Page 1

ASSEMBLY, OPERATING INSTRUCTIONS

AND

PARTS

LIST

SEARS

SICKLE

MODEL NUMBER

BAR

FOR

MOWER

917.253120

I Sears J

.

..

SEARS,

SIMPSONS-SEARS LIMITED-CANADA ·

8920H

3.11.62'

ROEBUCK

AND

CO.--U.S.A.; ·

Page 2

1.

Place

2.

Never

3.

Never

touch

4.

Do

engine

5.

Never

fuel

6.

Only

should

7.

Do

before

on

8.

Always

9.

Keep

10. If

11.

12. Wear

13.

14

16,

17.

18.

19.

20.

21.

22.

o

Always

su

Do

. Do

and mower

15.

Never

tractor

Always

removed.

Never

Remove

striking

to

Keep

Always

Do

necessary

declutching

idling

Do

gears.

ing

prevent

your

warning

re it

tractor shi

start

the

refuel

battery. A spark

not

fill

con

persons

not

getting

on

incline

knife

relatively

not

not

run

people

people,

not

speed

not

If

tractor

engine

store

equipment

cool

before

the

on

tonk.

thoroughly

operate

attempt

keep

broke

sharp.

equipment

of

trouble.

replace

is

tight.

mow

crossways

attempt

clutch

leave

machine

or

mower.

keep

all

engine

stones,

rocks

or

property.

drive

olowly

operate

to

stop

to

without

shift

gears

it

is

in motion

tractor

ft lever

engine

storing

fuel

this

to

get

off

tractor. Be

or

hill.

should

thrust

tight

to

clean

lever

shields

inside a building.

wires,

or

roots.

pets

the

tractor

tractor

braking

while

necessary

from

in

when

while

from

with

tonk

while

acquainted

machine

off

or

properly

start

Always

washer

fitting

on

cutter

is

running

and

cans,

Any

and

particularly

over

uneven

in

while

operation.

declutching

going

to

going

"rearing

neutral

anyone

it

is

in a bui l

the

fuel

fuel

in

in

any

enclosure.

the

engine

with

unless

on

adjusted.

clothing,

steep

in

disengaged

boards,

of

high

stop

uphi

up".

properly

tractor

sur e broke

vibrating,

replace

and

lock

slopes

bar,

or

unattended, and

guards

the

above,

ground,

gear

going

NOTE:

, and

up

steep

while

II,

use

SAFETY

and mower

is

near,

and

ding,

con

touching

the

tonk

is

the

rules

supervised.

when

mower

is

on

stop

the

ports

showing

nut

when

and

always

because

to

otherwise

position.

in

place.

branches,

if

struck

children

on

hills

going

down

down

hill,

The

this

procedure

hills.

going

up

one

of

PRECAUTIONS

clutch

and

inside

hot,

securely

of

remove key from

Mower

bones

away

enginP.

Choose

hill,

the

lever

never

ploc e hands

always

the

battery

a bui ld ing

and

wipe

of

safe

is

engaged

and

engine

keep

do

lowest

and

excessive

replacing

hands,

danger

clean, adjust,

or

tractor

and

other

by

the

from mowing

and

curves

hill,

and do

so

quickly

produces

is

recommended

a low

do

so

gears,

in

rear

when

terminal

where

off

any

operation

and

shift

check

wear.

knife,

feet

of

tra

ctor

must

foreign

knife,

to

prevent

not

to

cons

enough

quickly to

reduce

or

disengaged

or

feet

refuel

ing

could

fumes

gasoline

should

tractor

transmission

for

damage

and

check

or loose

tipping

or

repair

ignition

may

area

turn

prevent

gear

switch

never

objects

damage

when

tipping

sharp

iderable

before

to

prevent

engine

position

near

cutter

engine

be

engine

fitting

tractor

applying

climb

be

cause a fire.

may

reach

that

might

permitted

is

into

low

or

loose

lock

nut

clothing

over.

machine

to

be

ope

rated

from

area

knife

or

mowing

of

tractor.

corners

from

braking

hill

tractor

speed

and

bar.

careful

on

open

hove

to

use

running.

or

reverse gea

ports.

at

frequent

away

before

prevent

with

before

guards

with

while

picking

action

brake.

without

rolling

engage

before

that

fuel

flame

been

mower,

Wait

Vi

brat

intervals

from

stopping

children

any

shields

each

and

may

your

sickle

going

down

up

when

throttled

slopping

backward.

clutch

starting

con

or

spilled.

and

until

knife

r,

ion

is

mowing

tractor

from

mowing.

cause

hi II. If

speed

and

When

gradually

engine

does

spark.

Replace

no

minor

stops

especially

generally

to

make

belts.

engin

starting

or

guards

Avoid

injury

bar

mower.

it

during

bock

shifting

start-

not

Let

is

the

to

to

.

...

e

YOU

CAN

DO

WITH

THE

WIDE

MENTS --AND

MANY

VARIETY

JOBS

FIRST

OF

OF

EASILY

ATTACH-

ALL

BE

CAREFUL.

2.3.69

-2-

ONLY

:~~\)

ONE

PER

TRACTOR

SON

ON

THE

AT A Tl

ME.

~i

)

..

Page 3

INTRODUCTION

.•

Setting

Precautions

beginning

beginning

refers

when

L.H.

to

(or

Cut

NOTE:

of

Up,

should

to

of a

to

an

otherwise

(Left

Hand)

mean from a

direction

all

ports

wires.

The

must

of

two

Operating

assemble

paragraph

arrow

stated.

are

position

travel).

ext

ra

be

saved

be

your

in

used,

thick

Instructions

studied

in

the

When

behind

for

very

mower. A number

the

following

adjoining

R.H.

it

shou

and

flat

washers

use

in

and

closely

instructions

figure,

(Right

ld

be

facing

found in bog

Step

Safety

before

at

except

Hand)

and

understood

the

mower

14,

page

the

5.

FIG. 2

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

BEFORE

ALWAYS

OR

FIELD

CONSIDER

WEEDS,

OF

TERRAIN

AS

WELL

TRASH.

CERTAIN

AS

OUTLINED

MOWING A NEW

STOP

FOR

HAY,

ALSO

ETC.

TO

BEST

THE

ANALYZE

MOWING

TO

(LEVEL, HILLY

AS

THE

PRESENCE

EACH

CONDITION

ADJUSTMENTS

IN

THIS

MANUAL.

PLOT

HEIGHT

BE

MOWED,

WILL

OR

PRECAUTIONS

OF

GRASS,

THE

LAWN

PROCEDURE.

OF

GRASS,

TYPE

OR

PITTED),

OF

ROCK

OR

REQUIRE

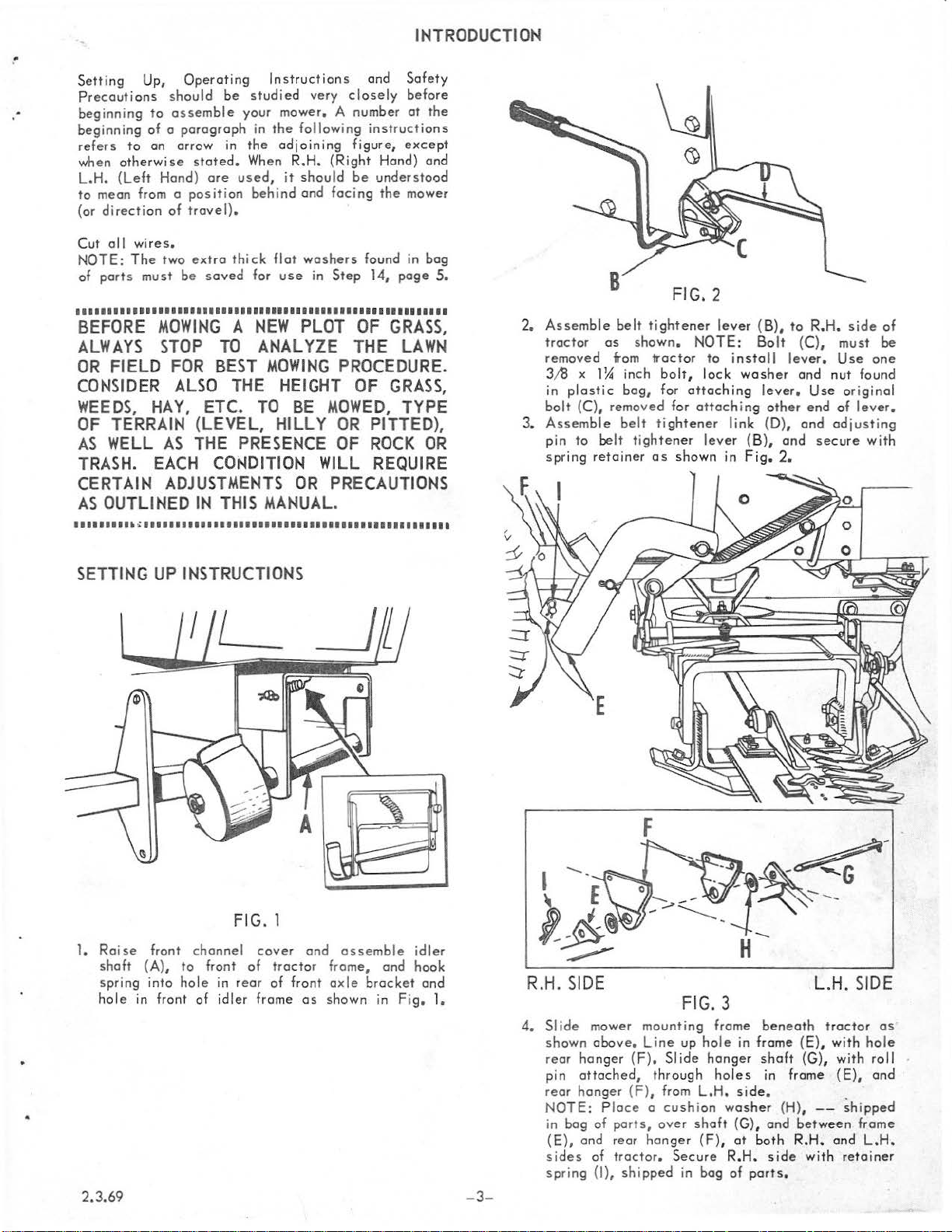

2.

Assemble

tractor

removed

3A3

in

bolt

3.

Assemble

pin

spring

x

1~

plastic

(C),

to

belt

retainer

belt

tightener

os

shown. NOTE:

from

tractor

inch

bolt,

bog,

for

removed

belt

for

tight

tightener

as

to

lock

attaching

attaching

ener

lever

shown

lever (B),

Bolt

install

washer

lever.

other

link

(D),

(B),

in

Fig.

to

(C),

lever.

and

and

2.

R.H.

Use

end

and

secure

side

must

Use

one

nut

found

original

of

lever.

adjusting

with

of

be

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

SETTING

1.

Raise

shaft

spring

hole

in front

2.3.69

UP

INSTRUCTIONS

front

channel

(A) ,

to

front

into

hole

in

of

idler

FIG. 1

cover

of

tractor

rear

of

frame

and

front

as

assemble

frame,

axle

show

and

brocket

n in

idler

hook

Fig.

and

1.

-3-

F

R.H.

SIDE

4.

Slide

mower

shown

rear

pin

rear

NOTE: Place a cushion

in

bag

(E),

sides

spring

above.

hanger

attached,

hanger

of

and

of

(1),

mounting

Line

(F).

(F),

ports,

rear

hanger

tractor.

shipped

through

Slide

from

over

Secure

FIG. 3

frame

up

hole

hanger

holes

L.H.

shaft

(F),

in bog

in

frame

side.

washer

(G),

at

both

R.H.

of

ports

beneath

(E),

shaft

(G),

in frame

(H),

and

between

R.H.

side

with

.

L.H. SIDE

tractor

with

--

and

as

hole

with

roll

(E),

and

~hipped

frame

L.H

retainer

.

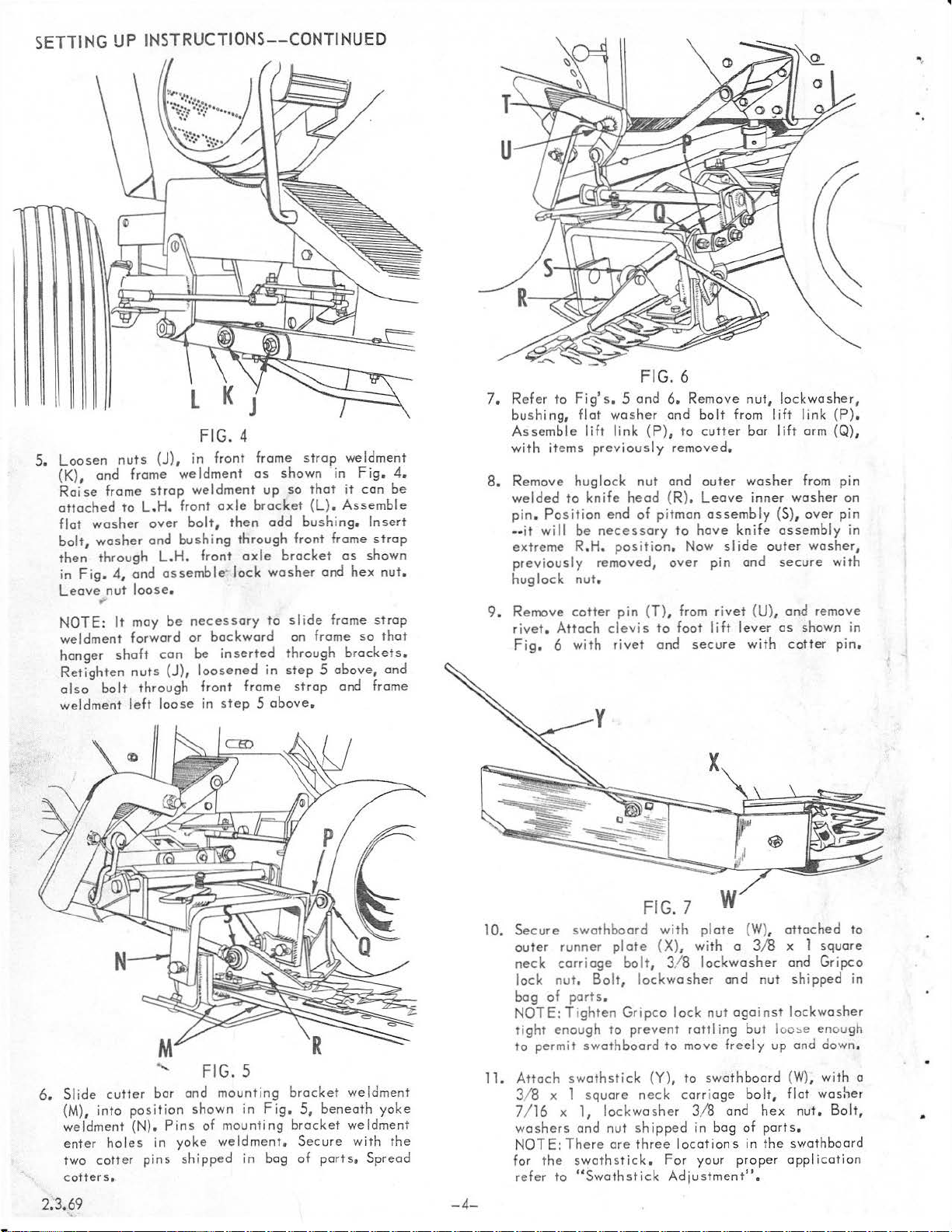

Page 4

SETTING

5.

Loosen nut s

(K),

Raise

attached

flat

bolt,

then

in

Leave

NOTE:

weldment

hanger

Retighten

ol

weldment left loose

UP

and

frame

washer

washer and

through

Fig.

4,

nut

>I'

It may

shaft

so

bo It

frame

to

and

loose.

forward

nuts

INSTRUCTI

FIG. 4

(J),

in front fr

weldment

strop

weldment

L.H.

front

over

bolt,

bushing

L.H.

front

assemble· lock

be

necessary

or

con

be

(J),

loosened

through

front

in

ONS--CO

ame

as

shown

up

axle

brocket

then

odd

through

axle

brocket

washer

to

backward

inserted

in

frame str

step 5 above.

NTINUED

strop

we ldme

in F ig.

so

that

it

con

(L).

Ass

embl e

bushing. Insert

front

frame

as

shown

and

hex

slide

frame

on

frame

so

through

step 5 above,

op

brackets.

and

nt

4.

be

strop

nut

strop

that

and

frame

FIG. 6

7.

Refer

to Fig's. 5 and

bushing,

Assemble

with

8. Remove

welded

pi_

n. P_osition

••

It

extreme

.

previously

huglock

9.

Remove

rivet.

Fig

items

wdl

. 6

flat

lift

huglock

to

knife

be

R.H.

nut.

cotter

Attach

with

washer

link

previously

end

necessary

position

removed,

pin

clevis

rivet

6.

Remo

and

(P), to cutter

removed.

nut

and

head (R).

of

pitman

to

. Now

over

(T), from

to

foot

and

ve

nut

bo lt from 1lift

bar li

outer

wash

Leave

hove

secure

ass

embly (S),

knife

slide

pin

rivet

lift

lever

inner

outer

and

(U),

with cotter

lockwoshe

link (P

ft arm {Q),

er from

washer

over

assembly

washer

secure

and

remove

as

shown in

r,

).

pin

on

pin

in

with

pin

.

FIG. 5

6. Slide

cutter

(M), into

weldment

enter hol

two

cot!

cotters.

bar

position

(N).

es

in

er

pins

and

Pins

yoke

shipped

mounting brocket

shown

in

of mounti

weldmen

in bog

Fig.

ng

5,

beneath

brocket weldme

t. Secure with t

of

ports. Sp

2.3.69

weldment

yoke

nt

he

read

-4-

10.

Secure

outer

neck

lock

bog

NOTE:

tight

to

11.

Attach

3/ 8 x

7/16 x 1,

washers

NOTE: There

for

refer

FIG. 7

swothboord

runner

carriage

nut. Bolt, lockwosher

of

T i

e~ough

perm1t

the

to

plate

ports

.

ghten

to prevent

swothboord

swothstick (Y),

1

squa

lockwo

and

nut

ore

swothstick.

"Swothstick

bolt

Gripco

re

neck

shipped

three

with

(X), with a

, 3/8

sher

X

w

plate

lockwosh

and

lock

nut

against

rottl

ing

to

move

freely

to

swo

th b

carria

ge

3/8

and hex

in bo g of port

I o

cot

ion s in t

Fo

r your

Adjustment" .

prope

(W), attached

3/8

x 1

square

er

and

Gripco

nut

shipped

lockwosher

but

loo:.e

enough

up

end

down.

oord (W)

bol

, with a

t,

flat washer

nut.

s.

he

swothboord

r a p

plicatio

to

in

Bolt

'

n

Page 5

1

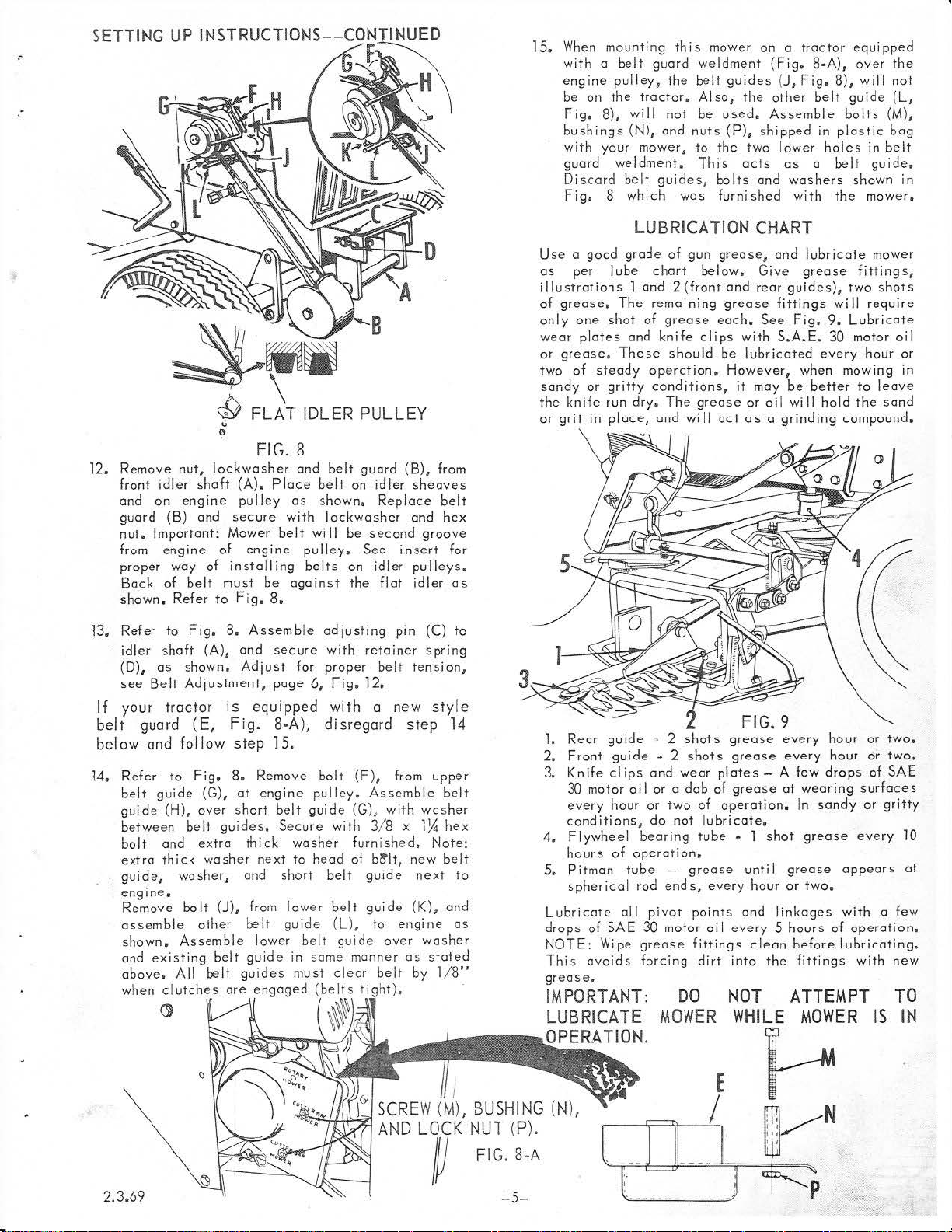

5.

When mounting

with a belt

engine

be

Fig.

bushings

wit h your mower,

guard

Discord

Fig

on

. 8

pul

the

8),

this

guard

ley, the

tractor. AI

wil

l n

ot

(N),

and nuts

weldment.

belt

guides, bolts and

which

was

mower on a tra

weldment (Fig.

belt guide

so,

be

to

the

This

s (J, F

the other belt

used.

furn

Assemble

(P), shipped

two lower

acts

as a

ished

washers

ig.

with

ctor

8-A),

8),

in

plastic

holes

belt

the

equipped

over

the

will

not

guide

(L,

bolts (M),

bag

in

belt

guide.

shown in

mower.

12.

Remove

front

and

guard

nut.

from

proper

shown.

13.

(D),

see

If

belt

below

l4.

guide {H),

~-111

nut,

i

dler

shaft (A).

on

engine

{B)

and

Important: Mower

engine

way of

Back

of

belt

Refer

Refer

to

F i

idler

shaft

as

shown.

Belt

Adjustment,

your

traG

tor

guard

Refer

belt

between

bolt

extra

guide,

engine.

Remove

assemb

shown.

and

above.

when

and

follow

to

guide

and

thick

washer,

bolt

le

Assemble

existing

All belt gu

clutches

(E,

Fig.

over

belt

extra thick

other

' \

{:;;

FLAT IDLER PULLEY

()

lockwosher

pulley

secure

of

engine

instal

must

to

Fig.

g.

8.

Assemble adjus

{A),

and

Adjust

is

equipped

Fig. 8-A),

step 15.

8.

{G),

at

short

gui

des. Sec

washer

and

(J),

from

belt

belt

gui

ore

engaged (belts

~

FIG. 8

and

belt

Place

belt

as

shown.

with

lockwasher

belt

wi

II

pulley. See

ling

belts

be

against

8.

secure

page

with retain

for

proper

6,

Fig.

with

disregard

Remove

engine

nex

lower b

de

ides

bolt

pulley.

belt

guide

ure

with 3/ 8 x

washer furnished.

t to

head

short

belt

lower belt

guide

elt

in

some

must

(L),

clear

~

guard

on

idler

Replace

be

second

on

idle

the

ting

belt

12.

a new

(F),

Assemb

(G), with

of

b~lt,

guide

gui

to engine

guide

manner

belt

ti

(B), from

ins

r pu

flat

pin (C)

er

from

de

over

as

),

sheaves

belt

and

groove

ert

lle

idler

spring

tensio

style

step

upper

le

washer

1)4

Note:

new

next

(K),

washer

stated

by

l/8"

hex

for

ys.

as

to

n,

14

belt

hex

belt

to

and

as

LUBRICATION

Use a good

as

per

illustrations 1 and

of

grease.

only

one

wear

or

grease,

of

two

sandy

the

knife

or

grit

l.

Rear

2.

Front

3.

Knife

30 motor oi I or a

every

conditions,

4.

F lywheel

hou

5. Pitm

spherical rod

Lubricate

drops

NOTE: Wipe grease fittings

This

greas

IMPORTANT:

LUBRICATE

OPERATION

grade

lube

The

shot

plates

These

steady

or

gritty

run

in

place,

guide

guide

clips

hour or

rs

of

an

tube -grease

all pivot

of SA E

ovoids

e.

of

chart

2 (front

remaining

of

grease

and

knife

should

operation.

conditions,

dry.

The

and

" 2

• 2

a~d

two

do

not lubricate

bearing

operation

ends,

30

motor oi I

forcing

MOWER

.

gun

grease

wi

shots

shots

wear

dab

.

points

DO

grease,

below.

each.

clips

II

oct

plates-

of

of

tube

every

dirt

CHART

and

Give

and

rear

grease

be

However

operation.

fittings

See

with

lubricated

it

may

or oil

as a grinding

grea

se

grease

grease

.

• 1

shot grease

unt

il

hour

and li

eve

ry 5

clean

into

the

NOT

WHILE

lubricate

grease

guides),

wi

Fig.

9.

S.A.E.

A few

30

every

, when mow i

be

better

wi

II

hold

compound.

every

hour or

every

hour

drops

at

wearing surfa

In

sandy

grease

or

nkages

hours

before

appears

two.

with

of

lubricating.

fittings

ATTEMPT

MOWER

mower

fittings,

two

shots

II

require

Lubricate

motor

oil

hour or

ng

in

to

leav

the sand

two.

or

two,

of

SAE

ces

or

gritty

every

10

a few

operation.

with

new

TO

IS

IN

e

at

2.3.69

FIG.

~

8-A

- 5-

Page 6

OPERATING

For

each

job

the

ground

In

thin

may

be

cases,

heavy

lower

engine

which

run

engine

reduce

DO

MOWER

CAUTION:

possible

knife.

above

It

is

area

types

sti

cks,

represent

operator,

assemble.

mowing,

while

NOTE:

ning

TO

TRANSPORT

trav

stan

ds

inc

reased

the

engine

blue

grass

gear

at o higher

seems

throttle

wear

NOT

ATTEMPT

IS

Run

to

reduce

Operating

level.

the

respon

where

to

the

of

foreign

cons, bottles,

potential dangers

and

Always

and

unattended.

Sickle

move

INSTRUCTIONS

of

mowing

e l

speed

of

(shift

(slower

to

do

and

vibration.

it may

it

with

material

to

may ol so

ground

speed.

the

best

ot

slower

be

Pick

TO

IN

OPERATION.

engine

angle

s ibi I ity

sickle

material.

ore

never

bar

through

vibration

of

of

bar

certain

be

on

leave

must

be

material

at

cutter

the

will

pipe,

the

the

wi

II

be

necessary

each

plot

the

ground

a higher

gear)

be

throttled

necessary

travel speed)

gear

and

job

of

spee

ds

LUBRICATE

reduced

and

wear

bar

not

operator

be

used

This

includes

rocks, etc.

to

the

to

damage

alert

for

sickle

in

operation

to

be

cut.

to

be

travel

and

to

engine

mowing.

if

possible

speed

on pitman

to

exceed

to

see

is

free

wire,

sickle

obstacles

bar in

before

to

vary

mowed.

speeds

in

most

bock.

shift

to

and run

speed

Always

WHILE

whenever

and

35°

that

the

of

all

rope,

These

bar

and

the

knife

when

operation

begin·

In

to

SWATHSTICK

ADJUSTMENT

·.

a

FIG.

11

There

adjustment.

hole

BELT

are

three

hol

Adjust

for

higher

weeds.

ADJUSTMENT

es

in

swothboord

to

best

turn

---

crop

......

for

being

swa

thstick

cut. Lower

\

I

I

I

I

Stop

until

Fig.

strop

tractor

latch

10.

Secure

(C).

engine.

brocket

bar in

FIG.

Depress

(B)

10

con

be

upright

on

foot

positioned

position

lift

as

with

lever

shown

tra

nsport

(A)

in

Turning

belt.

adjusting

directi

to

requires

(pu

that

to

in

the

Remove

on

tighten

a

sh

forward),

slip

wear

prevent

adjusting

STORAGE

Before

thoroughly

surfa

rust

clean

storing

ces

should

preventive

, dry

adjusting

retainer

pin

(A,

(when

belt.

fair

amount

when

out

premature

pin.

mower for

clean

be

especially

area.

---

--

FIG.

pin

(A,

spring

Fig.

12),

standing

Belt

rapidly.

away all

given o good

in

tightener

of

belt

is

Keep

failure. Replace

any

the

_,

12

Fig.

(D,

in o

front

effort

properly

belt

long

dirt

and

mower

.,

- v

12),

adjusts

Fig.

8),

and

counter-clockwise

of

the

tractor),

lever

(B,

Fig.

to

engage

adjusted.

properly

retainer

period

debris.

coot

of

knife.

Belts

adjusted

spring

of t

Wearing

grease

Store in a

the

turn

2},

lever

ime,

or

2.3.69

-

6-

Page 7

MAINTENANCE

AND

SERVICE

INSTRUCTIONS

DAILY

Ma

Keep

TO

1. Pos

2. Re

MAINTENANCE

ke

sure all nuts

mow

er lubric

REMOVE

ition

knife

move

hug

ossemb

with new

ly

KNIFE

lock nut

out from the

kni

fe. Adjust kni

KNIFE

A

dull knife, imprope

make

good

cutting

Guards

Align

choking

or

Remove

where

the clip just begi

wea ring pl

clip

hoi d the

these

led

bent,

nece

. When

wearin

ore

often

ger p

lates

may

result.

the po

the knif

ssary. After

ates

the

front

of the

g p

ints

that

plates

lotes.

on

bol

ts

ore tig

ht

and cotter

ate

d.

in

the extreme

and

rly

adjusted kni

impo

ssible.

knocked

by

striking thick portion of guard

Properly adjusted knife clips

of the knif

e;

sight

along

the

ns

to tighten

support the bo

become

knife

down

are inexpensive

out position

outer wash

L.H.

end of

fe

cli

Make

out

of

e wi

the

knife

ha s b

dow

worn,

on the

er

bar. Shar

ps

as

fe

clips, bent

the

I ine

by strik ing stones and

ll

rise

bock

een

n on

ck edge

the

guard

and

pins

spre

ad.

(knife

from

stated belo

following adju

when

and if bent,

straightened, adjust the

the

of

back

edge

plates.

should

farthest

pin

welded

pen

knife sectio

w.

guards

keep

cutting

knife

the

kni

of the

bereploce

or

stments bef

wit h o hammer. Do

the

and results

straighten

secti

fe soon bec

knife

Even though the knif

to

on.

Keep kni

away from tractor

worn

kni

d wh

fe sh

kni

fe

head.

ns.

Repair

wearing

ore each

obstructions.

fe

flat upon the ledg

in

pulling

it

carefully

knife clips.

If the

omes wor

is not

enev

er

mower

supported

badly

arp

and t

rue.

).

Slip pitm

pla

day's

not benc;llips

n.

e c I ips

an from pin and pu ll comple

or

str

aigh

tes

will

cutti

Remove

er

or

tearing

on f

loor

Tap

is

used

The

wear

high

hove

worn.

Obse

rve

ten kni

abs

ng.

knife and

plates.

or

it

with

in

enough.

been

fe

orb o great

of guards down

If

instead

block

by

light

loose

abrasive

plate

is

This

set

down

all

safety precaution

te

as

needed, or

deal

sight

through

above knife,

the clips become l

of o sh

striking wit

blows

of

soils, the

located

under the

makes

as out I i

of

pow

earing

hammer

it

difficult

ned

rep

guards.

action.

h hammer

s.

kni fe

lace

er and

as

oose

unt

steel

knife

above,

il

to

PITMAN

Tigh

ten

to

obta

Tighten

The

above

the

top

or

derin

g rep

A

ll

ports I is

ordering

f

urn

i shed

WH EN

REPLACEMENT

hex

jam n

in this

hex

uts (A),

dimension. Spherical

jam

nuts

and

securely.

SEARS

number

of the frame

air

ports

on

ORDERING

is the

Model

weldment.

port

s.

ted herein may be ord ered

by moil from t

request

or

ports

REPAIR

B

spherical

rod

SICKLE

Number

Always

he

moil order house

will

be shipp

PARTS,

FIG

. 13

rod

ends

(B),

ends

must

HOW

TO

ORDER

BAR

MOWER--

of

your

SEARS

ment

ion

the

Model

through

ed at

ALWAYS GIVE

SEARS, ROEBUCK

which

prevailing

in

be

pitman

at

SICKLE

THE

tub

e (

C),

until

90°

to

each other

REPAIR

MODEL

Number

serves

prices

FOLLOWING INFORMATION

BAR

of

the

and

PARTS

NUMBER

MOWER.

your

mower

AND CO.

territory

you

will

on

equal

with

zerk

917.253120

It

wi

II

when

or SIM

in

which

be

billed

amount

fitting

be

communicating with u:;

PSONS-SEARS LIMI

you live,

accordingly.

found

AS

of

threads

facing

on a

selling

SHOWN

ore

to

rear

plate attach

TED

prices

IN

THIS

exposed

of

mower.

or when

. When

will

LIST;

ed

to

be

1.

The

PART

NUMBER.

2.

The

PART

NAME.

Each port

the Key

SEARS, ROEB

change

letter

s or

has

been given 0 K

or

number

UCK AND CO. and S

imp

rovements

when ordering

witho

ey letter or

ut

imposing any obi igot

repair

IMPSON

number

ports.

S-SEARS

which

LIMITED

ion

to

3.

4.

is

install

T he

The

used

MODEL

NAME

reserves the

the same up

only

NUMBER··

of

OS

Implemen

a

guide

right

on

its

917.253120.

t · · SI

to

find

to make

products

CKLE

the

any

heretofore

BAR

part

number.

changes

MOWER.

Do

in

design

manufactur

not

use

and

ed

•

Page 8

SEARS

SICKLE

BAR

MOWER --MODEL

NUMBER

917.2531

20

8

c

/

c

'

'

'

/

/

/

/

/

M

' i

2.3.69

N 0 P R

49

©4

7

@

~48

~

'511

' 1

---

---

-8-

FOR

NEW

REFER

I J l

rt

@ ©

@43

44

®

STYLE BELT

TO

PAGE

i46

@41

tt::h42

~

GUARD--

5,

FIG.

8-A

v

S:l

~

47

f'Al

~48

®

Page 9

SEARS

SICKLE

BAR MOWER --MODEL

NUMBER

917.253120

KEY

NO.

-9

10

13 528

15 606A287

22 634A301

-

PART

NO. NO.

1 5309H

5235H1 Frome Hanger Shaft 37 272232 *Hex

2

3 5304H

5280H

4

131016 *Washer,

5

1554H Timken

6

6855M

7

?A

634A287 Frome Weldment with Bearing

8

2623M

606A286 Frome Strap Front Weldment

11

120388 *Washer,

12

5277H

2H

14

5249H

357H Huglock Nut 50 103384

16

19151616 Washer

17

18

19211612 Washer

5310H

19

1553H

20

21

9244H

2H

924

21A

278H

23

24 7939M

25

26 606A290

27

28

29 5234H

30 120394 *Washer, 13/ 32 x 13/ 16 x 16 Ga. M

31

32

33

34 5296H

35 5237H

35A 32

35B 122181

124944

6523H

634A286 Foot

1542U

5252H

606A278 Yoke Weldment

24M

DESCRIPTION

Cushion

Elastic

Dust

Grease

Model Number

Bushing

Bushing

Flywheel

Flywheel Guard

Belt

Grease Retainer

Timk

Spherical

Pitman

Flywheel

Grease Fitting

Bushing

*Nut, Hex Jam ASF 5/8-

Plated

Transport

Bushing

Clev

Spring

Cutter

Lift

Pull

Bushing

Bolt,

*

Washer 36 120389 *Washer,

Stop

Nut

5/8

• 18

Cop

21/32

x 1-5/ 16 x 13 Go.

Cone

Fitting

Plate

Cups

Flat

7/16

x 1 x 14

Guard

Bracket

Guide Weldment • Flywheel 49 120390

15/

32

x 1 x 12

21/32

x 1 x 12 Go.

Washer

en

Cup

Rod End

Tube

Assembly

Stop and Rivet

Lever

Wel

dment

is

Bar

Latch

Link

Rod 8920H

Hex

3/8

• 16 UNC x 2

Ga.

Ga.

18

UNF F 120696 *

}1

Plated

KEY

38

39

40

41

42

43

44 219431 *Hex

45

46 120388 *Washer, 7/ 16 x 1 x 14 Go.

47

48 219434

51

52 347H

53

- A

B 1572H

c

.--.o

E

G 122007 *

H

I 120696 *

J

L

N 122472 *

0 5297H

p

R 103408

PART DESCRIPTI

NO.

Nut,

131016

121574 *Lockwosfier 5/ 8

219436 *Hex Nut, 5/ 8 -

131099

120377 *H

120214 *

120393 *Washer,

120384 *

8238H

132295 *Machine Screw, Slotted Fill

4940M

122333 *Bolt, Hex

428691 - *

122145 *Bolt,-Hex 3/

122017 *

120233 *

122491 *

103384 *

456723

*Wash

er,

Cod.

*Lockwosher, 3/8

ex

Nut,

Lockwosher, 5/1

Nut,

Cad

. P

Lockwasher

Hex

*Nut

1

*Wash

er,

*

Cotter

Split Spacer

Hug lock Nut

~~

•

20

Retainer

Roll

Pin

Bolt,

Bolt

, Hex 5/ 16 • 18 x 2

Bolt,

Bolt,

Bolt,

Bolt,

Bolt,

Cotter

Bolt

, Hex

Drilled

*Cott

er

*Cott

er

Instruction

ON

}S

x

114

x 14 Go.

7/16

- 14

21/32 x 1-5/16

Plated

Cod.

11

Cod.

3/8-

16

6

5/16

• 18

11/3

2 x

11/16

lated

,

Y7

Cad.

Y7

- 13

Cad.

9/ 16 x 1-3/ 8 x 12'

Pin,

1/8

x %

UNC

x 3

14

Plated

Spring

7/16-

Hex 5

Hex

5/16

Hex 5/16Hex 5/ 16 - 18 x 2

Hex

3/8Hex

Y,

Pin,

Y7

Rivet

Pin

Pin 3/16

/8 • 11

8-

16 x 1

• 18 x %

16 x 1

• 13 x 3

1/8

x %

• 13 x

3/1

6 x 1

and

Parts

14 x 3

18 x 1

x 1

x 13 Go.,

Plated

Plated

x 16 Go.

Plated

Plated

x 2

Cad. Plated

14

14

Cad.

Cad.

14

14

2}1

14

Book

Ga.

ister

Hd.

Plated

Plated

3.11.69

-9

* Standard Hardware Item-·

Purchase

Locally

.

-

Page 10

SEARS

SICKLE

BAR

MOWER--MODEL

NUMBER

917.25l120

c

T

D

y

·~::::::::::::::::::::::::J~

I

~M

p__

P

--

1 I

~.....-49

~~48

1

~

--.J

I

---

y41

v

I

N

~-----48

Page 11

SEARS

SICKLE

BAR

MOWER

--MODEL

NUMBER

917.253120

KEY

NO. NO.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26 4569M 1 Wearing

27

28

29 606A280

30

31

32

33

34 6842M

35

36

37

38

39

PART

1 4379H Shift Handle Grip

634A 123A

2

3 6508H

4 6499H

5 4940M Retainer Spring

6

6501H

7 4301H Spring

8 606A294A

9 606A296

697H

5386H Bushing

606A295

12

0395 *Washer,

272233

4775H

5308H

4939M Retainer Spring

1689E Bushing 5

120214

219431

120382

219432

19141610 *Washer,

5232H

634A300

4572M

575X31

5311H

5285H

5290H Rear Guide

357H

1915161

19211612 Washer

634A299A

606A252

120383

DESCRIPTION

Lever

Lever

Belt

Tightener

Adjusting

Idler

Idler

Bearing

Idler

*Nut,

Hex

Belt

Guide

Y·Belt

*Lockwasher,

*Nut,

Hex 5/

*Lock

washer 1 3;13

*Nut 1 Hex

Swa

th

Knife

Knife

Knife

Cutter

Wear

Knife

Nut,

Huglock

Grease

Washer

6

Knife

Belt

Guide Weldment

*Lockwasher,

Weldment

Stop Strap

Pin

Shaft

Assembly

and

Bearing·

and Bearing • Outer

Flat

7/16.

(Engine

16 • 18

3;13 • 16

Flat

stick

Assembly

Plate

Clip

Sections

Bar and Mounting Bracket

Plate-

Head

Spacer·

Fitting

15/32

21/32

Head and

KEY

NO.

40

41

42

Link

Inner

43

44 5254H

45

46

47

48

49

so

51

15/32

x 1 x

12

Ga.

20

UNF

to

Flywheel)

5/16

C.P.

Cad. Plated Cad.

Cad. Plated

Cad. Plated

7/16

x 1 x

10

Ga. F 6801M

Only

(Box

of

25)

Rear

Rear

x 1 x

12

Ga.

x 1 x

12

Ga. Cad. Plated

Pin

-Front

7/16

52 120388 *Washer,

53 5394H

54

A 122040 *

B

c 122145

D

E 5480H

G

H 126402

J

K 6800M

L

M

N

0

p

-Q

R 120915

s

PART

NO.

5312H

5289H Front Guide

5284H

5247H

5248H

5256H

5233H

57SX32 Guard

575PA53

606A273 Outer Runner Weldment

606A292 Swathboard Assembly

120380 *Lockwasher,

180124

144531

120918

101536

103419

120915

126411

6802M

101535

120915-

123316

DESCRIPTION

Knife

Head

Plate

Knife

Head Spacer •

Wear

Plate·

Wear

Front

Knife

Back (Only)

Inner Runner

Inner Runner

Plate

Double

Nut,

Gripco

Bolt,

Hex

Bolt,

Hex

H.

T. Cad.

Bolt,

Hex

Plated

*Machine Screw,

Rivet,

Rivet,

Bolt,

*

*Bolt,

*

*Cotter

*

*

*Bolt,

*Bolt,

*Bolt,

*

Hex

Hex

Bolt,

Sq. Neck

Rivet,

Bolt,

Sq. Neck

3/8 • 16

Bolt,

Sq. Neck Carriage

3/8 • 16 X 1Y2

Rivet

CTSK #8 x

Sq.

Sq.

Sq. Neck Carriage

Cad.

Plated

Bolt,

Hex

Front

Plate

Divider

(Box

Guard

Flat

7/16

'!1.1

5/16 • 18 x 1Y2

3;13 • 16 x 1'!1.1

Plated

3/8

Flat

Head

Round Head

3/83;13- 16 x

Round Head

Pin

, !4 x 1

X 1

Neck

Neck Carriage

'!1.1 • 28

Front

Base

of

25)

Assembly

x 1 x 14 Ga.

·16

x 1

'!1.1

Truss

7/32

5/32

16

x 1

Y2

1'!1.1

Plow

3/8 • 16 x 1'!1.1

5/32 x 9/16

'!1.1

Carriage

1·1/8

Plow

3;13 • 16

x

Y2

Grade

H.T.

Hd.

'!1.1

- 20 x Y2

x%

Bag

of

3

x 13/16 Bag of 5

Bag

Bag

of

20

x 1

3/8-

16

x 1

3/8 -16

x 1

of

35

*Standard Hardware Item --Purchase

3.11.69

Locally

-11-

Page 12

--

~-

~~

~

KEEP

C~ILDREN

PETS

AN

A\JAY

___

_

CLEAR

AREA

BEFORE

REMOVE

OF

RUBBIS~

MOW'

THE

IGNITION

THE

I

NG

__

_

KE"l

__

FUEL

LEFT,

2.3.69

FROM

CAREFULLY

T~E

-12-

Page 13

SUPPLEMENT LIST

.

•

,

Disregard

i

nforma

tion:

step 9 and key

letters

T and U

SICKLE

MODEL

in

Fig.

FOR

BAR

MOWER

NUMBER

6,

page 4 of your

917.253120

main Instruc

tion

book.

Instead

usc

the

following

Remove

pin.

Now

cotter

follow

pin

from

steps

rivet

10

and

(A},

11.

and

remove

rivet.

Attach

clevis

to

foot

lift

lever

Comply

step

If you have a

sh

remove

(E),

behind

removed

retainer

this

securing

engine.

After

(C},

12,

own

at left,

attached

belt

completing

with

with

the

page 5 of

belt guard.

to

belt

guard

in

order to

is

not

retainer for

mounting

the

BELT RETAINER

(B},

following

late

remove

the

used

step

two

retainer

with

your

mode!

the

Also

engine

(C}.

assemble

with

future

plate

15,

rivet

information

main

tractor

two

you

will

with two

This

the

use.

and

page

springs

and

secure

Instruction

with

retain

er

have a belt

bolts

belt

reta

mower

Sickle Bar

Replace

guide

5,

reattach

(D}.

with

before

book.

belt

spr

ings

and located

iner mus

belt.

Mower,

the

assembly

starting

guard

(D),

retainer

This

two

belt

cotter

(C),

and.

t

b

bel

Sov{'

bolts

to

guard

~

t

Supplement

Parts

Book

to

Instruction

No.

8920H

and

4.3.69

Printed

in

U.S.A.

Page 14

•

i ,

SUPPLEMENT

FOR

SICKLE~

,.BAR

SHEET

MOWER

..

!

Disregard

information:

step

9 and

key

letters

T and U

MODEL

in

Fig.

NUMB

6,

page 4 of

ER

917.253120

your main

Instruction

book.

Instead

use

the

following

'

Remove

pin.

Now follow

cotter

pin from

steps

rivet

10

and

(A),

11.

and

remove

rivet.

Attach

clevis

to

Comply

step

If you

shown

remove

(E), attached

behind

removed

retainer

this

securing

engine.

NOTE::

retainer

washer

up

After

(C), with

~

foot

lift

with

12,

have a late

at

belt

belt

belt

The

removed.

gap.

completing

BELT

lever

the

page 5 of

left,

remove

guard.

to

guard

in

order

is

not

used

retainer

mounting

two

furnished

th~

two

RETAINER

(B), wi

following

your main

model

the

Also

the

engine

(C).

to

assemble

with

for future

plate

bolts

Therefore

under

step

retainer

th

rivet

information

tractor

two

you

with

This

the

use.

and

will

place a 7/16

head

15,

page

springs

and

secure

Instruction

with

retainer

will

have a belt

two

bolts

belt

retainer

mower

Sickle

be

Bar

Replace

guide

too long with

of

each

5,

reattach

(D).

with

before

book.

belt

guard

springs

and located

belt.

This

Mower.

the

two

assembly

x 1 x 10 Go.

bolt

belt

cotter

starting

(C),

(D),

and

retainer

must

belt

Save

bolts

belt

to

toke

guard

be

to

If

this

sickle

~r

is

assembled

disregard

. .

lf

repair

Supplement

Parts

3266R·

~----------------------------------L-----------

step~2

parts

Book No, 8920H

1.

6.72

are

to

Instruction

on

needed

Page 3 of

for

and

to

a 1972

mower book

belt

tightner

tractor,

and

lever,

it

will

discard

refer

'!

have

belt

to

the

tightner

Tractor

belt

tightner

lever

parts list

--------~----------~--

lever

shipped

.

mounted

with

the

on the

sickle

tractor.

bar

Printed

Therefore

mower.

in

U.S

-------

~

.A.

~

Loading...

Loading...