Sears 917. 270181 Owner's Manual

. -

....

(

--~·

[Sears~

,>-,':cJ°wners

_-

~-

/rilanuar~

·~

~-

..

'\,_1~

,.

,,

,"

.···

\

"'

...

) .

~;

<:;,

!.

~

..

~

~<

. D /

0

/~

.

.

...

·

- '

i

/~

--4

<<MODEL :NO. ·

917.

2'-70181

._

....

--:.:.

•:

. \

8 H.P.

SHREDDER-

-BAGGER.

-~.'

CAUTION:

Read

'·

~afe

and

Operation

·Instructions ·

Carefully

Rules

for

.

•Assembly

•Operating

~

•

Maintenance

··Repair

Sears,

ahcL$impsons

·.

·

....

:-

.

~-:~

~-;i_~~~L.&~t;.:;~:'{<~~-~M~>:

·)}_:'.

,_,._

Roebuck

..

~-·.

·,

.

Parts

arid

Sears

:.

.

_,

.·

Co.,·

.

Chicago,

Limited,

Ill.

Toronto

60684){)~;A.

.,,..

·

During

in

materia

any

of

days

if

the

I or

our

used

first

year,

workmanship.

stores

for

com mere

or

we

will

repair

Th

service

centers

i,a I purposes.

your

is

guarantee

Lawn

service

throughout

& Garden

is

available

the

United

Shredder-Bagger

by

simply

States

or

Canada.

w

\(!~j,'.~f~~'

free

of

charge,

returning

Guarantee

if

found

the

shredder-bagger

is I im

defective

ited

to

to

30

l.

The

operator

of

the

fore

2.

3.

4.

5.

. 6.

7.

8.

9.

10.

11.

12.

13.

14. Do

15.

16. It is

attempting

Children

Shredder-Bagger.

The

Shredder-Bagger

the

vicinity

The

Shredder-Bagger

base

is

located

Never

out

the

position

The

Shredding

the

Engine

gine

is

When

feeding

der-Bagger,

metal,-

ials

are

Always

time

the

The

Spark

the

Spark

Engine

to

cool

justments

If

the

foreign

J::..

Stop

B. Remove Spark

C.

Inspect

D.

Repair

restarting

All

screws,

be

sure

condition.

dirt

and

damage

If

your

unusual

stop

wire.

checked

tinued

Do

not

better

tended.

not

ger.

Do not

soft

wood

a

rate

R.

P.

Do

not

ial

to

prevent

recommended

der-Bagger

·times

17. Wear

6442R-29.

should

different

tight

near

start

Hopper

•

running,

rocks,

not

of your

down

blades

the

The

safe

job,

overload

M.'S.

allow

build

while

proper

4.

sections

must

disconnect

Engine

object,

Shredder-Bagger.

your

other

to

Shredder-Bagger

noise

for

force

that

proper

to

never

of

children,

in

place,

R.H.

or

operate

and

Blades

Crankshaft;

the

shreddable

be

extremely

bottles,

piaced

is

Plug

Wire

Plug

to

Shredder-Bagger

before

or

repairs

of your

follow

for

damage,

or

replace

your

nuts

Shredder-Bagger

Also

the

accumulations

Engine.

or

Engine

Shredder-Bagger

loose

operation.

your

safer,

the

feed_

'more

stick~

d'des

an

accumulation

up

in

discharge

obtain

operating

apparel,

7 4

SEARS,

become

operate

cannot

pivot

Ramp

Blades

in

the

stopped.

shou

prevent

to

Plug

Shredder-Bagger.

and

Engine

abnormal

and

parts

Shredder-Bagger,

at

hopper

at a time,

not

the

that

and

fully

of

this

this

be

a II

owed

shou

Id

never

pets

depressing

the

making

be

bracket.

your

Shredder-Bagger

secured

are

connected

therefore,

are

material

careful

can-5 or

the

Shredder-Bagger

these

any

bolts

disconnect

the

than

discharge

wear

this

Avoid

other

Shredder-Bagger.

Spark

Id

be

accidental

any

unit.

steps.

Wire.

damaged

must

is

must

in

should

vibration,

should

or

damage

rate

for

of your

two

Feed

substantially

and

the

operator

safety

machine.

wearing

ROEBUCK

IMPORTANT

RULES

familiar

Owners

Shredder-Bagger.

to

be

or

other

started

the

in

turning.

into

that

Plug

disconnected

must

inspection,

be

in

be

order

start

the

which

3/8

the

of

shredded

area

cause

with

Manual

operate

operated

persons.

unless

safety

switch

their

proper

directly

when

the

your

Shred-

pieces

foreign

starting.

safe

kept

then

to

Shredder-Bag-

inch

of

glasses

mater-

Wire

,

be

allowed

strike

parts

before

kept

tight

operating

clean

to

prevent

making

immediately

spark

be

as

sure

It

wi

II

it

is

diameter

machine

reduce

mater-

as

this

plugging.

this

Shred-

at

loose

fitting

AND

FOR

all

be-

this

in

the

with·

to

En-

of

every

from

The

ad··

any

to·

of

any

plug

fully

con-

do a

in-

at

the

will

all

CO. -SIMPSON-SEARS,

READ

SAFE

OPERATION

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

I

'·

31.

~

32.

33.

- l -

clothing

wear

Never

body or

charge

gine

Keep

working

Always

ing your

justable

ward

discharged,

marked on

Keep

per

teria

Do

ance

Keep

accidents,

This

level

Do

operate

Never

exhaust

oxide

poison.

Never

Bagger

hot.

wiped

highly

treme

The

must

The

ing

the

Store

Shredder-Bagger

dry,

dren,

,

an

age,

olin_e

to

cool

Use

use

that

Stop

Wire when

changing

Use

Shredder-Bagger.

Maintain

keeping

operation,

or

while

operating

allow

clothing,

chute

is

running.

guards

order

stand

Shredder-Bagger.

Deflector

angle

to

the

your

face

opening

I.

not

at

not

All

governor

governor

speed

Engine

high

open

the

the

your

for

only

to

overreach.

all

times.

work

areas

machine

surface

expose

it

in

run your

from

which

..

fi

II

the

while

spilled

prior

to

flammable

care.

not

be

of

from

idle

tools

or

locked-up

Keep

where

flame

gasoline

discarded

before

right

Shredder-Bagger

which

Shredder-Bagger

not

accessories

Sears

your

it

clean

1ewelry,

your

and

The

wet

- , --·

altered,

LTD.

and

wear

your

Shredder-Bagger.

hands,

or

near

deflectors

to

assure

c I

ear

control

side

and

avo_id

should

to

prevent

your

or damp

Shredder-Bagger

the

is

tasteless,

gaso I ine

the

Engine

or

starting

and

settings

controls

the

damge,

indoors.

shou

or

spark.

tank

in a

storing

machine

it

is

in

use,

approved

Shredder-Bagger

or

inside

of

and

minimum

of

body

Keep

clean.

Engine

'""

excess

Shredder-Bagger

gasoline

intended.

for

any

the

any

moving

continued

discharge

Never remove

always

direction

the

Deflector.

back

the

bounce

proper

Cluttered

be

operated

tipping.

Shredder-Bagger

locations.

contains

·

tank

is

the

must

on

your

changed

the

maximum

When

Id

be

place,

For

should

safe

place.

in

any

for

the

for

and

before

such

as

accessori~s

best

protective

other

ramp-hopper,

parts

in

place

and

safe

area

keep

it

of

material

suggested

from

the

back

footing

areas

only

indoors

Carbon

odorless

of your

running or

gasoline

Engine.

be

,

stored

oyt

fumes

long

be

enclosure.

any

remove

servicing,

and

Gasoline

handled

Shredder-Bagger

or

tampered

safe

an#"protects

not

iri

indoors

of

reach

will

periods.of

drained

Allow

right

job.

purpose

Spark

plastic

'with

care

continued

foot·

part

of

your

dis·

while

En·

in good

operation.

·when

oper·

the

at

a down-

being

angle

ramp0hop•

of

any

ma•

and

bal·

invite

upon a

to

rain

as

the

Mon·

and

deadly

Shredder•

while

it

should

with

ex·

with.

operat-

-use,

your

in a

of

chil-

not

reach

stor·

and

gas•

Engine

Do

not

except

Plug

and

when

bag.

. _..__I

with

your

such

safe

ad-

or

be

is

as

is

is

g_

. ·

~

.

.,.

~

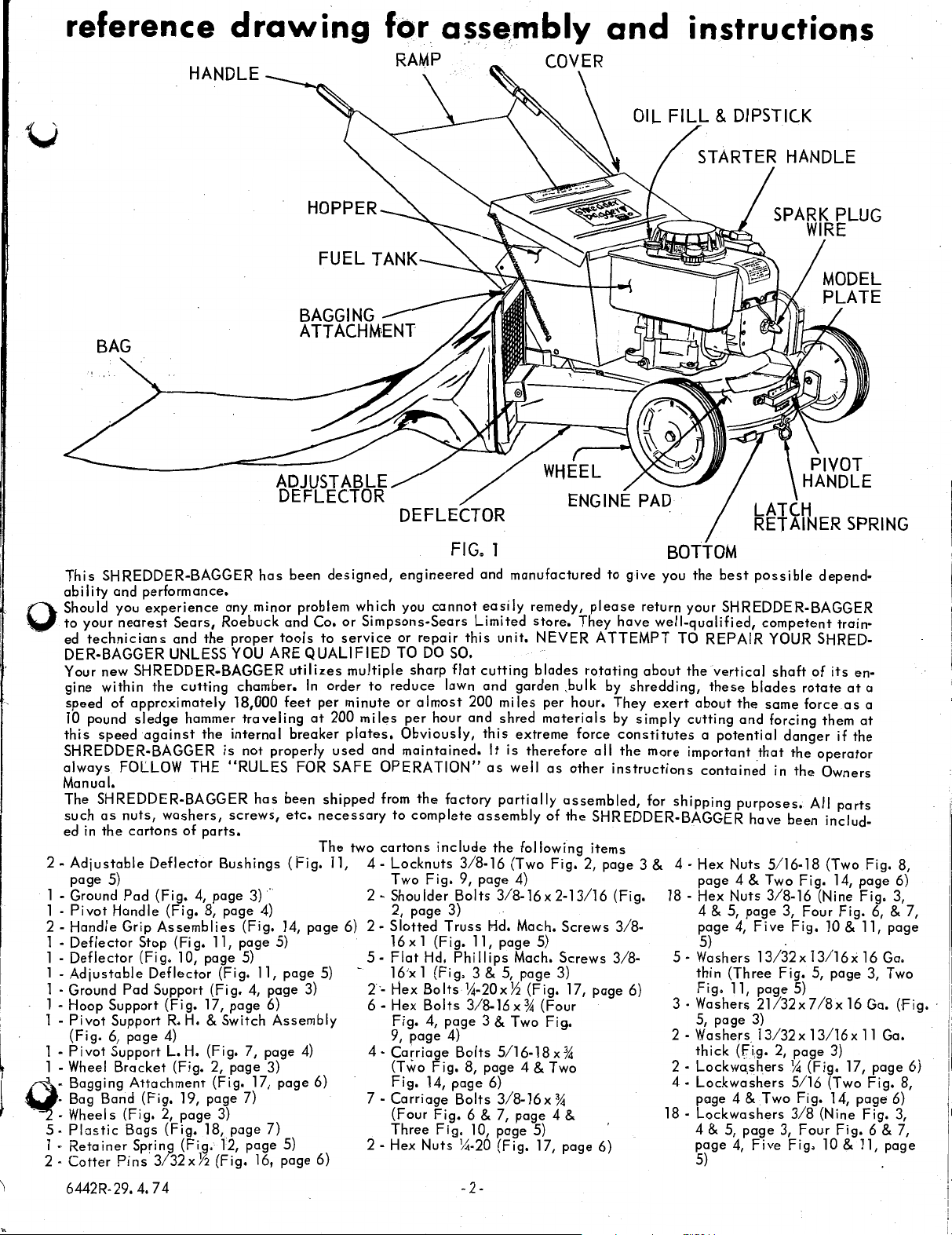

reference

u

BAG

drawing

for.

a~sembly

and

instructions

This

SHREDDER-BAGGER

ability

Should you

to

0

~

ed

DER-BAGGER UNLESS YOU

Your new SHREDDER-BAGGER

gine within

speed

10 pound

this

SHREDDER-BAGGER

always

Manual.

The SHREDDER-BAGGER

such

ed

2 -

l - Ground

l 2 l l l 1 - Ground

1 - Hoop Support

1 -

l 1 - Wheel

- Bagging

- Bag Band (Fig. 19, page 7) 7 -

- Wheels (Fig. 2,

5

·Plastic

l •

2

·Cotter

and

your

nearest

technicians

of

speed

FOLLOW THE

as

nuts,

in

the

Adjustable

page

5)

Pivot

Handle

Deflector

Deflector

Adjustable

Pivot

(Fig.

Pivot

Retainer

Pad

Handle

Grip

Pad

Support

6,

page

Support L.

Bracket

Bags

Pins

performance.

experience

Sears,

and

the

the

cutting

approximately

sledge

cartons

Attachment

Spring

hammer

against

Deflector

Stop

(Fig.

Deflector

Support

3/32xY2

the

washers,

of

parts.

(Fig,

4,

(Fig.

8,

Assemblies

(Fig.

10, page

(Fig.

(Fig.

17,

R.H.

& Switch

4)

H.

(Fig. 7, page

(Fig. 2, page 3) (Two

page

(Fig.

18,

(Fig.

has

been

any minor problem which you

Roebuck and

proper

internal

is

"RULES

screws,

Bushings

page

page

11, page 5)

(Fig. 11,

page

(Fig. 17,

3)

page

12,

(Fig.

tools

ARE

QUALIFIED

chamber.

18,000

traveling

not properly

(Fig.

5)

utilizes

feet

breaker

FOR

has

been

etc.

(Fig.

..

3)

· 2 - Shoulder

4) 2, page 3) · 4 & 5,

14,

page

4, page 3) 2·- Hex

6) 6 - Hex

Assembly

4)

page

7)

page

5) 2 - Hex

16, page 6) 5)

designed,

Co.

or

to

service

multiple

In

order

per

minute

at

200

plates.

used

SAFE

shipped

necessary

The

two

11,

page

6) 2 -

5)

6)

FIG.

engineered

Simpsons-Sears

to

miles

and

OPERATION"

from

cartons

4-

5 -

4 -

cannot

or

repair

TO

DO

SO.

sharp

reduce

or

per

Obviously,

maintained.

to

Locknuts

Two

Slotted

l6xl

Flat

16;x 1

Fig.

9,

Ca~riage

Fig.

Carriage

(Four

Three

flat

lawn

almost

hour

the

factory

complete

include

Fig.

Truss

(Fig.

Hd.

(Fig.

Bolts

Bolts

4,

page

page

4)

Fig.

14,

page

Fig.

Fig.

Nuts

l

and

manufactured

easily

Limited

this

cutting

and

200

and

this

assembly

3/8-16

9,

page

Bolts

11,

Phillips

3 & 5,

14-20xY:2

3/8-16

3 & Two Fig. 5, page

Bolts

8,

Bolts

6 & 7,

10,

14-20

remedy,

store.

unit.

NEVER

blades

garden ,bulk by

miles

per

shred

materials

extreme

It

is

therefore

as

well

as

partially

of

the

following

(Two

Fig,

4)

3/8-16x

Hd. Mach.

page

5/16-l8x

page

6) 4 - Lockwash.ers

3/8-16x%

page

(Fig.

2-13/16

5)

Mach.

page

3) thin (Three

(Fig.

x % (Four 3 - Washers 21732 x 7

4 & Two 2 - Lockwa,shers

page

4 & 18 -

5)

17,

to

please

They

have

ATTEMPT

rotating

hour.

They

by

force

constitutes a potential

all

the

other

instructions

assembled,

the

SHREDDER-BAGGER

items

2,

page

(Fig. 18 - Hex

Screws

Screws

17,

%

page

3/8-

3/8-

page

6)

BOTTOM

give

you

the

return your SHREDDER-BAGGER

well-qualified,

TO

REPAIR

about

shredding,

simply

6)

the

exert

about

cutting

more important

contain~d

for

shipping

3 & 4 - Hex Nuts

page

page

5) .

5 - Washers

Fig.

2-Washers.13/32xl3/16xll

thick

page

Lockwashers

4 & 5,

page

best

vertical

these

the

and

purposes,

4 & Two

Nuts

4,

11,

(f,ig. 2,

4 & Two

page

4,

possible

competent

YOUR SHRED-

shaft

blades

that

have

page

Five

13/32x

page

3)

Five

of

rotate

same

force

forcing them

danger

the

in

the

All

been includ-

5/16-18

Fig.

3/8-16

3, Four

Fig.

13/16x

Fig.

5, page 3, Two

5)

page

14

(Fig.

5/16

Fig.

3/8

3,

Four

Fig.

depend-

train·

its

en-

at

a

as

a

at

if

the

operator

Owners

parts

(Two

Fig.

14, page 6)

(Nine

Fig.

Fig.

10 & 11,

16 Ga.

/8

x 16 Ga.

3)

17,

(Two

14,

page

(Nine

Fig.

Fig.

10 & 11,

8,

3,

6, & 7,

page

(Fig.

Ga.

page

Fig.

8,

6)

3,

6 & 7,

page

·

6)

6442R·29. 4. 7 4

-2 -

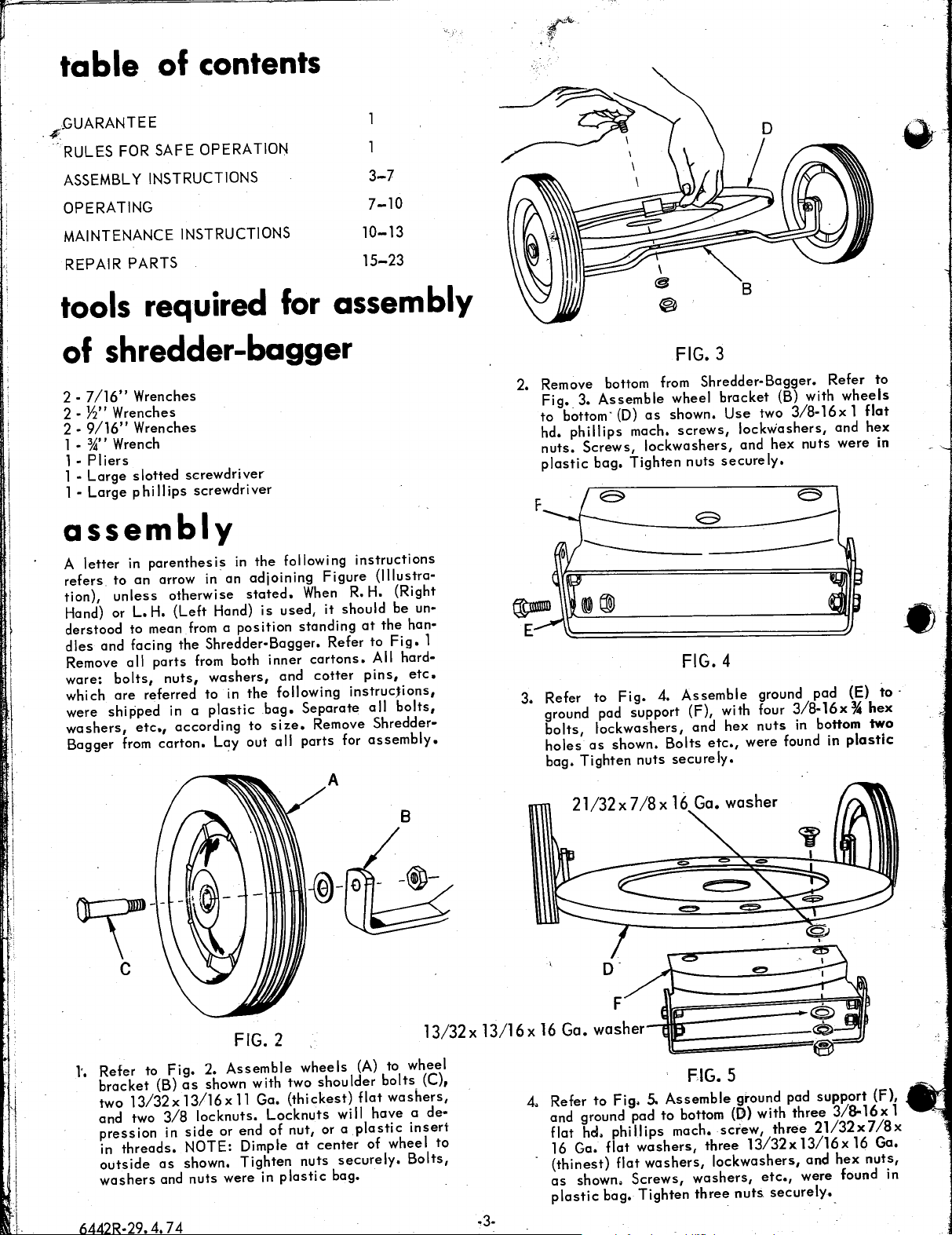

table

"GUARANTEE

. #.

-RULES FOR SAFE OPERATION

ASSEMBLY INSTRUCTIONS

OPERATING

MAINTENANCE INSTRUCTIONS

REPAIR PARTS

of contents

3-7

7-10

10-13

15-23

tools required for assembly

~-·

of shredder-bagger

2 - 7

/16"

Wrenches

Yi"

1 1 -

1 1 -

Wrenches

9/16"

%"

Wrench

Pliers

Large

Large

Wrenches

slotted

phillips

screwdriver

screwdriver

2 2 -

assembly

A

letter

in

parenthesis

refers

tion),

Hand) or

derstood to mean

dles

to

an

arrow

unless

and facing the Shredder-Bagger. Refer to

Remove

ware:

which

were

washers,

bolts,

are

shipped

Bagger

L.

H.

all

parts

referred to

etc.,

from

carton.

otherwise

(Left Hand)

nuts,

in a

according to

in

the

following

in

an

adjoining

stated.

is

used,

from a position

from

both inner

washers,

in

plastic

Lay out

the

bag.

and

following

size.

all

Figure

When

it should be un·

standing

cartons.

cotter

Separate

Remove Shredder-

parts

for

A

instructions

(Illustra-

R.H.

(Right

at

the

han-

Fig.

1

All hard-

pins,

etc.

instruc~ions,

all

bolts,

assembly.

FIG. 3

2. Remove bottom from Shredder-Bagger. Refer

Fig.

3.

to

bottom·

hd.

phillips

nuts.

plastic

Assemble

(D)

Screws,

bag.

wheel

as

shown.

mach.

screws,

lockwashers,

Tighten

nuts

bracket

Use

securely.

(B) with

two

3/8-16x 1 flat

lockw'ashers, and hex

and hex

nuts

wheels

were

--------

E

FIG. 4

3. Refer to

ground pad support (F), with four

bolts,

holes

bag. Tighten

Fig.

lockwashers

as

shown.

nuts

4.

Assemble

and

hex

B~lts

etc.,

securely.

ground pad (E)

3/8-16x % hex

nuts

in

bottom two

were found in

plastic

to

in

•

to·

. l

B

;

c

F

l'. Refer to

bracket

two

and two

pression

in

outside

washers

6442R-29. 4. 7 4

(B)

13/32x

3/8

in

threads.

as

and

FIG. 2

Fig.

2.

Assemble

as

shown with two

13/16x

side

NOTE: Dimple

shown. Tighten

nuts

11

lockouts,

or end of nut, or a

were in

wheels

Ga.

(thickest)

Lockouts

at

nuts

plastic

(A)

shoulder

will

center

securely.

bag. .

to wheel

bolts_ (C),

flat

washers,

have a de·

plastic

of wheel

Bolts,

l3/32x

insert

to

13/16x

4. Refer to

16

Ga. washer

FIG. 5

Fig.

S.

Assemble

and ground pad to bottom

flat hd.

16 Ga.

(thinest)

as

las

p

phillips

flat

flat

shown.

tic

bag. Tighten

mach.

washers,

washers,

Screws,

washers,

three

ground pad

(D)

with

screw,

three

lockwashers,

13/32x

nuts

three

etc.,

securely._

support

three

3/8-16x

21/32x7/8x

13/16x

were found in

and

hex

16 Ga.

nuts,

(F),

1

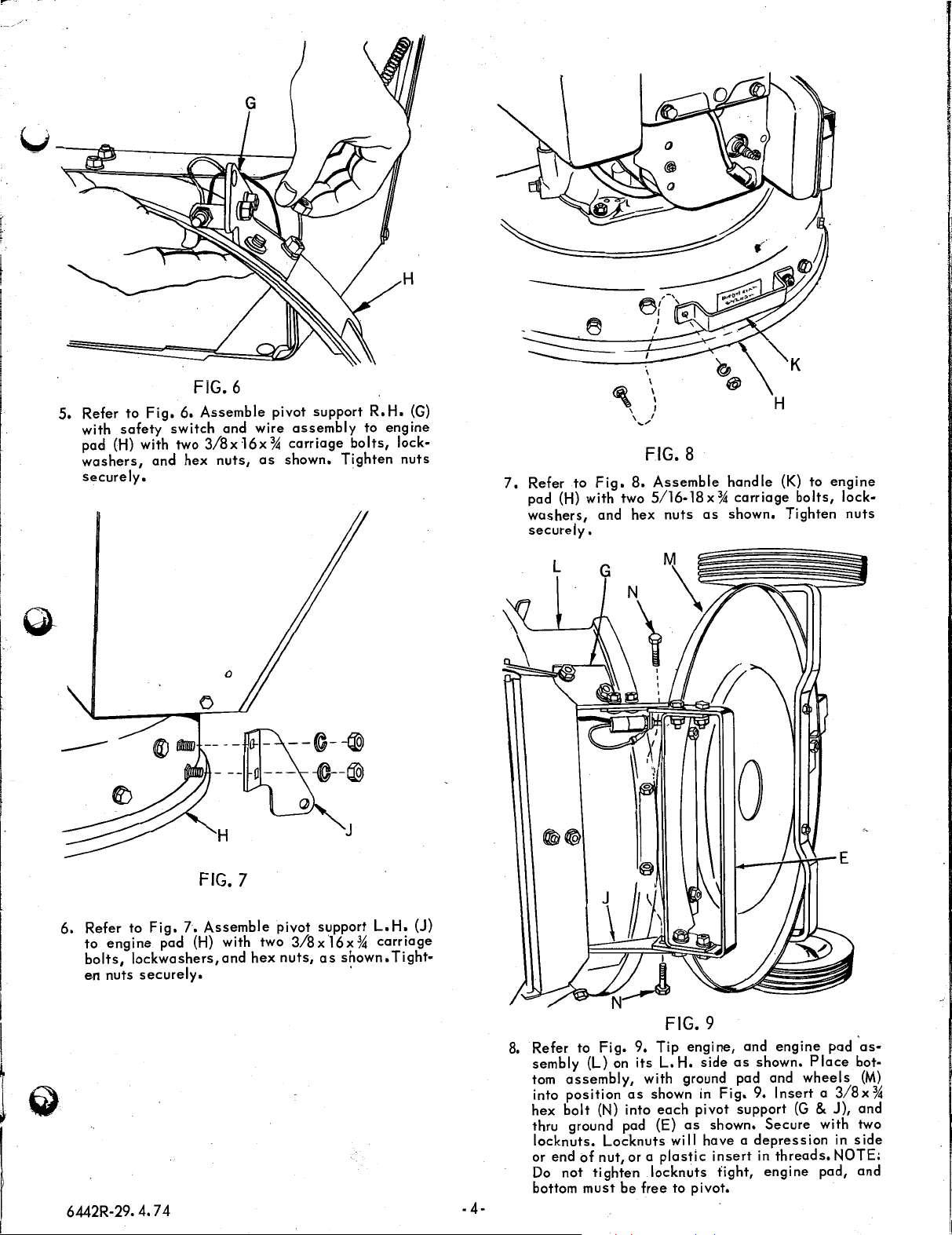

5.

Refer

to

with

safety

pad (H) with two

washers,

securely.

fig.

and

FIG. 6

6.

Assemble

switch

hex

G

and

3/8x

wire

16x % carriage

nuts,

as

pivot

assembly

shown.

support

bolts,

Tighten

·

R.H.

to

(G)

engine

lock-

nuts

7.

Refer

pad

washers,

securely.

I

\

\ I

~/

':

FIG. 8

to

Fig.

8.

(H)

with two 5/16-18 x %

and hex

Assemble

nuts

as

handle

carriage

shown.

H

(K) to

bolts,

Tighten

engine

lock-

nuts

6.

Refer to

to

engine

bolts,

en

nuts

H

FIG. 7

Fig.

7.

Assemble

pad

(H)

with two

lockwashers,and

securely.

-

--@--@

a---

pivot support

3/8x

hex

nuts,

-@--®

J

L.

l6x % carriage

as

shown.

'

H.

(J)

Tight-

L

0

6442R-29. 4. 7 4

-

4-

8. Refer to

sembly

tom

into

hex

thru ground pad (E)

locknuts.

or

end

Do

bottom

Fig.

(L) on

assembly,

position

bolt

(N)

Locknuts

of

nut, or a

not

tighten

must

FIG. 9

9.

Tip

engine,

its

L.

H.

side

as

with ground pad and

as

into

be

shown

locknuts

free

in

each

pivot

as

will have a

plastic

to pivot.

Fig.

shown.

insert

tight,

and

engine

shown.

9.

Insert a 3/8x

support

Secure

depression

in

threads.

engine

pad

Place

wheels

(G

& J), and

with two

pad,

'asbot·

(M)

in

side

NOTE:

and

%

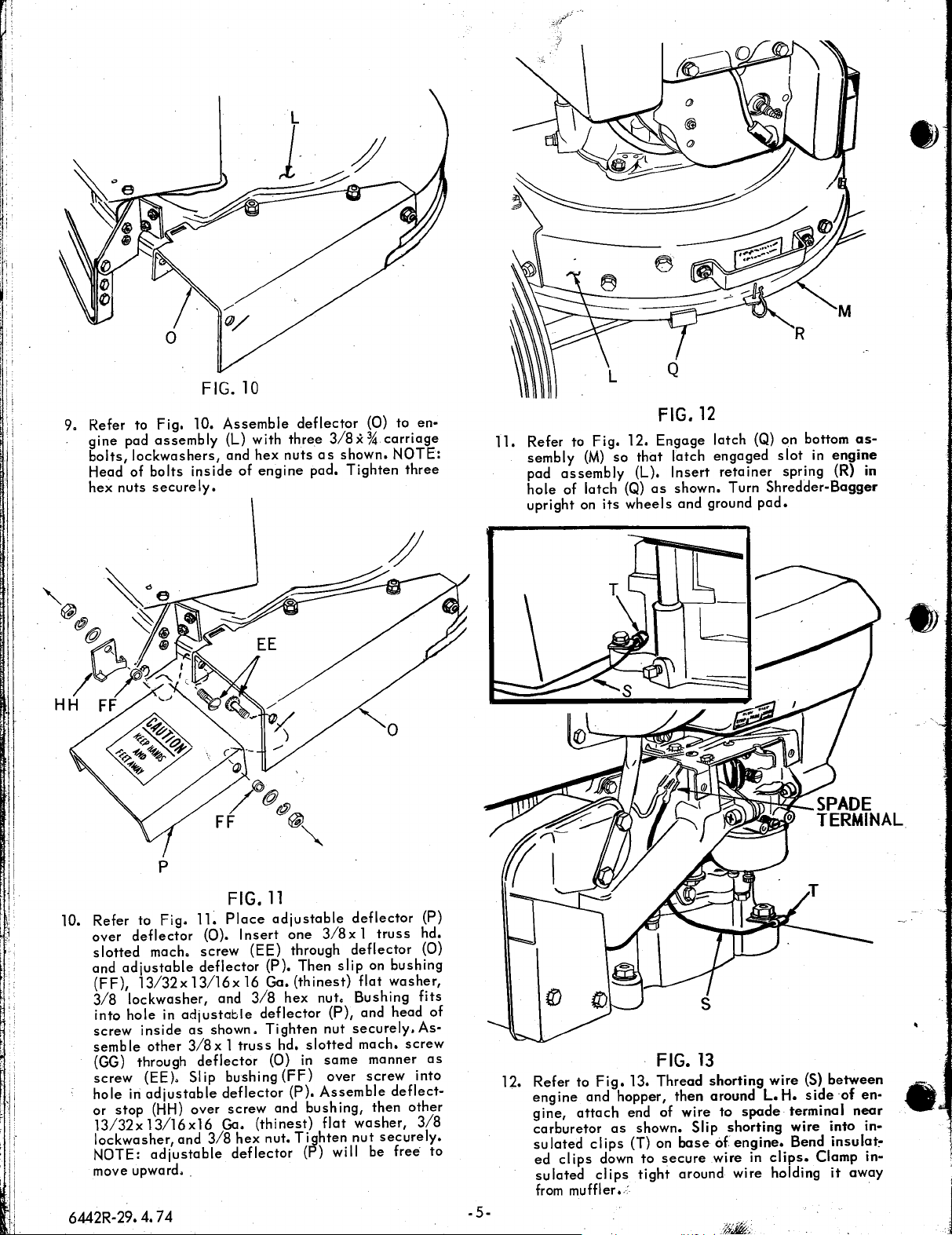

9. Refer to

gine

pad

bolts,

lockwashers,

Head of

hex

nuts

Fig.

10.

assembly

bolts

inside

securely,

FIG.

Assemble

(L) with

and

10

hex

of

three

nuts

engine

deflector

3/8.X %

as

shown.

pad.

Tighten

(0)

carriage

NOTE:

to

three

en·

11.

Refer to

sembly

pad

hole

upright on

(M)

assembly

of latch (Q)

Fig.

its

12.

so

that

(L).

wheels

FIG.

12

Engage

latch

Insert

as

shown. Turn

and

latch

engaged

retainer

ground

(Q) on bottom

slot

in

engine

spring (R) in

Shredder-Bagger

pad.

as-

10. Refer to

over

deflector

slotted

and

adjustable

(FF)

13/32x

3/8 1lockwasher,

into

hole

screw

inside

semble

(GG) through

screw

hole

or

13/32xl3/16xl6

lockwasher

NOTE:

move upward

6442R-29. 4. 7 4

other

(EE). Slip bushing

in

adjustable

stop

p

Fig.

11.

mach.

(HH)

ad(ustable

(0).

screw

deflector

13/16x

in

adjustable

as

3/8x l truss

deflector

over

and

3/8

•.

shown.

FIG.

Place

Insert

(EE) through

16 Ga.

and

3/8

deflector

Tighten

deflector

screw

Ga.

(thinest)

hex

nut.

deflector

11

adjustable

one

(P).

Then

(thinest)

hex

nut,

hd.

slotted

(0)

in

(FF)

(P).

Assemble

and

bushing,

Tighten

(P) will be

deflector

3/8x l truss

deflector

slip

on bushing

flat

washer,

Bushing

(P),

and head

nut

securely.As·

mach.

same

manner

over

screw

deflect·

flat

then

washer,

nut

securely.

free

(P)

hd.

(0)

fits

of

screw

as

into

other

3/8

to

-5-

12.

Refer to

engine

gine,

carburetor

sulated

ed

sulated

from

and hopper,

attach

clips

muffler

Fig.

as

clips

down

clips

13.

end

shown.

(T) on

•.

:

FIG.

13

Thread

of

to

tight

secure

shorting

then

around

wire

to

Slip

base

around wire holding

shorting

of

wire in

wire

L.

spade

engine.

clips.

(S)

between

H.

side

of

en·

te~min_al

wire into

Bend insulat!"

Clamp

it

n4:°r

in·

in·

away

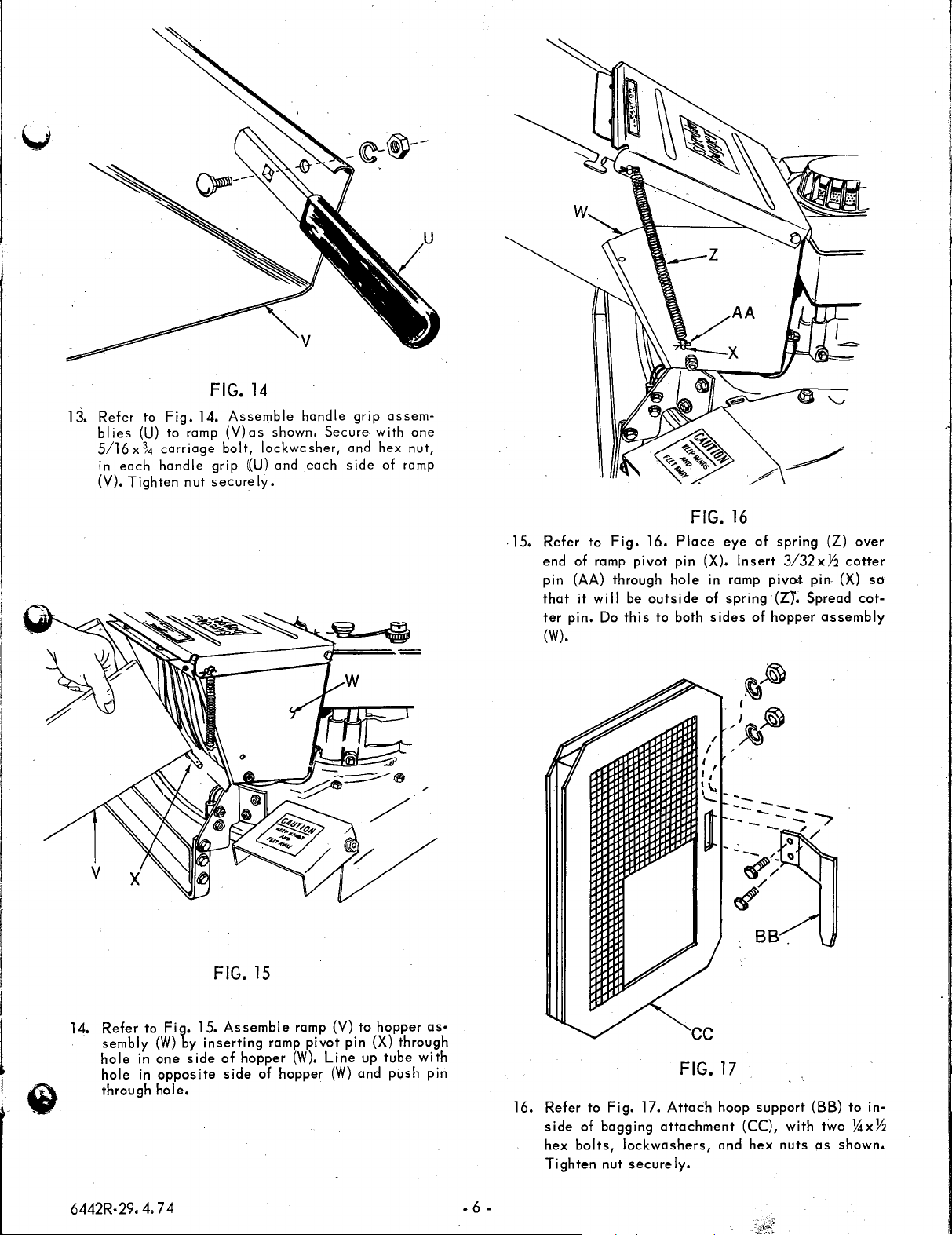

13.

Refer

blies

5/16

in

each

(V),

to

Fig.

(U)

to

x

~4

carriage

handle

Tighten

14.

ramp

nut

FIG.

14

Assemble

(V)as

bolt,

grip

((U)

securely.

handle

shown.

lockwasher,

and

Secure

each

grip

and

side

assem-

with

one

hex

nut,

of ramp

.15,

Refer

to

end

of ramp

pin (AA)

that

it

ter

pin.

(W).

Fig.

through

will

Do

pivot

be

this

16.

Place

pin (X).

hole

outside

to

both

FIG.

in ramp

of

sides

16

eye

Insert

spring

of

piveot.

of

spring

3/32xY:i

(ZY.

hopper

(Z)

pin (X)

Spread

assembly

over

cotter

so

cot-

I

I

I

14.

Refer

sembly

hole

hole

through

6442R-29.

to

Fig.

(W)

in

one

in

opposite

hole.

4. 7 4

15.

by

inserting

side

FIG.

15

Assemble

of

hopper

side

ramp

of

ramp (V)

pivot

(W).

hopper

pin (X)

Line

(W)

to

up

and

hopper

through

tube

push

as•

with

pin

- 6 -

16.

Refer

side

of

hex

bolts,

Tighten

to

Fig.

bagging

lockwashers,

nut

17.

Attach

attachment

securely.

cc

FIG.

17

hoop

and

support

(CC),

hex

with

nuts

(BB)

two

as

to

in·

!4xY2

shown.

I :

: :

~!

I

I.

DD

i1

BB

/

\

\

FIG.

18

17. Refer to

smaller

shown.

least

be

Fig.

flange

NOTE: bagging

2"

inside

outside

bag

18.

Assemble

of bagging

bag, and hoop support (BB)

as

shown.

plastic

attachment

attachment

bag (DD)

(CC)

must be

over

as

at

must

19. Refer to

embly over

support (BB) .down

enter

both

FIG.

Fig.

20. Slip bagging

adjustable

so

slots

in

deflector

20

deflector

that

hoop support

(0).

attachment

(P).

Slip hoop

{BB}

ass-

wi

11

instructions

before

operating

NEVER

IN

TERRAIN.

FOOTING

FIG.

19

18. Refer to

side

(CC).

tachment.

·:,

'.

;.:

;

i.

i

l

·11

6442R-29. 4.

of

This

Fig.

plastic

bag band

74

19.

Stretch

bag (DD) and bagging

bag band (EE)

secures

bag to bagging

over

out•

attachment

at-

- 7 -

WET

OPERATE

GRASS,

MUDDY,

ALWAYS

..

THE

SHREDDER-BAGGER

UNEVEN

BE

SURE

OR

OF

ROUGH

YOUR

Loading...

Loading...