Sears 917.257070 Owner's Manual

I Sears I

MODEL

917.257070

~?'?

&~

___,

NO.

OWNER'S

MANUAL

D®

Dao[po

lJWO[ill

DaY!LID~®

®ill~LIDrn[ill

Assembly

Maintenance

ll~ill~ll®~

Operation

Repair

Parts

Sears,

Roebuck

and

Co.,

Chicago,

Ill.

60684,

U.S.A. and

Simpsons

Sears

Limited,

Toronto,

Canada

.....

=-

·····\.•,

\, ~ , tK

., ,

,..•

v.,,'(~

.f.0 /

vARD

¥ '

'1

l ·

•IV,.

CARE

CONGRA

Twin

and manufactured

Should you experience any problem you cannot easily

remedy,

Simpsons

trained technicians and the proper tools and parts

or repair this unit.

Please

you

Always observe the

YOUR

,I

GARDEN

FEATURES

OPPOSED-PISTON, FOUR CYCLE,

H.P.

power

moval tasks.

TULATI

Hydro Garden Tractor. It

please

Sears

read

to

assemble,

ONS

on

your

purchase

has

to

give you dependability

contact

and retain this manual. The instructions

your

nearest

Limited sto

operate and maintain

NEW

re.

They have competent, well-

"R

ULES FOR SAFE OPERATION'.

SEARS

TRACTOR

...

ENGINE--to

to

take on a vari

run smooth ly

ety

of

and

yard, gardening

of a Sears

been designed, engineered

and

Sears,

Roe

buck and

your

Tractor properlx.

TWIN-CYLINDER

quietly

with

18 H.P.

performance.

Co.

to

service

will

enable

plenty

or

snow

or

18

of

re-

.n

--

_,u...

,..---,.--

I

< ,.

~£;.

__

.

_

GARDENS

SAFETY IN

when Drive Control Lever

Pedal

AUTOM

no

clutching. Regulate tractor

Drive Control Lever. Move lever forward from neutral

increase forward speed. Move Lever rearward

and regulate backward speed.

SE

RVICE HOUR METER--lets you

mainten

CONTRO

nition

Switch

use.

AT

TAC

Sears

42 AND 48 INCH MOWERS

to lift

LITTER

conventional lawn

only

SELF POWERED ROTO-TILLER

lawns

OTHER

Disc Harrow, Drag Harrow

CHEVRON Tl

or

SNOW BLOWER handles wet, heavy or powdery snow

ease

TERLOCK SYSTEM

is

in

"OFF"

ATIC TR

ance

L PANEL--with

Switch, Service Hour Meter and Power Assist

for

HMENT V

Yard

grass

the rotary brush touches the ground.

and

snow.

.

position.

ANSMISSION

is

due.

Three Point Hitch conveniently grouped

ERSATILITY

and

Garden Tractor Attachments including

up

for

sweepers

RES

level cuts.

wit

for

WHISK LAWN SWEEPER is more

gardens

SOIL TILLAGE

--a

llows engine

is

in neutral and

--means

speed

Throttle,

--handles a

with

because

h a 30 or 38 inch wide

ATTACHMEN

and

Cultivator.

added traction in l

Attachment

no gearshifting and

and direction

to

know

at a glance, when

Choke, Light Switch ,

large

three

"high-lift

of

its wheel-less design;

prepa

res

TS including Plow,

oose

to

back tractor

efficient

soil

tilling

start

only

Clutch

with

the

to

Ig-

Lift

for

ease

of

variety

soil, gravel

of

...

" blades

than

for

new

path.

with

SNOW

REMOVAL

WARRANTY.

RULES FOR SAFE OPERATION

ASSEMBLY INSTRUCTIONS

OPERATION INSTRUCTIONS

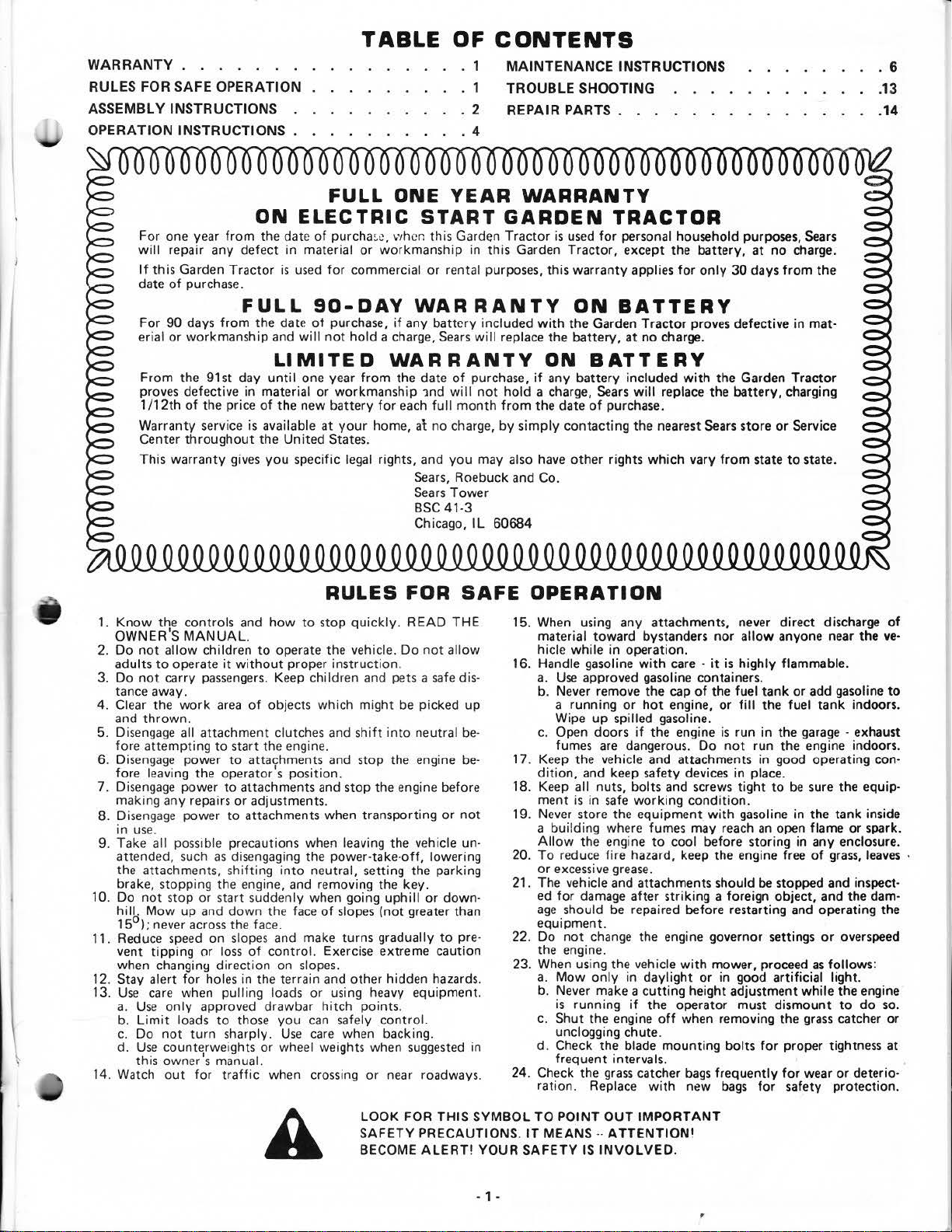

TABLE OF

.

CONTENTS

1

MAINTENANCE

1

TROUBLE SHOOTING

. 2

REPAIR PARTS

.4

INSTRUCTIONS

. . •

.6

.13

.14

ON

For

one year

will

repair any defect in material

If

this

date

of

Garden

purchase.

from the date

Tractor

is

FULL

For

90

days

from

erial

or

workma

the date ot

nship and

LIMITED

From

the 91st day

proves defective

1/12th

of

the price

Warranty service

Center

throughout

Th

is

warranty

1.

Know

the controls and

OWNER 'S

2.

Do

ad

ults

3.

Do

tance away.

Clear the

4.

and

5. Disengage all attachment clutch

fore attempting to start the engine.

6. Disengage p

fore leaving the operator's posit

7.

Disengage power

making any repairs

8. Disengage power

in

use

9.

Take all

attended, such

the attachments, shifting

brake, stopp ing the

10. Do

hill.

15°);

11. Reduce

vent tipping

wh

en changiny

2.

Stay alert

1

13.

Use

a.

Use only appr

b. Limit

c.

Do

Use

d.

th is owner's

14

. Watch

MANUAL.

not

allow

to operate

not

thrown.

.

not

Mow

never across the face.

care when pulling l

children

carry

passe

work

area

ow

er to attachments and stop the engine

poss

ibl

e precautions when leaving the vehicle u

as

stop

or

start suddenly when going

up and

speed

on sl

or

loss

direction

for hol

loads

not

counterweights

out

to

turn

manual.

for

until

in

material

of

the

is

available

the

United States.

giv

es

you

how

to

it

to

to

dow

es

oved drawbar

sharply. Use care when backing.

traffic

operate the vehicle.

without proper instruction.

ngers. Keep

of

objects which might

attachments and

or

adjustments.

attachments when transporting

disengaging the power ·take·off, lowering

into

engine

, and remov

n the face

opes

and make turns gradually

of

control.

on slopes

in the terrain and other hidden hazards.

oads

those

you

or

wheel weights when suggested in

when crossing

FULL

ELECTRIC

of

purcha~c.

used

for

90-DAY

purchase,

will

not

ONE

START

••,hen

or

workmanship in this Garden Tractor, except the battery,

commercial

this Garden

or

WARRANTY

if

any

hold

a charge,

battery

WARRANTY

one year

new

specific legal rights, and

from

or

workmanship 1nd

battery

at

your

the date

for

home,

each

full

ai

no

Sears, Roebuck and Co.

Sea

rs

sse

Chicago, I L 60684

RULES

to

stop

quickly.

children and pets a

es

and

shift

ion.

stop the engine before

neutral, setting the parking

ing the key.

of

slopes

Exercise extreme caution

.

or usin

g h

hit

ch points.

can

safely

FOR

READ

Do not

be

picked up

into

neutral

uphill

or

(not

greater than

eav

y equipment.

control.

or

near roadways.

safe

YEAR

WARRANTY

GARDEN

Tractor

rent

al

purposes, this warranty applies

is

used

ON

includ

ed

with

Sears will

replace

the

the

battery,

ON

of

purchase,

will

not

month

charge,

you

may also have

Tower

41·3

SAFE

THE

allow

dis-

bebe-

or

not

n-

down-

to

pre-

if

any

hold

a charge,

from

the date

by

simply

contacting

other

OPERATION

15. When using any attachments, never direct discharge

material toward bystanders nor

hide

16. Handle gasoline

17

18. Keep

19. Never store the equipment

20.

21. The vehicle and attachments should

22.

23. When using the vehic

24. Check the

while

a.

Use

b. Never remove the cap

a running

Wipe

Open doors

c.

fumes

. Keep the vehic

dition,

ment is in

a building where fumes may reach

Allow

To

reduce

or

excessive

ed

for

age

should

equipment.

Do

not

en

the

a.

Mow

b.

Never make a

is

running if the operator must

c. Shut the engine

unclogging chute.

Check the blade

d.

frequent intervals.

ration. Replace

TRACTOR

for

personal household purposes,

for

only

30

at

days

no

Sears

charge.

from

the

BATTERY

Garden

Tractor

at

no

proves defective in

charge.

mat·

BATTERY

battery

all nuts, bolts and screws

gine.

included

Sears

will

of

purchase.

the nearest

rights

in operation.

approved gasol ine containers.

or

up

spilled gasoline.

are

dangerous. Do

and keep safety devices in place.

the engine

damage after striking a foreign object, and the dam·

le

safe

working

fire

hazard, keep the engine free

grease.

be

repaired before restarting and operating the

change the

only

in

grass

with

replace the

which

with

hot

engine,

if

the engine

and attachments in good operating con·

to

engine governor settings

le with

daylight

cutting

off

mou

catcher

with

the Garden

battery,

Sears

store

vary

from

allow

care ·

it

is

highly

of

the fuel

or

fill

is

run

not

condition

cool before storing in any enclosure.

height adjustment

when removing the

nting bolts

bags

new

tight

with

gasoline

mower, proceed

or

in good

frequently

bags

Tractor

charging

or

Service

state

to

state.

anyone near

flammable.

tank

or

the fuel

in

run

.

an

be

for

for

add gasoline

tank indoors.

the

garage

the engine indoors.

to

be

sure the equip·

in

the tank inside

open flame

of

grass,

stopped and inspect·

or

as

artificial

dismount

follows:

light

while

grass

proper

for

tightness

wear

safety protection.

the

· exhaust

or

overspeed

.

the engine

to

do

catcher

or

deterio·

ve·

spark.

leaves

so.

of

to

·

or

at

A

LOOK

FOR

THIS SYMBOL

SAFETY PRECAUTIONS.

BECOME

ALERT! YOUR SAFETY

. 1 .

TO

POINT OUT IMPORTANT

IT

MEANS .. ATTENTION!

IS

INVOLVED .

I

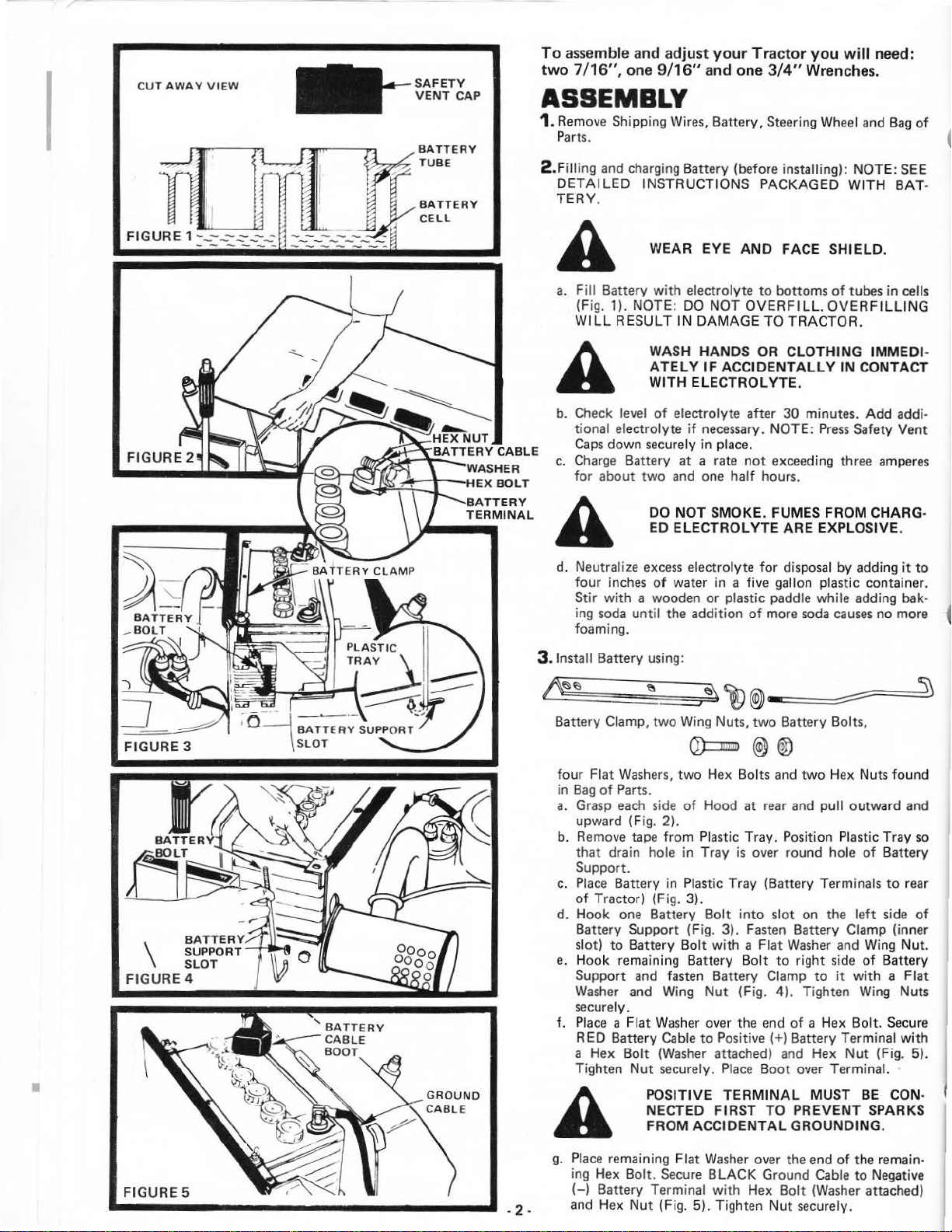

CUT AWAY VIEW

FIGURE 1

::

~-:.

, I

I

rrBA

......

_

..::.::.-:.

...::

___

------

-

--

----

-

SAFETY

VENT

BATT ERY

'?':

TUBE

TT

CELL

CAP

ERY

To

assemb

two

7

/16",

le

and adj u

st

one 9/16" and one 3/4" Wrenches.

ASSEMBLY

1.

Remove Shipping Wires, Batter

Parts

.

.Filli

ng

2

and charging Battery (before installing): NOT E:

DETAILED

TERY

INSTRUCTIONS PACKAGED WITH BAT-

.

WEAR EYE

A

a.

Fill Battery

(Fig.

WILL

A

b.

Check

tional electrolyte

Caps

c.

Cha

rge

for

about

with

1).

NOTE :

RESULT IN DAMAGE

level

down securely in place.

Battery at a rate

electrolyte

DO

WAS

H HANDS OR CLOTHING IMMEDIATELY

WITH

ELECTROLYTE.

of

electrolyte after

if

two

and one

your Tractor you wi

y,

Steering

AND

NOT

IF ACCIDENTALL

necessary. NOTE:

to

OVERFILL.

TO

not

exceeding three

half

hours.

Wheel

FACE SHIELD.

bottoms

TRACTOR.

30

minutes.

Press

ll

need:

and

Bag

of

SEE

of

tubes in cells

OVERF

Y IN CONTACT

ILLING

Add

addi-

Safety Vent

amperes

)

':

BAT TER Y

-BOLT

\

FIGURE 4

BAT

TERY

SUPPORT

OT

SL

DO

NOT

ED ELE CTRO

SMOKE. FUMES FROM CHARG·

LYTE

ARE EXPLOSIVE.

A

d. Neutralize

four

Stir

ing

foaming.

3 .1nstall Battery using:

Battery

four Flat

in

Bag

a. Grasp

upward (Fig.

b. Remove tape from Plastic Tray. Position Plastic Tray

that drain hole in Tray

Support.

c.

Place

of

Tractor) (Fig. 3).

d. Hook one Battery

Battery Support (Fig. 3).

slot)

e.

Hook remaining Battery

Support and fasten Battery Clamp to

Washer

securely.

f.

Place

RED Battery

a Hex Bolt

Tighten

excess

electrolyte

inches

of

water in a five gallon plastic container.

with

soda

Clamp,

a wooden

until

two

or

the addition

Wing Nuts, two Battery Bolts,

Q):::DD

Washe

rs,

two

Hex Bolts and

of

Parts.

each

side

of

Hood at rear and pull outward and

2).

Batter y in Plastic Tray (Battery Terminals

Bolt

to

Battery

and Wing

a Flat

Nut

Bolt

Washer

Cable

(Washer

securely.

with a Flat

Nut

over the end

to

for

disposal by adding

plastic paddle while adding bak-

of

more

soda

causes

@)

®

two

Hex Nuts found

is

over round hole

into

slot on the

Fasten

Bolt

(Fi

Positive (+

attached) and Hex

Place

Battery Clamp (inner

Washer

to right

g.

4).

of

)Battery

Boot over Terminal.

and Wing Nut.

side

it

Tighten Wing Nuts

a Hex

left

with a Flat

Bolt. Secure

Terminal

Nut

no more

of

Battery

to

side

of

Battery

(Fig. 5).

it

to

so

rear

of

with

•

FIGURE 5

POS

ITIVE

NECTED FIR ST TO PREV

A

g.

Plac

e remaining Flat Washer over the end

ing Hex Bolt.

(-)

Battery Terminal

. 2 . and Hex Nut (Fig. 5). Tighten

FROM ACCIDENT

Secure

TERMIN

BLACK

with

Hex

AL MUST

AL GROUNDING.

Ground

Cab

Bolt

(Washer

Nut securely.

BE

ENT

of

the remain-

le

to

CON·

SPAR

KS

Negative

attached)

4.

1nstall Steering Wheel using: Flat

Hex

Bolt

assembled

Key, and Steering

a.

Remove

Steering

b.

Insert

slide Steering

SURE WOODRUFF

SHAFT

c. Fasten

(Fig. 6). Tighten securely.

d.

Press

INITIAL

1.

Reduce

(Tires

2.

Seat

loosening Nut in

TIGHTENI NG NUT AFTER ADJUSTMENT.

SEAT PLATE HAS NOT TWISTED

MENT WITH SEAT SPRING.

Hex Bolt, Lockwasher and Flat Washer from

Shaft (Fig. 6).

Woodruff

.

with

Steering Wheel Insert

ADJUSTMENTS

Tire

pressure

were

overinflated for shipping purposes).

position

may

on

end

Wheel

Key in Keyway

Wheel

over Shaft and Key. NOTE:

KEY

Flat

Washer,

to 12 pounds in

be

adjusted forward or backward

Seat

Plate (Fig. 7). NOTE

Washer,

of

Steering Shaft; Woodruff

Insert found in

IS

SECURE IN STEER lNG

Lockwasher and

in

place.

Lockwasher, and

Bag

of

of

Steering Shaft and

Hex

front

and r

ear

WH-EN

MAKE

OUT

OF

ALIGN·

Parts.

BE

Bolt

Tires.

by

RE·

SURE

STEERING--~

WHEEL

INS

ERT

STEER I

FIGURE 6

3. The

By-Pass

rotates

Plate. Moving the Handle up or down

notch

The

By-Pass

down tight)

Index handle up

sary

to

NOTE:

Valve Handle (Fig. 8) slides in and out, and

so

that Handle

will

open

push

Do

not

or

Valve must

for

tractor

force Valve.

THIS

SAFETY

STARTING

WHILE

PEDAL

11)

IS

POSITIONS (FIG. 12).

IMMEDIATELY

THAT

ORDER.

THE

will

close By-Pass

be

tractor

at

IN

to

least

four

with

engine stopped.

TRACTOR

SWITCHES TO PREVENT

OF

THE

IS IN THE

AND

THE

" F" FORWARD

ARE

NOT

DO

PURPOSE

NOT

engage

the notch in Rotating

with

Handle engaging

Valve.

in closed

operate

notches

THE

ATTACHMENT

"ON"

DRIVE

REPLACE SWITCHES

IN

ATTEMPT TO

OF THESE SWITCHES.

pos1t1on

with

engine running.

if

it

becomes

IS EQUIPPED

TRACTOR ENGINE

POSITION (FIG.

CONTROL LEVER

OR " A"

PROPER WORKING

CLUTCH

REVERSE

DEFEAT

(rotate

neces

WIT

H

-

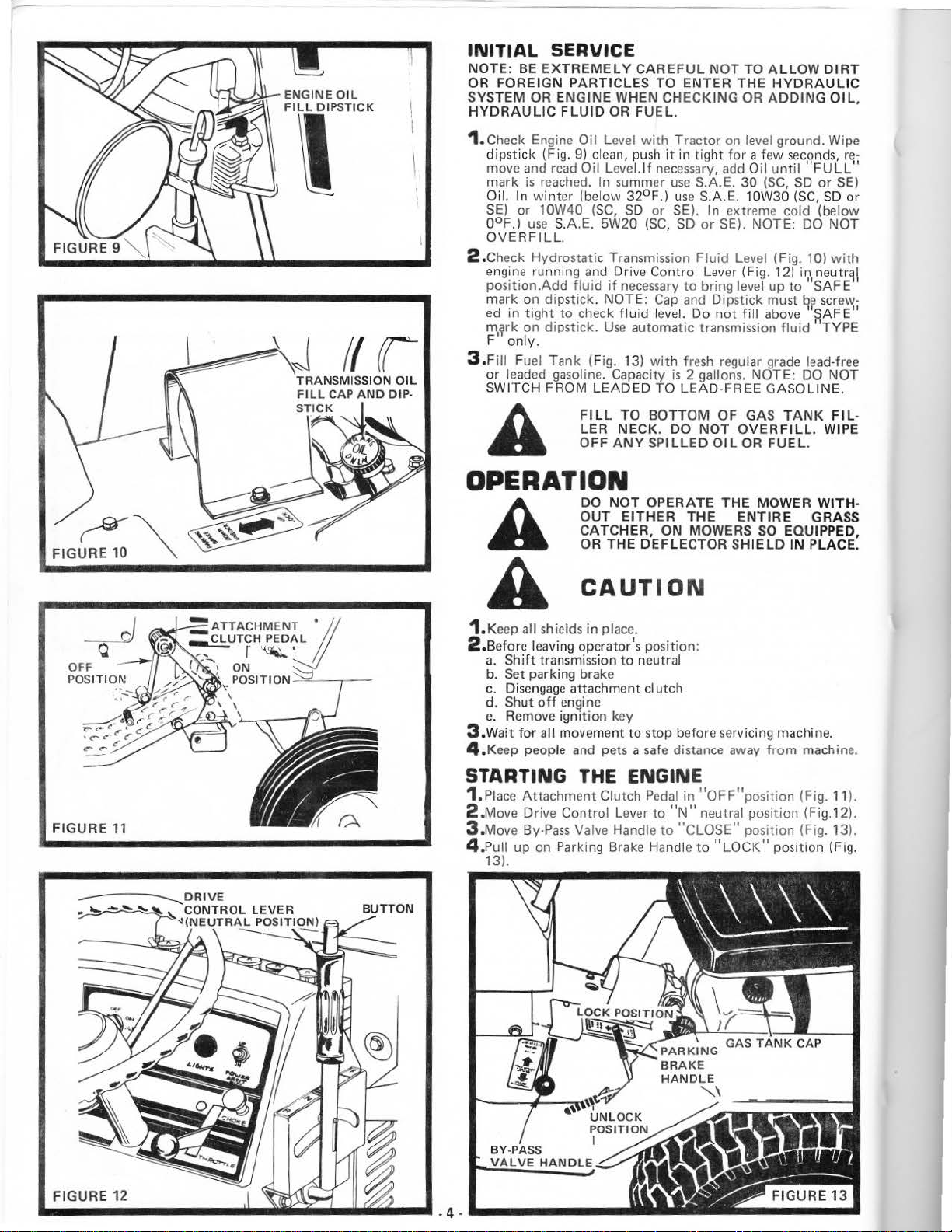

INITIAL

NOTE: BE

OR FOREIGN

SYSTEM OR ENGINE

HYDRAULIC

SERVICE

EXTREMELY

PART

FLU

ID OR

CAREFUL

ICLES

TO

WHEN CHECKING OR

FUEL.

NOT

ENTER

THE

TO A

ADDING

LLOW

HYDRA

DIRT

ULI

OI L,

C

1. Check Engine Oil Level

dipstick (Fig. 9)

move and read

ma

rk

is

Oil.

SE) or

ooF.)

OVERFILL.

2 .Check Hydrostatic Transmission

engine

position.Add

mark on dipstick. NOTE:

ed in

m,~rk

F only.

3.Fill Fuel

or

SWITCH FROM

rea

In

winter

10W40 (SC,

use

running

tight

on dipstick.

leaded gasoline. Capacity

clean, push it in tig

Oil

ched. In summer

(below

S.A.E. 5W20

and

fluid

to

check f

Tank (Fig. 13)

LEADED

FILL

LER

OFF

with

Tractor

Level.

If

necessary, add Oil

32°F.) use S.A.E. 10W30

SO

or SE).

(SC,

Drive Control Lever (Fig. 12) in neutral

if

necessary

Cap

lui

d level. Do not fill above

Use

automatic transmission

with

TO

TO BOTTOM OF GAS

NECK

. DO

ANY

SPILLED

ht

use

S.A.E.

In

SO

or

Fluid

to

bring level up

and

fresh

is

2 gallons. NOTE:

LEAD-FREE GASOLINE.

NOT

OPERATION

DO

NOT

OPERATE THE MOWER W

EITH

ER

THE

THE

DEFLECTOR

ION

A

OUT

CATCHER, ON MOWERS

OR

CAUT

A

1. Keep all shields in place.

le

avi

ng

2 .Before

a.

Shift

b.

Set

parking brake

c.

Disengage

d. Shut

e.

Remove ignition key

.W

ait

3

4.

for

Keep people and pets a safe distance away

operator's position:

transmission

attachment

off

engine

all movement

to

neutral

clutch

to

stop before servicing machine.

on l

eve

l ground . Wipe

for

a few

secf?nds,

until'

30

(SC,

extreme cold (below

SE). NOTE: DO

Level (Fig. 10)

Dipstick must

regu

lar grade lead-free

OVERFILL.

OIL OR

ENTIR

SO

SHIE LD

FULL"

SO

or

(SC,

to

"SAFE"

q~

SAFE"

fluid

"TYPE

DO

TANK FIL

FUEL.

E GRASS

EQUIPPED,

IN

PLACE.

from

machine.

sc

re-

SE)

SO

or

NOT

with

rew·

NOT

WIPE

ITH

·

-

FIGURE

FIGURE

11

12

STARTING

1.

Piace

Attachment Clutch

2 .Move Drive

3.

Move

By-Pass Val

4.Pull

up

13).

on Parki

BY-PASS

VE HANDLE

THE ENGIN

Co

ntrol

Lever

ve

Handle

ng

Brake Handle

Pedal

to

to

E

in

"OFF"position

"N"

neutral

"CL

OSE

to

"LOCK"

(Fig. 11).

posit

ion (F ig.12).

" position (Fig. 13

position (Fig.

).

5.

Push

Clutch-Brake

6.

Move

Throttle

7.

Pull Choke

8.

Turn Ignition Key

starts (Fig. 15).

Pedal

Control Lever

out

(Fig. 15).

Release

into

to

"START"

key

"BRAKE"

to

middle position (Fig. 15).

into

position (Fig. 14).

position

"ON"

position.

until

Engine

BRAKE

DRIVE

CLUTCH-BRAKE

PEDAL

NOTE:

FOR MORE

engine

Control Lever

try

NOTE: The Power Assist

lowers

Point Hitch (optional equipment).

WARMING UP

Move Throttle Control Lever

Choke in

WARM

When

in middle position, Choke may

DO

NOT RUN STARTER CONTINUOUSLY

does

again.

an

THAN

not

attachment when

THIRTY

start after

to

"F"

fast

several

pos

Lift

THE

to

as

engine warms. NOTE:

UP

FOR A FEW MINUTES BEFORE

restarting a warm engine,

ALWAYS WEAR SUBSTANTIAL FOOTWEAR

CLOTHING

IN MOVING PARTS.

LEARN TO START,

YOUR TRACTOR

SPACE.

move

AND

THAT

SECONDS

attempts, move

ition,

wait

Switch (Fig. 15)

used

with

AT

a few minutes, and

an

Electric Three

ENGINE

"s" slow

ALLOW

Throttle Control

not

AVOID

COULD GET CAUGHT

STOP

IN

pos1t1on. Push

ENGINE TO

OPE~ATING

have

to

LOOSE

AND

A LARGE,

A TIME.

throttle

raises

Lever

be

used.

FITTING

REVERSE

OPEN

If

or

.

TRACTOR

1.

With engine running and warm, move

to

Lever

2.

Push

position.

3.

Press

move

4.

Adjust Throttle Control Lever

that engine is

NOTE: Always operate power-driven equipment

tary Mower, Snow Thrower, etc. at full

otherwise specified in the attachment Owners Manual. Always

select a

the attachment being

middle position.

down on Parking Brake Handle

Button

Lev

er

safe

ground travel

OPERATION

(Fig. 12) on Drive Control L

forward and tractor

THE

SITIVE

MOVE

LY.

not

overloaded.

used.

DRIVE

CONTROL LEVER IS SEN-

TO THE SLIGHTEST MOVEMENT.

DRIVE

CONTROL LEVER SLOW-

to

desired engine

speed

that

will

5. To back-up, return Drive Control Lever

position

Lever

slowly.

and

to

"SLOW"

tractor

will

stop. Reduce

position,

NEVER PLACE

IN

OR

MENT

WHILE TRACTOR OR

ATTACHMENT

pull

UNDER

OR NEAR

ANY

Drive Control Lever back

YOUR HANDS OR FEET

ANY

IS RUNNING.

Thrott

le Con

tro

to

"UN

LOCK"

ever

and slowly

will

begin

to

move.

speed

so

such

as

Ro-

Throttle

POWERED ATTACH-

speed

unless

suit the terrain and

to

"N"

neutral

Throttle

MOVING PART

ANY

Control

POWERED

STOPPING

1.

l

Return Drive Control Lever

2.Reduce

3.P

iace

Attachment Clutch Pedal in

4.

Place

Parki

A

~

5.

Turn Ignition Key to

NOTE:

STOPS

CONTROL LEVER TO

THE CLUTCH-BRAKE PEDAL

THE TRACTOR

IN THIS POSITION. WHEN FOOT

PEDAL,

SPEED.

-

5-

USE

ONLY. FOR

TRACTOR

YOUR

Throttle

ng

CLUTCH-BRAKE PEDAL FOR EMERGENCY

Control

Brake in

MAKE

HOLD

REMOVE

TOR TO

NORMAL

AS

LONG AS THE PEDAL

NEVER

TO SLOW TRACTOR. ALWAYS

CLUTCH-BRAKE PEDAL

FORWARD

LEVER RETURNS TO

TRACTOR

to

"N''

neutral position.

Lever

to

"s" slow position.

"OFF"

"LOCK"

SURE PARKING BRAKE

TRACTOR SECURE.

"OFF"

PREVENT

NEUTRAL

WILL

USE

position.

position.

KEY WHEN LEAVING TRAC-

STOPS,

BY

HALF-WAY

RETURN TO

FOOT PEDAL

SO

THAT

position.

UNAUTHORIZED

RETURN

HAND

DEPRESSING

DECLUTCHES

IS

REMOVED FROM

TRAVELI

AS

ALL

DRIVE

NEUTRAL.

WILL

USE.

DRIVE

IS

HELD

NG

A CLUTCH

PUSH

THE

WAY

CONTROL

TRANSPORTING

TOWING IS

power transmission, internal

is

towed.

controls

1. Drive Control Lever in

2.

By-

3.

Parking Brake Handle pushed

tion.

Use

trailer to transport tractor

TRACTOR

1.

Avoid stopping on hills.

as

Pass

NOT

RECOMMENDED. As with any hydraulic

Push

tractor by hand

follows:

Valve in

OPERATION

DO

WI

TH SLOPES GREATER

DO

"N"

"OPEN"

NOT

NOT

YOUR

damage

neutral.

position.

down

for

DRIVE

DRIVE

TRACTOR

can

result when vehicle

only

short distances

to

"UN

long distances.

ON

UP

OR

THAN

ACROSS

LOCK"

HILLS

DOWN

15°,AND

ANY

with

posi-

HILLS

SLOPE.

STARTING

WITH

If

your

recharged.

follow

PED

THE OTHER

NEGA

A

1.

Connect

termina

cha

2.

Connect one

(-)

3.

Connect the other end

of

Tank

A

LOW

Battery

this procedure. NOTE: YOUR TRACTOR

WITH A 12

TIVE

ssis).

terminal

good CHASSIS GROUND

or Batt

is

If

"Jumper Cables" are

VOLT

VEHICLE

GROUNDED SYSTE M.

LEAD-ACID

PLOSIVE GASES.

AND

BATTERIES.

AROUN

each

end

ls

of

each

end

of

ery).

YOUR

BATTERY

too

low

to start the engine,

NEGATIVE

MUST ALSO

BATTERIES GENERATE EX-

SMOKING MATERI

D BATTERIES.

of

the RED cable

battery (taking

of

the BLACK cable

"GOOD"

battery.

of

the cable

TRACTOR

it

used

for

emergency starting

GROUNDED SYSTEM.

BE

KEEP SPARKS,

ALS

ALWAYS

to

the F"OSITIVE (+)

care

not

to

to

ENGINE BLOCK

on

tractor (away.

IS

A 12 VO LT

AWAY

SHIELD

to

short against

the NEGATIVE

sho

uld

EQUIP-

FLAME,

FROM

EYES

from

Gas

be

a.

If

slowing

slowly.

b.

If

stopping

neu

tral.

c.

Engage

d.

To resume travel push Drive Control Lever slowly for-

ward.

e.

Release

2.

Make."'ll turns gradually.

is

necessary,

is

necessary,

Parking Brake.

Parking Brake

~~

~~~~

pull Drive Control Lever back

pull Drive Control Lever

as

forward movement begins.

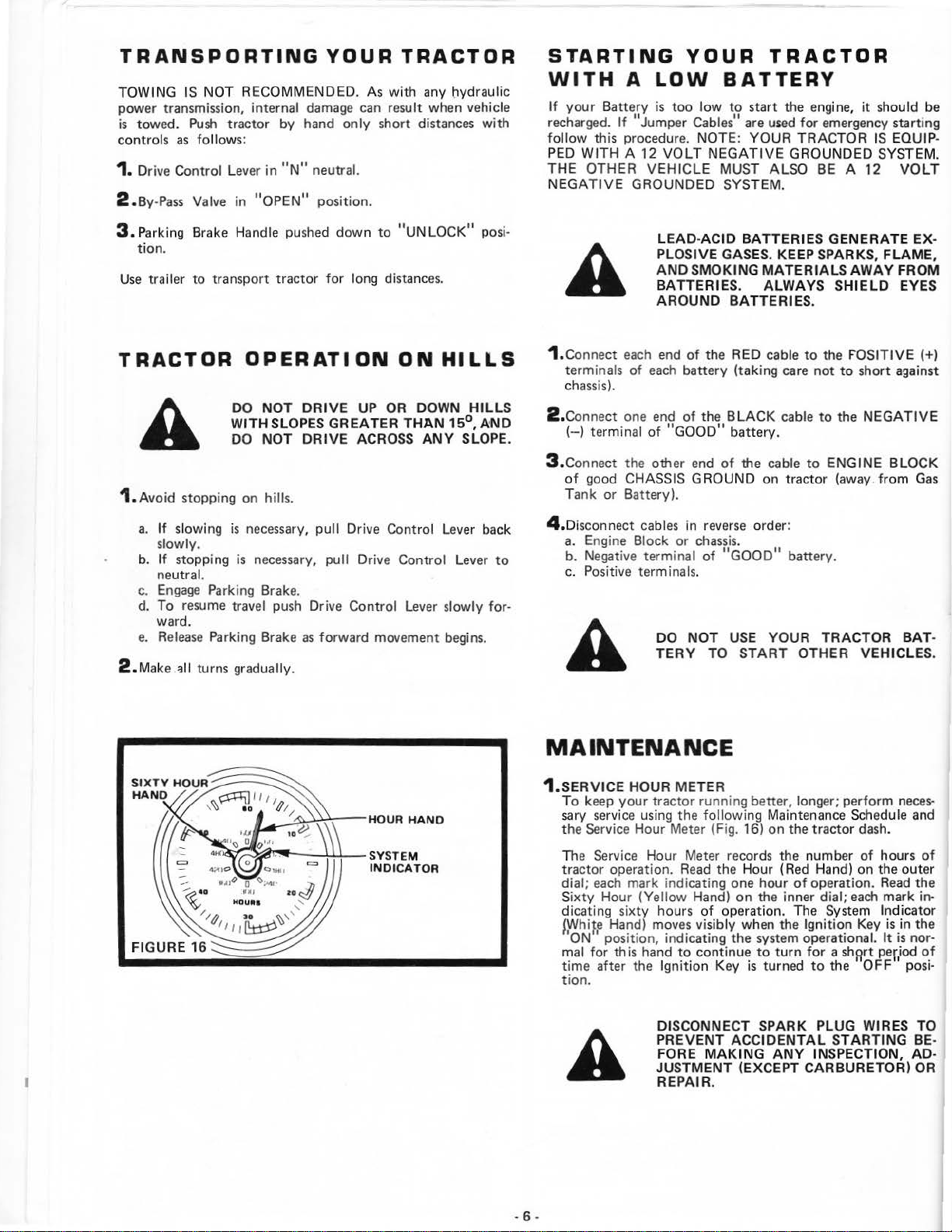

--~~-SYSTE

M

INDICATOR

to

4.

Disconnect cables in reverse order :

a.

Engine Block

b. Negat

c.

ive

Positive terminals.

or

terminal

DO

TE

RY

chassis.

of

NOT

TO

"GOOD"

USE

MAINTENANCE

1.

SERVI

CE

HOUR METER

keep

To

sary

the Service Hour Meter {Fig. 16)

The

tractor operation.

dial;

Sixty Hour

dicating sixty hours

~White

'oN"

mal

time

tion.

your tractor running better, longer; perform

service using the following Maintenance Schedule and

Service Hour Meter records the number

each

mark indicating one hour

Hand) moves visibly when the Ignition Key

pos

ition

for

this hand

after t

Read

the Hour (Red Hand)

(Yellow Hand) on the inner dial;

he Ignitio

of

operation. The System Indicator

, indicating the system operational.

to

continue

n Key is turned

YOUR

START

on

to

turn

battery.

TRA

CTOR

OTHER VE

the tractor dash.

of

operation.

for a shwt

to

the

of

on

each

'OFF'

HICLE

hours

the outer

Read

period

BA~

neces-

of

the

mark in-

is

in the

It

is

nor-

of

posi-

S.

DISCONNECT SPARK PLUG WIRES TO

PREVENT ACCIDENTAL S

FORE

A

-

6-

JUSTMENT (EXCEPT CARBUR ETOR) OR

REPAIR.

MAKING

ANY

TARTING BE-

INSPECTION, AD-

FIRST

~

HOURS

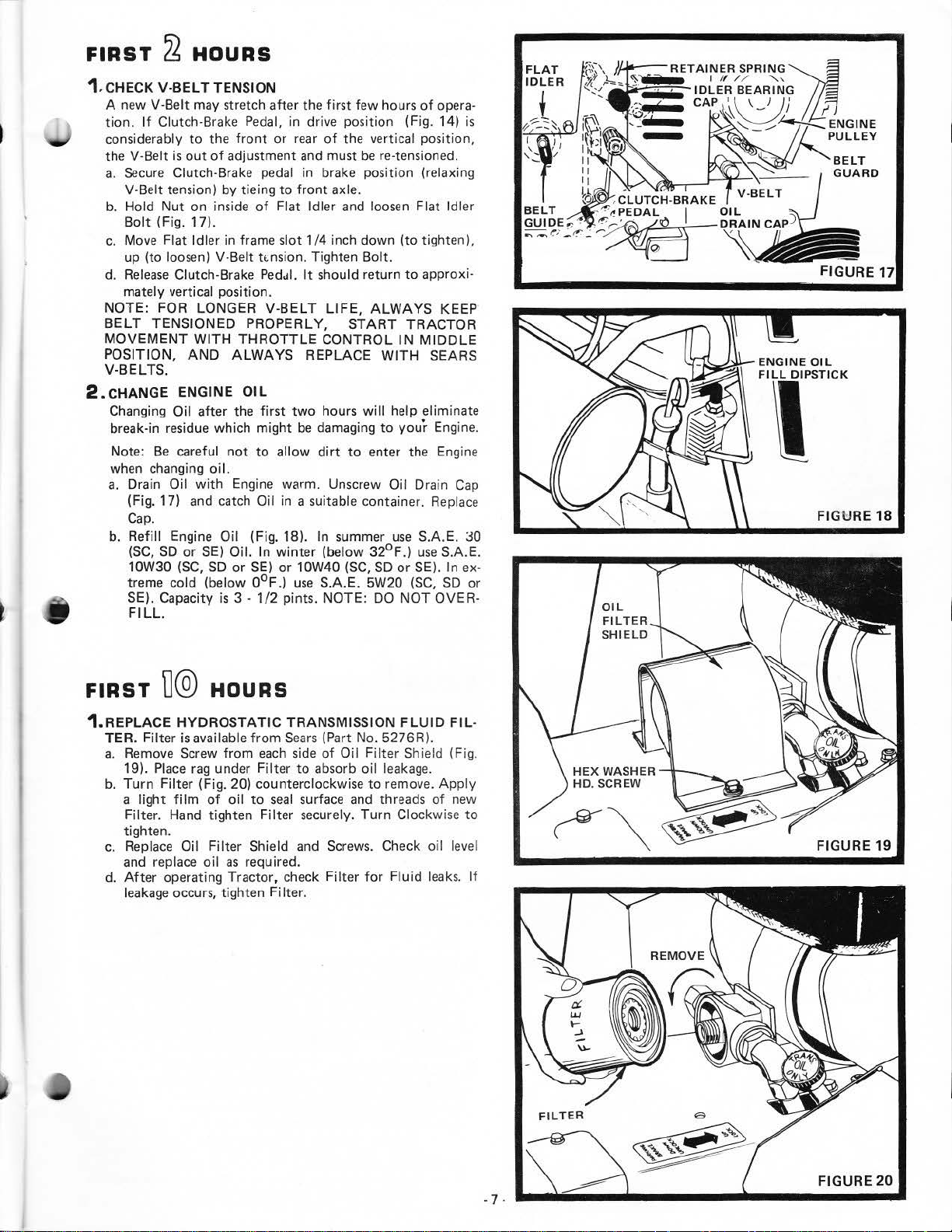

1. CHECK V-BEL T TENSION

A new V-Belt may stretch after the

If

tion.

considerably

he

t

a.

b. Hold

c.

d.

NOTE: FOR LONGER V-BE LT

BELT

MOVEME

POSITION,

V-BELTS.

2 . CHANGE

Changing Oil after the

break-in residue which

Note:

when changing

a.

b. Refill Engine Oil (Fig. 18). In summer

Clutch-Brake Pedal. in drive position (Fig. 14)

to

the

front

or

V-Belt

is

out

of

adjustment

Secure

V-Belt tension) by tieing

Bolt

Move Flat Idler in frame slot 1/4 inch down (to tighten

up (to loosen) V-Belt tt:nsion. Tighten Bolt.

Release

mately vertical position .

Clutch-Brake pedal in brake position (relaxing

to

Nut

on inside

(Fig.

17).

Clutch-Brake Pedul.

TENSIONED PROPERLY, START

NT

WIT

AND

E

NGINE

Be

careful

Drain Oil

(Fig. 17)

Cap.

(SC,

10W30 (SC,

treme cold (below

SE). Capacity

FI

LL.

SD

or

with

and

SE)

of

Flat Idler and loosen Flat Idler

H THROT

ALWAYS REPLACE

OIL

first

might

not

to

allow

oi

l.

Engine warm. Unscrew Oil Drain

catch Oil in a suitable container. Replace

Oil. In

SD

is

or

3 ·

SE)

0°F

1/2

winter

or

.)

first

few hours

rear

of

the verti

and

must

front

axle.

It

should return

LIFE,

TLE

CONTROL

two

hours

be

damaging

dirt

to

(below

10W40

use S.A.E.

pints. NOTE:

(SC,

be

ALWAYS

will

enter the Engine

32°F

5W20 (SC,

of

opera-

cal

position,

re-tensioned.

to

approxi-

TRACTOR

IN MIDDLE

WITH

to

SO

DO

SEARS

help eliminate

your

Engine.

use

S.A.E. 30

.)

use

or

SE). In ex-

NOT

OVER-

is

),

KEEP

Cap

S.A.

E.

SD

or

E

NGIN

F

ILL

'

FIGURE 17

E OIL

DIPSTICK

FIGU

RE

18

FIRST

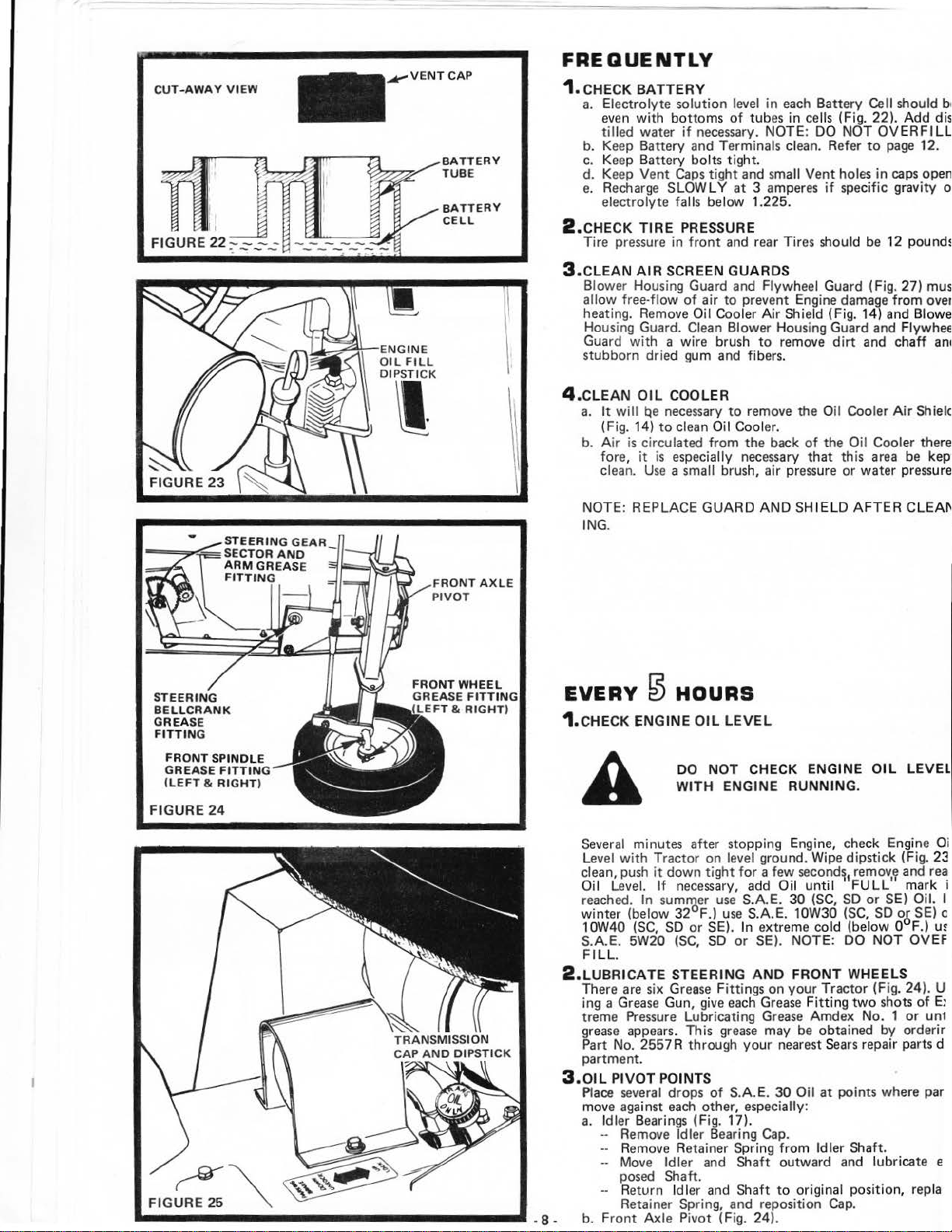

1.REPLA

TER. Fi

a.

b.

c.

d.

D@

CE HYDROSTA

lter

Remove Screw

19).

Place

Turn Filter

a

light

Filter. Hand tighten

tighten.

Replace Oil Filter Shield and Screws. Check oil level

and replace

After

operating Tractor, check

leakage

HOURS

is available

rag

(Fig. 20) counterclockwise

film

of

oil

occurs, tighten Filter.

TIC TRANSM ISSION FL

from

Sears

from

each

Filter

to

seal

Filter

side

to

surface and threads

securely.

under

oil

as

required.

(Part No. 5276R).

of

Oi I Fi Iter Shield (Fig.

absorb oil leakage.

to

remove.

Turn

Filter for

Clockw

Fluid

UID

of

leaks.

FIL

App

new

ise

·

ly

to

FIGURE 19

If

-1·

FIGURE

20

CUT-AWAY

VIEW

.....-VENT

CAP

BATTERY

TUBE

BATTERY

CELL

FREQUENTLY

1.

CHECK

a. Electrolyte solution

b.

c. Keep Battery bolts tight.

d.

e. Recharge

2.CHE

Tire pressure

BATTERY

level

even with bottoms of

water if necessary. NOTE:

tilled

in each Battery Cell should be

tub

es

Keep Battery and Terminals clean. Refer

Keep Vent Caps tight and small

SLOW

LY

at

3 amperes if specific gravity of

electrolyte falls below 1.225.

CK

TIRE PRESSURE

in

front and rear Tires should be 12 pounds.

in

cells (Fig. 22). Add dis·

DO NOT OVERFILL.

to

page 12.

Vent holes in caps open .

STEERING

BELLCRANK

GREASE

FITTING

FRONT

GREASE

(

FIGURE

SPINDLE

LEFT & RIGHT)

24

-'-'·--""""'-

FITTING

~1.&

~~-loNGINE

OIL

FILL

DIPSTICK

I

3.CLEAN

AIR SCREEN GUARDS

Blower Housing Guard and Flywheel Guard (Fig. 27) must

allow free·flow of air to prevent Engine

heating. Remove

Oil

Cooler

Air

Shield (Fig. 14) and Blower

dama~;~e

from over-

Housing Guard. Clean Blower Housing Guard and Flywheel

Guard with a wire brush

to

remove dirt and chaff and

stubborn dried gum and fibers.

4.CLEAN

a.

b.

NOTE:

OIL COOLER

It

will qe necessary

(Fig. 14)

Air

fore,

clean.

to

clean O

is circulated from

it

is

especially necessary

Use

a small brush, air pressure or water pr

REPLACE

to

remove the O

il

Cooler.

the

back of the

GUARD AND

il

Cooler Air Shield

Oil

that

Cooler there-

this area be

SHIELD AFTER CLEAN

lNG.

EVERY

1.CHE

0

HOURS

CK

ENGINE OI L LEVEL

DO

NOT

WITH

CHECK

ENGINE OIL

ENGINE RUNNING.

kept

ess

ure.

LEVEL

..

___________________

.. -8-

Several minutes after stopping Engine, check

Leve

l with Tractor on

clean, push

Oil

reached.

Level.

it

down tight for a few

If

necessary, add

In

sum~er

winter (below 32 F.)

1

OW40

(SC,

S.A.E. 5W20

F

ILL.

SO

(SC,

level

ground.

use S.A.E.

use

or SE).

S.A.E. 10W30

In

SO

extreme cold (be

or SE). NOTE: DO NOT OVEF

Wipe

second~

Oil

until FULL' mark i

30

(SC,

Engine

dipstick (Fig. 23

remov~

1

SO

or SE) Oil. I

(SC,

SO

low

0 F.)

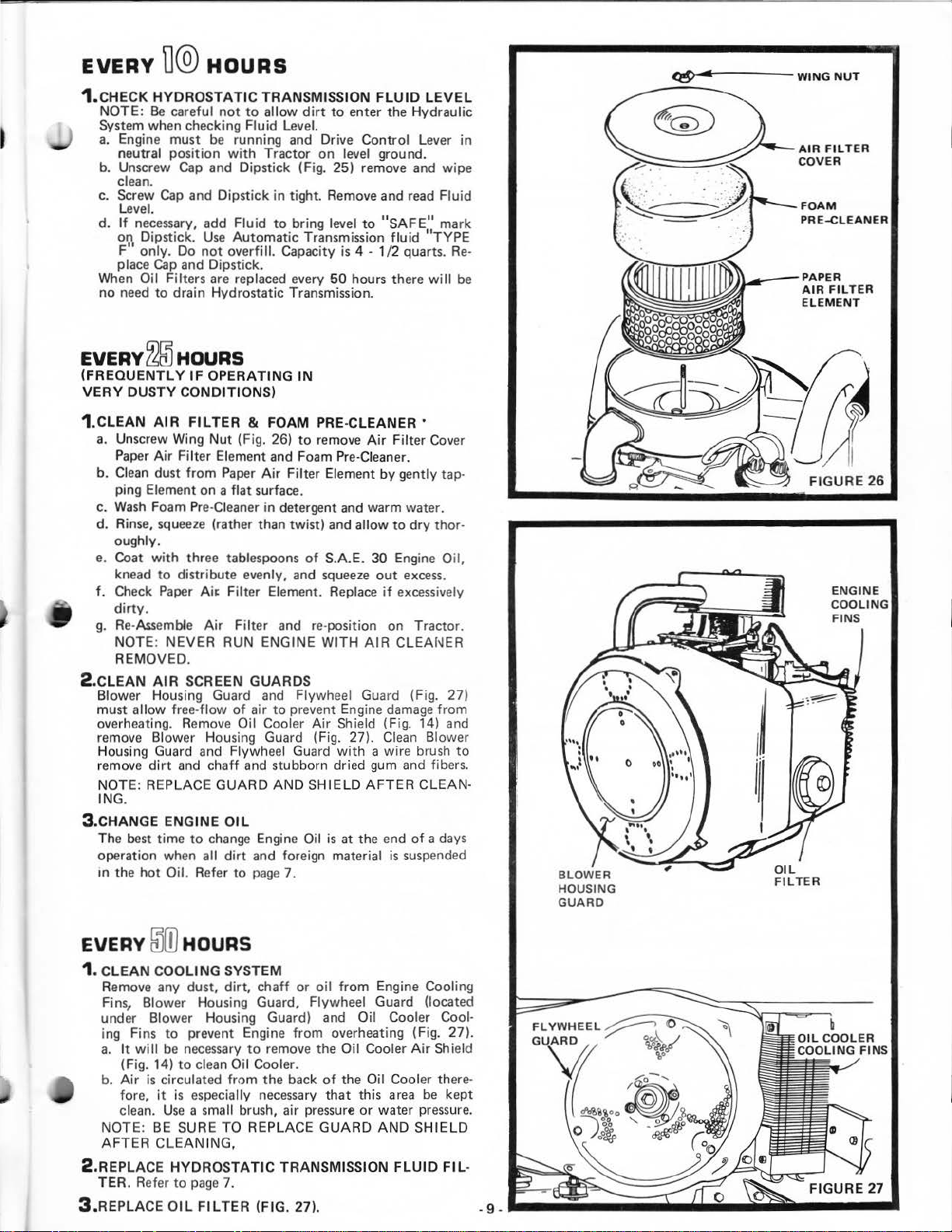

2 . LUBRICATE STEERING AND FRONT WHEELS

There are six Grease

ing a Grease Gun,

treme Pressure Lubricating Grease Amdex

grease appears. This grease may be obtained

Part

No.

2557 R through your nearest Sears repair parts d

Fittings

give

on your Tractor (Fig. 24). U

each Grease Fitting

two

shots of E:

No.

1 or

by

partment.

3.0IL

PIVOT POINTS

Place several

move

aga

a.

Idler Bearings (Fig. 17).

--

Remove Idler Bearing Cap.

drops of S.A.

inst each other, especially:

E.

30

Oil

-- Remove Retainer Spring from Idler

••

Move

Idler and Shaft outward and lubricate e

at

points where par

Shaft.

posed Shaft.

--

Return

Retainer Spring, and reposition Cap .

b.

Front Axle Pivot (Fig. 24).

Idl

er and Shaft

to

original

posi

tion, repla

and rea

o6

SE) c

un1

orderir

Oi

U!

EVERY

1.CHECK

NOTE:

System when checking Fluid Level.

a.

b. Unscrew

c.

d.

When

no

TI®

HOURS

HYDROSTATIC

Be

careful

Engine

neutral position

clean.

Screw

Level.

If

on Dipstick.

F"

place

need

must

be

Cap

and Dipstick (Fig. 25) remove and

Cap

and Dipstick

necessary, add Fluid

only. Do

Cap

Oil Filters are replaced every

to

Use

not

and Dipstick.

drain Hydrostatic Transmission .

TRANSMISSION

not

to

allow

running and Drive

with

Tractor

Automatic

overfill. Capacity

dirt

on

in

tight. Remove and read

to

bring level

Transmission

FLUID

to

enter the Hydraulic

Control

level ground.

to

"SAFE"

is

50

fluid

4 - 1/2 quarts.

hours there

LEVEL

Lever in

wipe

Fluid

mark

"TYPE

Re-

will

be

~,.-------WING

AIR

COVER

FOAM

PRE-CLEANER

.---PAPER

AIR

ELEMENT

NUT

FILTER

FILTER

EVERY

(FREQUENTLY

VERY

1.CLEAN

a.

b. Clean dust

c.

d. Rinse,

e. Coat

f.

g.

2

.CLEAN

Blower Housing Guard

must

overheating. Remove Oil Cooler

remove

Housing Guard and Flywheel Guard

remove

NOTE: REPLACE

ING.

3 .CHANGE ENGINE

The best time

operation when

m the

~

HOURS

IF

OPERATING

DUSTY

Unscrew Wing

Paper

ping

Wash

oughly.

knead

Check

dirty.

Re-Assemble

NOTE: NEVER RUN ENGINE WI

REMOVED.

allow

CONDITIONS)

AIR

FILTER & FOAM

Nut

(Fig. 26)

Air

Filter Element and Foam Pre-

from

Paper

Air

Element on a

Foam Pre-Cleaner in detergent and warm water.

squeeze

with

to

distribute evenly, and

Paper

AIR

free-flow

Blower Housing Guard (Fig. 27). Clean Blower

dirt

and

hot

Oil. Refer

flat

surface.

(rather than twist) and

three tablespoons

Ai~

F

ilter

Element. Replace

Air

Filter and re-position on Tractor.

SCREEN GUARDS

chaff and stubborn dried gum and fibers.

to

change Engine Oil

all

and

of

air

to

GUARD

OIL

dirt

AND

and foreign material

to

pag

e 7.

IN

PRE-CLEANER •

to

remove

Filter Element

of

Flywheel Guard (Fi

prevent Engine

Air

SHIELD

Air

Filter

Cleaner.

by

allow

to

S.A.E.

30

Engine Oil,

squeeze

is

out

if

excessively

TH

AIR

CLEAhlER

Shield (Fig. 14) and

with

damage

a wire brush

AFTER

at the end

is

Cover

gently tap-

dry

thor-

excess.

g.

27)

from

CLEAN-

of

a days

suspended

to

FIGURE

ENGINE

COO

26

LING

EVERY

1.

CLEAN

Remove any dust,

Fins, Blower Housing Guard, Flywheel Guard (located

under Blower Housing Guard) and Oil Cooler Cooling Fins

a.

b.

NOTE: BE SURE TO REPLACE

AFTER

2 .REPLACE

TER . Refer

3.REP

~(D

COOLING

to

It

will

be necessary

(Fig. 14)

Air

is

circulated

fore,

it

clean.

Use

CLEAN

HYDROSTATIC

LACE

OIL

HOURS

SYSTEM

dirt,

chaff

or

oil

prevent Engine

to

clean Oil Cooler.

is especially necessary

a small brush, air pressure or water pressure.

to

page

FILTER

to

from

ING,

7.

from

overheating (Fig. 27).

remove the Oil Cooler

the

back

of

that

GUARD

TRANSMISSION

(FIG. 27). - 9 -

from

Engine Cooling

Air

Shield

the Oil Cooler there-

this

area

be

kept

AND

SHIELD

FLUID

FIL

-

.__;;;;:;__;;;;.iiijii;

......

~~~·----·

FIGURE

AIR

INTAKE

HOSE

FIGURE

28

28A

EVERv

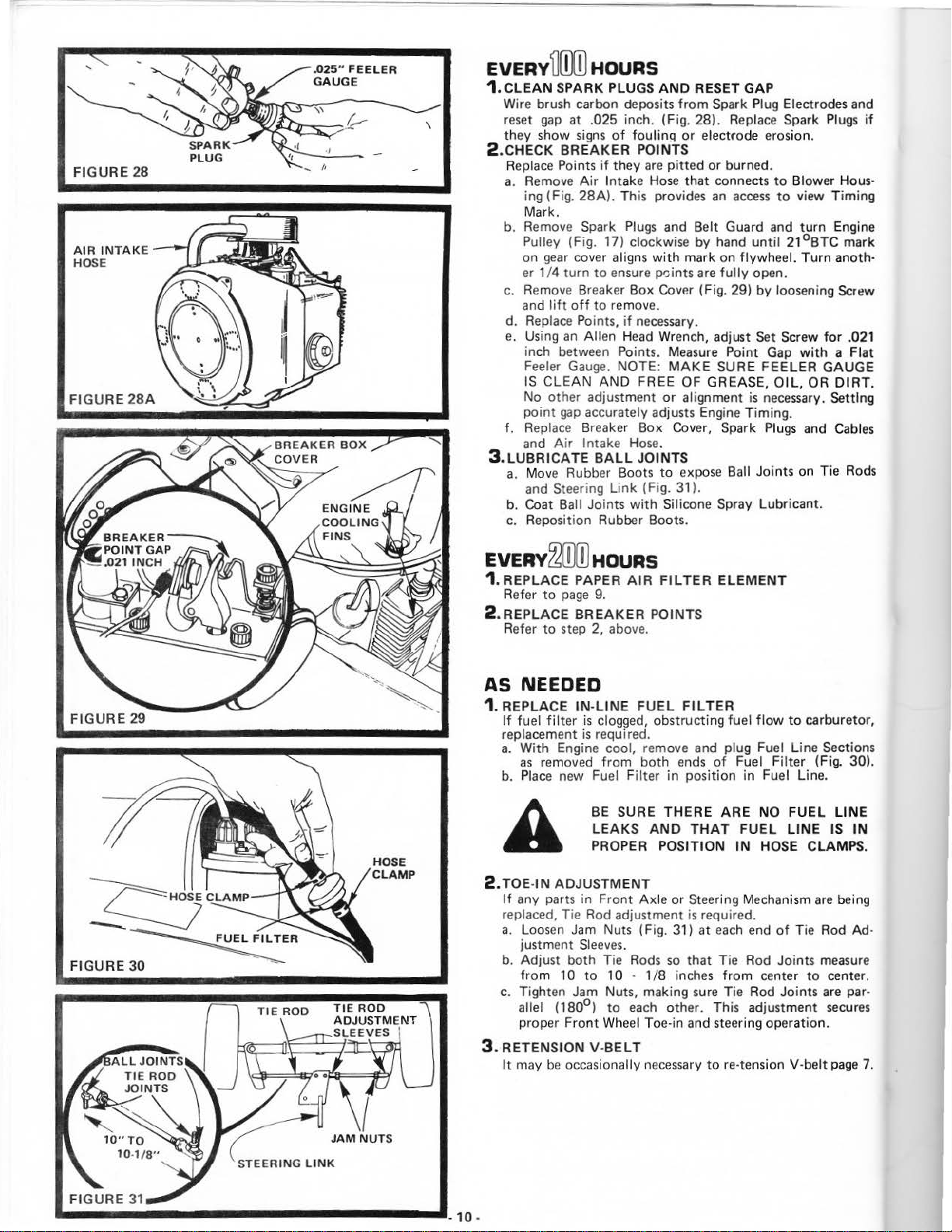

1.

CLEAN

Wire brush carbon deposits

\

reset

they show

2.CH

b. Remove

c.

3.LU

TI[OOJ

HOURS

SPARK PLUGS A

gap

at .025 inch. (Fig. 28). Replace Spark

signs

ECK

Replace Points

a.

d. Replace Points,

e.

f.

a.

b. Coat Ball Joints

c.

BREAKER

Remove

ing (Fig.

Mark.

Pulley (Fig. 17) clockwise

on

gear

er 1/4 turn

Remove

and

lift

Using

inch between Points. Measure Point Gap

Feeler Gauge. NOTE:

IS

CLEAN

No other adjustment

point

gap

Replace

and Air Intake Hose.

BRICATE BALL

Move Rubber Boots

and

Steering Li

Reposition Rubber Boots.

of

if

they

Air

Intake

28A).

This provides

Spark

cover aligns

to

ensure points

Breaker Box

off

to

remove.

an

Allen

AND

accurately adjusts Engine Timing.

Breaker Box Cover. Spark

nk

ND

RESET GAP

from

Spark Plug Electrodes and

foulin!l

Plugs

if

Head

with

or

POINTS

are

Hose

with

necessary.

FREE OF GREASE, O

JOINTS

(Fig.

electrode erosion.

pitted

or burned.

that connects

an

access

and Belt Guard and

by

hand

mark on flywheel. Turn anoth-

are

fully

CovP.r

(Fig. 29) by loosening Screw

Wrench, adjust Set Screw

MAKE

or

to

Silicone Spray Lubricant.

SURE FEELER

alignment

expose Ball Joints on Tie Rods

31

).

Plugs

to

Blower Hous·

to

view

Timing

turn

Engine

until

21°BTC

open.

for

with a Flat

GAUGE

IL,

OR

DIRT.

is

necessary. Setting

Plugs

and

Cables

if

mark

.021

EVERY

1. REPLACE PAPER

2 . REPLACE

AS

1. R

a.

2. TOE-IN ADJUS

c.

3. RETENSION

~

HOURS

AIR

FIL

TER

Refer

Refer

to

page

9.

BREAKER

to

step 2, above.

POINTS

ELEMENT

NEEDED

EPLA

CE IN-

LINE

If

fuel filter

replacement

With Engine cool, remove and plug Fuel

as

b.

Place

If

any parts in Front Axle

replaced. Tie Rod adjustment is required.

a.

Loosen

justment

b. Adjust

from

Tighten Jam Nuts. making sure Tie Rod Joints

allel

proper

It

may

is

is

removed

new Fuel F

Jam

Sleeves.

both

1 0

to

(180°)

Front

V-

be

occasionally necessary

FUEL FILTER

clogged, obstructing fuel

required.

from

both

ends

ilter

BE SURE THERE

LE

AKS

AND

PROPER POS

TMENT

Nuts (Fig. 31) at

Tie

Rods

1 0 -

to

Whee

BELT

so

1/8

each

other. This adjustment

l Toe-in and steering operation.

of

in position in Fuel Line.

ARE

THAT

ITION

or

Steering Mechanism

each

that Tie Rod Joints

inches

from

tore

flow

to

carburetor,

Fuel

FUEL

IN

-tension V-belt

Line

Filter

(Fig. 30).

NO

FUEL

LINE

HOSE CLAMPS.

are

end

of

Tie Rod Ad·

center

to

Sections

LINE

IS

IN

being

measure

center.

are

par·

secures

page

7.

Loading...

Loading...