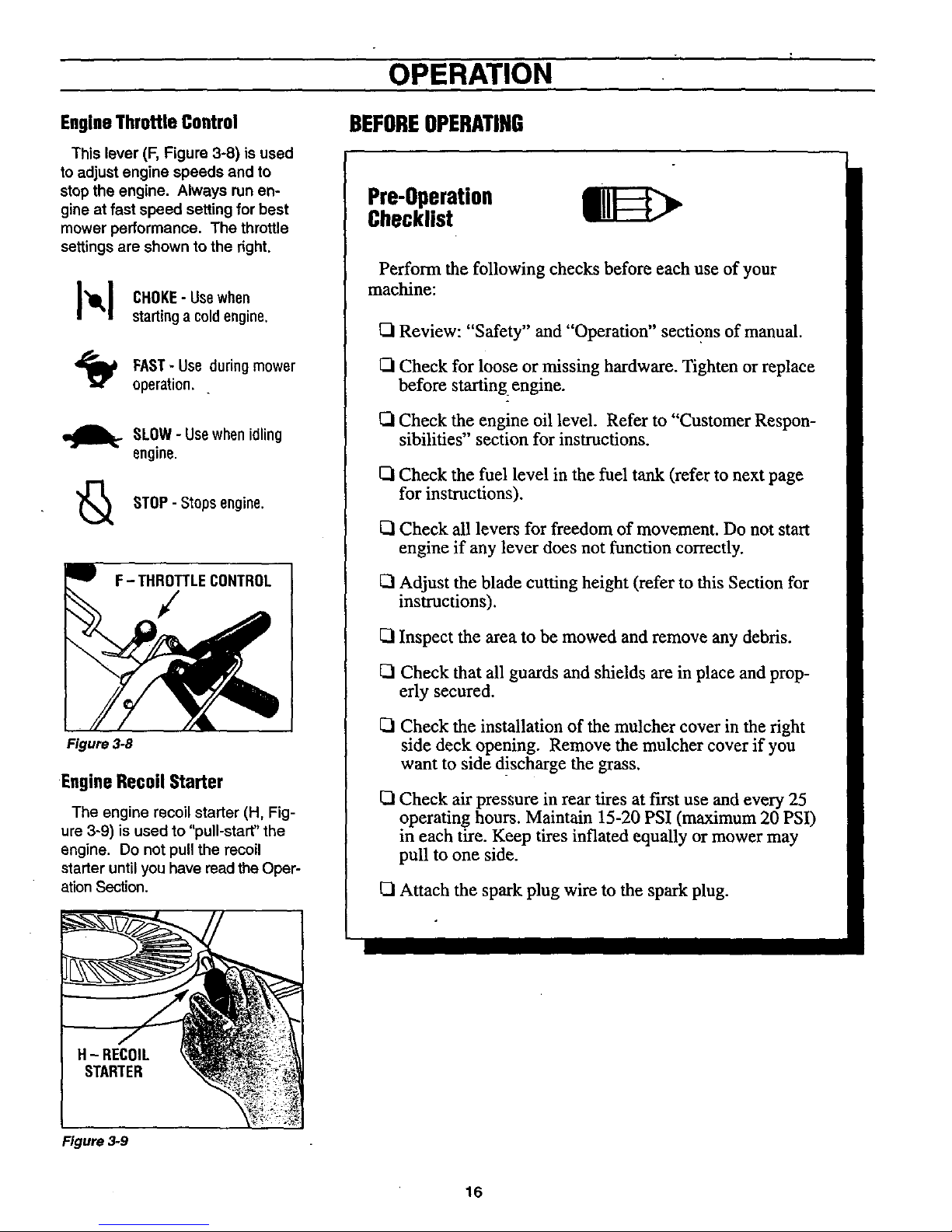

EngineThrottle Control

This lever (F, Figure 3-8) is used

to adjust engine speeds and to

stop the engine. Always run en-

gine at fast speed setting for best

mower performance. The throttle

settings are shown to the right.

]_1_1 CHOKE- Usewhen

startinga coldengine.

FAST- Use duringmower

operation. _

SLOW- Usewhenidling

engine.

'_ STOP- Stopsengine.

F- THRoJiLECONTROL

J

Figure 3-8

EngineRecoilStarter

The engine recoil starter (H, Fig-

ure 3-9) is used to "pull-start"the

engine. Do not pull the recoil

starter until you have read the Oper-

ation Section.

BEFOREOPERATING

Pre-Operation

Checklist

Perform the following checks before each use of your

machine:

ISlReview: "Safety" and "Operation" sections of manual.

Q Check for loose or missing hardware. Tighten or replace

before starting engine.

Q Check the engine oil level. Refer to "Customer Respon-

sibilities" section for instructions.

ISICheck the fuel level in the fuel tank (refer to next page

for instructions).

Q Check all levers for freedom of movement. Do not start

engine if any lever does not function correctly.

Adjust the blade cutting height (refer to this Section for

instructions).

Inspect the area to be mowed and remove any debris.

Check that all guards and shields are in place and prop-

erly secured.

_1 Check the installation of the mulcher cover in the right

side deck opening. Remove the mulcher cover if you

want to side d!scharge the grass.

I_1Check air pressure in rear tires at first use and every 25

operating hours. Maintain 15-20 PSI (maximum 20 PSI)

in each tire. Keep tires inflated equally or mower may

pull to one side.

ISIAttach the spark plug wire to the spark plug.

H- RECOIL

STARTER

Figure 3-9

16

Loading...

Loading...