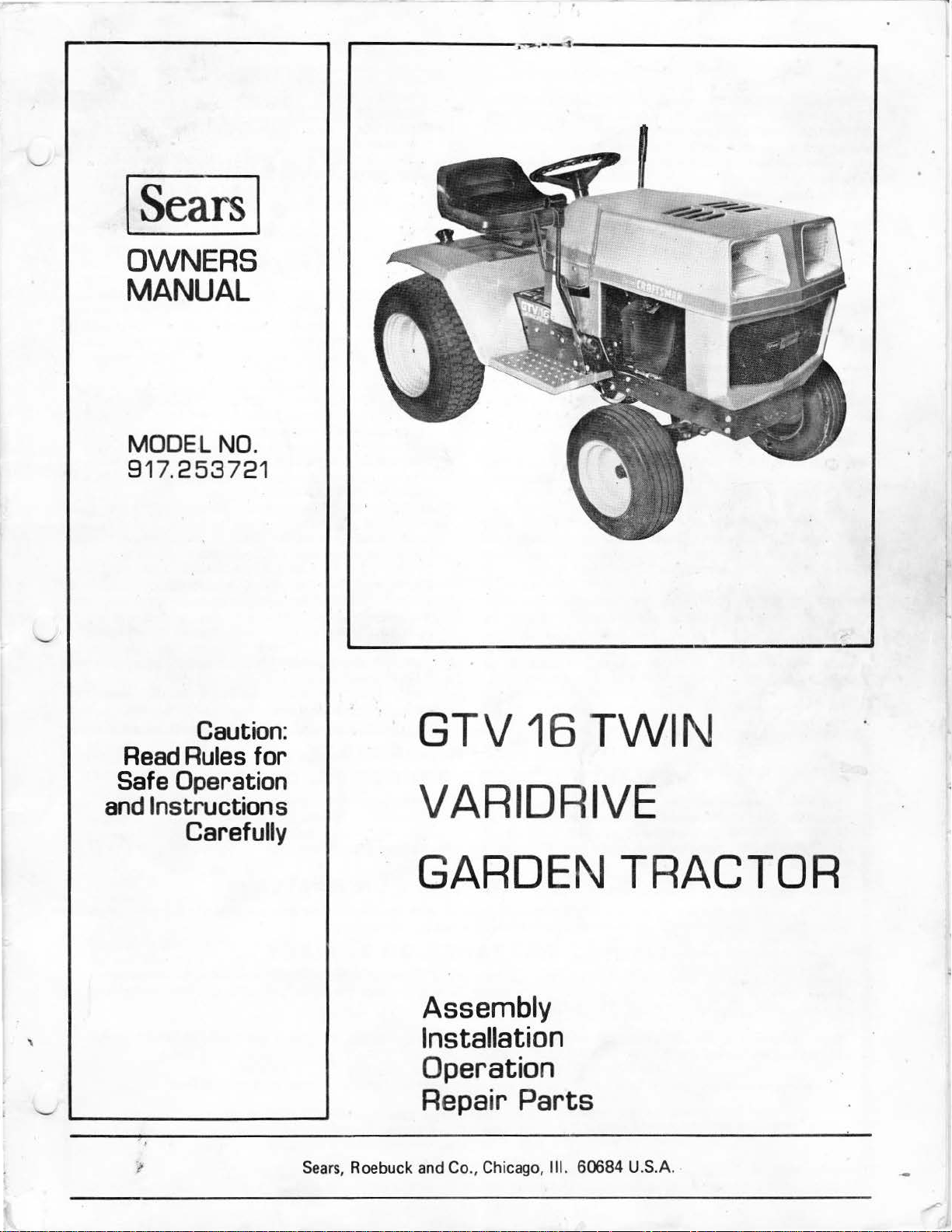

Page 1

..--------

I Sears I

OWNERS

MANUAL

..........

-----

~

-----'*

---------.

MODEL

917.253721

Read

Safe Operation

Instructi

and

NO

.

Caution:

Rules

Carefully

for

ons

GTV

16

TWIN

VARIDRIVE

GARDEN

TRACTOR

'

"-'

----------

Sears

Assembly

Installation

Operation

Repair

, Roebuck and Co., Chicago, Ill. 60684 U.S.A.·

Parts

Page 2

CONGRATU

16

GTV

and

manufactured

Sho

uld you

edy,

please

They

tools

and

Please read

you

to

Always observe

H.P.

cont

have

competent,

parts

and

assemble,

LATIONS

experience

Garden

to

act

to

service or

retain

operate

the

on

your

Tractor.

give

your nearest

well·trained

this

"RU

you

any

repair

manual.

and

LES

problem

FOR

It has

dependability

maintain

purchase

been

you cann

Sears,

Roebuck and

technicians

this

unit

The

instruction

SAFE

of

a Sears Varidrive

designed,

.

your Tractor

OPERATION".

engineered

and

performance.

ot easily

and

the

s will

rem·

Co. s

tore.

proper

enable

properly.

MODEL

NUMBER

SERIAL

NUMB

ER

THE

MODEL AND

BE

FOUND

ED

TO

{REFER

YOU

SHOULD

S

ERIAL

PLACE

FOR

______________________

___________

ON

THE

TO

THE

TOP

PAGE

RECORD

NUM

BERS

FUTURE REFERENCE

____________

SERIAL NUMBERS WILL

MODEL

RIGHT

16).

AND

SIDE

BOTH

KEEP

PLATE

OF

MODEL

IN A

.

_

__

ATTACH·

DRAWBAR

AND

SAFE

YOUR

GARDEN

NEW

TRACTOR

FEATURES

CRAFTSMAN

and

long life

yard,

gardening

INTERLOCK

when tracto

Clutch

ALL

reverse

the

scuffing.

VARIDRIVE SPEED

load

overloaded,

throw

operate

Lever

GEAR TRANSMISSION--thr

to

job.

is

ing,

Lever

to

at

For

repair

16

H.P. ENGINE--cool-running

with

plenty

or

snow

SWITCH

r Cl

utch-Brake

is

in

"OFF"

let

you

such

ground

speed.

year

defect

select

as

the

from the

Automotive-type

not uniform.

the

relieve

full

one

any

GTV

16

...

performance

of

power

remova

SYSTEM-allows

Pedal is

position.

the

proper

differential

CONT

ROL--is

When

with

heavy

speed

may

lo ad

while

to

take

l tasks.

engine

depressed

ee

speeds forward,

match

helps

especially valuable

engine-driven

lawn

mowing

be

reduced with

the

attachment conti

FULL

on a variety

to

start

only

and

Attachm

for

the terr

gua

rd

aga

attachments

or

deep

the

ent

plus

ain

and

inst

turf

when

are

snow

Control

nues

ONE YEAR WARRANTY

ON ELECTRIC START GARDEN TRACTOR

date

of

in

material

purchase, when

or

workma

nship in this

this

Garden

Garden

CONTROL

of

n

Li

ATTACHMENT

Sears

to

Tractor

Tractor,

PANEL--

ition

Switch,

ft

Switch--conveniently

Yard

MANUAL

Ammeter,

VERSATILITY--handles a large

and

Garden

OR

ELECTRIC

44 INCH MOWER

grass

up

for

SELF

lawns

OTHER

Disc Harrow, Drag

CHEVRON

or

snow.

46 INCH

removes

42

INCH SNOW BLOWER

snow

REAR

yards,

is

except

level

POWERED ROTO

and

gardens

SOIL

TILLAGE

TIRES

DOZER

snow.

with

ease.

GRADER

g_rading lanes, drive

used

for

personal

the

battery,

cuts.

with

Throttl

e,

Parking Brake Lever

grouped

Tractor

with

with

a 30 inch

Harrow

for

BLADE levels

AND

at

for

Attachments

LIFT

three

TILLER

ATTACHMENTS

and

Cultivator

added

traction

handl

LEVELER

ways

and

household

no charge.

Choke,

ease

of

.

"high-lift"

prepares

wide

tilling

in loose soil, gravel

or

moves

es

wet,

BLADE

parking

purposes

Light

Switch,

and

use.

variety

including .

blades

to

soil

for

path

.

including Plow,

.

dirt

and

gravel

heavy

powdery

levels

areas.

, Sears w

Electr

stand

new

new

ill

Ig-

ic

of

or

If

this

Garden

purchase.

Tractor

is

used

FULL

For

90

days

from

the date of

workmanship

and

will

not

hold

..

From

the

91st

day

until

one

tive in material

the

new

Warranty

throughout

This w

arra

batte

service

the

nty

or

workmanship

ry for

each

is

available

United

gives

you

full

States

spec

for

comme

rcial

or rental

90-DAY

purchase,

a charge, Sears will replace

if

any

battery

purposes, this

warra

nty

applies

for

WARRANTY ON BATTERY

inclu

ded

with

the

the

battery,

at

Garden

no

cha

Tractor

rge •

proves defective

LIMITED WARRANTY ON BATTERY

year

from

the

date

of

and

will

month

from

the

at

your

home,

.

ific legal rights,

purchase,

not

hold a charge,

date

of

at

no

charge,

and

you

Sears,

may

Chicago, I L

purchase

by

also have

Roebuck

Sears

BSC 41-3

if

any

battery

Sears will replace

.

simply

other

and

Towe

r

60684

included

contacting the nea

rights which vary from

Co.

with

the batte

the

ry,

charging 1/

rest

only

30 days from

Garden Tractor

12th

Sears

store

or

state

to

state

the

date

in

mater

ial

proves defec-

of

the price

Service

Center

.

of

or

of

Page 3

TABLE OF

RULES FOR SAFE OPERATION

ASSEMBLY INSTRUCTIONS

OPERATION INSTRUCTIONS . .

....•

.•....

....

......

..

........

........

RULES FOR SAFE OPERATION

1.

Know

the

contro

ls

and

how

to

stop

OWNER'S

2.

Do

adu

3. Do

tance away.

4. Always

clothing that could get caught in moving parts.

5.

Keep

area

6. Do

not

7. Always get on

hand side.

8.

Clear the

and thrown.

9.

Disengage

l

ever

10.

Disengage

fo

re l

11. Disengag

spark

ing an

12.

Disengage

in u

13. Take all possible precautions when leaving the vehicle unattended, such

the attachments, returning drive

\......../

shifting

the engine, and removing the key.

14

. Do

hill.

150);

15.

Reduce

vent tippi

when changing direction on

16.

While going up or down

to

negotiate the slope wi

move drive control lev

17.

Never

su

re or at a

18.

Stay alert for hol

19

. Do

ways.

20. Exercise

in order

deliberately run tractor or mower i

object.

21

. Never shift

22. Never

chute

running. Always keep clear

MANUAL.

not allow chi

lts

to

operate it

not

carry

wea

your

being cut. Don't let other intere

not

attempt

in driv

to

neutral before attemptin g

eav

ing the operator's

e power

plug wi

adj

ustment or repair

se.

into

not

stop or start suddenly when going uphill

Mow

nev

er

speed

mow

not

dri

specia

to

place hands

or

near any moving parts while

ldr

en

to oper

ate

without

passengers.

r substantial footwear. Do n

eyes

and

to

ers

seat.

or

off your

work

area

all

attachment

power

to

to

re(s)

from spark plu

power

to

as

disengaging the power-take-off, lowering

neutral, setting the parking brake, stopping

up and down the

across

the

on

ng

slopes

or

loss

in wet or slippery

speed

whi

es

in the terrain

ve

too close

l care when

prevent the

gears

until

or

proper instruction.

Keep children

mind

on

your

operate your tracto r or mower when

tractor from t

of

objects whi

clutches

attachments

positio

mower, stop t

s.

attachments when transporting or not

face

face

.

and make turns

of

control. Exercise extreme caution

slopes

slopes

tho

ut

er toward neutral

ch

could

cause a sk

to

creeks, ditches

mowing

blades

tractor

comes

feet under the mower, in discharge

of

discharge chute .

quickly.

the vehicle. Do

ot

tractor, mower

sts

distract you.

ch

might

and

return

to

start the engine.

and

stop the engine be-

n.

he

eng

g(s)

before cleanin

control

of

slopes

.

choose a

stopping. To reduce

grass,

when traction

and

other hidden

around fixed objects

from striking them. Never

nto

or over

to

a stop.

tractor

READ THE

and

pets a

wea

r l

oose

he

operato

be

speed

ine

and

lever

(not greater than

gradually

speed

low

positio

n.

id.

and

public h

any

or

LOOK

SAFETY

BECOME

CONTENTS

BELOW

2

4

not

allow

safe

dis-

fitting

and the

rs left

picked up

control

disconnect

g,

mak-

to

neutral,

or

down-

to

pre-

enough

speed

,

is

un-

haza

rds.

igh-

foreign

mower

FOR

are

THIS

PRECAUTIONS.

ALERT!

SYMBOL TO POINT

YOUR

MAINTENANCE INSTRUCTIONS •...•••..•••

TROUBLE

REPAIR PARTS .

23.

Use

a.

b.

c.

d.

24. Watch

25. When using any attachments, never direct discharge

material toward bystanders

hicle while in operation.

26.

Handle gasoline

a.

b. Never remove the cap

c.

27. Keep the vehicle

di

tion,

28. Keep

ment

29. Never store the equipment

a building where fumes may

Allow

30.

To

or

31. Except

cleaner

moved. Removal

32. DO

PER

or

ically

33 . The vehicle

spected

damage

the equipment.

34. Do

the engine.

35

. When using the vehicle

a.

b. Never make a

c.

d. Check the blade mounting bolts

36. Check the

ration.

37. Do

on mowers so equipped,

38. Disengage

in

careful observat

IT

SAFETY

SHOOTING .

....

care when pulling loads

Use

only

Limit

Do

Use

the owner's

Use

a running or

Wi

Open doors if the engine

fumes

reduce fire hazard, keep the

excessive

NOT

spark arresters could create a fire hazard. Inspect period·

not

Mow only in daylight

is

Shut the engine

unclogging chute.

freque

not

reverse

MEANS-ATTENTION!

approved drawbar hitch points.

loads

to

those you

not

turn

counterweig

out

approved gasoline containers.

pe

and keep safety devices in place.

all

is

the engine

WITH

and repl

running

Rep

sharply.

manual.

for traffic when crossing

with

up spilled gasoline.

nuts, bolts and screws tight

in

for

or

for

should

change the engine governor settings

nt

operate the Mower

hot

are

dangerous. Do

and

safe

working condition.

to

grease.

adjustment; DO NOT operate Engine

cover directly over carburetor air intake

of

OPERATE

THE EXHAUST SYSTEM. Damaged mufflers

ace

if necessary.

and

attachments should

damage

be

repaired before restarting and operating

cutting

if

the operator must dismount

intervals.

grass

catcher

lace

with

power

to

unless absolutely necessary and then

ion

OUT

IMPORTANT

IS

INVOLVED.

...

..•.••.•.•..

...•

. .

•••••••••.•.....

or

using heavy equipment.

can

safely

control.

Use

ht

cool before storing in any enclosu

such

after striking a foreign object, and the

off

mower before backi

of

care when backing.

or

wheel weights when

or

near roadways.

nor

allow anyone near the

care-

it

is highly flammable.

of

the fuel tank

engine,

new

or

fill

is

run in the

not

attachments in good operating con·

with

gasoline in the tank inside

reach

engine

part

could create a fire hazard.

WITHOUT A MUFFLER

with

mower, proceed

or

in good artificial light.

height adjustment while the engine

when removing the

bags

frequently

bags

for

safety protection .

without

or

the deflector shield in place.

the entire

area

or

the fuel tank indoors.

run the engine indoors.

to

be

an

open flame

free

be

for

proper tightness at

for

the entire

ng

behind the mower.

..•..

suggested

add

gasoline

garage

- exhaust

sure

the equip·

or

spark.

of

grass,

OR TAM·

stopped and in-

or

overspeed

as

follows:

to

do

so.

grass

catcher

wear

or

deterio·

grass

catcher,

up.

Do not

only

..

6

13

15

in

of

ve-

to

re.

leaves

if

air

is

re-

or

mow

after

This

unit

is

covered

laws

In

the State

have

677A936.

equipped

or

grass-covered l

(if

any).

If

of

similar laws. Federal laws apply on federal lands.

with

an

and

a spark arrester

California t

he

internal combustion engine and should

unless the engine's exhaust system

is

used, it should

above

is

required by law (Section 4442

WARNING

be

maintained in effective working order by the operator.

See

your

not

be

used

on

or

is

equipped w.ith a spark arrester meeting applicable local

of

the California Public Resources Code). Other states may

Authorized

Serv

near any unimproved forest-covered, brush-

ice Center

for

spark arrester

. 1 .

muffler

part

or

state

number

Page 4

CAUTION

(FIG

OCCUR TO

FIGURE 1

: DO

NOT

OPERATE VARIDRI

. 11) UNLESS ENGINE IS RUNNING.

\?

U=

T

==A=

W

VARIDRIVE

=

A

=

Y

=

V

=

I

=

E

~ S

__.Lj

--

- - - • - - - - - -

SYSTEM.

=

W

============

1

ln

lr

i I : J

l : :

!

~:

1

:

-- . -- - -- .

'-

VE CONTROL

DAMAGE

MAY

==<~VENTCAP

To

assemble and adjust

one 3/4" socket,

11

/16" wrench

NOTE : RIGHT

DETERMI NED FROM OPERATOR

SEATED ON TRACTOR.

HAND

two

(R.H.)

ASSEMBLY

~BATTERY

~

:

~

::

: : •'

..:.J

r1

~

r;

·:

l•

:

TUBE

BATTERY

CELL

1. Remove Shipping

St

eering

Wheel

Rod (shown below) holding f

crate. Remove

crate. Discard Rod and Screw.

St

rap Banding, Bundling Wires, Battery,

and

Bag

Lag Screw from

your

Tractor you

7/ 16" wrenches and

AND LEFT HAND

'S

POSITION WHILE

of

Parts. Al

ront

Hold

so

end

there

is a Ho

of

tractor

Down Rod and

will

need:

(L.H .) ARE

ld

to

one

Down

wood

wood

FIGURE 2

BA

TTERY

TRA

Y

GRILL

SCREEN

2. Fill and charge Battery (before installing). NOTE:

DETAILED

TERY

a.

Fill Batte

(Fig. 1). NOTE: DO NOT OVER

IL

W

b. Check

tional electrolyte if necessary. NOTE:

CAPS SECURE LY.

c.

Charge

for about

d.

Neu

four

Stir

i

ng

foamin

3. Install Battery using:

INSTRUCTIONS PACKAGED WI

.

WEAR EYE

ry

with

L RESULT IN DAMAGE TO TRACTOR.

WASH

ATEL Y IF

WITH ELEC

level

of

Battery

two

and

DO NOT SMOKE,

ED ELEC

tral

ize

exce

inches

of

with

a wooden or plastic paddle while adding bak·

soda

unt

il the addition

g.

e~

;======

AND

FACE

SHIELD

electrolyte

HANDS OR CLOTHING

ACCIDENTALLY IN

electrolyte after 30 minutes. Add addi·

at

a rate

one

TROLYTE ARE

ss

electrolyte

water in a five gallon plastic container.

to

TROLYTE

not

half hours .

FUM

for

of more

==e

bottoms

.

exceeding three amperes

of

FILL.

OVERFILLI

TIGHTEN

ES FROM

EXPLOSIVE.

disposal

soda

causes

TH

.

tubes in cells

IMMED

CONTACT \j_J

CHARG·

by

addi

no more

SEE

BAT

NG

I·

VENT

ng

to

·

<S

Battery Rod,

tery Bolts,

two

Fiat

two Hex

a. Lift

b. Remove tape from Plastic Tray. Make

(Fig. 3) is fastened

Battery Tray

Place

c.

of Trac

NOTE:

YOUR

TOOLSCRACK

· 2 ·

two Wing

Q)::::B

Wash

ers, tw

Nuts found in

Hood from rear

Battery in Plastic Tray (Battery Terminals

TIGHTEN

THUMB AND FOREFINGER. DO NOT U

THE

is

tor) (Fig. 3).

OVER

BATTERY

Nuts,

@)

o Lockwash

Bag

sides

to

positioned in hole

WING NUTS SECURELY USING

TIGHTENING

CASE.

®~

two

Flat

Washers,

(g

®

ers, two

of Parts.

(Fig. 2).

su

Drain Hole in Batt

of Battery Support .

MAY

OVERSTRESS OR

two

Hex Bolts

re

Drain Tube

ery Tray and

to

front

Bat·

and

SE

Page 5

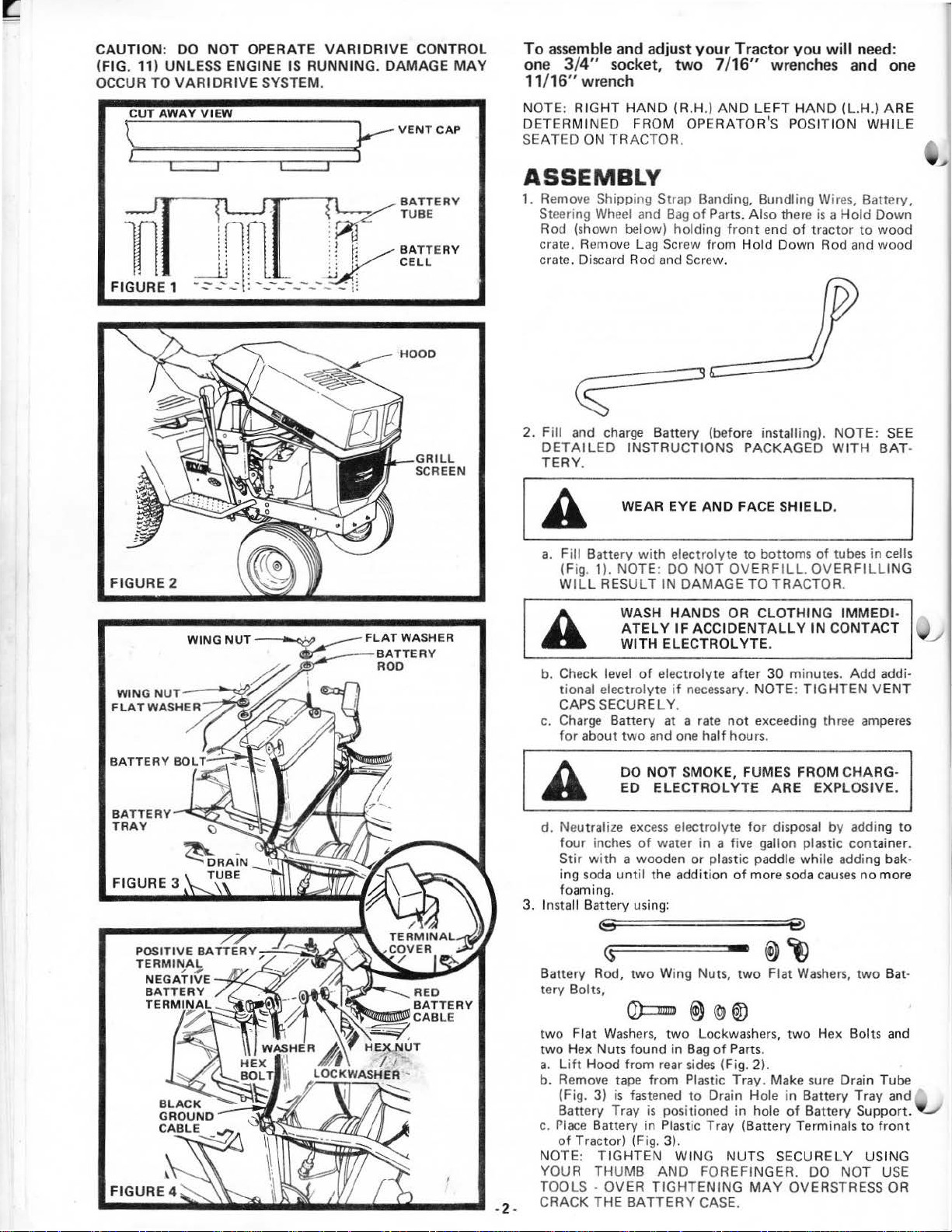

d. Hook Battery

Suppo

rt

with

a Flat

e. Hook remaining Battery

of

Battery Support

Washer

ly.

Pos

iti

f.

on

Bolt

(Fig. 3). Fasten Battery Rod

Washer

and

Wing

Terminal Cover over RED Battery Cable (Fig.

into sl

and Wing Nut.

and

fasten Battery Rod

Nut

(Fig. 3). Tighten Wing Nuts secure-

4).

g. Connect RED Battery Cable

minal

with

Hex

Nut

(Fig. 4). Form

and tighten securely.

nal. NOTE:

ENCLOSE

Bolt, Fiat

Cable

PULL

BATTERY TERMINAL

Place

TERMINAL

ot

on

the

left

side

of Battery

to

Battery

Bolt

into slot in R.H. side

to

Positive

Washer,

in

Lockwasher and Hex

an

upward position (Fig.

Terminal Cover over Termi-

COVER FORWARD

(FIG. 4 - INSET).

with

(+)

Battery Ter·

a Flat

Bolt

4)

TO

POSITIV

NECTED FI

FROM ACCIDENTAL GRO

h. Connect

tery Terminal

Lockwasher and Hex

ly.

4. Close Hood.

5.

Install Steering

BLACK

@

Hex

Nut

Place

Steering

Press

Steering Wheel

and Steering

with

SPARK ARRESTOR

parts.

a.

b. Fasten

c.

NOTE: A

AVAILABLE

TRACTOR. CHECK

AREA.

E TERM

Ground Cable

with

Wheel

using:

Wheel

on Shaft (Fig. 5).

Hex

Nut

. Tighten

AS AN ACCESSORY PART FOR YOUR

LEGAL

INAL

MUST BE CON-

RS

T TO PREVENT

UNDI

to

remaining Hex Bol

Nut

(Fig. 4). Tighten

Wheel

Insert

secure

Insert

Cap

MUFFLER

REQUIREMENTS IN YOUR

Negative (- ) Bat-

Cap

found in

ly.

in

place

.

t,

(PA

SPARKS

NG.

Flat Washer,

Nut

secure-

bag

GE

1)

of

IS

FIGURE 5

INITIAL

1. Red

uce

Tire pressure

re

ar

in

poses).

2.

Seat

loosening Bolt in

TIGHTENING

SURE SEAT PLATE HAS NOT TWISTED

ALIGNMENT

Tires. (Tires were overinflated

position may

INITIAL

NOTE: BE

THE

FUEL.

1. Check Engine

Wipe dipstick (Fig. 7) clean, push

onds, remove and read

"

FULL"

\,.__..

SO,

'IOW30

use

OIL.

2. Fill Fuel Tank (Fig. 6)

ed

gallons. NOTE:

LEAD-FREE GASOLINE. .

CAREFUL

ENGINE WHEN CHECKING

mark

SE

or

(SC,

S.A.E. 5W20

NOT

E:

or

low-l

ead

ADJUSTMENTS

to

14 pounds in

be

adjusted forward

Seat

Plate

(Fig. 6). NOTE: WHEN

BOLT

WITH

AFTER

SEAT SPRING.

ADJUSTMENT,

SERVICE

NOT

TO

ALLOW

OR

Oil

Level

with

Tractor

it

Oil

Leve

l.

is

reached. In summer

SF)

Oil. In

SO,

(SC,

DO

NOT

automotive gasoline

DO

SE

or

SO,

OVERFILL.

NOT

winter

SF). In

with fresh,

If necessary,

(below

ext

reme

SE

or

SF). DO NOT

clean regular

SWITCH FROM LEADED

only

front

and 10 pounds

for

shippi

or

backward by

DIRT

TO ENTER

ADDING

on

in

level ground .

tight

for a few

add Oil

use

S.A.E.

32°F

.)

use

cold (below 0°F.)

USE

grade

. Capacity

ng

MAKE

OUT

OIL

until

30

S.A.

10W40

lead-

is 3-1/2

pur-

RE-

OF

OR

sec-

(SC,

E.

TO

WARNING:

react

strong acids which can corrode metal parts, even eat rubber

and plastics.

A

3.

Do

not

use

with

water content in the fuel and tend

FI

LL

TO BOTTOM OF GAS

ER NECK. DO

OFF ANY

Gasohol. Gasohol type alcohols

NOT OVERFILL. WIPE

SPILLED

OIL

OR

TANK

FUEL

FIGURE 7

to

form

FIL

L-

.

Page 6

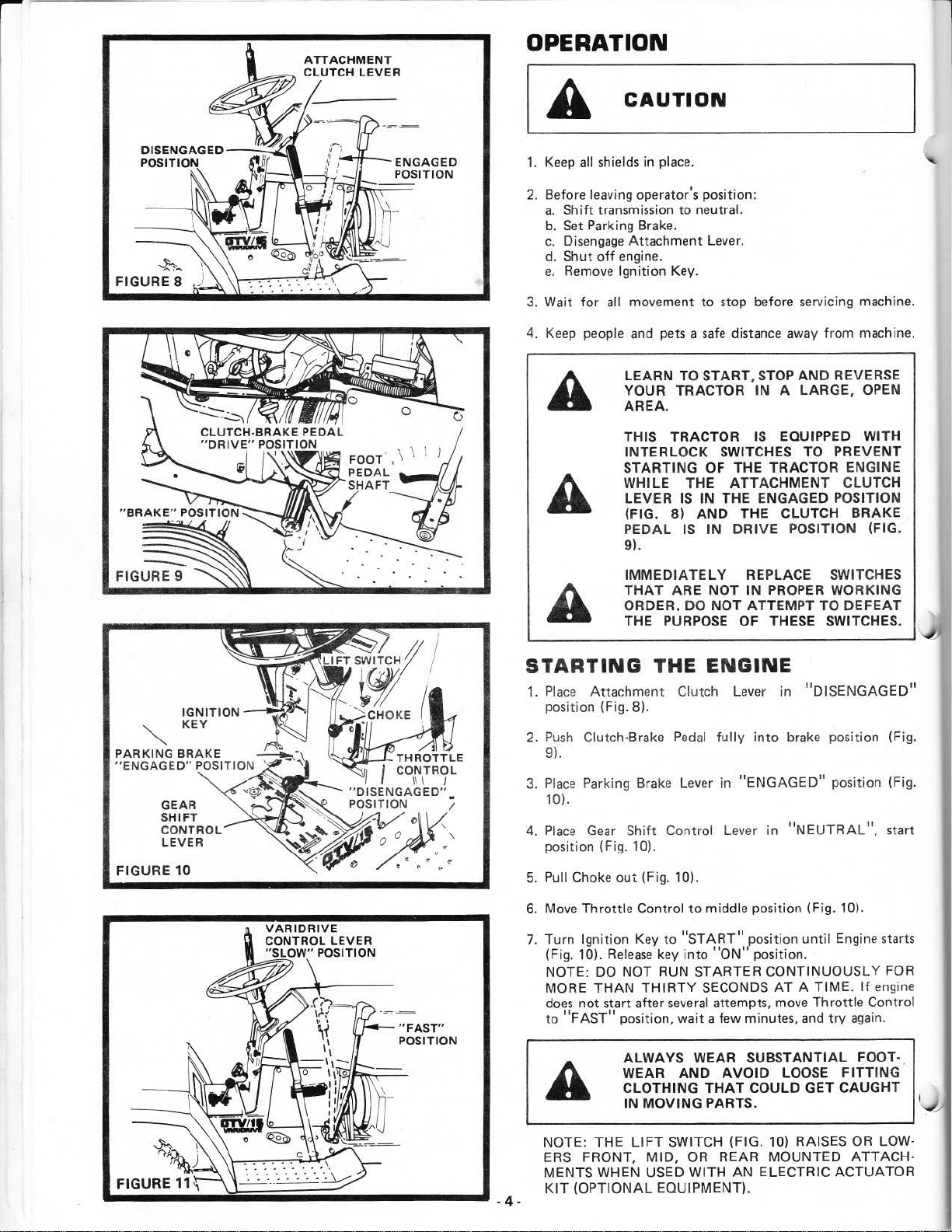

ATTACHMENT

CLUTCH

LEVER

OPERATION

--h_

FIGURE 8

[A

1.

Keep

2.

Before leaving operator's position:

a.

Shift

b.

Set

c.

Disengage

d. Shut

e.

Remove

3. Wait for all movement to stop before

Keep people

4.

CAUTION

all shields in place.

transmission to neutral.

Park

ing Brake.

Attachment

off

engine.

Ignition Key.

and

pets a

LEARN

YOUR TRACTOR IN

AREA.

THIS TRACTOR

INTERLOCK SWITCHES TO

STARTING

WHILE

LEVER

(FIG.

PEDAL

9).

Lever.

safe

TO START,

OF

THE ATTACHMENT CLUTCH

IS

IN

8)

THE ENGAGED POSITION

AND

IS

IN

distance

STOP

IS

THE TRACTOR ENGINE

THE CLUTCH BRAKE

DRIVE

serv

icing machine.

away

from machine.

AND

A LARGE, OPEN

EQUIPPED WITH

REVERSE

PREVENT

POSITION (FIG.

PARKING

"ENGAGED"

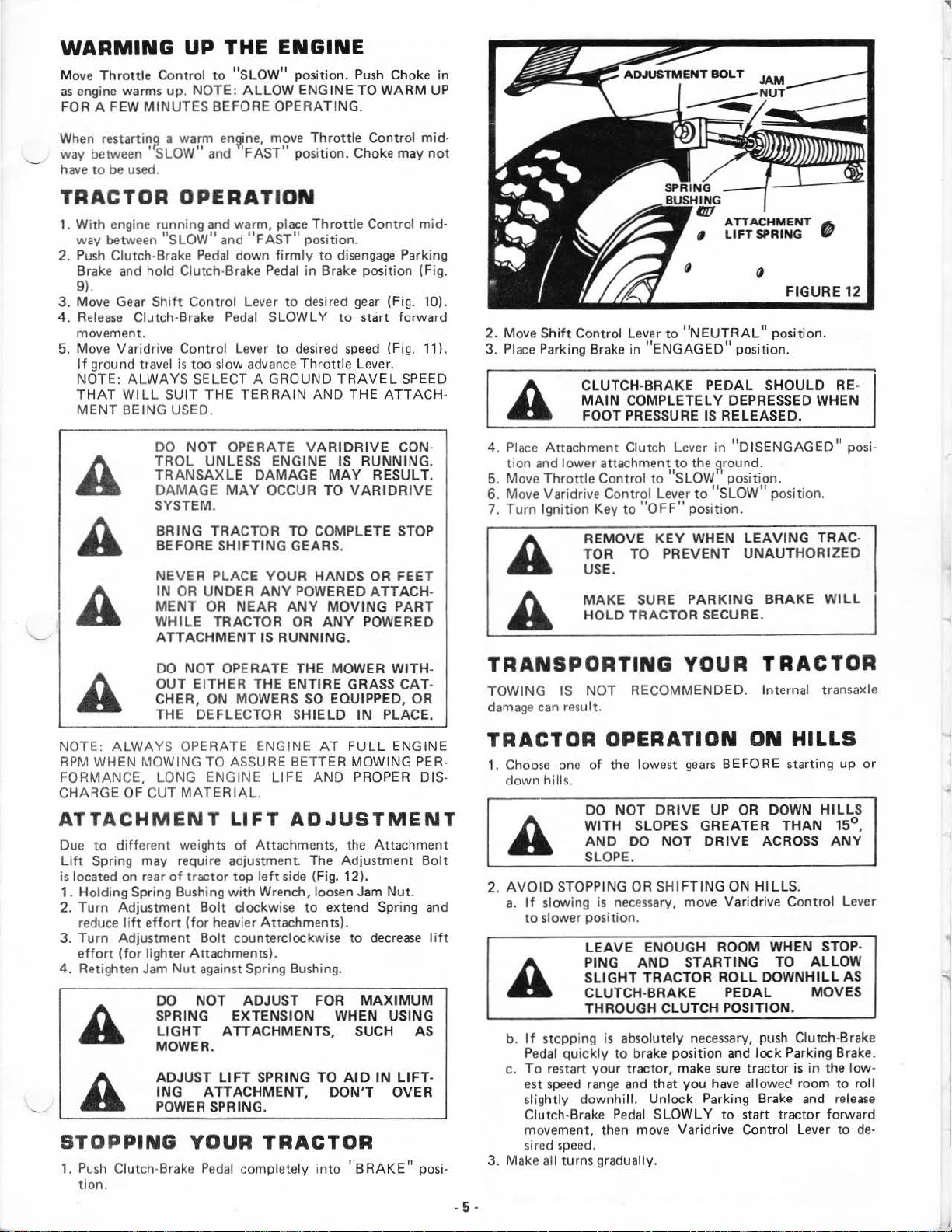

FIGURE 10

BRAKE

GEAR

SHIFT

CON

LEVER

IGNITION

KEY

POSITION

TROL

~

~

_.....,;::.QJ""ol

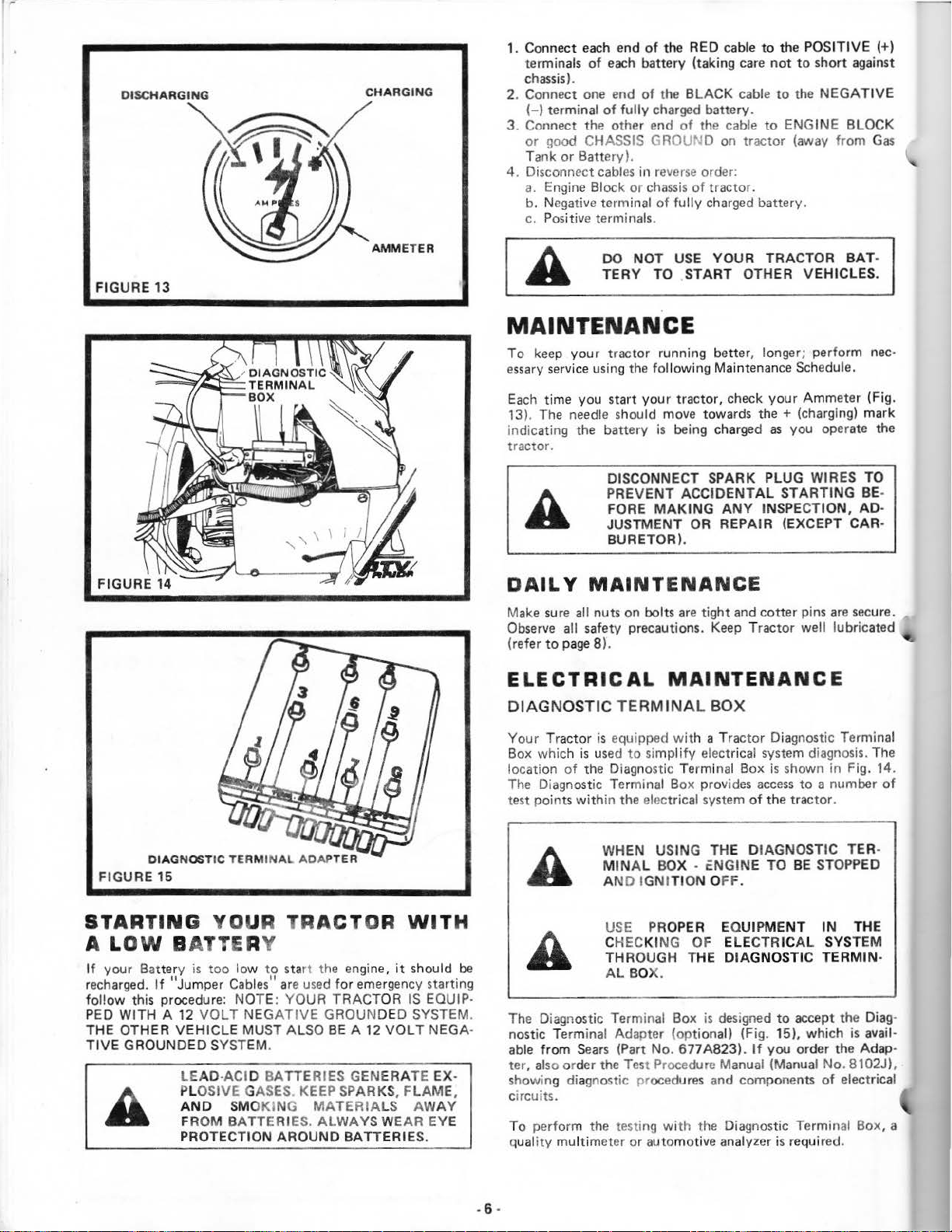

VARIDRIVE

CONTROL

"SLOW"

LEVER

POSITION

--~--------

"FAST"

POSITION

IMMEDIATELY

THAT

ORDER. DO

THE

STARTING

1. Place

2.

3.

4.

5. Pull Choke

6.

7.

Attachm

position (Fig. 8).

Push

Clutch-Brake

9).

Place

Parking Brake Lever in

10).

Place

Gear

Shift Control

position (Fig.

Move

Throttle Control

Turn Igni

(Fig.

10).

NOTE:

MORE

does

not start after

to

"FAST"

10).

out

tio

n Key to

Release

DO

NOT RUN STARTER CONTINUOUSLY FOR

THAN

position, wait a few minutes,

ALWAYS WEAR

WEAR

CLOTHING

IN

REPLACE SWITCHES

ARE NOT

PURPOSE

THE

ent

Clutch Lever in "DISENGAGE

Pedal

(Fig. 10).

to

"START"

key

into

THIRTY

several

AND

MOVING

IN

PROPER WORKING

NOT

ATTEMPT TO

OF THESE SWITCHES.

ENGINE

fully

into

brake position (Fig.

"ENGAG

Lev

er

middle position (Fig. 10).

position

"ON"

SECONDS

attempts, move Throttle Control

SUBSTANTIAL

AVOID

THAT

COULD GET CAUGHT

PARTS.

in

"NEUTRAL",

position.

AT

LOOSE

ED"

until

A TIME.

and

DEFEAT

D"

position (Fig.

start

Engine starts

If

engine

try

again.

FOOT-

FITTING

I

~

~

\..,l

}'

NOTE: THE

ER

S FRONT,

MENTS WHEN USED WITH

KIT

(OPTIONAL EQUIPMENT).

LIFT

SWITCH (FIG. 10) RAISES

MID,

OR

REAR MOUNTED

AN

ELECTRIC ACTUATOR

OR

LOW-

ATTACH-

Page 7

WARMING

Move

Throttle

as eng

ine warms up. NOTE:

FOR A

FEW

Control

MINUTES BEFORE OPERATING.

UP

THE

to

"SLOW"

ENGINE

ALLOW

position.

ENGINE TO WARM UP

Push

Choke in

When restartinP. a warm en9ine, move T

way between

have

to

be

'SLOW"

used.

and

'FAST"

position. Choke

TRACTOR OPERATION

1. With engine running and warm, place

way between

2.

Push

Clutch-Brake

Brake

9)

.

3. M

ove

4.

Releas

movement.

5.

Move Varidrive Control Lever to desired

If

grou

NOTE: ALWAYS SELECT A GROUND

THAT

ME

NT

A

A

"SLOW"

and

hold Clutch-Brake

Gear

Shift

e Clutch-Br

nd

trave

l is too slow

WILL SUIT THE

BEING USED.

DO

TROL UNLE

TRANSAXLE

DAMAGE

SYSTEM.

BRING

BEFORE SHIFTIN G GEARS.

NEVER PLACE YOUR HANDS

IN

MENT

WHILE TRACTOR

ATTACHMENT IS RUNNING .

and " F

AST"

Pedal

down

firmly

Peda

Control Lever to desired

ake

Pedal

SLOWLY to start forward

advance

TERRA

NOT OPERATE

OR

SS

ENGINE IS RUNNING .

DAMAGE

MAY

OCCUR TO

TRA

CTOR TO COMPLETE

UNDER

OR

ANY POW

NEAR

position.

l in Brake

Throttle Lever.

IN AND THE

VAR

ANY

OR

hrottle

Throttle

to

Control

may

Control mid-

disengage

position (Fig.

gear

(Fig. 10).

speed (Fig.

TRAVEL

ATTACH

IDRIVE

MAY

VARIDRIVE

ERED ATTACHMOVING

ANY POWERED

CON-

RESULT.

STOP

OR

FEET

PART

mid

not

Parking

11)

SPEED

·

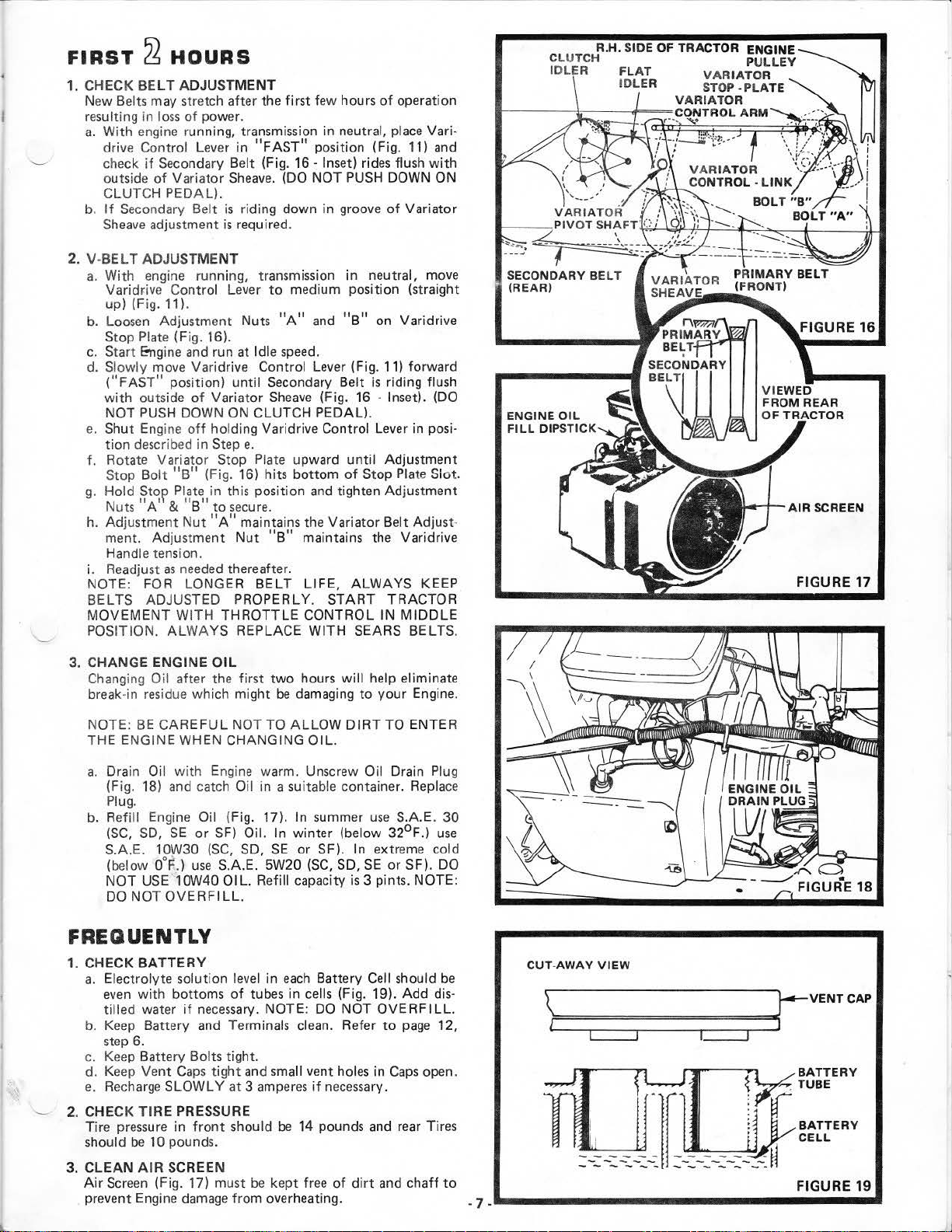

FIGUR E 12

2.

Move

Shift

.

3. P

lace

-

4.

Place

tion

5.

Move Throttle Contr

6.

Move

7.

Turn Ignition Key to

Control Le

Parking

and

Brake in

CLUTCH-BRAKE PEDAL

MAIN

FOOT PRESSURE IS RELEASED.

Attachment Clutch Lever in

lower attachment to the wound.

Varidrive Control Lever

REMOVE

TOR TO

US

MAKE

HOLD

ver

to

"NEUTRA

"ENGAGED"

COMPLETELY DEPRESSED WHEN

ol to "SLOW position.

"OF

E.

SURE PARKING BRAKE

TRACTOR SECURE.

to

F" position.

KEY

WHEN

PREVENT

L" position.

position.

SHOULD RE·

"DISENGAGED"

"SLOW" position.

LEAVING

UNAUTHORIZ

posi

TRAC-

ED

WILL

-

DO

NOT OPERAT

OUT E

ITH

ER THE

CHER,

THE DEFLECTOR SHIE

NOTE: ALWAYS OPERATE ENGINE

RPM

WHEN MOWING TO ASSURE BETTER MOWING

FORMANCE, LONG ENGINE

CHARGE OF CUT

ON

MATERIAL.

ATTACHMENT LIFT

Due

to

different weights

Lift

Spring may require adjustment. The Adjustment

is

located on rear

1. Holding Spring Bushing

2. Turn Adjustment

reduce

lift

3.

Turn Adjustment

effort

4. Retighten

(for

STOPPING

1.

Push

Clutch-Brake

tion.

of

tractor top

with

effort

lighter Attachments).

Jam

Bolt

(for

heavier Attachments).

Bolt

counterclockwise to

Nut

against Spring

DO

NOT ADJUST FOR

SPR

IN G EXTENSION WHEN USING

LIGHT

MOWER.

ADJUST

ING

POWER

ATTACHMENTS, SUCH AS

LIFT

ATTACHMENT,

SPRING.

YOUR TRACTOR

Pedal

E THE MOWER WITH-

MOWERS

ENTIRE GRASS

SO

EQUIPPED,

LD

AT

LIFE

AND PROPER DIS-

ADJUSTMENT

of

Attachments, the Attachment

left

side

Wrench, loosen Jam

clockwise to extend Spring

SPRING TO

completely i

(Fig. 12}.

Bushing.

DON'

nto

IN

PLACE.

FULL

Nut.

decrease

MAXIMUM

AID

IN

T OVER

"BRAKE"

CAT

·

OR

ENGINE

PER

Bolt

and

lift

LIFT

-

posi-

TRANSPORTING

TOWING

damage

can

IS

NOT

result.

RECOMMENDED. Internal transaxle

YOUR

TRACTOR

TRACTOR OPERATION ON HILLS

-

1.

Choose

down hills.

2.

AVOID

a.

b.

c.

3. Make all turns gradually.

. 5 .

one

of

the lowest g

DO

NOT

WI

TH SLOPES GREATER

AND

DO

SLOPE.

STOPPING

If

slowing

to

slower pos

If

stopping

Pedal

quickly to bra

To restart your tractor, make

est

speed

slig

htly downhill. Unlock Parking Brake

Clutch-Brake

movement, then move Varidrive Control Lever to

sired

speed.

OR

is

necessary,

iti

on.

LEAVE

PING

SLIGHT TRACTOR

CLUTCH-BRAKE

THROUGH C

range

ENOUGH ROOM WHEN STOP-

AND

is

absolutely

and

Pedal

ears

DRIVE

NOT

DRIVE

.

SHIFTING

move Varidrive

STAR

LUT

CH

necessary,

ke

positi

on

that you

SLOW

LY

BEFORE starting up

UP

OR

ACROSS

ON

HILLS

TIN

G TO

ROLL

DOWNHILL AS

PE

DAL

POSITION.

push Clutch-Brake

and lock Parking Brake.

sure

tractor

have

allow

to

statt tractor forward

DOWN

HILLS

THAN 15°

.

Control Lever

ALLOW

MOVES

is

in the low-

ed

room

and

AN

Y

to

roll

release

de·

or

,

Page 8

CHARGING

1. Connect

terminals

chassis)

2. Conne

(-)

3. Connect the other end

or

Ta

4. Disconnect

a.

b. Negative terminal

c.

each

end

of the

of

each

of

fully

cables

ck

or

battery (taking

of

the

charged battery.

in

revers

chassis

of

.

ct

one end

terminal

good CHASSIS GROUND

nk

or

Battery).

Engine Blo

Positive terminals.

RED cable to the POSITIVE (+)

care

not

to

short against

BLACK cable

of

the cable

on

e order:

of

tractor.

fully

charged battery.

to

the

to

ENGINE BLOCK

tractor (away

NEGAT

from

IVE

Gas

FIGU RE

FIGU

13

AMMETER

DO NOT

TERY TO .START OTHER

USE

YOUR TRACTOR

MAINTENANCE

To

keep

essary

Each time

13).

indicating the battery

tractor.

DAILY MAINTENANCE

Make

Observe

(refer

ELECTRICAL

DIAGNOSTIC TERM

your tractor running better, longer; perform

service using the following Maintenance Schedule.

you start your tractor, check

The

needle

should move towards

is

DISCONNECT SPARK PLUG WIRES TO

PREVENT

FORE

JUSTMENT OR REPAIR (EXCEPT CARBURETOR).

sure all nuts on bolts

all safetY precautions.

to

page 8).

MAK

being charged

ACCIDENTAL

ING

are

tight and cotter pins

ANY

Keep

the+

INSPECTION, AD·

Tract

MAINTENANCE

INA

L BOX

VEH

ICLES.

your

Ammeter (Fig.

(charging) mark

as

you operate the

STARTING BE-

well

are

lub

or

BAT

nee·

secure.

ricated

·

DIAGNOST

FIGU

RE

15

STARTING YOUR

A LOW B

If your Battery is too low to start the engine,

recharged.

follow

PED WITH A

THE OTHER VEHICLE MUST ALSO

TIVE

If

this procedur

GROUNDED SYSTEM.

IC

TERMI

NAL

ADAPTER

TR

ACTOR WITH

ATTE

"Jumper Cables" are

12

VOLT

LE

AD

PLOSIVE GASES.

AND

FROM BATTERIE

PROTECTION AROUND BATTERIE

RY

e:

NOTE: YOUR

NEG

ATIVE

-ACID

BAT

SMOKING

used

for emergency starting

TRACT

GROUNDED SYSTEM.

BE

A 12

TERIES GEN

KEEP SPARKS,

MATERIA

S.

ALWAYS WEAR EYE

it

OR

IS EQUIP·

VOLT

ERA

FLAME,

LS

should

NEGA·

TE EX-

AW

AY

S.

be

Yo

ur

Tractor

Box which

locati

on

The Diagnos

test points

The Diagnostic Terminal Box

nostic Terminal Adapter (optional) (Fig. 15), which is avail·

able from

als

ter,

showing diagnostic procedures and components

circuits.

To perform the testing

q

ua

lity mul

is

equipped

is

used

to

simp

of

the Diagnostic Termi

tic Terminal Box provid

withi

n the electrical system

WHEN

MIN

AL BOX - eNGINE TO

AND IGNITION O

USE

PRO

CHECKING OF ELECTRICAL SYSTEM

THROUGH

AL BOX.

Sears

(Part No. 677A823).

o order the

timet

Tes

t Procedure Manual (Manual No. 8102J).

er

or

automot

wit

h a Tractor Diagnostic Terminal

lify

electrical system diagnosis.

nal

Box

is

shown in Fig. 14.

es

access

to

a number

of

the tractor.

US

ING TH E DIAGNOSTIC TER-

BE STOPP

FF.

PER

EQUIPMENT

THE DIAGNOSTIC TERMIN·

is

designed

If

you order the Adap·

with

the Diagnostic Terminal Box, a

ive

analyzer

to

accept the

is

requir

IN

of

ed

The

of

ED

THE

Diag

electrical

.

·

. 6 .

Page 9

FIRST

1.

CHECK

New Belts may stretch after the

resulting in

a.

b.

2.

V-BEL T ADJUSTMENT

a.

b. Loosen Adjustment Nuts

c.

d. Slowly move Varidrive Control Lever (Fig. 11) forward

e.

f. Rotate Variator Stop Plate upward until Adjustment

g.

h. Adjustment

i. Readjust

NOTE: FOR LONGER

BELTS ADJUSTED PROPERLY.

MOVEMENT

POSITION.

~

HOURS

BELT

ADJUSTMENT

loss

of

With engine running, transmission in neutral, place Varidrive Control Lever in

check

if

outside

CLUTCH PEDAL).

If

Sheave

With engine running,

Varid~ive

up) (Fig. 11).

Stop Plate (Fig. 16).

Start Engine

("FAS

with

NOT

Shut Engine

tion

Stop

Hold

Nuts

ment. Adjustment

Handle tension.

of

Secondary Belt

adjustment

T"

outside

PUSH

described in Step

Bolt

Stop Plate in this position

"A'

power.

Secondary Belt (Fig. 16 · Inset) rides flush

Variator

Control Lever

position) until Secondary Belt

DOWN ON CLUTCH PEDAL).

"B"

& "

as

need

WITH

ALWAYS

Sheave

is

is

required.

and

run at Id

of

Variator

off

holding Varidrive Control Lever in posi-

(Fig. 16) hits

B"

to

secure.

Nut

"A"

Nut

ed

thereafter.

THROTTLE

REPLACE

first

few hours

"FAST"

riding down in groove

transm1ss1on

e.

maintains the Variator Belt Adjust·

BEL

position (Fig. 11) and

. (DO NOT PUSH DOWN

to

medium position (straight

"A"

and

le

speed.

Sheave

"B"

(Fig. 16 · Inset). (DO

bottom

and

maintains the Varidrive

T LIFE,

START

CONTROL IN

WITH

of

ope

of

Variator

in neutral, move

"B"

on Varidrive

is

riding flush

of

Stop Plate Slot.

tighten Adjustment

ALWAYS

TRACTOR

MIDDLE

SEARS BELTS.

ration

with

ON

KEEP

ENGINE

FILL

DIP

OIL

STICK

AIR

SCREEN

FIGURE 17

3. CHANGE ENGINE

Changing Oil after the

break-in residue which might

NOTE:

THE

a.

b.

BE

CAREFUL

ENGINE WHEN CHANGING

Drain Oil wi

(Fig. 18) and catch

Plug.

Refill Engi

(SC,

SD,

S.A.E. 10W30

(below

NOT

DO

0°F.)

USE

NOT

OVERFILL.

OIL

first

two

be

damaging

NOT TO

th

Engi

ne

Oil in a suitable container. Replace

ne

Oil (Fig. 17). In summer

SE

or

SF)

Oil. In winter (below

(SC,

use

.10W40

SD,

S.A.E. 5W20

OIL.

ALLOW

warm. Unscrew Oil Drain Plug

SE

or

Refill capacity

hours

will

help eliminate

to

your

Engine.

DIRT

OIL.

SF). In extreme cold

(SG,

SO,

TO ENTER

use

S.A.E.

32°F

SE

or SF). DO

is

3 pints. NOTE:

30

.)

use

FREQUENTLY

1. CHECK

a.

b. Keep Battery and Terminals clean. Refer

c.

d. Keep

e.

2. CHECK

Tire pressure in

should

CLEAN

3.

Air

prevent Engine damage from overheating. • 7 _

BATTERY

Electrolyte solution

even

with

bottoms

tilled

water

if

step 6.

Keep Battery Bolts tight.

Vent

Recharge

Screen

Gaps

SLOWLY

TIRE

PRESSURE

be

10 pounds.

AIR

SCREEN

(Fig. 17) must

leve

of

necessary.

tight

at 3 amperes

front

should

and small vent holes in

l in

each

Battery Cell should

tubes in cells (Fig. 19). Add dis-

NOTE: DO NOT

if

necessary.

be

14 pounds and rear Tires

be

kept free

of

dirt

OVERFILL.

to

page

12,

Gaps

open.

and

chaff

be

to

CUT-AWAY

\?======================~

_,..,...1

-

~

..

______________

VIEW

~VENT

I I 1=-==:J

~

:

.:~~-:.:::.-::.-:

·lr

.:-::-::-:-::-W

:rr

BATTERY

::::

CELL

FIGURE

_______

CAP

..

v

19

•

Page 10

V

ARIATOR

ASSEMBLY

(GREASE FI

ARM

TTING

- n

)

EVERY

1. CHECK ENGINE

Several

l evel

clean,

r

ead

reached. In

In

winter

SF).

SO,

NOT

~

HOURS

DO

WITH

mi

nute

w

ith

Tractor

push

it down

Oil

level.

summer

(below

In

extreme

SE

or

SF).

OVERFILL.

OIL

LEVEL

NOT

CHECK

ENGINE

s aft

er stopping

on

level

tight

If necessary,

use S.A.E.

32°F.)

cold

use S.A.E. 10W30 (SC, SO,

(below o· F.) use

DO NOT USE 10W40

ENGINE OIL

RUNNING

Engine,

ground

for a few seconds,

add Oil

30

LEVEL

.

check

Engine Oil

. Wipe dipstick (Fig.

remo

ve and

until

"FULL" mark

(SC, SO,

SE

S.A.E.

OIL.

or

SF)

5W20

NOTE: DO

SE

17)

is

Oil.

or

(SC,

FIGURE

FI

GURE 21

20

® • WASHER

c

c<===>

~

~t:;:

ID

GE

O

IL

FOAM

PRE.CLEANER

BODY

EVERY

(EVERY

IN VERY

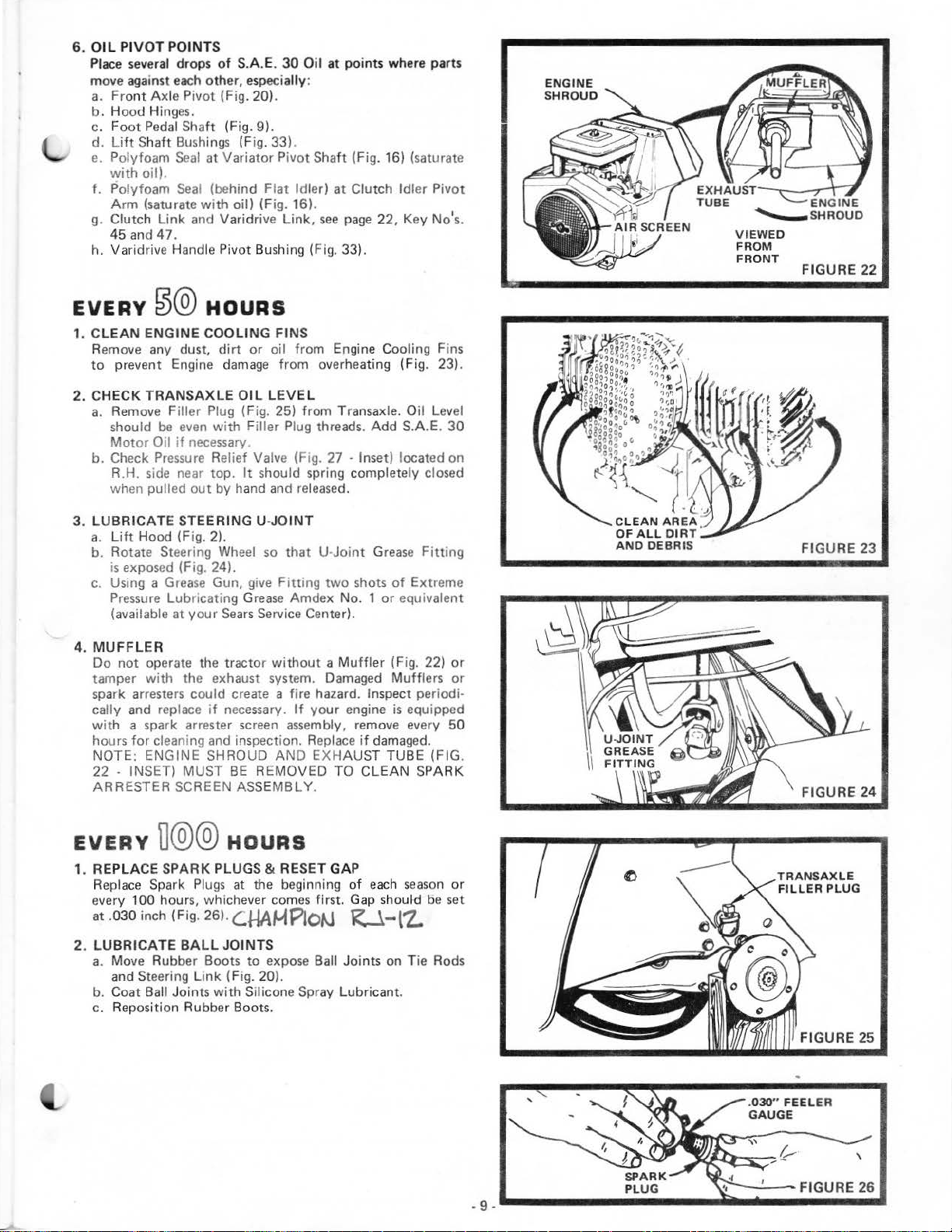

1. CLEAN

a. Unscrew

b.

c.

d.

e.

f.

g. Reassemble Paper Cartridge

NOTE:

MOVED.

2.

CLEAN

Air

Engine

compressed

stubborn

3.

CHANG E ENG INE

The

operation

in

~0

15 HOU

Remove

Paper Cartridge

Wash

Rinse,

t

horoughly.

Coat

squeeze

Check

Screen

damage

best

the

hot

RS

DUS

TY

CONDIT IONS)

FOAM PR

Knob

Nut

Foam

Pre·Ciea

squeeze

with

three

to

distribute

Paper Cartridge. Repl

NEVER

AIR

SCREE

(Fig.

from

air

dri

ed

gum

time

to

when

Oil. Refer

HOURS

IF

OPERATING

E·CLEANE R.

(Fig.

and

Washer

and Oil Foam

ner

(rather

tablespoons

RUN ENGINE WITH

N

22)

must all

overheating. Clean

or

water

and

OIL

change Engine Oil

all

dirt

to

21)

to

remove Cover.

to

in

detergent

than twi

evenly ,

and

ow free-flow

pressure

fibe rs.

and

foreign material

page 7.

remove Cartridge Plate,

Pre-Cl

eaner.

and

water.

st)

and

allow

to

of

S.A.E.

30

Engine Oil,

and

squeeze

ace

if excessively

re-

position

AIR

with

to

remove

is

at

out

on

CLEANER

of

air

to

a wire brush,

dirt,

the

end

is

suspended

excess.

dirty.

Tracto

prevent

chaff,

of

a days

dry

r.

RE·

-8 -

4 . CLEAN

The

Front

to

prevent

a. Remove

b.

Clean

sure

fibers.

c. Replace

5.

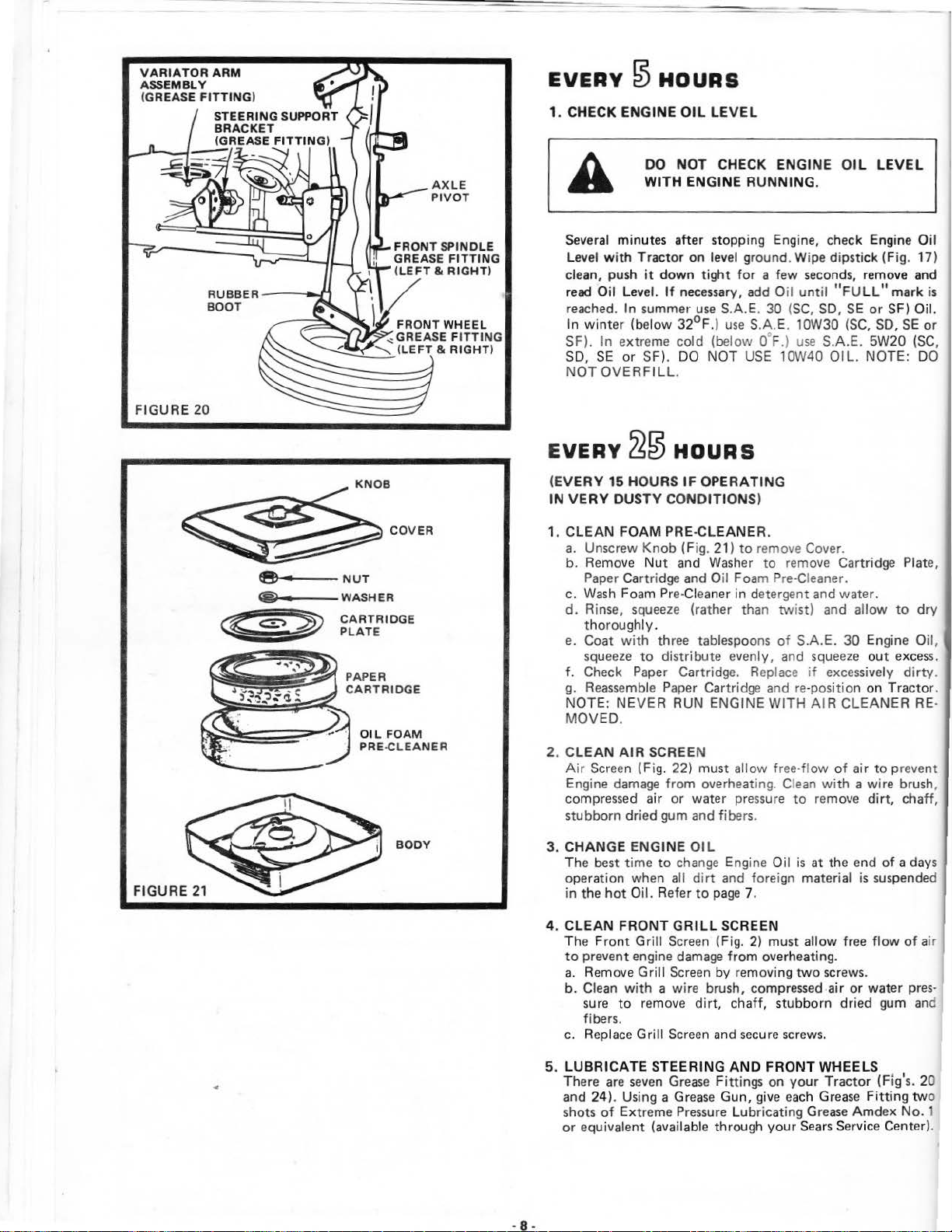

LUBRICATE

There

and

24 ). Using a Grease Gu

shots

of

or

equivalent

FRONT GRILL

Grill

Screen

engine

Grill

Screen

with

a wire

to

remove

Gri

ll

Screen

STEERING

are seven Grease Fittings

Extreme

(available

SCREEN

(Fig. 2)

damage

Pressure Lubricat ing Grease

from

by removing

brush,

dirt,

chaff,

and

secure

AND

n,

through

compressed

must

allow free flow

overheating

two

stubborn

screws.

FRONT

on

your

give

each

your

Sears Servi

water

gum

S

(Fi

ce

Center) .

of air

g's.

No.

pres-

anc

20

.

screws.

air

or

dried

WHEEL

Tractor

Grease Fitting two

Amdex

1

Page 11

6.

0 1 L PI

VO

T POINTS

Place several drops

aga

move

a.

b. Hood Hinges.

c.

d.

e. Polyf

f.

g.

h. Varidri

inst

Fro

nt

Axle

Foot

Pedal

Lift

Shaft Bushings (Fig. 33) .

oam

with

oil).

Polyfoam

Arm

(saturate

Clutch

45an

Link

d47.

ve

of

S.A.E.

each

other, especia

Pivot (Fig. 20).

Shaft (Fig.

Seal

at

Variator

Seal

(behind

with

oil)

and Varidrive

Handle P

ivot

30

Oil

at points where

lly

:

9).

Pivot

Shaft (Fig. 16) (saturate

Flat

Idler)

at

Clutch Idler Pivot

{Fig. 16).

Link,

see

page 22, Key No's.

Bushing (Fig. 33).

part

.s

ENGINE

SHROUD

VIEWED

FROM

FRONT

FIGURE

22

EVERY

1. C

LEAN

Remove any dust,

to

2.

CHECK

a.

b.

3. LUBRICATE

a.

b. Rotate Steering Wheel so

c.

4.

MUFFLER

Do

tamper

spark arresters could create a fire hazard. Inspect periodi·

cally and replace

with

hours

NOTE: ENGINE SHROUD

22

ARRESTER SCREEN ASSEMBLY.

~@

ENGINE

preve

nt

TRANSAXLE

Remove Filler Plug (Fig. 25) from Transaxle. Oil Level

be

should

Motor

Oil

Check

Pressure

R.H. side near top.

when pulled

Lih

Hood (Fig. 2).

is

exposed (Fig. 24).

Using a

Pressure

(available at

not

operate the tractor

with

a spark arrester screen assembly, remove every 50

for

cleaning and inspection. Replace

· INSET) MUST

HOURS

COOLING

Engine d

Grease

Lubricating

dirt

even

with Fill

if

necessary.

Rel

out

by

STEERING U-

Gun, give

your

Sears

the exhaust system. Damaged

if

necessary.

FINS

or

oil from Engine Cooling Fins

amage

BE

from overheating (Fig. 23).

OIL

LEVEL

er Plug threads.

ief

Valve

(F1g.

It

should spring completely closed

hand

and

JOINT

Fitting

Grease

Service Center).

without a Muffler

AND

REMOVED TO

27 · Inset) located on

released

that

U·Joint

two

Amdex No. 1

If

your

EXHAUS

Add

S.A.E.

.

Grease Fitting

shots

of

or

equivalent

(Fig. 22)

Muff

engine

is

if

damaged.

T TUBE (FIG.

CLEAN

Extreme

equipped

30

or

lers

or

SPARK

FIGURE

FIGURE

23

24

EVERY

1. REPLACE

Replace

every 100 hours, whichever comes first. Gap should be set

.030 inch (Fig. 26).

at

2.

LUBRICATE

a.

b. Coat Ball Joints with Silicone Spray Lubricant.

c.

D@@

SPARK

Spark

HOURS

PLUGS & RESET GAP

Plugs

at the beginning

C.HA~Plo~

BALL

JOINTS

Move Rubber Boots

and Steering L

Reposition Rubber Boots.

ink

(Fig. 20).

to

expose Ball Joints on T

of

each

season

R-.1-l'Z.

ie

or

Rods

TRANSAXLE

FIL

LER PLUG

FIGURE

25

Page 12

FIGURE

27

EVERY~@

1. REPLACE

Refer

to

page 8.

2.

REPLACE IN-

filte r

If fuel

replacement

a. With Engine

removed

b. Place n

on

side

L.

H.

SIDE

@

HOURS

AIR

CLEANER PAPER

LINE FUEL

is

clogge

is

required.

cool,

from

both

ew

Fuel Fil

of

Filter

in

BE

SURE THERE ARE NO

LEAKS

PROPER POSITION IN

FIL

d,

obs

tructing

remo

ve

ends

of

ter

in

direction

AND

and

position

THAT

CARTRIDGE

TER

fuel flow

plug Fuel

Fuel Filt

in Fuel Line

of

fuel flow) .

FUEL

HOSE

to

carb

Line Sections

er (Fig. 28).

FUEL

LINE

CLAMPS.

uretor

(arrow

LINE

IS

,

as

IN

STEERING

LINK

EVERY~

1. CHANGE

a. Bl

ock

move

b. Drain Transaxle

and cat

Plug.

Ref

c.

Oil. Capac i

of

Transaxle)(F

Transaxle

d. Check

closed

e.

Repo

AS

NEEDED

1. TOE-IN ADJUSTMENT

If

any

replaced, Tie Rod

a. Loosen

justment

b.

Adjust

10

- 1 /

c.

On

ce

nter

d.

On

ce

nter

e.

Compar

1/8

f.

If

not

surement.

g.

Tight

parallel (180

proper

@@

TRANSAXLE

up

Rear Axle securely

left

Rear Wheel by removing

Oil

ching

Oil in

ill

Transaxle

Pressure Relief Va lve.

when

sition

parts in F r

Jam

Sleeves.

bot

2"

from

front

(measurement

rear

of

(mea

e measurem

- 1/4 less than

adjust

en

Jam

front wheel Toe-In

with

ty

is 5 quarts

ig.

27

to

fill

more

pulled

wheel.

Secure

ent

Axle

adjustment

Nuts

(Fig.

h Tie Rods

center to center.

of

front

tires measure dista nce

front

tires measure distance

surement No.2).

measureme

each

Nuts

°)

to

HOURS

OIL

by

suitable

quickly.

out

No. 1).

ents -measurement

Tie

making

each

or

use a

Tractor

Hub

Bolts (Fig.

removing Drain Plug (Fig.

container. Replace

S.A.E.

- Inset)

30 (SC, SD

. Pressure Relief Valve (R.H . side

may

be

It

should

by

hand

and

with

Hub

or

Steering

is

required .

29)

at

each

so

that

Tie Rod

nt

equally

other.

No.

sure

This adjus

and

Rod

held

spring

released.

Bolts.

Mechani

end

of

Joints

from

from

No. 1

2.

to

get

Tie

Rod

Steer

ing

or

SE)

open

comple

sm

Tie

correct

Joints

tment

operation.

Jack

. Re-

36)

27)

Drain

Motor

to

allow

tely

are being

Rod Ad-

measure

center

center

shou

ld be

mea-

secures

.

to

to

are

•f

-10-

Page 13

2.

BRAKE

a.

b. Loos

c.

d. Depress Brake-Clutch

e.

f.

3.

CARBURETOR

Never

preset at the factory and should only

fied servi

a. Adjust Carburetor

ADJUSTMENT

IF

TRACTOR

SIX

FEET

HIGHEST

CONCRETE OR

BRAKE

Remove (4) Hex Washer Head Tapping Scre

Shift

Cover Plate (Fig. 30) located on

and remove the plate.

en

(Fig. 31).

Rotate Brake Rod

Band Assembly (E)

31

Lever (G) in the

(H) (Fig.

Rotate Brake Rod (B) clockwise

pressed

Tight

(Fig. 31).

.. Turn Needle Valve clockwise, closing finger

--

CAUTION

Jam

).

31A)

to

en

Jam

attempt

ce

technician

ONLY,

(Fig. 32).

Turn Idle Valve clockwise, closi

and then

MUST

Nut

fo

.

1 -

3/8"

Nut

ADJUS

to

change

and then turn counterclockwise 1 -

turn

counterclockwise 1 -

: Valves may

REQUIRES MORE

STOPPING DISTANCE

GEAR

(A) on Brake Rod

(B)

counterclockwi

is

clear

rward second notch on the Lockbar

(Fig. 31).

(A) on Brake Rod (B)

TMENT

who

to

suggested

ON A

PAVED

BE ADJUSTED.

of the

Pedal

maximum

has

be

damaged

SURFACE

Brake Drum (F) (Fig.

and position Park Brake

until

eng

be

the necessary equipment.

initial settings.

ng

THAN

IN

LEVEL

top

(B)

se

unt

Spring (D)

ine

changed by a quali-

finger

1/2

if

turned in

DRY

THEN

ws

tractor

at Clevis (C)

at

speed

tight

turns.

from

frame

il the Brake

is

com-

Clevis

. This

tight

1/2

turns

ONLY,

too

(C)

far.

D

1.

is

3/8"

B

(

~?

l.

~

--

..

~

FIGURE

tR\

31

b.

Sta

rt Engine and all

fin

al adjustments

.. With Thro

Throttle Lever against Idle Stop

Ad

RP

begins

clockwise.

--

Set Idle

RPM. When

Stop,

RPM

NOTE:

ADJUSTMENTS MUST

THROTTLE

STOP

With Thr

··

Needle Va l

gins

NOTE:

THROTTLE

"

FAST"

COUNTERCLOCKWISE 1

4.

ADJUSTMENT

It

may

page

7).

REFER TO

PAGE

ttle

justing Screw

M. T

urn

Idle Val

to

miss

Speed Sc

engine

, controlled by governor.

ALL

AND

AT

ott

ve

to miss

IF

ENGINE HESITATES WHEN

POSITIONS,

be occasionally necessary

V-BELT

"STARTING

4.

ow

to warm

with

Engine running .

Control in

to

give an

ve clockw

and

then open 1/2 t

rew

to

Thrott

le Lever

speed

should

ABOVE SPEED

LEVER

le Control in

and then

CONTROL FROM

HELD

SPEEDS NOTED.

slowly

clockwise

set

TURN

THE

for

five minutes. Make

"SLOW"

and

eng

ine

ise slowly

give

engine

is

rel

be

between 1000

AND

FUEL

BE

DONE

AGAINST

"FAST"

1/2 t

/8

until

urn

counterclockwise.

NEEDLE

TURN

to

re-adjust V-Belt.

ENGINE"

position,

set Idle Speed

speed

of

unt

il engine

urn

counter-

speed

of

ease

from Idle

and

MIXTURE

WITH

THE

position, turn

engine

MOVING

"SLOW"

VALVE

MORE.

hold

1400

900

1400

THE

IDLE

be·

TO

(See

Page 14

FIGURE

33

5.

BELT

REPLACEMENT

The be

lts

on this

when replacing Belts always replace

a. Disconnect Battery, Negative Ground Cable.

b.

Set

Parking Brake (Fig. 10).

c.

Pull Varidrive Control L

giving

Pr

imary Belt slack.

d. Remove Prim ary Belt

e.

Remove 3 Bolts and Nuts holding Primary Idler

to

Frame (Fig. 33).

f.

Remove

(Fig. 34). Slide P

Shaft

g.

Remove Belt

h. Remove Id

Sheaves

i.

Primary (Front) Belt can

j.

To

trol

(Fig. 34) and remove Secondary

k.

Rem

I.

Remove Transmission Pulley B

be

m.

Reverse

place Primary Idler

Idler

n. Connect Battery.

NOTE: WHEN A NEW

ED, YOU MUST CHECK

TO

(Fig. 34).

replace Secondary (Rear) Belt move

Lever

ove

Clutching Idler

removed from Transmission Pulley.

the above procedures

and Transmission Pulley Belt

"CHECK

tractor

Klip

Ring and Washer

from

ler

Nuts and Idler

to

fast position. Remove Variator Belt

BELT

are

special

ever to slow

from Engine Pulley (Fig. 34).

ivot

Variator

ADJUSTMENT",

Arm inwards .

now

(Fi

g.

Package,

BELT

BELT

Sheave.

OR BELTS

for

with

from

Sheaves

be

removed.

Belt from Variator.

34).

elt

Guard. Belt can

to

install new Belts. Re·

Belt

Guard.

ADJUSTMENT. REFER

PAGE

this application,

Sears

belts.

position (Fig. 11)

Sheaves

Variator

from

Primary Idler

Varid

Keeper, Clutching

ARE

7.

Pivot

rive Con·

Keeper

now

INSTALL

·

FIGUFIE

35

WASHER

,,

KLIP RING

6. CLEAN

Corrosion and dirt on the Battery and Terminals

the Battery

th

a.

b.

7. TIRE CARE

a.

· b. Keep tires free

c.

d. Removing

e. Removing rear

BATTERY

e charger.

Rem

ove

the Battery from the Tractor and

four

tablespoons

NOTE :

SOLUT ION

plain wate

Clean termin

bright. Replace Battery

ti

Maintain tire pr

at 10 pounds.

cals

Avoid stumps, stones, deep ruts

may

··

··

..

.. Remove (5) H

..

BE

ons with

whi

ch

cause tire

Block

up

Ja

ck.

Remove

moval.

Repa

ir

Klip

Ring securely in axle groove.

BI'Ock

: up rear axle securely

Jack.

Repair tire and

Bolts securely.

AND

TERMINALS

to

"leak"

power and hinders the operation

of

baki

ng

soda

CAREFUL

IN

TO

r, dry and reinstall on Tractor.

als

and cable ends

Vasoline.

essure in

of

gasoline, oil,

can

destroy rubber.

damage.

front

wheel

front

Klip

Ring

tire and

reassemble.

wheel

ub

rea

NOT

THE

CELLS

Cables.

front

for tire

axle securely or use a S

and

Washer

for

tire repair (Fi

Bolts

ssemble

to one gallon

TO GET

. Rin

se

th e Battery

with

a wi

Coat terminal connec·

at 14 pounds

or

insect

control

and

other hazards

repair (Fig. 35).

to

allow wheel

Rep

lace

wash

g. 36).

or

use a Sears

to

allow wheel removal.

. Replace

and

cause

wash with

of

water.

THE

SODA

with

re

bru

sh

until

and

rear ti

chemi·

that

ears

Tractor

er and

snap

Tractor

tighten Hub

of

res

re·

._

____________________________

FIGURE

36

... ·12

WHEN

BEADS

CAN CAUSE

8.

FINISH

Keep tractor finish and seat free

chemica

w

ls

or

battery electrolyte. Protect painted surfaces

ith

automotive type wax.

MOUNTING

ARE

·

SEATED,

AN

EXPLOSION .

TIRES, UNLESS

OVER

INFLATI

of

gasoline, oil, insect

/

ON

Page 15

TROUBLE

POSSIBLE CAUSE

W

ILL NOT START

C

lut

ch-Brake Pe

Attachment Clutch Lever in ' ENGAGED " position

No

gasoline!

1e

Li

Blown

Fus~

Dead

Battery

1---

Defective

·

HARD

TO

START

Choked improperly, flooded Engine

Clogged Fuel Tank, Fuel Line,

D

irty

Air Cleaner

Spark Plug di

Defecti

ve

Defective Igni

Water in

Improper Carburetor adjustment

SHOOTING

dal

in driv e P9Sition

in Fu

el

rty

tio

or

n or l

or

Tank or clog

ter

or

loose Wiring

imp roper

oose

old fuel

or

Fuel Fil

Ignition

Battery

gasoline

or

gap

wiring

ged Fuel

Fuel

Filter

POSSIBLE

Push

Move Lever

Fill Tank

28} and Carburetor (clean

Check

Recharge

Check

Place

run starter several times

Remove and clean (Fig. 28)

Re

move and clean (Fig. 21}

Replace

Recharge

Check the

Drain Fuel Tank and Carburetor,

replace Spark Plug

Make necessary adjustments (Fig. 32)

REMEDY

Pedal

into

brake position (Fig.

to

"DISENGAGED"

with

fresh Gasoline. Check Fuel Line (Fig.

for

fault and replace

or

replace Battery

Wir

ing and Spark Plug

Throttle

Control in fast position (Fig. 10) and

Spark Plug and adjust

or

replace

wir

ing and Spark Plug

Fuse

to

if

clear

position

necessary}

out

gap

(Fig. 26)

use

9}

gas

fresh fuel

and

ENGINE MI

ENGINE

NO

LIGHT

WON

SSES

OR LACKS POWER

Eng·ne

over oad

C

logged Fuel F

Clogged Fuel Tan k

Partially plugged A

Improper Carburetor adjustment

rty

Air

Di

Low oil level

Spark Plug di

Fau

lty

ignation

Poor compression

Oil in gasoline

OVERHEA

Dirty

Air

Low

oil level

D

irty

Engine

Pa

rtially

Partia

lly

Sta

le fuel

S

No

Hea

dlight

and

engme

'T

CHARGE

Blown Fuse

Defective Battery

ilt

er

ir

Screen

or

dir

ty

rty

, improper

TS

Screen

or

dirty

plugged

plu

Muff

gge

d Air Cleaner

or

improper Carburetor adjustment

with

runni

Cleaner

oil

gap

or wrong type

oil

ler

Light Switch in

ng

"oN"

position

Shift

to a low

Remove and replace (Fig. 28)

Remove and clean

Remove

Make

necessa

Clean A

Add

or

Replace

Check

or

Maj

Drain and

Clean

or

Add

Clean Cylinder Fins,

Remove and clean

Remove and clean (Fig. 21}

Use

fresh fuel and adjust Carburetor (Fig. 32}

Ch

eck Wire Connections and Switch.

Replace Li

Check

Replace

er

gear

or

reduce load

an

d clean (Fig. 21}

ry adjustments (Fig. 32}

ir

Screen, Cylinder Fins (Fig.23) &

change oil (Fig. 7}

Spark Plug and adjust

Spark Plug and

Engine

ove

refill

Air

Screen

change

ght

for

fault

for

rhaul

Gas

Tank and Carburetor

(Fig. 17}

oil (Fig. 7}

rotati

Muffler

Bulbs

and

replace

gap

loose wires

ng

Screen and Mu

(Fig. 22}

Muff

(Fig. 26 )

ffler

ler

area

area

STORAGE

1. ENGINE

Drain

Refer

2.

FUEL

a. Drain fuel tank

;,

b. Di

3. CYLIND

a. Remove Spark

b. Po

c.

d. Replace

0111

(with

engine warm) and replace

to

page

7.

SYSTEM

run

out

of

YOUR ENGINE

GING

spose of

LINE

ITS

VOLATILITY

IVELY)

ERS

ur

one ounce

linders.

Tum

seconds

gaso

FUEL

SYSTEM.

gaso

STORED FOR

.

lgnitidtl

to

distribute oil.

with

new Spark Plugs. • 13.

and

carburetor by allowing the

line. NOTE: GASOLINE

WILL

LEAVE

line if

not

(AB

Plugs

.

of

oil through spark plug

Key

to

GUM DEPOSITS CLOG·

to

be

SEVERAL

ILITY

"ST

ART"

with

~4\n

engine oil.

~

-

eng

ine

LEFT

used. NOTE: GASO·

MONTHS LOSES

TO

BURN

posi

hol

tion

EFFECT-

es into

for

a few in

to

IN

cy·

4.

BATTERY

a.

Remove battery

winter

mo

·NOTE:

CONCRETE SURFACE.

b. Re-charge

NOT

KEPT

DEPOSITS ON PLATES WHICH

MOVED

5.

GENERAL

C

lean

6.

STORE

Sears,

Roebuck and Co.

design

to

install the

DO

IN

FULLY

BY

CLEANING

engine, battery, finish etc.

IN A CLEAN

or

improvements without

same

if

nths. Store in cool,

each

USE

tractor

NOT

STORE

month

FOR

CHARGED, PRODUCE SULPHUR

RECHARGING.

AND

reserves

upon

its

is

not

used

dry

BATTE

if necessary. NOTE:

SEVERAL

DRY

AREA.

the right

items heretofore manufactured.

imposing any obligation

regularly during

place (above

RY D

IRECTLY

BATTERIES

MONTHS

CANNOT

of

all foreign matter.

to

AND

BE

make any changes

50°F}.

ON

NOT

RE-

•

Page 16

REPAIR

PARTS

SEARS

GTV

16

TWIN--MODEL

NUMBER 917.253721

RED~

V.

RED

BLACK

...

'

RED

~

--

-------------------------------------------cr

~

SWITCH

RED

WHIT

~

WHITE

INTERLOCK

'

W

HITE*

INTERLOCK

RED

' •

WHITE

SWITCH SOI.FNOID

BLACK

BLACK

STARTER

WH

ITE

o'.:_:,~~.r----4f

PLUGS

----------

8

G

L

BLACK

RED~

LIGHTS WILL

METER

YOUR TRACTOR

SPECIAL

LIGHTS

BATTERY, BUT

ELECTR

THIS,

LIGHTS

ENGINE SPEED.

LIGHTS

SPEEDED UP,

COME

If Insulated

vicing

properly

four

ARE

ICAL

THE BRIGHTNESS OF

THEIR

WIR ING

of

Insulated Clips on

IGNITION

POSITION CIRCUIT

NOT REGISTER ON AM·

ALTERNATOR

NOT

SOURCE. BECAUSE OF

WILL

WILL

DIM.

THE

BRIGHTEST.

INSULATED

Clips were

unit,

they should

secure

STD365400

OFF M·G

IS

EQUIPPED

CONNECTED TO THE

HAVE

CHANGE

AT

IDLE

AS

THE

LIGHTS

rem

your

wiring. There

your Tra

SWITCH

WITH

SYSTEM. THE

THEIR

WITH

SPEED THE

ENGINE

WIL

L BE·

CLIPS

oved for

be

replaced

ctor.

o----...;.R.;.;;E_D~------a.

OWN

THE

THE

IS

ser·

to

are

A

RED

RECTIFIER

(DIODE)

ORANGE

YELLOW

WHITE AC COIL

~

LIGHT

~SWIT

_____

YELLOW J

...

BLACK

CH

ARGING COIL

BROWN

CH

I

,l,

' ...

LIFT

M'

MOTOR

~'

ASS'Y

HEADLIGHT

ON

START

B·L

B·S

DIAGNOSTIC

.THRU.AND.

-

14.

TERMINALS

CHASSIS

GROUND

Page 17

REPAIR

PARTS

~.

•

ELECTRICAL

A C D E F

::

ill

i22

,46

@23

@ 4

@25

SEARS G

~

48

~

49

TV

16 TWIN--MODEL NUMBER 917.253721

~47

20

45

32

KEY

NO.

1

2

3

4

5

8

9

10