Page 1

CRAFTSMAN

Model No.

OWNERS MANUAL FOR

CRAFTSMAN

PERMANENTLY LUBRICATED

919.727321

IMPORTANT:

Read the Safety Guidelines

and All Instructions Carefully

Before Operating

TANK MOUNTED

AIR COMPRESSOR

SAFETY GUIDELINES

ASSEMBLY

OPERATION

MAINTENANCE

TROUBLESHOOTING

REPAIR PARTS

Record in the spaces provided.

(1) The Model Number can be found on the

maintenance label on top of the motor

shroud or on the bar code label on the

rear of air tank.

(2) The Date Code Number can be found on

the bar code label on the rear of the air

tank.

(3) The Serial Number can be found on the

bar code label on the rear of the tank.

(4) The Tank Registration Number is located

on the metal data plate which is welded

onto the backside of the air tank. (This

data plate is painted the same color as the

tank.)

Retain these numbers for future reference.

Model No_______________________________

Serial No________________________________

Date Code_______________________________

Tank Registration No______________________

D20015 Rev. 1 6/28/00

Sold by Sears Canada, Inc., Toronto, Ont. M5B 2B8

Page 2

TABLE OF CONTENTS

WARRANTY ......................................................... 2

SAFETY GUIDELINES ......................................... 2

WARNING CHART ............................................ 3-5

GENERAL INFORMATION ................................... 6

GLOSSARY .......................................................... 6

SPECIFICATION CHART ..................................... 7

DESCRIPTION OF OPERATION .......................... 7

TOOLS NEEDED FOR ASSEMBLY ...................... 7

ASSEMBLY .......................................................... 8

BREAK-IN PROCEDURES ................................... 8

Location of Air Compressor ............................ 8

Lubrication and Oil ......................................... 8

Grounding Instructions .................................... 8

Voltage and Circuit Protection ......................... 9

OPERATING PROCEDURES ....................................... 9

MAINTENANCE ........................................................... 10

Air Filter - Inspection and Replacement .................. 10

Check Valve -Replacement .................................... 10

Safety Valve - Inspection ........................................ 10

Motor ...................................................................... 10

Storage ................................................................... 10

TROUBLESHOOTING GUIDE ................................ 11-12

AIR COMPRESSOR DIAGRAM ................................... 14

PARTS LIST ................................................................. 15

COMPRESSOR PUMP DIAGRAM .............................. 16

PARTS LIST ................................................................. 17

SERVICE NOTES .......................................................... 18

HOW TO ORDER REPAIR PARTS ................ Back Cover

Break-in Procedure ......................................... 9

FULL ONE YEAR WARRANTY ON AIR COMPRESSORS

If this air compressor fails due to a defect in material or workmanship within one year from the date

of purchase, RETURN IT TO THE NEAREST SEARS SERVICE CENTER THROUGHOUT CANADA AND

SEARS WILL REPAIR IT, FREE OF CHARGE.

If this air compressor is used for commercial or rental purposes, the warranty will apply for ninety

days (90) from the date of purchase.

This Craftsman Air Compressor warranty gives you specific legal rights and you may have other

rights which vary from province to province.

Sears Canada, Inc., Toronto, Ont. M5B 2B8

SAFETY GUIDELINES - DEFINITIONS

This manual contains information that is important for you to know and understand. This information relates to protecting

YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the symbols

to the right. Please read the manual and pay attention to these sections.

DANGER indicates an imminently hazardous situation which, if

not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if

not avoided, could result in death of serious injury.

CAUTION indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate injury.

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may result

in property damage.

D20015 Rev. 1 6/28/00

2 ENG

Page 3

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

IMPROPER OPERATION OR MAINTENANCE OF THIS PRODUCT COULD RESULT IN SERIOUS INJURY AND PROPERTY

DAMAGE. READ AND UNDERSTAND ALL WARNINGS AND OPERATING INSTRUCTIONS BEFORE USING THIS EQUIPMENT.

HAZARD

RISK OF EXPLOSION OR FIRE

WHAT CAN HAPPEN

IT IS NORMAL FOR ELECTRICAL CONTACTS WITHIN THE

MOTOR AND PRESSURE SWITCH TO SPARK.

IF ELECTRICAL SPARKS FROM COMPRESSOR COME INTO

CONTACT WITH FLAMMABLE VAPORS, THEY MAY IGNITE,

CAUSING FIRE OR EXPLOSION.

RESTRICTING ANY OF THE COMPRESSOR VENTILATION

OPENINGS WILL CAUSE SERIOUS OVERHEATING AND

COULD CAUSE FIRE.

UNATTENDED OPERATION OF THIS PRODUCT COULD

RESULT IN PERSONAL INJURY OR PROPERTY DAMAGE.

RISK OF BURSTING

HOW TO PREVENT IT

ALWAYS OPERATE THE COMPRESSOR IN A WELL VENTILATED AREA FREE OF COMBUSTIBLE MATERIALS,

GASOLINE OR SOLVENT VAPORS.

IF SPRAYING FLAMMABLE MATERIALS, LOCATE COMPRESSOR AT LEAST 20 FEET AWAY FROM SPRAY AREA. AN

ADDITIONAL LENGTH OF HOSE MAY BE REQUIRED.

STORE FLAMMABLE MATERIALS IN A SECURE LOCATION

AWAY FROM COMPRESSOR.

NEVER PLACE OBJECTS AGAINST OR ON TOP OF COMPRESSOR. OPERATE COMPRESSOR IN AN OPEN AREA AT

LEAST 12 INCHES AWAY FROM ANY WALL OR OBSTRUC-

TION THAT WOULD RESTRICT THE FLOW OF FRESH AIR TO

THE VENTILATION OPENINGS.

OPERATE COMPRESSOR IN A CLEAN, DRY, WELL VENTILATED AREA. DO NOT OPERATE UNIT INDOORS OR IN ANY

CONFINED AREA.

ALWAYS REMAIN IN ATTENDANCE WITH THE PRODUCT

WHEN IT IS OPERATING.

AIR TANK: THE FOLLOWING CONDITIONS COULD LEAD TO A WEAKENING OF THE TANK, AND RESULT IN A

VIOLENT TANK EXPLOSION AND COULD CAUSE PROPERTY DAMAGE OR SERIOUS INJURY.

WHAT CAN HAPPEN

1. FAILURE TO PROPERLY DRAIN CONDENSED WATER

FROM THE TANK, CAUSING RUST AND THINNING OF THE

STEEL TANK.

2. MODIFICATIONS OR ATTEMPTED REPAIRS TO THE TANK.

3. UNAUTHORIZED MODIFICATIONS TO THE UNLOADER

VALVE, SAFETY VALVE, OR ANY OTHER COMPONENTS

WHICH CONTROL TANK PRESSURE.

4. EXCESSIVE VIBRATION CAN WEAKEN THE AIR TANK

AND CAUSE RUPTURE OR EXPLOSION.

ATTACHMENTS & ACCESSORIES:

EXCEEDING THE PRESSURE RATING OF AIR TOOLS, SPRAY

GUNS, AIR OPERATED ACCESSORIES, TIRES AND OTHER

INFLATABLES CAN CAUSE THEM TO EXPLODE OR FLY

APART, AND COULD RESULT IN SERIOUS INJURY.

DRAIN TANK DAILY OR AFTER EACH USE. IF TANK DEVELOPS A LEAK, REPLACE IT IMMEDIATELY WITH A NEW TANK OR

REPLACE THE ENTIRE COMPRESSOR.

NEVER DRILL INTO, WELD, OR MAKE ANY MODIFICATIONS

TO THE TANK OR ITS ATTACHMENTS.

THE TANK IS DESIGNED TO WITHSTAND SPECIFIC OPERATING

PRESSURES. NEVER MAKE ADJUSTMENTS OR PARTS

SUBSTITUTIONS TO ALTER THE FACTORY SET OPERATING

PRESSURES.

FOR ESSENTIAL CONTROL OF AIR PRESSURE, YOU MUST

INSTALL A PRESSURE REGULATOR AND PRESSURE GAUGE

TO THE AIR OUTLET OF YOUR COMPRESSOR. FOLLOW THE

EQUIPMENT MANUFACTURERS RECOMMENDATION AND

NEVER EXCEED THE MAXIMUM ALLOWABLE PRESSURE

RATING OF ATTACHMENTS. NEVER USE COMPRESSOR TO

INFLATE SMALL LOW-PRESSURE OBJECTS SUCH AS

CHILDREN’S TOYS, FOOTBALLS, BASKETBALLS. ETC.

3 ENG

HOW TO PREVENT IT

D20015 Rev. 1 6/28/00

Page 4

HAZARD

RISK FROM FLYING OBJECTS

WHAT CAN HAPPEN

THE COMPRESSED AIR STREAM CAN CAUSE SOFT TISSUE

DAMAGE TO EXPOSED SKIN AND CAN PROPEL DIRT, CHIPS,

LOOSE PARTICLES AND SMALL OBJECTS AT HIGH SPEED,

RESULTING IN PROPERTY DAMAGE OR PERSONAL INJURY.

RISK TO BREATHING

WHAT CAN HAPPEN

THE COMPRESSED AIR FROM YOUR COMPRESSOR IS NOT

SAFE FOR BREATHING! THE AIR STREAM MAY CONTAIN

CARBON MONOXIDE, TOXIC VAPORS OR SOLID PARTICLES

FROM THE TANK.

HOW TO PREVENT IT

ALWAYS WEAR ANSI Z87.1 APPROVED SAFETY GLASSES

WITH SIDE SHIELDS WHEN USING THE COMPRESSOR.

NEVER POINT ANY NOZZLE OR SPRAYER TOWARD ANY

PART OF THE BODY OR AT OTHER PEOPLE OR ANIMALS.

ALWAYS TURN THE COMPRESSOR OFF AND BLEED PRESSURE FROM THE AIR HOSE AND TANK BEFORE ATTEMPTING

MAINTENANCE, ATTACHING TOOLS OR ACCESSORIES.

HOW TO PREVENT IT

ALWAYS OPERATE AIR COMPRESSOR OUTSIDE IN A CLEAN,

WELL VENTILATED AREA. AVOID ENCLOSED AREAS SUCH AS

GARAGES, BASEMENTS, STORAGE SHEDS, WHICH LACK A

STEADY EXCHANGE OF AIR. KEEP CHILDREN, PETS AND

OTHERS AWAY FROM AREA OF OPERATION.

NEVER INHALE AIR FROM THE COMPRESSOR EITHER

DIRECTLY OR FROM A BREATHING DEVICE CONNECTED TO

THE COMPRESSOR.

SPRAYED MATERIALS SUCH AS PAINT, PAINT SOLVENTS,

PAINT REMOVER, INSECTICIDES, WEED KILLERS, CONTAIN

HARMFUL VAPORS AND POISONS.

RISK OF ELECTRICAL SHOCK

WHAT CAN HAPPEN

YOUR AIR COMPRESSOR IS POWERED BY ELECTRICITY.

LIKE ANY OTHER ELECTRICALLY POWERED DEVICE, IF IT IS

NOT USED PROPERLY IT MAY CAUSE ELECTRIC SHOCK.

REPAIRS ATTEMPTED BY UNQUALIFIED PERSONNEL CAN

RESULT IN SERIOUS INJURY OR DEATH BY ELECTROCUTION.

ELECTRICAL GROUNDING: FAILURE TO PROVIDE ADEQUATE

GROUNDING TO THIS PRODUCT COULD RESULT IN SERIOUS

INJURY OR DEATH FROM ELECTROCUTION. SEE GROUND-

ING INSTRUCTIONS.

WORK IN AN AREA WITH GOOD CROSS-VENTILATION. READ

AND FOLLOW THE SAFETY INSTRUCTIONS PROVIDED ON

THE LABEL OR SAFETY DATA SHEETS FOR THE MATERIAL

YOU ARE SPRAYING. USE A NIOSH/MSHA APPROVED

RESPIRATOR DESIGNED FOR USE WITH YOUR SPECIFIC

APPLICATION.

HOW TO PREVENT IT

NEVER OPERATE THE COMPRESSOR OUTDOORS WHEN IT IS

RAINING OR IN WET CONDITIONS.

NEVER OPERATE COMPRESSOR WITH COVER COMPONENTS

REMOVED OR DAMAGED.

ANY ELECTRICAL WIRING OR REPAIRS REQUIRED ON THIS

PRODUCT SHOULD BE PERFORMED BY AUTHORIZED

SERVICE CENTER PERSONNEL IN ACCORDANCE WITH

NATIONAL AND LOCAL ELECTRICAL CODES.

MAKE CERTAIN THAT THE ELECTRICAL CIRCUIT TO WHICH

THE COMPRESSOR IS CONNECTED PROVIDES PROPER

ELECTRICAL GROUNDING, CORRECT VOLTAGE AND

ADEQUATE FUSE PROTECTION.

D20015 Rev. 1 6/28/00

4 ENG

Page 5

HAZARD

RISK FROM MOVING PARTS

WHAT CAN HAPPEN

MOVING PARTS SUCH AS THE PULLEY, FLYWHEEL AND BELT

CAN CAUSE SERIOUS INJURY IF THEY COME INTO CONTACT

WITH YOU OR YOUR CLOTHING.

ATTEMPTING TO OPERATE COMPRESSOR WITH DAMAGED

OR MISSING PARTS OR ATTEMPTING TO REPAIR COMPRESSOR WITH PROTECTIVE SHROUDS REMOVED CAN

EXPOSE YOU TO MOVING PARTS AND CAN RESULT IN

SERIOUS INJURY.

RISK OF BURNS

WHAT CAN HAPPEN

TOUCHING EXPOSED METAL SUCH AS THE COMPRESSOR

HEAD OR OUTLET TUBES, CAN RESULT IN SERIOUS BURNS.

HOW TO PREVENT IT

NEVER OPERATE THE COMPRESSOR WITH GUARDS OR

COVERS WHICH ARE DAMAGED OR REMOVED.

ANY REPAIRS REQUIRED ON THIS PRODUCT SHOULD BE

PERFORMED BY AUTHORIZED SERVICE CENTER PERSONNEL.

HOW TO PREVENT IT

NEVER TOUCH ANY EXPOSED METAL PARTS ON COMPRESSOR DURING OR IMMEDIATELY AFTER OPERATION. COMPRESSOR WILL REMAIN HOT FOR SEVERAL MINUTES AFTER

OPERATION.

DO NOT REACH AROUND PROTECTIVE SHROUDS OR ATTEMPT

MAINTENANCE UNTIL UNIT HAS BEEN ALLOWED TO COOL.

RISK OF FALLING

WHAT CAN HAPPEN

A PORTABLE COMPRESSOR CAN FALL FROM A TABLE,

WORKBENCH OR ROOF CAUSING DAMAGE TO THE COM-

PRESSOR AND COULD RESULT IN SERIOUS INJURY OR

DEATH TO THE OPERATOR.

RISK OF PROPERTY DAMAGE WHEN TRANSPORTING

COMPRESSOR

(Fire, Inhalation, Damage to Vehicle Surfaces)

WHAT CAN HAPPEN

OIL CAN LEAK OR SPILL AND COULD RESULT IN FIRE OR

BREATHING HAZARD, SERIOUS INJURY OR DEATH CAN

RESULT. OIL LEAKS WILL DAMAGE CARPET, PAINT OR OTHER

SURFACES IN VEHICLES OR TRAILERS.

HOW TO PREVENT IT

ALWAYS OPERATE COMPRESSOR IN A STABLE SECURE

POSITION TO PREVENT ACCIDENTAL MOVEMENT OF THE

UNIT. NEVER OPERATE COMPRESSOR ON A ROOF OR

OTHER ELEVATED POSITION. USE ADDITIONAL AIR HOSE

TO REACH HIGH LOCATIONS.

HOW TO PREVENT IT

ALWAYS PLACE COMPRESSOR ON A PROTECTIVE MAT WHEN

TRANSPORTING TO PROTECT AGAINST DAMAGE TO VEHICLE

FROM LEAKS. REMOVE COMPRESSOR FROM VEHICLE

IMMEDIATELY UPON ARRIVAL AT YOUR DESTINATION.

ESW-99 9/26/99

5 ENG

D20015 Rev. 1 6/28/00

Page 6

GENERAL INFORMATION

You have purchased an air compressor unit consisting

of a one cylinder, single-stage air compressor pump

and air tank. Included are wheels, regulator, gauges,

and handle.

This air compressor requires no oil. Now you can enjoy

all the benefits of having an air compressor without

ever having to purchase, add or change oil.

Your air compressor can be used for operating paint

spray guns, air tools, blow guns, nailers/staplers, air

brushes, and inflator kits. An air pressure regulator is

required for most of the applications.

GLOSSARY

CFM: Cubic Feet per Minute.

SCFM: Standard Cubic Feet per Minute; a unit of mea-

sure of air delivery.

PSI: Pounds per Square Inch; a unit of measure of pressure.

An inline air filter which removes moisture and dirt from

compressed air should be used where applicable.

An inline regulator can be used if a more precise

adjustment of air pressure is needed downstream.

Cut-Out Pressure: When you turn on your air compressor and it begins to run, air pressure in the air tank begins to build. It builds to a certain high pressure before

the motor automatically shuts off - protecting your air tank

from pressure higher than its capacity. The high pressure at which the motor shuts off is called “cut-out pressure.”

ASME: American Society of Mechanical Engineers; made,

tested, inspected and registered to meet the standards

of the ASME.

Cut-In Pressure: While the motor is off, air tank pressure drops as you continue to use your accessory. When

the tank pressure drops to a certain low level and the

pressure switch lever is in "Auto", the motor will restart

automatically. The low pressure at which the motor automatically restarts is called “cut-in pressure.”

SPECIFICATION CHART

Model No.

Bore

Stroke

Voltage - Single Phase

Minimum Branch Circuit Requirement

Fuse Type

Amperage at Maximum Pressure

Air Tank/Capacity

Approximate Cut-in Pressure

Approximate Cut-out Pressure

SCFM @ 40 psi

SCFM @ 90 psi

CSA: Electrical products sold in Canada are required to

be certified to the applicable CSA standard (s). Canadian

Standards Association (CSA) is a standards writing and

safety testing organization. Products that are CSA certified have been evaluated and tested and found to meet

or exceed the applicable CSA standard (s) for safety and

electrical performance.

919.727321

2 3/8"

1.35"

120

15 amps

Time Delay

15.0

ASME/25 gal. (U.S.)

100

130

7.8

5.5

D20015 Rev. 1 6/28/00

6 ENG

Page 7

DESCRIPTION OF OPERATION

Air Compressor Pump: To compress air, the piston

moves up and down in the cylinder. On the downstroke,

air is drawn in through the air intake valves. The exhaust

valves remain closed. On the upstroke of the piston, air

is compressed. The intake valves close and compressed

air is forced out through the exhaust valves, through the

outlet tube, through the check valve and into the air tank.

Check Valve: When the air compressor is operating, the

check valve is “open”, allowing compressed air to enter

the air tank. When the air compressor reaches “cut-out”

pressure, the check valve “closes”, allowing air pressure to remain inside the air tank.

Pressure Switch: The pressure switch is fitted with a

small lever. It is labeled "Auto/O" for automatic run or

off. In the "O" position, the motor will not run. In the "Auto"

position, it automatically starts the motor when the air

tank pressure drops below the factory set “cut-in” pressure. It stops the motor when the air tank pressure reaches

the factory set “cut-out” pressure.

Pressure Release Valve: The pressure release valve located on the side of the pressure switch is designed to

automatically release compressed air trapped within the

compressor head and outlet tube. This short release of

air will occur when the air compressor reaches "cut-out"

pressure or the unit is shut off. If the air is not released,

the motor will not be able to start when next required.

Flow Valve: The flow valve allows air to flow from the

head as the motor is getting “up to speed”. Once the

motor reaches normal operating speed, the flow valve

closes and the pump begins to compress air, thus requiring less amp draw on initial start.

Regulator: The air pressure coming from the air tank is

controlled by the regulator. The regulator control knob is

a vibration proof design. Lift the regulator knob to engage and depress the knob to lock. Turn the regulator

knob clockwise to increase pressure and counter-clockwise to decrease pressure. To avoid minor readjustment

after making a change in pressure setting, always approach the desired pressure from a lower pressure. When

reducing from a higher to a lower setting, first reduce to

some pressure less than that desired, then bring up to

the desired pressure. Depending on the air requirements

of each particular accessory, the outlet regulated air pressure may have to be adjusted while operating the accessory.

Regulator Gauge: The outlet pressure gauge indicates

the air pressure available at the outlet side of the regulator. This pressure is controlled by the regulator and is

always less than or equal to the tank pressure. See “Operating Procedures”.

Tank Pressure Gauge: The tank pressure gauge indicates the reserve air pressure in the tank.

Cooling System: This compressor contains an advanced

design cooling system. At the heart of this cooling system is an engineered fan. It is perfectly normal for this

fan to blow air through the vent holes in large amounts.

You know that the cooling system is working when air is

being expelled.

Drain Valve: This valve is located at the bottom of the

tank. To drain accumulated moisture from the tank, pull

on the safety valve until tank pressure is 15 PSI. Unscrew the drain valve and allow the water to drain.

Safety Valve: If the pressure switch does not shut off the

air compressor at its cut-out pressure setting, the safety

valve will protect the tank against high pressure by “popping out” at its factory set pressure (slightly higher than

the pressure switch cut-out setting).

TOOLS NEEDED FOR ASSEMBLY

• a 9/16" socket and an open end wrench for attaching

the wheels

• a 3/8" open end wrench or socket to tighten handle

screws

7 ENG

D20015 Rev. 1 6/28/00

Page 8

ASSEMBLY

Installing Wheels, Handles, Rubber Foot

Strip

THE WHEELS AND HANDLE DO NOT PROVIDE

ADEQUATE CLEARANCE, STABILITY OR SUPPORT FOR PULLING THE UNIT UP AND DOWN

STAIRS OR STEPS. THE UNIT MUST

BE LIFTED, OR PUSHED UP A RAMP.

BREAK-IN PROCEDURES

Location of the Air Compressor

Locate the air compressor in a clean, dry and well ventilated area. The air filter must be kept clear of obstructions which could reduce air delivery of the air compressor. The air compressor should be located at least 12"

away from the wall or other obstructions that will interfere

with the flow of fresh intake and cooling air.

Lubrication and Oil

1. Attach the handle to the compressor saddle by

inserting the handle

and lining up the two bolt holes on each side. Install

the four screws, two on each side. Tighten securely.

2. Install one shoulder bolt and one nut for each wheel.

Tighten securely. The compressor will sit level if the

wheels are properly installed.

3. Clean and dry underside of air tank leg opposite

wheels. Remove the protective paper strip from the

adhesive backed rubber foot strip. Attach the rubber

foot strip to the bottom of leg. Press firmly into place.

If repairing or replacing cord or plug, the grounding wire

must be kept separate from the current-carrying wires.

Never connect the grounding wire to a flat blade plug

terminal. The grounding wire has insulation with an outer

surface that is green with or without yellow stripes.

If these grounding instructions are not completely understood, or if in doubt as to whether the compressor is

properly grounded, have the installation checked by a

qualified electrician.

inside

the compressor saddle

This unit needs no lubrication or oiling.

Grounding Instructions

RISK OF ELECTRICAL SHOCK. In the event of a

short circuit, grounding reduces the risk of shock

by providing an escape wire for the electric

current. This air compressor must be properly

grounded.

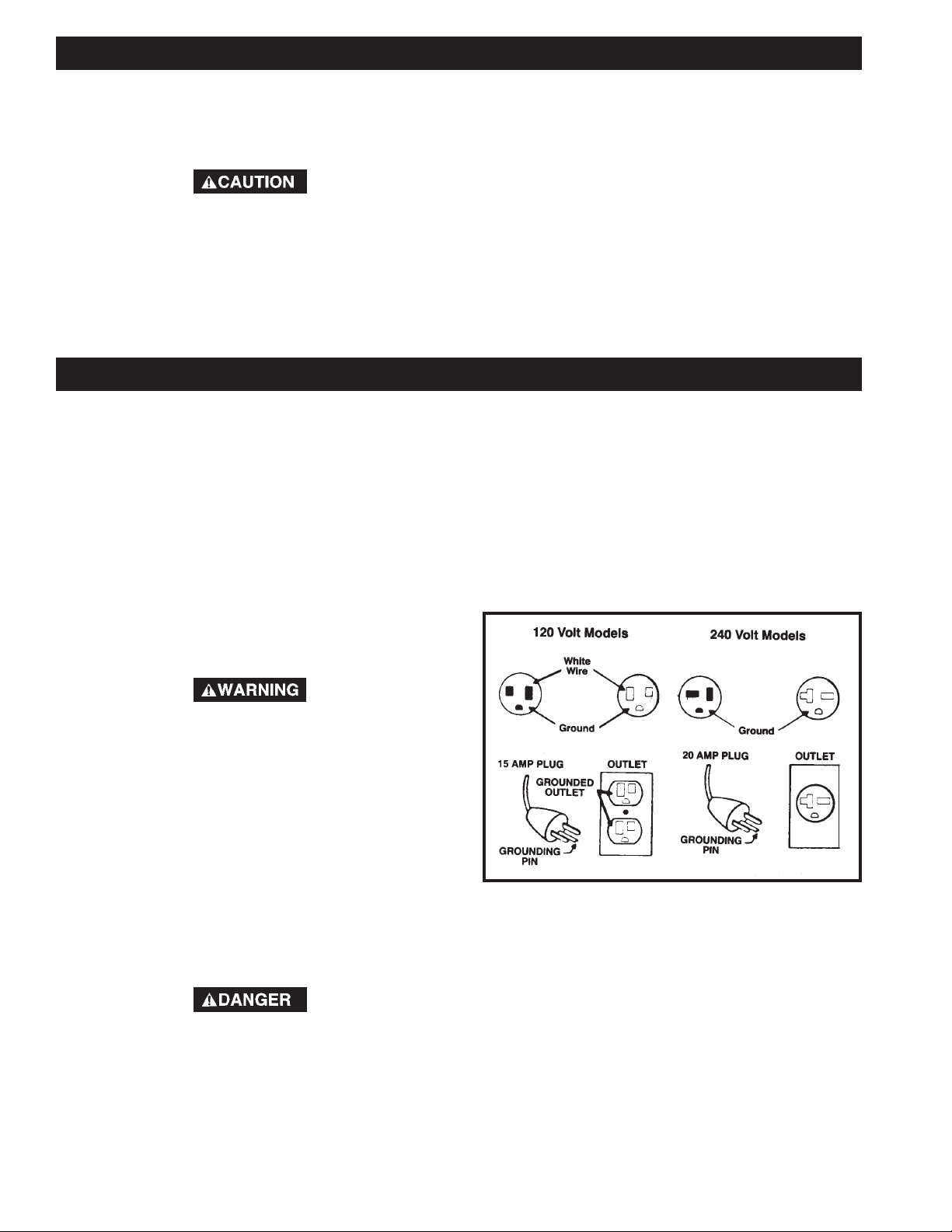

This portable air compressor is equipped with a cord having a grounding wire with an appropriate grounding plug.

The plug must be used with an outlet that has been installed and grounded in accordance with all local codes

and ordinances. The outlet must have the same configuration as the plug. DO NOT USE AN ADAPTER.

Inspect the plug and cord before each use. Do not use if

there are signs of damage.

IMPROPER GROUNDING CAN RESULT IN

ELECTRICAL SHOCK.

Do not modify the plug that has been provided. If it

does not fit the available outlet, the correct outlet

should be installed by a qualified technician.

Voltage and Circuit Protection

Refer to page 5 (Specification Chart) for the voltage and

circuit protection requirements of your compressor. Use

only a fuse or circuit breaker that is the same rating as

the branch circuit the air compressor is operated on. If

the compressor is connected to a circuit protected by

fuses, use only dual element time delay fuses.

Refer to Parts List Manual for your compressor. Certain

air compressor models can be operated on a 15 amp

circuit if:

1. Voltage supply to circuit is normal.

D20015 Rev. 1 6/28/00

8 ENG

Page 9

2. Circuit is not used to supply any other electrical needs

(lights, appliances, etc.)

Break-in Procedure

3. Extension cords comply with a 15 amp circuit breaker

or 15 amp time delay fuse.

4. Circuit is equipped with a 15 amp circuit breaker or

15 amp time delay fuse.

If any of the above conditions cannot be met, or if operation of the compressor repeatedly causes interruption of

power, it may be necessary to operate it from a 20 amp

circuit. It is not necessary to change the cord set.

Extension Cords

It is preferable to use extra air hose instead of an extension cord to avoid voltage drop and power loss to the

motor, and to prevent overheating.

If an extension cord must be used, be sure it is:

• 12 gauge (AWG) or heavier. (Wire size increases as

gauge number decreases. 10 AWG and 8 AWG

may also be used. DO NOT USE 14 OR 16 AWG.)

• a three-wire extension cord that has a three-connec

tor grounding plug, and a three-slot receptacle that

will accept the plug.

• no longer than 50 feet

• in good condition

Serious damage may result if the following

break-in instructions are not closely followed.

This procedure is required only once, before the air compressor is put into service.

1. Set the pressure switch "AUTO/O" lever in the

"O" position for "Off".

2. Plug the power cord into the correct branch circuit

receptacle.

3. Do not attach hose to outlet. Leave the outlet open

to the atmosphere.

4. Turn the regulator

prevent air pressure build-up in the tank.

5. Move the "AUTO/O" lever to "AUTO". The compressor will start.

6. RUN THE COMPRESSOR FOR 15 MINUTES.

Make sure the regulator is open and there is no tank

pressure build-up.

7. After 15 minutes, close the regulator by turning it

counterclockwise

pressure and then the motor will stop.

clockwise

. The air tank will fill to cut-out

, opening it fully, to

OPERATING PROCEDURES

1. Before attaching air hose or accessories, make

sure the "AUTO/O" lever is set to “O” and the air

regulator is closed.

2. Attach hose and accessories.

TOO MUCH AIR PRESSURE CREATES A

HAZARDOUS RISK OF BURSTING. CARE-FULLY

FOLLOW STEPS 3 AND 5 BELOW EACH TIME

THE COMPRESSOR IS USED.

Compressed air from the outfit may contain water

condensation. Do not spray unfiltered air at an

item that could be damaged. Some air operated

tools or devices may require filtered air. Read the

instructions for the air tool or device.

3. Check the manufacturer’s maximum pressure rating

for air tools and accessories. The regulator outlet

pressure must never exceed the maximum

pressure rating.

4. Turn the "AUTO/O" lever to “AUTO” and allow tank

pressure to build. Motor will stop when tank

pressure reaches “cut-out” pressure.

5. Open the regulator by turning it clockwise. Adjust

the regulator to the correct pressure setting. Your

compressor is ready for use.

6. Always operate the air compressor in wellventilated areas; free of gasoline or other solvent

vapors. Do not operate the compressor near the

spray area.

WHEN YOU ARE FINISHED:

7. Set the “AUTO/O” lever to “O”.

8. Turn the regulator

outlet pressure to zero.

9. Remove the air tool or accessory.

10. Open the regulator and allow the air to slowly

bleed from the tank. Close the regulator when

tank pressure is approximately 20 psi.

11. Drain water from air tank.

WATER WILL CONDENSE IN THE AIR TANK. IF

NOT DRAINED, WATER WILL CORRODE AND

WEAKEN THE AIR TANK CAUSING A RISK OF

AIR TANK RUPTURE.

counterclockwise

and set the

NOTE:

If drain cock valve is plugged, release all air

pressure. The valve can then be removed,

cleaned, then reinstalled.

12. After the water has been drained, close the drain

valve. The air compressor can now be stored.

9 ENG

D20015 Rev. 1 6/28/00

Page 10

MAINTENANCE

UNIT CYCLES AUTOMATICALLY WHEN POWER IS ON. WHEN DOING MAINTENANCE, YOU MAY BE EXPOSED TO

VOLTAGE SOURCES, COMPRESSED AIR OR MOVING PARTS. PERSONAL INJURIES CAN OCCUR. BEFORE

PERFORMING ANY MAINTENANCE OR REPAIR, UNPLUG THE COMPRESSOR AND BLEED OFF ALL AIR PRESSURE.

ALL MAINTENANCE AND REPAIR OPERATIONS NOT LISTED MUST BE DONE BY A QUALIFIED SERVICE TECHNICIAN.

Air Filter - Inspection and Replacement

Hot surfaces. Risk of burn. Compressor heads

are exposed when filter cover is removed. Allow

compressor to cool prior to servicing.

Filter Retainer

Filter

Keep the air filter clean at all times. Do not operate the compressor with the air filter removed.

A dirty air filter will not allow the compressor to operate at full

capacity. Before you use the compressor, check the air filter to

be sure it is clean.

Check Valve Cleaning - Replacement

Risk of personal injury. Manifold assembly contains compressed air which can be hazardous.

Manifold gets hot during operation.

Before servicing:

• Unplug or disconnect electrical supply to

compressor.

• Bleed tank of pressure.

• Allow compressor to cool.

1. Release all air pressure from air tank and unplug outfit.

2. Remove shroud. (Key Nos. 1 and 2)

3. Loosen the top and bottom nuts and remove the outlet

tube. (Key Nos. 31, 33, and 34)

4. Remove the pressure release tube, fitting, and

connector. (Key Nos. 25, 26 and 27)

5. Unscrew the check valve (turn counterclockwise) using

a socket wrench. (Key No. 17)

6. Check that the valve disc moves freely inside the check

valve and that the spring holds the disc in the upper,

closed position. The check valve may be cleaned with a

solvent, such as paint and varnish remover.

7. Apply a Teflon based pipe sealant to the check valve

threads. Reinstall the check valve (turn clockwise).

8. Replace the pressure release tube and fitting.

9. Replace the outlet tube and tighten top and bottom

nuts.

10. Replace the shroud.

Safety Valve - Inspection

If the safety valve does not work properly,

over-pressurization may occur, causing air tank

rupture or an explosion. Before starting compressor, pull the ring on the safety valve to make sure

that the safety valve operates freely. If the valve is

stuck or does not operate smoothly, it must be

replaced with the same type of valve.

Motor

The motor has an automatic reset thermal overload protector. If

the motor overheats for any reason, the overload protector will

shut off the motor. The motor must be allowed to cool down

before restarting. The compressor will automatically restart

after the motor cools.

If the overload protector shuts the motor off frequently, check

for a possible voltage problem. Low voltage can also be suspected when:

1. The motor does not get up to full power or speed.

2. Fuses blow out when starting the motor; lights dim

and remain dim when motor is started and is running.

Storage

Before you store the air compressor, make sure you do the

following:

1. Review the Maintenance and “Operating Procedures”

sections and perform maintenance as necessary. Be

sure to drain water from the air tank.

2. Protect the electrical cord and air hose from damage

(such as being stepped on or run over). Wind them

loosely around the compressor handle.

Store the air compressor in a clean and dry location.

D20015 Rev. 1 6/28/00

10 ENG

Page 11

TROUBLESHOOTING GUIDE

PERFORMING REPAIRS MAY EXPOSE VOLTAGE SOURCES, MOVING PARTS OR COMPRESSED AIR SOURCES.

PERSONAL INJURY MAY OCCUR. PRIOR TO ATTEMPTING ANY REPAIRS, UNPLUG THE COMPRESSOR AND

BLEED OFF TANK AIR PRESSURE.

PROBLEM

Excessive tank pressure - safety

valve pops off.

Air leaks at fittings or hose.

Air leaks at pressure switch

release valve.

CAUSE

Pressure switch does not shut off

motor when compressor reaches

cut-out pressure.

Pressure switch cut-out too high.

Tube or hose fittings are not tight

enough.

Defective pressure switch release valve.

Defective or dirty check valve.

CORRECTION

Move the pressure switch lever to the “O”

position. If the compressor doesn’t shut off,

disconnect from the electrical outlet source

and return to a Sears Service Center to replace the pressure switch.

Return the compressor to Sears Service Center

to check and adjust, or replace switch.

Tighten fittings using teflon tape where air

can be heard escaping. Check fittings with

soapy water solution. DO NOT OVER-

TIGHTEN.

Return to Sears Service Center for replacement of pressure switch.

Check to see if the pin in the bottom of the

pressure release valve is stuck. If it does not

move freely, return to the Service Center for

replacement of pressure switch.

A defective check valve results in a constant

air leak at the pressure release valve when

there is pressure in the tank and the compressor is shut off. Remove and clean or replace check valve. DO NOT OVERTIGHTEN.

Air leaks in air tank or at air tank

welds.

Air leaks between head and valve

plate.

Pressure reading on the regulated pressure gauge drops when

an accessory is used.

Air leak from safety valve.

Knocking noise

Defective air tank.

Leaking seal.

It is normal for some pressure drop

to occur.

Possible defect in safety valve.

Defective check valve.

Air tank must be replaced. Do not repair the

leak. Return compressor to Sears Service

Center.

DO NOT DRILL INTO, WELD OR OTHERWISE MODIFY AIR TANK OR IT WILL

WEAKEN. THE TANK CAN RUPTURE OR

EXPLODE.

Torque head screws to 7-10 ft. lbs. If this

does not stop leak, replace seal.

If there is an excessive amount of pressure

drop when the accessory is used, adjust the

regulator.

NOTE

Adjust the regulated pressure under flow conditions (while accessory is being used).

Operate safety valve manually by pulling on

ring. If valve still leaks, it should be

replaced .

Remove and clean, or replace.

11 ENG

D20015 Rev. 1 6/28/00

Page 12

CAUSEPROBLEM

CORRECTION

Compressor is not supplying enough air to operate

accessories.

Motor will not run or restart. Present tank pressure exceeds

Compressor is not large enough

for air requirement.

Restricted air intake filter.

Check valve restricted.

Air leaks.

pressure switch "cut-in" pressure.

Fuse blown, circuit breaker tripped.

Check the accessory air requirement. If it is higher

than the SCFM or pressure supplied by your air

compressor, you need a larger compressor.

Clean or replace air intake filter. Do not operate

the air compressor in any paint spray or drywall

sanding area.

Check and replace if required.Hole in hose.

Remove and clean, or replace.

Tighten fittings.

Motor will start automatically when tank pressure

drops below "cut-in" pressure of pressure switch.

1. Check fuse box for blown fuse and replace, if

necessary. Reset circuit breaker. Do not use a

fuse or circuit breaker with higher rating than

that specified for your particular branch circuit.

2. Check for proper fuse; only Time Delay fuses

are acceptable.

3. Check for low voltage conditions and/or

proper extension cord.

Regulator knob continuous

air leak. Regulator will not

shut off at air outlet.

Motor overload protection switch

has tripped.

Possible defective motor or

capactior.

Paint spray on internal motor

parts.

Check valve stuck open, putting

pressure on head.

Pressure release valve on pressure

switch has not unloaded head

pressure.

Broken exhaust valve.

Dirty or damaged regulator

internal parts.

4. Disconnect the other electrical appliances

from circuit or operate the compressor on its

own branch circuit.

5. Check for loose electrical connections.

Let motor cool off and overload switch will

auto- matically reset.

Return to Sears Service Center for inspection or

replacement, if necessary.

Have compressor checked at Sears Service Center.

Do not operate the compressor in the paint spray

area. See flammable vapor warning.

Remove and clean, or replace the check valve.

Bleed the line by pushing the lever on the pressure

switch to the "O" position; if the valve does not

open, replace it.

Inspect and replace if necessary.

Replace regulator.

D20015 Rev. 1 6/28/00

12 ENG

Page 13

OWNERS MANUAL FOR

CRAFTSMAN

MODEL NO.

SERVICE

PERMANENTLY LUBRICATED

TANK MOUNTED

AIR COMPRESSOR

The model number of your Sears Air Compressor can be

found

on the maintenance label on the top of the shroud or on the

bar code label on the rear of the air tank.

SERVICE AND REPAIR PARTS

CALL 1-800-665-4455*

Keep this number handy should you require a service call or

need to order repair parts.

If ordering parts make sure you have the name, make and

model no. of the merchandise and the name and number of

the part you wish to order.

HOW TO ORDER

REPAIR PARTS

*If calling locally, please use one of the following num-

bers:

Regina - 566-5124 Montreal - 333-5740

Toronto - 744-4900 Halifax - 454-2444

Kitchener - 894-7590 Ottawa - 738-4440

Vancouver - 420-8211

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE

FOLLOWING INFORMATION:

• PART NUMBER • PART DESCRIPTION

• MODEL NUMBER • NAME OF ITEM

All parts listed may be ordered from any Sears Service Center

and most Sears stores.

If the parts you need are not stocked locally, your order will be

electronically transmitted to a Sears Repair Parts Distribution

Center for handling.

Sold By Sears Canada, Inc., Toronto, Ont. M5B 2B8

Page 14

CRAFTSMAN

MANUEL D'INSTRUCTIONS

COMPRESSEUR D’AIR

CRAFTSMAN

N° de modèle

919.727321

IMPORTANT:

Lire attentivement les directives

de sécurité et le mode d’emploi

avant d’utiliser l’appareil.

LUBRIFICATION PERMANENTE

MONTÉ SUR RÉSERVOIR

Inscrire à l’endroit désigné:

1) Le numéro de modèle indiqué sur

l’étiquette d’entretien apposée sur le

moteur ou sur l’étiquette du code

à barres située à l’arrière du réservoir.

2) Le numéro de code de date indiqué

sur l’étiquette apposée à l’arrière du

réservoir d'air.

3) Le numéro de série indiqué sur

l’étiquette apposée à l’arrière du

réservoir d'air.

4) Le numéro d’enregistrement du

réservoir indiqué sur la plaque

signalétique métallique située à

l’arrière du réservoir. Cette plaque

est peinte de la même couleur que

le réservoir.

Consignes de

sécurité

Assemblage

Utilisation

Entretien

Dépannage

Pièces

Noter ces numéros pour référence.

Numéro de modèle______________________

Numéro de série________________________

Code de date___________________________

Numéro du réservoir____________________

D20015 Rev. 1 6/27/00

Vendu par Sears Canada Inc., Toronto, Ontario M5B 2B8

Page 15

TABLE DES MATIÈRES

GARANTIE ........................................................... 2

MISE EN MARCHE ...................................................... 9

CONSIGNES DE SÉCURITÉ .............................. 2

SYMBOLES DE MISE EN GARDE ................3-5

INFORMATION GÉNÉRALE ............................... 6

GLOSSAIRE ......................................................... 6

TABLEAU DES SPÉCIFICATIONS .................... 6

DESCRIPTION DU FONCTIONNEMENT ....... 7

OUTILS NÉCESSAIRES À L’ASSEMBLAGE .... 7

ENTRETIEN .................................................................... 10

Filtre à air - Inspection et remplacement .................... 10

Clapet de retenue - Inspection et remplacement ..... 10

Soupape de sûreté - Inspection et remplacement.... 10

Moteur ........................................................................ 10

Entreposage ............................................................... 10

ASSEMBLAGE ..................................................... 7

GUIDE DE DÉPANNAGE.........................................11-12

PROCÉDÉS DE RODAGE ................................. 8-9

Emplacement du compresseur ..................... 8

Lubrification et huile ...................................... 8

Mise à la masse .............................................. 8

Tension et protection du circuit ....................... 8

Directives de rodage ....................................... 9

SCHÉMA - APPAREIL ................................................... 13

LISTE DES PIÈCES ...................................................... 14

SCHÉMA - BLOC COMPRESSEUR ............................. 15

LISTE DES PIÈCES - BLOC COMPRESSEUR ........... 16

NOTES ........................................................................... 17

COMMANDE DE PIÈCES ................

GARANTIE COMPLÈTE D'UN AN SUR LES COMPRESSEURS

D'AIR SEARS

Si ce compresseur fait défaut, au cours de l'année suivant la date d’achat, pour cause de

défaut de matériau ou main-d’oeuvre, LE RETOURNER À L’UN DES MAGASINS SEARS LE

PLUS PROCHE QUI LE RÉPARERA GRATUITEMENT.

Couverture arrière

Si le compresseur est utilisé à des fins commerciales ou de location, cette garantie se limite

à 90 jours à partir de la date d’achat.

Cette garantie est complémentaire à toute autre garantie statutaire qui peut varier d'une

province à l'autre.

SEARS CANADA INC, TORONTO ONT. M5B 2B8

MESURES DE SÉCURITÉ - DÉFINITIONS

Ce guide contient des renseignements importants que vous devez bien saisir. Cette information porte sur VOTRE SÉCURITÉ et sur LA PRÉVENTION

DE PROBLÈMES D’ÉQUIPEMENT. Afin de vous aider à identifier cette information, nous avons utilisé des signes de danger plus bas. Veuillez lire

attentivement ce guide en portant une attention particulière à ces sections. CONSERVEZ CES DÉFINITIONS/INSTRUCTIONS.

DANGER

DANGER : Indique un danger imminent qui, s'il n'est pas évité,

causera de graves blessures ou la mort.

AVERTISSEMENT

AVERTISSEMENT : Indique la possibilité d’un danger qui, s’il

n’est pas évité, pourrait causer de graves blessures ou la

mort.

MISE EN GARDE : Indique la possibilité d’un danger qui, s’il

n’est pas évité peut causer des blessures mineures ou

moyennes.

MISE EN GARDE (sans le symbole d'attention) : Indique la

possibilité d'un danger qui, s'il n'est pas évité, peut causer des

dommages à la propriété.

MISE EN GARDE

MISE EN GARDE

D20015 Rev. 1 6/27/00

2 FR

Page 16

MESURES DE SÉCURITÉ IMPORTANTES

CONSERVER CES DIRECTIVES

AVERTISSEMENT

UN EMPLOI OU UN ENTRETIEN NON APPROPRIÉS DE CE PRODUIT PEUT CAUSER DES BLESSURES GRAVES ET DES DOMMAGES

À LA PROPRIÉTÉ. LIRE ATTENTIVEMENT TOUS LES AVERTISSEMENTS ET LES DIRECTIVES D’UTILISATION AVANT D’UTILISER CET

APPAREIL.

DANGER

RISQUE D’EXPLOSION OU D’INCENDIE

RISQUE

LES ÉTINCELLES QUI PROVIENNENT DES CONTACTS ÉLECTRIQUES DU

MOTEUR ET DU MANOSTAT SONT CONSIDÉRÉES NORMALES.

SI DES ÉTINCELLES ÉLECTRIQUES DU COMPRESSEUR ENTRENT EN CONTACT

AVEC DES VAPEURS INFLAMMABLES, ELLES PEUVENT S’ENFLAMMER,

PROVOQUANT UN INCENDIE OU UNE EXPLOSION.

TOUTE OBSTRUCTION DES ORIFICES D’AÉRATION DU COMPRESSEUR

ENTRAÎNERA UNE SURCHAUFFE DANGEREUSE ET RISQUE DE CAUSER UN

INCENDIE.

.

SI CET APPAREIL FONCTIONNE SANS SUPERVISION, CELA RISQUE DE

CAUSER DES BLESSURES GRAVES OU DES DOMMAGES À LA PROPRIÉTÉ.

TOUJOURS UTILISER LE COMPRESSEUR DANS UN ENDROIT BIEN AÉRÉ,

LOIN DE TOUTE MATIÈRE COMBUSTIBLE ET DES VAPEURS D’ESSENCE OU

DE SOLVANTS.

SI DES MATIÈRES INFLAMMABLES DOIVENT ÊTRE VAPORISÉES, SITUER LE

COMPRESSEUR À UNE DISTANCE D’AU MOINS 20 PIEDS DE LA ZONE DE

VAPORISATION. IL PEUT S’AVÉRER NÉCESSAIRE D’UTILISER UN BOYAU

SUPPLÉMENTAIRE.

ENTREPOSER LES MATIÈRES INFLAMMABLES DANS UN ENDROIT

SÉCURITAIRE, LOIN DU COMPRESSEUR.

NE JAMAIS PLACER DES OBJETS CONTRE OU SUR LE COMPRESSEUR.

UTILISER LE COMPRESSEUR DANS UN ENDROIT OUVERT, À AU MOINS 12

POUCES (30 cm) DE TOUT MUR OU OBSTRUCTION QUI RÉDUIT LE DÉBIT

D’AIR FRAIS VERS LES ORIFICES D’AÉRATION.

UTILISER LE COMPRESSEUR DANS UN ENDROIT PROPRE. NE PAS UTILISER

L’APPAREIL À L’INTÉRIEUR OU DANS UN ENDROIT CLOS.

TOUJOURS RESTER À PROXIMITÉ DE L’APPAREIL LORSQU’IL EST EN

FONCTION.

PRÉVENTION

RISQUE D’ÉCLATEMENT

RÉSERVOIR D’AIR : LES CONDITIONS SUIVANTES PEUVENT AFFAIBLIR LES PAROIS DU RÉSERVOIR ET PROVOQUER UNE

EXPLOSION VIOLENTE DU RÉSERVOIR QUI RISQUE DE CAUSER DES DOMMAGES À LA PROPRIÉTÉ

OU DES BLESSURES GRAVES.

RISQUE

1. LE DÉFAUT DE VIDANGER DE FAÇON APPROPRIÉE L’EAU CONDENSÉE

DANS LE RÉSERVOIR RISQUE DE CAUSER LA ROUILLE ET L’AMINCISSEMENT

DES PAROIS EN ACIER DU RÉSERVOIR.

2. DES MODIFICATIONS OU TENTATIVES DE RÉPARATION FAITES SUR LE

RÉSERVOIR.

3. DES MODIFICATIONS NON AUTORISÉES APPORTÉES À LA SOUPAPE DE

DÉCHARGE, À LA SOUPAPE DE SÛRETÉ OU À TOUTE AUTRE COMPOSANTE

QUI CONTRÔLE LA PRESSION DU RÉSERVOIR.

4. DES VIBRATIONS EXCESSIVES PEUVENT AFFAIBLIR LE RÉSERVOIR ET

CAUSER UNE RUPTURE OU UNE EXPLOSION. DES VIBRATIONS EXCESSIVES

SERONT PRODUITES SI LE COMPRESSEUR N’EST PAS FIXÉ DE FAÇON

APPROPRIÉE.

FIXATIONS ET ACCESSOIRES :

LE FAIT D’EXCÉDER LA PRESSION NOMINALE DES OUTILS PNEUMATIQUES,

PISTOLETS PULVÉRISATEURS, ACCESSOIRES PNEUMATIQUES, PNEUS ET AUTRES

OBJETS GONFLABLES RISQUE DE PROVOQUER L’EXPLOSION DE CES

DERNIERS ET LA PROJECTION DE PIÈCES, CE QUI RISQUE DE CAUSER DE

GRAVES BLESSURES.

PRÉVENTION

PURGER LE RÉSERVOIR QUOTIDIENNEMENT OU APRÈS CHAQUE

UTILISATION. SI LE RÉSERVOIR ACCUSE UNE FUITE, LE REMPLACER

IMMÉDIATEMENT PAR UN NOUVEAU RÉSERVOIR OU REMPLACER LE

COMPRESSEUR AU COMPLET.

NE JAMAIS PERFORER AVEC UNE PERCEUSE, SOUDER OU FAIRE UNE

MODIFICATION QUELCONQUE AU RÉSERVOIR OU À SES ACCESSOIRES.

LE RÉSERVOIR EST CONÇU POUR SUBIR DES PRESSIONS DE SERVICE

PARTICULIÈRES. NE JAMAIS EFFECTUER DES RÉGLAGES NI SUBSTITUER

DES PIÈCES POUR MODIFIER LES PRESSIONS DE SERVICE ÉTABLIES À

L’USINE.

POUR LE CONTRÔLE ESSENTIEL DE LA PRESSION D’AIR, IL FAUT POSER UN

RÉGULATEUR DE PRESSION ET UN MANOMÈTRE À LA SORTIE D’AIR DU

COMPRESSEUR. SUIVRE LES RECOMMANDATIONS DU FABRICANT DE

L’ÉQUIPEMENT ET NE JAMAIS EXCÉDER LA VALEUR NOMINALE DE PRESSION

SPÉCIFIÉE DES ACCESSOIRES. NE JAMAIS UTILISER LE COMPRESSEUR POUR

GONFLER DES OBJETS À FAIBLE PRESSION, TELS QUE LES JOUETS

D’ENFANT, LES BALLONS DE FOOTBALL OU DE BASKET-BALL, ETC.

3 FR

D20015 Rev. 1 6/27/00

Page 17

DANGER

RISQUE DE PROJECTION D’OBJETS

RISQUE

LE JET D’AIR COMPRIMÉ PEUT CAUSER DES LÉSIONS AUX TISSUS DE

LA PEAU EXPOSÉE ET PEUT PROJETER DE LA SALETÉ, DES COPEAUX, DES

PARTICULES LIBRES ET DE PETITS OBJETS À HAUTE VITESSE, CE QUI

RISQUE DE CAUSER DES DOMMAGES À LA PROPRIÉTÉ OU DES BLESSURES.

RISQUE PAR INHALATION

RISQUE

L’AIR COMPRIMÉ DE VOTRE COMPRESSEUR D’AIR N’EST PAS SÉCURITAIRE

POUR L’INHALATION. LE JET D’AIR PEUT CONTENIR DU MONOXYDE DE

CARBONE, DES VAPEURS TOXIQUES OU DES PARTICULES SOLIDES DU

RÉSERVOIR.

LES MATIÈRES VAPORISÉES TELLES QUE LA PEINTURE, LES SOLVANTS DE

PEINTURE, LES DÉCAPANTS, LES INSECTICIDES ET LES HERBICIDES

CONTIENNENT DES VAPEURS NOCIVES ET TOXIQUES.

PRÉVENTION

PORTER TOUJOURS DES LUNETTES DE PROTECTION HOMOLOGUÉES

ANSI Z87.1 AVEC DES ÉCRANS LATÉRAUX LORS DE L’UTILISATION DU

COMPRESSEUR.

NE JAMAIS DIRIGER LA BUSE OU LE PULVÉRISATEUR VERS SOI, VERS

D’AUTRES PERSONNES OU VERS DES ANIMAUX.

TOUJOURS METTRE LE COMPRESSEUR HORS FONCTION ET PURGER LA

PRESSION DU BOYAU D’AIR ET DU RÉSERVOIR AVANT D’ENTAMER

L’ENTRETIEN OU D’ATTACHER DES OUTILS OU ACCESSOIRES.

PRÉVENTION

TOUJOURS UTILISER LE COMPRESSEUR D’AIR À L’EXTÉRIEUR, DANS UN

ENDROIT PROPRE ET BIEN AÉRÉ. ÉVITER DES ENDROITS CLOS TELS QUE

GARAGES, SOUS-SOLS ET HANGARS D’ENTREPOSAGE QUI NE SONT PAS

DOTÉS DE SYSTÈMES D’ÉCHANGE D’AIR. GARDER LES ENFANTS, LES

ANIMAUX DOMESTIQUES ET AUTRES, LOIN DE LA ZONE DE TRAVAIL.

NE JAMAIS INHALER L’AIR ÉMIS PAR LE COMPRESSEUR, QUE CE SOIT

DIRECTEMENT OU AU MOYEN D’UN DISPOSITIF RESPIRATEUR BRANCHÉ AU

COMPRESSEUR.

TRAVAILLER DANS UN ENDROIT OÙ IL Y A UNE BONNE VENTILATION

TRANSVERSALE. BIEN LIRE ET RESPECTER LES DIRECTIVES DE SÉCURITÉ

INDIQUÉES SUR L’ÉTIQUETTE OU LA FICHE SIGNALÉTIQUE DE LA MATIÈRE

QUI EST VAPORISÉE. PORTER UN RESPIRATEUR HOMOLOGUÉ PAR LE

NIOSH/MSHA ET CONÇU POUR L’APPLICATION EN QUESTION.

RISQUE DE CHOC ÉLECTRIQUE

RISQUE

VOTRE COMPRESSEUR D’AIR EST ALIMENTÉ PAR ÉLECTRICITÉ. COMME

AVEC TOUS LES APPAREILS ÉLECTRIQUES, SI L’APPAREIL N’EST PAS

UTILISÉ DE FAÇON APPROPRIÉE, IL PEUT CAUSER DES CHOCS

ÉLECTRIQUES.

TOUTE RÉPARATION EFFECTUÉE PAR UNE PERSONNE NON QUALIFIÉE

PEUT ENTRAÎNER DES BLESSURES GRAVES OU LA MORT PAR

ÉLECTROCUTION.

MISE À LA TERRE : LE DÉFAUT D’ÉTABLIR UNE MISE À LA TERRE

APPROPRIÉE POUR CET APPAREIL PEUT ENTRAÎNER DES BLESSURES

GRAVES OU LA MORT PAR ÉLECTROCUTION. VOIR LES DIRECTIVES DE

MISE À LA TERRE.

D20015 Rev. 1 6/27/00

PRÉVENTION

NE JAMAIS FAIRE FONCTIONNER LE COMPRESSEUR À L’EXTÉRIEUR

LORSQU’IL PLEUT OU DANS DES CONDITIONS HUMIDES.

NE JAMAIS FAIRE FONCTIONNER LE COMPRESSEUR SANS LES

COUVERCLES OU LORSQUE CEUX-CI SONT ENDOMMAGÉS.

TOUT CÂBLAGE ÉLECTRIQUE OU TOUTE RÉPARATION REQUIS SUR CET

APPAREIL DEVRAIT ÊTRE EFFECTUÉ PAR LE PERSONNEL D’UN CENTRE

DE SERVICE APRÈS-VENTE AUTORISÉ, CONFORMÉMENT AUX CODES

ÉLECTRIQUES NATIONAUX ET LOCAUX.

S’ASSURER QUE LE CIRCUIT ÉLECTRIQUE ALIMENTANT LE COMPRESSEUR

FOURNIT UNE MISE À LA TERRE ÉLECTRIQUE APPROPRIÉE, UNE

TENSION APPROPRIÉE ET UNE PROTECTION ADÉQUATE PAR FUSIBLES.

4 FR

Page 18

DANGER

RISQUE RELIÉ AUX PIÈCES MOBILES

RISQUE

LES PIÈCES MOBILES TELLES QUE LA POULIE, LE VOLANT-MOTEUR ET LA

COURROIE PEUVENT ENTRAÎNER DES BLESSURES GRAVES SI ELLES

ENTRENT EN CONTACT AVEC UNE PARTIE DU CORPS OU DES VÊTEMENTS.

EN TENTANT DE FAIRE FONCTIONNER LE COMPRESSEUR AVEC DES

PIÈCES MANQUANTES OU ENDOMMAGÉES, OU DE RÉPARER LE

COMPRESSEUR SANS LES GARDES DE PROTECTION, ON S’EXPOSE AUX

PIÈCES MOBILES, CE QUI PEUT ENTRAÎNER DES BLESSURES GRAVES.

RISQUE DE BRÛLURES

RISQUE

LE FAIT DE TOUCHER AUX SURFACES DE MÉTAL EXPOSÉES TELLES QUE

LA TÊTE DU COMPRESSEUR OU LES TUBES DE SORTIE PEUT CAUSER DE

GRAVES BRÛLURES À LA PEAU.

LA TÊTE DU COMPRESSEUR ET LES TUBES DEVIENNENT TRÈS CHAUDS LORS

DU FONCTIONNEMENT.

PRÉVENTION

NE JAMAIS FAIRE FONCTIONNER LE COMPRESSEUR SANS LES GARDES

OU LES COUVERCLES OU LORSQUE CEUX-CI SONT ENDOMMAGÉS.

TOUTE RÉPARATION REQUISE SUR CET APPAREIL DEVRAIT ÊTRE

EFFECTUÉE PAR LE PERSONNEL D’UN CENTRE DE SERVICE APRÈSVENTE AUTORISÉ.

PRÉVENTION

NE JAMAIS TOUCHER AUX PIÈCES DE MÉTAL EXPOSÉES DU MOTEUR

OU DU COMPRESSEUR DURANT OU IMMÉDIATEMENT APRÈS LE

FONCTIONNEMENT. LE MOTEUR ET LE COMPRESSEUR DEMEURENT

CHAUDS PENDANT PLUSIEURS MINUTES APRÈS LEUR FONCTIONNEMENT.

NE PAS TENTER D’ATTEINDRE LES COMPOSANTES DERRIÈRE LES GARDES DE

PROTECTION ET NE PAS EFFECTUER DE L’ENTRETIEN AVANT D’AVOIR LAISSÉ

REFROIDIR L’APPAREIL.

RISQUE DE CHUTE

RISQUE

UN COMPRESSEUR PORTATIF PEUT TOMBER D’UNE TABLE, D’UN ÉTABLI OU

D’UN TOIT. L’IMPACT PEUT CAUSER DES DOMMAGES AU COMPRESSEUR

ET DES BLESSURES CORPORELLES OU LA MORT DE L’UTILISATEUR.

TOUJOURS S’ASSURER DE LA STABILITÉ DU COMPRESSEUR AVANT DE LE

FAIRE FONCTIONNER AFIN DE PRÉVENIR TOUT MOUVEMENT ACCIDENTEL DE

L’APPAREIL. NE JAMAIS UTILISER UN COMPRESSEUR SUR UN TOIT OU

DANS UNE POSITION ÉLEVÉE ; UTILISER PLUTÔT UN BOYAU D’AIR

SUPPLÉMENTAIRE POUR ATTEINDRE LES ENDROITS ÉLEVÉS.

RISQUE DE DOMMAGES À LA PROPRIÉTÉ PENDANT LE

TRANSPORT DU COMPRESSEUR

(incendie, inhalation, dommages aux surfaces du véhicule)

RISQUE

DES FUITES OU DES DÉVERSEMENTS D’HUILE PEUVENT SE

PRODUIRE ET ENTRAÎNER DES RISQUES D’INCENDIE, OU DES

PROBLÈMES AUX VOIES RESPIRATOIRES, DES BLESSURES GRAVES

OU LA MORT. DES FUITES D’HUILE ENDOMMAGENT LES TAPIS, LA

PEINTURE ET TOUTE AUTRE SURFACE DES VÉHICULES OU DES

REMORQUES.

TOUJOURS PLACER LE COMPRESSEUR SUR UN TAPIS DE

PROTECTION POUR ÉVITER L’ENDOMMAGEMENT DU VÉHICULE PAR

DES FUITES. RETIRER LE COMPRESSEUR DU VÉHICULE

IMMÉDIATEMENT À L’ARRIVÉE.

PRÉVENTION

PRÉVENTION

ESW-99 — 9/26/99

5 FR

D20015 Rev. 1 6/27/00

Page 19

INFORMATION GÉNÉRALE

Vous avez acheté un compresseur d'air comprenant un

bloc compresseur à un cylindre, muni d'une pompe de

compresseur monocellulaire et d'un réservoir d'air

comprimé. Les accessories suivants sont fournis avec le

compresseur: roues détendeur, manomètres et poignée.

Le compresseur ne requiert pas d’huile de lubrification.

Vous pouvez donc jouir de votre compresseur sans

devoir acheter, ajouter ni changer l'huile.

Votre compresseur peut être utilisé pour faire fonctionner

des pistolets vaporisateurs de peinture, outils

GLOSSAIRE

CFM: (Cubic feet per minute) pi.cu.par minute

SCFM: (standard CFM) pi.cu/min. standard. C’est une

mesure du débit d'air.

PSI: (Pounds per square inch) lbs./po.ca., unité de

mesure de pression.

ASME: American Society of Mechanical Engineers.

L’équipement est fabriqué et testé conformément aux

standards ASME.

Point de déclenchement du pressostat: Quand le

moteur est à l’arrêt, la pression à l’intérieur du réservoir

diminue au fur et à mesure qu’on utilise les accessoires.

Quand la pression à l’intérieur du réservoir baisse

au-dessous d’un certain niveau, le moteur redémarre

automatiquement. Ce niveau est appelé “point de

déclenchement du pressostat” (Cut-in pressure)

pneumatiques, canons ou pistolets pneumatiques,

brocheuses pneumatiques, brosses pneumatiques ou

accessoires de gonflage. Un régulateur de pression est

généralement utilisé dans ce genre d’applications.

Des filtres à air déshydrateurs supplémentaires qui

éliminent les impuretés et l’humidité contenues dans l’air

doivent être branchés au tuyau dans certains cas.

Si l’on désire un réglage de pression très précis de l’outil,

l’ajout d’un second détendeur est recommandé.

Point de consigne d’arrêt du pressostat: Quand on

met en fonctionnement le compresseur, la pression à

l’intérieur du réservoir augmente jusqu’à un certain

niveau auquel le compresseur s’arrête, protégeant

ainsi le réservoir de pressions excessives. Ce niveau

est appelé “point d’arrêt du pressostat” (Cut-out

pressure)

ACNOR: Les appareils électriques vendus au Canada

doivent porter la certification de l’Acnor. L’Acnor est

l’Association canadienne de normalisation. C’est elle qui

établit les normes de sécurité et qui effectue les

vérifications. L’équipement Sears certifié Acnor dépasse

souvent les normes électriques et sécuritaires exigées

par l’ACNOR.

D20015 Rev. 1 6/27/00

TABLEAU DES SPÉCIFICATIONS

N° de modèle

Alésage

Course

Tension - monophasée

Capacité minimum du branchement électrique

Type de fusible

Ampérage à la pression maximum

Capacité du réservoir d’air

Point de déclenchement du pressostat (marche)

Point d'arrêt du pressostat (arrêt)

SCFM (pi.cu./min.std).@ 40 psi

SCFM (pi.cu./min.std).@ 90 psi

6 FR

919.727321

2 3/8 po

1.35 po

120

15 A

à action différée

15 A

É

ASME / 25 gal.

100 psi

130 psi

.-U.

7.8

5.5

Page 20

DESCRIPTION DU FONCTIONNEMENT

Pompe de compresseur d'air : Pour comprimer l’air, le

piston se meut de bas en haut et vice versa, dans le

cylindre. Pendant la descente du piston, l'air est aspiré

dans les soupapes d'admission. Les soupapes

d'échappement demeurent fermées. Pendant la montée

du piston, l'air est comprimé. Les soupapes d'admission

se ferment et l'air comprimé est aspiré dans les soupapes

d'échappement et ensutie dans le tuyau de sortie, le

clapet de retenue et dans le réservoir d'air.

Clapet de retenue : Quand le compresseur fonctionne,

le clapet de retenue est ouvert permettant ainsi à l’air

comprimé de passer dans le réservoir. Quand le

compresseur s’arrête au point d’arrêt, le clapet de

retenue se ferme, empêchant le retour d’air du réservoir.

Pressostat : Le pressostat est muni d’un petit levier et

d’une étiquette indiquant “Auto/O”.

compresseur ne fonctionne pas.

pressostat met en marche automatiquement le moteur

quand la pression dans le réservoir baisse au-dessous

du point de déclenchement. Il arrête le moteur quand la

pression du réservoir atteint le point d’arrêt du pressostat.

Détendeur de pression : Le détendeur de pression situé

du côté du prressostat, est conçu pour libérer

automatiquement l'air comprimé de la culasse du

compresseur et du tuyau de sortie lorsque le «point

d'arrêt» est atteint dans le compresseur ou que celui-ci

est fermé. Si l'air n'est pas libéré, le moteur tentera de

démarrer mais ne pourra le faire.

Valve de décharge : Cette valve permet d’évacuer l’air

de la culasse du compresseur, au démarrage, jusqu’à ce

que le compresseur atteigne sa vitesse de croisière.

moment, la valve se ferme et le compresseur comprime

l’air. Ce dispositif réduit l’ampérage au démarrage.

Soupape de sûreté : Si le pressostat n’arrête pas le

compresseur au point d’arrêt, la soupape de sûreté

protège l’unité contre des pressions excessives en

faisant évacuer l’air à un point de pression préalablement

fixé par le fabricant de la soupape (légèrement supérieur

au point d'arrêt.

À la position “O” le

À la position “Auto”, le

À ce

Régulateur de pression : La pression de l’air arrivant du

réservoir est contrôlée par le bouton du régulateur. Le

bouton est du type insensible aux vibrations. Tirer le

bouton vers le haut pour modifier la pression et le presser

vers le bas pour le bloquer. Tourner le bouton dans le

sens des aiguilles d’une montre pour augmenter la

pression, et le tourner dans le sens inverse pour la

diminuer. Pour éviter les rajustements nécessaires quand

on change le point de déclenchement, commencer par

une pression inférieure pour atteindre la pression de

réglage désirée. Si vous partez d’un point de pression

supérieur à celui désiré, descendez plus bas que ce

dernier et remontez pour atteindre le point désiré. La

pression de sortie pour un outil devra tenir compte des

exigences de celui-ci et devra probablement être réglée

pendant son fonctionnement.

Manomètre du détendeur : Le manomètre de sortie

indique la pression de l’air sortant du détendeur vers

l’outil. Cette pression est contrôlée par le détendeur et est

toujours égale ou inférieure à la pression du réservoir (Voir

“Mise en marche”).

Manomètre du réservoir : Le manomètre du réservoir

indique la pression d'air dans le réservoir.

Système de refroidissement : Le compresseur est

équipé d’un système de refroidissement perfectionné.

L’élément principal est un ventilateur qui dans son

fonctionnement normal débite une grande quantité d’air

à travers les trous de ventilation. La présence de cet air

est une indication que le système de refroidissement

fonctionne adéquatement.

Vanne de vidange : La vanne est située au bas du

réservoir et sert à vidanger l’eau de condensation qui

s’est accumulée dans le réservoir. Pour vidanger, dégager

la pression par la vanne de sûreté jusqu’à 15 psi.

Dévisser ensuite la vanne de vidange pour vidanger

l’eau.

OUTILS NÉCESSAIRES À L’ASSEMBLAGE

• Douille 9/16 po et clé ouverte pour enlever les cartons

d'emballage.

• Clé ouverte ou douille 3/8 po pour fixer les vis de la

poignée.

7 FR

D20015 Rev. 1 6/27/00

Page 21

ASSEMBLAGE

Montage des roues, des poignées et de la bande de

caoutchouc.

Les roues et la poignée ne sont pas conçus pour

supporter le poids de l’appareil. Pour transporter

l’appareil, ce dernier doit être soulevé à l’aide d’un

appareil de levage ou poussé sur une rampe.

1. Fixer la poignée au compresseur en l’insérant dans

l’étrier tout en alignant les deux trous de part et

PROCÉDÉS DE RODAGE

Emplacement du compresseur

Le compresseur doit fonctionner dans un milieu sec,

propre et bien aéré. Le filtre à air doit être dégagé de toute

obstruction qui pourrait diminuer le débit d’air. Le

compresseur doit être installé à au moins 12 pouces du

mur ou de toute obstruction qui pourrait limiter le débit

d’air de refroidissement.

Lubrification et huile

Ce compresseur ne requiert pas d’huile de lubrification.

d’autre. Monter les deux vis de chaque côté et bien

serrer.

2. Pour monter les roues, fixer un boulon à épaulement

et une rondelle pour chaque roue. Bien serrer. Si les

roues sont bien montées, le compresseur sera de

niveau.

3. Nettoyer et sécher le pied du réservoir situé à

l’opposé des roues. Enlever le papier de protection

du repose-pied de caoutchouc. Coller la bande sur

le pied. Bien la presser pour la coller.

Lors de la réparation ou du remplacement du cordon

ou de la fiche, le fil de mise à la masse doit être isolé

des fils sous tension. Ne jamais raccorder le fil de

mise à la masse à une fiche à broche plate. Le fil de

mise à la masse est isolé et est de couleur verte avec

ou sans raie jaune.

Si la procédure de mise à la masse telle que décrite

n’est pas bien comprise ou si l’on n’est pas sûr de la

mise à la masse existante, demander l’aide d’un

électricien qualifié.

Mise à la masse

Un contact avec la masse pourrait occasionner

des chocs électriques. La mise à la masse

canalise ce courant accidentel vers la masse,

éliminant ainsi les risques d’électrocution. Cet

appareil doit être mis à la masse correctement.

Le compresseur est équipé d’un cordon d’alimentation

dont la fiche est pourvue d’une broche de mise à la

masse. Cette fiche doit être branchée à une prise compatible, ayant une mise à la masse conforme aux réglements

locaux. La prise doit avoir la même forme que la fiche.

Inspecter la fiche et la prise chaque fois qu’on branche le

compresseur et les changer si elles sont endommagées

ou usées.

UNE MAUVAISE MISE À LA MASSE POURRAIT

OCCASIONNER DES CHOCSÉLECTRIQUES.

Ne pas modifier la fiche du cordon d’alimentation

électrique de l’appareil. Si la prise existante n’est

pas compatible, en faire installer une par un

électricien.

Lors de la réparation ou du remplacement du cordon

ou de la fiche, le fil de mise à la masse doit être isolé

des fils sous tension. Ne jamais raccorder le fil de

mise à la masse à une fiche à broche plate. Le fil de

mise à la masse est isolé et est de couleur verte avec

ou sans raie jaune.

D20015 Rev. 1 6/27/00

8 FR

Modèles de 120 volts Modèles de 240 volts

Fil blanc

Mise à la terre

FICHE DE 15 AMP

PRISE AVEC

MISE A LA

TERRE

POINTE DE

MISE À

LA TERRE

PRISE

Mise à la terre

FICHE DE 20 AMP

POINTE

MISE À

LA TERRE

PRISE

Tension et protection du circuit

Voir le tableau des spécifications en page 5 pour la

tension adéquate et la protection du circuit électrique.

N’utiliser qu’un fusible ou un disjoncteur ayant la même

capacité que le circuit alimentant le compresseur. Si le

circuit est protégé par un fusible, n’utiliser qu’un fusible

à action différée, à double élément.

Voltage and Circuit Protection

Consultez la Liste des pièces de votre compresseur.

Certains modèles de compresseur d’air peuvent

fonctionner sur un circuit de 15 ampères, à condition

que :

1. L’alimentation de la tension du circuit soit normale.

2. Le circuit ne soit pas utilisé pour fournir du courant à

d’autres besoins électriques (éclairage, appareils

ménagers, etc.).

Page 22

3. La rallonge soit conforme aux spécifications de ce

guide.

4. Le circuit soit muni d’un disjoncteur de 15 ampères

ou d’un fusible à retardement de 15 ampères.

Si les conditions plus haut mentionnées ne peuvent être

satisfaites, ou s’il y a une interruption de courant à

maintes reprises durant le fonctionnement du

compresseur, il se peut que vous deviez utiliser un circuit de 20 ampères. Dans un tel cas, il n’est pas

nécessaire de changer le cordon d’alimentation.

Rallonges

Si la distance est grande, il est préférable d’utiliser un

boyau d’air supplémentaire au lieu d’utiliser une rallonge

électrique. Cette dernière occasionne au moteur, une

chute de tension, une perte de puissance et son

échauffement.

Si l’on est forcé d’utiliser une rallonge électrique, se

conformer à ce qui suit:

• N’utiliser qu’une rallonge de calibre 12 AWG ou plus

gros (10 AWG ou 8 AWG). Noter que dans les fils, plus

le chiffre est petit plus le fil est gros. Ne pas utiliser du

14 ou du 16 AWG.

• Utiliser une fiche et une prise à trois broches dont une

de mise à la masse.

• La longueur de la rallonge ne doit pas dépasser 50 pi

• La rallonge doit être en bon état.

Directives de rodage

Des dégâts sérieux peuvent s’ensuivre si on ne

suit pas scrupuleusement les directives

suivantes de rodage.

Cette procédure n’est requise qu’une seule fois avant la

mise en service initiale du compresseur.

1. Mettre le levier Auto/O du pressostat à la position

d’arrêt “O” (off)

2. Enficher la fiche du cordon d’alimentation dans sa

prise.

3. Ne pas brancher le boyau au raccord de sortie d’air.

4. Tourner le détendeur dans le sens des aiguilles d’une

montre pour l’ouvrir complètement et empêcher une

montée de pression dans le réservoir.

5. Mettre le levier du détendeur à la position “Auto”. Le

compresseur se mettra en marche.

6. LAISSER LE COMPRESSEUR FONCTIONNER

DURANT 15 MINUTES. S’assurer que le détendeur

est ouvert et qu’il n’y a pas de montée de pression

dans le réservoir.

7. Après 15 minutes, fermer le détendeur en le tournant

dans le sens contraire des aiguilles d’une montre.

Le réservoir commence à se remplir d’air et le moteur

s’arrête quand la pression dans le réservoir atteint le

point de consigne d’arrêt du pressostat.

MISE EN MARCHE

1. Avant de brancher le boyau d’air ou un accessoire,

s’assurer que le levier AUTO/O est à la position “O”

et que le détendeur est fermé.

2. Brancher le boyau et les accessoires.

Une pression d’air excessive est un danger

potentiel pouvant provoquer l’éclatement d’un

outil.Suivre scrupuleusement les étapes 3 et 5

suivantes chaque fois qu’on utilise le

compresseur.

L’air comprimé peut contenir de l’eau de condensation. Ne pas vaporiser avec de l’air comprimé

non filtré, des objets pouvant être détériorés.

Certains outils pneumatiques exigent de l’air

comprimé filtré. Lire les instructions se

rapportant à l’outil.

3. Vérifier la pression maximum permise par le

fabricant de l’outil. La pression à la sortie du

détendeur ne doit jamais dépasser ce maximum.

4. Mettre le levier à la position “Auto”. Le réservoir se

remplit d’air et le moteur s’arrête quand la pression

dans le réservoir atteint le point d’arrêt du pressostat.

5. Ouvrir le détendeur en le tournant dans le sens des

aiguilles d’une montre. Régler le détendeur à la

pression de sortie adéquate. Le compresseur

est à présent prêt à l’utilisation.

6. N’utiliser le compresseur d'air que dans des locaux

bien ventilés et dépourvus de vapeurs d’essence ou

de solvant. Ne pas faire fonctionner le compresseur

près des locaux de vaporisation.

Une fois les travaux terminés:

7. Mettre le levier à la position d’arrêt “O”

8. Tourner le détendeur dans le sens contraire des

aiguilles d’une montre et régler la pression de sortie

à zéro.

9. Débrancher l’outil ou l’accessoire.

10. Ouvrir le détendeur et évacuer l’air du réservoir.

Fermer le détendeur quand la pression atteint

20 psi

11. Vidanger l’eau de condensation du réservoir.

La vapeur d’eau contenue dans l’air comprimé se

condense dans le réservoir Si cette eau n’est pas

vidangée, elle occasionnera la corrosion et

l’affaiblissement du réservoir, pouvant provoquer

sa rupture.

Note

Si la vanne de vidange est bouchée, dégager toute

la pression du réservoir. Démonter la vanne, la

nettoyer et la remonter.

12. Une fois le réservoir vidangé, fermer la vanne de

vidange. Le compresseur est à présent prêt pour

l’entreposage.

9 FR

D20015 Rev. 1 6/27/00

Page 23

ENTRETIEN

L'appareil fonctionne et s’arrête automatiquement quand il est branché. Quand on entreprend des travaux

d’entretien, on s’expose à une tension électrique, à de l’air comprimé et à des pièces en mouvement et de

graves blessures peuvent en résulter. Pour éviter tout danger, toujours débrancher le compresseur de

l’alimentation de courant et vider l’air du réservoir avant de procéder aux travaux d’entretien.

Tous les travaux autres que ceux décrits dans ce manuel ne doivent être effectués que par un technicien qualifié.

Filtre à air - Inspection et remplacement

Surfaces chaudes. Risque de brûlures. Quand le

couvercle du filtre est ôté, la culasse du

compresseur est accessible. Attendre que le

compresseur refroidisse avant de procéder aux

travaux d’entretien.

Filtre à air

Bague de

Filtre

retenue

Maintenir toujours le filtre à air propre. Ne pas faire

fonctionner le compresseur sans filtre à air. Un filtre

sale ne permet pas au compresseur de fonctionner à

sa capacité maximale. Donc, avant de faire fonctionner

le compresseur, s’assurer que le filtre à air est propre.

Clapet de retenue - Nettoyage et remplacement

8. Remonter le tuyau de dégagement

9. Remonter les tuyaux de refoulement et serrer

les deux écrous du haut et du bas.

10. Remonter le boîtier.

Soupape de sûreté - Inspection

Si la soupape de sûreté ne fonctionne pas

correctement, une pression excessive peut

s’accumuler à l’intérieur du réservoir, causant sa

rupture ou son explosion. Avant de mettre en

marche, tirer sur l’anneau de la soupape de

sûreté afin de s’assurer qu’elle fonctionne

correctement. Si la soupape est bloquée ou

fonctionne difficilement, la remplacer par une

soupape neuve ayant les mêmes caractéristiques.

Moteur

Le moteur est pourvu d’un dispositif de protection

thermique de surcharge, à réarmement automatique. Si

le moteur surchauffe pour une raison quelconque, le

dispositif de protection arrête le moteur. Le moteur

doit refroidir avant de se remettre en marche. Le

moteur démarre automatiquement aussitôt refroidi.

Risques de blessures. Les tuyaux contiennent de

l’air comprimé pouvant occasionner des

blessures.

Le collecteur est chaud durant le fonctionnement.

Avant de procéder aux travaux d’entretien:

• Débrancher l’alimentation du compresseur

• Libérer la pression du réservoir

• Attendre que le compresseur refroidisse

1. Vider l’air du réservoir et débrancher l’appareil.

2. Retirer le boîtier (réf. 1 et 2).

3. Dévisser les écrous du haut et du bas et

retirer le tuyau de refoulement (réf. 31, 33, 34).

4. Retirer le tuyau de dégagement et ses

raccords (réf. 25, 26, 27).

5. À l’aide d’une clé à douille, dévisser le

clapet (tourner dans le sens contraire des aiguilles

d’une montre) (réf. 17).

6. S’assurer que le disque se meut librement dans

la valve et que le ressort qui le maintient vers le

haut est en position fermée. Le clapet peut être

nettoyé avec du solvant à vernis.

7. Recouvrir le filetage du clapet avec du teflon pour

tuyaux. Remonter le clapet en le tournant dans le

sens des aiguilles d’une montre.

Si le dispositif de protection intervient fréquemment,

vérifier la tension à l’arrivée au moteur. Une basse

tension au moteur peut être aussi la cause des

observations suivantes :

1. Le moteur n’atteint pas sa vitesse ni sa puissance

maximales.

2. Le fusible saute au démarrage. Les lumières baissent

au démarrage et demeurent faibles pendant le

fonctionnement du moteur.

Entreposage

Avant d’entreposer le compresseur, effectuer les

travaux suivants:

1. Effectuer les travaux d’entretien tel que décrit

ci-dessus. Vidanger l’eau contenue dans le réservoir.

2. Enrouler autour du bras le boyau d’air ainsi que le

cordon afin d’éviter qu’on marche dessus ou qu’on

les endommage.

Entreposer l’appareil dans un endroit sec et propre.

D20015 Rev. 1 6/27/00

10 FR

Page 24

GUIDE DE DÉ PANNAGE

Durant les réparations et les travaux d’entretien, on est souvent en contact avec les parties électriques,

mécaniques ou pneumatiques du compresseur et des accidents peuvent survenir. Il est donc important de

débrancher le courant au compresseur et de libérer la pression d’air du réservoir avant d’entreprendre des

travaux d’entretien ou de réparation.

PROBLÈME

Pression excessive dans le

réservoir - La soupape de

sûreté s’ouvre.

Fuites d’air du boyau ou des

raccords

Fuites d’air au détendeur de

pression du pressostat

Fuites d’air dans le réservoir

d’air comprimé ou dans ses

soudures

CAUSE

Le pressostat n’arrête pas le moteur

quand le compresseur atteint le point

de consigne d’arrêt.

Le point de consigne d’arrêt du

pressostat est trop élevé.

Les raccords ne sont pas

suffisamment serrés.

Détendeur de pression défectueux.

Clapet de retenue défectueux ou sale.

Réservoir défectueux.

SOLUTION

Mettre le levier du pressostat à la position d’arrêt “O”.

Si le compresseur ne s’arrête pas, débrancher

l’alimentation électrique et s’adresser à un centre de

service Sears pour remplacer le pressostat.

S’adresser à un centre de service Sears pour vérifier,

régler ou remplacer le pressostat.

Serrer les raccords là où l’air fuit. Vérifier ces raccords

avec une solution d’eau savonneuse.

NE PAS SERRER OUTRE MESURE.

S’adresser à un centre de service Sears pour remplacer

le pressostat et le détendeur de pression.

Vérifier si la tige qui se trouve au bas du détendeur

de pression, est coincée. Si elle ne se déplace pas

facilement, retournez le compresseur au Centre de

service pour faire remplacer le pressostat.

Un clapet défecteux laisse fuir l’air par le détendeur

quand le moteur est à l’arrêt et que le réservoir est

sous pression. Démonter le clapet. Le nettoyer ou le

remplacer. NE PAS SERRER OUTRE MESURE.

Le réservoir d’air doit être remplacé. Ne pas réparer

un réservoir. S’adresser à un centre de service Sears.

L’air fuit entre la tête de

culasse et la culasse

Le manomètre du détendeur

indique une chute de pression

dès qu’on branche un outil

Fuites d’air à la soupape de

sûreté

Bruit de cognement

Le compresseur ne fournit pas

suffisamment d’air pour faire

fonctionner les accessoires.

Boulons lâches ou joint de culasse

défectueux.

Une “petite” chute de pression est

normale.

Soupape de sûreté défectueuse.

Clapet de retenue défectueux.

La capacité du compresseur est

insuffisante à la demande.

Filtre à air bouché

Ne pas percer, souder ni modifier le réservoir

car cela risquerait de l’affaiblir et provoquer

sa rupture ou son explosion.

Serrer les boulons à 7-10 pi.lb. S’il y a encore fuite,