Page 1

/W/nN°

MODEL N BER 917.372851

• Assembly

• Operation

• Customer

Responsibilities

• Service

OWNER'S MANUAL

°

Convertible

oAdjustments

. Repair Parts

Caution:

Read and Follow

all Safety Rules

and Instructions

Before Operating

This Equipment

148746 Rev. 2, 06.06.95 Printed in U.S.A.-

II1[[11ill ..................................

x

Page 2

Safe Operation Practices for Walk-Behind Mowers

IMPORTANT: THIS CUTTING MACHINE IS CAPABLE OF AMPUTATLNG HANDS AND FEET ANDTHROVVlNG OBJECTS.

FAILURE TO OBSERVE THE FOLLOWING SAFETY INSTRUCTIONS COULD RESULT ta SERIOUS INJURY OR DEATH.

SAFETY STANDARDS REQUIRE OPERATOR PRESENCE CONTROLS TO MINIMIZE THE RISK OF INJURY, YOUR UNIT IS

EQUIPPED WITH SUCH CONTROLS, DO NOT ATTEMPT TO DEFEAT THE FUNCTION OF THE OPERATOR PRESENCE

CONTROLS UNDER ANY CIRCUMSTANCES,

TRAINING:

. Read this operator's manual carefully. Become famifiar with

the controis and know how to operate your mower properly,

Learn how to quickly stop mower.

• Do not allow chitdren to use your mower. Never atfow adults

to use mower without proper instructions,

• Keep the area of operation ctear of ait persons, especially

small children and pets,

• Use mower only as the manufacturer intended and as de-

scribed in this manual.

• Do not operate mower if it has been dropped or damaged in

any manner. Always have damage repaired before using

your mower.

,, Donotuse accessory attachments that are not recommended

by the manufacturer. Use of such attachments may be

hazardous/

* The blade turns when the engine is running.

PREPARATION:

• Always thoroughly check the area to be mowed and clear it of

all stones, sticks, wires, bones, and other foreign objects.

These objects will be thrown by the blade and can cause

severe iniury,

• Always wear safety glasses or eye shields when starting and

while using your mower.

° Dress properly. Do not operate mower when barefoot or

wearing open sandals, Wear only solid shoes with good

traction when mowing.

• Check fuel tank before starting engine. Do not fill gas tank

indoors, when the engine is running or when the engine is hot.

Allow the engine to cool for severa_ minutes before filling the

gas tank. Clean off any spilled gasoline before starting the

engine.

• Always make wheel height adiustments before starting your

mower, Never attempt to do this while the engine is running.

• Mow only in daylight or good artificial light.

OPERATION:

• Keep your eyes and mind on your mower and the area betng

cut. Do not let olher inlerests distract you.

• Do not mow wet or sIippery grass. Never run while operating

your mower. Always be sure of your footing - keep afirm hold

on the handles and walk.

• Do not put hands or feet near or under rotating parts, Keep

clear of the discharge opening at all times.

• Always stop ihe engine whenever you leave or are not using

your mower, or before crossing driveways, walks, roads, and

any gravel-covered areas.

° Never direct discharge of material toward bystanders nor

allow anyone near the mower while you are operating it.

• Before cleaning, inspecting, or repairing your mower, stop the

engine and make absolutely sure the btade and all moving

parts have stopped. Then disconnect the spark plug wire and

keep it away from the spark plug to prevent accidental

starting,

SAFETY RULES

• Do not continue to run your mower if you hil aforeign object.

FolLow the procedure outlined above, then repair any dam-

age before restarting and operating you mower,

• Do not change the governor settings or overspeed the

engine, Engine damage or personal injury may result.

° Do not operate your mower if it vibrates abnormaIly, Exces-

sive vibration is an indication of damage; stop the engine,

safely check for the cause of vibration and repair as required,

• Do not run the engine indoors, Exhaust fumes are danger-

OUS.

, Never cut grass by pulling the mower towards you. Mow

across the face of sIopes, never up and down or you might

lose your footing, Donot mow excessively steep slopes. Use

caution when operating the mower on uneven terrain orwhen

changing directions - maintain good footing.

° Never operate your mower without proper guards, plates,

grass catcher or other safety devices in place.

MAINTENANCE AND STORAGE:

• Check the blade and the engine mounting bolts often to be

sure they are tightened properly.

° Check all bolts, nuts and screws at frequent intervals for

proper tightness to be sure mower is in safe working condi-

tion,

• Keep alt safety devices in place and working.

• To=i:#duce fire hazard, keep the engine free of grass, leaves

or excessive grease and oil.

Check grass catcher often for deterioration and wear and

replace worn bags. Use only replacement bags that are

recommended by and comply with specifications of the

manufacturer of your mower,

Always keep a sharp blade on your mower.

• Allow engine to cool before storing in any enclosure,

- Never store mower with fuel in the tank inside a building

where fumes may reach an open flame or an ignition source

such as a hot water heater, space heater, ciothes dryer, etc,

The engine exhaust from this product con-

tains chemicals known to the State of Califor-

nia to cause cancer, birth defects, or other

Look for this symbol to point out im-

CAUTION!!! BECOMEALERT[[! YOUR

portant safety precautions. It means

SAFETY IS INVOLVED.

CAUTION: Always disconnect spark

plug wire and place wire where it can-

not contact spark plug in order to pre-

vent accidental starting when setting

up, transporting, adjusting or making

repairs.

WARNING

reproductive harm.

2

Page 3

CONGRATULATIONS on your purchase of a Sears Lawn

Mower, It has been designed, engineered and manufac-

tured to give you the best possible dependability and

performance,

Should you experience any problem you cannot easily

remedy, please contact your nearest Sears Authorized

Service Center/Department. We have competent, well-

trained technicians and the proper tools to service or repair

this lawn mower.

Please read and retain this manual. The instructions will

enable you to assemble and maintain your lawn mower

properly. Always observe the "SAFETY RULES",

MODEL

NUMBER 917_372851

SERIAL

NUMBER

DATE OF PURCHASE

THE MODEL AND SERIAL NUMBERS WILL BE FOUND

ON A DECAL ATTACHED TO THE REAR OF THE

LAWN MOWER HOUSING

YOU SHOULD RECORD BOTH SERIAL NUMBER AND

DATE OF PURCHASE AND KEEP IN A SAFE PLACE

FOR FUTURE REFERENCE.

PRODUCT SPECIFiCATiONS

HORSEPOWER: 5.5

DISPLACEMENT: 12.6 cu. in.

GASOLINE CAPACITY 1.25quart

AND TYPE: UNLEADED REGULAR

OIL TYPE (API-SFiSG): SAE 30 (above 32°F)

SAE 5W-30 (below 32°F)

OIL CAPACITY: 20 oz.

SPARK PLUG: CHAMPION J19LM, RJ19LM

(GAP: .030") STD36t458

VALVE CLEARANCE: INTAKE: .008"

EXHAUST: .008"

SOLID STATE IGNITION

AIR GAP: .0125 in.

BLADE BOLTTORQUE: 35-40 FT. LBS.

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this product. Contact your nearest Sears store for details.

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

• Follow a regular schedule in maintaining, caring for and using your lawn mower.

Follow the instructions under "Customer Responsibilities" and "Storage" sections of this owner's manual.

LIMITED TWO YEAR WARRANTY ON CRAFTSMAN POWER MOWER

For two years from date of purchase, when this Craftsman Lawn Mower is maintained, lubricated, and tuned up

according to the operating and maintenance instructions in the owner's manual, Sears will repair free of charge any

defect in material or workmanship.

If this Craftsman Lawn Mower is used for commercial or rental purposes, this warranty applies for only 90 days from

the date of purchase.

This Warranty does not cover:

, Expendable items which become worn during normal use, such as rotary mower blades, blade adapters, belts,

air cleaners and spark plug.

• Repairs necessary because of operator abuse or negligence, including bent crankshafts and the failure to maintain

the equipment according to the instructionscontained in the owner's manual.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN POWER MOWER TO THE NEAREST

SEARS SERVICE CENTER/DEPARTMENT IN THE UNITED STATES. THIS WARRANTY APPLIES ONLY WHILE

THIS PRODUCT IS tN USE tN THE UNITED STATES.

This Warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

SEARS, ROEBUCK AND CO., D/817 WA, HOFFMAN ESTATES, ILLINOIS 60179

3

Page 4

TABLE OF CONTENTS

SAFET'_ RULES ....... _ .................................................... 2

PRO[_UCT S PEC_F_C,AT|ONS ...................................... 3

CUSTOMER RESPONSIBILITIES ..................... 3, 12-!4

WARRANTY .................................................................. 3

ASSEMBLY ................................................................... 6

OPERATION .................................................................. 8

iNDEX

A

Accessories .......................................... 5

Adjustments:

Carburetor ................................... 16

Engine Speed ............................. 16

Handle Height ............................. 16

Height of Cut ................................. 9

Air Filter:

Replacement ............................... t4

Service ........................................ 14

Assembly .............................................. 6

8

Blade:

Sharpening ................................. 13

Replacement ............................... 13

C

Controls:

Drive Control ................................. 9

Engine Zone Control ..................... 9

Engine Speed Control ................... 9

Operator Presence Control Bar .... 8

Customer Responsibilities ........ 3, 12-14

Air Filter ............... ........................ 14

Blade Care/Replacement ............ t 3

Drive Wheels ............................... 13

Engine ......................................... 14

Lubrication .................................. 14

Spark Plug .................................. 14

Cutting Levels ...................................... 9

Engine:

Air Fiiter ....................................... 14

Oil Change .................................. 14

Oil Level ...................................... 14

Oil Type ....................................... 14

Starting ........................................ 10

Stopping ...................................... 10

Storage ....................................... t7

Fuel:

Capacity ........................................ 3

Storage ....................................... 17

Type ............................................ 10

Lubrication:

Engine .......................................... 14

Lawn Mower ................................ t2

Maintenance Agreement ...................... 3

Maintenance Schedule ...................... 12

Mowing Tips ....................................... 1t

Oil:

Engine ......................................... 10

Storage ....................................... 17

MAINTENANCE SCHEDULE ..................................... 12

SERVICE AND ADJUSTMENTS ................................ 15

STORAGE ................................................................... 17

TROU BLESHOOTtNG ................................................. 27

REPAIR PARTS - LAWN MOWER ........................ 18-22

REPAIR PARTS - ENGINE .................................... 23-25

PARTS ORDERING/SERVICE ................................... 28

E

Operation:

Drive Control ................................. 9

Engine Control .............................. 9

Grass Catcher ............................. 10

Mower ........................................... g

Operator Presence Control Bar .... 9

Options:

Accessories ................................... 5

R

F

Repair Parts:

Engine .................................... 23-25

Lawn Mower ........................... 18-22

Responsibilities, Customer ....... 3, 12-14

S

L

M

O

Safety Rules ......................................... 2

Service and Adjustments ................... 15

Carburetor ................................... 16

Engine Speed ............................. 16

Handle ......................................... 16

Spark Plug .......................................... t4

Specifications ....................................... 3

Speed Control:

Engine ......................................... 10

Starting the Engine ............................ 10

Stopping the Engine ........................... 10

Storage ............................................... 17

T

Troubleshooting Chart ....................... 27

W

Warranty ............................................... 3

4

Page 5

LAWN MOWER ACCESSO IES

These accessories were available when this lawn mower was produced. They are also available at most Sears retail outlets

and service centers. Most Sears stores can also order repair parts for you, when you provide the model number of your lawn

mower. Some of these accessories may not apply to your lawn mower.

LAWN MOWER PERFORMANCE

- ,, _ - _ ,

CLIPPING DEFLECTOR

FOR REAR DISCHARGE LAWN MOWERS

GRASS CATCHERS

FOR

REAR DISCHARGE

LAWN MOWERS

MULCHER KITS

GRASS CATCHERS

FOR

SIDE DISCHARGE

LAWN MOWERS

STABILIZER

GAS CANS

LAWN MOWER MAINTENANCE

AIR FILTERS

7

SPARK PLUGS

BLADES

BLADE ADAPTERS

5

WHEELSBELTS

ENGINE OIL

Page 6

Read these instructions and this manual in its entirety

before you attempt to assemble or operate your new lawn

mower, your new lawn mower has been assembled at the

factory with the exception of those parts left unassembled

for shipping purposes. To ensure safe and proper opera-

tion of your lawn mower, all parts and hardware you

assemble must be tightened securely. Use the correct

tools as necessary to ensure proper tightness. All parts

such as nuts, washers, botts, etc., necessary to complete

the assembly have been placed in the parts bag.

TO REMOVE LAWN MOWER FROM

CARTON

o Remove loose parts included with mower.

- Cut down two end corners of carton and lay end panel

down flat,

o Remove allpacking materials except padding between

upper and lower handle and padding holding operator

presence control bar to upper handle.

° Roll lawn mower out of carton and check carton thor-

oughly for additional loose parts.

HOW TO SET UPYOUR LAWN MOWER

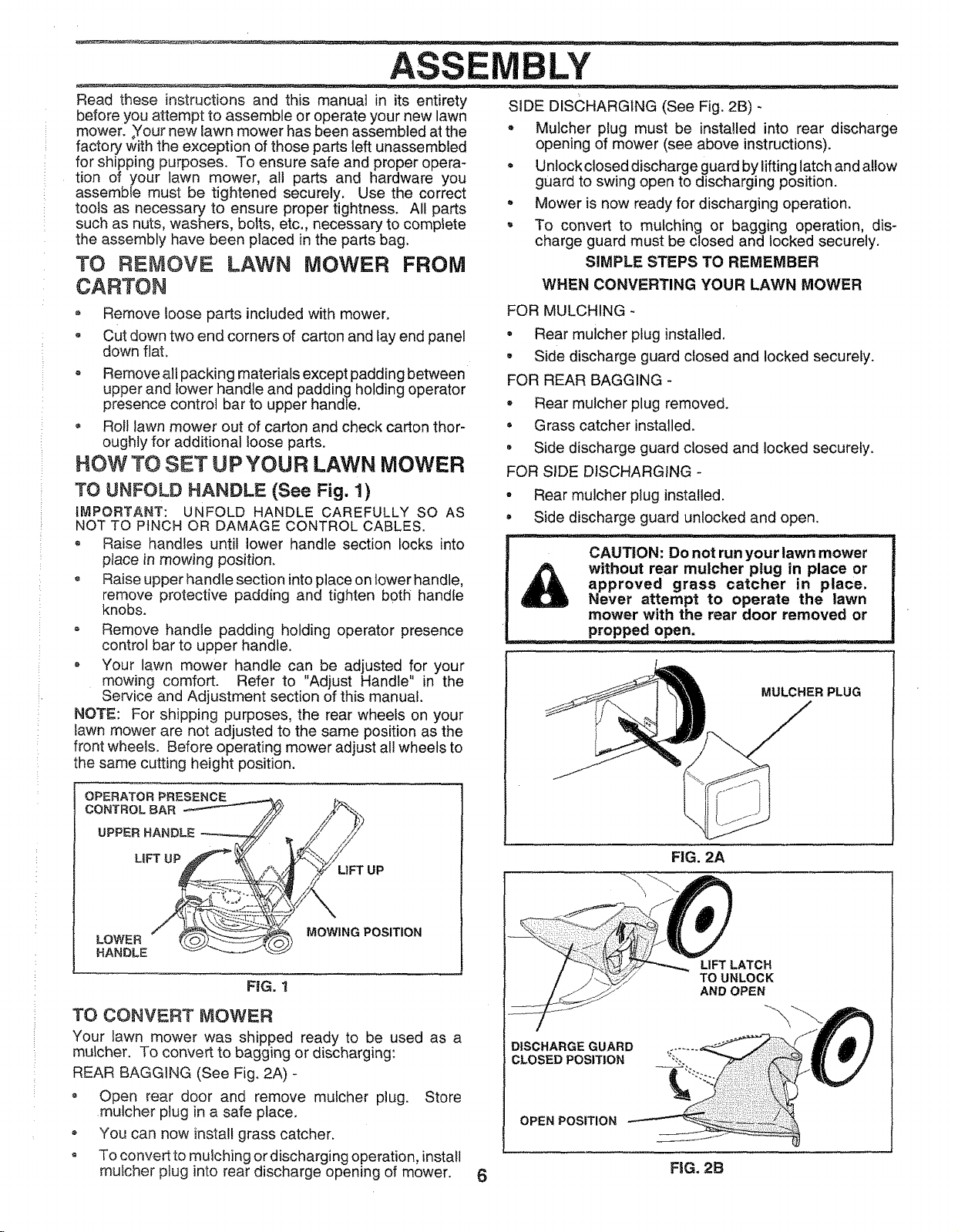

TO UNFOLD HANDLE (See Fig. 1)

iMPORTANT: UNFOLD HANDLE CAREFULLY SO AS

NOT TO PINCH OR DAMAGE CONTROL CABLES.

° Raise handles until lower handle section locks into

place in mowing position.

o Raise upper handle section intoplace on lower handle,

remove protective padding and tighten both handle

knobs.

o Remove handle padding holding operator presence

control bar to upper handle.

® Your lawn mower handle can be adjusted for your

mowing comfort. Refer to "Adjust Handle" in the

Service and Adjustment section of this manual.

NOTE: For shipping purposes, the rear wheels on your

lawn mower are not adjusted to the same position as the

front wheels. Before operating mower adjust all wheels to

the same cutting height position.

SIDE DISCHARGING (See Fig. 2B) -

= Mulcher plug must be installed into rear discharge

opening of mower (see above instructions).

• Unlock closed discharge guard by lifting latch and allow

guard to swing open to discharging position.

, Mower is now ready for discharging operation.

, To convert to mulching or bagging operation, dis-

charge guard must be closed and locked securely.

SIMPLE STEPS TO REMEMBER

WHEN CONVERTING YOUR LAWN MOWER

FOR MULCHING -

, Rear mulcher plug installed.

, Side discharge guard closed and locked securely.

FOR REAR BAGGING -

= Rear mulcher plug removed.

• Grass catcher installed.

• Side discharge guard closed and locked securely.

FOR SIDE DISCHARGING -

• Rear mulcher plug installed.

• Side discharge guard unlocked and open.

CAUTION: Do not run your lawn mower

without rear mulcher plug in place or

approved grass catcher in place.

Never attempt to operate the lawn

mower with the rear door removed or

propped open.

MULCHER PLUG

OPERATOR PRESENCE

CONTROLBAR

UPPER HANDLE

LIFT UP

LOWER

HANDLE

LIFT UP

MOWING POSITION

FIG. I

TO CONVERT MOWER

Your lawn mower was shipped ready to be used as a

mulcher. To convert to bagging or discharging:

REAR BAGGING (See Fig. 2A) -

o Open rear door and remove mulcher plug. Store

muicher ptug in a safe place.

o You can now install grass catcher.

• To convert to mulching or discharging operation, install

mulcher plug into rear discharge opening of mower.

FIG. 2A

DISCHARGE GUARD

CLOSED POSITION

OPEN POSITION

B FIG. 2B

Page 7

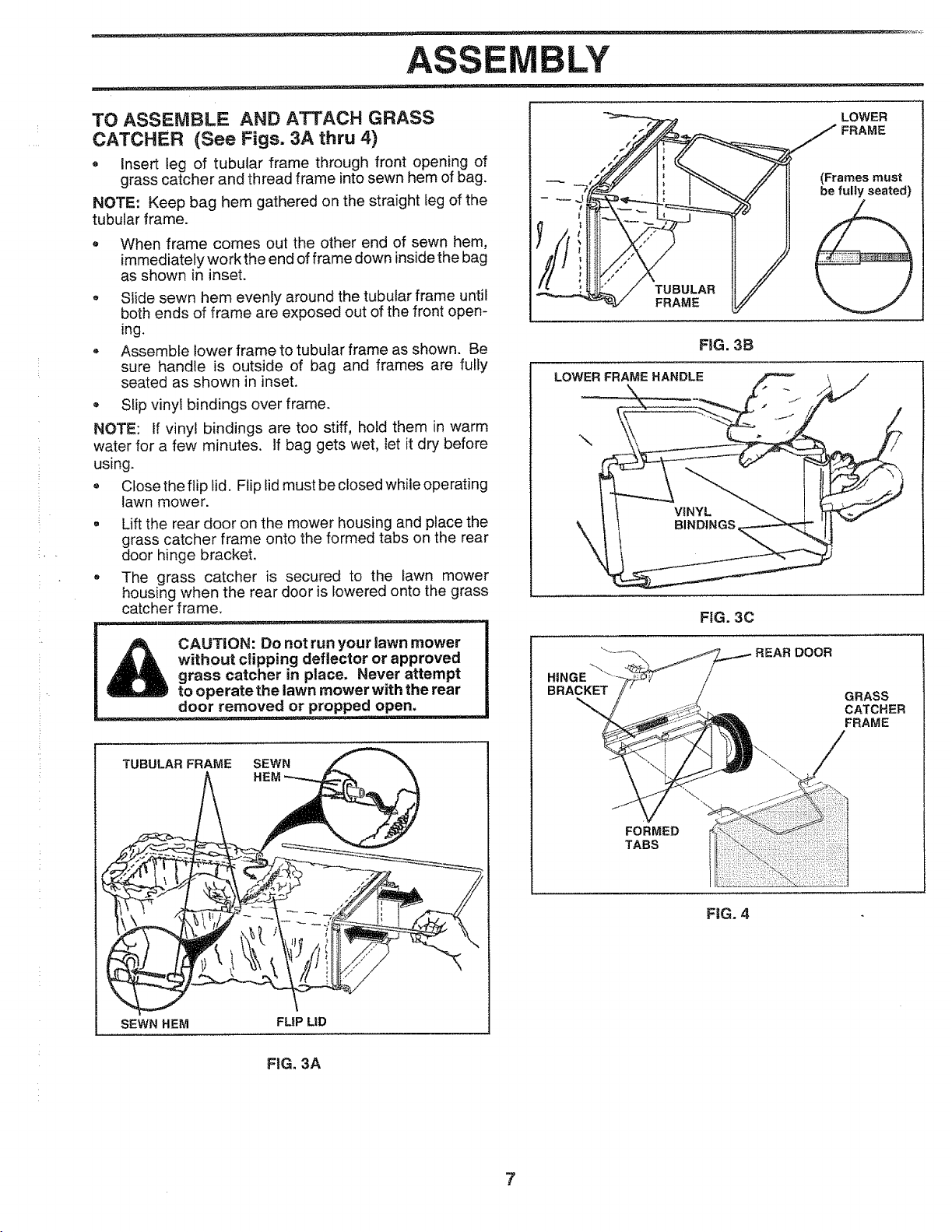

TO ASSEMBLE AND ATTACH GRASS

CATCHER (See Figs. 3A thru 4)

• Insert leg of tubular frame through front opening of

grass catcher and thread frame intosewn hem of bag.

NOTE: Keep bag hem gathered on the straight leg of the

tubular frame.

o When frame comes out the other end of sewn hem,

immediately work the end of frame down inside the bag

as shown in inset.

* S1idesewn hem evenly around the tubular frame until

both ends of frame are exposed out of the front open-

ing.

, Assemble lower frame to tubular frame as shown. Be

sure handte is outside of bag and frames are fufly

seated as shown in inset.

• Slip vinyl bindings over frame.

NOTE: If vinyl bindings are too stiff, hold them in warm

water for a few minutes. If bag gets wet, let it dry before

using.

Close the flip lid. Flip lid must be closed while operating

lawn mower.

, Lift the rear door on the mower housing and place the

grass catcher frame onto the formed tabs on the rear

door hinge bracket.

o The grass catcher is secured to the lawn mower

housing when the rear door is lowered onto the grass

catcher frame.

LY

TUBULAR

FRAME

LOWER FRAME HANDLE

\

amesmust

fully seated}

//

FiG. 3B

Oo,,owomow°,

I _out clipping deflector or approved

grass catcher in place. Never attempt

I to operate the lawn mower with the rear

door removed or propped open.

TUBULAR FRAME SEWN

SEWN HEM

HEM

FLIP LID

FiG. 3A

GRASS

CATCHER

FRAME

FORMED

TABS

FiG. 4

7

Page 8

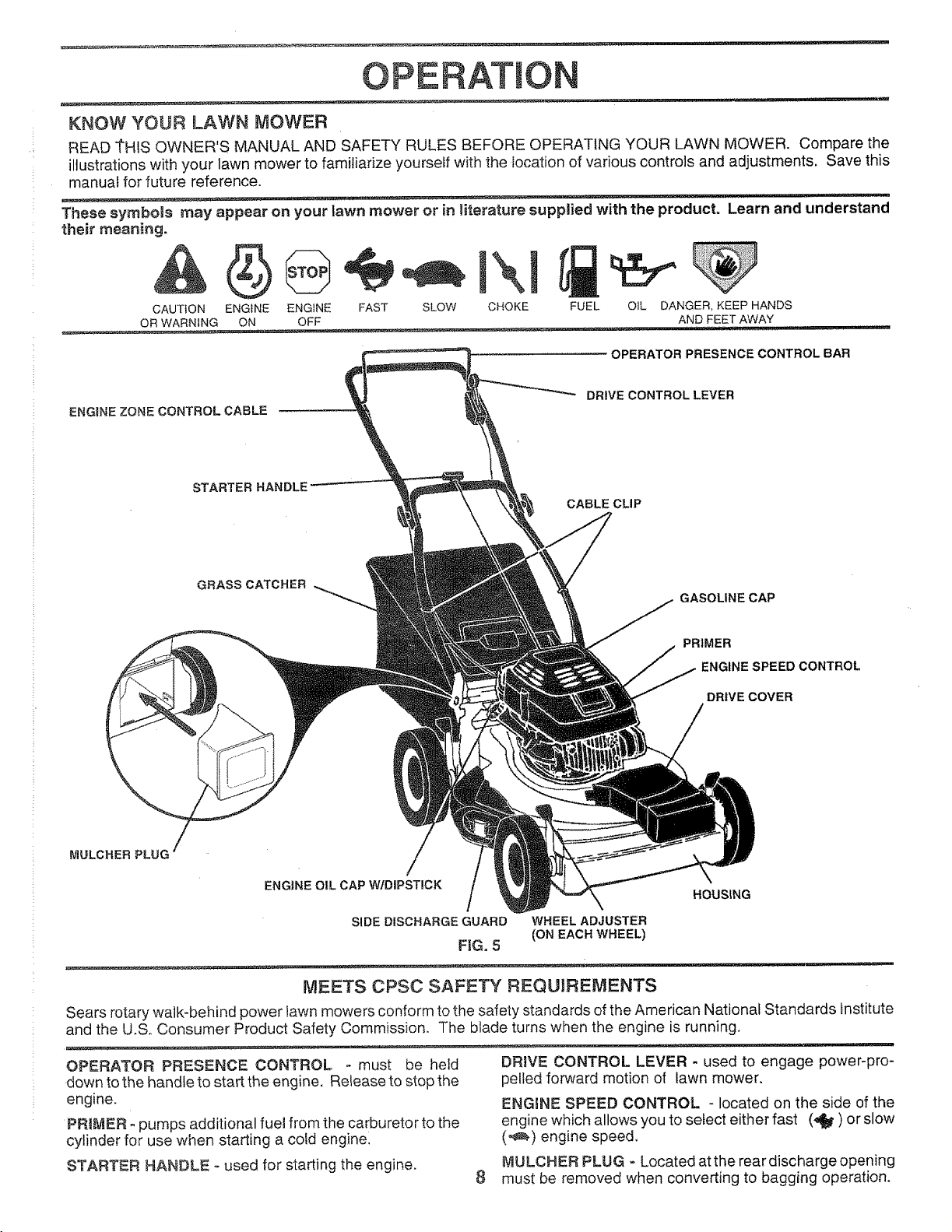

OPERATION

KNOW YOUR LAWN MOWER

READ _HIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR LAWN MOWER, Compare the

illustrations with your lawn mower to familiarize yourself with the location of various controls and adjustments. Save this

manual for future reference.

These symbols may appea, on your |awnmow_ror-i, literat_e-suppmied withtheP';oduct. Learn and understand

their meaning°

,i ,i mmnum I i iinlll

CAUTION ENGINE ENGINE FAST

OR WARNING ON OFF

ENGINE ZONE CONTROL CABLE

STARTER HANDLE

GRASS CATCHER

!\l

SLOW FUEL

CHOKE

CABLE CLIP

'_i_¸"

OIL DANGER KEEP HANDS

AND FEET AWAY

OPERATOR PRESENCE CONTROL BAR

DRIVE CONTROL LEVER

GASOLINE CAP

PRIMER

ENGINE SPEED CONTROL

DRIVE COVER

\

MULCHER PLUG

/

ENGINE OIL CAP WtDIPSTICK

SIDE DISCHARGE GUARD WHEEL ADJUSTER

FIG. 5

(ON EACH WHEEL)

MEETS CPSC SAFETY REQUIREMENTS

Sears rotary walk-behind power lawn mowers conform to the safety standards of the American National Standards Institute

and the U°S.,Consumer Product Safety Commission. The blade turns when the engine is running.

OPERATOR PRESENCE CONTROL - must be held

down to the handle to start the engine. Release to stop the

engine,

PRIMER. pumps additional fuel from the carburetor to the

cylinder for use when starting a cold enginel

STARTER HANDLE _ used for starting the engine.

DRIVE CONTROL LEVER - used to engage power-pro-

pelled forward motion of lawn mower,

ENGINE SPEED CONTROL - located on the side of the

engine whichallows you to select either fast (4) or slow

(_) engine speed.

MULCHER PLUG - Located at the rear discharge opening

8

must be removed when converting to bagging operation.

HOUSING

Page 9

OPERATIC

The operation of any lawn mower can result in foreign objects thrown into the eyes, which can

result in severe eye damage. Always wear safety glasses or eye shields while operating your

lawn mower or performing any adjustments or repairs. We recommend a wide vision safety

mask over the spectacles or standard safety glasses.

HOW TO USE YOUR LAWN MOWER

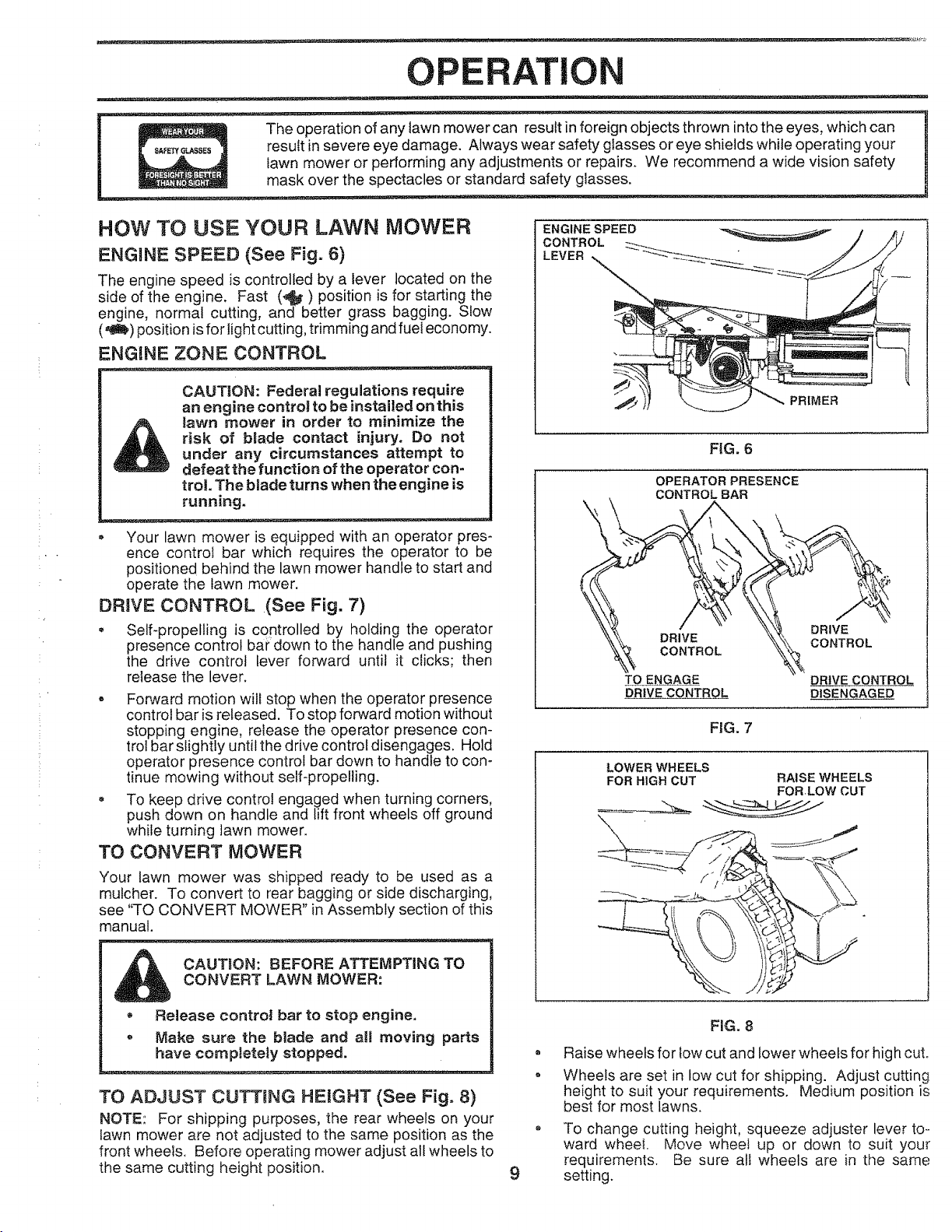

ENGINE SPEED (See Fig. 6)

The engine speed is controlled by a lever located on the

side of the engine. Fast (_) position is for starting the

engine, normal cutting, and better grass bagging. Stow

(,_) position is for light cutting, trimming and fuet economy.

ENGINE ZONE CONTROL

CAUTION: Federal regulations require

an engine control to be installed on this

lawn mower in order to minimize the

risk of blade contact injury. Do not

under any circumstances attempt to

defeat the function of the operator con-

trol. The blade turns when the engine is

running.

Your lawn mower is equipped with an operator pres-

ence control bar which requires the operator to be

positioned behind the lawn mower handle to start and

operate the lawn mower.

DR_VE CONTROL (See Fig. 7)

, Self-propelling is controlled by holding the operator

presence control bai"down to the handle and pushing

the drive control lever forward until it clicks; then

release the lever.

= Forward motion will stop when the operator presence

control bar is released. To stop forward motion without

stopping engine, release the operator presence con-

trol bar slightly until the drive control disengages. Hold

operator presence control bar down to handle to corn

tinue mowing without self-propelling.

= To keep drive control engaged when turning corners,

push down on handle and lift front wheels off ground

while turning lawn mower.

TO CONVERT MOWER

Your lawn mower was shipped ready to be used as a

mulcher. To convert to rear bagging or side discharging,

see "TO CONVERT MOWER" in Assembly section of this

manual.

ENGINE SPEED

LEVER

CONTROL ._

LOWER WHEELS

FOR HIGH CUT

FiG. 6

OPERATOR PRESENCE

CONTROLBAR

DRIVE

CONTROL

TO ENGAGE

DRIVE CONTROL

FIG. 7

/

DRIVE

CONTROL

DRtVECONTROL

DISENGAGED

RAISE WHEELS

FOR.LOW CUT

CAUTI_ON: BEFORE ATTEMPTING TO

CONVERT LAWN MOWER:

Release control bar to stop engine.

o

Make sure the blade and atl moving parts

have completely stopped,

TO ADJUST CUTTING HEIGHT (See Fig. 8)

NOTE: For shipping purposes, the rear wheels on your

lawn mower are not adjusted to the same position as the

front wheels. Before operating mower adjust all wheels to

the same cutting height position.

FIG. 8

a

Raise wheels for low cut and lower wheels for high cut°

o

Wheels are set in low cut for shipping. Adjust cutting

height to suit your requirements. Medium position is

best for most lawns.

To change cutting height, squeeze adjuster lever to-

ward wheel. Move wheel up or down to suit your

requirements. Be sure all wheels are in the same

9

setting.

Page 10

OPE 0

TO EMPTY GRASS CATCHER (See Fig. 9)

Simply lift up rear door and remove the grass catcher

by the handle.

NOTE: Do not drag the bag when emptying; itwilt cause

unnecessary wear.

BEFORE STARTmNG ENG|NE

OIL (See Fig. t0)

Your lawn mower is shipped without oil in the engine.

o Be sure mower is level and area around oil fill is clean.

• Remove engine oit cap w!dipstick and fill to the full line

on the dipstick.

o Use20ozs. of oil. Fortypeandgradeofoiltouse, see

"ENGINE" in Customer Responsibilities section of this

manual°

Pour oil slowly. Do not over fill.

o Check oil level before each use. Add oil if needed. Fill

to full line on dipstick.

o To read proper level, tighten engine oil cap each time.

Reinstall engine oil cap and tighten.

After the first two (2) hours of mowing, change the oil,

and every 25 hours thereafter. You may need to

changethe oil more often under dusty, dirty conditions.

GAS (See Fig, 10)

Fill gasoline tank with fresh, clean, unleaded gasoline.

DO NOT USE PREMIUM GASOLINE. BE CAREFUL

NOT TO OVER FILL TANK.

WARN|NG: Experience indicates that alcohol blended

fuels (called gasohol or using ethanol or methanol) can

attract moisture which leads to separation and formation of

acids during storage. Acidic gas can damage the fuel

system of an engine while in storage. To avoid engine

problems, the fuel system should be emptied before stor-

age of 30 days or longer. Drain the fuel tank, start the

engine and let it run until fuel lines and carburetor are

empty. Use fresh fue! next season, See Storage Instruc-

tions for additional information. Never use engine or

carburetor cleaner products in fuel tank or permanent

damage may occur.

J

f

FIG. 9

GASOLINE FILLER CAP

ENGINE OIL CAP

W/DIPSTICK

FIG. 10

TO START ENGINE

To start a cold engine, push primer five (5) times before

trying to start. Use a firm push. This step is not usually

necessary when starting an engine which has already

run for a few minutes.

,, Push engine speed control lever to fast (,_J_)position.

• Hold operator presence control bar down to the handle

and pull starter handle quickly. Do not allow starter

rope to snap back.

To stop engine, release operator presence control bar.

NOTE: In cooler weather it may be necessary to repeat

priming steps. Inwarmer weather over priming may cause

flooding and engine will not start. If you do flood engine,

wait a few minutes before attempting to start and do not

repeat priming steps.

10

Page 11

0 ERATION

MOWING TiPS

= Undercertain conditions, such as very tall grass, itmay

be necessary to raise the height of cut to reduce

pushing effort and to keep from overloading the engine

and leaving clumps of grass clippings.

• For extremely heavy cutting, red uce the width of cut by

overlapping previously cut path and mow slowly.

, For better grass bagging and most cutting conditions,

the engine speed should be set in the fast (4_') posi-

tion.

When using a rear discharge lawn mower in moist,

heavy grass, clumps of cut grass may not enter the

grass catcher. Reduce ground speed (pushing speed)

and/or runthe lawn mower over the area a second time.

If a trail of clippings is left on the right side of a rear

discharge mower, mow in a clockwise direction with a

small overlap to collect the clippings on the next pass.

o Pores in cloth grass catchers can become filled with dirt

and dust with use and catchers will collect less grass.

To prevent this, regularly hose catcher off with water

and let dry before using.

• Keep top of engine around starter clear and clean of

grass clippings and chaff. This will help engine airflow

and extend engine life.

FiG. 11

MULCHING MOWING TtPS

IMPORTANT: FOR BEST PERFORMANCE, KEEP

MOWER HOUSING FREE OF BUILT-UP GRASS AND

TRASH. SEE "CLEANING" tN CUSTOMER

RESPONSIBILITIES SECTION OF THIS MANUAL,

The special mulching blade will recut the grass clip-

pings many times and reduce them in size so that as

they fal! onto the lawn they wil! disperse into the grass

and not be noticed. Also, the mulched grass will

biodegrade quickly to provide nutrients for the lawn.

Always mulch with your highest engine (blade) speed

as this will provide the best recutting action of the

blades.

* Avoid cutting your lawn when itis wet. Wet grass tends

to form clumps and interferes with the mulching action.

The best time to mow your lawn isthe early afternoon.

At this time the grass has dried and the newly cut area

wilt not be exposed to the direct sun.

, For best results, adjust the lawn mower cutting height

so that the lawn mower cuts off only the top one-third

of the grass blades (See Fig. 11). If the lawn is

overgrown it will be necessary to raise the height of cut

to reduce pushing effort and to keep from overloading

the engine and leaving clumps of mulched grass. For

extremely heavy mulching, reduce your width of cut by

overlappingpreviously cut path and mow slowly.

Certain types of grass and grass conditions may re-

quire that an area be mulched a second time to

completely hide the clippings. When doing a second

cut, mow across or perpendicular to the first cut path.

Change your cutting pattern from week to week. Mow

north to south one week then change to east to west the

next week. This will help prevent matting and graining

of the lawn.

11

Page 12

CUSTOME RESPO ILITIE

MAINTENANCE SCHEDU LE

FILL IN DATES

AS YOU COMPLETE

REGULAR SERVICE

._ckfor Loose Fasteners _i iiiii

MI

O}

Wl

El

RI

El

NI.

G[

I.

Ni

Et

1 - Change more often when operating under a heavy load or in high ambient temperatures.

2 _Service more often when operating in dirty or dusty conditions.

3 - Replace blades more often when mowing in sandy soil.

4 - Charge 48 hours at end of season.

_nilnspeCt Grass'Catcher

(if [quipped) if

Clean Lawn Mower

Clean Under Drive Cover

If-Propelled Mowers) 1

!cWSharPen/Replace Blade

Lubrication Chart

(: _n Battery/Recharge

( ,ctric,_art M_o_wers.__) ... .................

Check ngine Oil Level

nggeEngi.ne Oil ..........................................

Clean Air Fitter

Ins!_ectMuffler

C _nor Repiace'"Spark Plug ...................

Re!_lace Air Filter Paper Cartridge

.................... i =

.... = ....... i

_/1,2

_2

t/

SERVICE DATES

v'

v'

v'

v'

v'4

LUBRICATION CHART

GENERAL RECOMMENDATIONS

-Thewarranty on this lawn mower does not cover items that

have been subjected to operator abuse or negligence. To

receive full value from the warranty, operator must maintain

mower as instructed in this manual.

Some adjustments will need to be made periodically to

properly maintain your unit.

All adjustments in the Service and Adjustments section of

this manual should be checked at least once each season.

• Once a year, replace the spark plug, replace air filter

element and check blade for wear. A new spark plug

and clean/new air filter element assures proper air-fuel

mixture and helps your engine run better and last

longer.

Follow the maintenance schedule in this manual.

BEFORE EACH USE

o Check engine oil level.

Check for loose fasteners.

LUBRmCAT!ON

Keep unit well lubricated (See "LUBRICATION CHART").

WHEEL

ADJUSTER

BRAKESPRING

BRACKET

ENGINE OIL

HANDLE BRACKET

MOUNTING PIN

(_) SPRAY LUBRICANT

(_ REFER TO CUSTOMER RESPONSIBILITIES "ENGINE" SEC-

TION.

IMPORTANT: DO NOT OIL OR GREASE PLASTIC WHEEL

BEARINGS. VISCOUS LUBRICANTS WILL ATTRACT

DUST AND DiRT THAT WILL SHORTEN THE LIFE OF

THE SELF LUBRICATING BEARINGS. IF YOU FEELTHEY

MUST BE LUBRICATED, USE ONLYA DRY, POWDERED

GRAPHITE TYPE LUBRICANT SPARINGLY.

(_REAR DOOR

HINGE

t2

Page 13

CUSTO ONS TtES

LAWN MOWER

Always observe safety rules when performing any mainte-

nance.

TIRES

® Keep tires free of gasoline, oil, or insect control chemi-

cals which can harm rubber.

• Avoid stumps, stones, deep ruts, sharp objects and

other hazards that may cause tire damage.

BLADE CARE

For best results, mower blade must be kept sharp.

Replace bent or damaged blades.

TO REMOVE BLADE (See Fig. 12)

• Disconnect spark plug wire from spark plug and place

wire where it cannot come in contact with spark plug.

, Turn lawn mower on its side. Make sure air filter and

carburetor are up.

, Use a wood block between blade and mower hous-

ing to prevent blade from turning when removing

blade bolt.

• Protect your hands with gloves and/or wrap blade

with heavy cloth.

• Remove blade bolt by turning counter-clockwise.

- Remove blade and attaching hardware (bolt, lock

washer and hardened washer).

NOTE: Remove the blade adapter and check the key

inside hub of blade adapter. The key must be in good

condition to work properly. Replace adapter if damaged.

TO REPLACE BLADE (See Fig. 12)

- Position the blade adapter on the engine crankshaft.

Be sure key in adapter and crankshaft keyway are

aligned.

® Position blade on the blade adapter aligning the two (2)

holes in the blade with the raised lugs on the adapter.

• Be sure the trailing edge of blade (opposite sharp

edge) is up toward the engine.

• Install the blade bolt with the lockwasher and hardened

washer into blade adapter and crankshaft.

• Use block of wood between blade and lawn mower

housing and tighten the blade bolt, turning clockwise.

• The recommended tightening torque is 35-40 ft. Ibs.

IMPORTANT: BLADE BOLT tS GRADE 8 HEAT TREATED.

NOTE: We do not recommend sharpening blade - but if

you do, be sure the blade is balanced.

TO SHARPEN BLADE

Care should be taken to keep the blade balanced. An

unbalanced blade will cause eventuat damage to tawn

mower or engine.

® The blade can be sharpened with a file or on a

grinding wheel. Do not attempt to sharpen while on

the mower.

, To check blade balance, drive a nail into a beam or

wall. Leave about one inch of the straight nail

exposed. Place center hole of blade over the head

of the nail. If blade is balanced, it should remain in

a horizontal position. If either end of the blade

moves downward, sharpen the heavy end until the

blade is balanced. 1 3

BLADE CRANK-

ADAPTER ..., KEYWAY

BLADE

%

HARDENED

WASHER

LOCK WASHER EDGE

TRAIUNG

BLADE ADAPTER

SHAFT

CRANK-

SHAFT

FIG. 12

GEAR CASE

To keep your drive system working properly, the gear

case and area around the drive should be kept clean

and free of trash build-up. Clean under the drive cover

twice a season.

The gear case isfilled with lubricant to the proper level

at the factory. The only time the lubricant needs

attention is if service has been performed on the gear

case,

o If lubricant is required, use only Texaco Starplex Pre-

mium Grease, part no, 750355. Do not substitute.

DRIVE WHEELS

Check front drive wheels each time before you mow to be

sure they move freely.

The wheels not turning freely means trash, grass cuttings,

etc. are inthe drive wheel area and must be cleaned to free

drive wheels.

If necessary to clean the drive wheelsl check both front

wheels.

Remove hubcaps, hairpin cotters and washers.

® Remove wheels from whee! adjusters.

Remove any trash or grass cuttings from inside the

dust cover, pinion and/or drive wheel gear teeth.

Put wheels back in place.

• If after cleaning, the drive wheels do not turn freely,

contact your nearest authorized service center.

GRASS CATCHER

The grass catcher may be hosed with water, but must

be dry when used.

e

Check your grass catcher often for damage or deterio-

ration. Through normal use it will wear. If catcher

needs replacing, replace only with a manufacturer

approved replacement catcher. Give the lawn mower

model number when ordering.

Page 14

CUSTOME

PO

LITIES

ENGINE

LUBRaCATION

Use only high quality detergent oil rated with APt service

classification SF orSG. Select the oil's SAE viscosity grade

according to your expected operating temperature.

SAE VISCOSITY GRADES

.20 ° 0o 30 ° 32 ° 40 _ 60° 80°

_3oo -2o° 40° o° _oo _oo 30° 40°

TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OiL CHANGE

NOTE: Although multi-viscosity oils (5W30, 10W30 etc.)

improve starting in cold weather, these multi-viscosity oils

will result in increased oil consumption when used above

32°F. Check your engine oil level more frequently to avoid

possible engine damage from running tow on oil,

Change the oil after the first two hours of operation and

every 25 hours thereafter or at least once a year if the lawn

mower is not used for 25 hours in one year.

Check the crankcase oil level before starting the engine

and after each five (5) hours of continuous use, Tighten oil

plug securely each time you check the oil level,

TO CHANGE ENGINE OIL (See Fig, 13)

NOTE: Before tipping fawn mower to drain oil, drain fuel

tank by running engine until fuel tank is empty.

o Disconnect spark plug wire from spark plug and place

wire where it cannot come in contact with spark plug.

o Remove engine oil cap; lay aside on a clean surface,

- Tip lawn mower on its side and drain oil into a suitable

container, Rock lawn mower back and forth to remove

any oil trapped inside of engine,

o Wipe off any spilled oil on lawn mower and on side of

engine,

• Fill engine with oil, Fill only to the "FULL" line on the

dipstick, DO NOT OVER FILL.

o Replace engine oil cap.

• Reconnect spark plug wire to spark plug.

AiR FILTER

Your engine will not run properly and may be damaged by

using a dirty air filter.

Replace the air filter every year, more often if you mow in

very dusty, dirty conditions, Do not wash air filter.

TO CHANGE AIR FILTER (See Fig. 14)

o Remove the air filter cover by turning counterclockwise

to the stop and pull away from collar.

Remove filter from inside of cover,

• Clean the inside of the cover and the collar to remove

any dirt accumulation,

Insert new filter into cover.

Put air filter cover and filter into collar aligning the tab

with the slot,

Push in on cover and turn clockwise to tighten.

\

\

\

CONTAINER

FIG. 13

COLLAR

TURN

COUNTER-

CLOCKWISE

SLOT

TAB

AIR FILTER s- CLOCKWISE

AIR FILTER COVER TO TIGHTEN

FIG. 14

MUFFLER

Inspect and replace corroded muffler as it could create afire

hazard and/or damage.

SPARK PLUG

Change your spark plug each year to make your engine

start easier and run better. Set spark plug gap at .030 inch.

CLEANING

IMPORTANT: FOR BEST PERFORMANCE, KEEP

MOWER HOUSING FREE OF BUILT-UP GRASS AND

TRASH. CLEAN UNDERSIDE OF MOWER HOUSING

AFTER EACH USE.

I CAUTION: Disconnect spark plug wire

from spark plug and place wire where it

i cannot come in contact with the spark

I plug.

, Turn lawn mower on its side, Make sure air filter and

carburetor are up. Clean the underside of your lawn

mower by scraping to remove build-up of grass and

trash.

, Clean engine often to keep trash from accumulating. A

clogged engine runs hotter and shortens engine life.

• Keep finished surfaces and wheels free of all gasoline,

oil, etc.

= We do not recommend using a garden hose to clean

lawn mower unless the electrical system, muffler, air

filter and carburetor are covered to keep water out.

Water in engine can result in shortened engine life.

CLEAN UNDER DRIVE COVER

Clean under drive cover at least twice a season. Scrape

underside of cover with putty knife or similar toot to remove

any build-up of trash or grass on underside of drive cover.

14

TO REMOVE

Page 15

SERVICE ADJUSTIVlENTS

..... ..... := _ :=L=:,:,,L _ ,, Ll

CAUTION: BEFORE PERFORMING ANY SERVICE OR ADJUSTMENTS:

Release control bar.

• Make sure the blade and a!l moving parts have completely stopped.

- Disconnect spark plug wire from spark ptug and place where it cannot come in contact with plug,

lAWN MOWER

TO ADJUST CUTTING HEtGHT

See "TO ADJUST CUTTING HEIGHT" in the Operation

section of this manual.

REAR DEFLECTOR

The rear deflector, attached between the rear wheels of

your lawn mower, is provided to minimize the possibility

that objects wilt be thrown out the rear of the lawn mower

into the operator's mowing position. If the rear deflector

becomes damaged, it should be replaced.

TO REMOVEIREPLACE DRWE BELT

(See Fig. 15)

• Remove drive cover. Remove belt by pushingdown on

gear case pulley.

- Turn lawn mower on its side with carburetor and fuel

cap up.

- Remove blade.

i.

= Remove debris shield.

= Remove belt from engine pulley on crankshaft.

= Install new belt by reversing above steps.

, Always use factory approved belt to assure fit and tong

life.

DRIVE

COVER

BELT

PRESS

FiG. 15

15

Page 16

SERVIC AND ADJ ENTS

TO A#JUST HANDLE (See Figs. 16 Thru 18)

Your lawn mower handle can be raised or lowered for you r

mowing comfort. Four (4) positions are available: high,

medium high, medium low and low. Handles are shipped

mounted in the medium low position.

o To change from medium low to medium high position,

the upper and lower handle sections will have to be

turned over (See Fig. 16B).

o Remove the controls and operator presence control

bar from the upper handle.

o Remove the starter rope guide from the lower handle.

o Remove hairpin cotters.

, Disconnect the lower handle from the handle brackets

(See Fig, t8),

o Turn the handle over and reassemble the hairpin

cotters that have been removed.

o Reassemble the starter rope guide.

o Reassemble the controls and the operator presence

control bar to the upper handle.

CAUTION: The operator presence con-

brake engagement when control bar is

troi bar must pivot freelyto permit btade

re|eased. Do not over tighten the fas-

teners holding the controls to the up-

per handle.

SHIPPING POSITION

MEDIUM LOW

FIG. 16A FIG. 16B

HIGH

MEDIUM HIGH

° To change from medium low to high position only the

upper handle section will have to be turned over (See

Fig. 17A).

o To change from medium low to low position, only the

lower handle section will have to be turned over (See

Fig. 17B).

ENGINE

ENGINE SPEED

Your engine speed has been factory set. Do not attempt

to increase engine speed or it may result in personal injury.

Ifyou believe that the engine is running too fast ortoo slow,

take your lawn mower to an authorized service center!

department for repair and adjustment.

CARBURETOR

Your carburetor has a non-adjustable fixed main jet for

mixture control. If your engine does not operate properly

due to suspected carburetor problems, take your lawn

mower to an authorized service center/department for

repair and adjustment.

FIG. 17A FIG. 17B

LOWER HANDLE

SQUEEZE\x

TO REMOVE\

HANDLE

BRACKET

HAIRPIN COTTER

FIG. 18

!6

Page 17

STORAGE

immediately prepare your fawn mower for storage at the

end of the season or if the unit will not be used for 30 days

or more.

LAWN MOWER

When lawn mower is to be stored for a period of time, clean

it thoroughly, remove all dirt, grease, leaves, etc. Store in

a clean, dry area,

• Clean entire lawn mower (See "CLEANING" in the

Customer Responsibilities section of this manual).

, Lubricate as shown in the Customer Responsibilities

section of this manual.

, Be sure that all nuts, bolts, screws, and pins are

securely fastened. Inspect moving parts for damage,

breakage and wear. Replace if necessary.

• Touch up all rusted or chipped paint surfaces; sand

lightly before painting.

HANDLE (See Fig. 19)

You can fold your lawn mower handle for storage.

- Squeeze the bottom ends of the lower handle toward

each other until the lower handle clears the handte

bracket, then move handle forward.

- Loosen upper handle mounting bolts enough to allow

upper handle to be folded back.

IMPORTANT: WHEN FOLDING THE HANDLE FOR

STORAGE OR TRANSPORTATION, BE SURE TO FOLD

THE HANDLE AS SHOWN OR YOU MAY DAMAGE THE

CONTROL CABLES.

• When setting upyour handle from the storage position,

the lower handle will automatically lock into the mow-

ing position.

LOWER HANDLE

HANDLE

BRACKET

ENGINE

FUEL SYSTEM

iMPORTANT: IT tS IMPORTANT TO PREVENT GUM

DEPOSITS FROM FORMING tN ESSENTIAL FUEL

SYSTEM PARTS SUCH AS CARBURETOR, FUEL FILTER,

FUEL HOSE, OR TANK DURING STORAGE. ALSO,

EXPERIENCE INDICATES THAT ALCOHOL BLENDED

FUELS (CALLED GASOHOL OR USING ETHANOL OR

METHANOL) CAN ATTRACT MOISTURE WHICH LEADS

TO SEPARATION AND FORMATION OF ACIDS DURING

STORAGE. ACIDIC GAS CAN DAMAGE THE FUEL

SYSTEM OF AN ENGINE WHILE IN STORAGE.

* Drain the fuel tank.

- Start the engine and let it run until the fuel lines and

carburetor are empty.

• Never use engine or carburetor cleaner products in the

fuel tank or permanent damage may occur,

• Use fresh fuel next season.

NOTE: Fuel stabilizer is an acceptable alternative in

minimizing the formation of fuel gum deposits during stor-

age. Add stabilizer to gasoline in fuel tank or storage

container, Always follow the mix ratio found on stabilizer

container. Run engine at least 10 minutes after adding

stabilizer to allow the stabilizer to reach the carburetor. Do

not drain the gas tank and carburetor if using fuel stabilizer,

ENGINE OiL

Drain oil (with engine warm) and replace with clean engine

oil. (See "ENGINE" in the Customer Responsibilities

section of this manual).

CYLINDER

• Remove spark plug,

• Pour one ounce (29 ml) of oil through spark plug hole

into cylinder.

= Pull starter handle slowly a few times to distribute oil

• Replace with new spark plug.

OTHER

SQUEEZETO FOLD

OPERATOR PRESENCE

CONTROLBAR

FOLD FORWARD

FOR STORAGE

LOWER HANDLE

FOLD BACKWARD

MOWING

POSITION

FgGo19 17

Do not store gasoline from one season to another.

* Replace your gasoline can if your can starts to rust.

Rust and/or dirt in your gasoline will cause problems.

, tf possible, store your unit indoors and cover it to give

protection from dust and dirt.

, Cover your unit with a suitable protective cover that

does not retain moisture. Do not use plastic. Plastic

cannot breathe which allows condensation to form and

will cause your unit to rust.

IMPORTANT: NEVER COVER MOWER WHILE ENGINE

AND EXHAUST AREAS ARE STILL WARM.

J CAUTION: Never store the lawn mower

_ with gasoline in the tank inside a buiid-

,_A ing where fumes may reach an open

J _ flame or spark. Al!ow the engine to cool

L _ --..-_,.bef°re_m any enclosure.

Page 18

REPAIR PARTS

ROTARY LAWN MOWER MODEL NUMBER 917.372851

9

24

27

3O

12

Qo

24

28

3O

56

56

65

55

12

35

51

44

62

47

Page 19

REPAIR PARTS

ROTARY LAWN MOWER MODEL NUMBER 9t7.372851

._s.

KEY PART

NO. NO

1 145646X479

2 130861

3 74350424

5 85827

6 136376

7 STD541425

8 145793

9 147612

1! 128415

12 STD512505

14 700483X479

15 700365X479

16 133190X479

17 140661X479

20 140540

21 702813

22 85543

23 87677

24 77400

26 83923

27 146249

28 84921

29 62335

30 145935X004

31 701037

32 850855X004

34 84920

35 700327X007

36 700326X007

37 55187

39 140629X459

40 140628X459

41 850998

42 750097

43 87930

DESCRIPTION

Upper Handle

Engine Zone Control Cable

Hex Head Bolt 1/4-20 x 1-t/2

Cable Clip

Handle Knob

Locknut 1/4-20

Control Bar

Rear Door Kit

Pop Rivets

Hex Tapping Screw 1/4-20 x 1/2

Back Plate

Side Baffle

Discharge Baffle

Rear Baffle

Rear Skirt

Mulcher Plug

Engine Pulley

Hi-Pro Key #505

Hubcap

Hex Flange Locknut 3/8-16

Wheel & Tire Assembly

Shoulder Bolt 3/8-16

Be!leville Washer

Axle Arm Assembly

Selector Knob

Selector Spring

Spacer

Wheel Adjusting Bracket (Left)

Wheel Adjusting Bracket (Right)

Thread Cutting Screw 5/16-18 x 3/4

Handle Bracket Assembly (Left)

Handle Bracket Assembly (Right)

Hex Head Thread Rolling Screw 3/8-16 x !-1/8

Hex Washer Head Screw #10-24 x 1/2

Guide Clip

KEY PART DESCRIPTION

NO. NO

44 48398 Lawn Mower Housing (Incl. Key #14,15,51 &52)

46 851514 Blade Adapter

47 141443 Blade 22"

48 851074 Hardened Washer

49 850263 Helical Washer 3/8-24 x 1-3/8 Grd. 8

50 851084 Hex Head Machine Screw 3/8-24 x 1-3/8 Grd. 8

51 700869X479 Front Baffle

52 85463 Danger Decal

55 75t592 Locknut 3/8-16

56 88652 Hinge Screw

57 51793 Hairpin Cotter

58 84676X479 Lower Handle

59 131959 Handle Bolt

61 103672X Rope Guide

62 134612 Debris Shield

64 146389 Engine - Craftsman - Model No, 143.955500

65 701458 Door

66 146595 Door Latch

67 702807 Side Discharge Guard

68 141839 Speed Nut

69 702808 Hinge Spring

70 702809 Hinge Rod

7! 141841 Screw

72 148278 Spacer, Blade Adapter

-- !41763 Decal

-- !48746 Owner's Manual (English/Spanish)

Available accessories not included with lawn mower:

7_!33723 High Wheel Kit

7__[133623 Gas Can (2.5 gal.)

7_1_133500 Fue! Stabilizer

71 33300 SAE 30W Oil (20 oz.)

71 33417 Dust Shield

7_!33316 Mower Cover

Page 20

REPAIR PARTS

54

ROTARY LAWN MOWER MODEL NUMBER 917,372851

11

5

1

Po

o

18

14 16

15

18

10

14

8

11

15

40

1-31

10

13

12

13

Page 21

REPAIR PARTS

LAWN MOWER MODEL NUMBER 917.372851

==,&,

KEY PART

NO, NO.

1 48385

2 48386

3 63601

4 144929

5 146527

6 700875

8 77400

9 145212

10 86960

11 700783

12 12000058

13 137054

14 88080

15 88118

16 67725

18 701037

DESCRIPTION

Drive Head Kit

Drive Control Cable Kit

Locknut 1/4-20

Hex Washer Head Screw 1/4-20 x 2-1/8

V-Belt

Carriage Bolt 1/4-20 x 2-3/4

Hubcap

Hex Flange Locknut

Nylon Bushing

Wheel & Tire Assembly

E-Ring

Pinion

Dust Cover

Felt Washer

Washer 1/2 x !-1/2 x .134

Selector Knob

KEY PART

NO. NO

19 63601

25 141764

27 143603

28 702806

31 132010

32 137052

35 148493

36 702511

37 146467

38 STD541425

40 75192

41 148492

52 144747

53 144748

54 141245

55 86012

DESCRIPTION

Hex Locknut 1/4-20

Drive Cover Decal

Hex Washer Head Screw #t0-24 x 3/4

Drive Cover

Hex Flange Nut

Drive Pulley

Wheel Adjuster Assembly (Left)

Gear Case Assembly

Spring

Hex Locknut 1/4-20

Spring

Wheel Adjuster Assembly (Right)

Catcher Frame

Frame Tube

Grassbag Assembly

Driveshaft Cover

Page 22

PARTS

ROTARY LAWN MOWER - - MODEL NO. 917.372851

GEAR CASE ASSEMBLY PART NUMBER 70251,1

I 1

13

15

J

I

9

10

J

17

10

18

I

10

KEY

NO.

PART

NO. DESCRIPTION

1

17490416 Tapping Screw 1/4-20 x 1-1/4

2

137055X004 Engagement Bracket

137053 Shifter

3

57072 Seal

4

6

48373 Gear Case Halves Kit (Includes Key

Nos. 4, 5, and 7)

7

77881 Bearing

8

137051 Worm Shaft

9

137074 Drive Shaft

!0

57079 Hardened Washer

KEY PART

NO. NO.

11 131484

12 700343

13 86447

14 137050

15 750436X

i6 750369

t7 12000003

18 850848

19 81585X004

NOTE:

22

DESCRIPTION

Clutch Yoke

Bushing

Plug

Helical Gear

Clutch Jaw

Grease

E-Ring

Hi-Pro Key

Spring Bracket

All component dimensions given in U.S. inches.

1 inch = 25,4 mm

Page 23

CRAFTSMAN 4=CYCLE ENGINE MODELNUMBER143.955500

MODEl, a_ SERIAl,_UMBERS HERE

l

23

Page 24

CRAFTSMAN 4=CYCLE ENGINE MODELNUMBER143.955500

REF PART REF PART

NO. NO. DESCRiPTiON NO. NO. DESCRIPTION

1 36,478A

2 26727

6 33734

7 36557

8 33735

9 30200

!2 36558

12B 34695

14 28277

15 30589

16 31383A

17 31335

18 650548

19 36281

20 32600

30 35801

40 36073

36074

36075

41 36070

36071

36072

42 36076

36077

36078

43 20381

45 32875

46 32610A

48 27241

50 35992

52 29914

69 35261

70 3431tD

72 30572

73 28833

75 27897

80 30574A

81 30590A

82 30591

83 30588A

86 650488

89 611004

90 611109

92 650815

93 650816

100 34443A

101 610118

I03 650814

110 34961

119 36477

120 36476

125 36471

36472

t26 f!9314B

29315C

130 6021A

135 35395

150 35991

!51 31673

Cylinder 0ncludes Reference t66 35827

Numbers 2, 7, 20 and 125) 169 27234A

Dowel Pin 172 32755

Breather Element 178 29752

Breather Assembly (Includes 182 6201

Reference Numbers 6 and 12) 184 26756

* Breather Gasket t85 31384A

Screw #10-24 x 9/16 186 34337

Breather Cover and Tube 189 650839

Breather Tube Elbow 191 36559

Washer 195 610973

Governor Rod (Includes Ref. #14) 200 35727

Governor Lever

Governor Lever Clamp 202 36482

Screw #8-32 x 5/16 203 31342

Extension Spring 204 650549

Oil Seat 205 650777

Crankshaft 207 34336

Piston, Pin & Ring Set, Std. Size 215 35511

Piston, Pin & Ring Set, .010" Over 223 650451

Piston, Pin & Ring Set, °020" Over 224 34690A

Piston & Pin Assembly, Std. Size 238 650932

Piston & Pin Assembly, .010" Over 239 34338

Piston & Pin Assembly, .020" Over 241 35797

(Assemblies Include Ref. #43) 245 35066

Ring Set, Piston, Standard Size 250 35065

Ring Set, Piston, .010" Oversize 260 35826

Ring Set, Piston, .020" Oversize 262 650831

Piston Pin Retaining Ring 263A 35821

Connecting Rod Assy. (IncL#46) 275 36473

Connecting Rod Bolt 277 650988

Valve Lifter 285 35000A

Camshaft (BCR) 287 650926

Oil Pump Assembly 290 34357

* Mounting Flange Gasket 292 26460

Mounting Flange (Incl. #72 thru 83) 300 35586

Oil Drain Plug 301 35355

Oil Drain Plug Gasket 305 358t9A

Oil Seal 306 34265

Governor Shaft 307 35499

Washer 309 650936

Governor Gear Assy,(Includes #81) 310 35822

Governor Spool 313 34080

Screw 1/4-20 x 1-1/4 347 650898

Flywheel Key 370 35167

Flywheel 370A 36261

Belleville Washer 380 632681

Flywheel Nut 390 590702

Solid State ignition 400 36481

Spark Plug Cover

Screw, Torx T-15 #10-24 x 1 416 36085

Ground Wire

* Cylinder Head Gasket 417 650760

Cylinder Head

Exhaust Valve, Standard Size

Exhaust Valve, 1/32" Oversize

intake Valve, Standard Size

intake Valve, 1/32" Oversize

(All Valves include Reference #151)

Screw 5/16-18 x 1-1/2

Resistor Spark Plug (RJ19LM)

Valve Spring

Valve Spring Cap

RPM Settings: Low Speed: 2450-2750

NOTE: This engine could have been built with 590637

Starter. Refer to design of air intake louvers for part

identification. Individual starter parts do not interchange.

NOTE: All component dimensions given in U,S, inches

1 inch = 25.4 mm

Engine Shroud

* Valve Cover Gasket

Valve Cover

Nut and Lock Washer 1/4-28

Screw t/4-28 x 7/8

* Carburetor To Intake Pipe Gasket

intake Pipe (Includes Ref. #224)

Governor Link

Screw !/4-20 x I/2

S.E. Brake Bracket (Includes #195)

Terminal

Control Bracket (Includes

Reference Numbers 202 thru 205)

Compression Spring

Compression Spring

Screw #5-40 x 7/16

Screw #6-32 x 21/32

Throttle Link

Control Knob

Screw 1/4-20 x 1

* Intake Pipe Gasket

Screw #10-32 x 49/64

* Air Cleaner Gasket

Air Cleaner Collar

Air Cleaner Filter

Air Cleaner Cover

Blower Housing

Screw 1/4-20 x 1/2

Starter Grill

Muffler (includes Reference #277)

Screw 1/4-20 x 2-1/4

Starter Cup

Screw #8-32 x 21/64

Fuel Line

Fuel Line Clamp

Fuel Tank (Includes #292 and 301)

Fuel Cap

Oil Fill Tube

* O-Ring

O-Ring

Screw #10-32 x 13132

Dipstick

Spacer

Screw #10-32 x 27/32

Control Decal

Lubrication Decal

Carburetor (Includes Ref. #184)

Rewind Starter

Gasket Set

(Includes All Items Marked *)

Spark Arrester Kit, Optional

(Includes Reference Number 417)

Screw #8-32 x 3/8 (Optional)

High Speed: 2900-3200

24

Page 25

CRAFTSMAN 4-CYCLE ENGINE MODELNUMBER143.955500

CARBURETOR NO. 632681

#

i

REWIND STARTER NO. 590702

REF PART

NO. NO,

- - 632681

1 631615

2 631767

4 631184

5 631183

6 6325O4

7 650506

16 631775

25 631867

27 631024

28 632019

29 631028

3O 631021

31 631022

35 632694

35A 632647

40 632682

44 27110

48 631027

REF PART

NO. NO. DESCRIPTION

-- 590702

1 590599A

2 590600

3 590696

4 590601

5 590697

6 590698

7 590699

8 590700

11 590703

12 59O535

t3 590701

DESCRIPTION

Carburetor, Complete (Includes

Ref. #184 of Engine Parts List)

Throttle Shaft and Lever Assembly

Throttle Return Spring

Dust Seal Washer

Dust Seal, Throttle

Throttle Shutter

Shutter Screw

Fuel Fitting

Float Bow!

Float Shaft

Float

Float Bowl O-Ring

Inlet Needle, Seat and Clip

(Includes Reference Number 3t)

Spring Clip

Primer Bulb/Retainer Ring

Primer Bulb Filter

High Speed Bowl Nut

Bowl Nut Washer

Welch Plug, Atmospheric Vent

Recoil Starter, Complete

Spring Pin (Includes Reference #4)

Washer

Retainer

Washer

Brake Spring

Starter Dog

Dog Spring

Pulley & Rewind Spring Assembly

Starter Housing Assembly

(40 Degree Grommet)

Starter Rope (98" Long, 9/64" Dia.)

Starter Handle

NOTE: All component dimensions given in U.S. inches

1 inch = 25.4 mm

r= r_l ........... -

REWIND STARTER NO. 590637 REF PART

NO. NO. DESCRIPT|ON

-- 590637 Recoil Starter

1 590599A Spring Pin (Includes Reference #4)

2 590600 Washer

3 5906t5 Retainer

4 590601 Washer

5 590598 Brake Spring

6 5906t6 Starter Dog

7 5906!7 Dog Spring

8 590618A Pulley Assembly (Includes

9 590619 Rewind Spring

10 590620 Spring Cover

tl 590638 Starter Housing Assembly

12 590535 Starter Rope (98" Long, 9/64" Dia.)

13 590452 Starter Handle

NOTE: All component dimensions given in U.S. inches

1 inch = 25.4 mm

25

Reference Numbers 9 and 10)

(40 Degree Grommet)

Page 26

SERVICE NOTES

26

Page 27

.................................. M .............

TROU LES OOTING POINTS

PROBLEM

i,,,Ull: ,hi,ill,i ,,, ,;,i n

Does not start

Loss of power

Poor cut - uneven

Excessive vibration

CAUSE

1. Dirty air filter,

2, Out of fuel,

3. Stale fuel.

4, Water in fuel,

5. Spark ptug wire is disconnected.

6. Bad spark plug,

7. Loose blade or broken btade adapter,

8. Control bar in released position

9. Control bar defective

t. Rear of lawn mower housing/blade dragging

in heavy grass.

2. Cutting too much grass.

3. Dirty air filter.

4. Buildup of grass, leaves and trash under mower.

5. Too much oil in engine.

6. Walking speed too fast.

t. Worn, bent or loose blade,

2, Wheel heights uneven,

3. Low engine speed,

4. Buildup of grass, teaves, and trash under mower,

t. Worn, bent or ioose blade,

2. Bent engine crankshaft.

CORRECTION

,,,,,,,,,,,,, .,,,.,,, , ,,,..........

1, clean/replace air filter.

2. Fill fuel tank.

3. Drain tank and refill with fresh clean fuel

4. Drain fuel tank and carburetorand refill tank with fresh

gasofine,

5. Connect wire to plug.

6. Replace spark plug,

7. Tighten blade bolt or replace blade adapter.

8. Depress control bar to handle.

9. Replace control bar.

1. Set in "Higher Cut" position.

2. Set in "Higher Cut '_position.

3. Clean/replace air filter.

4, Clean underside of mower housing,

5, Check oil level,

6. Cut at slower walking speed,

t. Replace blade, Tighten blade bolt,

2. Set all wheels at same height,

3. Set engine speed control in HIGH position,

4. Clean underside of mower housing.

1. Replace blade. Tighten blade bolt,

2, Contact Sears Service Department.

__,,_,÷ _

Starter rope hard to pull

...... ,,,,

Loss of drive

Grass catcher not filling

(If so equipped)

Hard to push

1. Engine flywheel brake is on when control bar is

released.

2. Bent engine crankshaft

3. Blade adapter broken.

4. Blade dragging in grass.

I. Drive wheels not turning with drive control engaged.

2, Belt not driving.

1. Cutting height too low.

2. Lift on blade worn off.

3, Catcher not venting air.

4. Low engine speed.

t. Grass is too high or wheel height is toe low.

2. Rear of lawn mower housing/blade dragging

in grass.

3, Grass catcher too ful!.

4. Handte height position not right for you.

1. Depress control bar to upper handle before

pulling starter rope.

2. Contact Sears Service Department,

3. Replace blade adapter.

4, Move lawn mower to cut grass or to hard surface

to start engine.

1. Adjust or reptace drive control cable, if broken,

2. Put belt on pulleys or replace belts if broken.

t. Raise cutting height.

2. Replace blade.

3. Clean grass catcher.

4. Set engine speed control in HIGH position.

t, Raise cutting height,

2. Raise rear of lawn mower housing one (1)

setting higher.

3. Empty grass catcher,

4. Adjust handle height to suit,

27

Page 28

£RRFTXMnN®

OWNER'S

MANUAl.

MODEL NO.

917.372851

IF YOU NEED

REPAIR SERVICE

OR PARTS:

FOR REPAIR SERVICE, CALL

THIS TOLL FREE NUMBER:

1-800-4-REPAIR

(1-800-473-7247)

5.5 HORSEPOWER

22"3 in ONE Convertible

POWER PROPELLED

ROTARY LAWN MOWER

Each lawn mower has its own model number. Each en-

gine has itsown model number.

The model number for your lawn mower will be found on a

decal attached to the rear of the lawn mower housing.

The model number for your engine will be found on the

blower housing of the engine.

All parts listed herein may be ordered from any Sears,

Roebuck and Co. Service Center/Department and most

Retail Stores.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE

FOLLOWING INFORMATION:

• PRODUCT- LAWN MOWER

• MODEL NUMBER - 917.372851

° ENGINE MODEL NO. - 143.955500

= PART NUMBER

° PART DESCRIPTION

FOR REPLACEMENT PARTS

INFORMATION AND

ORDERING, CALL THIS

TOLL FREE NUMBER:

1-800"FON'PART

(1-800-366-7278)

Your Sears merchandise has added value when you

consider Sears has service units nationwide staffed with

Sears,trained technicians.., professional technicians

specifically trained to insure that we meet our pfedge to

you, we service what we sell.

28

Loading...

Loading...