Page 1

91

GAssembly

o Operation

° Customer Respensibilities

oService and Adjustments

_,Repair Pa_s

OWNER'S MANUAL

CAUTION: Read and follow atl safety ruses and _nstructlons before operating this equipment.

Page 2

SAFETY RULES

Safe Operation Practices for Ride-On Mowers

iMPORTANT: TH_S CUTTING MACHINE _S CAPABLE OF AMPUTATING HANDS AND FEET AND THROWING

OBJECTS, FAILURE TO OBSERVE THE FOLLOWING SAFETY INSTRUCTIONS COULD RESULT _N SERIOUS

NJURY OR DEATH

l, GENERAL OPERATION

Read, understand_ and foilow al_instractio_s in the manua!

and on the machine before sta_ing.

Only alIow responsiMe adutts who are familiar with the

instructions, to operate the machine

* C_ear the area ot objects such as recks, toys wire, etc.

which could be picked _:_pand thrown by the b_ade,

Be sure the area isctear of other people before mewing Stop

mace Re if anyor_e enters the area

_, Never carry passengers.

_' Do r_otmow in _everse unless absolutely necessary Aways

took down and behind before and whiie backing.

. Be aware of the mower discharge direction and do not point

}t at anyone. De not operate the mower without either the

eeti_e grass catche_ or the guard in piace.

SI@_ down before taming.

bdore dismounting

Turn off biades when not mowing_

. Stop engine before removing grass catehe_ or unclogging

chute

. Mow on_yin daylight or good a_tficial lighL

. Do not operate the machine whi_e under the influence of

alcohol or drugs

*, Watch for traffic when operating near or eros ing roadways_

_, Use extra care when loading or unloading the mace ne into

a trailer or truck.

tL SLOPE OPERATION

t[_L CHILDREN

and the mowing activity Nevetassume that children wfi remain

were you last s_w them

Keep children out of the mowing area and under the watchful

care of another responsible aci]_Jtt.

o Be aie_ and turn machine off if ehildre_ enter he area

. Before and when backing _oekbehnd and down for small

cMIdren

. Never carry children They may fali off and be sedously

iniured or ir'_tedere with safe machine operation.

- Never allow children to operate the mace no,

• Use extra care when approaching blind corners shrubs,

trees, or other objects that may ob_cure vision.

SERVICE

Use extra care in haedling gasoine and other fuels. They are

fiammable and vapors are exp!osive_

Use on_yan approved container

Never remove gas cap or add faei with the engine

ruenir g_ Allow engine to coo_ before iefue_ir_g. Do no!

smoke

Never _'efuel the machine indoors

Never tore the reacttins or rue! container nsde where

there is an open fin he, such as a water _eater

Never ren a machine inside a closed area

Keep nu_s and bolts., especiaf_y binds attachment bolts, tight

and keep eq_iprnen_ in good condition

Never tamper with safety devices. Check thor proper

req_ire extra caution If you cannot back up the stops or if you fee_

uneasy on it, do not mow ii,

DO_

Mow up and down s_opes, not across

. Remove obstacles such as rocks, tree limbs, etc.

,, Watch for hoIes, ruts or bumps. Uneven terrain could

ove_lurn the machine. Taft gr_:_sscan hide obstacle&

Use s_owspeed Choose a k_wgear so that you w ; not have

to atop or shift while on the slope.

Follow the manufacturers recommendations for whee_

weights or counterweights to reprove stability

. Keep all movement on the s;opes stow and graduat De not

make sudden changes ;r_speed or direction_

'_ Avoid starling or stopping on a slope If tires lose traction,

disengage the Mades am:] proceed s_ow_ystraight down the

DO NOT:

Do net mow near drep..offs, ditches, or embankments The

mower co_._ldsuddenly turn over if a whee_ is over the edge

of a cliff or ditch, or if an edge caves in.

Do net mow on wet grass Reduced traction could cause

. Do not try to stabilize the machine by putting your foot on the

Keep machine free of grass teaves, or other debrs bu td_ap.

C!ean oi or tue_ spiI_age_ Allow machine to cod before

Stop and inspect the equ{pment if you strike an obiect.

Repair, f necessary, before resta£ing.

Never make adi_._stmerdsor repa rs wth the engne runnii'_g

Grass catcher components are subject to wear, damage, and

deterioration which could expose moving pa_s or show

objects to be throws Frequently check components arid

repines wth manufacturers r¢_ommended parts, when hoe

essaq/

_' Mower blades are sharp and carl euL Wrap the Made(s) or

wear g_oves, and use extra caution when serv;cieg them

,_ Check brake operation freqaently. Adjust and service as

Look for this symbof to point out impor-

tant safety precautions, It means

CAUTiON!i! BECOME ALERT!i! '/OUR

SAFETY IS INVOLVED,

CAUTION: Always disconnect spark

plug wire and place wire where it cannot

transporting, adjusting or making

Do not use grass catcher on steep slopes.

2

Page 3

tured to give you the best possble dependabitty and

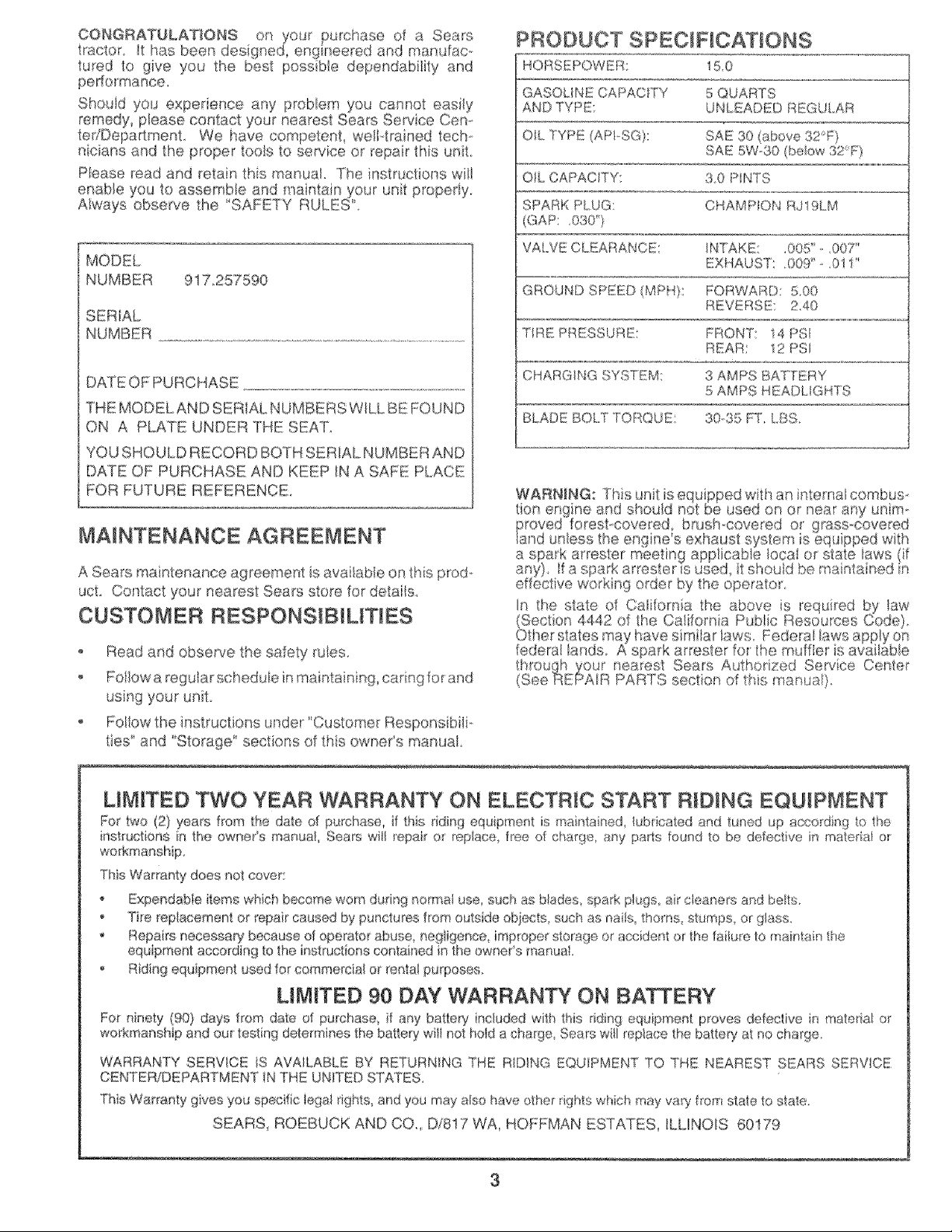

PRODUCT SPECIFICATIONS

150

GASOLINE CAPAC TY 5 QUARTS

AND TYPE: UNLEADED REGULAR

tedDepa£ment We have cor'npetent wetbtraned tech.,

nicians _nd the prape_ too_s to sewice or repair this unt

P_ease read and retain this manual, }he instructions wli

enable you to assemble and maintain your unit properly_

Atways observe the 'SAFETY RULES',

MODEL

NUMBER 917,257590

SERIA{

NUMBER

DA'TEOF PURCHASE

THE MODELAND SERIAL NUMBERSW_LL BE FOUND

ON A PLATE UNDER THE SEAT

YOU SHOULD RECORD BOTH SERIAL NUMBER AND

DATE OF PURCHASE AND KEEP iN A SAFE PLACE

FOR FUTURE REFERENCE_

MAINTENANCE AGREEMENT

A Sears maintenance agreement s ava tabte on this prod-

uct. Cot tact your nearest Sears store fer deta Is.

CUSTOMER RESPONSIBILITIES

O_L TYPE (AP/ SG} SAE 30 above 32'_ )

SAE 5W-30 (beow 32F}

eL CAPACITY: 3.0 PNTS

SPARK PLUG: CHAMP}ON RJ19LM

(GAP: 030")

NTAKE: _005 -. 007'

EXHAUSTs .009 011 _

GROUND SPEED MPH>: FORWARD: 5.00

REVERSE; 2.40

TIRE PRESSURE: FRONT: 14 PS}

REARI 12 PSI

CHARGING SYSTEM: 3 AMPS BATTERY

5 AMPS HEADLtG qTS

BLADE BOLT TORQUE: 30-35 _sT'.LBS

Read and obsewe the safety rules.

Folow a regular schedule inmaintainin 9,caring for and

fttrough yeur nearest "

(See REPAIR PARTS section of i'_s manua }.

Sears Aathor zed Servce Centel

using your unit.

Fo/ow the instructions unde_ 'Customer Responsibili-

ties" and "Storage" sections of this owner's manua

L{M{TED TWO YEAR WARRANTY ON ELECTRIC START RIDING EQUIPMENT

For two (2) years from the date of purchase, if this riding equipment is maintained _ubiieated and tuned up accord nq ta the

instructions in the owners manual, Sears wil repair o rep/_ce free of ch_trge ary pa_ls found to be defective n matera_ or

This Warranty does not cover:

" Expendable items which become warn during normal use, such as blades spa'k pl;gs air c_eaners and belts

" Tie replacement or repair caused by punctures from outside obiects, such as hats, thorns stumps, or glass.

,_ Repairs necessary because of operator abuse, negligence, improper .storage or accident or the faiure ta mair tan the

equipment accarding to the instructions conlained in the ewr_er's manua_

,, R}ding e%ipment used for commercial or rents} purposes

L{MITED 90 DAY WARRANTY ON BAKERY

Far ninety (g0} days trom date of purchase, if any battery included with this riding equipment prowls defectiw:_ n materia_ or

workmanship and our testing determines the battery will not hold a charge, Sears will replace the batte_ at na charge.

WARRANTY SERVICE S AVAILABLE BY RETURNING THE RIDING EQU PMENT TO THE NEAREST SEARS SERVICE

CENTERJDEPARTMENT IN THE UNITED STATES

This Warranty gives you specific iegsl rights, arid you may also have ether rights which may vary fl_omstate to state.

SEARS, ROEBUCK AND CO., D/817 WA HOFFMAN ESTATES, _LL[NO[S 60179

3

Page 4

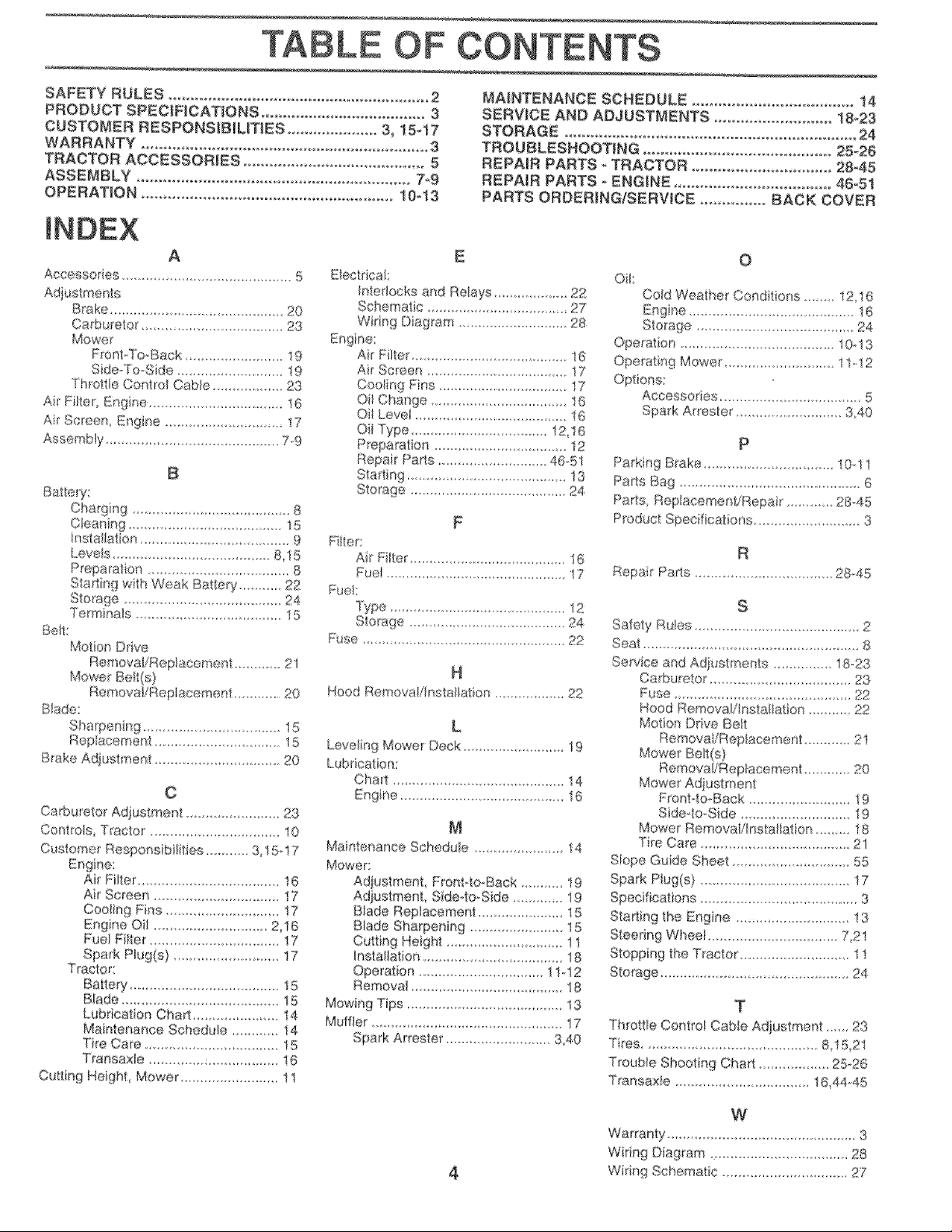

iNDEX

A

Accessories 5

Brake 20

Cal'burete_ .........................23

Mower

FrontoT@Back .................19

S de-To-Side ............................19

Throttb Centrol Cable ..................23

A_ Fi!ter, Enghe. ............................16

Air Screen, Engine ............................t7

Assembly ............................................79

Charging 8

Cleaning 15

inetaiiat}en 9

Levee &t5

Preparation 8

Start ng wth Weak Battery ...... 22

Slorage ...................................24

Term nals.....................................15

Belt:

MotionD(we

RemowWReplacoment ............21

Mower Be_f(e)

Removai/Replacement 20

Blade:

Sharpening 1S

Reptacernent ..................15

B_'ake Adjustment .........................20

C

Carburetor Adiustment ..................23

Contr@s,Tractor.........................I0

Customer Responsibilities ...........3,15o17

Air Filter .............................16

Air Screen ...........................17

CoolingFins...........................17

Engine Oil ...............................2!6

FuelFilter..................................17

Span Plug(s)..........................t7

Tractor:

Balte_y ............................15

Biade .......................................!5

Lubrication Char ....................14

Maintenance Schedule ............! 4

Tire Care !5

Transa?xte ................................16

Curt ng Height, Mower .......................11

E

Electrical:

Interlocks and Relays ............ 22

Schen' eric 27

Wdng Diagram 28

Air Fi_ter 16

Air Screen 1'7

Coo_ing Fins 17

Oi_Char_ge .................. 16

OilLever.......................................16

OilType ...................................12 t6

P_eparation ..................................12

Repair Parts ...........................4851

Starting ..........................................13

Storage ..........................................24

F

FtJter:

Ar FIter ................................16

Fuet ...............................17

Fuel:

Type .............................12

Stora9e. ..........................................24

Fuse .....................................................?2

H

Hood Remeva[/fnstsI/ation .................22

L

Leve_ing Mower Deck ...................19

Lubrication:

Cha_l t 4

Engine 16

M

Maintenance Schedule 14

Mowers

Adiustment Front Io*Back ..........19

Adiustment Side4o-Side .........I9

Blade Replacement ...............15

Blade Sharpening ......................15

Cutting Height ............................. 11

Installation .............................18

Operation ................................11-12

Removal .......................................18

Mowing Tips ....................................t3

Muffler..........................................."I7

Spark Attester ...........................340

0

OiL

Cotd Weather Cendit ons ......12,16

Engine ...................................16

Storage 24

Operation t 0-13

OperatbE_ Mower .......................11-.12

Acceseedes 5

Spark Attester ............................3,40

P

Parking B_ake 18-11

Pads Bag ..........................................6

Parts, Replacement/Repair .............28-45

Product Specifications ............................3

R

Repair Pa_l ..............................28_45

S

Safety Ru_es 2

Seat 8

Sewce and Adiustments 18-23

Carburetor 23

F_,_ce................................22

Hoed RemovaV_nstallagon ...........22

Moton Driw_Belt

Removat/Repk_cemont ............2,I

Mower Belt(s)

Remova!/Rep_acement ........ 20

Mewer Adiustment

Front to-Back ..................1g

Side4o Side .......................t9

Mower Remow_l/Instelfation ........ t 8

Tire Care ...............................51

Sbpe Guide Shee.t .............................55

Spark Pug(s} ........................................17

Specifications .........................................8

StaMing the Engine .............................18

Steering Wheel ................................7,2"t

StoppingtheTractor............................!

Storage .................................................24

T

Throttle Control Cable Adiustment 23

Tires ...........................515,2'1

Trouble Shooting Cha_t ............ 25..26

Transax_e ...............................!6,44o45

W

Warranty 3

Wiring Diagram ...................25

Widng Schematic ...............................27

Page 5

These accessories and attactanents were avai_aMe thro sgh most Sears retail outlets and senrice centers when the tractor was purchased

Most Sears stores cars order these terns for you when you provide the modeJ numl er of your tract(y.

SPARK PLUG GAS CAN ENGINE OiL FUEL STABiLiZER

BLADES BELTS

Sears offers a wide variety of att_ chments that fit your tractor_ Many of these are %ted below with brief explanations of how they (;an help

you This _istwas current at the tree of publication; however, t may change in future years - r'nore attachreents may be added changes

may be made }n these attachments er some may _o beget be ave }abie or fit your _odeL Contact your nearest Sears store for the

accessories and attachments that are available for year tractor.

Most of these attachments do not reqaire additional h tches or conversion kits (those iha_ do are indicated} and are designed for easy

attaching and detaching.

AERATOR promotes deep root growth for a healthy lawn. 'Ta_

pored 2.54rich stee_ spikes mounted on 10 inch diameter discs

punctare hobs in soii at cone inter,vals to _et moisture soak in

Stee_ weight tray for increased penetration

SNOW BLADE forsnow removat say 14qnch high424nch wide

Made ciears 38qnch path when angled _eftor dght Raises, b,aers

with side bver Adiustab!e skds rep_aceaMe, reversiMe scraper

bar (Use with tire chains and wheel we ghts andor rear drawbar

BAGGER lets you collect grass clippings and bares for a

healthier, nearer looking lawn. 'Two Permaeex containers hotd

30_ga_lon plastic bag&

BUMPER protects front end of tractor from damage

DARTS make hauiing easy Vade!i_ of szes availabie, pk_s

accessories such as side panei kits, too_ caddy, cad cover,

pratective mat and doly

CORING AERATOR takes small plugs out of soil to allow mo}s

ture and nutrients to reach grass _oots. 36inch swath. 24

SNOWTRROWER has 40._rich swath Drum_type auger h_ndles

powdery and weVheavy snow Mounts easily wit'_ simple pn

arrangement. Discharge chute adjusts from tractor seat. 6qnch

diameter spout discharges snow !0 to 50 feet. Lft contro_bd at

tractor seat (Use with chains and whe®_ weghts anWor rear

SPRAYERS use 12-volt DC e_eetdc motor that connects to the

tractor battery sr other 12ovott source nciudes booms for

hardened steel coring tips 150 _b.capac ty weight tray

EASY O_L DRAIN VALVE makes o;_changes easier_ faster.

FRONT NOSE ROLLER canters ir front of mower deck to reduce

chances of scalping '_on uneven terrain

GANG H_TCN iets you taw 2 or 3 pui. behind attachments at once

such as sweepers dethatchers, aerators (not for use w}th tel}era,

caps or other heavy attachments)

GAUGE WHEELS on both sides of the mower deck _educe

SPREADER/SEEDERS make seed ng fert Izing and weed ki_l._

ng easy. Broadcast spreaders a_e abe useful _or granular d@

_:els and sand.

SWEEPERS _etyou collect grass clippings and teaves.

T_LLER has 5 hp engine and 36- nch swath to prepare seed beds,

cultivate and compost garden residue. Titler has its own builtoin

chances d '°sca_ping"on uneven terrain For mower decks not so

MULCH RAK_DETHATCHER loosens aoi! and flips thatch and

MULCH|NG CLOSE_OUT PLATE K_T, once insta_ed, lets you

manual

RAMP TOPS AND FEET let you bad and unload tractor from a

pickup truck. Use with 2 x 8 or 2 x 10 _umber

ROLLER for smeother _awn sudace. 364nch wide, 18.cinch

diameter water4ight drum holds up to 390 tbs_ofweight Rounded

edges prevent harm to tad. Adjustable scraper autoraaticat_y

cleans dram

drawbar and go! Optiona_ accessories conved unit for

dethatching_ aerating, hilling ,without tools,

T_RE CHAINS are heavy duty; closely spaced extraqarge cross

_inksgive smooth ride, outstanding traction.

visibility, Hinged metal doors with catch Keeps operator warm

and d_, Remove vinyl eden and windshields for use as sun

protector n summer Opt_ona! accessories I_cl_de, tinteW

tempered solid salety glass windshield with hand operated wiper

12_volt amber caution Hght for mounting on cab top.

VAC$ for powedui coi/ection of heavy grass clippings and ieaves,

Opt_oaa! wand attachment to pick up debris in hard to-reach

p_aces, VAC/CHIPPER includes a chipper shredder

WEIGHT BRACKET tot drawbar for snow removal applications

Uses (1) 55/b, weight,

WHEEL WEIGHTS for rear wheels provide needed traction for

snow removal or dozing heavy mateda}s.

Page 6

OF

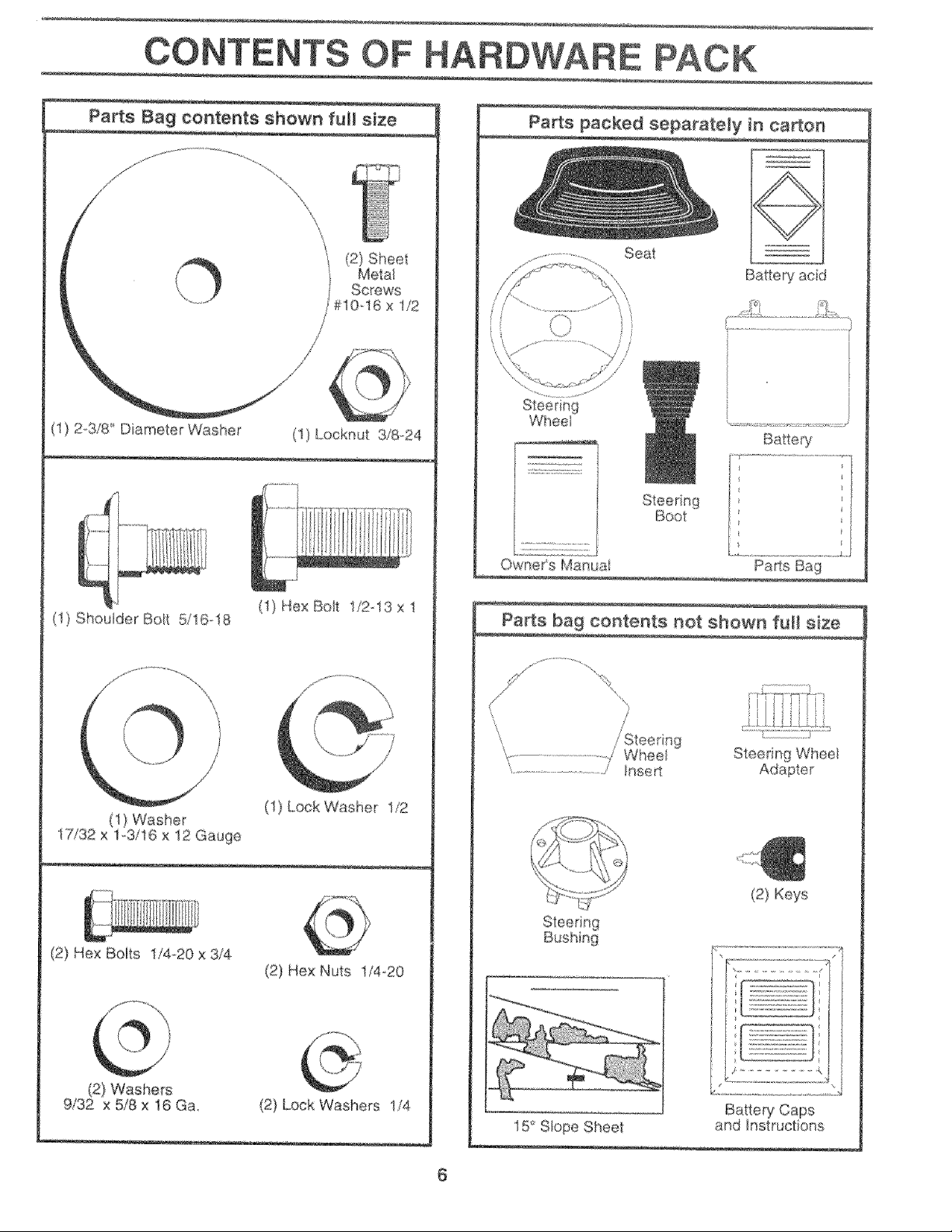

Parts Bag contents shown fuji size

(2) Sheet

Metal

Screws

1/2

(1) 2o3/8_'Diameter Washer (I) Locknut 3/8o.24

Wheel

ii

Ji

I

I

/

(1) Shoulder Bolt 5/16d8

(1) Washer

17/32 x I.-3/16 x 12 Gauge

(2) He× Boits 1/4-20 × 3/4

(I) Hex Bolt 1/2-13 x !

(1) Lock Washer i/2

(2) Hex Nuts !/4-20

Boot

Owner's ManuaI

Pads bag contests not shown full size

_,........................................................../ Whee

x.............................................../ /r_Ser_

Steerir_g Wheet

(2) Keys

(2} Washers

9/32 x 5/8 x 16 Ga, (2) LockWashers 1/4

Battery Caps

15 Slope Sheet and Instructions

6

Page 7

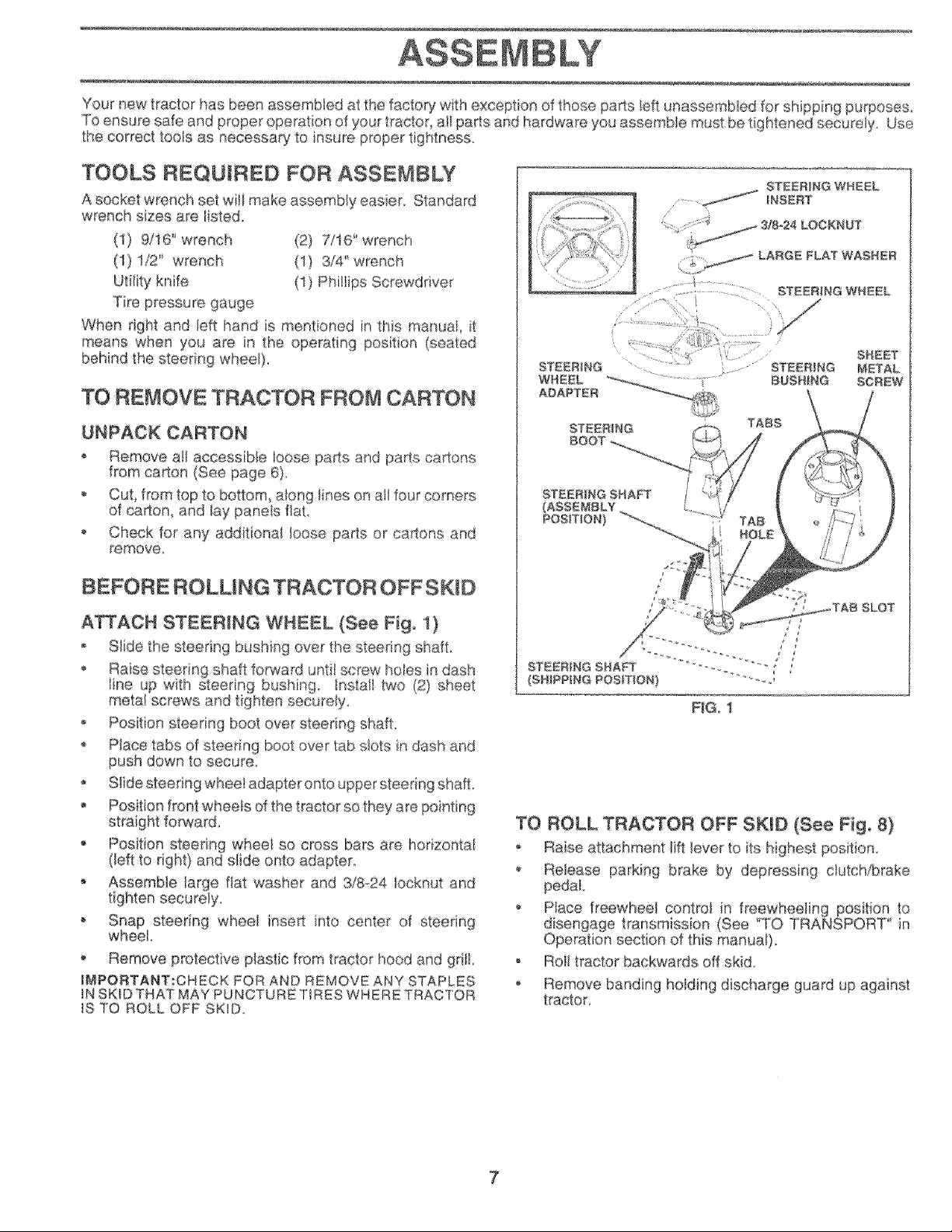

Your new tractor has been assembled at the factory with exception of those parts bft unassembled for shipping purposes.

To ensure safe and proper operation of your tractor, all parts and hardware you assemble must be tightened securely_ Use

the correct tools as necessapj to insure proper tightness

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench set wiii make assembly easier. Standard

wrench sizes are listed

(!) 9/16" wrench (2) W16" wrench

(1) 1/2" wrench (1) 3/4" wrench

Utility knife

Tire pressure gauge

When nght and/eft hand is mentioned in ths manual, it

means when you are in the operat ng position (seated

behind the steering whee0,

TO REMOVE TRACTOR FROM CARTON

UNPACK CARTON

Remove aH accessible bose pa_s and parts cartons

from carton (See page 6}.

CuL from top to bottom along ires on all four corners

of caPon, and lay paneis fiat

o Check for any additiona_ loose parts or cartons and

remove,

STEERtNG

WHEEL

ADAPTER

STEERING

BOOT

STEERING SHAFT

TABS

BEFORE ROLLING TRACTOR OFF SKiD

A_ACH STEERING WHEEL (See Fig, 1)

o Slide the steering bushing over the steering shaft.

o Raise steering shaft forward untif screw holes in dash

Iine up with steering bushing Instal two (2} sheet

meta! screws and tighten securely,

o Position steedng boot over steering shaft.

o Place tabs of steering boot over tab slots in dash and

push down to secure

Slide steering wheel adapter onto upper steering shaft,

Position front wheets of the tractor so they are pointing

, Position steering wheel: so cross bars are horizontal

(left to right) and slide onto adapter.

Assemble large fiat washer and 3/8_24 Iocknut and

, Snap steering wheel insert into center of steering

wheel,

o Remove protective plastic from tractor hood and gr/I

IMPORTANT;CHECK FOR AND REMOVE ANY STAPLES

iN SKID THAT MAY PUNCTURETIRES WHERE TRACTOR

IS TO ROLL OFF SKID,

TO ROLL TRACTOR OFF SKID (See Fig, 8)

o Raise attachment lift lever to ts highest position

o Release parking brake by depressing clutch/brake

_' Place freewheel control in freewheeling position to

disengage transmission (See "TO TRANSPORT" in

Operation section of this manual}_

o Ro_ttractor backwards off skid.

, Remove banding holding discharge guard up against

tractor,

7

Page 8

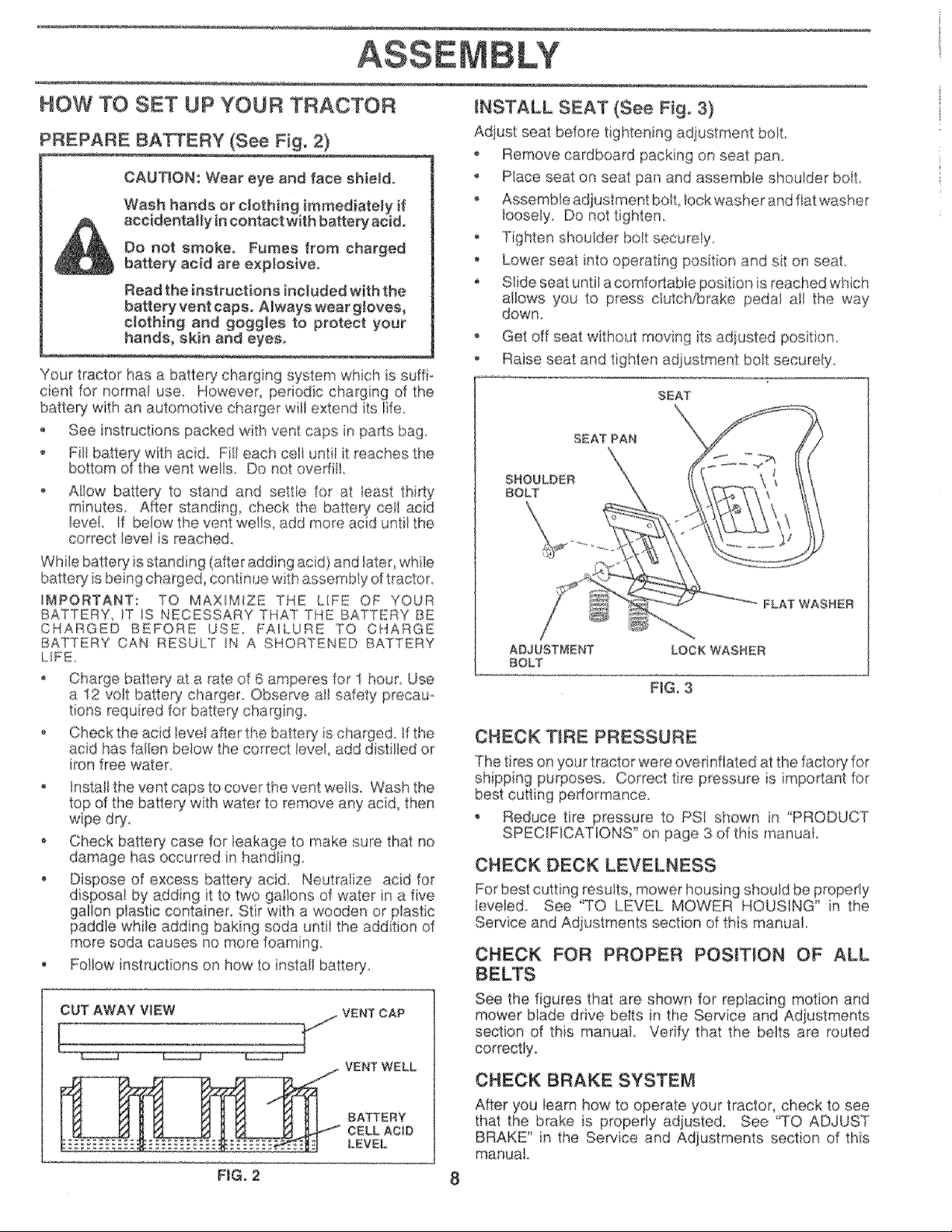

HOW TO SET UP YOUR TRACTOR

PREPARE BAKERY (See Fig, 2)

CAUTION: Wear eye and face shiol&

Do not smoko_ Fumes from cha_ged

bakery acid are exp[osive_

Read the instructions included with the

battery vent caps, Always wear gloves,

clothing and goggles to protect your

hands, skin and Byes,

Your tractor has a battery charging system which is suffio

cient for normal use However periodic charging of the

batter;/with an automotive charger wilt extend ts life

, See instructions paek÷d with vent caps in pa_s bag.

o Fill battery with ac{& Fill each cell until it reaches the

bottom of the vent wells. DB not ovedilt.

correct level is reached_

Whiie battery is standing (after adding acid) and later, whiIe

batteG_s being charged, continue wth assembiy of tractor

IMPORTANT: TO MAXIMIZE THE LIFE: OF YOUR

BATTERY T/S NECESSARY THAT THE BATTERY BE

CHARGED BEFORE USE FAILURE TO CHARGE

BATTERY CAN RESULT IN A SHORTENED BATTERY

LiFE

o Charge batteD, at a rate of 6 amperes for 1 hour Use

a 12 vBtt battery charger Observe a_lsafety precau.

tions required for battery charg ng

o Cheek the acid evet after the battery is charged If the

acid has faIIen below the corroct eveL add distif ed or

iron frBe water.

o Install the vent caps to cover the vent wels_ Wash the

top of tisebattery with water to romove any acid, then

wpe dry_

Check batteq¢ case for teakage to make sure that no

damage has occurred in handling.

- Dispose of excess battery acid NeutraIize acid for

paddle whi_eaddng baking: soda unti! the addition of

more soda causes no more foaming.

Follow instructions on how to insta

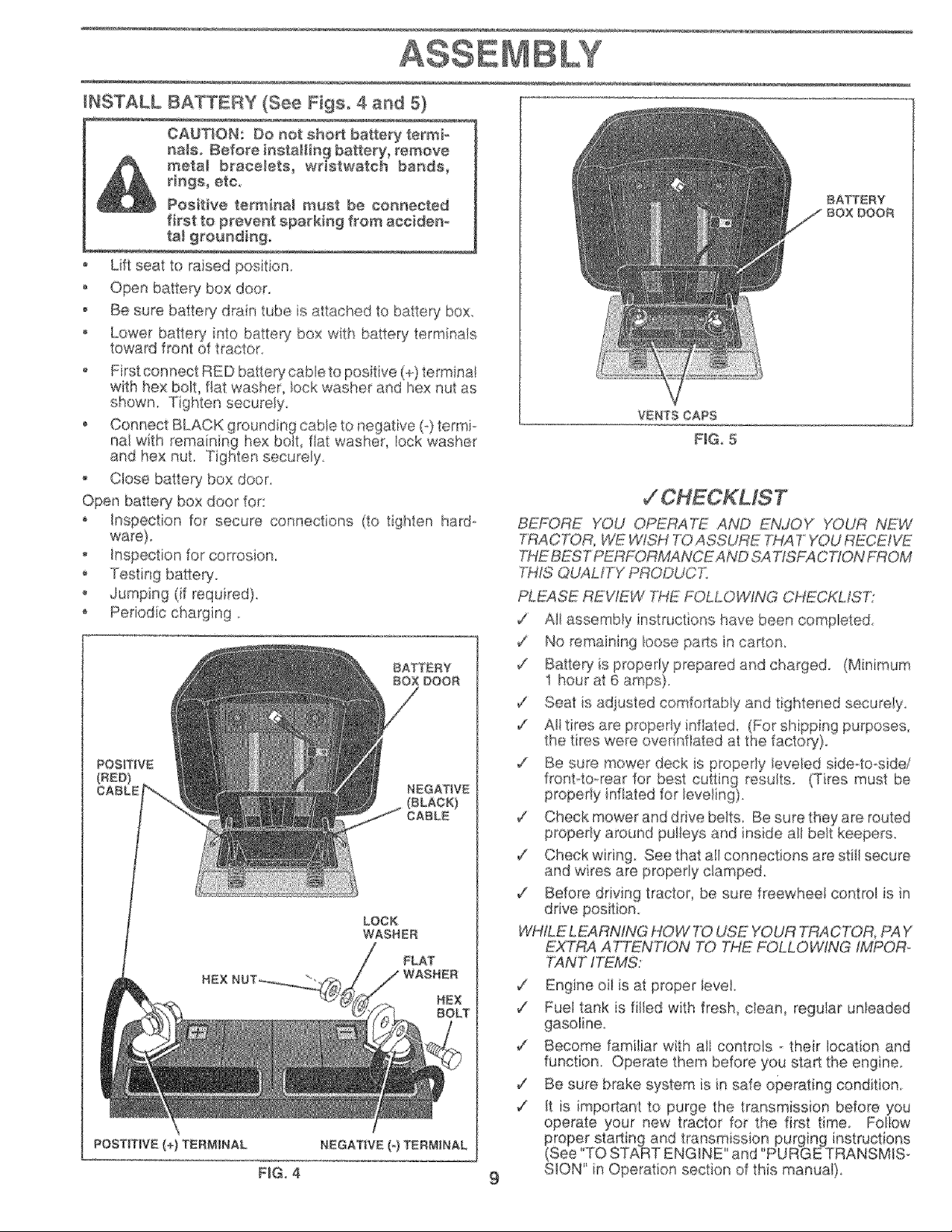

INSTALL BATTERY (See Figs,4 and 5)

CAUTtON: Do not shoA batte_'y termi_

nats_ Before instsIHn 9 baAery_ remove

meta_ bracetets_ wristwatch bands_

Positive terminat must be connected

first to prevent sparking from accideno

tat 9_oundtng,

Lift seat to raised position,

o Open battery box dDor.

o Be sure battery drain tube is attached to battehf box

o Lower batten/ into battery box wth battery term hats

toward front of tractor.

, First connect RED battery cable to positive (+) terminal

with hex bo}t, flat washer, lock washer and hex nut as

shown, T ghten securely°

o Connect BLACK grounding cab e to negatwe (_)termio

nai wth remaining hex [_olt, flat washer, bck washer

and hex nut. Tighten securely

, Close batteP/box dOBr.

Open battery box door for:

o hspection foi secure connectons (to tighten hard

Test ng battery.

o ,Jumping (if required)

Periodic charging,

BATTERY

BOX DOOR

NEGATIVE

(BLACK)

CABLE

LOCK

WASHER

FLAT

HE×

BOLT

BATTERY

DOOR

VENTS CAPS

FtG, 5

BEFORE YOU OPERATE: Ak_ LT'qJOY YOUR NEW

TRACTOR, WE W/St:_'TOASSURE THAT YOU RECEIVE

%H\EBESTP_R NCE AND SA TISF74CTION FROM

7HtS QUAUT Y PRODUCX

PLEASE REVfEW THE FOLLOWING CHECKLIST:

/ Ali assembly instruc'Iions have been completed

/ No remaining tDBSBparts in cartDn

v" Battery is properly prepared and charged. (Minimum

1 hour at 6 amps)_

v" Seat is adjusted comfortably and tightened securely.

v" All tires are properly infiated_ (For shipping purposes_

the tires were overinflated at the factory)

/ Be sure mower deck is properly Ieve/ed side.4o_sidd

frontqo._rear for best cutting resu}ts_ (Tires must be

property inflated for bveiing).

/ Check mower and drive belts, Be sure they are routed

prBpedy around pulleys and inside all be_tkeepers.

/ Check wiring See that aI!connections are stll secure

and wires are properly clamped,

/ Before driving tractor, be sure freewheel control is in

WHILE LEARNffqG HOW 70 USE YOUR 'TRACTOR, PAY

EXTRA A TT_NTION TO "THEFOLLOWtNG JMPOR

TANT ITEMS.:

/ Engine oH is at proper level,

/ Fuel tank is filled with fresh, ciean, regular unleaded

POSTmVE (÷) TERMSNAL NEGATIVE (-) TERMINAL

FIG, 4

_/ Become famiiiar with ail contn_ls _ their location and

function, Operate them before you sta_ the engine.

¢ Be sure brake system is in safe operating condition,

,/ It is imporlant to purge the transmission before you

operate your new tractor for the first time. Follow

9

S_ON" inOperation section of this manual),

Page 10

KNOW YOUR TRACTOR

READ THIS OWNER'S _IANUAL AND SAFETY RULES BEFORE OPERATING YOUR TRACTOR

Compare the illustrations with you rtractor to familiarize yourself with the eLations of various controls and ad ustrRents. Save

this manual for future reference

UGHT SWITCH

CLUTCH!

BRAKEPEDAL

THROTTLE/

CHOKE

CONTROL

FREEWHEEL

CONTROL

ATTACHMENT CLUTCH LEVER

IGNiTiON SWITCH

PARKING DRAKE

LEVER

MOT}ON CONTROL LEVER

Our tractors conform to the safety standards of the Amer can National Standards hstitute,

A_ACHMENT CLUTCH LEVER; Used to engage the

mower btades, or other attachments mounted to your

tractor.

LIGHT SWITCH: Turns the headlights on and offi

THRO_L_CHOKB CONTROL: Used for starting and

controlling engine speed,

CLUTCHTBRAKE PEDAL: Used fordec/utchingand brako,

ing the tractor and sta_ing the eng Re,

PARKING BRAKE LEVER: Locks clutch/brake pedal rite

the brake position°

F_G. 6

MOTION CONTROL LEVER: Selects the speed and

direction of tractor.

U_ LEVER PLUNGER: Used to re,ease attachment Iift

lever when changing its position,

A_ACH_gENT LIFT LEVER: Used to raise, lower, and

adiust the mower deck or other attachments mounted to

IGNITION SWITCH: Used for stading and stopping the

FREEWHEEL CONTROL; Disengages transmssion for

pushing or slowly towing the tractor with the engine oil

10

Page 11

HOW TO USE YOUR TRACTOR

TO SET PARKING BRAKE (See Fig, 7)

Your tractor is equipped with an operate rpresence sensing

switch When engine is running, any attempt by the

ope_tDr to leave the seat without first setting the parking

brake wili shut off the engine

Depress clutch/brake pedal into full 'BRAKE '_positior_

and hold.

Place parking brake lever in 'ENGAGED _position and

release p_essure from ciutchibrake pedal Pedal should

remain in"BRAKE '_pos tion Make sure park ng biake

wil! hold vehicle secure.

_GNtT{ON

MOT}ON

CONTROL

LEVER

CLUTCH/DRAKE

PEDAL"DmVE*'POSmON

STOPPING (See Fig, 7)

MOWER BLADES -

° Move attachment dutch iever to "DISENGAGED" po.*

sitios.

GROUND DRIVE

Depress clutch/brake pedal into fuII "BRAKE*' pDsitiOn.

, Move motion control lever to neutral (N) position.

_IPaPORTANT; THE MOTION CONTROL LEVER DOES

NOT RETURN TO NEUTRAL (N) POSITION WHEN THE

CLUtCH/BRAKE PEDAL 1SDEPRESSED

ENGINE -

Move throttle control to sbw (_) position.

NOTE: Failure to move throttle contrel to sbw (_}

position and allowing engine to idle before stopping may

cause engine to "backfire*'.

o Turn ign tion key to 'OFF" position and remove key

Always remove key when leaving tractor to prevent

unauthorized use.

, Never use choke to stop engine,

NOTE: Under ce_ain conditions when tractor is standing

idle with the engine running, hot engine exhaust gases may

cause "browning' of grass, To eliminate this possibility,

always stop engine when stopping tractor on grass areas.

PABKfNG DRAKE

'DISENGAGED' POS_T_ON

FIG, 7

TO USE THRO_LE CONTROL (See Fig° 7)

Always operate engine at fut! throttle,

Operating engine at _essthan fun thmttb reduces the

batleq_,charging rate_

Fu!! thmttte offers the best bagging and mower pedor_

mance

TO MOVE FORWARD AND BACKWARD

(See Fig, 7)

The direction and speed of movement is contrelted by the

motion cDntrDI !ever.

- Stad tractor wth motion control lever n neutral (N)

, Release pa_king brake and c!utch/brake pedal.

S_owiy move motion co_trO lever to desired post on.

TO ADJUST MOWER CU_[NG HEIGHT

(See Figo7}

The pestion of the attachmer_t iift /ew_r determi_es the

cutting heght

, Grasp Ift lever

, Press plunger with thumb and move ever to des red

The cutting height range is approx mately t -1/2 to 4. The

heights are measured from the ground to the blade tip wit/_

the engine nDt runn[ng_ These heights are approximate

and may vary depending upon soil conditions, height of

grass and types of grass being mowed.

° The average _awnshould be cut tD approximately 21/2

inches during the cool season and to over 3 inches

durng hot months. For healthier and better IDDk_ng

lawns, mow often and after moderate growth_

° For best cutting pedDrmance, grass over 6 inches in

height should be mowed twicD. Make the first cut

relatively high; the second to desired heighL

TO OPERATE MOWER (See Fig, 8)

Your tractDr is equipped witi_an operator presence sensing

switch. Any attempt by the operator to leave the seat with

the engine running and the attachment clutch engaged wl/

shut off the engine.

, Select desired height of cut

, Stad mower blades by engaging a_tachment clutch

control.

° TO STOP MOWER BLADES odisengage attachment

dutch control.

11

Page 12

CAUTION: Do not operate the mower

without e_ther the entire grass catcher,

on mowers so equipped, or the dis-

charge guard tn place,

"ENGAGED" ATTACHMENT

POSITION LEVER

HiGH POntoON

LOW

POS_T_ON

FIG 8

TO OPERATE ON HILLS

o Choose the slowest speed before stading up or down

hills.

Avod stepping or changing speed on Mils

o If slowing is necessary, move th_oltte con' rol tever to

slower position.

If stoppin 9 is absok.ltely necessary push clutch/brake

pedal quickly to brake position and engage parking

brake

o Move motion control ever Io neutra_ (N) position_

iMPORTANT: THE MOTION CONTROL LEVER DOES

NOT RETURN TO N UTRAL (N) POSITION WHEN THE

CLUTCH/BRAKE PEDAL _SDEPRESSED.

o To testa dmovement, slowly r*e_easeparking brake and

c_utch/brake pedal.

o Sfow/y move motion controi lever to slowest setting.

, Make all turns siowly.

TO TRANSPORT (See Figs. 6 and 9)

When pushing or towing your tractor be sure to disengage

transmission by placing freewheel control in freewheeling

position Free wheel control is located at the rear drawbar

d tractor

, Raise attachment lift to highest position with attacho_

meat lift contret.

F_G,9

BEFORE STARTING THE ENGINE

CHECK ENGINE O}L LEVEL (See Fig, 14 & 15)

o The eng nen your"tractor has been sh pped, from the'

factoryl aiready fIed wth sum_'_er wei{ii:_t ol.

o Check engine el wth tractor on tevel ground

o Unthread and remove oi fill cap/dipstick; wipe oil off.

Reinsert the dipstick into the tJbe and rest el fii/cap on

the tube. Do not Ihread the cap onto the tube. Rernove

and read oii ieveL ff necessary, add oi unti FULL'*

mark on dipstick is reached. Do not oved l/.

o For coid weaiher operation you should change oi for

easier sta£ing (See OIL. VISCOSITY CHART' in the

Customer Respons b Ities secl or_ of ths manuat}

o To change engine el, see the Cus omer Responsib i

tes section in ths man al

ADD GASOUNE

'_ FI fu_}I tank Use fresh, clean re _xb:_.luneaded

gasefine (Use of leaded gasoline wlI ncrease cal_bon

and bad oxide deposits and reduce rave ire}.

_MPORSANT: WHEN OPERATING IN TEM_:_ERATURES

BELOW 32"F(@CX USE P:_ESH CLEAN WINTER GRADE

GASOL NE TO HELP NSURE GOOD COL[:} WEATHER

START NG

WARN_NG; Experence indcates that a_coho blended

fueB (caNed gasoho or using ethanol or methanol) can

attract moisture whch leads to separat}on and format on of

acids during storage. Acidc gas can damage the fuel

system of an engine whie in storage. To avoid engine

prob/ems, the fuel system shouId be emptied before stor-

age of 30 days or Ionger_ Drain the gas tank, sta_l the

engine and Iet t run untit the fuel fees and carburetor are

em_y Use fresh fuel next season. See Storage _nstruc

tions for addtonal information. Never use engne or

carburetor cleaner products n the rue tank or permanent

damage may occur.

Donor push or taw tractor at more than twe (2) MPH.

To reengage transmission reverse above procedure.

NOTE: Te protect hood from damage when transporling

your tractor on atruck or atrailer, be sure hood isclosed and

secured to tractor. Use an appropriate means of tying hood

to tractor (rope, cord, etc).

12

Page 13

OPE

TO START ENGIINE (See Fig_ 7)

When sta_ing engine for'the frst time or f engine has rur'l

out of fue!, it wiff take extra cranking tree to move fuet fcom

the tank to the engine,

o Depress dutch/brake pedaI and set parking brake,

- Place motion control lever in neutra_ (N) pos tion.

o Move attachment clutch to "DISENGAGED" posit on.

Move throttle control lever to choke (i's!) position for

cold engine start. For warm engine star1, move thrott e

centre! to fast (@) posit;on.

o InseRkey into ignition arid turn keyc!ockwiseto"START"

seconds per minute, ff engine does not sta_ after

several attempts_ move throttle contro_ to fast (@)

position, wait a few minutes and try again

When engine starts, slowly move throttle control ever

to desired running speed,

o Aiow engine to warm up for a few minutes before

engaging drive or attachments

NOTE: if at a hfgh altitude (above 3000 feet) or in cetd

temperatures (below 32{F), the carburetor fuel mxture

may need to be adjusted for best engine pedormance, See

"TO ADJUST CARBURETOR" in the Service and Adjust

merits section of ths manua_

PURGE TRANSMISS_ON

To ensure preper operation and pedormance, t is recom_,,

mended that the transmiss on be p Jrged before operating

tractor for the first trne. Ths precedure wtl remove any

trapped a{r nside the transmission which may have devel_

oped during shipping of you_ t_sctor,

IMPORTANT: SHOULD YOUR TRANSMISSION REQUIRE

REMOVAL FOR SERVICE OR REPLACEMENT, T

SHOULD BE PURGED AFTER REINSTALLATION

BEFORE OPERATING THE TRACTOR_

o Place tractor safely on level sudace with engne off and

parking brake seL

o Sitting in the tractor seat, stalt engine. After the engine

Sitting inthetraclor seat, start engine, Aftertheengine

is running, move throttle contro_ to half (1/2) speed,

With motion contrei lever in neutral (N) position, s!owly

disengage clutch/brake pedaI,

o Slowly move motion cont_)l _ever fo_dard after the

traCtOr moves appmxmately five (5) feet return the

moton control _ever to the neutraI (N) position, Repeat

ths procedure with the rnotion contre_ iever three (3)

tmes.

Your tractor is now purged and now ready for normai

MOWING TiPS

o Tre chains cannot be used when the mower housing

is attached to tractor.

o Mower should be properly leveled for best mowing

performance See TO LEVEL MOWER HOUSING"i

the Ser_..,iceand Adjustments section of this manuai

o The ieft hand side of mower shou}d be used for trim

° Drive so t_at c/ppings are discharged onto the area

that has been cut Have the cut area to the dght of the

machine This w_i result in a more even distribution of

clippings and more uniform cutting

o When mow _g fa,rge areas, stail by turning to the right

so that clippii'_gs' witi discharge away friJm shrubs

fences, driveways, ete,_After one or two rounds, mow

in the opposite d rection making teft hand turns until

finished (See Fif_. i0 )

o is extremely tail, it should be mowed twice to

load and possible fire hazard from dried cIip-

pings. Make first cut relatively high; the second to the

desired heig!' t.

o Do not mow grass when it is wet, Wet grass will plug

mower and leave undesirable clumps, Allow grass to

dry before mowing.

• Always operate engine at full throttle when mewing to

assure better mowing performance and proper dis

charge of material, Regulate greund speed by select

ing a _ow enough gear to give the mower cutting

pedormanee as well as the quality of cut desired.

When operating attachments, select a ground speed

that wil! suit the terrain and give best performance of

the attachment being used

disengage clutch/brake pedal

Move motion control lever to fut! forward position and

hold for five (5) seconds, Move lever to full reverse

position and hold for five (5) seconds, Repeat this

procedure three (3) times.

NOTE: During this procedure there wil! be no movement of

drive wheels. The air is being removed from hydraulic drive

Move motion control Ieverto neutral (N) position. Shut

off engine and set parking brake

of manual). 13

l

F_G. 10

Page 14

GENERAL RECOMMENDATIONS

The warranty on this tractor does not cover items that have

been subjected to operator abuse or neg[igence ]o

receive flf[I vat_e from the warranty_ operater must maintain

tractor as instructed in this manual

Some adiustments wiil need to be made periodicaly to

properly ma r_tainyour tractor

All aqustrnents in the Service and Adjustments section of

this mant_a_should be checked at least once each season.

Once a year you shoud replace the spark pk_g ciean

or replace air filter, and check btades and beets _or

wear A new spark plu9 and c_ean air fi_ter assure

proper airquel mixture and help your engine run bette_

BEFORE EACH USE

,, Check engine oil levet,

o Check b_ake operation

o Check tire pressure.

,, Check for loose fasteners.

LUBRICAT_ON CHART

CLUTCH PIVOT

(_SAE 3(} MOTOR OIL APi., 5G

_GENERAL PURPOSE GREASE

@REFER TO CUSTOMER R_SPONSIBIL[TtES "ENGINE" SECTION

tMPORTANT: DO NO'}" O{L OR GREASE THE PSVOT PO}NTS

WHICH HAVE SPECALNYLON BEARINGS VISCOUS LUBRb

CANTS WiLL ATTRACT DLJ_STAND DIRT 'THAT WILL SHORTEN

THE IFE OF THE SELF LUBRICATING BEARINGS IF YOU

FEEL THEY MUST' BE LUBRICATED, USE ONLYADRY POW-

14 DERED GRAPHITE TYPF L JBRICANT SPARING.Y,

Page 15

AIways observe safety rules when pedormieg any mainteo

nance

BRAKE OPERATION

if tractor requires more than six (6) feet stopping distance

at high speed in highest gear, then brake must be adiusted

(See "TO ADJUST BRAKE" in the Sewice and Adiusb

meets section of this manual)

Maintain proper' ar pressure in all tires (See 'PROD°

UCT SPECIFICATIONS '_or page 3 of this manuai)

Keep tires free of gaso/ine_ oil or insect control chemi_

ca/s which can harm rubber

o Avoid stumps, stones, deep ruts, sharp objects and

other hazards that may cause tire damage.

BLADE CARE

For best results mowe blades must be kept sharp, Re

p_ace bent or damaged blades_

BLADE REMOVAL (See Fig, 11)

Rase mower to highest position to atiow access to

blades

. Remove hex bolt, lock washer and flat washer secudng

blade.

Install new or resharpened blade with traiiing edge up

towards deck as shown

o Reassemble hex bolt, fock washer and flat washer n

exact order as shown

o Tighten bo_t securely (30G5 Ft Lbs torque)_

IMPORTANT: BLADE BOLT IS GRADE 8 HEATTREATED,

NOTE: We do not recommend sharpening Made-. but if you

do, be sure the btade is ba arced,

MANDREL

BLADE

_ REX BOLT (GRADE 8)_

_AGRADE 8 HEAT TREATED BOLT CAN BE

iDENTIFIED BY SiX LINES ON THE BOLT HEAD,

FIG, 11

ASSEMBLY

o To check blade balance, you will need a 5/8" diameter

S_ideblade on to an unthreaded po_ion of the steeI bet

or pin and hold the bolt or pin paral/et with the ground

If blade is balanced, it shoWd remain in a horizontal

position, If either end of the blade moves downward

sharpen the heavy end until the blade is balanced

NOTE: Do not use anai! for balancing blade. The lobes of

the center hole may appear to be centered, but are not,

5/8" BOLT BLADE

OR PIN

F_G. !2

BATTERY (See Fig. 13)

Your tractor has a battery charging system which is suffi.-

cient for _orma} use. However periodic chac:_ing of the

batten! with an ¢_utomotw; charger will e×tend ts fife

o Acid soiut on ievel in each battery cell shoud be ew:_n

wilh bottoms of vent weIIs_ Add only distilled or i_onfree

water if necessarj. Do not ovediit

o Keep batte_ and terminals clean.

o Keep battery bolts tight

o Keep vent caps tght and small vent holes in caps open.

Recharge at 6 amperes for 1 hour°

TO CLEAN BATTERY AND TERMINALS

Corrosion and d_l on the batte_'7and termina s can cause

the battery to 'teak!' power.

Open battery' box doer.

o Disconnect BLACK batter! came first then RED bat-.

teq/cable and remove battery from tractor

o Wash battery with solution of four tablespoons d

baking soda to one gallon of water. Be careful not to get

the soda solution into the ceils.

o Rinse the batten/with plain water and dry,

Clean terminals and battery cable ends with wire brush

until bright.

o Coat terminais with grease or petroleum ieHy.

• Reinstall batter,/ (See "INSTALL BATTERY" in the

Assembly secti6n of this manual),

CUT AWAY VIEW VENT CAP

TO SHARPEN BLADE (See Fig, 12)

Care should be taken to keep the blade bafance& An

unbalanced blade wili cause excessive vibration and even°

tual damage to mower and engine,

o The blade can be sharpened with a file or on a grinding

wheel, Do not attempt to sharpen while on the moweh

15

VENT

WELL

BATTERY

CELL ACID

LEVEL

FiG. 13

Page 16

TRANSAXLE COOLING

The fan and cooiing fins of transmission sho._ld be kept

ctean to assure proper cooling

Do not attempt to clean fan or transmiss on white engine is

runn ng or while the transmission is hot.

o Inspect cooling fan to be sure fan blades are intact and

clean.

- inspect cooting fins for di_t grass clippings and other

materials To prevent damage to seals, do not use

compressed air or high pressure sprayer to clean

TRANSAXLE PUMP FLUID

The transaxie was sealed at the factory and fiuid ma nteo

nance is not required for the/fe of the transaxle Shoutd the

transax/e ever _eakor require servicing, contact your near

est authorized service centeffdepadment.

manual.

O_L F_LL

CA[_IPSTlCK

OiL DRAIN

PLUG

Cheek V.-beits for deterioration and wear after 'i00 hours of

operation and replace if necessary The belts are not

adjustable_ Replace beits if they begin to slip from wear.

Only use high qual ty deterge_ t oi rated with API sewice

ciassification SG SeIect the ols SAE viscosity grade

accord ng to your expected operating temperature

SAE VISCOSiS Y GRADES

_'_ 28 0" 3:} 82 4;}' _3 B0 10 '[_'

'C 59* -2g" ,i0" i0 20 30 40

] EMPERA_T JRB RANGI:[ AN]° C PA' _;;} BE _'©RE t,,iEX'[ el, C ¢#NG_I

FIG, 14

NOTE; Aithough mu/tioviscosity oits (5W30_ 10W30 etc)

mprove starling in cad weather, these multioViSCOsityois

wilt result in increased oil consumptior_ when used above

32_'F. Check your engine oil level more frequently to avo d

possible engine damage frorn running _owon oii.

Change the oil after the first two hours of operat on and

every 50 hours thereafter or at least once a year if the tractor

is not used for 50 hours in one year.

Check the crankcase oil ievel before sta rting the engine and

after each eight (8) hours of operation. Tighten oii filf cap/

dipstick securely each time you check the oil ievel.

TO CHANGE ENGINE OIL (See Fig. 14 and !5)

Determine temperature range expected before oil change.

All oi! must meet APi sewice classification SG.

- Be sure tractor s on levei sudace

o Oil wi_/drain more freely when warm.

o Catch oii in a suitable container.

, Remove oil fii/cap/dipstick. Be careful not to allow dirl

to enter the engine when changing oil

, Remove drain pk_g.

After ot has drained completely, replace oil drain plug

and tighten securely.

F_G. 15

AR HLTER (See Fig, 16)

Your engine wil not tun propedy using a d_y air fi!te_

Clean the foam pro-cleaner after every 25 hours of opera.-

ties or every season. Sewice paper ca_ridge ever}, 100

hours of operation or every season, wh chever occurs first.

Service air c!eaner more often under dusty conditions

Remove knob and cever_

Remove wing nut and air cIeaner from base.

TO SERVICE PRE._CLEANER

o Slide foam preo.cleaner off ca_ridge.

Wash it n liquid detergent and water_

Squeeze t dry in a clean cloth.

o Saturate it in engine oit. Wrap t in clean, absorbent

cloth and squeeze to remove excess oil

TO SERVICE CARTRIDGE

o Gently tap the flat side of the paper cartridge to dis°

todge dirt. Do not wash the paper cadddge or use

pressurized air, as this wiii damage the ca_ddge.

Replace a dffly, bent or damaged cartridge.

Reinstall the pro cleaner (cleaned and o/ed) over the

paper ea£_idge.

o Reassembie air ctesner wing nut cover and tighten

knob securely.

COVEI

CARTR_DGENUT

PAPER

CARTRIDGE

BASE

FIG, 16

16

Page 17

CLEAN A_R SCREEN (See Fig, 15)

Ar screen must be kept free of dirt and chaff to prevent

engine damage from overheatin G C_ean with a wire brush

or compressed air to remove did and stubborn dded gum

fibers.

ENGINE COOLING FINS (See Fig, 17)

Remove any dust, di_ or oil frem engine cooling fns to

prevent engine damage from overheating°

o Remove screws from blower housing and iifl housing

and dipstick tube assembly off engine

o Cover oi{ fill opening to prevent entry d did

o Use compressed air or stiff br stle brush to tt_o_eugMy

clean engine cooiing fins_

To reassembie, reverse above pracedure

SCREWS BLOWER ROUSING

}N-LINE FUEL F}LTER (See Fig, 18)

The fueI %er shoud be replaced once each season. _ffuet

filter becomes clogged, obstructing fuel flow to carburetor,

replacement is required

, With engine coo_, remove fiiter and plug fuel Iine

sections.

Ptace new fuei fiiter in position in fuel Ine with arrew

pc nting towards carburetor

Be sure there are no rue! iine _eaks and c_amps are

properly positioned.

o Immediately wipe up any spilled gasoline

CLAMP

NG, 18

SPARK

PLUG

ENGINE COOUNG F_NS

F_G. 17

Inspect and replace co_roded muffter and spark arrester (f

equipped) as it could create a fire hazard and/or damage.

SPARK PLUGS

first. Spark p_ug type and gap setting is shown in "PROD°

UCT SPECIFICATIONS" on page 3 of this manual

• Ciean engine, battery, seal finish, etc. of all foreign

matter_

o Keep finished sudaces and wheels free of all gasoline,

oil, elc_

o Protect painted sudaces with automotive type wax.

We do not recornmend using a garden hose to e_eanyour

tractor unless the eiectricaJ system, muffler, air filter and

carburetor are covered to keep wa£er ouL Water inengine

can result in a shodened engine ire.

17

Page 18

CAUTION: BEFORE PERFORMING ANY SERV|CE OR ADJUSTMENTS:

- Depress clutchtbrake pedal fully and set parking brake.

o P_ace motion contro_ _ever tn neutral (N) position,

, Place attachment clutch in "DtS,ENGAGED" position,

, Turn ignition key "OFF" and remove key,

o Make sure the b|ades and all moving parts have completely stopped,

o Disconnect spark plug wire from spark ptug and place wire where it cannot come tn contact with

TO REMOVE MOWER (See Fig° I9)

Mewer wilt be easier to remove from the rght sde of tractor.

o Place attachment clutch _n DISENGAGE poe t on

• Move attachment lift tever forward to lower mower to its

_, Roll belt off engir_e putiey

o D _ssonr_ectc_utch rod from clutch _ever by removiR_

retainer spring.

o Disconnect anti._sway bar frem chassis bracket by

removing retafner spr}ng_

o Disconnect suspension arms from rear deck brackets

by removing retainer spdngs.

o Disconnect front links from deck by removing retainer

• ' D" i

E

CLUTCH LEVER

CLUTCH ROD

SPR_NG

SUSPENSION ENGINE

ARMS PULLEY

o Raise lift _ever to raise suspens on arms_ Side mower

out from under tractor,

_MPORTANT: IF AN ATTACHMENT OTHER THAN THE

MOWER _S TO BE M©UNTED 1O _HE _RACTOR, THE

R,H AND LH, SUSPENSION ARMS MUST BE REMOVED

FROM TRACTOR,

TO _NSTALL MOWER (See Fig, 19)

o Rafse attachment lift lever to ts highest position.

o S_kJemower under tractor with d scharge guard to right

side af tractor_

o Lower lift lever to its lowest position.

o Insta_i mower in reverse order of removal instruct ors

ANTe-SWAYBAR

RETAINER

SPRINGS

(BOTH SfBES)

F_G, 19

t8

Page 19

TO LEVEL MOWER HOUSING

Adiust the mower whle tractor is parked on fevet ground or

Make sure tires are propedy inflated (See

'PRODUCT SPECIFICATIONS" on page 3 ofthis manual).

If tires are over or undednfiated, you wil not proper_y adi Jst

your mower,

SIDE,.TO_SIDE ADJUSTMENT (See Figs 20 and 21}

o Raise mower to its highest position.

At the midpoint of both sides of mower_ measure height

from bottom edge of mower to ground Distance'A'on

both sides of mower should be the same or within 1/4"

of each other,

• If adjustment is necessary, make adiustrTent on one

side of mower oniy.

To raise one side of mower, tighten tiff rink adjustment

nut on that side.

o To lower one side d mower, loosen iift link adjustment

nut on that side.

NOTE: Three fut_ turns of adjustment nut wifl change

mower height about 1/8'

o Recheck measurements after adjusting

FRONT TO-BACK ADJUSTMENT (See Fig& 22 and 23)

IMPORTANT: DECK MUST BE LEVEL StDE_T'O_SiDE iF

THE FOLLOWING FRONT-TO.BACK ADJUSTMENT IS

NECESSARY BE SURE TO ADJUST BOTH FRONTUNKS

EQUALLY SO MOWER W_LL STAY LEVEL SIDE-TOo

SIDE

To obtain the best cutting results, the mower housing

should be ad}usted so that the front is approximately I/4," to

3/4' Iower than the rear when the mower is in its highest

Check adjustment on right side of tractor, Measu e dis.-

tance "D' directly n front and behind the mandrel at bottom

edge of mower housing as shown

o if Inks are not equa_ n length, adiust one tink to same

_ength as other link

To tower fn:>ntof mower bosen nut 'E" on both front

/inks an equal number of tums_

When distance 'D' s 1/4' to 3/4,'_lower at front than

rear tighten nuts "F' aga nst trunnion on both fi_ont

links.

o "10raise front d mower, loosen nut"F' from trunn on on

both front links. T ghten nut 'E_on both front links an

equal number of turns

o When distance D" is 1/4' to 3/4 ' lower at front than

rear, tig _tennut _F'_against trunnion or' both front links.

Recheck sideqo.,s de adjustment

FiG 20

FIG, 21

FIG, 22

BOTH FRONT LINKS MUST BE EQUAL IN LENGTH

LIFT LINK

ADJUSTMENT NUT

NUT "E'

NUT "F"

FRONT LINKS TRUNNION

19 FIG, 23

Page 20

TO REPLACE MOWER BLADE DRIVE BELT

(See Fig. 24)

The mower Made drive belt rnay be replaced withoL_ttools_

Park the tractor on leve_ surface. Er_gage parking brake°

BELT REMOVAL

o Remove mower from t@_ctor (See "TO REMOVE

MOWER" in this section of this manual

o Work belt off both mandrel pulleys and id{er pulley.

, Pull belt away from mower

BELT INSTALLATION ..

, Instaii new belt in reverse order of removal

o Make sure belt is in ali puItey grooves and inside a}l belt

MANDREL

_DLER

PULLEY

TO ADJUST BRAKE (See Fig. 25)

Your tractor is equipped with an adjustable brake system

which is mounted on the fight side of the transaxte.

if tractor requffes mere than six (6) feet stopping distance

at high speed in highest gear, then brake must be adiusted

, Depress ciutch/brake pedal and engage parking brake.

o Measure distance between brake operating arm and

nut "A" on brake rod.

o _fdistanceisotherthant_3/4" !oosen jam nut andtum

nut "A" until distance becomes 1_3/4L Retighten iam

nut against nut 'W'.

still greater ttsan six (6) feet in highest gear further

maintenance is necessa_ Contact your r earest au_

thorized sewice center.

W_TN PARKtNG BRAKE "ENGAGED"

FIG, 24

DO NOT" TOUCH THiS NU_ _F FURTHER

BRAKE ADJUSTMENT _S NECESSARY

CONTACT YOUR NEAREST AUTHORIZED

SERVICE CENTER!DEPARTMENT

F_G. 25

2O

Page 21

TO REPLACE MOTION DRIVE BELT

(See Fig. 26)

Park the tractor on Ievei su#ace. Engage park ng b_ake_

For assistance, there is a beit insta/ation guide decal on

bottom side of left footrest

, Remove mower (See 'TO REMOVE MOWER" in tMs

section of this manual)

, Remove upper belt keeper.

o Remove beit from stationary idler and clutching idler.

Pull belt slack toward rear of tractor. Carefully remove

belt upwards from transmission input pulley and over

cooling fan blades.

o Pull belt toward front of tractor and remove downward

from around engine pulley,

o Install new belt by rever:s ng above procedure.

IMPORTANT; MAKE SURE UPPER BELT KEEPER iS

POSiTiONED PROPERLY BETWEEN LOCATER TABS.

\

ADJLtS _ MFN'f

,,OCKNU'_

F_G. 27

TRANSMISSION REMOVAUREPLACEMENT

Should you_ transmission require removal for service or

replacemenL t shoutd be purged after reinstal/atioe and

before operating the tractor. See _PURGE TRANSM/S

SION '_'in Operat on sect on of this manual

TO ADJUST STEERING WHEEL AUGNMENT

_[steering wheei crossbars are not horizontal (!eft to right)

when wheels are positioi'sed straight forward remove steer.

ing wheel ard reassemble per insb uctions in the Assembly

sect on of this manual.

FiG, 26

TO ADJUST MOTION CONTROL LEVER

(See Ftg, 27)

The motion control lever tx_sbeen preset at the factory and

adiustment should not be necessary

if for any reason the motion control/ever will not hold its

position while at a selected speed, it may be ad)usted at the

friction pack tocated on the right side of transmission,

Park tractor oR leve_ su_ace, Stop tractor by turning

ignition key to "OFP position, and engage parking

brake,

, Adiust motion control lever by tightening adjustment

iocknut one half (1/2) turn.

NOTE: If for any reason the dfo_ to move the motion

control lever becomes too excessive, reverse the above

adjustment procedure by loosening Iocknut 1/4 to 1/2 turn.

Road test tractor after adiustment and repeat procedure if

necessaB_,

FRONT WHEEL TOE4N/CAMBER

The frort whee! toeqn and camber are not adjustable on

your tractor If damage has occ_._rredto affect the front

wheef toein or camber contact your nearest author zed

sew}ce center/depadment

TO REMOVE WHEEL FOR REPAIRS

(See Fig, 28}

, Block up axle securely,

o Remove axle cover, retaining rungand washers to allow

wheel removal (rear wheet contains a square key _Do

o Repair tire and reassemble

o On rear wheels onIy: align grooves in rear whee_ hub

and axle. hse_ square key.

, Replace washers and snap retaining ring securely ir_

axle groove

, Replace axle cover

1

AXLE COVER

_S@UARE KEY

(REAR WHEEL ONLY)

FIG, 28

21

Page 22

TO START ENGINE W_TH A WEAK BAKERY TO REPLACE HEADLIGHT BULB

(See Fig, 29) • Raise hood.

o Putt bulb holder out of the tote n the backside of the

, Repiace bulb n holder and push bulb holder securely

back into the hole n the backside of the grE

o Close hood.

If your batteR' is too weak to stad the engine, t should be

if 'jumper cables' are used for emergency

starling, follow this procedure:

IMPORTANT: YOUR TRACTOR }S EQUPPEDWTH A !2

VOLT NEGATIVE GROUNDED SYSTEM THE OTHER

VEHICLE MUST ALSO BE A 12 VOLT NEGATIVE

GROUNDED SYSTL:M_ DO NOT USE YOUR TRAC'TOR

BATTERY TO START OTHER VEH_CL.ES

TO ATTACH JUMPER CABLES

Connect each end of the RED cable to the POSITIVE

(+) terminal of each batlery taking care not to shod

against chassis.

, Connect one end of the BLACK cable to the NEGAo

TIVE (.) terminal ol fully charged battery.

o Connect the other end of the BLACK cable to good

CHASSIS GROUND_ away from fuel tank and batter},.

TO REMOVE CABLES REVERSE ORDER

BLACK cable first from chass s and then from the fuiy

RED cabe last from both batteries

POSiTiVE TERMINAL NEGATIVE TERMINAL

INTERLOCKS AND RELAYS

[..BOSeor damaged wiring may cause your tractor to run

poorly, stop running, or prevent it from sta4ing

Check wring See electricai wiring diagram n the

Repair Pads section of this manual

TO REPLACE FUSE

Replace with 30 amp automofive4ype plugo n fuse The

fuse holder is located behind the dash.

TO REMOVE HOOD AND GRILL ASSEMBLY

(See Fig. 30)

o Raise hood.

o Unsnap headlight wre connector.

" Stand in frent d tractor, Grasp hood at sides, t ftreward

engine and ft off of tracton

o To mp_ace reverse above procedures_

FI_G,29

CHARGED

BATTERY

HOOD

HEADLIGHT

WIRE

CONNECTOR

FIG, 30

Page 23

TO ADJUST THRO_LE CONTROL CABLE

(See Fig, 31)

The throttie control has been preset at the factohi and

adjustment should Rot be necessaPy. Check adiustment as

described below before !oosening cab{e_ If adjustment is

necessary, proceed as fotfows:

o With engine not running, move throttte contre/_ever

from slow (_) to choke (/',.) position Siowly move

lever from choke (/'_.i)to fast (@) position.

o Check that holes "A°' in governor control _everand hole

GOVERNOR

CONTROL LEVER

GOVERNOR

CONTROLPLATE

FINAL S£'TTtNG --

o Sta_l engne and anew to warm for five minutes Make

fina_adjustments with engine running and sh ftimotion

control lever in neutraI (N) pos tion

Move throttle control _ever to stow (_) position. With

o WMle still holding throttle lever against idle speed

screw, turn idle mixture vatve in (clockwise) until en

gee begns to die and then turn out (countercbckwise)

unt_ engne runs rough. Turn vaive to a point midway

between those two positions. Retease throttie iever_

ACCELERATION TEST _-

o Move thrott e contrnl Iever from skwv (_) to fast (@)

position_ If engine hesitates or dies, turn idle m xture

valveout(counterdockwse) t!8tum Repeat test and

cont Rue to adiust if necessary_ until engine acceIeb

High speed stop is factory adiusted Do not adiust

damage may resutt

_MPORTANT: NEVER TAMPER WITH THE ENGINE

GOVERNOR, WHICH S FACTORY SET FOR PROPER

ENGINE SPEED OVERSPEED/NGTHEENG_NEABOVE

"THE FACTORY HiGH SPEED SETT!NG CAN BE

DANGEROUS, IF YOU TH_NK THE ENGINE GOVERNED

H_GH SPEED NEEDS ADJUSTING, CONTACT YOUR

NEAREST AUTHORIZED SERV!CE CENTER/

DEPARTMENT, WHiC _,,_HAS PROPER EQUIPMENT AND

EXPERIENCE TO MAKE ANY NECESSARY

ADJUSTMEN'TS

F}G. 31

TO ADJUST CARBURETOR (See Fig, 32)

The carburetor has been preset at the factory and adiusb

meet shouid ROt be necessary, However, minor adiust

ment may be required to compensate for differences in fuel

temperature, altitude or iead ff the carburetor does need

adjustment, proceed as fo{fows:

In general, turning idle mixture valve in (clockwise) de_

creases the supply of fuet to the engine giving a fearer fueti

air mixture, Turning the idle mixture valve out (counter

clockwise) increases the supply of fuel to the engine giving

a dcher fuel/air mixture,

fMPORTANT,, DAMAGE 'TO THE NEEDLE VALVE AND

THE SEAT IN CARBURETOR MAY RESULT IF SCREW/S

TURNED _NTOO TIGHT

PREUMINARY SETTING ..

Air clearer assembly must be assembled to the carbu--

retor when making carburetor adjustments

o Be sure the throttle control cable is adiusted propedy

(see above)

, With engine off turn idie mixture valve in (clockwise)

ctosing it finger tight and then turn out (counterclock-

wise) 1 fuli turn.

tDLE MIXTURE

VALVE

FiG. 32

23

Page 24

Immed ately prepare your tractor for storage at the end of

the season or if the tractor wilt not be used for 30 days or

more_

Remove mower from tractor for winter storage When

mower is to be stored for a period of time, clean t thor°

ough/y, remove aHdid, grease, _eaves etc, Store n a

c_ean, dry area.

, C/can entire tractor (See "CLEAN ING*'in the Customer

Responsibil ties section of this manua ).

o Inspect and replace belts, if necessary (See belt re_

placement instructior_s inthe Sewee and Adjustments

section of this manuai}.

° Lubricate as shown in the Customer Responsibilties

section of this manual

- Be sure that alt nuts, bo}ts and screws are, securety

fastened Inspect moving pa£s for damage, breakage

and wear. Replace if necessary

Touch up ail rusted or chipped pant sudaees; sand

Ightly before painting.

• Fully charge the battery for storage

o After a period _f tirne n sto age battery rnay require

To heip prevent corros on and powe_' }eakage during

k_ng periods of storage battery cabtes should be

tomer Responsibi! ties section of this manual)

After cleaning, leave cables d sconnected and place

cables where they cannot come in contact with batte_y

terminais_

• Be sure battery dran tube is securely attached.

° if ba£teEyis removed from tractor for storage, do not

store battery directiy on concrete or damp surfaces.

FUEL SYSTEr'_

_MPORTANT: T IS iMPORTANT TO PREVENT GUM

DEPOSITS FROM FORMING iN ESSENTIAL FUEL

SYSTEM PARTS SUCH AS CARBURETOR, FUEL FILTER,

FUEL HOSE, OR TANK DURING STORAGE_ ALSO,

EXPER ENCE _ND/CATES THAT ALCOHOL BLENDED

FUELS (CALLED GASOHOL OR USING ETHANOL OR

METHANOL1 CAN ATTRACT MOISTURE WHICH LEADS

TO SEPARATION AND FORMATION OF ACIDS DURING

STORAGE. ACIDIC GAS CAN DAMAGE THE FUEL.

SYSTEM OF AN ENGINEWHLE N STORAGE

Drain the _uei tank.

, Sta_ the engine and iet it run until the fueJ ines and

carburetor are empty.

, Never use engine or carburetor c eanet products n the

fuei tank or permanent damage may occur.

Use fresh fuel next season.

NOTE: Fuei stabi_zer is an acceptaMe altematve in

m nimizing the formation of fue_ gum deposits durng stor

age. Add stabilizel to gasoline in rue! tank or storage

container Always fo_Iow the mx ratio found on 5'iabil zer

contaner Run engine at east 10 mnutes after adding

stabilizer to atlow the stab lize' to reach the carburetor_ Do

not drain the gas tank and carburetor if using fuel stabilizer.

ENGINE OIL

Oran oi{ (wth engne warm) and eplace ,_4thck_n eng_e

oil, (See 'ENGINE' in the Customer Responsiblities

section of this manual)

Remove spark plug(s}.

Pour one ounce of oii through spark plug hole(s) nto

f urn gnt on key t_ START pos tfon for a few second_

to distribute oL

Replace with new spark pfug(s}_

- Do not store gasoline from one season to another.

Replace your gasoline can if your can sta_s to rust.

Rust and/or di_ in your gasoline will cause problems.

f possib!e, store your tractor ndoors and cover it to

give protection from dust and did.

, Cover your tractor with a suitable protective cover that

does not retain moisture. Do not use p{ast{c_ Pfastic

cannot b_eathe which aitows condensation to form and

wiil cause your tractor to n.4st.

iMPORTANT: NEVER COVER TRACTOR WHfLE ENGINE

AND EXHAUST AREAS ARE ST{LL WARM.

24

Page 25

PROBLEM

CAUSE

CORRECTION

W_J|not Start

Ha_d _o a_ar_

Engine wI{Inot _tumover

1 Oat of tue.

2 Engine net 'CHOKED" propedy

3 Engine fooded_

4 Bad spark peg_

5_ Didy a_rfiter

6 Drtyf_e liter.

7, Water is fuei

8. Loose o darnaged wiring

9 Carbu efer out ol adustmenl

10 Er gins raves eat of ad ustme_t

I. Di_ty air filte_

2 Badspa_kpug

3 Weak or dead bal_ery

4 Dr_y fuel fitter.

5 Stale or d}f_y fuel

6 Loose or damaged wineg.

7 Carburetor out of adiustment

8 Engine valves out d ed _slmeet

1 C_utsh/Prake peda_ not dep_essed_

2 Attachment dutch is engaged.

3 Weak or dead b_teh!

4 %own fuse

5. Corraded batte_ylermee}s

6 Loose or damaged wring

7_ Pasty g_iflon swtch

8. Fauity se}eneid or starter

9_ Faui_y operat/_r presence switch(as}

1 Ftl fi.;e ark.

2. See 'tO START NG{NE' in Operation section

3. War severn minutes before atlemphng to start

4 Rap ace spek p_ug

5 Cea[Frepaee a}r fter

6. Repass fuel f/ter_

7 Dra}n f_e/lank and cad_uretor rafif tank wit_" freer

gasol ne and replace fl_el fi_ter_

8 Cheek a_ wi ing_

9. Contact an authorzed service oenter/_epartment

10. Contact an auIhorzed service cenler!depadment

1 OlearFrep_ec÷ air fte_

2 Replace spark plug_

3 Recharge or repla se batleL/_

4. Replace fee f}!ter.

5. Dr_n fuei tank and refii/wth fresh gasoline

& C_eckal wrng

7 Co_tacl an euthohzed sewce eenteddepartment

8 Contact an nut _o zed sewee center/depadmel t_

1. Depresse!_ehf{}take peda

2. Dseagage a_taehment ddLh.

3 Recharge or _ep_acebee W

4 Repines R_se

!'_ Cean ballery len ne_s

6. Checkaif wrin%

7, ChecW_epiaceignIen sw}_ch,

8 C ec!repacesobnodorstarter

g Ce_}tac_ an author}zed servce eenteddepartn ant.

Engine e#¢ks but writ mot

_ta_

Loss of power

Excessive vibration

1 Weak or dead ba_sery.

2. Co,reded bakery termna!s.

3. Loose or damaged wring

4 Fauty solenoid o starter

1 Cull ng tcx) much grass/too fast

2_ Thretfle in "CHOKE" p_asitor_

3. Ba#d up of grass _eaves and reeh under rrower.

4 Di_y ar flter

5 Lrx_ oi bvei/d_y o_

6 Faulty spark pfu%

7. Ddyfl_af fi!te_

8 State st dirty fuel

g. Water in fuel.

I0 Spark pk_g wre toese.

1i. Dirty engine air screen/fins

12 Di£yielogged muffler.

13 Loose or deranged wring.

I4. Carburetor auf of adiustment.

I5. Engine valves out of adiustment.

1_ Worn bent or _oose Made

2. Bent blade mandrel

3 Loose/damaged pad(s},

1 Rechag or r_p/aee battery

2. Clean baits 9 term _a_s

3. Cfeeka w_r ig

4. ChecW_ep}aea s-_eneid or etader

1, Set n Higi_e Cul'_post_on/redasespas&

2_ Adiust throttle centre

3 Clean _nderside of mower housing.

4. CeerJrep_ac_ ar f_er

5. Check oi_ tarsi/change o

6. Cear_ and regap or change spark ptug_

7 Rap!ace fuel flter.

8. Dra_e fuel tank ard refiit w_h fresh gasoline

9. O_sai[rue! tank and carburetor, refill tank with fish

ga_:_o_ineand repines f_._e_Hter

10 Cot nest and tighten spark pug wire

1 Cean engine air screen/lies.

12 C_ean/replace muff er_

13 Check all wfdn#_

I4 Contact an authorized service ce_feddepadmer_t.

Cer_tael an authorized service center/depa_meet.

'1_ Replace blade. Tighten biade her

2_ Repines blade ma_det,

3 Tghten loo!_e pari(s}_ Repass damaged pade_

Page 26

PROBLEM

CAUSE

Engine centia_es to run

when operator _eaves seat

withattachment clutch

engaged

Poo_utouneeen

Mower blades wfli net

rotate

1, Fairy eperater-szfety press_'oe coat otsystem

1 Worn bent or koss blade.

2 Mower deck not _evs

3. Buildup of grass leaves, arid fra_h under mower

4 Bent blade ma'_drs.

5. C_ogged mower deck vent ho_es from buiidup of

grass _aaves and trash around msrsdre s

1 Obsbuetic¢_ r_ clutch mecha_ism

2 Were/damaged mower drive bet

3 Frozen id!er p Iley.

4 Frozen blade mendeL

1 Engine speed too stow

2 Traw;_ speed toe fast

3, Wetgraee

4 Mower deck not [eve_

5 t ow/ur_even tre air pressure.

6, Worn bent or loose bade_

7. Bi idup d gass, leaves and trash under mower

8 Mower drve bet worn

9 Blades improperly installed.

10, Improper b_adestsed

1'i Ciogged mower :tack vent hoes fen buildup of

g_ss eaves, and trash around rnan@e_s.

t, Ch_ck wirir _ swtches aed conr_eations_ If not

corrected sea,act an euthor zed service canted

dsparlment

1 Replace biade Tghten biade bet.

2. Levai mower deck

3, Ciean unde;s}ds of mows houssg

4, Replace blade mandrel

5 Ciean around mandre s to open venf ho_ss

t Remove obstruct oe

2 Replace mower drive belt

3. Replace idler puey,

4_ Replace blade man#eL

1, Place throttle centrei "FAST' pasties.

2 Shft to slower speed

3, Alk_w grass to dry betsre mowing,

4. Levelmower deck

5 Cheek ires for p 'spar a_' press re.

6. Replaee/sharpe_ bade. Tighten bade bet.

7_ C_san underside ef mower housng,

& Rep_acemewe ddvs bet

9 Raisers i bades sharp edge down.

10, Rap ace wth blades tared n ths menus,

11. Clean around mandre s to open vent holes

Trecter"¢taeps_wi_h

met_on sont_offeser fn

Lose of drive

Eng_ee 'backfires _'

when turning engine

'OFF'

t. Switch s OFF"

2 Bulb(s} burned out

3 Faulty lght swtch

4. Loose or damaged wrng_

5 Blown fuse.

1 Bad belts W ca(s}

2 Poet' cable cannectiene_

3. Faulty regulate_ (if so equipped)

4 Yauty a_f®m tar

1, M )t_encontrol ever is o_t of adjustmer_t

1 Freewheel control in 'd sengeged _posit on.

2. Moron d_ve belt has worn damaged or broken

3. Air trapped in transmission dudsg shpment

or sew sing

t Engine throttle eontre_ not sat at "SLOW _'

position for 30 seeo -_dsbefore stopping sng se.

1. Tern swtch'*ON'.

2. Replace hub(s}

& ChecWrepaee _ght switch

4. Check wrng and cenneetons

5 Repfaee fee

f Replace baftery

2 Cheek/s_e_n a_ connect ons

3 Replace r®_._u_eteL

4. Replace e_terlater

1. Adiust motion centre Iever.

! Place ffeewk eel centre! engaged' pesif en

2 Replace moron eve belt

3 Purge transm ss_on

1, M:>va fhrett e control t( *S£OW' position and aliow

to ida for 30 seconds before stepping engine,

Page 27

CE

Page 28

SUGGESTED GUIDE FOR SiGHTiNG SLOPES FOR SAFE OPERATION

ONLY RiDE UP AND DOWN HILL,

NOT ACROSS HiLL

GUIDE

SIGHT AND HOLD THIS LEVEL WITH

SKY LiNE OR TREE.

Page 29

MANUAL

MODEL NO.

15.0 HP

ELECTRIC START

42" MOWER

AUTOMATIC (HYDROSTATIC}

DRIVE

LAWN TRACTOR

917o257590

iF YOU NEED

REPAIR SERVWCE

OR PARTS:

FOR REPAIR SERVICE, CALL

THIS TOLL FREE NUMBER:

FOR REPLACEMENT PARTS

INFORMATION AND

ORDERING, GALL THiS

TOLL FREE NUMBER:

Each tractor has its own model number. Each engine has

its own model number.

The reodei number for your tractor wili be found on the

model plate located under the seat,

The model number for your engine wit! be found on the

blower housing of the engine.

Ail parts listed herein may be ordered from any Sears,

Roebuck and Co, Sewice Center/Depa£ment and most Re_.

tail Stores

WHEN ORDERING REPAIR PARTS, ALWAYS GLOVETHE

FOLLOWING INFORMATION:

PRODUCT - TRACTOR

MODEL NUMBER - 917.257590

ENGINE MODEL NO, - 28N7_7o0121 01

* PART NUMBER

'_ PART DESCRiPTiON

Your Sears merchandise has added value when you

consider Sears has service units nationwide staffed with

Sears trained technicians°_ professional technicians

specificaiiy trained to insure that we meet oar p_edge to

you, we sewice what we sell.

144617 032594 Printed in US.A.

Loading...

Loading...