Page 1

Operators Manual

FLOOR JACK

Model 950524 - 2-1/4 Ton Capacity

•Safety

•Operation

•Maintenance

• Parts

BEFORE using this product, read this manual

!

and follow all its Safety and Operating

instructions. Failure to do so may result in

personal injury and/or property damage.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

Visit our Craftsman website: www.sears.com/craftsman

Printed in China

Page 2

TABLE OF CONTENTS

Warranty .....P. 2

Save these instructions .....P. 2

Safety instructions .....P. 3

Assembly instructions .....P. 4

Operation .....P. 4 & P. 5

Maintenance .....P. 6

Troubleshooting .....P. 7

Parts .....P. 7

Service .....Back cover

WARRANTY

CRAFTSMAN ONE YEAR FULL WARRANTY

If this Craftsman product fails due to a defect in material or workmanship within one year from

the date of purchase, return it to any Sears store or other Craftsman outlet in the United

States for free replacement.

This warranty applies for only 90 days from the date of purchase if this product is ever used

for commercial or rental purposes.

This warranty gives you specific legal rights, and you may also have other rights which vary

from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

SAVE THESE INSTRUCTIONS

For your safety, read, understand, and follow the information provided with and on this jack.

• The owner and operator of this equipment shall have an understanding of this jack and safe

operating procedures before attempting to use. The owner and operator shall be aware

that use and repair of this product may require special skills and knowledge. Instructions

and safety information shall be conveyed in the operators native language before use of

this product is authorized. If any doubt exists as to the safe and proper use of this jack,

remove from service immediately.

•Inspect before each use. Do not use if broken, bent, cracked, or damaged parts (including

labels) are noted. Any jack that appears damaged in any way, operates abnormally or is

missing parts, shall be removed from service immediately.

• If the jack has been or suspected to have been subjected to a shock load (a load dropped

suddenly, unexpectedly upon it), immediately discontinue use until jack has been checked

by a Sears or other qualified service center. It is recommended that an annual inspection

be done by qualified personnel.

• Labels and Operators Manual are available from Sears (see PARTS section on page 7).

2

Page 3

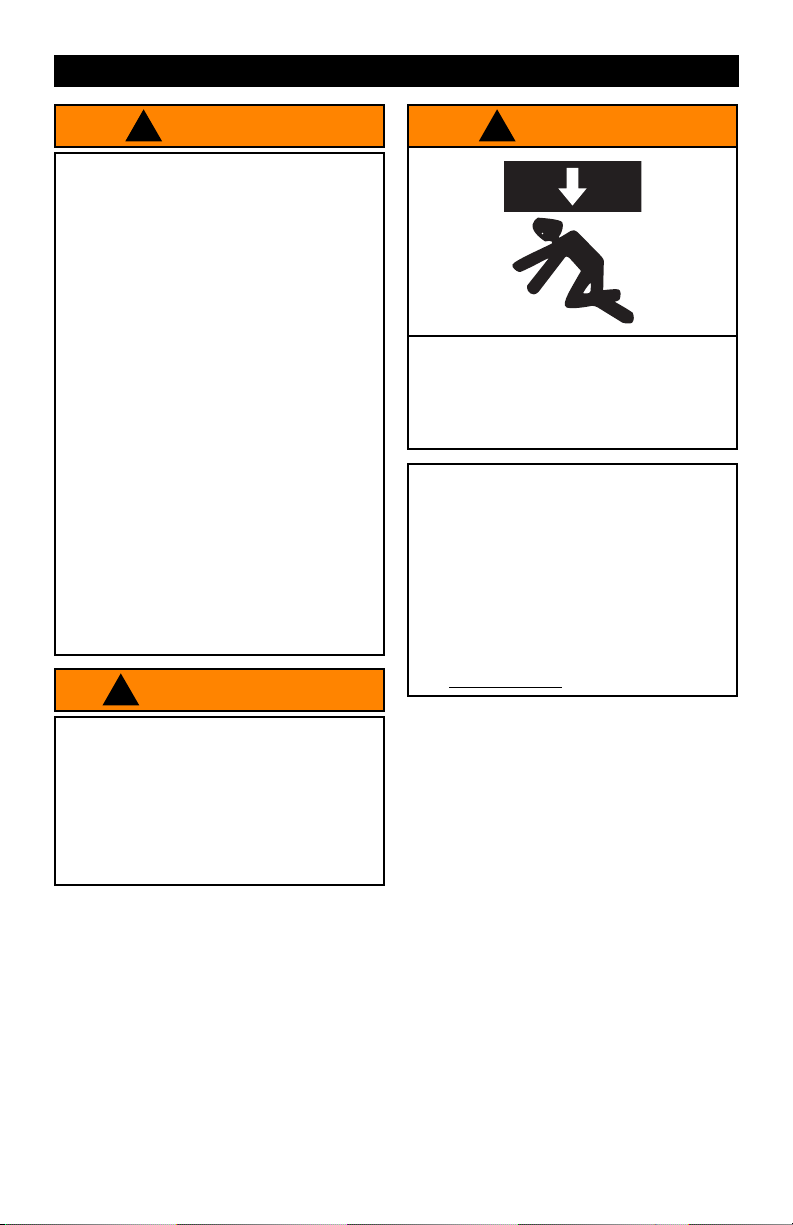

SAFETY INSTRUCTIONS

!

WARNING

•Study, understand, and follow all

instructions with and on this device before

operating this device.

• Do not exceed rated capacity.

•Use only on hard, level surfaces capable

of sustaining rated capacity loads.

•Lift only on areas of the vehicle as

specified by the vehicle manufacturer.

• This is a lifting device only. Immediately

after lifting, support the vehicle with

appropriately rated vehicle stands.

•Never work on, under, or around a load

supported only by this device.

• Do not move or dolly the vehicle while on

the jack.

•No alterations shall be made to this

product.

• Only attachments and/or adapters

supplied by the manufacturer shall be

used. Contact 1-888-332-6419 for more

information.

• Failure to heed product markings or

warnings may result in personal injury or

property damage.

!

ADVERTENCIA

!

WARNING

To avoid crushing and related injuries:

• NEVER work on, under or around a load

supported only by a jack.

•ALWAYS use appropriately rated jack

stands.

! SAFETY MESSAGE !

Be sure all tools and personnel are clear

before lowering load. No alterations shall

be made to this device. Only attachments

and/or adapters supplied by the

manufacturer shall be used. Lift only on

areas of the vehicle as specified by the

vehicle manufacturer.

NOTE: Jack stands are rated per pair

unless otherwise noted.

Use

1 matched pair per vehicle only.

• Leer, comprender, y seguir las

instrucciónes antes de utilizar el aparato.

•El manual de instrucciónes y la

información de seguridad deben estar

comunicado en lengua del operador

antes del uso.

• No seguir estas indicaciónes puede

causar daños personales o materiales.

3

Page 4

ASSEMBLY INSTRUCTIONS

TO ASSEMBLE THE CARRY HANDLE ONTO THE JACK

Snap the carry handle onto the nuts of jack’s middle axle. (see Fig. 1)

Carry handle

middle axle

KNOW YOUR JACK

Compare Fig. 2 illustration with your jack

BEFORE operation to become familiar with

the location of various jack components.

oil filler plug

(not shown,

handle

sleeve

release

valve

base

cover plate

(remove to

access oil

filler plug)

carry

handle

on reservoir)

lifting arm

castor

jack handle

saddle

frame

engage release

valve with this end

FIG. 2

SPECIFICATIONS

Rated Capacity: 2-1/4 Ton/4500 Lbs

Jack Dimensions: 21” x 8-1/2” x 5-1/2”

Lifting Range: 5-1/2” ~ 15” (Approx.)

(140mm - 381mm)

Oil Capacity: 90 cc ± 5 cc

Net Weight: 27.1 lbs. (Approx.)

1 2

Nut of

OPERATION

BEFORE USE

•Read the operator's manual completely

and familiarize yourself thoroughly with the

product, its components and recognize the

hazards associated with its use.

•Occasionally during shipment and/or

handling air can get trapped in the system,

which can interfere with the jacks lifting

performance.

• It is recommended to cycle the jack a few

times without applying load:

front

wheel

• Engage release valve with notched end

of jack handle. Close release valve by

turning the jack handle clockwise until

tight.

• Insert jack handle into handle sleeve.

Pump the handle until the jack saddle

reaches its maximum height.

• Engage release valve with notched end

of jack handle. Open release valve by

turning jack handle counterclockwise, but

no more than 1/2 full turn. Allow the saddle

to reach its lowest position.

• Repeat the above procedure a few times.

•To release air from the hydraulic system:

• Engage release valve with notched end

of jack handle. Open the release valve

by turning the jack handle

counterclockwise, but never by more than

1/2 full turn.

• Remove the oil filler plug from the cylinder.

(see Fig. 3)

• Insert jack handle into handle sleeve.

Rapidly pump jack handle through several

full strokes.

• Reinstall the oil filler plug into the cylinder

again and jack is now ready to use.

4

FIG. 1

Page 5

OPERATION

OPERATING PRINCIPLES

•With release valve closed, an upward

stroke of the jack handle draws oil from the

reservoir tank into the plunger cavity.

Hydraulic pressure holds a valve closed,

which keeps the oil in the plunger cavity.

•A downward stroke of the jack handle

releases oil into the cylinder, which forces

the ram out. This raises the saddle. (NOTE:

To avoid damage to the cylinder if the load

exceeds the rated capacity of the jack, oil

is automatically released back into the

reservoir through the safety overload

valve.)

•When the ram reaches maximum

extension, oil is bypassed back into the

reservoir to prevent an over-extended ram

stroke and possible damage to the jack.

• Opening the release valve allows oil to flow

back into the reservoir. This releases

hydraulic pressure on the ram, which

results in lowering the saddle.

HOW TO USE YOUR JACK

RAISING THE JACK

•With notched end of the jack handlle (see

Fig. 2) close release valve by turning the

handle clockwise.

• Chock the vehicle’s wheel with appropriate

devices to ensure lifting stability.

•Refer to the vehicle manufacturer’s owners

manual to locate approved lifting points on

the vehicle. Position jack so that the saddle

is centered under the load at an appropriate

lift point.

•Insert jack handle into handle sleeve. Pump

jack handle until saddle almost contacts the

vehicle. Check to see that the saddle is

centered and will contact the load lifting

point firmly.

• Continue to pump the jack handle to lift the

vehicle to the desired height. After lifting,

support the load with appropriately rated

jack stands BEFORE working on the

vehicle.

Rated capacity of jack stands is per

!

pair, it is NOT the sum of individual

capacities unless specifically noted to the

contrary by the jack stand manufacturer.

Do Not exceed rated capacity. Ensure that

the vehicle support points are fully captured

between the outer lugs of both jack stands.

Use a matched pair of jack stands per

vehicle to support 1 end only. Use 1 pair

per vehicle only. Failure to do so may

result in sudden loss of load, which may

cause personal injury and/or property

damage.

LOWERING THE JACK

To avoid crushing injuries and property

!

damage: Keep hands and feet clear of work

area when lowering load.

•Raise load high enough to clear the jack

stands, then carefully remove jack stands

(always used in pairs).

•With notched end of jack handle, SLOWLY

open the release valve by turning the

handle counterclockwise, but never more

than 1/2 full turn. If the load fails to lower:

a. Use another jack to raise the vehicle

high enough to reinstall jack stands.

b. Remove the affected jack and then the

stands.

c. Using the other jack, lower the load by

turning the operating handle counterclockwise, but no more than 1/2 full turn.

•After removing jack from under the load,

push saddle down to reduce ram exposure

to rust and contamination.

5

Page 6

MAINTENANCE

MAINTAINING OIL LEVEL

Important: When adding or replacing oil,

ALWAYS use a good grade Hydraulic Jack

oil. We recommend Mobil DTE13M or

equivalent. DO NOT use Hydraulic Brake

Fluid, Alcohol, Glycerine, Detergent, Motor

Oil or dirty oil. Use of an improper fluid can

cause serious internal damage to your jack.

ADDING OIL

•Position the jack on level ground and fully

lower the saddle. (Ram will be all the way

in). Remove oil filler plug located under

cover plate (see Fig. 3).

•Oil should be filled to the level of about

3/16” above the inner cylinder as seen from

the oil filler hole. If low, add oil as needed.

• Re-install oil filler plug and cover plate. The

jack is now ready to use.

LUBRICATION

• Add lubricating oil to all moving parts as

needed.

PREVENTING RUST

• Check ram and pump plunger (see Fig. 3)

every few months for any signs of rust or

corrosion. Clean as needed by wiping with

an oily cloth.

•When not in use, ALWAYS store jack with

saddle lowered all the way down.

ANNUAL INSPECTION

To ensure that it is in optimum condition,

annual inspection of the jack at a Sears

Service Center is recommended.

REPLACING OIL

•To drain oil, remove cover plate and oil filler

plug and open release valve. Turn jack over

and drain old oil out through the oil filler

hole and into a suitable container.

Note: Dispose of hydraulic oil in accordance

with local regulations.

•Refill with new oil through the oil filler hole.

DO NOT allow dirt or foreign material to

enter the hydraulic system when filling.

•After refilling, remove any air from the

hydraulic system by opening the release

valve and rapidly pumping the jack handle

several times.

• Re-install oil filler plug and cover plate and

the jack is ready to use.

Release Valve

Oil Filler Plug

Proper Oil Level

Ram all the way in

Plunger Down

FIG. 3

6

Page 7

TROUBLESHOOTING

PROBLEM-SOLVING HINTS

Symptom Possible Causes

Jack does not lift load

Jack bleeds off

(starts to lower) after lift

Jack does not lower after

unloading

Poor lift performance

Does not lift to full

extension

•Release valve not tightly closed

•Overloaded - too much weight on jack

• Release valve not tightly closed

• Hydraulic unit malfunction

•Oil reservoir overfilled

•Linkages binding

•Fluid level low

•Air trapped in system

•Fluid level low

•Ensure release valve is tightly closed

• Reduce weight on jack

•Ensure release valve is tightly closed

•Replace power unit assembly

•Drain fluid to proper level

•Clean and lubricate moving parts

•Ensure proper fluid level

•With ram fully retracted, open release

•Ensure proper fluid level

Corrective Action

valve, pump handle several times to

expel trapped air

PARTS

MODEL NUMBER: 50524

The Model Number and Serial Number are found on the lifting arm and handle sleeve

respectively. Always mention the Model Number and Serial Number when requesting service

or repair parts for your jack.

INDIVIDUAL PARTS ARE NOT AVAILABLE FOR REPLACEMENT ASSEMBLIES

Key Description

1 Saddle

2 Power Unit Assembly

3Handle Assembly

4Front Wheel Assembly

5 Rear Castor Assembly

6Cover Plate

7Oil Filler Plug

—Operators Manual

–– Warning Label

6

7

2

3

1

4

5

For after sale support and assistance:

Call 1-888-332-6419, 8:00 AM - 4:45 PM CST., Monday - Friday

7

FIG. 4

Page 8

Get it fixed, at your home or ours!

Your Home

For repair – in your home – of all major brand appliances,

lawn and garden equipment, or heating and cooling systems,

no matter who made it, no matter who sold it!

For the replacement parts, accessories and

owner’s manuals that you need to do-it-yourself.

For Sears professional installation of home appliances

and items like garage door openers and water heaters.

1-800-4-MY-HOME®

(1-800-469-4663)

Call anytime, day or night

(U.S.A. and Canada)

www.sears.com www.sears.ca

Our Home

For repair of carry-in items like vacuums, lawn equipment,

and electronics, call or go on-line for the location of your nearest

Sears Parts and Repair Center.

1-800-488-1222 Call anytime, day or night (U.S.A. only)

www.sears.com

To purchase a protection agreement (U.S.A.)

or maintenance agreement (Canada) on a product serviced by Sears:

1-800-827-6665 (U.S.A.) 1-800-361-6665 (Canada)

Para pedir servicio de reparación

a domicilio, y para ordenar piezas:

1-888-SU-HOGAR

®

(1-888-784-6427)

Au Canada pour service en français:

1-800-LE-FOYER

MC

(1-800-533-6937)

www.sears.ca

© Sears Brands, LLC

®

Registered Trademark /

®

Marca Registrada / TM Marca de Fábrica / SM Marca de Servicio de Sears Brands, LLC

MC

Marque de commerce / MD Marque déposée de Sears Brands, LLC

TM

Trademark / SM Service Mark of Sears Brands, LLC

Loading...

Loading...