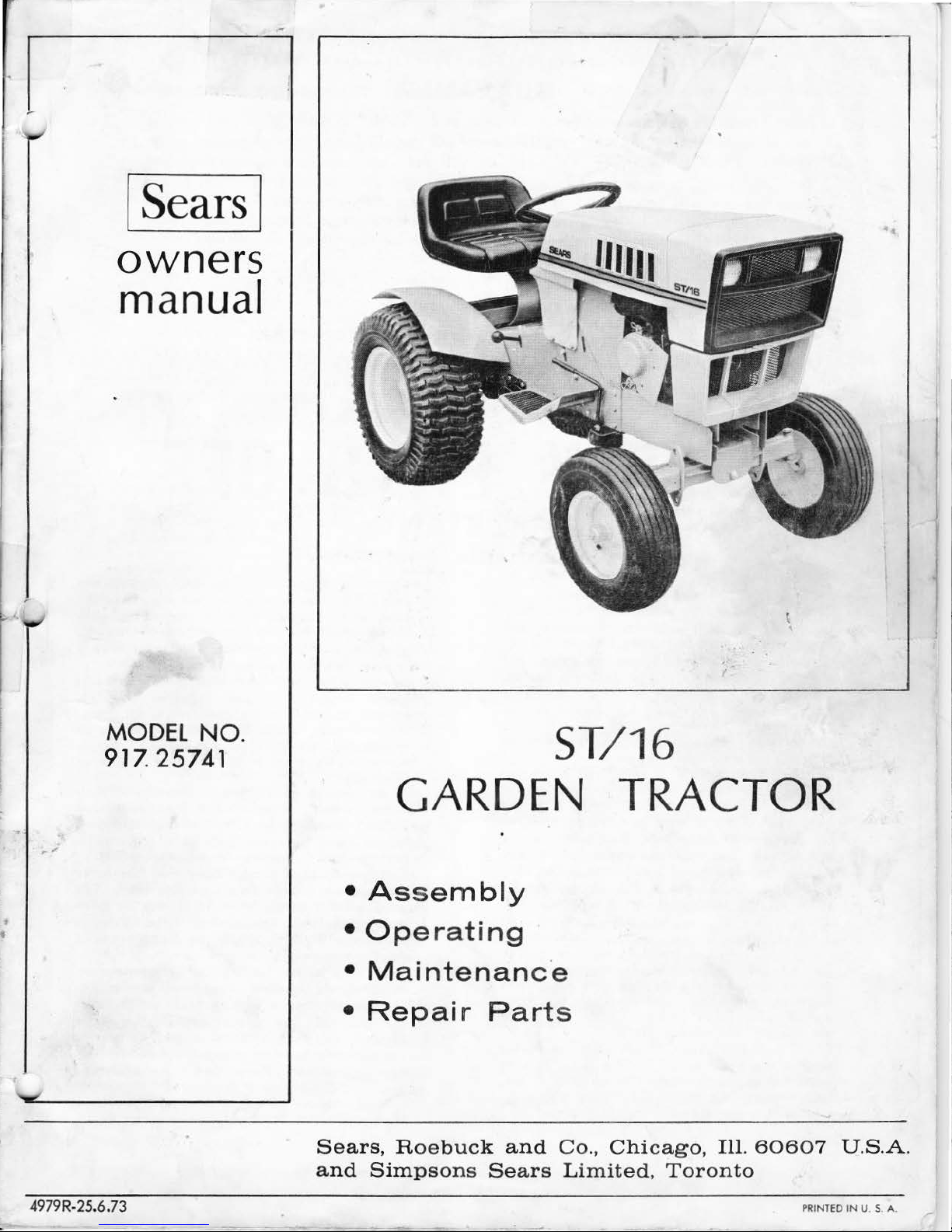

Sears 917.25741 Owner's Manual

I Sears I

owners

manual

MODEL

91Z

25741

NO.

•

•

Ope

•

•

Sears,

and

ST/16

GARDEN TRACTOR

As

sembly

rating

Maintenanc

Repai

Roebuck

Simpsons

r

Parts

Sears

and

·e

Co., Chicago,

Limited,

Toronto

Ill.

60607

U.S.A.

4979R-25.6.73

PRINTED

IN U. S. A.

,

.~------------------------------------

GUARANTEE

Your

Tractor

should appear during

throughout the United

parts

and labor,

defective

first

90 days-replace battery at

tomer l /

If

the tr

actor

is

guaranteed for one

at

and

will

l2t

h of the price

is

used for comme

full

year. If any defect in mater

this

time,

simply

States or Canada.

no charge to you.

contact our nearest Sears store

We

Tractors

not hold o charge, in exchange for the battery,

no

charge.

of the

new battery for each ful l month from date

rcial

or rental purposes,

days .

SEAR

S,

ROEBUCK AND CO. - SIMPSON-SEARS L TO .

~~~~~~

---

ial

or workmanshi p

or

service

wi II make

equipped

After

90-days-replace battery, charging cus-

all

necessary

with

batteries:

we

repairs,

If

battery

will:

of

this

guarantee

applies

center

including

proves

During the

sale.

for

thirty

TRAINING

1.

Read

the

familiarize

proper

tachment.

powered

Only

persons

for Safe

your

tractor.

2.

Do

not a II

start

3.

PR

EPARAT

4.

5.

4979R-25.6.73

or

Do

not

erating

pets

in

fr

ont

yard.

or

passers-by.

attachments

ore

in

porticulorlyh

Ju

red

by

Do

not

wearing

footwear,

do not

get

caught

Check

remove

when

the

When

filling

SAFETY

PAYS

IMPORTANT

Owners

yourself

use

of

your

Be

prepared

ottochment(s)

well

Operation

ow

children

operate

allow

your

the

the

anyone

tractor.

bock

Keep a wary

and

vicinity

could

t e

tractor

ION

operate

open

sandals.

preferably

wear loose

in moving

your fuel

the

gas

engine

the

Manual

with

tractor

acquainted

should

your

Keep

yard

Di

sengoge

stop

of

get

or

the

tractor

Always

ste

fitting

supply

cop

or

is

running

fuel

rules

carefully

the

as

well

to

stop

the

on a second

with

be

allowed

or

young

tractor.

in

the

area

the

while

the

your tractor.

in

before

tonk, leave

eye

the

engine

the

on

el-

toed

clothing

ports.

fill

or

using

out

way

attachment

when

wear

each

the

while

for

and

controls

as

any

engine

's

notice.

these

to

teenagers

while

children

it

in

for c

hildren

power to

while

Children,

of

and in-

.

barefoot

substantial

sho

es.

that

use.

gasoline

it

is

space

safe

fully

and

at-

and

Rules

use

to

op-

and

the

all

they

or

Also,

could

Never

tank

hot.

for

operation

expansion,

in mind

gasoline

oline

gasoline

be

6.

A

pi

eces

extreme

7.

Never

attachment,

attempting

attachment.

8.

Never c.ttem

safety

9.

Before

tractor

neutral

disengaged,

and

parking broke must

you

operated

damage

10.

Each

be

is

the

is

parts

key is removed.

seat

running.

the

- 1 -

do

that the

to

expand.

before

is

highly

handled

tractor

be

put

absolutely

disengaged,

gear shift

shut

and

of

equipment,

caution

attempt

to start

as

well

attempting

make

and

sure

the tractor

with

may

time

off,

hove

completely

with the

Always

operato

always

pt

before

r's

OFF

not

fi

II

it to

the

heat

of

the

sun

Wipe

starting

flammable

with

extreme

all

must

to

operate a damaged

to

corry

as

your

to

sure

power to

firmly

release

the

parking

sure

the

lever

the

attachments

engine

get

left-hand

the

always

leaving

the

Never

the

then

to

result.

off

the

engine.

attachments

not

be

repair

or

safety

start

in motion. If

parking

is

or any

on

care.

pi

ayth

exercised

any

operate

any

will

the

gear

all

apply

the

parking

be

brake

the

power

broke

in

neutral,

stopped

leave

powered

or

off

side.

to

brim and

can

any

spilled

and

must

are

ings,

at

damage

your

passengers, the ir

be

engine

shift

attachments

the

disengaged

the

engaged

operator's

all

and

and

the

your

keep

cau:.e

the

gas

Reme mber,

always

prec

is i

on

therefore

all

t i

mes.

tractor or

before

tractor

endangered.

lever

foot br

brake.

tractor

attachments

is

the

all

the

operator's

attachment

tractor

or

of

your

is in

is

ake

The

when

is

serious

seat,

engaged,

engine

moving

igniti

on

from

-

rules

11.

12

.

for

Always operate

or

dark -use

Opera

te

your

slippe

ry

Never

ot a spe

OPERATION

1

3.

Do

not

attempt

or

over

speed

the

engine

damaging,

speeds

14.

When

with a pull

your

tachments.

15.

Never

powered

wh

is

Always

16.

set

off

ed

pletely

each

a

pets

17.

If

v

erten

disengage

parking

engine,

attachment

pletely

connect

plug

prevent

thoroughly,

for

before

attachment.

If

18.

start

lever

posit

neutral,

sure

ports

ignition key,

from

plug

then

vibrat

of

19.

Before adjus

specting

ment,

set

absolutely

all

remo ve

plug

to

ore

starting

feet

place

attachment

i I e

the

runnin

~.

d1sengoge

the

parking

the

eng

attachm

stopped

time you

second.

may

your

tractor

tly

broke,

make

stopp

the

and

injury

any

damage.

restarting

the

tractor

to

vibrate

for

powered

ion,

shut

the

hove

the

spark

to

prevent

check immed i

ion

troub

le.

disengage

the

parking

moving

the

wire and

prevent

safe

your

your

tractor

surfaces,

ed

to

change

the

engine. The

speed

excessive

ore

tractor

ine,

ent

Children,

be

str

the

keep

set the

powered

as

your

injury

and

dangerous.

your

starter,

well

your

hands

or

the

broke,

make

and

and

dismount

endangered.

or

any

ike a foreign

power

shift

absolutely

and

all

ed,

remove

spark

the

wire

or

inspect

Such

and

or

any

abnormally,

attachment

off

the

comp

letely

disconnect the

plug

injury

ately

vibration

ting,

tractor or

the

broke,

sure

the

ports

ignition

keep

or

operation

tractor

lights.

at

where

which

protects

speed

engine

stand

away

or

any

power to

absolutely sure

all

moving

remove

yourself,

attachment

to

into

moving ports

plug

occidental starting,

the

damage

operating

powered

park

engine,

attachment

and

cleaning,

power

shut

powered

hove

key, disc

it

away

occ

safe

traction

could

the

s.

on

firm and

from a

or

feet

near

powered

shift

your

object,

the

attachment,

neutral,

sure

the

wire

away

tractor

s in

ing

stopped,

keep

or

occiden

for

is

generally

any

to all

off

compl

from

ide

ntal start

in d

aylight; dusk

speeds

is

cause

governor

governor

the

engine

Excessive

tractors

any

into

the

other

ignition

attachment

place

broke,

the

II

powered

in

or

moving

all

attachments,

neutral,

ports

ignition

tractor,

should

immediately

shut

any

from

from

the

or

must

be

the

the

the

make

and

remove

spa

rk

it

away

tal

cause

repo1r

powered

attachments,

the

engi

attachm

ete

ly

onnect

the

make

attachment

any

hove

persons

hove

attachment

disengaged

absolutely

all

1ng

spark

ing.

{cont.)

on wet or

unsure.

a skid.

setting

controls

from

engine

equipped

sure

at-

under

any

ports

shut

power-

com-

key

even

for

or

inad

set

the

off

the

powered

com-

key,

dis-

the

spark

plug to

then

repaired

tractor

shift

plug

a warning

the

should

control

into

moving

wire

from

starting,

of

this

or

attach-

ne,

make

ents

and

stopped,

spark

plug

or

the

the

in-

20.

Do

not

run

the

engine indoors

eng

ine exhaust fumes

which

21.

Nev

s

good

tipping

tractor

speed,

ercise

on

tractor

with more

22. Do

down a terrace slope

cessary

do

up

ing

going

enough to

ping

the

slow.

23.

Never

attachments without

plates

-

fully

24.

Before

carefully

bystanders,

of

25.

Never

attachment

26.

Be

your

prevent

striking

or

2.7.

Use

drowbor

con

counterweight

in

28.

Never

travel

29.

Always stay

and

upsets con

Use

or any

always

before

30. The u

ment

tention

vent

31.

Always

when

o grovel

tron

is o tasteles

er

operate

lope

or

incline that

stability

or

up

do

extreme

inclines. Never

on

not

sta

to

so

firml y

je

speed

any

sure

on

cts.

the

during

the broke

up

or

and

shi

tractor

attempt

or

other

functioning.

and

to

kind o

allow

to

tractor

the

them.

attachme

core

when

hitch

safely

attachment

shift

until the

other

low

gear

attachment

disengage

attempt

se

of

requires

to

inju

ry

disengage

not

actually

drive,

spo

rting

and

sideways

and

down

not

ope

caution

steep

than

rt or

stop

stop

to

prevent

position.

down

negotiate

fting

on on

to

protective

while

be

pets,

re

anyone

while they

exercise

around

tractor

Never

nt

pulling loads.

points.

control.

or

gears

tractor

alert

hid

den

happen easily

on

ing

any precis

your full

the job being done

or

damage.

the

cont

s,

odorless,

your

tractor

is

con

trol in o

upsets.

such

rat

e it

when

attempt

terra

ces, slopes

a

15

deg

suddenly

or incline.

your

tracto

the

declutching

Do

inclines.

the

gears.

absolutely

not

wheel

unfamiliar

sidewalk

tractor.

To

incline

opera

te

the

proper

attempting

foreign

behind

near

special

fixed

or

deliberately

into

or

Limit

Do

not

weight(s)

Owners

to

reverse

comes

to ovoid

hazards.

becom

the

power

to

free it.

ion

the

power

in

use

ain

too

on

across.

ree

r upon

tractor

not

Choose a gear

incline without

reduce

move

your tr

devices

sure that

objects

you.

the

ore

core

objects

any

over

Manual.

holes

Tipping

in

ground.

es

piece

conc

such

or

because

carbon monoxi

deadly

upon a terrace,

steep

rder

Always

incline,

chang

to

slope.

when

and before

shift

throttle

shields,

to

bock

tractor

operating.

when

attachmen

any

Use

loads

turn

when

your

to a complete

holes

stuck

to

all

of

entrat

in or

to

all

as

when

roadway

poison.

to

preserve

to

prevent

operate

at a slow

Always ex-

ing

direction

ope

rate

or

inclines

going up

If

it

on

incline,

from

picking

gears while

the

speed

lever

actor

or

guards,

in

place

up,

children,

or

obstacles

or

operating

in

order

t from

run a tractor

foreign

only

approved

to

those

sharply.

suggested

directio

in the terr

or

sideways

or

ditches.

If

the

tractor

in a

atta

chments

power

ion

and

der

to

attachments

crossing

or

the

de

your

is

ne-

reach-

low

stop-

any

and

look

any

ob-

you

Use

n ·

stop.···.

ain

hole,

equip-

at-

pre-

when

a

or

of

to

to

of

rules for safe operation (cont.)

32. Watch

roadways.

MAINTENANCE

33. Keep

to

is

and

in

attochmen

quent

performing any

the

broke, shift

make

and

remove

plug

from

starting.

carb

out

all

be

sure

in

safe

all

proper

intervals

power

absolutely

all

wire

the

ure

tor

powered

the

for

traffic

nuts,

bolts

that the

working

adjustment

·t

and

to

moving ports

ignition key,

from

plug

The

adjustment,

condition.

attachment

engine

for

maintenance,

all

attachments,

into

neutral,

sure

the

spark

to

prevent

only

when

and

scr

tractor

and repa

mounting

proper

shut

the

powered

hove

comp

disconnect

plug

injury

exception

page 12.

crossing

ews

tight

and any

Be

controls

tightness.

always

attachment

sure the

ore

ir.

Check

bolts

disengage

set the parking

off

the

attachment

let

ely

the

and keep

or

occidentSJI

to

this

or

near

in

order

brake

always

the

at fre·

Before

engine,

stopped,

spa

rk

it

away

rule

is

34.

Keep

gross,

accumulations

in a

attachments

make

other

your

maintenance

serviceman

at least

35.

Do not

(more

Do

ta

iner in

on

in o

cool

use

go

sol

and

prevent

with them.

the

engine

leaves

fire.

su

re

that

protective

tractor

once a y

store

than

30

not

sto

re

side o building

open

flame or

cool,

dry

before

an

approved

ine

and

go

sol ine

children

free

from

or

excessive

ore

combustible

Always

in

and

they

make o thorough

your

days)

your

place.

storing

container

good

all

devices

all

need

ear.

tractor

spark,

gasoline

keep

from

keep

operat

shields,

attachments the

and

for

with

gasoline

tractor

where

they

Be

sure

in

any

your

in

play

acc

umulations

grease

and

your

ing

guards, plates

ore

in

hove a competent

inspection

prolonge

or a go

fumes may

should

to let

enclosure. Always

container

tractor,

locked

ing

as these

could result

tractor

condition

and tamper ing

and a ll

place.

regular

of

d per i

in

the

sol

ine con-

be

store

the

engine

for

stor

attachme

storage

and

and

Give

them

ods

tank.

reac

ing

nts

of

h

d

to

introduction

This

tract

or

has

been

formance.

Should you

Sears,

this

It

instructions

efficiency.

We

Ltd.

unit.

is

important

suggest

table

experience

Store.

We

They

that

contained

urge you

that

you

of

designed,

any problem

have

the

ope

in

this

to

toke core

contents

engineered and

you

cannot

well

qualified,

rato

r ALWAYS OBSERVE

Man

ual.

We

study

this

Manual

of

your Manual

easi

competent

have

so

GU

ARAN

RULES FOR

ASSEMBLY

O

PER

MAINTENANCE INS

REP

assembly instructions

manufactured

ly

remedy,

trained

THE

provided

you will

so

that

this

understand

it

TEE

SAFE

INSTRUCTIONS

ATING INST

AIR PAR

TS

to

give

pleas~

will

contact

technicians

"RULES

Manual

be

available

OPERATION

RUCTIONS

TRUCTI

you t

FOR

to help

your

he

your

and

SAFE

new

ONS

best

possible

nearest

the

proper tools

OPERATION"

you

operate

Tractor

for

future referen

1 • 3

3

5 - 7

8

15 • 33

dependability

Sears, Roebuck

to

your

Tractor

thorooghly

ce

before

should

• 5

•

14

service

as

well

and per-

or

Simpsons

or

repair

as

with utmo

operat

ing it.

you

need

other

st

it.

A

letter

in parenthesis

when

otherwise

were seated

one

1.

Remove

2. Your

3. Your

4979R-25.6.73

Tractor

battery

Tractor •was

operation.

battery.

was

stat

shipp

on

has

in

the

ed.

When

the

Tractor seat

Cut

been

ed dry.

lubric

following

R.H.

(Right

banding

com!Jietely

Instructions

ated

at

the

hol

inst

Hand)

facin

ding

assemb

are

factory

ructio

ns

or

g forward.

Trac

tor

led

at

giv

en

on

however, we

refers

to

L.H. (left

to

bottom

the

factory exce

page 4 fo

- 3 •

on arrow in

Hand)

of

suggest

r f

is

crate.

pt,

illin

g,

you

the

adjoining

used,

it

to

fill,.charge

charg

ing

follow

should

and

ins

the

Lube

Figure

be

und

and

install

tallat

Chart

(illustra

erstood to

the

ion.

on

page

tion ),

mean

battery.

10

except

as

The

before

if

4.

Tires

were over-inflated

ti

res.

5. A plastic

1 • Batt

•

2

• Bat

2

2

• Flat Washe rs

fill

This

low ing

items:

ery

Wing

Nut s

tery

These items

(

They

are

and

CAUTION:

TRACTOR

ED

AND

CHARGED

FILL

CORRECT

TUBES

for

will

improve traction

bag

of

parts

was shi

Clamp

Bolts

hold batt

used

in

steps

ery in

3 a nd

charge

DO

NOT

ASSEMBLE

UNTIL BATTERY

.

BATTERY

DO

IN

NOT

LEVEL

CELLS.

OVERFILL

IS

BOTTOM

shipping

and give

pped

JX>Sit ion on

5,

page

battery

BATTERY

HAS

BEEN

AS

SHOWN

purposes.

you

with

your

Tractor.

5).

__

OF

the

Tractor

TO

FILL-

Reduce

comfortable

air

and

pressure

ride

should

2 •

Hex

(They

to

page

2 •

Ignition Keys

(We

ring

second

There

the

be

refi

5

with

spillage

electrolyte

(baking

stirred

bonate

wooden

now

sewage

tralized,

result.

It

em

tact

to 12

you

will

be

container

disposed

II T roctor

gallon

is

pty

want.

opened

Nuts

secure

battery. They

5).

suggest

and

kept

key

will

be

polyethylene

a minimum

on

to

soda)

or

agitated

no

longer

or

plastic

be

safe

system.

no

preferable,

ac id

pak

with

acid.

lbs.

at

ground s

one

in

an

after

of

and

or

any

person

water.

should

to

critic

to

in

front

this

time.

trap

are

used

key

be

in a safe

the

Tractor

amount

battery

not

used

other

battery.

garbage

of

four

inches

or

clothing,

Then

be

until

causes

dispose

Since

where

foaming. Agitate

stake

the

ism from

permissible,

prevent

tires

It

will

and

in

removed

place.

of

electrolyte

is

filled.

sodium

added

the

or

stick

of

this

product

authorities

possible

and

12

lbs.

contain

positive

steps 6 and

from

the wire

Position

ignition).

(acid)

This

at

a I

ater

Using

a common

can

or

pail,

of

water.

add

left

bicarbonate

and

the

addition

of

only.

down a reguiar

is

well

to

burn

further

in

rear

the

fol·

cable

7,

the

in

should

date

to

fill

Avoid

over

mixture

bicar-

with

It

will

neu

should

the

con·

a

-

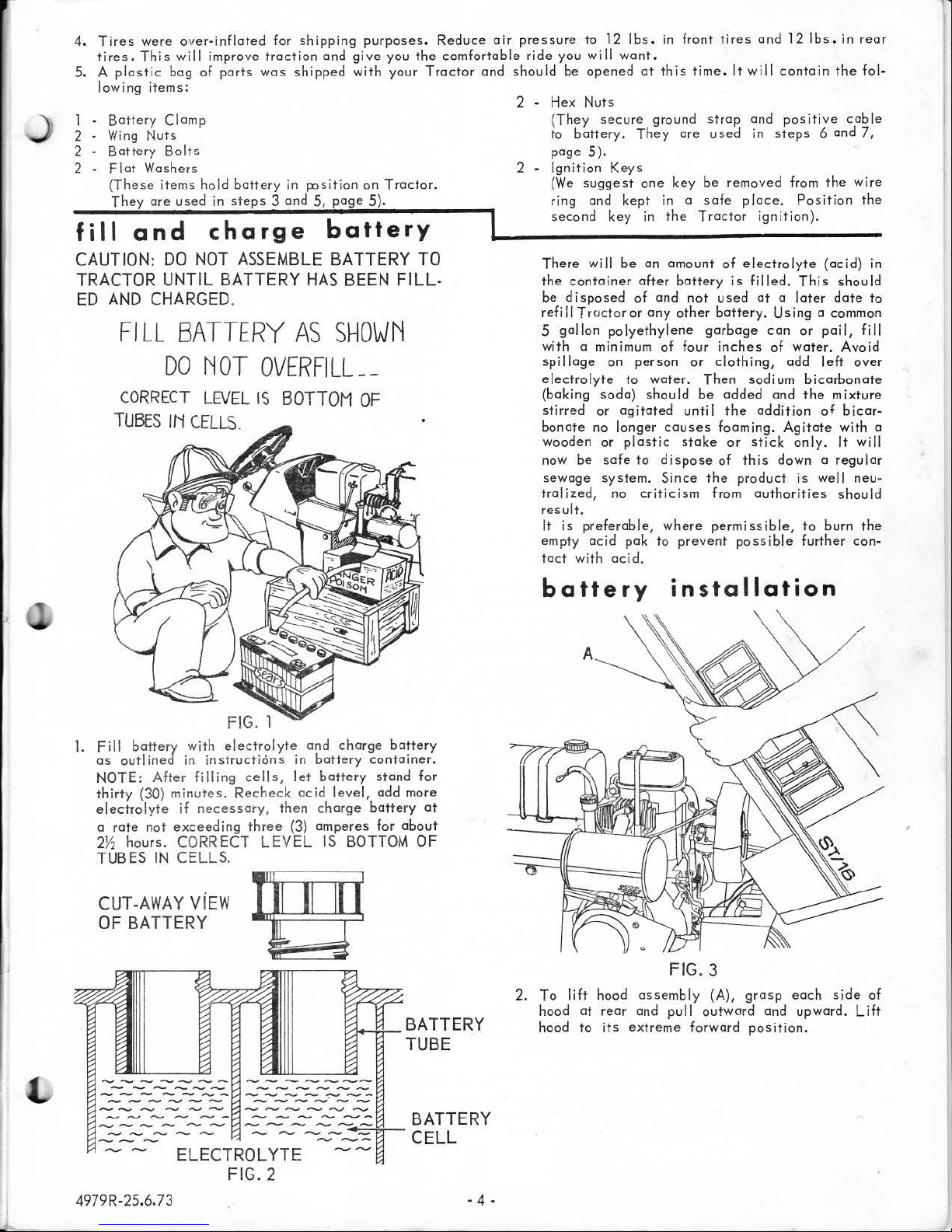

1.

F ill

batterJ

as outl

NOTE:

thirt

electrolyte

a

2

TUBES

rate

Y2

ine

Afte

y (

30)

no t exce

ho

urs.

IN CELLS.

minutes

CORRECT

CUT -AWAY ViEW

OF

BATTERY

with

e lect

. Re

rolyte

ns

check

y,

LEVE

in instru ct io

r filling cells,

if

necessar

eding three

and

charge

in b

att

ery

let

battery

acid level,

then

char

ge

(3) am p

eres

L IS BOTTOM

V1+--i-+--

battery

container.

stand

for

add

more

battery

for

at

about

OF

BATTERY

TUBE

battery

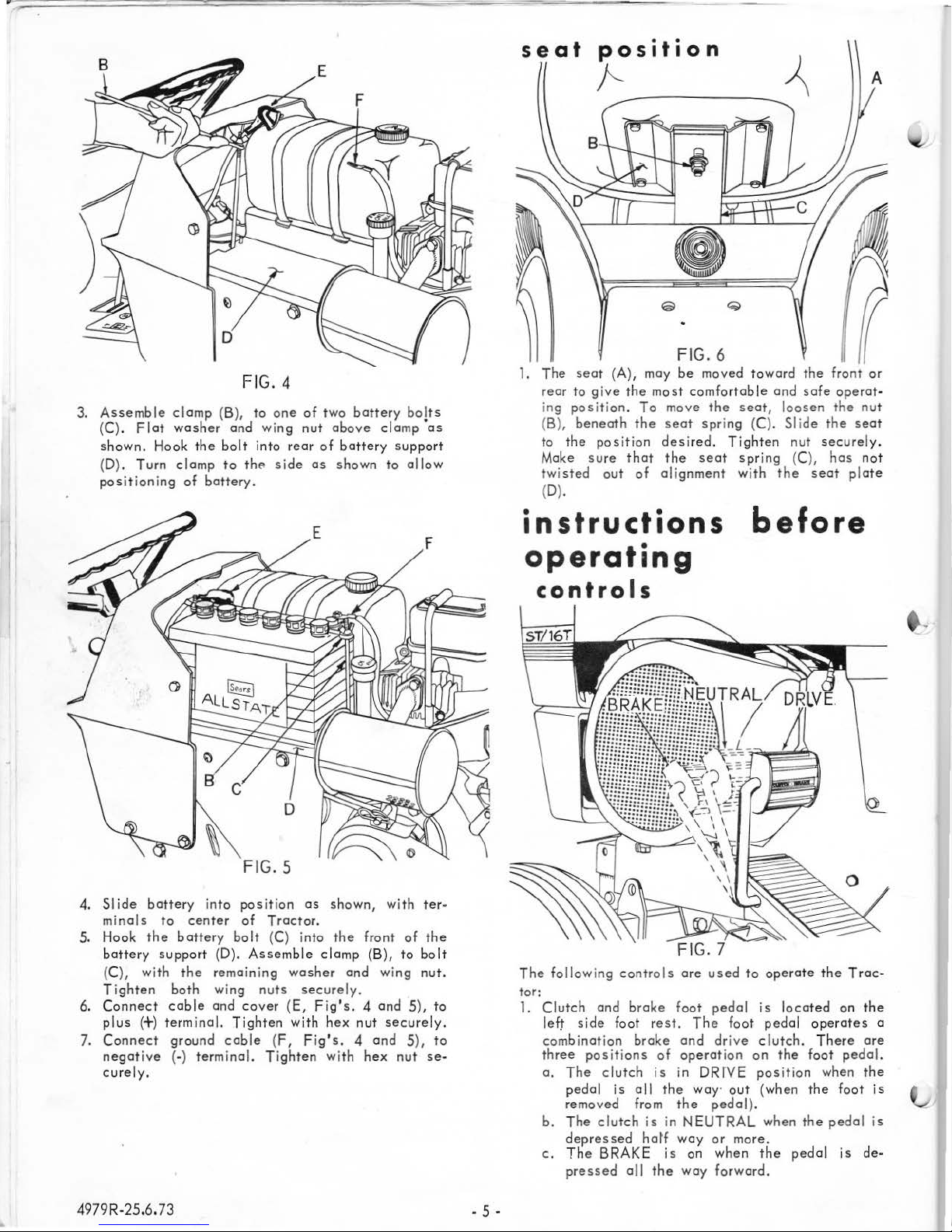

2.

To

hood

hood

lift

hood assembly (A),

at

rear

and

to

its

extreme

installation

FIG. 3

grasp

pull

outward

forward

and

position.

each

upward.

side

of

Lift

..........

..._-

------

__

-----

_..._

,:-

~--

4979 R · 25.6.

----

_

,......_,

___

__

,_-

__

__,

-------

~ ~-; L;CTRO~

73

-------

------

- -

-----

-------

_____

_:- :

~

-2'

Y;E -..... :-:.:;-,::;

FIG.

2

Z

--

........,....._

~:::..

~

BATTERY

CELL

. 4 .

3.

Assemble

(C) . F lot

shown.

(D).

positioning

Hook

Turn

clomp

washer

the

clomp

of

battery.

FI

G.

4

(B),

to

one

and wing nut

bolt

into

rear

to

tht'!

side

of

as

two

above

of

battery

battery

shown

clo

suppor

to

bolts

mp

allow

'as

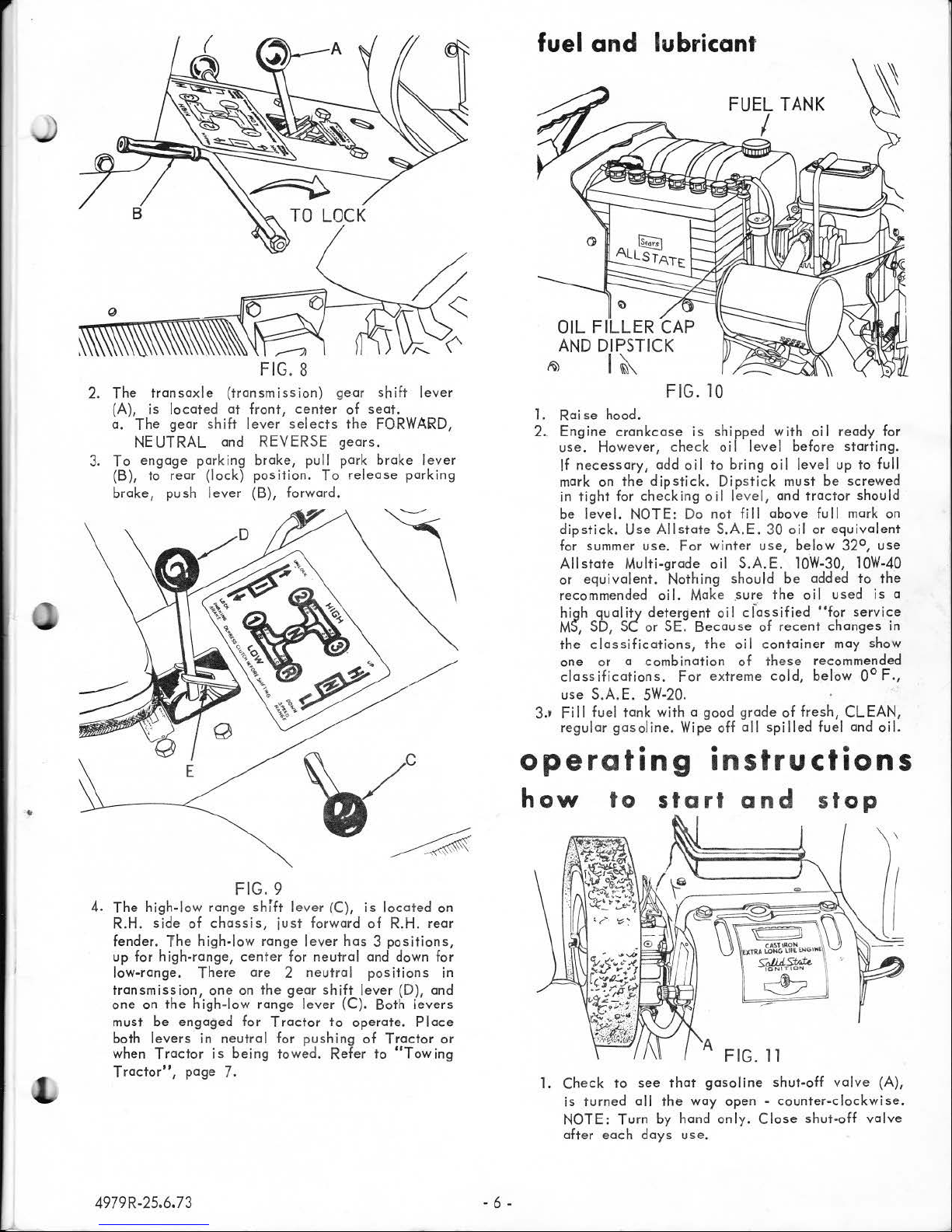

seat

position

)'--

----

-------------

FIG. 6

l.

The

sea

t (A), may

rear

to

give

the

ing position.

(B),

beneath

to

the

sted

position

sure

out

that

t

Make

twi

(D).

be

most

To

move

the seat

desi

the

of

alignment

moved

comfortable

spr

red.

seat

toward

the

seat,

ing (C). Sl i

Tighten

spring

with

and

loosen

nut

(C),

the

the

front

safe

operat

the

de

the

securely.

has

seat plate

or

-

nut

seat

not

4.

Slide

minals

5. Hook

battery

(C}, with

Tighten

6.

Connect

pl

us

7.

Conne

negative

curely.

battery into

to

center

the b ottery

support

the

both

cable

(+)

termina

ct

ground

(·)

ter

FIG. 5

position

of

bo It (C) into

(D).

Assemble

remaining

win g

and

cover

l.

Tighten

cable (F, Fig's. 4 an

minal.

Tractor.

washer

nuts

(E,

with

Tighten

as

shown,

the

clomp (B),

and

securely.

Fig's

hex

with

. 4

front

and

nut

hex

with

ter-

of

to

bolt

wing

nut.

5),

securely.

d 5

),

nut se-

the

to

to

instructions

operating

controls

The

following controls

tor:

l.

Clutch

l

eft side

combination

thr

o.

b.

c.

and

ee

positions

The

pedal

removed from

The

clutch

depressed

The

BRAKE

pressed

broke

foot

clutch

is

all

rest.

broke

of opera

is

all

the

is in

hotf

the

ore

foot

The

and

in DRfVE

way·

the

NEUTRAL

way

is

on

way

before

used

to

operate the

pedal

is

located

foot

pedal

drive clutch.

tion

on

the

position

out

pedal).

or

(when

more.

when

the

forward.

when

on

operates

There

foot

when

the

foot

the

pedal

pedal is

Trac-

the

ore

pedal.

the

is

de·

o

is

• _

V

4979R-25.6.73

. 5 •

2.

The

transaxle

(A),

is

a.

3.

To

(B), to

brake, push lever

located

The

gear

shift

NEUTRAL and REVERSE

engage

rear

parking

(lock)

(transmission)

at

front,

lever

center

selects

brake,

position.

(B), forward.

pu

gear

II

To

of

seat.

the

gears.

park

release

shift

lever

FORWAgD,

brake I ever

parking

fuel

OIL

and

FILLER

AND DI

~

1.

Raise

2.

Engine

use

. However,

If

necessary,

mark

in

tight

be

level.

dipstick.

for summer

Allstate

or

equivalent.

recommended

high

quality

MS,

SD,

the

classifications,

one

classifications.

use

S.A.E.

3.•

Fill

fuel

regular

PSTICK

I~

hood.

crankcase

on

the

for

NOTE: Do

Use

Multi-

SC

or a

tank

gas

lubricant

CAP

FIG.

10

is

shipped

check

add

dipstick.

checking

Allstate

use.

grade

Nothing

oil.

detergent

or

SE.

combination

SW-20.

with a

olin

e.

o i I I

oil

to

Dipstick

oil

not

S.A.E.

For

winter

oil

Make .

oil

Because

the

For

extreme

good

Wipe off

FUEL TANK

I

with

eve I before

bring

level,

fill

use,

S.A.E.

shou

ld

sure

ciassified

of

oil

containe

of

grade

all

oi I

oil

level

must

and

tractor

above

30

these

cold,

sp

full mark on

oil or

below

lo'W-30,

be

added

the

oil

"for

recent

recommended

below

of

fresh,

iII ed fuel and oi I.

ready

starting.

up

to

be

screwed

should

equivalent

32°,

lOW-40

to th

used

service

changes

r may

0°

CLEAN,

for

full

use

e

is

a

in

show

F.,

•

FIG.

9

4.

The

high-low

side

R.H.

fender.

up for

high-range,

low-range .

tr

ansmission,

one

on

must

be

b

oth

levers

when Tr

Tractor

4979R-25.6.73

" ,

of

The

the

high-low

engaged

actor

page

range shfft

chassis,

high-low

center

There

in

one

neutral

is

7.

are

on

for

being

just

range

the

range

Tractor

for

towe

lever

lever

for

2

neutral

gear

lever

pushing

forward

neutral

d.

(C), is

shift

located on

of

R.H.

has 3 positions,

and down for

positions

lever

(C). Both

to

operate.

of Tractor

Refer

to

"Towing

(D),

ievers

Place

rear

in

and

or

- 6 -

oper

how

1.

Check

is

NOTE:

after

a

to

to

turned

each

ting

start

see

all

the

Turn

by

days

instr

that

gasoline

way

open -counter-clockwise

hand only.

use

.

uctions

and

shut-off

Close

shut-off

sto p

valve

valve

(A},

.

~

~==~======

2.

Pull

out

choke

to

start

in

3.

Advance

throttle.

4.

This

es.

(D,

locat

The

position). The

be

start.

clockwise

release

control

worm

not

seconds

engine does

(C),

again.

NOTE:

feres

CAUTION:

then

remove

tachment

5.

To

clockwise

be removed

Tractor

One

switch

Fig.

ed

on

gear

in

disengaged

Turn

key.

(B),

up

run

to

fast

If

attachment

with

for

stop

engine,

throttle

9,

shift

starter

at o time.

attachment

First

================

FIG.

12

control

cold

weather.

is

equipped

is

at

attachment

attachment

key

to

engage

Aft

as

before

not

pas

move

nut

and

which

direction

to

(B),

to

full

contra I lever (C),

with

two

located

point

lever

(out),

(F),

er

engine

apply

continuously

it ion. Wait

clutch

handle.

it

turn

prevent

E).

clutch

must

in

starter.

engine

ing

If

start,

to

be

handle

is requ

ignition

to

OFF

on

the

The

lever

be

clutch

position

ignition-starter

When

starts,

worms up.

load.

for more

after

move

two

lever

(F,

used,

to

Save

ire

key

position.

unoutho

in

several

====~~===-~-=--

choke position

to

about

Y2

safety

gear shift

other

neutral

lever

push

CAUTION: Do

throttle

minutes

remove

"OUT"

for

d.

(F),

ri

zed

switch-

switch

(F,

Fig.

must

for

engine

engine

in

Let

than

attempts,

and

Fig

.

18

),

position,

use

with

in o counter-

Key

operation.

lev~r

is

18).

(center

also

to

switch

starts,

choke

engine

30

control

try

inter-

handle.

at-

should

c

8

--~--

4.

To

stop

and

reduce

engage

to

neutral,

pedal.

hold

Tractor

switch.

Keep

Never

ed.

5.

Do

not

down

going down

Tractor

prevent

declutching

NOTE:

ing

action

without

commended

DO

NOT

DO

NOT

SLOPES

6.

Do

not

Choose

stopping

to

stop

prevent

ing

Tractor

the lowest

gage

..

rear

7.

Upsets con

for ho

8.

If

tractor

ro

;.1

er

towing

l.

Place gear

tral

neu

a

reasonable sa

per

hour.

en

g i n e

to

use

attach

----

Tractor, push

throttle

power

to

attachment.

set

parking broke

Always

key

leave

hill.

The

OPERATE

OPERATE

WITH

Clutch

. ,,

rng

les

than driving

check

secure.

This

will

in a

safe

engine

operate

while

Tractor

declutching.

shift

a low

while

T roc

up

becomes

the

Do

not

hill. If

going

from

to

broke position.

engine

when

throttled

before

TRACTOR

MORE THAN A

gears

enough

and

shifting

going

tor

ro IIi

in motion going

gears.

gradual

.

happen

or

other

yard

tractor

shift

position. Tractor

lever

fe

pulley

for

me

nts

---

foot

lever

to

to

make

Shut-off

prevent

place

running

Tractor

turn

it

down

picking

produces

This

applying

TRACTOR

while

gear

gears.

up

ng

bock

Reduce

I y

to

easily

hazards.

mired

in a

forward.

and

speed

not

your

pedal

all

about

Y2

Move

gear

lock

and release

sur

e broke

and

remove

unauthorized

out

of

reach

with

Tract

in high

sharp

is

hill,

bock

15

going

to

hill,

eng

prevent T roc

in

con

corners

necessary

do

so

up

speed

considerable

to

procedure

broke.

ACROSS

UP

DEGREE

up

climb

If

it

is

do so

word.

Before start

uphill, use

ine

speed

ditches. Stay

hole,

try

range

shift

then

foster

grooves

v

the

way

down

throttle

idling

OR

steep

hill

be

than 6 miles

ar

. Dis -

shift

lock

key

operatio

of

children

or

unattend

gea

r going

while

to

stop

quic

kly

during

the

brak

speed

is re-

SLOP

ES.

DOWN

SLOPE.

hills.

without

necessary

quickly

one

and en ·

tor from

aler

to

bock

leve

r in

towed

ious

lev

foot

will

from

to

to

of

out

at

er

n.

.

-

-

·

t

..

C.Z.

.....,

safe

1.

Try

start,

2.

Start

1/ 3

shift

Release

to

engaged),

ground

about

slower

travel

and

3. Do

operating

your

Tractor

stop

and

the

engine

throttle.

lever

and

foot

move.

After

move

travel

Y2

throttle,

ground

speed

not

overload

not

shift

gears

reverse.

and

Push

range

pedal

foot

throttle

is

too

depress

travel

that

the

in a

Iorge,

put

the

down

on foot

shift

slowly,

pedal

lever

fast,

speed. Always

wi I i

suit

engine.

while

Tractor

open

throttle

lever

and

is

fully

to

reduce

foot

pedal

attachment

4979R-25.6.73

space.

pedal,

to

Tractor

released

fast

throttle

is

Learn

lever

at

move

speed

desired

will

position.

and

shift

select o ground

being

moving.

about

gear

start

(clutch

lever

to

used

to

If

to

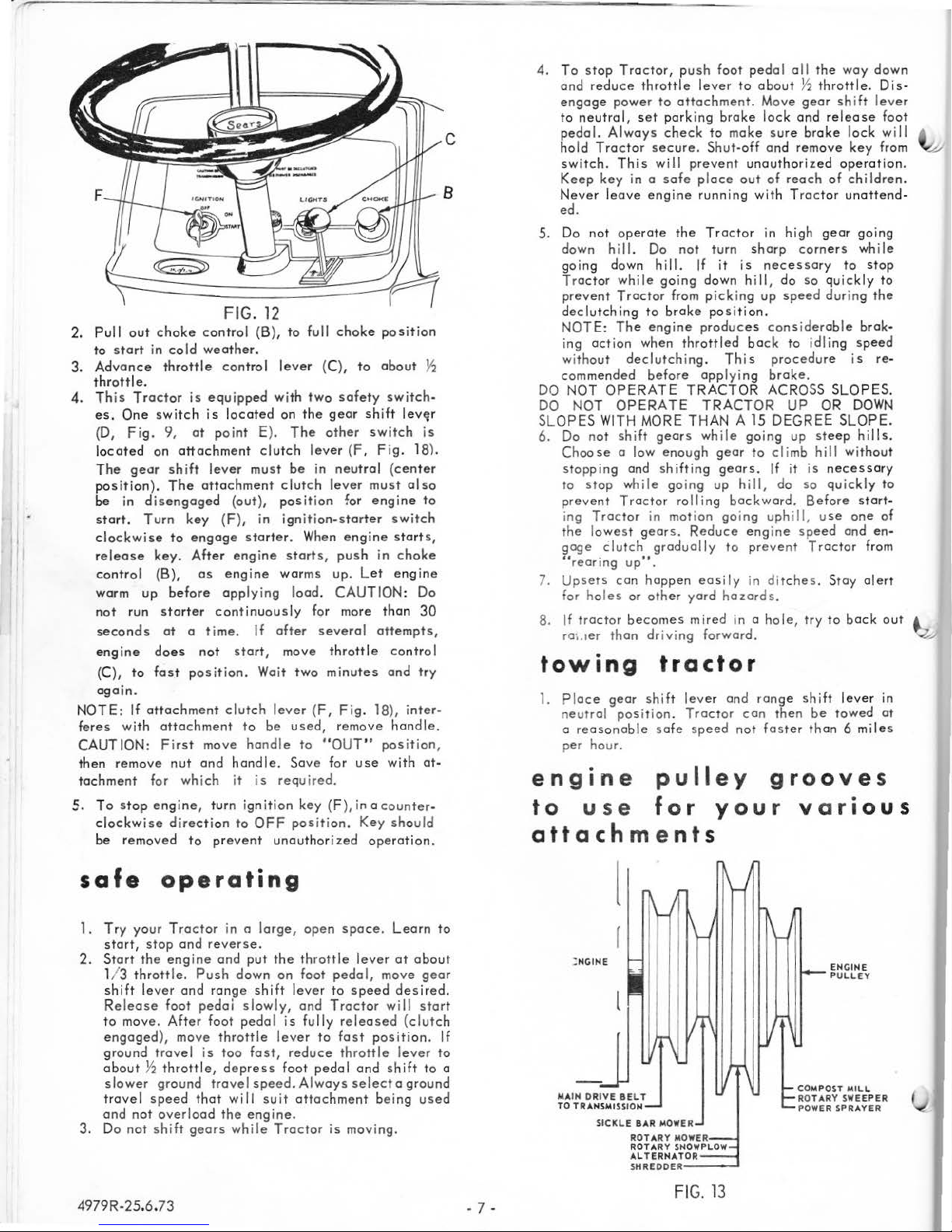

: NGINE

.

a

_j

MAIN

DRIVE

TO TRA N

BELT

SMISSION

SICKLE BAR

MOWER

FIG.

13

ENGINE

PULLEY

- 7 -

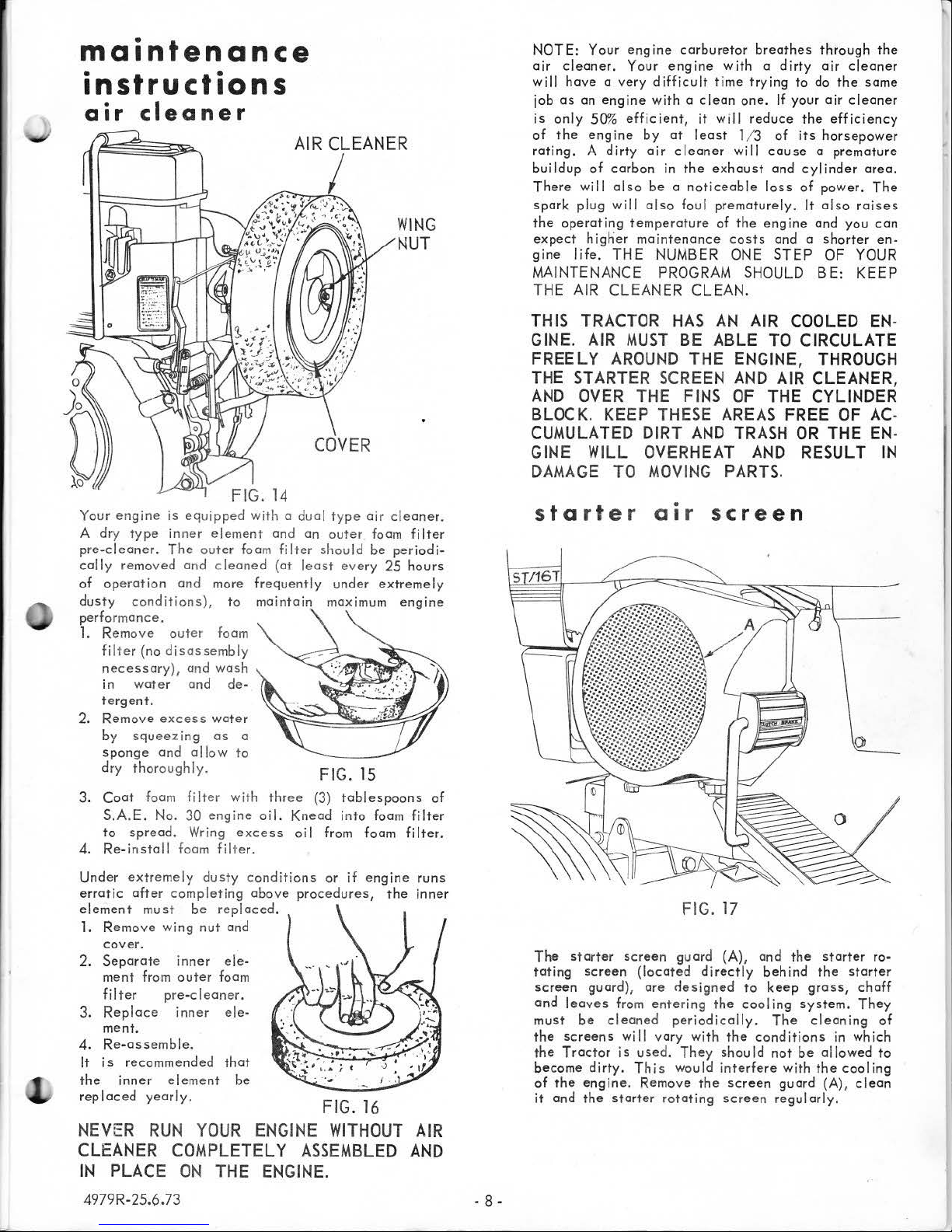

maintenance

instructions

air

cleaner

WING

NUT

NOTE:

air

will

job

is

of

rating. A dirty

buildup

There

spark

the

expect

gine

MAINTENANCE PROGRAM SHOULD

THE

Your

cleaner.

have a very

as

an

engine

only

50%

the

engine

of

carbon

will

also

plug

will

operating

higher

life.

THE

AIR

CLEANER

engine

Your

efficient,

temperature

carburetor

engine

difficult

with a

by

at

air

cleaner

in

the

be a noticeab

also

foul

maintenance

NUMBER ONE

CLEAN.

with a dirty

time

clean

one

it will

least

1/ 3

will

exhaust

prematurely.

of

the

costs

breathes

trying

. If your

reduce

of

cause a premature

and

le

loss

engine

and a shorter

STEP

through

air

to

do

air

the

efficiency

its

horsepower

cylinder

of

power.

It a l

and

OF

BE:

cleaner

the

cleaner

so

raises

you

YOUR

KEEP

the

same

area.

The

can

en-

Your

engine

A

dry

typ

pre-cleaner.

cally remo

of

ope

rat

dusty

performan

l.

2.

conditions),

ce.

Remove

filter (no

necessary),

in

water

tergent.

Remove

by

squeezing

sponge

dry

thor

is

equipped

e in

ner

element

The

out

ved

and

cleaned

ion

and

more

outer

disassembly

and

wash

and

excess water

as

and

allow

oughly.

with a

er foam

frequently

to

foam

de-

a

to

dual

and

filter

(at

least every

maintain

type

on

outer

shou

maximum

FIG.

ld

under

air

cleaner.

foam

be

periodi-

25

extremely

1S

fi

Iter

hours

engine

THIS

GINE.

TRACTOR

AIR

FREELY

THE

STARTER

AND

OVER

BLOCK.

CU

MULATED

GINE

WILL

DAMAGE

starter

MUST

AROUND

SCREEN

THE

KEEP

THESE

DIRT

OVERH

TO

MOVING

aar

HAS

BE

THE

FINS

AND

EAT

.

AN

AIR

COOLED

ABLE

TO

CIRCULATE

ENGINE, THROUGH

AND

AIR

CLEANER,

OF

THE

CYLINDER

AREAS

TRASH

PARTS

AND

.

FREE

OR

RESULT

OF AC-

THE EN-

screen

EN-

IN

3.

Coat

foam fil

S.A.E.

to

spread.

4.

Re-install

Under

erratic

element

2.

3.

4.

the

replaced

NEVER

extremely

afte

1.

Remove wing

cover.

Separate

ment

fi

Iter

Replace

ment.

Re-assemble.

It

is

reco

inner

must

from

yearly.

RUN

CLEANER

IN

PLACE

4979R-25.6.73

ter

with

No.

30

engine

Wring

foam

r completing

inner

outer

pre-cleaner.

inner

mmended

element

excess

filter.

dusty conditions

be

replaced.

nut

and

ele-

foam

ele-

that

be

YOUR

COMPLETELY

ON

THE

three

oil.

Knead

oil

above

procedures,

ENGINE

ASSEMBLED

ENGINE.

(3)

tablespoons

into

foam

from foam

or

if

engine

FIG.

16

WITHOUT

the

of

filter

filter.

runs

inner

AIR

AND

- 8 -

The

tating

screen

and

leaves

must

the scr

the

Tractor

become

of

the

it

and

starter

screen

guard),

from

be

cleaned

eens

dirty. This

engine.

the

starter

screen

(located

ore

will

is

used.

Remove

FIG.

guard

directly

designed

ente

ring

periodically.

vary

with

They

would

the

rotating

17

(A),

to

the

cooling

the

should

interfere

screen

screen

and

the

behind

keep

gross,

system.

The

cleaning

conditions

not

be

with

guard

regularly.

starter

the

starter

in

allowed

the

cooling

(A),

ro-

chaff

They

of

which

to

clean

engine

STOP

BEFORE

.

BE

AND

ING OIL

ENGINE

SURE

ENGINE

~

OIL

lubrication

AND

CHECKING

TRACTOR

IS

STOPPED

L~VEL.

FILL

PLUG

1\

WAIT

OIL

IS

SEVERAL

LEVEL

ON

LEVEL

BEFORE

MINUTES

GROUND

CHECK

-

transaxle

lubrication

Rear

1.

2.

3.

Check

To

check

axle.

Change

eration.

oil in

To

fill

30

motor

F ill

throu

wheel

oi I

in

oil

Oil

level

oi I in

To

suitable

transaxle,

o il for

gh

is

transaxle

level,

drain,

filler

{transmission)

FIG.

19

removed

should

transaxle

service

for

illustrating.

every

50

hours

remove

remove

container.

use 5 qts. of All

plug

be

MM

as

filler

even

after

drain

or

shown.

500

MS

plug

with

plug

or

of

operation

from tr

this

hours

and

state

equ

plug.

of op-

catch

S.A.E.

ival

.

ans-

ent.

FIG.

18

1.

Change

operation.

changed.

2.

To

side

3.

Refill

under "Fuel

3

operation

correct

4.

After

after

dirty

hours

NOTE: THE

THE

TIME

FOREIGN

oil

drain

oil,

of

engine.

engine

pints.

Check

level

first

each

or

dusty

of

operation.

END

OF A DAY'S

THE

and

OIL

MATERIAL IS

in

crankcase

Engine

unscrew oil

Catch

crankcase

and

Lubricant

oil

add

on

oil

change,

25

hours

conditions,

BEST

IS

TIME

HOT

after

sho

uld

drain

oil

with oil

level aft

oil,

if

necessary,

dipstick.

oil

of

operation.

TO

OPERAT

AND

SUSPENDED

FIRST

be

worm

plug

in

suitable

" ,

page

er

each 8 hours

should

change

DRAIN

ALL

OIL.

IMPORTANT: BE

PREVENT

FROM

OR

TRANSMISSION

LEVEL

4979R-25

DIRT

ENTERING

OR

.6.

73

EXTREMELY

OR

FOREIGN

THE

ENGINE

WHEN

CHANGING

CHECKING

OIL.

2 HOURS

when

oil

at

lower

R. H.

container.

as

instructed

6.

Capacity

to

bring

be

changed

In

extremely

oil

every

OIL

IS

ION

AT

WHIC

DIRT

IN

AND

THE

CAREFUL

PARTICLES

CRANKCASE

of

is

of

to

15

AT

H

TO

OIL

- 9 -

~~

BEFORE

B.

ACKING

__

·

~

'

_

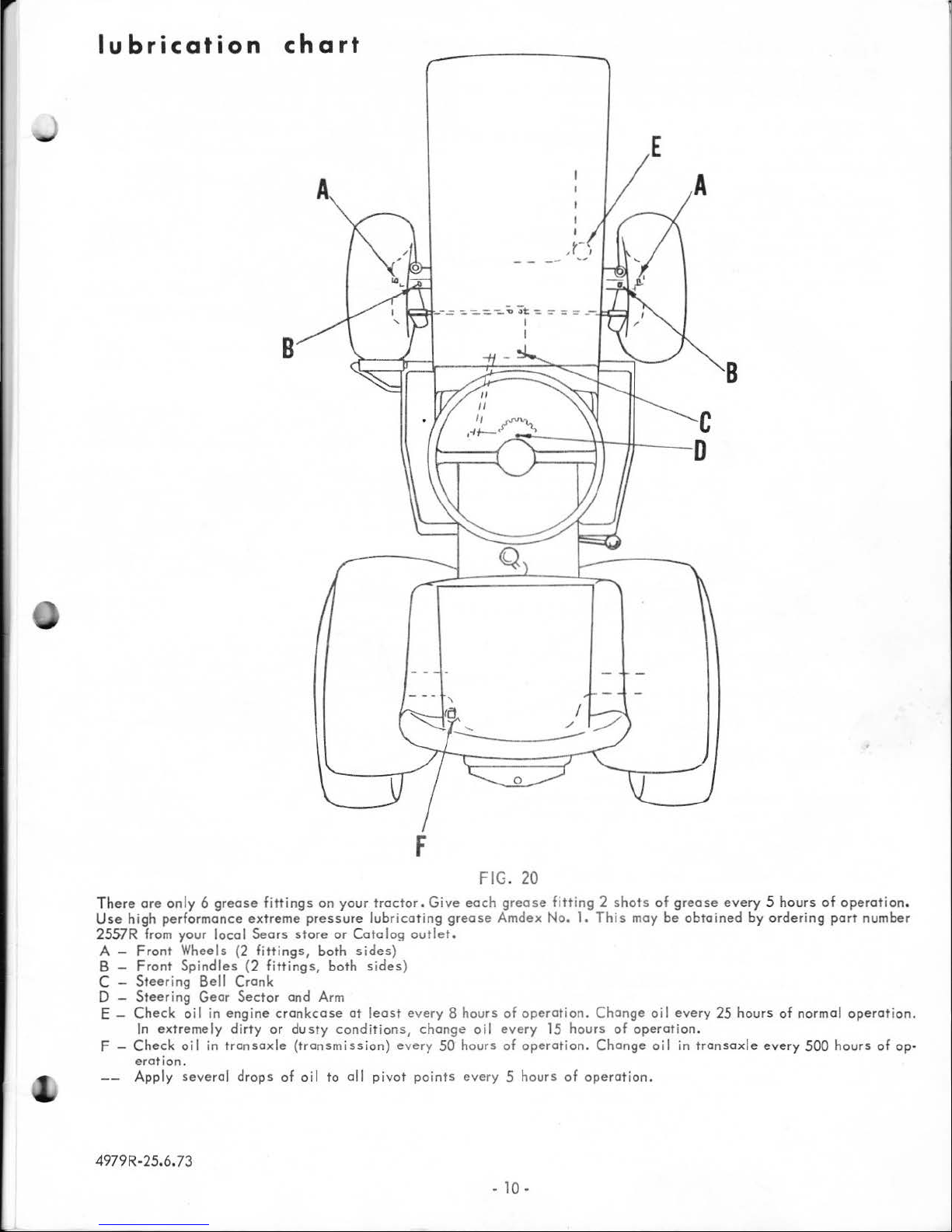

lubrication

chart

8

--

-=

~-;..-:;.-_;,

':;'t

1

I

"::.

=-::

=-

--

8

There

ore

Use

high

performance

2557R from

A

Front

B

Front

C -

Steer

D -

Steering

E-

Check

In

extremely dirty

F

-Check

erotion.

--

Apply

only 6 grease

your

local

Wheels (2

Spindles

ing

Bell

Gear

oil in

oil

in

several drops

fittings

extreme

Sears

store

fittings,

(2

fittings,

Cronk

Sector

engine

transoxle (tr

and

crankcase

or

dusty

of

on

pressure

both

Arm

ansmission)

oil

4979R-25.6.73

your

tractor.

lubricating

or

Catalog

sides)

both

sides)

at

least

conditions,

to

all

pivot

F

Give

each

grease

outlet.

every 8 hours

change

every

SO

hours

points

every 5 hours

FIG.

grease

Amdex No.

of

oil

every

of

- 10 -

20

fitting 2 shots

operation.

15

hours

operation.

of

l.

This

Change

of

Change

operation.

of

grease

may

be

obtained

oil

every

operation.

oil

in

every 5 hours

25

hours

tronso

xle

by

ordering

every

of

of

port

normal

500

operation.

number

operation.

hours

of op·

Loading...

Loading...