Page 1

OWNERS

MANUAL

MODEL NO.

917,254710

Caution:

Read and Follow

All Safety Rules

And Instructions

Before Operating

This Equipment

CRnFTSMRN

YT 14 TWIN CYLINDER

5 SPEED - 38" MOWER

YARD TRACTOR

• Assembly

• Operation

• Maintenance

• Repair and Adjustment

• Repair Parts

, ii ,= = i , ,,i,ii,l, lllunlul,,,,

S'e_ars, Roebuck and Coo, Chicago, IL 60684 U 5 A.

Page 2

SAFETY RULES

1 Know the controls and how to stop quickly READ THiS

OPERA TOR'S MANUAL and instructions furnished with

attachments.

2_ Do not allow children to operate the machine. Do not allow

adults to operate it without proper instruction.

3 Do not carrypassengers Do not mow when children end

others are around.

4. Always wear substantial footwear. Do not wear loose fit-

ling clothing that coutd get caught in moving parts,

5 Keep your eyes end mind on Four tractor, mower end the

area being cut. Do not let other interests distract you

6 Do not attempt to operate Your tractor or mower when

not in the drivers seat.

7, Always get on or off your traetor from the operator'o feft

hand side,

El Clear the work area of objects {wire. rocks, eta ) which

might be picked up and thrown.

9. Disengage all attachment clutches before attempting to

start the engine.

i 0 Disengage power to attachments and stop the engine

before leaving the oparator'o position,

I I Disengage power to mower, stop the engine and discon-

nect spark plug wire{s) from spark plugis) before clean-

m •

• g makmg an adjustment or repair Be careful to avoid

touching hot muffler or engine components_

I 2o Disengage power to attachments when transporting or not

in use,

13 Take aU possible precautions when leaving the vehicle un.

attended. Disengage the power.take*bit, lower the at-

tachments, shift into neutral, set the perking brake, stop

the engine and remove the key,

74, Do not stop or start suddenly when going uphill or

downhill. Mow up and down the face of slopes {not

greater than 15=l; never across the face Refer to page 5 t

75., Reduce speed an slopes and make turns gradually to pro.

vent tipping or loss of control Exercise extreme caution

when changing direction on slopes.

76 While going up or down slopes, place Gear Shift Control

Lever in 1st gear position tO negotiate the slope without

stopping,

f 7., Never mow in wet or slippery grass, when traction is un,,

sure or at a speed which could cause a skid.

78 Stay alert for hotas in the tarrain and ether hiddan hazards

Keep away from drop.otis,

19 Do nor drive too close to creeks, ditches and public

highways,

20 Exercisespecialcarewhenmowingsroundfixedobjects

in order to prevent the blades from striking them Never

deliberately run tractor or m owet into or over an y foreign

objects,

2 I Never shift gears until tractor comes to a stop.

22. Never place hands or feet under the mower, in discharge

chute or near any moving parts while {rector or mower

are running Always keep clear of discharge chute

LOOK FOR THIS SYMBOL TO POINT OUT IMPORTANT

SAFETY PRECAUTIONS, IT MEANS - ATTENTIONI BECOME

ALERTI YOUR SAFETY IS |NVOLVED,

CAUTION: LOOK FOR THIS WORD TO POINT OUT IMPORTANT EQUIP,

MENT PR ECAUTIONS_

23, Use core when pulling loads or using heavy equipment

a, Use only approved drswbar hitch points,

b, Limit loads to those you can safely control

c. Do not turn sharply. Use care when backing,

d, Use counterweight or wheel weights when suggested

in the owner's manual

24 Watch out for traffic when crossing or near roadways.

25 When using any attachments, never direct discharge el

meteriat toward bystanders nor allow anyone near the

vehicle while in operation

2 6 Handle gasoline with care - it is highly flammable,

a, Usa approved gasoline containers

b, Never remove the fuel cap of the fuel tank or add

gasoline to a running or hot engine or an engine that

has not been allowed to cool for several minutes after

running. Never fill tank Indoors, always clean up spill.,

ed gasoline,

c Open doors if the engine is run in the gara[/e - exhaust

fumes era dangerous, Do not run the engme indoors.,

27 Keep the vehicle and attachments in good operating con-

dition, and keep safety devices in place end working,

2 El Keep olt nuts, bolts and screws tight to be sure the equip ,

ment is in safe working condition

29 Never store the equipment with gasoline in the tank In-

side o building where fumes may reach an open flame or

spark. Allow the engine to cool before storing in any

enclosura

30 To reduce fire hazard, keep the engine free of grass, leaves

or excessive grease, Do not clean product while engine

iS running.

31, Except for adjustments: DO NOT operate Engine if air

cleaner or cover directly over carburetor air intake is

removed Removal of such pert could create a fire hazard.

32, Do not operate without a muffler or temper with exhaust

system. Damaged mufflers or spark arrestors could craete

a fire hazard Inspect periodically and replace if necessary,

33 The vehicle end attachments should be stopped end in-

spected for damage after striking a foreign object and the

damage should be repaired before restarIing and operating

the equipment°

34 Do not change the engine governo; settings or overspeed

the engine;' severe damage or injury may result_

35 When using the vehicle with mower, proceed as follows:

a. Mow only in dayfight or in good artificial light

b, Shut the engine off when unclogging chute.

¢, Check the blade mounting bolts far proper tightness

at frequent; Intervals,

36, Do not operate the mower without the deflector shield in

place,

3 7 Disengage power to mower before backing up Do not

mow in reverse unless absolutely necessary end then On.

ly after careful observation of the ent#e area behind the

mower_

38, Under normal usage the grass catcher bag material is sub

ject to deterioration and wear. It should be checked fre-

quently for bag replacement Replacement bags should

be checked to ensure compliance with the original

manufacturer's recommendations or specifications

This unit is equipped with an internal combu_ion engine and shouid not be used on or near any unimproved forest

severed, brush covered or grat_ covered land unle_ the engine'_ exhaust _stem is equipped with a spark arrestor

meeting applicable local or state laws (if any) If a spark armorer is used, it should be maintained in effective working

order by the operator

fn the State ot California the above is raqulred by law [Section 4442 of the Caii/amie Public Resources Code) Other states may have

similar taws Federal taws apply on federal lands Rater to Repair Pans Section [Page 34)

Page 3

CONGRATULATIONS on your purchase of a Sears 14HP

Yard Tractor. It has been designed, engineered and

manufactured to give you the best possible dependability

and performance.

5houtd you experience any problem you cannot easily

remedy, please contact your nearest Sears Service

Department,, We have competent, well-trained technf.

cians and the proper tools to service or repair this unit

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement iS available on this

product. See the nearest Sears store or Service Center

for details,

sERIAL

NUMBER

DATE OF

PURCHASE

THE SERIAL NUMBER WILL BE FOUND ON THE

MODEL PLATE UNDER THE SEAT,

YOU SHOULD RECORD THESE NUMBERS AND

KEEP FOR FUTURE REFERENCEr

CUSTOMER RESPONSIBILITIES

Read and retain this manual. Study and observe the safety rules, Always use care when using your tractor Always

keep your tractor and mower clean. Follow a regular schedule in maintaining, caring for, and using your tractor A

welt cared for tractor will run better and last longer.

A TTA CHMEN TS

Thisunit can usa many attachments now available atyour Searsstore, It canuse a tiller, but cannot use other attachments

that engage theground fike aprow,harrow, or cu/tivator_Seapage 50 fora fistof available attachment,s,.

LIMITED TWO YEAR WARRANTY

ON ELECTRIC START RIDING EQUIPMENT

Far two years from date of purchase, when this riding equipment is maintained, lubricated, and tuned up

according to the operating and maintenance instruction in the owner's manual, Sears will repair free of charge

any defect in material or Workmanship in this electric start riding equipment

This warranty e_cludes btadels}, blade adapteris), spark plugls}, air cleaner and belHsi, which are expem

dsbla and become worn during normal use

This warranty does not cover:

For 90 days from the date of purchase, if any battery included with this riding equipment proves defective

in material or workmanship and our testing determines the battery wilt not hold a charge, Sears will replace

the battery at no charge

WARRANTY SERWCE IS A VAfLABLE BY CONTACTING THE NEAREST SEARS SERVICE CENTER/DEPART.

MENT IN THE UNITED STA TES Thi,_ warranty applies only while this product is in use in the United States

This warranty gives you specific legal rights, and you may also have other rights which may vary from state

to state

Tire replacement or repair caused by punctures from outslde objects {such as nails, thornSo stumps,

or glass); and

repairs necessary because of operator abuse or negligence, including the failure to maintain the

equipment according to instructions contained in the owner's manual: and

riding equipment used for commercial or rental purposes

FULL 90-DAY WARRANTY ON BATTERY

SEARS, ROEBUCK and CO,, D/698-731A, Sears Tower, Chicago, 1160684

Page 4

INDEX

Adjustments:

Brake 17

Carburetor . 22

Mower Drive Belt 11

Mower

Front*To.Rear 25

Sfde.,To Stde ,, 24

Throttle Control Cable 21

Air Cleaner

Cleaning 18

, Paper Cartridge . 19

Air Intake Screen, Engine .18

Assembly , 5,I t

Attachments ......................... ,50

Battery:

Charging

Cleanlng

Installation

Levels ,

Preparation .....

Starting with Weak Batlery

Storage.

Terminals

Belt:

Motion Drive Replacement

Mower Drive Adjustment

Mower Ddve, Removal

Blade:

Sharpening

Replacement .....

Brake Adjustment

Carburetor Adjustment.

Controls, Tractor

Cutting Level, Mower

Engine:

Air Screen ,

Oil Change

011 Level

Oil Type

Starting

Storage ..........

C

Fuel:

Type

Storage

Fuse

Hood Removal 23

Lubrlcatlen:

Chart 20

Tractor Pivot Points t9

Maintenance : .... I6-20

21 Air Filter I B

18 Air Cleaner "Paper Cartridge 19

: 8 Air Intake Screen, Engine la

I7 gat_erv t8

7 Bfade*Sherpen}ng 17

2f Brake Adjustment I7

26 Engine Oil . . 16

tg Lubrication Chert 2g

23 Tire Care 17

tt Mower:

I0 Adjustment, Front-to.Rear 25

17 Blade Sharpening, I7

25 Blade Replacement 25

I7 Cutting Level II

22 Removal , 24

12 Muffler ..... 18

t I Spark Arrestor 2

Spark Plugs 19

Adjustment. Side.to.Side 24

Installation 10

Oparatlon 14

Oil

0

Cold Weather CondMone 16

18 Engine...... 16

IB Storage .26

tB Operation........ ,, , I245

tB Operating YourMower , 14

13 Operetit_gYour Tractor f4

26 Starting the Engine ..... t3

13 Tractor Operation on Hills 15

Stopping Your Tractor , 13

26 Options

22 Attachments ................. 50

Spark Arrestor ................ 2

Farts Bag 5,B

Repair and Adjustments 20-26

glade 25

Carburetor 22

Fuse . 22

Hood Removal • , 23

Motion Drive Bett Repfa_ement 23

Mower Adjustment, Front-to-Rear 2El

Mower Adjustment, Side,to,Side 24

Mower Removal 24

S ;

Safety Rules 2

Seat .... 7

Service Record 28

Slope Guide Sheet 51

Spark PloDs , 1_q

Speed Control Chert 14

Starting the Englne 13

Staerittg Wheel " . 8

Stopping the Tre_tor I3

Storage • 26

Throttle Control Cable Adjulttment 2I

Tires .......... 17

Trouble Shooting Chart 2 2

W

Warranty .................. 3

W'_ng (Schematic! 29

Page 5

Know Your Tractor

ASSEMBL Y

READ THIS OWNER'S MANUAL BEFORE OPERATING YOUR YARD TRACTOR. If you understand

the machine and its operation, you will achieve efficient and peak performance_ While reading the

manual, compare the illustrations with your Yard Tractor to familiarize yourself with the location

,of various controls and adjustments, Study the operating instructions and safety precautions

'thoroughly to insure proper functioning of your Yard Tractor and to prevent injury to yourself and

others. Be sure to pay strict attention to all notes and cautions; they are included for your safety.

Save this manual for future,reference,

Unpacking Instructions

1. Take items our ofcarton; the box contains the items

shown below,

2. Cutdown four comers of thecation witha utilityknife

and fold down sides.

3. Disengage Parking Brake°

4 Carefully guide the tractor backwards off the skid. Be

The operation of any tra¢tor can result in

foreignobjectsthrown into theeyes,which

can result in Severeeye damage, Always

wear safety glassesor eyeshields before

starting your traetorandwhile mowing.We

recommendWideVisionSafety Maskworn

over spectaclesorstandardsafety g/a_es,

availableatSearsRetailor Catalog Stores,

careful of staples tnskid,

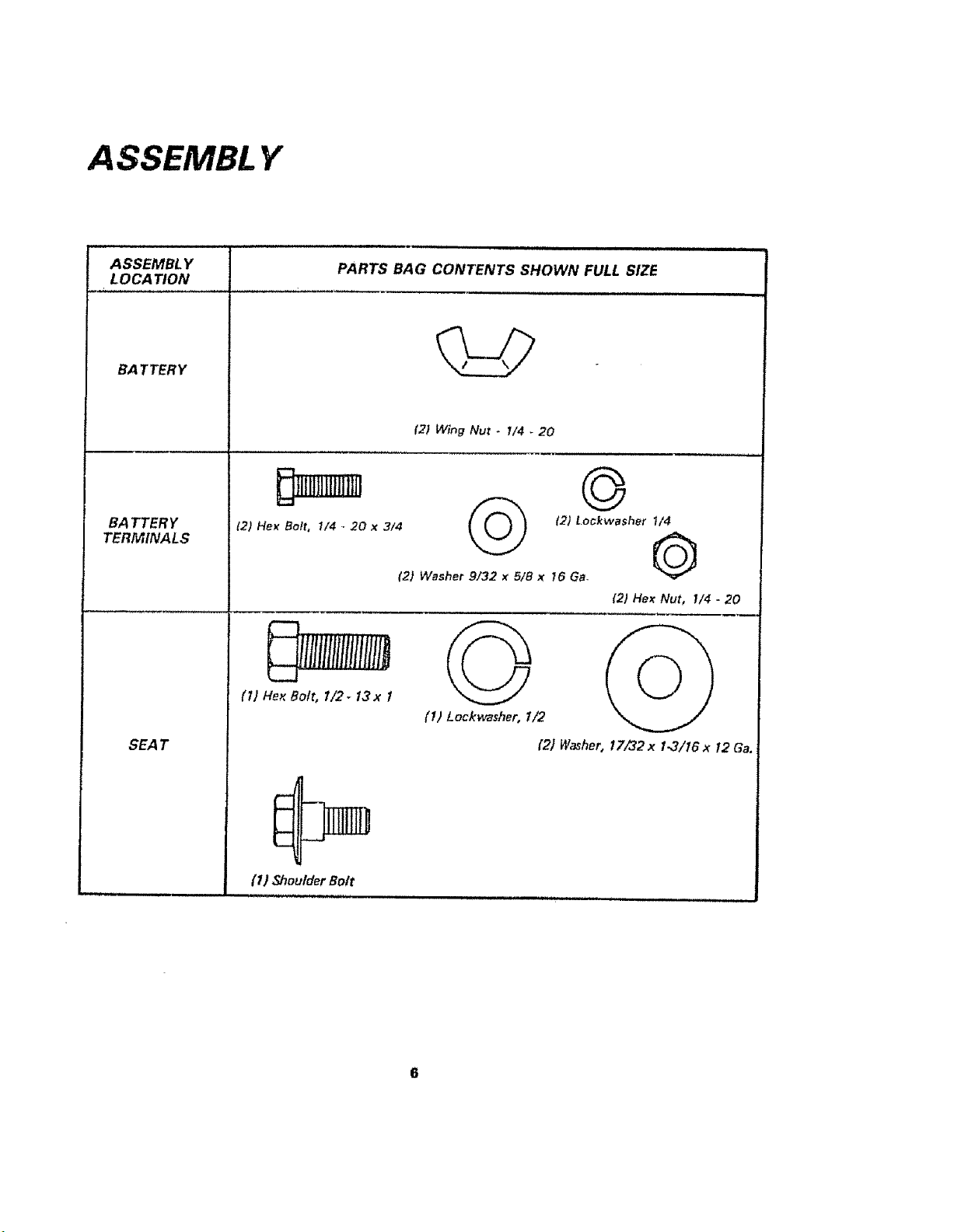

Parts Bag Contents Not Shown Full Size:

i!!!!!!!!!}!!!!!!)j!!!ll[

A SSEMBL Y

ASSEMBL Y

LOCATION

BATTERY

BA TTERY

TERMINALS

PARTS BAG CONTENTS SHOWN FULL SIZE

t2} Hex Bolt, I/4 -,20 x 3/4

(21 Wing Nut - I/4 - 20

©

{2) Lockwasher 1/4

©

©

(2) Washer 9/32 x 5/8 x 16 Ga

(21 Flex Nut, I/4 - 20

(1) Lockwasher, I/2

SEAT

[2) Washer, 17/32x I-3/16x 12 Ga.

[ 1) Shoulder Bolt

Page 7

Toassemble andadjust your tractor you will need;

I2) 7/16" wrenches Tire PressureGauge

I) 9/16" wrench Screwdriver

(I) 1/2" wrench Utility Knife

(1) 3/4" wrench Ratchet Wrench

(l) 3!4"socket

NOTE: RIGHT HAND (R.H.) AND LEFT HAND (L.H.) ARE

DETERMINED FROM OPERATOR'S POSITION WHILE

SEATED ON THE TRACTOR.

WEAR EYE AND FACE SHIELD.

WASH HANDS OR CLOTHING IM-

MEDIATELY IF ACCIDENTALLY IN

CONTACT WITH BATTERY ACID,

DO NOT SMOKE= FUMES FROM

CHARGED BATTERY ACID ARE

EXPLOSIVE°

READ THE INSTRUCTIONS iNCLUD_

ED WITH THE BATTERY VENT

CAPS IN THE BAG OF PARTS, AL-

WAYS WEAR GLOVES, CLOTHING

AND GOGGLES TO PROTECT YOUR

HANDS, SKIN AND EYES.

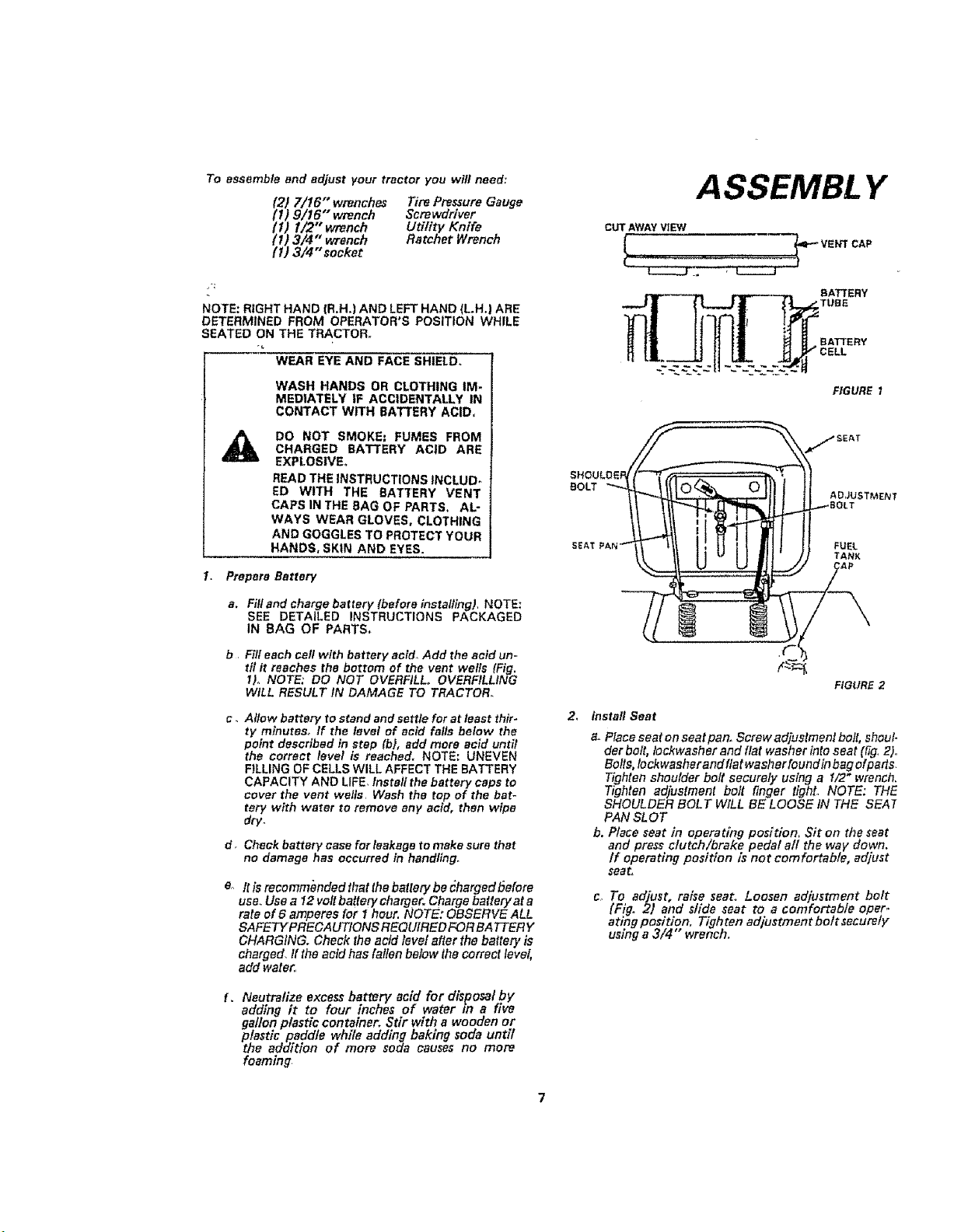

t. Prepare Battery

a. Fill and charge battery (before installing). NOTE:

SEE DETAILED INSTRUCTIONS PACKAGED

IN BAG OF PARTS.

CUTAWAYVIEW

BOLT

SEAT

A SSEMBL Y

BATTERY

BATTERY

FIGURE 7

ADJUSTMENT

FUEL

TANK

b Fill each cell with battery acid. Add the acid un-

til it reaches the bottom of the vent wells {Fig.

1). NOTE; DO NOT OVERFILL. OVERFILLING

WILL RESULT IN DAMAGE TO TRACTOR.

C.

Allow battery to stand and settle for at least thir-

ty minutes° If the level of acid falls below the

point described in step {b}, add more acid until

the correct level is reached. NOTE: UNEVEN

FILLING OF CELLS WILL AFFECT THE BATTERy

CAPACITY AND LIFE, Install the battery caps to

cover the vent wells. Wash the top of the bat-

tery with water to remove any acid, then wipe

dry.

d.

Check battery case for leakage to make sure that

no damage has occurred in handling.

eo Itisrecommendedthatthebatterybechargedbafore

use,Use a 12volt batten/charger, Charge batteryat a

rate of 6 amperesfor I hour. NOTE: OBSERVE ALL

SAFETYPRECAUTIONSREQUIRED FORBATTERY

CHARGING. Check the acid levelafter the battery is

charged,ff the acid has latfen below the correct level,

add water,

f . Neutralize excess battery acid for disposal by

adding it to four inches of water m a five

gallon plastic container. Stir with a wooden or

plastic paddle while adding baking soda until

the addition of more soda causes no more

foaming.

2_

Install Seat

a. Place seat on seat pan. Screw adjustment bolt, shouk

der bolt, Iockwasher and flat washer into seat (fig. 2)°

Bolt _,leckwashe rand flat washer found in bag of parts.

hten shoulder bolt securely using a 1/2" wrench.

hten adjustment bolt finger tight. NOTE: THE

SHOULDER BOLT WfLL BE LOOSE IN THE SEAT

PAN SLOT

b. Place seat in opel'ating position. Sit on the teat

and press clutch/brake pedal all the way down.

If operating position is not comfortable, ad/ust

seat.

c. To adjust, raise seat_. Loosen adjustment bolt

(Fig. 2} end slide seat to a comfortable oper.

atingposition. Tighten ad/ustmentbottsecumly

using a 3/4" wrench.

FIGURE 2

Page 8

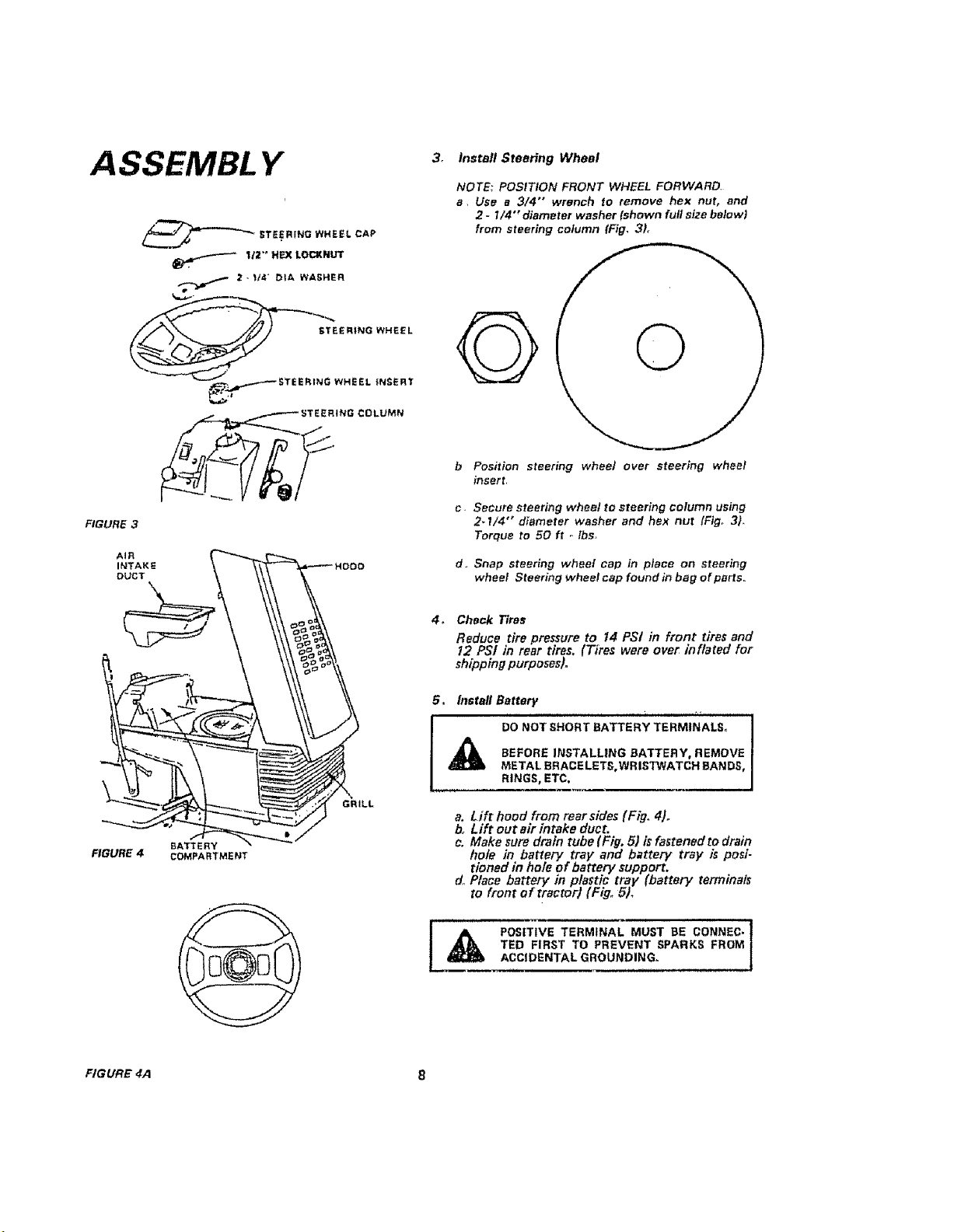

ASSEMBL Y

112 'o HEX LOCKNUT

2 - 1t4" DfA WASHER

FIGURE 3

AiR _ '.-_r""_-.

CAP

STEER;NG WHEEL

WHEEL _NSERT

STEERtNG COLUMN

3, Install Steering Wheel

NOTE; POSITION FRONT WHEEL FORWARD,

a Use a 3/4" wrench to remove hex nut, end

2 - 1/4"" diameter washer {shown full size below)

from steering column (Fig, 3j,

b Position steering wheel over steering wheel

insert,

c Secure steering wheel to steering column using

2,1/4" diameter washer and hex nut lFigo 3),,

Torque to 50 ft - lbs_

d.. Snap steering whee! cap in place on steering

wheel Steering wheel cap found in bag of parts..

FIGURE 4 COMPARTMENT

4,

Check Tires

Reduce tire pressure to 14 PS/ in front tires and

12 PSi in rear tires, (Tires were over inflated for

shipping purposes}°

Install Batter),

DO NOT SHORT BATTERY TERMINALS,

BEFORE INSTALLING REMOVE

METAL BRACELETS, WRISTWATCH BANDS,

RINGS, ETC.

a, Lift hood from rearside; (Fig. 4).

b. Lift out air lntake duct.

c. Make sure drain tube (Fig, 5) is fastened to drain

hole in battery tray and battery tray is posi-

tioned in hole of battery support.

d, Place battery in plastic tray (battery terminals

to front of trector) (Fig. 5),

TED FIRST TO PREVENT SPARKS FROM

[

POSITIVE TERMINAL MUST BE CONNEC.

ACCIDENTAL GROUNDING.

BATTERY,

FIGURE 4A 8

Page 9

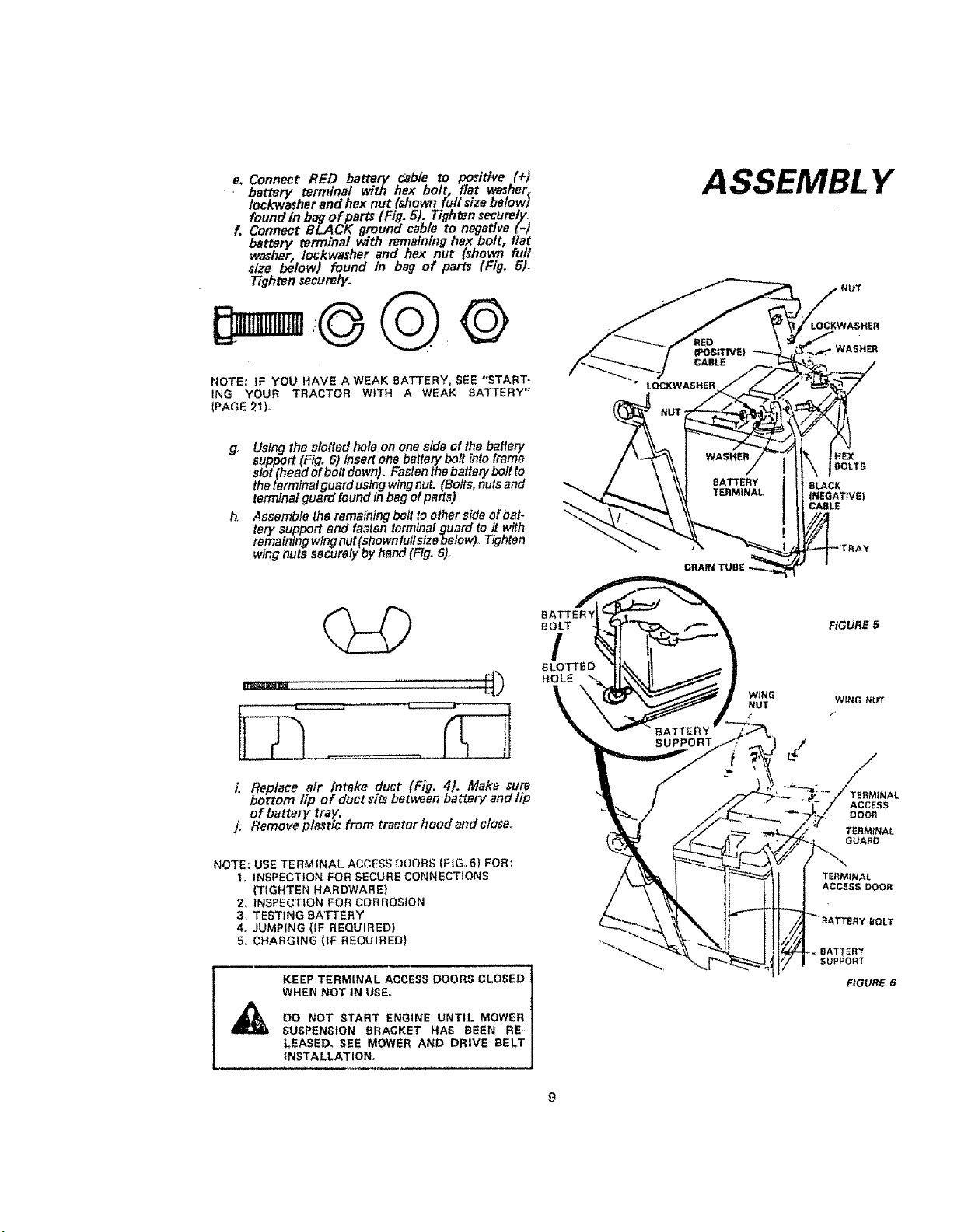

e. Connect RED battery cable to positive (+)

battery terminal with bax bolt, fiat washer,

/ockwasher and hex nut (shownfull size below)

found in bagof par_ (Fig_5). TlghWn securely.

f. Connect BLACK ground cable to negative (-)

battery terminal with remaining he,,,:bolt, flat

washer, lockwasher and hex nut (shown full

size below) found in bag of parts (Fig. 5),

Tightensecurely.

ASSEMBL Y

.o@o

NOTE: IF YOU HAVE A WEAK BATTERY, SEE "*START-

ING YOUR TRACTOR WITH A WEAK BATTERY"

(PAGE 21),,

g, Using the slotted hole on oneside of the battery

support (Fig, 6) insert onebattery bolt into frame

slot (head ofbo# down), Fasten the batterybolt to

the terminalguard usingwingnut. (Bolts,nutsand

terminal guard found in bagof parts)

h. Assemble theremaining belt to other side of bat-

tory support and fastenterminal guard to it with

remainingwfngnut(shownfutlsizebalow)_ Tighten

wingnuts securelyby hand (Fig° 6),

_eemm 0

BATTERY

BOLT

/

SLOTTED

HOLE

• LOCKWASHER

W_NG

NUT

/

WASHER

HEX

BOLTS

FIGURE 5

WING NUT

L Replace air intake duct (Fig. 4)° Make sure

bottom llp of duct si= between battery and lip

of battery tray,

[ Removeplasb'c from tractor hood and close.

NOTE: USE TERMINAL ACCESS DOORS (FIG,, 6) FOR:

t. INSPECTION FOR SECURE CONNECTIONS

(TIGHTEN HARDWARE)

2, INSPECTION FOR CORROSION

3 TESTING BATTERY

4. JUMPING (IF REQUIRED)

5. CHARGING OF REQUIRED)

WHEN NOT IN USEr ]

DO NOT ENGINE UNTIL MOWER

SUSPENSION BRACKET HAS BEEN RE-[

KEEPTERMINALAccEssDOORSCLOSEDI

LEASED, SEE MOWER AND DRIVE BELT |

START

INSTALLATION,

TERMINAL

ACCESS

DOOR

TERMINAL

GUARD

bOLT

FIGURE a

1

I

I

Page 10

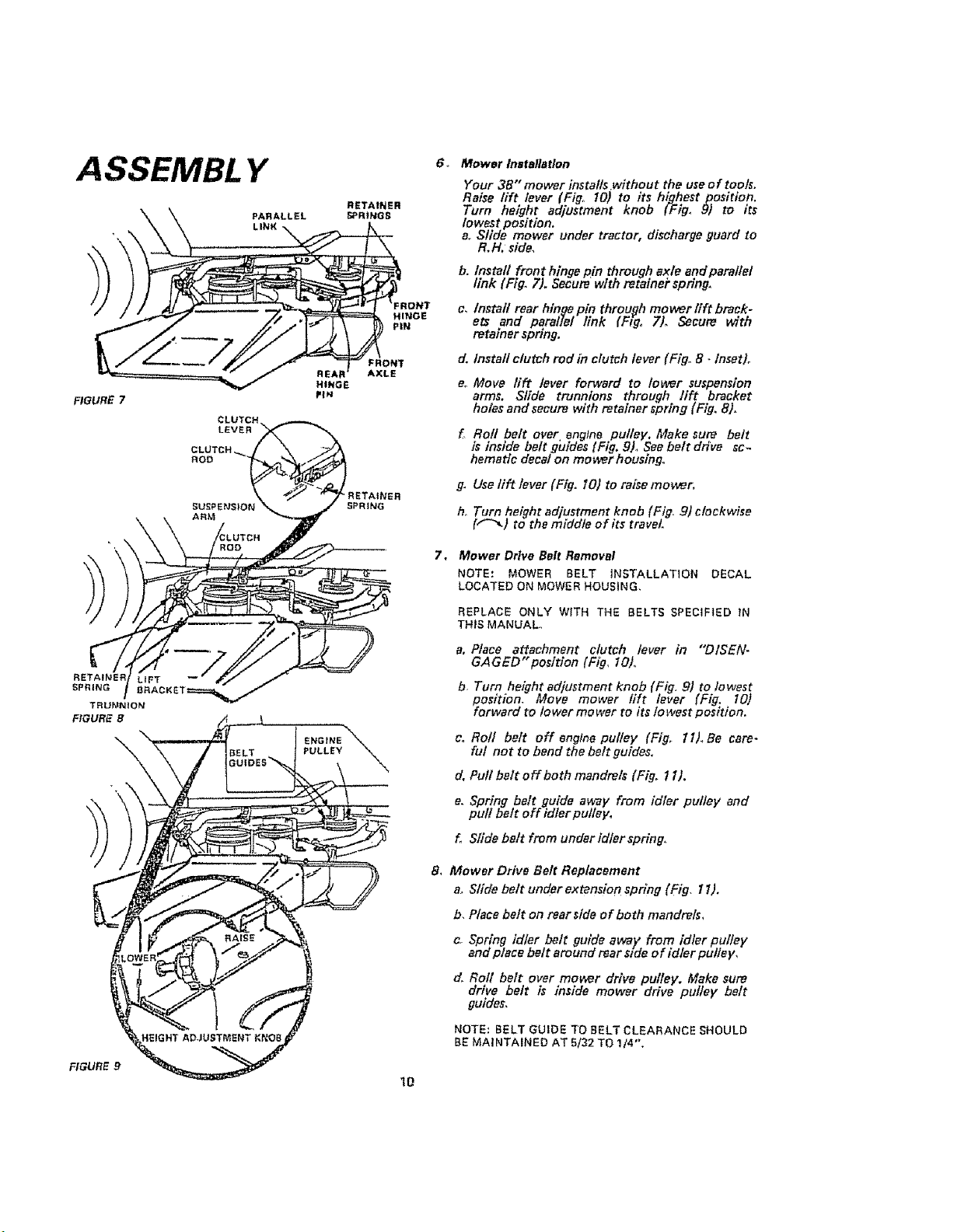

ASSEMBL Y

FIGURE 7

TRU_NtON

FIGURE e

\

PARALLEL

LiNK

REAl AXLE

HINGE

FRONT

6,_ Mower Installation

Your 38" mower installs .without the use of tools.

Raise lift lever (Fig. 10) to its highestposlrion.

Turn height adjustment knob (Fig. 9) to its

lowest position. , . .

eo Slide mower under tractor, discnarge guard to

R.H, side,

b. Install front hinge pin through axle and parellel

link (Fig. 7). Secure wfth retaine_ spdng_

HINGE

PIN

c. Install rear hinge pln through mower lift brack-

ets and parallel link (Fig, 7J. Secure with

retaln er spring.

d. Install clutch rodin clutch lever (Fig. 8. Inset)o

eo Move lift lever forward to lower suspension

arms. Slide trunnlons through lift bracket

holes end secure with retainer ;pring (Fig. 8).

f Roll belt over engine pulley. Make sure belt

is inside belt guides [Fig. 9)_ See belt drive sc-

hematlc decal on mower housing.

g. Use lift lever (Fig. 10} to raise mower,

h. Turn height adjustment knob (Fig. 9} clockwise

(f-_) to the middle of its travel

7. Mower Drive Belt Removal

NOTE: MOWER BELT iNSTALLATION DECAL

LOCATED ON MOWER HOUSING.

REPLACE ONLY WITH THE BELTS SPECIFIED IN

THIS MANUAL.,

a, Place attachment clutch lever in "DISEN.

GAGED" positton (Fig. 10)..

b. Torn height adjustment knob (Fig. 9] to lowest

position. Move mower rift lever (Fig. lO)

forward to lower mo war to its lowest position.

co Roll belt off engine pulley (Fig, t 1). Be care-

ful not to bend the belt guides,

d, Pull belt off both mandrels (Fig. ! 1).

e. Spring belt guide away from idler pulley and

pull belt off idler pulley,

f. Slide belt from under idler spring.

FIGURE 9

8, Mower Drive Belt Replacement

ao Slide belt under extension spring (Fig, 11).

b, Place belt on rearstde of both mandrels,

c_ Spring idler bait guide away from idler pulley

and p/ace belt around mar st'de of idler pulley,

d. Roff belt over mower drive pulley. Make sure

drive belt is inside mower drive pulley belt

guides.

NOTE: BELT GUIDE TO BELT CLEARANCE SHOULD

BE MAINTAINED AT 5/32 TO 1/4'L

I0

Page 11

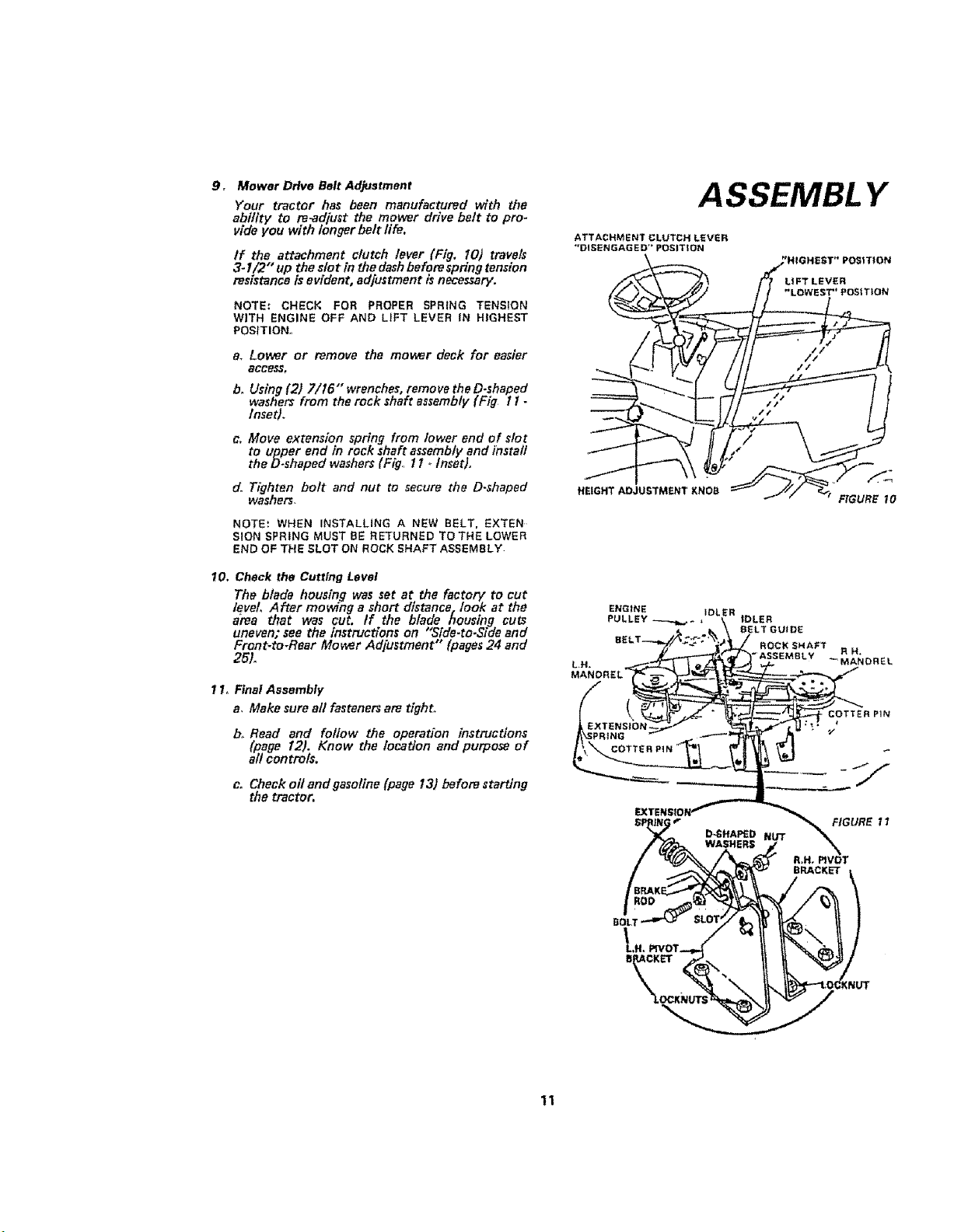

9_

Mower Ddve Belt Adjustment

Your tractor has been manufactured with the

ability to m_djust the mower drive belt to pro-

vide you with longer belt life.

If the attachment clutch lever (Fig, 10) travels

3- I/2" up the slot in the dash before spring tension

resistanca is evident, adjustment is necessary.

NOTE.* CHECK FOR PROPER SPRING TENSION

WITH ENGINE OFF AND L_FT LEVER IN HIGHEST

POSITION,,

a, Lower or remove the mower deck for easier

access,

b_ Using (2) 7/t6"' wrenches, remove the D-shaped

washers from the rock shaft assembly (Fig I i -

Inset).

e_ Move extension spring from lower end of slot

to upper end in rock thaft assembly and install

the Doshaped washers (Fig., 1 t oInset},

do Tighten bolt and nut to secure the D.shaped

washer;,

NOTE', WHEN INSTALLING A NEW BELT. EXTEN

SION SPRING MUST BE RETURNED TO THE LOWER

END OF THE SLOT ON ROCK SHAFT ASSEMBLY

10. Check the Cutting Level

The blade housing was set at the factorF to cut

level, After mowing a short distance, look at the

area that was cut, If the blade housing cuts

uneven; see the instructions on "Side.to,Side and

Front-to-Rear Mower Ad[ustment" (pages 24 and

25L

ASSEMBL Y

ATTACHMENT CLUTCH LEVER

"DIS£NGAGE D" POSITION

HEIGHT ADJUSTMENT KNOB

ENGINE IDLER

PULLEY

FIGURE t0

1Io Final Assembly

a, Make sureall fasteners are tight,

b_ Read and follow the operation instructions

(page 12). Know the location and purpose of

al! contmls.

c. Check oll and gasoline (page 13) before starting

the tractor,

11

BOLT

R.H_ PIVOT

BRACKET

FIGURE t I

Page 12

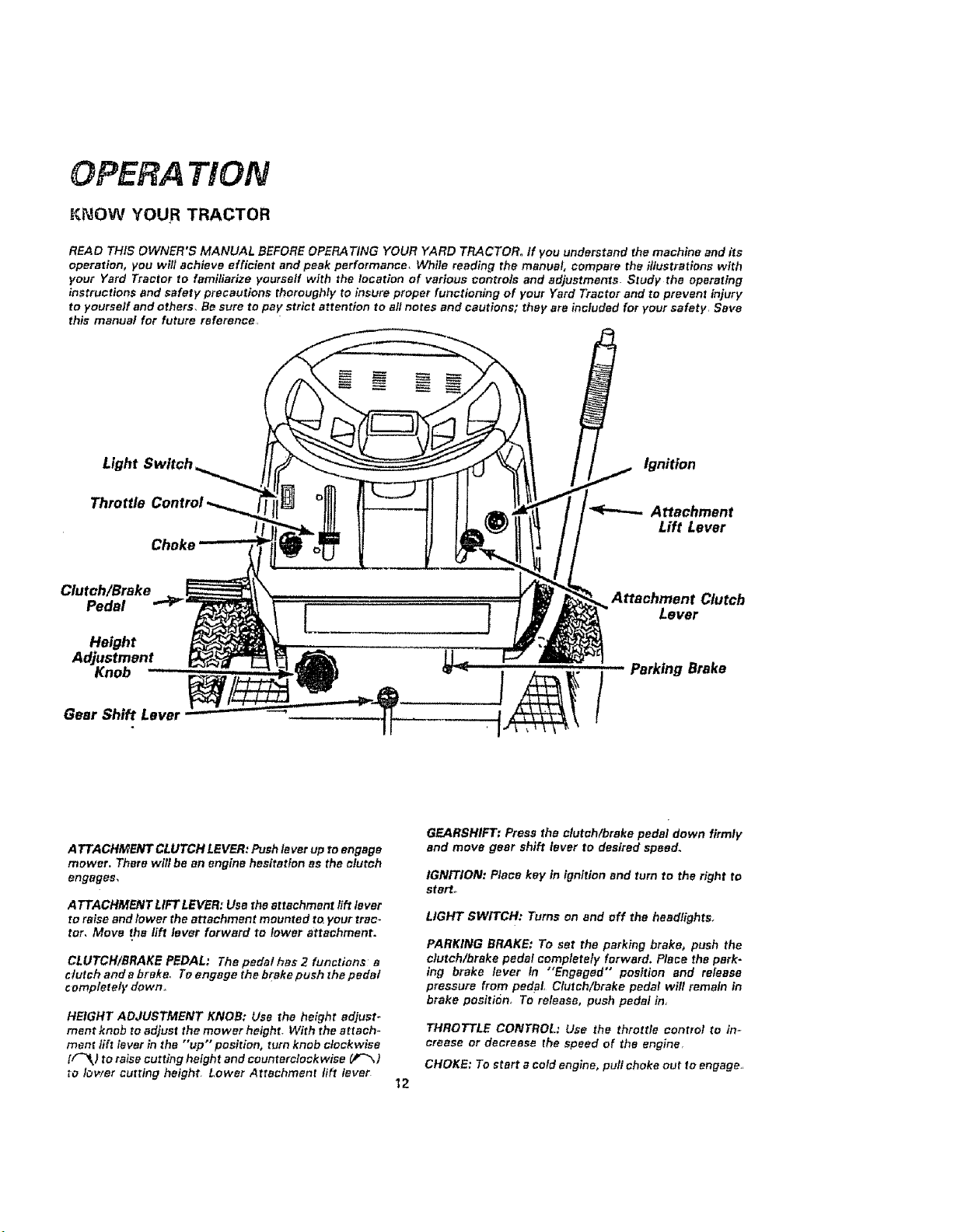

OPERA T/ON

KNOW YOUR TRACTOR

READ THIS OWNER'S MANUAL BEFORE OPERA TING YOUR YARD TRACTOR° If you understand the machine and its

operation, you will achieve efficient and peak performance, While reading the manual, compare the illustrations with

your Yard Tractor to familiarize yourself with the location of various controls and adjustments. Study the operating

instructions and safety precautions thoroughly to insure proper functioning of your Yard Tractor and to prevent injury

to yourself and others, Be sure to pay strict attention to all notes and cautions; they are included for your safety, Save

this manual for future reference,

Light Switch Ignition

Throttle _ Attachment

Lift Lever

Clutch/Brake Attachment Clutch

Pedal Lever

He_ht

Adjustment

Knob

Gear Shift Lever

A TTACHMENT CLUTCH LEVERzPush levar up to engage

mower. There will be an engine hesitation as the clutch

engages,

A TTACHMENT LIFT LEVER: Use the attachment rift lever

to raise and lower the attachment mounted to. your trac-

tor, Move the lift lever forward to tower attachment.

CLUTCH/BRAKE PEDAL: The pedal has 2 functions a

clutch and abrBke, To engage the brake push zhe peda/

completely down,

HEIGHT ADJUSTMENT KNOB: Use the height adjust-

ment knob to adjust the mowar height. With the attach-

ment lift lever in the "up"position, turn knob clockwise

{f"_} to raise cutting height and counterclockwise (f_)

to lower cutting height Lower Attachment rift lever

.... Parking Brake

GEARSHIFT: Press the clutch/brake pedal down firmly

and move gear shift laver to desired speed,

IGNITION*, Place key in ignition end turn to the right to

start.

LIGHT SWITCH: Turns on end off the headlights°

PARKING BRAKE: To set the parking brake, push the

clutch/brake pedal completely forward. Place the park-

ing brake lever tn "Engaged" position and release

pressure from pedal, Clutch/brake pedal will remain in

brake poaitibn_ To release, push pedal in,

THROTTLE CONTROL: Use the throttle control to in-

crease or decrease the speed of the engine,

CHOKE: To start acold engine, puff choke out to engage_,

12

Page 13

1, Stopping Your Tractor

DO NOT CHOKE CARBURETOR TO STOP |

THE ENGINE,=

NOTE; REMOVE KEY WHEN LEAVING TRACTOR TO

PREVENT UNAUTHORIZED USE.

a. Push clutch/brake pedal into full "'BRAKE'"

position,

b o Move gear shift lever to "'NEUTRAL" position.

c, Place parking brake in "ENGAGED*' position and

release pressure from clutch/brakeD Pedal should

remain in "BRAKE" posltion_ NOTE: MAKE SURE

PARKING BRAKE WILL HOLD TRACTOR

SECURE.

d. Place attachment clutch leverin "'DISENGAGED"

positlon_

eo Move throttle control to "S" {slow) position.

f . Turn ignition key to "OFF" position. Never use

choke to stop engine_

OPERA TION

!

2. Starting The Engine

LEARN TO START, STOP AND REVERSE

YOUR TRACTOR IN A LARGE, OPEN AREA.

THIS TRACTOR IS EQUIPPED WITH IN-

TERLOCK SWITCHES TO PREVENT STAR-

TING OF THE TRACTOR ENGINE WHILE

THE *'ENGAGED" POSITION AND/OR THE

THE MOWER BLADE CLUTCH LEVER IS IN

FOOT PEDAL |S NOT FULLY DEPRESSED.

IMMEDIATELY REPLACE SWITCHES THAT

ARE NOT IN PROPER WORKING ORDER,

DO NOT ATTEMPT TO DEFEAT THE PUR-

...... POSE OF THE,_E SWITCHES. ,_,

a. This engine has been shipped filled with sum-

mer_ weight oil, For cold weather operation,

see chart on page 16, Check engine oil level

with tractor on level ground, Remove and

wipe dipstick (Fig, 17) clean, screw it in tight

for a few seconds, remote and read oil level,

If necessary, add oil until "FULL" mark is

reached,

bo Fill fuel tank, Use fresh, clean, regular UN-

LEADED automotive gasoline. (Use of leaded

gasoline will increase carbon and lead oxide

deposits and reduce va/te life). Capacity is

3-I/2 gallons°

CAUTION: EXPERIENCE INDICATES THAT ALCOHOL

BLENDED FUELS (CALLED GASOHOL OR USING

ETHANOL OR METHANOL) CAN ATTRACT MOIS-

TURE .WHICH LEADS TO SEPARATION AND FOR=

MATfON OF ACIDS DURING STORAGE, ACIDIC

GAS CAN DAMAGE THE FUEL SYSTEM OF AN

ENGINE WHILE IN STORAGE

TO AVOID ENGINE'PROBLEMS. THE FUEL SYS-

TEM SHOULD BE EMPTIED BEFORE STORAGE

FOR 30 OAYS OR LONGER, DRAIN THE GAS

TANK. START THE ENGINE AND LET IT RUN UN-

TIL THE FUEL LINES AND CARBURETOR ARE

EMPTY, USE FRESH FUEL NEXT SEASON SEE

STORAGE INSTRUCTIONS FOR ADDITIONAL IN.

FORMATION

NEVER USE ENGINE OR CARBURETOR CLEANER

PRODUCTS IN THE FUEL TANK OR PERMANENT

DAMAGE MAY OCCUR

GEAR SHtFT

: LEVER FIGURE 12

FILL TO BOTTOM OF GAS TANK FILLER |

NECK. DO NOT OVERFILL, WIPE OFF ANY

SPILLED OIL OR FUEL. DO NOT STORE,

SPILL OR USE GASOLINE NEAR AN OPEN

FLAME.

c, Place attachment clutch lever tn "DISEN-

GAGED" position (Fig° 12).

d, Push clutch/brake pedal fully into brake

position.

eo Place gear shift /eter in "WEUTRAL " position

(Fig. 12).

f, Pull choke out (Fig. 12},

go Move throttle control to middle position

(Fig, 72)_

h, Turn ignition key clockwise ((_-_) to "START"

position and release key as soon as engine starts,

NOTE: DO NOT RUN STARTER CONTINUOUSLY

FOR MORE THAN FIFTEEN SECONDS PER

MINUTE. If engine does not start after several at-

tempts, move throttle control to "F" (fast)

position, wait a few minutes and try again.

NOTE: tF YOU HAVE A WEAK BATTERY, SEE "START,

tNG YOUR TRACTOR WITH A WEAK BATTERY"

(PAGE 21)

t After engine is warm, push choke in. The first

time you start the engine, it will take extra crank-

Ing time to move fuel from tank to the engine.

NOTE: ALLOW ENGINE TO WARM UP FOR A

FEW MINUTES BEFORE ENGAGING CLUTCH OF

TRACTOR OR ATTACHMENT

j When restarting a warm engine, move throttle

control midway between "_S" (slow) and

"F" (fast) positioned Choke may not have

to be u_ed.

IMPORTANT: BEFORE DRIVING THE TRACTOR, _

INSTALL MOWER OR REMOVE

MOWER PARALLEL LINK (Fig° 7).

J

13

Page 14

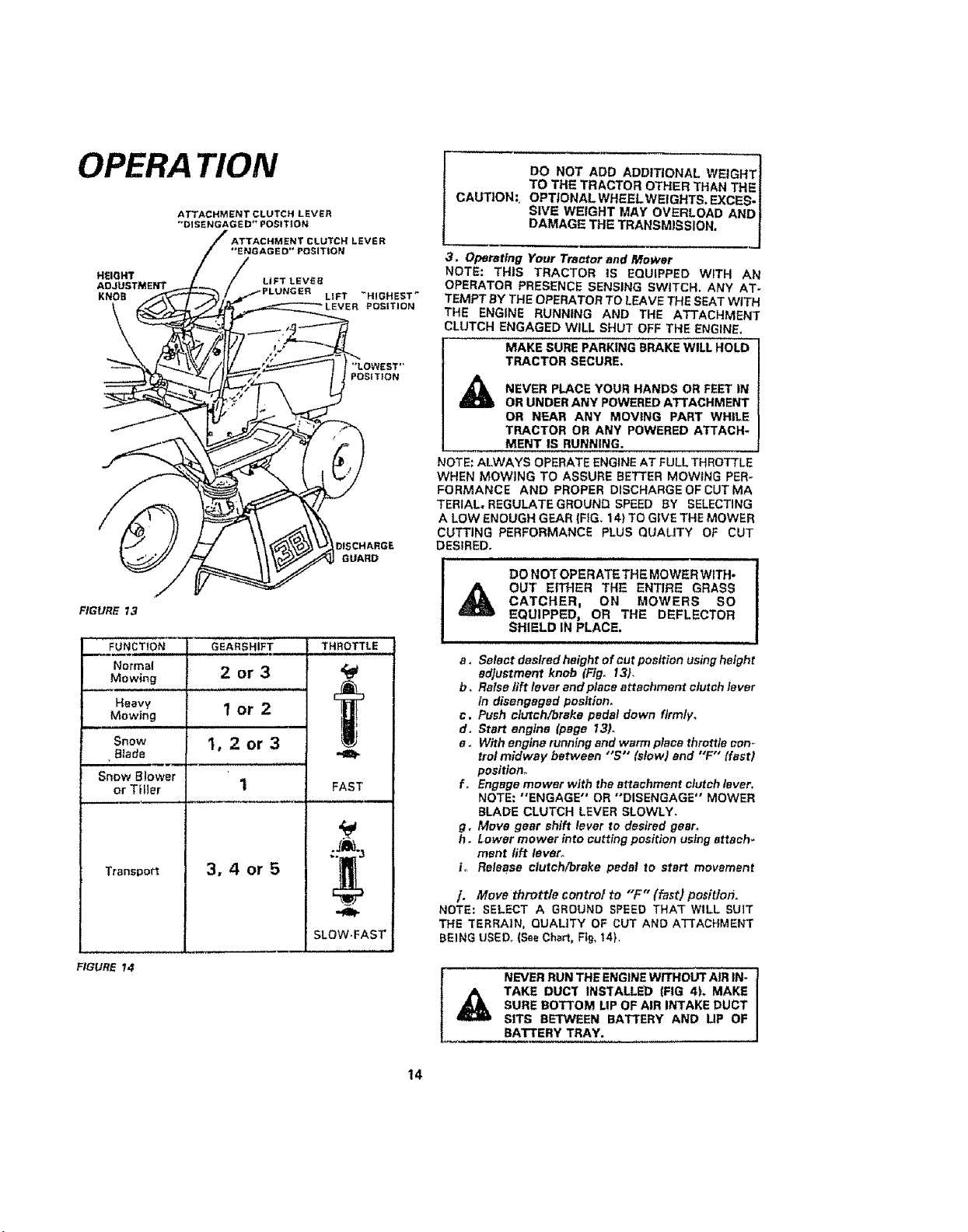

OPERA TION

ATTACHMENT CLUTCH LEVER

"DIS£NGAGED'*POSITION

"ENGAGED"POSITtQN

HEIGHT

ADJUSTMENT

KNOB

BGURE 13

FUNCTION

_L L

Normal

Mowing

Heavy

Mowing

Snow

. B_ade

Snow Blower

or TiIler

Tt'aRsport

GEARSHIFT

2or3

lor2

1, 2or3

1

3,4or5

UTCH LEVER

THROTTLE

FAST

SLOW-FAST'

r ,,,,,,, ,,

DO NOT ADD ADDITIONAL WEIGHT !

CAUTION: OPTtONAL WHEEL WEIGHTS. EXCES. t

3. Operating Your Tractor and Mower

NOTE: THIS TRACTOR IS EQUIPPED WiTH AN

OPERATOR PRESENCE SENSING SWITCH. ANY AT.

TEMPT SY THE OPERATOR TO LEAVE THE SEAT WiTH

THE ENGINE RUNNING AND THE ATTACHMENT

CLUTCH ENGAGED WILL SHUT OFF THE ENGINE.

NOTE: ALWAYS OPERATE ENGINE AT FULL THROTTLE

WHEN MOWING TO ASSURE BETTER MOWING PER-

FORMANCE AND PROPER DISCHARGE OF CUT MA

TERIAL. REGULATE GROUND SPEED BY SELECTING

A LOW ENOUGH GEAR (FIG. 14) TO GIVE THE MOWER

CUTTING PERFORMANCE PLUS QUALITY OF CUT

DESIRED.

J A DONOTOPERATETHEMOWERWITH"

a, Select desired height of CUtposition using height

adjustment knob (Fig. 13).

b _ Raise lift lever and place attachment clutch lever

tn disengaged position_

c. Push clutch/brake pedal down firmly.

d. Start engine (page 13).

eo With engine running and warm place throttle con-

tre/midway between "S" (slow) and "F" {fast)

positton_

f o Engage mower with the attachment clutch lever.

NOTE: "ENGAGE" DR "DISENGAGE" MOWER

BLADE CLUTCH LEVER SLOWLY.

go Move gear shift lever to desired gear_

h. Lower mower into cutting position using ettaeh_

ment rift lever..

i o Release clutch/brake pedal to start movement

/. Move throttle control to "F" (fast) position.

NOTE: SELECT A GROUND SPEED THAT WILL SUiT

THE TERRAIN, QUALITY OF CUT AND ATTACHMENT

BEING USED_ (See Chart. Ftg. t4).

TO THE TRACTOR OTHER THAN THE l

SIVE WEIGHT MAY OVERLOAD AND

DAMAGE THE TRANSMISSION. {

MAKE SURE PARKING BRAKE WILL HOLD

TRACTOR SECURE,

NEVER PLACE YOUR HANDS OR FEET IN

OR UNDER ANY POWERED ATTACHMENT

OR NEAR ANY MOVING PART WHILE

TRACTOR OR ANY POWERED ATTACH-

MENT IS RUNNING.

OUT EITHER THE ENTIRE GRASS

CATCHER, ON MOWERS SO

EQUIPPED, OR THE DEFLECTOR

SHIELD IN PLACE.

....................,L u,,,, ,

t

J

FIGURE 14

14

NEVER RUN THE ENGINE WITHOUT AIR IN-

TAKE DUCT INSTALLED (FIG 4). MAKE

SURE BOTTOM LiP OF AIR INTAKE DUCT

SITS BETWEEN BATTERY AND LiP OF

BATTERY TRAY.

J

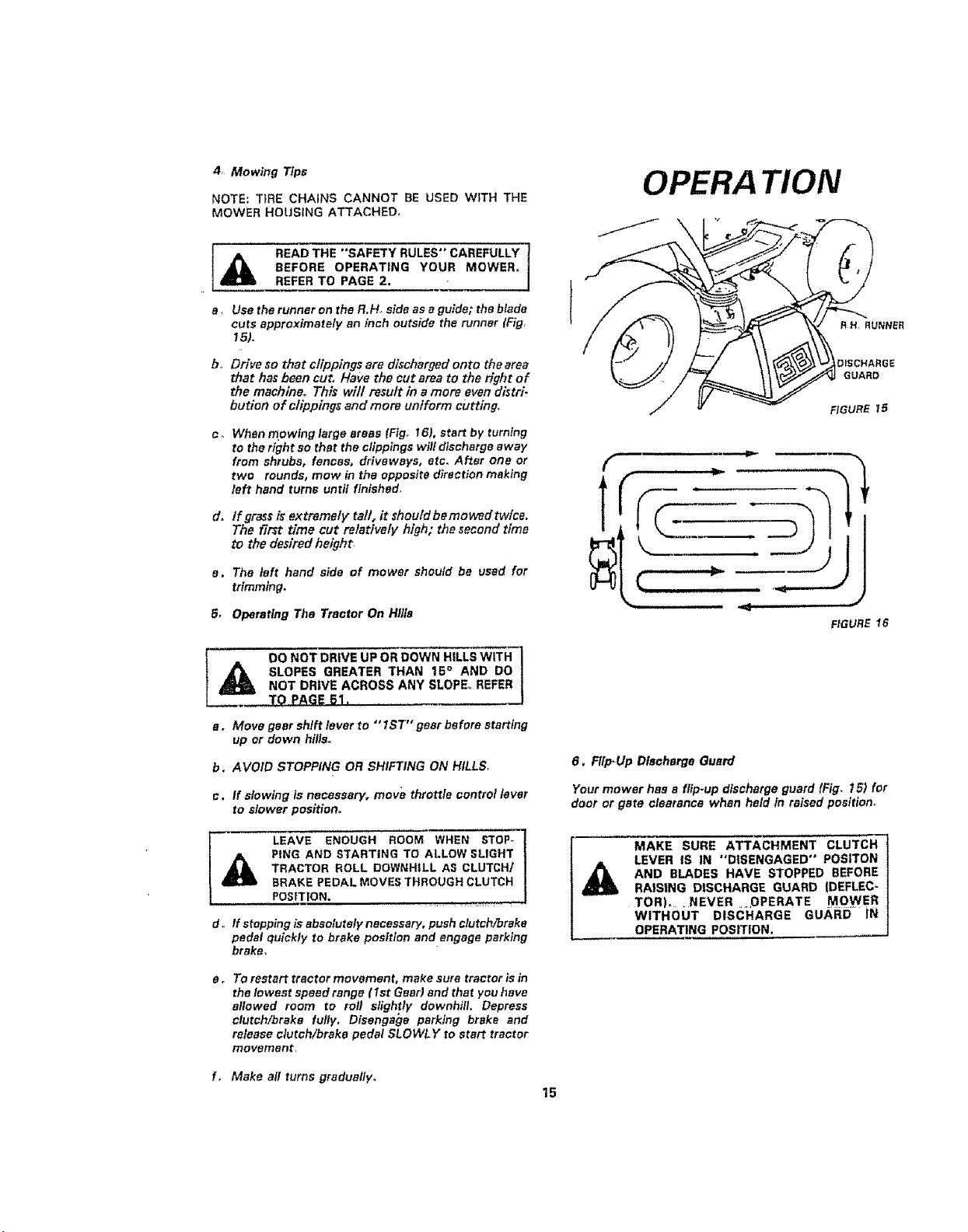

Page 15

4, Mowing Tips

NOTE: TiRE CHAINS CANNOT BE USED WITH THE

MOWER HOUSING ATTACHED,

READ THE "SAFETY RULES" CAREFULLY

BEFORE OPERATING YOUR MOWER,

REFER TO PAGE 2.

a. Use the runner on the R.H.. side as e guide; the blade

cuts approximately an inch outside the runner IFig.

15).

b. Drive so that clippings are discharged onto thearea

that has been cut. Have the curates to the fight of

the machine. This will result in a more even distri.

but/on of clippings and more uniform cutting.

o, When mowing large areas (Fig. 16), start by turning

to the right eo that the clippings wllf dtsohsrge away

from shrubs, fences, driveways, etc. After one or

two rounds, mow in the opposite direction making

left hand turns until flnished.

d. If grass is extremely tall, it shoutd be mow_d tw/ce.

The first time cut relatively high; the second time

to the desired height_

e, The left hand side of mower should be used for

trimming.

OPERA TION

f

r

T

DISCHARGE

GUARD

FIGURE 15

5, Operating The Tractor On Hills

DO NOTDRtVEUPORDOWN HILLSWITH

A LOPES GREATER THAN 15 ° AND DO

......... TO PAGE 61,

a, Move gear shift lever to "'IST" gear be fore starting

b . AVOID STOPPING OR SHIFTING ON HILLS,

c. If slowing is necessary, mov'e throttle control lever

d° If stepping is absolutely necessary, push cfutch/brake

e. To restart trector movement, make sure tractor is in

NOT DRIVE ACROSS ANY SLOPE. REFER

up or down hills_

to slower position.

LEAVE ENOUGH ROOM WHEN STOP°

TRACTOR ROLL DOWNHILL AS CLUTCH/

PiNG AND STARTING TO ALLOW SLIGHT

BRAKE PEDAL MOVES THROUGH CLUTCH

POSITION.

pedal quickly to brake position and engage parking

brake,

the lowest speed range 11st Gear) and that you have

allowed room to roll slightly downhill. Depress

clutch/brake fully, Disengage parking brake and

release clutch/brake pedal SLOWLY to start tractor

movement,

FIGURE 16

6. Flip.Up Discharge Guard

Your mower has a flip-up discharge guard lFig_ 15) for

door or gate clearance when held tn raised position.

MAKE SURE ATTACHMENT CLUTCH

LEVER IS IN "DISENGAGED" POSITON

A

AND BLADES HAVE STOPPED BEFORE

RAIS|NG DISCHARGE GUARD IDEFLEC-

TOR) ..... NEVER ,_OPERATE _MQ_WER

WITHOUT DISCHARGE GUARD IN

OPERATING POSITION,

f. Make all turns gradually_

15

Page 16

MAINTENANCE

ENGINE OIL

DIPSTICK

AND FILL TUBE

FIGURE 17

FIGURE 1B

To keep your tractor running better,

longer, perform necessary service using

the following maintenance schedule:

BEFORE MAKING ANY INSPECTION,

ADJUSTMENT OR REPAIR:

1, PUSH TRACTOR CLUTCHIBRAKE

PEDAL COMPLETELY INTO

"BRAKE" POSITION_

2, MOVE GEAR SHIFT LEVER TO "N"

NEUTRAL POSITION.

3. PLACE PARKING BRAKE IN "EN-

GAGED" POSITION, REMOVE

FOOT FROM PEDAL,

4. PLACE ATTACHMENT CLUTCH

LEVER IN "DISENGAGED" POS1-

TION_

With Every Mowing

1_ Make sum all nuts on bolts am tight and cotter

pins and retainer spdngsaresecure.

2, Observeallsafety precautions,

3o Keep tractor we!l lubricated fmfer to page20jo

First 2 Hours (Two Mowings)

1. Change Engine Oil

Changing oil after the first two hours (or two mow-

inge) will help eliminate break-in residue which might

be damaging to your engine.

NOTE: BE CAREFUL NOT TO ALLOW DIRT TO ENTER

THE ENGINE WHEN CHANGING OIL,

a Drain oil with engine warm,

b, Loosen off drain wing nut [Fig, t8} end remove

dipstick,

c. Catch oil in a suitable container,

do Tighten oil drain wing nut.

e. Refill engine otL See off chart, below, Refill capeck

ty is 1-I/2 quarts. NOTE: DO NOT OVERFILL.

f. Replace dipstick°

Recommended SAE Viscosity Grades

Determine temperature range expected before next oil

change. All oilmust meet A.P..L service classification SD,

SE or SF.

.20_ 0 _ 32 _ 60 _ 80 ° !00 _

Capacity is I-I/2 quarts° NOTE: DO NOT OVERFILL.

Dipstick assembly must be securely tightened into tube

at aft times when engine is operating_

......... TO _,VOiD DAMAGE TO THE STARTING

CAUTION: SYSTEM, USE SAE SW30 OIL WHEN

THE TEMPERTURE FALLS BELOW 32 °

Every 5 Hours (Five Mowings)

5, TURN IGNITION KEY TO "OFF"POSITION. SHUT OFF THE EN-

GINE.

6, MAKE ABSOLUTELY SURE THE

BLADE AND ALL MOVING PARTS

HAVE COMPLETELY STOPPED,

7, REMOVE THE IGNITION KEY,

8, DISCONNECT THE SPARK PLUG

WIRES FROM THE SPARK PLUGS

AND KEEP WIRES AWAY FROM

THE PLUGS TO PREVENT INJURY

FROM ACCIDENTAL STARTING,

BE CAREFUL TO AVOID TOUCH-

ING HOT ENGINE OR MUFFLER

COMPONENTS.

1. CheckEngine OilLevel

DO NOT CHECK ENGINE OIL LEVEL I

WITH ENGINE RUNNING.

Several minutes after stopping engine, check engine

ell level with tractor on level ground, Wipe dipstick

(Fig 17) clean, screw it down tight for a few seconds/,

remove and read oil level If necessary, add oil until

"FULL" mark is reached. (See chart above). NOTE:

DO NOT OVERFILL.

1R

!

I

Page 17

Every 25 Hours (Twice a Mowing Season)

1_ Brake Adjustment

This tractor is equipped with an adjustable brake

system mounted on the right side of the transaxle

(Fig. 191_

SIX FEET STOPPING DISTANCE IN

_ IF TRACTOR REQUIRES MORE THAN ]

IMPORTANT: PARKING BRAKE MUST BE DISEN-

GAGED AND GEAR SHIFT LEVER IN NEUTRAL WHILE

MAKING ADJUSTMENT.

a_ Depress clutch/brake pedal end engage parking

brake.

b, Measure distance between brake operating arm

and nut "A" on brake rod.

C. If distance is other than 1- I/2"; disengage park-

ing brake, loosen jam nut (Fig. f9) and turn nut

"'A" until distance becomes 1-t/2", Retlghten

jam nut against Nut "A"°

d. Engage parking brake and recheck distance.

Road test tractor for proper stopping distance as

stated above, Readjust if necessary,,

2. Tire Care

Maintain tire pressure in front at 14 PSI and rear tires

at 12 PSI,

3. Blade Sharpening

For best results mower blades must be kept eharp_

The blades can be sharpened with a few strokes of

a flle or on a grinding wheel,. We suggest they be

sharpened after every 25 hours of mowfng_ Do not

attempt to sharpen while on mower.

a. When grinding, care should be taken to maintain

blade balance and the blade should be checked

for'proper balance before reinstallstion on mower.

Unbalanced or bent blade will cause excessive

vibration when running, end eventual damage to

mower or engine. Replace bent or damaged

blades,

b. To check blade balance, drive a nail into a beam

• or well Leave'about one inch of the straight nail

exposed. Place center hole of clean blade over the

head of the nail (Fig. 201, NOTE: CENTER HOLE

OF BLADE ON NATL. IF BLADE iS PROPERLY

BALANCED, BLADE SHOULD REMAIN IN POSI-

TION SHOWN IN FIG. 20, IF EITHER END OF THE

BLADE MOVES DOWNWARD, BLADE IS NOT

BALANCED. SHARPEN THE HEAVY END UNTIL

BLADE 1S BALANCED ....

Every 60 Hours (Once a Mowing Season)

(Operating industy conditions may require more frequent

servicing.)

1o Check Battery

a. Acid solution level in each battery cell should be

even with bottoms of tubes in ceils (fig. 21). Add

ONL Ydistilled waterifnecsssaryo NOTE: DO NOT

OVERFILL.

b, Keep battery and terminals clean.

c. Keep battery bo/ts tight,

d, Keep vent caps tight and emall vent holes in caps

open.

e, Recharge at 6 amperes for I hour 17

HIGHEST GEAR, THEN BRAKE MUST

BE ADJUSTED,

MAINTENANCE

BRAKE

BRAKE ROD NUT"A

CUTAWAYViEW

L ................ _P" VENT CAP

OPERATING ARM JAM NUT

DRAKE ENGAGED)

BAT3'ERY

TUBE

BATTERY

CELL

FtGURE 19

FIGURE 20

FIGURE 21

Page 18

MAINTENANCE

PRE,CLEANER

BODY

2o Clean Battery and Terminals

Corrosion and dirt on the battery and terminals cause the

battery to "leak" power°

LEAD.ACID BATTERIES GENERATE EXo

PLOSIVE GASES. KEEP SPARKS, FLAME

AND SMOKING MATERIALS AWAY FROM

BATTERIES, ALWAYS SHIELD YOUR EYES

AROUND BATTERIES.

a. Remove terminal guard,

b. Disconnect BLACK battery cable then RED bat-

tery cable and remove battery from tractor,

c. Wash battery with four tablespoons of baking

soda to one gallon of water, NOTE:' BE CAREFUL

NOT TO GET THE SODA SOLUTION INTO THE

CELLS.

d.. Rinse the battery with plain water, dry and

reinstall on tractor,

e . Clean terminals and battery cable ends with wire

brush until bright

fo Replace battery cables, connecting RED battery

cable to positive terminal first, then BLACK bat_

tory cable to negative terminal Coat terminal con-

nections with Vasotineo

g, Replace terminal guard,

3. Change Engine Oil

FIGURE 22

_GURE 23

GREASE BOTH * 1

_FRONT WHEELS X .} /

O_L SPINDLES

The best time to change engine oil is at the end of

a day's operation when all dirt and foreign materlalB

are suspended in the hot oil. See chert, page 16.

4, Clean Air Cleaner Foam Pro_Cfeansr (Fig, 221

a. Remove knobs and cover.

b. Remove foam pm-cleaner element by sliding it

off of the paper cartridge.

co Wash foam pro-cleaner in liquid detergent and

water.

d. Wrap foam prO.cleaner in cloth and squeeze dry.

e. Lightly coat foampre_leaner with englneo//o

Squeeze in towel to remove excess oil Do not

saturate,

f. Install foam pro=cleaner over paper cartridge,

g. Reassemble cover and screw down tight.

B. Clean Air Screen

Air screen (Fig, 22) must be kept free of dirt and chaff

to prevent angina damage from overheatlng_ Clean

with a wire brush or compressed air to remove dirt,

stubborn dried gum fibers,,

e, Check Muffler

Inspect and replace corroded muffler as it could

create a fire hazard and/or demage_

_ DO NOT TOUCH HOT MUFFLER,]

CYLINDER OR FINS AS CONTACT MAY

CAUSE BURNS,

18

Page 19

7, Lubricate Steering And Front Wheels

There is a greasefitting on each front wheel. Use

a greasegun to giveeach grease fitting two shots

of extreme pressure lubricating grease Amdex

No, I or equivalent (available through your Sears

Service Center), Use 30 weight ott to lubricate

front si_indles(Fig, 23),

8_ Oil Pivot Points

Place several drops of SAE 30 oi/atpn/nts where

parts move against each other, especially."

an Front wheet sptndles,

b, Hood hlnges.

c. Foot pedal shaft (both ends).

do Lift shaft (both ends).

SEE L UBRICA TION CHAR 7",PA GE 20,

MAINTENANCE

2o Replace Air Cleaner Paper Cartridge

(Refer to Page 18).

3o Replace In-Line Fuel Filter

If fuel filter is clogged, obstructing fuel flow to

carburetor, replacement is required.

a, With engine cool, rereove filter and plug fuel

line sections as removed from both ends of

fuel filter (Fig. 26}

b° Place new fuel filter in position in fuel line,

I BE SURE THERE ARE NO FUEL LtNE I

LEAKS AND THAT FUEL LINE tS IN

PROPER POSITION IN HOSE CLAMPS. "

I

J

PREVENT ACCIDENTAL STARTING BE-_

_k FORE MAKING ANY INSPECTION, ADJUST-

l DISCONNECT SPARK PLUG WIRE{S) TO I

MENT OR REPAIR {EXCEPT CARBURE-|

TOR). BE CAREFUL TO AVOID TouCHING J

HOT ENGINE CQMPONENTS_ j

9. Clean Engine Cooling Fins

Remove any dust, dirt or oil from engine cooling

fins to prevent engine damage from overheating.

Air guide cover; must be removed,(Fig 24)

Remove eight 7/I6" bolts and six 5/16" bolts to

remove side and top covers. See hood removal,

page 23,

Every 100 Hours

1. Replace Spark Plugs

Replace spark plugs at the beginning of each mowing

season or avery 100 hours, whichever comes first. Gap

should be set at 0_030 Inch (Fig,25LA deep well 13/I8

socket is required to remove the spark plug.

OP AIR

GUIDE

COVER

"" _ _ I"",,/"_ F,030'_FEELe"

FIGURE 25

\

HO_E

HOSE CL

FUI[t, F|LYER

FIGURE 26

FIGURE 24

19

Page 20

MAINTENANCE

® w,,.L

(_) MDWERCLUTCH PIVOT ( _-:

BOTHENDSOF

\_J FOOT PEDAL SHAFT f 1| ...... _'_'lr_sr_''L'--_'*---'_

EXTREME PRESSURE

LUBRICATING GREASE

AMDEX NO, t, SEARS

PART NO 2557R

_ REFER TO ENGINE OIL SPEC'$.

IUNDER |N{TiAL PREPARATION

IN OWNERS MANUAL)

LUBRICATIONCHART

--SPINDLE (_

"-'---_WHEEL BEARINGS _

I---

...... {.-.3..=._

L OLUTc.PIVOT@

DSLIFT SHAFT (_

REPAIR & ADJUSTMENT

FIGURE27

20

BEFORE MAKING ANY INSPECTION,

ADJUSTMENT OR REPAIR:

1. PUSH TRACTOR CLUTCHIBRAKE

PEDAL COMPLETELY INTO

"BRAKE" POS_TION_

2. MOVE GEAR SHIFT LEVER TO "N"

NEUTRAL POSITION,

3. PLACE PARKING BRAKE IN "EN-

GAGED" POSITION. REMOVE

FOOT FROM PEDAL.

4, PLACE ATTACHMENT CLUTCH

LEVER IN "DISENGAGED" POSI-

TION.

5. TURN IGNITION KEY TO "OFF"

POSITION. SHUT OFF THE EN-

GINE,

6_ MAKE ABSOLUTELY SURE THE

BLADE AND ALL MOVING PARTS

HAVE COMPLETELY STOPPED,

7, REMOVE THE IGNITION KEY.

8, DISCONNECT THE SPARK PLUG

WIRES FROM THE SPARK PLUGS

AND KEEP WIRES AWAY FROM

THE PLUGS TO PREVENT iNJURY

FROM ACCIDENTAL STARTING,

BE CAREFUL TO AVOID TOUCH-

ING HOT ENGINE OR MUFFLER

COMPONENTS.

Page 21

REPAIR & ADJUSTMENT

1_ Starting your Tractor W/lh e Weak Battery

If your battery is too weak to start the engine, it

should be recharged, If "_umpercables" are used

for emergency starting, follow thisprocedure:

NOTE; YOUR TRACTOR IS EQUIPPED WITH ,_, 12

VOLT NEGATIVE GROLINDEO SYSTEM. THE OTHER

VEHICLE MUST ALSO BE A =t2 VOLT NEGATIVE

GROUNDED SYSTEM,

LEAD.ACID BATTERIES GENERATE EX..

PLOSIVE GASES. KEEP SPARKS, FLAME

AND SMOKING MATERIALS AWAY FROM

BATTERIES° ALWAYS WEAR EYE PRO-

TECTION WHEN AROUND BATTERIES.

a_ Connect each end of the RED cable to the

POSITIVE (+) terminals of each battery

(taking care not to short against chassis)

(Fig 27j

b, Connect one end of the BLACK cable to the

NEGA TIVE (-) terminals of fully charged

battery,

co Connect the other end of the cable to the L.H,

side pane/ bolt (Fig. 28J NOTE: KEEP

AWAY FROM GAS TANK AND BATTERY.

do Disconnectcablesin reverseorder:

I, L.H_ sidepanel bolt (Fig. 28)_

2, Negadve terminals of fully charged batten/o

3. Posidveterminals:

IDLE SPEED

SCREW

MIXTURE

VALVE

GOVERNOR CONTROL

L_VER

FIGURE 29

|MPORI"ANT; DO NOT USEYOURTRACTOR BAT. I

. t ,Y ToSTA,'rOT" "W"'CL SIJ

2, Throttie Control Cable Adjustment

Never attempt tO change maximum engine speed.

This is preset at _e factory (3600 ± 100 RPMJ

and shou/d only be changed by a qua/ified service

technician who has the necassarF equipment.

a. Remove hood, page 23.

b. Loosen casing clamp screw until throttle cable

is free to move,

c, Move throttle control (on the dashboard) to

"FAST" posiu_on,

dr Pull throttle cable light (until swivel beneath

carburetor is against side of quarter clrcle)_

Retlghten casing clamp screw,

_ REFER TO "STARTING THE ENGINE,"}PAGE 13o

21

Page 22

REPAIR & ADJUSTMENT

3, Carburetor Adjuslment

NOTE: ADJUST THROTTLE CONTROL CABLE

BEFORE MAKING ANY ADJUSTMENT TO CAR_

BURETOR, AIR CLEANER MUST BE ASSEMBLED TO

CARBURETOR WHEN RUNNING ENGINE

Minor carburetor adjustments may be required to

compensate for differences in fuel, temperature

or altitude° Adjust the carburetor fuel mixture

as follows:

a° Gently turn idle mixture valve clockwise

(_**) fFia 30) until it just closes and then

counterclockwise (,_-- ) 1-1/2 turns.

CAUTION; Valve may be damaged if turned

in too far.

b. Start engine and allow to warm for five

minutes. Make final adjustments with engine

running and choke pushed in.

co Move throttle control lever (on dashboard) to

"SLOW " position.

d, Hold governor control lever against idle speed

_erew, and adjust idle speed screw to obtain

1200 to !400 RPM (Fig, 29).

e, While still holding the governor control lever

against idle speed screw, turn idle mixture valve

slowly clockwise _-_ ){lean mixture) until speed

just starts to stow,

f, Turn idle mixture valve back to the midpoint

between rlch and lean.

g. Adjust the idle speed screw to obtain 900 to

1200 RPM, Release governor control lever,

h, Move throttle control (on the dashboard) to

"FAST." If engine hesitates or dies, tum idle

mixture valve approximately i/8 turn counter-

clockwise (,_") until engine will accelerate

as throttle control is moved from "SLOW"

to "FAST, "

4. Fuse Retgecement

Replace with 30 amp automotlve.type plug.in

fuse.

22

Page 23

5. Motion Drive Belt Replacement

The tractor drive belt may be replaced without tools°

Park the tractor on level area Engage parking brake,

NOTE: BELT INSTALLATION DECAL UNDER LEFT

FOOTREST.

am Remove mower. (See page 24).

b Remove two retainer springs from belt guide

bracket below transaxie pulley, Remove bracket

(Fig 31)

c Swing belt guides away from belt, toward rear of

tractor {Fig_ 3 I)

d, Roll belt over top of transexle pulley

e. Roll belt over engine pulley and off idler (Fig_ 33),

REPAIR & ADJUSTMENT

BELT

f . Release parking brake.. Pull belt as far as possible

over top of clutch pulley

g. Reset parking broke. Pull belt over top of clutch

pulley {Fig 33)

h, Pull bett out through shift gate to remove from

tractor {Fig. 32},

Install belt by reversing above procedure.

NOTE: REPLACE ONLY WITH BELT LISTED IN

MANUAL.

6, Hood Removal

a, Lift hood. Disconnect headlight wiring connection

iFig. 35L

b, Urrscrew one screw at rear of eash side panel {Fig,

34),

c. Pivot hood and sidepanel forward and lift off trac-

tor {Fig° 35).

d, To replace, reverse the above procedure,

TRANSAXLE

PULLEY

BELT

SHIFT GATE

ENGINE

PULLEY

DRIVE BELT

CLUTCH

PUL

SCHEMATIC

REAR

VIEWED FROM BOTTOM OF TRACTOR

FIGURE 32

L H, SIDE

FIGURE33

f I

RETAINER BELT GUIDE RETAINER

SPRING BRACKET SPRING

FIGURE 31

23

FIGURE 34

Page 24

REPAIR & ADJUSTMENT

FIGURE 35

RETAINER

SPR}NG_;

FIGURE 38

LIFT LEVER_

PLUNGER

F--

RH.

HINGE PINS

ROD

7. Mower Removal

a, Remove mower belt per instructions under

"Mower Drive Belt Removal" through step(c).

b, Remove retainer spring from clutch rod;' pull

clutch rod out of clutch bracket,

e_

Puff retainer springs out of rear suspension

trunnions. Remove rear suspension trunnlons

from lift brackets (Fig, 36)°

d_

Purl retainer spring out of rear hinge pin. Remove

rear hinge pin (Fig, 36).

e, Pull retainer sprlng out of front hinge pin. Remove

front hinge pin (Fig,, 361.

f_ Use rift lever to raise suspension arms_ Slide

mower out from under tractor.

NOTE: 1F AN ATTACHMENT OTHER THAN THE

MOWER DECK IS TO BE MOUNTED ON THE TRACTOR,

THE Loll, AND R.H, SUSPENSION ARMS |FIG, 36)

SHOULD BE REMOVED FROM TRACTOR,

8. Level Mower Housing

Adjust the mower while tractor is parked on level

ground or driveway,, Make sure tire pressures are 14

PSi in front tires end 12 PSI in rear tires. If tires are

over or under inflated, you will not properly adjust

Four mower,

Side.to.Side Mower Adjustment

am Depress lift lever plunger end use lift lever to

raise mower to maximum cutting height,

b, Measure height from bottom of curl to ground

lave! at front of roDware Distance "A " should be

the same on both sides of mower IFigo 37).

c. If distance ",4" needs to be ehan_d, snap out

access hole cover on L,Ho side above footrest,

Use 11/16" wrench on nuts "B" and "C" at

side-to-side adjustment trunnion (Fig, 38),

d, To raise left side of moor, loosen nut "/]"and

tighten nut "C'",

e. To lower left side of mower, loosen nut "'C" end

tighten nut "B';

NOTE: ONE ROTATION OF ADJUSTMENT NUTS

IS EQUIVALENT TO APPROXIMATELY 3/16"

HEIGHT CHANGE°

f _ Be sure all nuts are securely tightened.

BOTTOM_

GROUND

LEVEL

FIGURE 37

_-.._TA

GROUND

LEVEL

_;IDE.TO*SlDE

ADJUSTMENT ,_ NUT "_R"

TRUNNION

24 RGURE 3B

Page 25

REPAIR

Front-To.Rear Mower Adjustment

a To obtain the best cutting results, your mower

housing should be adjusted So the front and rear

flange distance "'D" (Fig, 391 is 1/2"" lower in

front when the mower ispositioned in the highest

cutting position. NOTE: MEASURE DISTANCE

"D °" FROM GROUND LEVEL TO BOTTOM OF

CURL ON RIGHT REAR FLANGE AND COMPARE

TO DISTANCE "D" AT RIGHT FRONT FLANGE

b. To raise rear of mower, Ioosannut "E"on both

rear suspension arms. Screw bdth nuts "F" up

an EQUAL NUMBER OF TURNS (Fig. 40).

c. When distance "D" is I/2" lower at front than

rear, tighten nuts "E."_

do To lower rear of mower, loosen nut "F" on

both rear suspension arms an EQUAL NUM-

BER OF TURNS (Fig_ 40).

e. When distance "D" is l /2" lower at front than

rear, retighten nuts "E"

NOTE: WHEN ADJUSTING REAR SUSPENSION TRUN-

NfONS, ALWAYS ADJUST BOTH EQUALLY SO MOWER

WILL STAY LEVEL.

9, Blade Replacement

Raise mower to highest position to permit access

to blades or remove moor (page 24)..

a. Remove bolt, lockwasher end washer (Fig_ 41)

(turn counterclockwiselii_-_)o

b. Remove and discard old blade..

c Clean top and bottom of mower housings.

d Place new blade between flanges, (the word

"TOP" is stamped on afl blades to assure proper

installation), and secure with washer, lockwasher

and bolt previously removed. TIGHTEN SECURE-

LY. Torqbe to 30-35 ft.. Ibs.

& ADJUSTMENT

"_LrFT BOTTOM

6RACKET OF CURL

REAR

SUSPI

TRUNNION

NUT "F

REAR

SUSPENSION

TR_JNN_ON FIGURE 39

LIFT

$

GROUND

LEVEL

ALWAYS USE GRADE 5 HEAT TREATED

BOLTS TO ATTACH BLADES, CHECK

A

10, Roar Wheel Installation

BOLTS tN BLADES OCCASIONALLY TO

MAKE SURE BOLTS ARE TIGHT. TORQUE

BOLTS TO 30-35 FT, LBS,

A GRADE 5 HEAT TREATED BOLT

CAN BE IDENTIFIED BY THREE

LINES ON THE BOLT HEAD AS

SHOWN AT LEFT°

Coat axle with grease to prevent corrosion or rust

accumulation and eventual seizing of wheel hub

to axle shaft.

WHEN REPLACING WHEELS ON THE

TRACTOR, THEY MUST BE MOUNTED

WITH THE LONG HUB SIDE TOWARD THE

CENTER OF THE TRACTOR. INCORRECT

INSTALLATION COULD AFFECT LATERAL

STABILITY_ {SEE FIG°44L

FIGURE 40

FIGURE 41

25

Page 26

REPAIR

11o Tire Care

a Maintarn tire pressure of t4 P.51 m front _res

and 12 PSi in rear tires

b, Keep tires free of gasohne, oil, or insect control

chemicals which can harm rubber.

c. Avoid stumps, stones, deep ruts an_ other

hazards that may cause dre damage.

d, Removing front wheel for tire repair (Fig. 42):

-=-Block up front axle securely,

.... Remove hub cap, klip ring and washer to

allow wheel removal,

.... Repair tire and reassemble, Replace washer

and snap klip ring securely in axle groove,

Replace hub cap,

e, Removing rear wheel for tire repair (Fig 43):

.....Block up rear axle securely,,

-*° Remove hub cap, E-ring and washer to allow

wheel removal

.... Repair tire and reassemble, While maintaining

key position, replace washer and snap E-ring

securely in axte groove. Replace hub cap,

& ADJUSTMENT

D,, Battery

I, Prior to storage, clean terminals and top of

battery,,

2 After a period of time in storage, battery may

require recharging.

E_ General Cleaning

Clean eng[ne, battery', seat, finish, etco of all

foreign matter

F, Store in a Clean Dry Area

_ WHEN MOUNTING TIRES_ UNLESS BEADS 1

! Z Storage

A. Fuel System

ARE SEATED, OVER INFLATION CAN

CAUSE AN EXPLOSION,,

Remove mower from tractor for winter storage,

When mower is to be stored for a period of time,

clean it thoroughly, remove all dirt, grease, leaves,

etc. Give blades and unde_ide of housing a good

coat of grease or rust preventative Store in a

clean dry area°

IT IS IMPORTANT TO PREVENT GUM DEPOSITS FROM

FORMING IN ESSENTIAL FUEL SYSTEM PARTS SUCH AS

THE CARBURETOR, FUEL FILTER, FUEL HOSE, OR TANK

DURING STORAGE, ALSO, EXPERIENCE INDICATES

THAT ALCOHOL BLENDED FUELS (CALLED GASOHOL OR

USING ETHANOL OR METHANOL) CAN ATTRACT MOIS-

TURE WHICH LEADS TO SEPARATION AND FORMATION

OF ACIDS DURING STORAGE. ACIDIC GAS CAN DAM-

AGE THE FUEL SYSTEM OF AN ENGINE WHILE IN STOR-

AGE. TO AVOID ENGINE PROBLEMS, THE FUEL SYSTEM

SHOULD BE EMPTIED BEFORE STORAGE FOR 30 DAYS

OR LONGER

B. EngineOg

Drain (with engine warm) and replace with clean

engine oil (Seechart, page 16).

Co Cylinder=

I, Removespark plugs,

2_Pour one ounce of oil through spark plug holes

into cy/inderso

3, Turn ignition key to "START" position for a

few secondsto distribute oil

4, Replace with new spark plugs.

t O '"i'

L

LONG HUe

' L..2

FIGURE 42

WASHER

HUBCAP

FIG (]RE 43

FIGURE 44

26

Page 27

TROUBLESHOOTING"

PROBLEM

WILL NOT START

r',/tLLNOT TURN OVER

ENGINE CLICKS BUT WON'T START

HARD TO START

ENGINE MISSES OR LACKS POWER

ENGINE OVERHEATS

CAUSE / REMEDY (SEE INDEX)

Fill Tank with Gasoline, Check Fuel Line and Carburetor

(clean if necessary), Replace Fuel Filter Use Fresh Fuel

Recharge or replace Battery

Check Wiring

Replace Spar# Plug(s) and adjust gap

Drain and replace oil for proper tempera rure

Push Clutch/Brake Pedal into brake poaition

Charge or replace Battery

Move Arteehment Clutch Lever to "DISENGA GED "position

Replace Ignition Switch

Replace Interlock Switchfes)

Replace Solenoid or Starter

Replace .Spark Plug(s}

Replace Fuse

Check all Wire Connections and "'Ground" Points

Clean Battery Termlna/s

Replace Starter or Solenoid

Charge or Replace Battery

Check Wire Connections and "Ground'" Points

Place Throttle Control in "FAST'position and run

starter leveret times to clear cut gas

Remove Air Filter and clean

Replace Spark Plug(s) and adjust gap

Recharge or replace Battery

Check the Wiring

Drain Fuel Tank and Carburetor, Use Fresh FueL,

Replace Fuel Filter

Make necessary adjustments to Carburetor

Major Engine Overhaul

Shift to a lower gear or reduce feed

Drain Gas Tank and Carburetor Use Fresh Fuel

Rome ve at_d clean Air Cleaner

Make necessary carburetor adjustments

Clean Air Screen

Add or change oil

Replace Spark Plug(s) and adjust gap

Replace Fuel Filter

Major Engine Overhaul

Shift to Iower gear or reduce load

Clean Air Screen

Add or change oil

Clean Engine Cooling Fins

Remove and clean Muffler or replace

Remove and clean Air Ftlter

U_e fresh fuel and adjust Carburetor

NO LIGHTS

WON'T CHARGE

OPERATOR PRESENCE SYSTEM W! LL NoT

SHUT DOWN ENGINE WHEN OPERATOR LEAVES EngageAttaehmentClutch

SEAT CheckSeatSwitch

NOTE:' This tractor ia equipped with at_ opet"ator pre_ence

tensing ry_te'n. Any attempt bY the oper#torto leave the _t

;with the engine running and the attachment clutch engaged

will shut down the engine.

Cheek Fuut, Switch and Wire Connections. Replace

Headlight Bulbs

Replace Switch

Check Fu_e for fault and replace

Replace Battery

Replace Diode Aeeembfy

! Replace Alternator

I

l

Check all Wire Connections

27

Page 28

TROUBLESHOOTING

Place Throttle Control in "FAST" poaltion

Cheek air pressure in Tires

Check front-to-rear and side,,to.atde Mower adjustment

UNSATISFACTORY MOWER PERFORMANCE

UNEVEN DISTRIBUTION OF CLIPPINGS

MOWER BLADES WILL NOT ROTATE ReinstatlMowerOrivaBelt

EXCESSIVE MOWER VIBRATION Replace Mandrel Straighten Deck or replace

WIND ROWING STRIPPING OR DROPPING Letgrassdryout

OF GRASS CLIPPINGS Readjust Mower front-to.,rearendslde, to-side

UNEVEN CUT OR SCALPING ReplaceBlades

U_e a slower ground speed

Replace Mower Blades

Reinstall Mower Blades with Top of Blade up

Clean under_ide of Mower Deck

Readjust Mower Drive Belt

Correct Clutch Maohani_'n Interference

Install new Mower Drive Belt

Adjust Mower Drive Belt

Replace frozen Mandrel

Replace frozen Idler Pulley

Replace bent or unbalanced Blades

Set Throttle for maximum engine speed

Clean underside of Mower Deck

Replace Blades

Readiust Mower front.to.rear and side.to-aide

Replace bent Man dml[s}

SERVICE RECORD

SERVICE RECORD

SCHEDULE

t , W.,oo

.......... HoURStHOU"SI .OURS.OURS!HOURS

Blades

Brake Adjustment

Check Battery X

Change Engine 011 X

Check Engine Oil Leve_

;lean Air Fitte=" X

Cheek Muffler X

Clean A_r Screen and Engine Cooling F}ns X

Clean Front Grill X

Lubricate Tractor X

Replace Spark Ptugs X

Replace Air Fiber Cart[}dge X

Tires

FUe_ Filter X

Seam, Roebuck and Co, reserves the right to make any changes in design or

improvements without imposing any obligation to install the same upon its

terms hereto fore manufactured, 2B

, i ......

VERY

200 i

IOURS

i,,

1

Page 29

SCHEMATIC

14 HP 38" RIDING YARD TRACTOR - MODEL NUMBER 917.254'710

RED

RED

RED

WIRE

LOOP

WttlE

FUSE

0 B

_P

i=_moli ' CIRCUIT

Oil

START I_

YOUR TRACTOR tS EQUIPPED WITH A

SPECIAL ALTERNATOR SYSTEM> THE

LIGHTS ARE NOT CONNECTED TO THE

BATTERY, BUT HAVE THEIR OWN

ELECTRICAL SOURCE. BECAUSE OF

THIS, THE BRIGHTNESS OF THE

LIGI_ITS WILL CHANGE WITH THE

ENGINE SPEED, AT IDLE SPEED THE

LIGHTS WiLL DIM, AS THE ENGINE IS

SPEEDED UP, THE LIGHTS WILL

BECOME THEIR BRIGHTEST.

i,iii

I,I,G

_NmON

SWITCH

ORANGE

14YOLTS^C(1,tNI [ /,;0

LIGHTSOFFAT

WIRING INSULATED CLIPS

NOTE: IF WIRING INSULATED CLIPS

WERE REMOVED FOR SERVICING OF

UNIT. THEY SHOULD BEREPLACED TO

PROPERLY SECURE YOUR WIRING.

.,..,.,.il_. NON°REMOVAB LE

-"O'-- REMOVABLE CONNECTIONS

CONNECTIONS

29

/-7

GROt_C

Page 30

%°

N

3O

Page 31

0

r_

I.U

r_

o

<o __¢__

h.

0')

W

_r

,.I

ILl

Q

0

i

0

!-

u

o

o

€_

,I*

Ill

W

3t

Page 32

REPAIR PARTS

14 HP 38" RIDING YARD TRACTOR - MODEL NUMBER 917.254710

CHASSIS AND ENCLOSURES

G

30"

36

27

32 38

Page 33

REPAIR PARTS

14 HP 38" RIDING YARD TRACTOR - MODEL NUMBER 917.254710

CHASSIS AND ENCLOSURES

KEY PART DESCRIPTION KEY PART DESCRIPTION

NO. NO. NO, NO+

i 120039X Seat

3 1055133( Bracket-Pivot-Seat

,,4 I05529X Bolt-ShoulderS/t6- 18

5 74780818 Bolt1/2-13x.1

£, 73680500 Nut.,Lock S/16- 18

7 73680800 Nut+ Lock3/8 16

8 121642X Fender

9 106202X Rallector- Rear

10 105801X Decal

11 17490612 Screw, Hex Washer Thd,, Rof1.,8/8 +

12 19131312 Washer13/32x13/t6xl"2Ga.

13 STD523707 * Bolt, Hex 3/8 - 16x3/4

14 1055!1X Strap-Fender

!6 STD55It37 * Washer. Lock3!8

17 I21093X Cap * Spring '.

19 121067X Cempres+ien bpnng

20 19131614 Washer13/32 x l x14 Ga_

21 1055093( Bracket. Fender

22 105531X Nut+ Push

23 106020X Tank. Fuel

24 !21221X Cap- Fuel

25 6999R Clamp +Hose

26 5277J Line - Fuel

27 106082X Pad- Spacer

28 121277X Chassis Assembly

29 121306X Drawbar

30 105523X PaneI-Dash-L.H.

31 121794X Cover.. Access

32 1 I0828X Panel- Dash- [7+H.

33 105525X Bracket + Support - Dash

35 105465X Footrest - L. H.

36 105464X Footrest - RoHo

37 STD533707 * Bolt, Carl. 3/8- 18x3/4

38 165466X Pad, Footrest

39 110923X Bracket- Clutch +Mover

40 3645J Bushing

41 105809X Decal. 5 Speed. 38"

42 108885X Guard- Muffler

43 110436X Grommet. Split

44 105839X Receptacle

45 1058383( Retainer

46 10575IX Stud. I/4 Turn

47 105867X Shield- Heat

48 109015X Bracket- Pivot- L, H,

49 109018X Bracket +Pivot. R. H.

18 x 3/4

50 106013X012 Hood

51 2751R Cu/i_

52 108402X lip

53 !06910X Washer

54 108067X Pa/ Nuf

55 I05528X Grill

56 I05806X Decal

57 105568X Decal- Slripe

58 19131616 Washer13/32xlx16Ga+

61 108403X Panel - Side - R. H+

62 108410X Panel. Side - L, H

63 108091X Hinge. [7+Ho

64 106090X Hinge +L. H,

65 108909X Screw - Special

68 106003X Lens - R, H,

67 106004X Lens - L. H.

68 ! 10897X Bezel - Headlight

69 121144X Belt - Shoulder

70 I08512X Bracket. Pivot - It+ H.

71 !08513X Bracket. Pivot+L.H_

72 4900J Decal + Clutch/Brake

73 109!99X Decal - Drive Belt

74

STD523710 * Bolt-Hex3/8.16x 1

75

8710J Stem., Tank,Fuel

76

119350X StrapAssembly- Grill

77

11050600 Washer- Lock, Ext. Tooth 3/8

78

108813X Decal. S!ripe, SidePanel- L. H+

79

106814X Decal -Stripe, Side Panel- It+H,

80

106974X Decal, Caution

81

17490816 Bolt, Hex Washer ThdoRoll.378.18

84

17490608 Screw, Hex Washer Thd. Roll. 3/8.

68

$77J551150 " Washer- Lock I/2

89 19171912 Washer17/32xl-3/16x12Ga,,

90 121247X Pan Seat

9I 121251X Strip Foam

92 121246X Bracket, Switch Mount

93 121249X Spacer Split

94 72170410 Bo/t Cam I/4.20x 1 I/4

95 121250X Compression Spring

98 121248X uushtng, Snap

97 73900400 Nut, Range, Lock I/4 +20

xl

16x 1/2

"STANDARDHARDWARE--PURCHASE LOCALLY

A B

_e. s

c D E F. G H J K L N

_'l;+ @88 _62

@89 ®7

_ 77

33

P Q R

@7

Page 34

REPAIR PARTS

14 HP 38" RIDING YARD TRACTOR - MODEL NUMBER 917.254710

DRWE

76

13

/

7O

_6B

36

57

g9

57

,, //

-- OPTIONAL EQLIIPMENT--

SPARK ARRESTER KIT

]

Page 35

REPAIR PARTS

14 HP 38" RIDING YARD TRACTOR

DRIVE

KEY PART DESCRtPTION

NO, NO.

f t05703X

2 12000028

4 121319X

5 106963X

8 110658X

9 108373X

t0 100229L TubeAssembly.Exhaust

11 STD522507 * Bolt, Hex t/4.20_ 3/4

12 STD651125 * Washer, Lock 1/4

13 8545,1 Gasket

!6 t10902X Valve,Drain, Oil

17 120302X V-Belt, Drive

18 275tR Ctip

19 105933X Knob

20 106699X Rod, Shifter

21 !0670tX Washer- $haft Plate

22 19151216 WashertS/32x3/4xf6Ga.

23 STD561210 "Pin, Colterl/8 x l

24 17490612 Screw, Hex Washer Hd ThdoRoll,

25 I05730X Keeper, Belt, Engine

26 STD523707 ° Bolt, He_ 3/8- I6 x 3/4

27 19131312 Washer 13/32x 13/16x 12 Ga.

28 73680600 Nut, Lock 3/8.16

29 8883R Cover, Pedal

30 109037X Shaft, Foot Pedal

31 STD5718t0 " Pin, Rol13/16x f

32 121749X Washer25/32x 1-t/4 x 16 Ca,

33 I05918X Arm, Brake

34 STD580025 " Key, Wood_ff Na_ 9

35 121440X Guide, Belt, Lower, Eng. Pulley L

36 121441X Guide, Belt, Lower, Eng. Pulley R.

37 104777X Retainer, Belt Chassis

38 109070)( Keeper, Belt

39 4470J Spacer

40 4859J Idler, Flat

41 STD523727 *Bolt, Hex3/8.16x2-3/4

42 I0573tX

43 1004O7O0

44 74770720

45 I09366X

46 4921H

47 109370X

46 1O8190)(

49 190.91210

Pulley, Transaxle (Driven)

_ing, Retainer ......

! ransaxle, 5 Speea, t-oote Mooel

/voo4160.61 (see pages 42 and 43

for parts breakdown)

Duct, Air Intake

Engine, Briggs and Straiten Model

No.. 400707, Type No° I507-01

Muffler

3/8- 16 x 3/4

H.

H.

Pulley, Engine

Washer, Lock 7/16

*Bolt, Hex 7/18- 20 x 1_1/4

Keeper, Belt L. H.

Retainer Spring

Strap, Locater

Clamp

Washer9/32 x 3/4 x 10 Ca..

- MODEl. NUMBER 917.254710

KEY PART DESCRIPTION

NO, NO,

51

STD523107 ' Bolt, He_ 5/16- !8x3/4

62

73680600 Nut, Lock 5/16- 18

53

STD523727 " Bolt, Hex 3/8.16x 2-3/4

54 I05842X

55 1O9167)(

56 106t57X

57 76020412

68 105844X

59 110437X

60 71673

61 106888X

62 STD551037

64 STD541237 " Nut, Hex, Jam3/8 .16

65 105724X Bracket, Clutch

66 STD533707 • Bolt, Cart. 3/8 - 16x3/4

67 f08298X Pulley, Idler

68 105707X Bellorank Assembly

69 106499X Retainer, Be#

70 STD623715 " Bolt, Hex3/8- 16x 1-1/2

71 110812X Washer, Hardened

72 12000039 xsss Ring

73 105709X Spring, Return, Clutch

74 105710X Link, Clutch

76 121488X Control, Throttle

77 17080408 Screw, Hex Thd.. Cut. 1/4- 20x 1/2

78 59192 Cap, Valve

79 65139 Stem, Valve

80 106268X 7ire, Rear18 x 9.60 x 6

8! 106108X Rim, 8"

82 109502X Spacer, Split

83 121749X Washer25/32 x 1-1/4 x 16 Ca.

84 12000001 EoRipg

85 I04757X Cap, Hub, Rear

86 STD580105 " Key, Square 3/16x2

87 t09369X Keeper, Belt, R, H.

68 17490624 Boll, Hex Washer Thd. Roll. 3/8 - 16

89 17490512 Screw, Hex Washer Thd. Roll. 5/16

90 STD523710 * Bolt, Hex 3/8.16 x I

91 105706X Bearing

92 71040412 Bolt, Hex 1/4.26x3/4

93 19132012 Washer13/32x1-1/4xt2Ga

94 I06919X Plate, Red, Shift

95 105700X Spring, Torsion

97 7152J Tube (Not fumishedwith tractor)

98 110422X Spring, Brake Return

99 674A380 Spark Arrestor Kit

IOOSTD541437 Nut Kepso 3/8- 16

10tSTD551237 Washer Lock Tooth 3/8

"STANDARD HARDWARE-PURCHASE LOCALL Y

Strap, Torque

Bracket, Transaxle

Plate, Strap, Torque

Pin, Cotter t/8 x 3/4

Rod, Brake, Park

Red, Brake

Cap

• Spring, Red, Brake

Washer 13/32x 13/16x 16 Ca.

x 1.1/2

• !8x3/4

A B C D

@ 27 sz

E F

_26 (_66

928

28

G _ J K L M ,q

"sT ss_ 28 ss eo 9o 88

28 @g3 '_,_ lol

35

Page 36

REPAIR PARTS

'14HP 38" RIDING YARD TRACTOR- MODEL NUMBER 917.254710

STEERING ASSEMBLY

20"_'_ D "_...._I 7

_,o

,o,-,.--1

_f2

13

_4

83

\

27

3

36

38

Page 37

REPAIR PARTS

14 HP 38" RIDING YARD TRACTOR - MODEL NUMBER 917.254710

STEERING ASSEMBLY

KEY PART DESCRIPTION KEY PART DESCRIPTION

NO. NO. NO, NO,

1 106810X

2 100710L

3 73940800

4 100712K

5 I00713N

6 1007t1L

7 106015X

8 120028X

9 120003X011

10 1098t6X

11 17490608

12 121749X

13 108705X

14 2882J

15 71208

16 109432X

17 108685X

18 17490612

19 108683X

20 12000029

2I 6268H

22 108684X

23 106126X

24 1055t8X

25 74180512

26 73680500

27 108263)(012

28 73680600

29 STD523120

30 121236X

31 106001X

-32 STD523707

34 19111216

35 121232

36 121526

38 11050600

39 72110608

40 105669X

41 105663X

Decal - Cap Steering Wheel 42 74761060

Insert. Steering Wheel 43 I06664X

* Nut. Top Lock 1/2-20 UNF 45 110438X

Washer , 46 73901000

Wheel-Steering 47 17490508

• Adapter- Ste_rtng Wheel

Sleeve - Steering 48 I06656X

Dash 49 I05654X

Dash Plate 50 121748X

NsYcliner Snap-In 51 121321X

row- Hex Washer Thd Roi13/8 - 52 STD551131

16x 1/2 53 STD541131 *

Washer 26/32 x 1-1/4 x 166A 54 3366R

Shaft- Steering 55 t06727X

Pin.Drive 56 STD551137 *

Bushing ; 67 STD641137 "

Bracket-Steering 58 1654J

Gear- Pinion 59 17431008

Screw- Hex Washer Thd. Roll. 3/8 - 60 104757X

16x3/4 61 2751R

Rod- Steering 62 STD641037 *

Ktlp Ring 64 59192

Bearing. Thrust 65 65139

Gear., Sector 66 278H

Key- Woodruff 67 9040H

Dash - Lower 68 106732X

Screw. Crown Truss Hdo 6/16 - 18 x 69 106222X

3/4 70 101930X

Nut - Lock 5/16 - t8 7I 108456X

Saddle 72 69904

Nut-Lock3/8- 18 73 72110622