Sears 917.25170 Owner's Manual

Sears

MODEL NO

s4t .ilstt

Senial t'/e.

A??7BD

vssz

OWNER'S

MAITIUAL

16[6

@AREEN

ti

Assembly

MaintenanGe

llperation

flepair

Pails

--

--*d'i;

.*$q(

your purchase

CONGBATULATIONS

Garden Tractor.

factured to

you

please

sons Sears Limited store. They

technicians and

this unit.

Please read

you

to assemble,

give

experience any

and

your

the

retain

contact

Always observe

on

lt has been designed, engineered

you

dependability and

problem you

nearest

proper

operate

the

Sears,

tools and

manual. The instructions will

this

maintain

and

"RULES

of a Sears 16/6

and manu-

performance.

cannot easily

Roebuck and Co. or Simp-

have competent, well-trained

parts

to service or repair

your

Tractor

FOR

SAFE OPERnttOtt".

Should

remedy,

enable

properly.

\w

YOUR

1f6IA GARDEN

IUEW

TRAGTOR

FEATURES...

CRAFTSMAN

running

on a variety oI

take

SAFETY

when tractor Clutch-Brake Pedal is

Lever is in

Clutch

GEAR TRANSMISSION-'SiX

ALL

speeds-to

job.

the

ing.

CONTROL

nition Switch,

Point Hitch conveniently

ATTA.CHMENT VE RSATIL|TY-{andles

Yard

Sears

AND 48

42

lift

to

LITTER

conventional lawn sweepers because

only the

SELF

lawns and

OTHER SOIL TILLAGE ATTACH

Disc

CHEVRON

OVEHHEAD

performance

yard,

INTERLOCK

"OFF"

you

let

Auto-type

select

differential

PANEL-with Throttle,

Ammeter and

and Garden

INCH

grass

POWERED ROTO SPADER

Harrow, Drag Harrow and Cultivator.

for level cuts.

up

WHISK LAWN SWEEPER is

rotary

brush

qardens

TIRES

VALVE 16 H.P. ENGINE

long lire with

and

gardening

SYSTEM*allows engine

position.

proper

the

grouped

Tractor Attachments

I\,IOWERS with three

or

depressed and

speeds

match

guard

helps

Choke,

Electric

for ease of use.

of its wheel-less design;

touches the

with

a

for

added

ground.

30 to 38 inch wide tiiling

lVlE NTS including

traclion in

plenty

snow

power

oI

removal tasks-

to start only

Attachment

forward, two

for the terrain and

against

turf scuff-

Light Switch,

Lift Switch

a

"higtr

more efficient than

prepares

for Three

large variet} of

including

lift" btades

lor new

soil

loose soil,

cool

to

ieverse

lg-

path.

Plow,

gravel

GARDENS

SNOW

ease.

BLOWER

handles wet,

heavy

powdery

or

snow with

TABLE

WARRANTY

RULES FOR SAFE OPERATION

ASSEMBLY

OPERATION

INSTRUCTIONS

I NSTRUCTIONS

. .4

OF

GONTENTS.

.1

. 1

MAINTENANCE

TROUBLE

REPAIR

SHOOTING

PARTS .

INSTRUCTIONS

.6

11

12

FULL

For

r

will

lf the tractor

date

For 90

or workmanship

From the 91st day until one

defective in material or workmanship

1/12th of the

Warranty service

United States.

This warranty

ONE

year

one

repair any

purchase.

of

days from the

YEAN WABRANTY

purchase,

the date

from

defect

is used

FULL

will not hold a charge, Sears will replace the battery at no

and

of

in material

for commercial

gO.DAY

date of

purchase,

LIMITED

year

from the date of

price

is

gives you

new battery for each

of the

available

by simply contacting the

specific Iegal

when this

or workmanship

rental

or

WAERANTY ON BATTEPY

if

any battery included with the tractor

WANEAilTY

and will not

rights,

and

Sears, Roebuck and Co.

Sears

BSC

Chicaqo, lL 60684

ON ELEGTBIC START

tractor

in this tractor.

purposes,

is

used

warranty applies for

this

for

personal

except

charge.

ON BATTEBY

purchase,

hold

if any battery

charge, Sears will replace the battery, charging

a

full month from the date of

nearest Sears store or Service Center throughout

you

Tower

41-3

may also

have

other

included wrth

purchase.

rights which vary from

household

battery,

the

proves

TNACTOR

purposes,

no

at

charge.

only 30days

defective in material

the

from the

tractor

state

to state-

Sears

proves

the

NULES FOR SAFE OPENATION

1. Know the controls and how 10 stop

OWNER,S MANUAL.

2. Do not allow

to operate it without

adults

3. Do not carry

tance away.

4.

Clear the

and thrown.

children

passengers.

work

to operate the

proper

Keep children and

of objects which might be

area

quickly.

vehicle. Do not allow

instruction.

5. Disengage all attachment clutches and shift into

fore

attempting to

Disengage

6.

fore

7.

Disengage

making

8. Disengage

tn use.

9. Take all

attended, such as disengaging the

the

brake,

10.

Do not stop or start

hill NIow

15"); never

'11.

Reduce speed

vent

when changing

Stav alert for holes in the terrain and other hidden hazards-

Stay alertStay alert

12.

13.

Use

power

leaving the operator's

power

repairs

any

power

possible

attachments. shifting into neutral,

stopping the engine, and removing the key.

up and down the face ol slopes

across the

on slopes and

or

tipping

tipping

or

for holes in

care when

a. Use only approved drawbar hitch

b. Limit

c, Do not

d.

14. Watch out for traffic

loads

turn

counterweights

Use

thrs owner s manual.

the engine.

start

to attaehments and stop the

to attachments and stop the engine before

or adjustments.

to

precautions

loss of control.

loss of control.

direction on slopes.

pulling

to those

sharply.

position.

attachments when

leaving

when

power-take-off,

suddenly when

face.

the terrain and other

loads

you

Use

or wheel weights when suggested in

going

make

turns

Exercise extreme cautionvent

Exercise extreme caution

using heavy equipment.

or

can safely control.

care when backing.

when c(ossinq or near roadwavs.

READ THE

pets

safe dis-

a

picked

neutral

engine

transporting or

vehicle

the

lowering

setting the

uphill or down-

(not

gradually

hidden hazards.

points-

parking

greater

to

up

bebe-

not

un-

than

pre-

15. When using

materia! toward bystanders nor allow anyone

hicle while in operation.

'16.

Handle

a. Use approved

any attachments,

gasoline

with care

gasoline

b- Never remove the cap of the

running

a

Wipe up spilled

or hot engine, or

gasoline.

never direct discharge of

-

it is highly flammable.

containers-

fuel

tank or add

fill

the

fuel

c. Open doors if the engine is run in the

fumes

17.

Keep the

dition,

18. Keep all nuts,

ment

'19.

Never store the equipment

a building where fumes may reach an open flame or

Allow

20.

To reduce fire hazard, keep

or

excessive

21. The

ed for damage

age

equipment.

22. Do not change

the

23. When using the vehicle

a. Mow

b. Never make

c.

d. Check

24. Check the

ration.

are dangerous. Do not run the engine indoors.

vehicle

and

is in safe working

and attachments in

keep

safety devices in

bolts and screws tight to be sure the equip-

condition.

with

the engine to cool before storing in any enclosure.

vehicle

should be repaired

engine.

grease.

and attachments

after striking a foreign object, and

the engine

only in daylight

is running

Shut the engine

unclogging

frequent

a cutting height

if the operator must

off when removing

chute.

the blade mounting bolts for

intervals.

grass

Replace

catcher

with new

the engine

should be stopped and inspect-

restarting

before

governor

with mower,

in

or

frequently

bags

bags

good

place.

gasoline

good

adiustment while

in the tank inside

free

and operating

settings or overspeed

proceed

artificial light.

dismount to do

the

proper

for wear

for

safety

near the ve-

gasoline

tank indoors.

garage -

grass

exhaust

operating con-

spark.

grass,

of

as follows;

leaves

the dam-

the engine

catcher or

Lightness at

or deterio-

protection.

to

the

so.

LOOK FOR THIS SYMAOL TO POINT OUT IMPORTANT

SAFETY PRECAUTIONS.

BECOME ALERT! YOUR

MEANS,-

IT

SAFETY

ATTENTION!

IS INVOLVED.

,1-

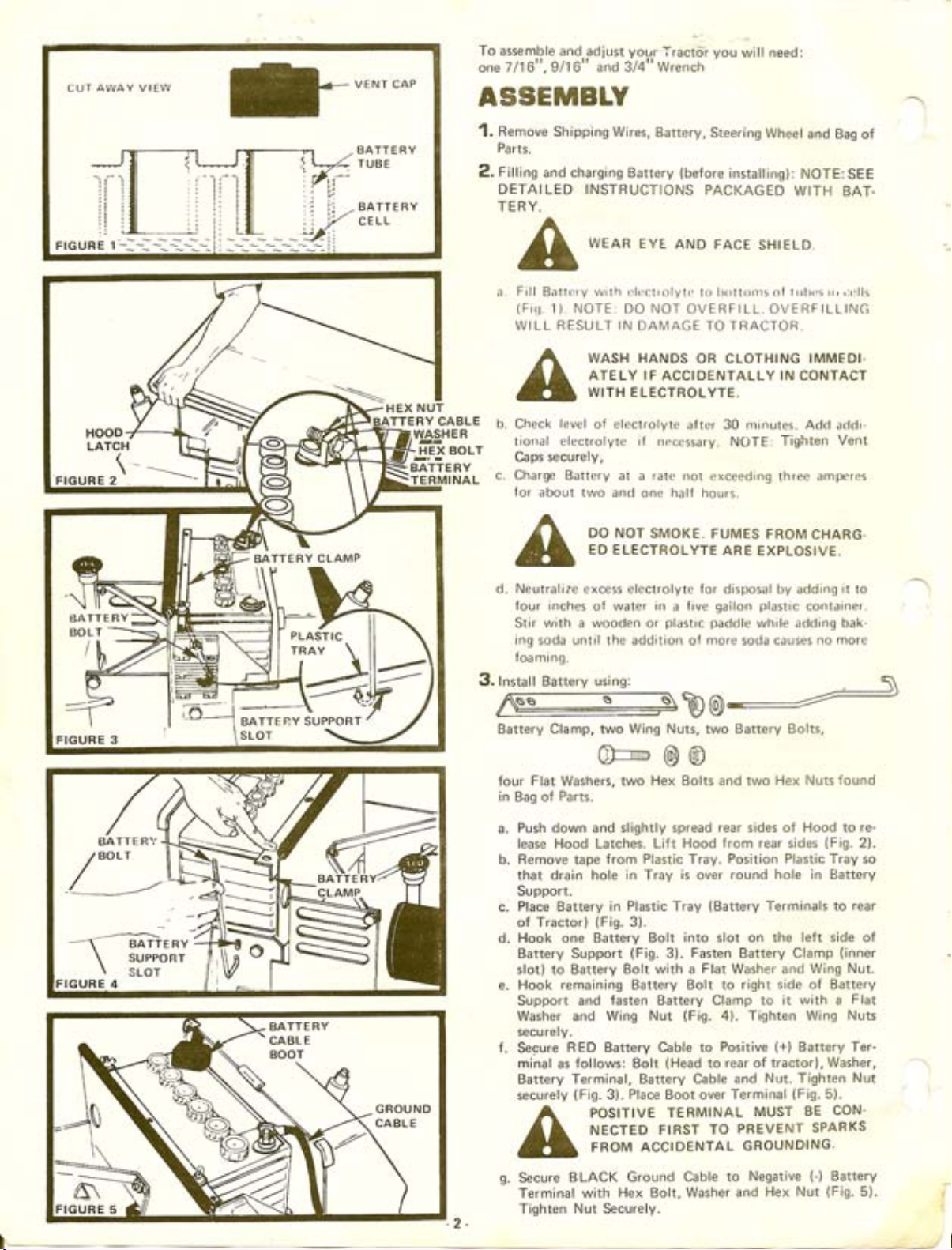

CUT AWAY VIEW

t--u.rr.o,

BATTERY

TUBE

BATTERY

CELL

To assemble

7/16". 9/16" and 3/4" wrench

one

and.adiust

yoLr

ASSEMEIY

Remove

1.

Parts.

Filling

2.

DETAILED INSTRUCTIONS

TERY,

a.

Shipping Wires,

and charging Battery

WEAR

A

Fill

Battcry

(Fiq.

WILL RESULT IN

wilh r)loctrolytc

1) NOTE:

DO

EYE

NOT

DAMAGE TO

Tracto-r

Battery,

you

Steering Wheel

{before

installing):

will need:

PACKAGED

AND

FACE

.HIELD-

to lx)tt()rr)s ol llllxrs

OVERFILL. OVERFILLING

TRACTOR,

and Bag

NOTE:

of

SEE

WITH BAT.

ll,rolls

BATTERY CLAMP

BATTE RY SUPPORT

TTERY CABLE

WASHER

.HEX

BOLT

WASH HANDS OR

ATELY IF ACCIDENTALLY IN

WITH ELECTROLYTE-

b. Check

c. Charge

level

electrolyte

of

tional eiectro,yte if

securely,

Caps

Battery at a rate not

for

about

two and one half hours.

DO NOT

ED E

LECTROLYTE

necessary.

SMOKE. FUMES

d. Neutralize excess electrolyte for

Jour

inches of water in a

Stir with a wooden or

ing

soda until the addition of

foaming.

3.

lnstall Battery

Battery

four

in

Clamp, two Wing Nuts, two Battery Bolts,

Flat

Washers, two

of Parts.

Bag

usinq:

C\*-,

plastic

@

Hex Bolts

CLOTHING

CONTACT

alter 30 minutes.

NOTE:

exceeding three ampcr{rs

ARE EXPLOSIVE.

disposal by

five gailon

paddle

nrore

Tighten

FROM

adding

plastic

while addiog bak-

soda causes

@

two Hex Nuts

and

IMMEDI.

Add addi

Vent

CHARG.

it

container-

no more

found

to

E R\.'

BA TT

-r--'--iiii

\ supponr

\

e n vl

sror

Push down and slightly spread

a.

lease Hood Latches. Lift

b. Remove tape

from Plastic Tray.

rear

Hood from rear sides

that drain hole in Tray is over

Support.

Place

c.

of Tractor)

Battery

in

(Fig.

Plastic

3).

d. Hook one Battery

Battery Support

slot) to Battery Bolt

(Fig.

Bolt into slot on the

with a

Tray

3).

(Battery

Fasten

Flat

e. Hook remaining Battery Bolt to

Support and

Washer and Wing

securely.

f. Secure

minal

as

Battery Terminal, Battery

securelV

Secure

s.

Terminal with

Tighten

fasten Battery Clamp to it with a

(Fig.

Nut

RED Battery Cable to

follows: Bolt

(Fig.

3).

POSITIVE

NECTED

FROM ACCIDENTAL

BLACK Ground Cable

Place

FIRST

(Head

Boot over

TERMINAL

4). Tighten Wing Nuts

Positive

rear of tractor), Washer,

to

Cable and

TO

to

Hex Bolt. Washer and

Nut

Securely,

sides of

Position Plastic

Hood to re-

{Fig.

Tray so

round hole in Battery

Terminals to

rear

left side

Battery

Washer and Wing

Clamp

right side of Battery

(+)

Nut. Tighten Nut

Terminal

(Fig.5).

MUST

PREVENT

GROUNDING.

Negative

Hex Nut

(inner

Nut.

Flat

Battery Ter-

CON.

BE

SPARKS

(')

Battery

{Fig.

2}.

of

5).

4.lnstall

Steering Wheel

using:

oc

Washer, Lockwasher,

Flat

of Steerinq

Woodrulf

Parts.

a- Remove

Steering Shaft

lnsert Woodruff Kev in Kevway

b.

slide

SURE

SHAFT.

Fasten

c.

6t.

Insert

d.

Shaft;

-

Key,

and

Steering

Hex

Bolt, Lockwasher

lFig.

Steering Wheel

WOODRUFF KEY

Flat

with

I rgnren

Steering Wheel Cap in

Washer, Lockwasher

secu.cly

and

Wheel Cap

6).

over Shait

IS

place.

q

Bolr assembled

found

in Bag of

Flat

and

of Steering Shaft and

and Key.

SECURE

Washer

NOTE:

IN STEERING

Hex Bolt

and

on end

,rom

BE

(Fiq.

INITIAL

Reduce Tire

1.

(Tires

2.Seat

loosening

TIGHTEN ING

SEAT

MENT WITH SEAT

A spark arrestor

3.

vo..

INITIAL

NOTE:

THE

FUEL,

l.Check

Wipe dipstick

onds, remove

"FULL"

SD or SE) Oil.

(SC.

(below

DO NOT OVERFILL.

ADJUSTMENTS

pressure

were overlnflated

position

Nut

PLATE HAS NOT

lr,,.ror

C", ck

SERUICE

BE CAREFUL

ENCINE WHEN CHECKING OR

Engine

(Fig.8)

and

mark is

or

SD

SE)

ooF.) use

to

for shipping

SPRING.

mLrftler

qa

l,

NOT

.rcljusted

Plate

may b(i

in Scat

NUT AFTE

Oil Level with Tractor

clean,

read

Oil Level. lf necessary,

reached.

ln winter

or low4o

S.A.E.

pounds

12

(Fig.7).

R ADJUSTMENT,

TWISTED

is available as an accessory

r,,rlrrr,'

TO ALLOW DIRT

in

purposes).

forward

m',11\

tront

or

NOTE

OUT

.n y.r,r

and

backward

WHEN

I\IAKE SURE

OF

o,r

TO

ADDING

level

push

ln summer

(below

32oF.) use S.A.E.

(SC.

SD or SE).

(SC,

5W2O

on

it in tight for

add Oil

use S.A.E. 30

ln extreme cold

or

SD

SE).

a

rear Tires.

by

RE

ALIGN'

part

for

d.

ENTER

OIL OR

ground.

few sec'

until

(SC,

1OW3O

NOTE:

ENGINE OIL

DIPSTiCK

Fill Fuel Tank

2.

leaded

NOT

SWITCH

LINE,

gasoline.

(Fiq.

7)

Capacity

FROM

fresh regular

with

is 3 1/4

LEADED

FILL TO BOTTOM

TO LEAD.FREE

OF

ER NECK. DO NOT OVERFILL. WIPE

OFF ANY SPILLED OIL OR FUEL.

grade

gallons.

GAS TANK FILL.

free

lead

NOTE: DO

GASO.

or

,3-

OPEPATIOil

FIGUBE9

FIGURE'IO

PostrtoN

oFF

ATTACHMENT

CLUTCH

LEVER

GEAR SHIFT

LEV E

REVERSE

PARKING BRAK

LEVER

t.t'

i,f

, )y l::

/ lo"

RANGF SHIFT II

LEVEB

^

--11+^)

l^l ii.

/;"'ll

\

\1 T HIGH

NEUTRAL

tlrt

oll

:1

"ll

STANTING

P

Parkrng

ace

1.

Place

2.

3.Place Gear

4.Move

5.Push

6.

7.

l\,4ove

Prlt

Chok" out

Attachrnent

Range

Clutch-Brake

Throttle

8.Turn lgnition Key

(Fig.

13). Release key

NOTE:

FOR MOR€

engine does not

Control Lever

try again.

NOTE:

an

equipment).

The Electric

attachment when used with a Three Point Hitch

WARMING

Move Throttle

in

as engine warms. NOTE: ALLOW ENGINE

FOR

UP

"r

I

When

to middle

A

restarting

position,

THE

Shift Lever

Shift Lever

Conrrol Lever

DO NOT RUN

THAN

to "FAST"

Control Lever to slow

FEW

MINUTES BEFORE

a warm engine, move

ALWAYS WEAR SUBSTANTIAL FOOT.

WEAR AND AVOID LOOSE FITTING

CLOTHING THAT

IN MOVING PARTS.

LEARN TO START, STOP AND REVERSE

YOUR TRACTOR IN A LARGE. OPEN

SPACE.

ENGINE

Brake Lever ill

Clurch Lever in

in netltral

to

Padal into

'13).

(Fig.

"START" position

to

into

THIRTY

start after several

Lift Switch

THE

UP

Choke may not have

lockecl

"OFF" position

"N"

neutral

brake

middle

to

"ON" position.

STARTER

SECONDS AT A TIME. If

position,

(Fig.

ENGINE

OPERATING.

position

positon

"N"

pos

position (Fig.

position (Fig.

Llntil Engine

CONTINUOUSLY

attempts, move throttle

few

wait a

13)

position.

Throttle Control Lever

COULD GET CAUGHT

(Fiq.

(Fiq.

(Fig.

(Fig.

tion

minutes, and

raises

or lowers

(optional

Push

TO WARM

to be

g).

l0i.

l1).

11).

12).

13).

starts

Choke

used.

\

TRACTOR

OPERATION

1.With engine

middle

Push

2.

3.

Move

" Low".

4.

R"l"us" Parking

5.

Release

movement.

l{

6.

tion

gear.

SPEED THAT

ATTACHI\4ENT

position.

Clutch-Brake Pedal

cear

Clutch-Brake Pedal

ground

travel is too slow move

press

or

NOTE: ALWAYS

running

Shift

Clutch'Brake

Lever to

Brake.

and warm,

down to brake

"2ND"

SELECT

WILL SUIT THE

BEING USED.

BRING TRACTOR TO COMPLETE

BEFORE SHI FTING GEARS.

NEVER PLACE

IN

OR UNDER ANY POWERED ATTACH.

place

Throttle

position.

and Range Shift Lever

SLOWLY

Throttle Lever

pedal

to start forward

and

shift ro a different

A GROUND TRAVEL

TERRAIN AND

YOUR HANDS OR FEET

MENT OR NEAR ANY MOVING

WHILE

ATTACHMENT IS RUNNING-

TRACTOR

ANY POWERED

OR

Lever in

{ast

to

posi

THE

STOP

PART

TNACTON OPERATION OiI HILLS

qears

BEFORE

DRIVE UP OR DOWN HILLS

GREATER THAN 150.AND,

ACROSS ANY SLOPE.

hills.

on

move Throttle C.ntrolto middle

push

Clutch-Brake

prevent

to

rolling.

Pedal

Pedal

\hitrinq

of the lowest

DO NOT

WITH SLOPES

DO NOT DRIVE

\toppinU

or

l.Choose one

down hills.

to

2.Avoid

a. lf slowing is necessary,

position.

b. lf

stopping is necessary,

ly to brake

Engage Parking

c.

d.

Partially

ment

Release

e.

f. Completely

ke

3.[,4a

all turnc

position

Brake and shilt 10

release Clutch-Brake

begins.

Park ing

Brake.

release Clutch-Brake

gradually.

starting

lowest

Lrntil forward move-

Pedal

speed

up

quick.

rang..

or

STOPPING

1.

Reduce Throttle

YOUB

Lever to

2.Push Clutch-Brake Pedal

3. Release Attachment

4.

Move Gear ShiIt Lever

5.Place

6. lutch-Braketi.

Parkrng

Release

Clut

Clutch.

to

Brake in

MAKE

HOLD TRACTOR

"l

SURE

A

7,

Turn

lqnition

"OFF"

Key

to

REMOVE KEY

TOR TO PREVENT

A

TNANSPONTIiIG

pushinq

For

and

Range

or towing

Shifl

DO NOT TOW YOUR

IV] IL ES PER

HOUR.

Lever

yoLrr

in neutral

TRACTOR

TPACTOR

"SLoW" position.

into

Brake

netrtral

OCK"

YOUN

"N".

posrrron.

PARKING

SECURE.

positiorr.

WHEN

UNAUTHORIZED

TRACTON

tractor,

place

position

FASTER

posttion.

BRAKE

LEAVING

Gear ShifI Lever

(Fig.

TRAC.

11). NOTE:

THAN SIX

WILL

USE.

STARTING

WITH A

your

lf

recharged.

fottow

PED

THE

NEGATIV E

l.Connect

2.Connect one end

3.Connect

4.D.,conno' I

.5

Battery is

thls

WITH A 12

OTHER VEHICLE IVIUST

terminals

chassis

(

)rerminal

good

or

Tank or Battery).

Enqine

a.

b. Negative

Posltive

c.

YOUN

LOW

"Jumper

lf

procedurei

GROUNDED

each end of the

of each battery

).

of

the orher

CHASSIS GROUND

.dblP\

Block or chassis

terminal of

terminals

BATTERY

too low to start

Cables"

NoTE:

VOLT NEGATIVE

LEAD,ACID

PLOSIVE

AND SMOKING

BATTERIES.

AROUND

o{ rhe BLACI<

"GOoD"

end of the cabte

r. r(v€.,e

DO NOT USE YOUR

TERY

TO START OTHER VEHICLES.

TNACTOR

the engine,

Lrsed {or

are

YoUR

SYSTEI\,I,

BATTERIES GENEBATE

GASSES.KEEP

MATERIALS

ALWAYS

BATTERIES.

RED cable

(takinq

battery.

on lractor

urdel

"GOOD"

emergency startinq

TRACTOR tS EoUIP

GROUNDED SYSTEM,

ALSO

BE A 12 VOLT

SPARKS, FLAME,

SHIELD EYES

to the

care not

cable to rhe NEGATTVE

to short aqainst

ENGINE

to

(awav

batt"'v

TRACTOR BAT,

it

should be

EX.

AWAYFROM

POSITIVE

BLOCK

from

Gas

(+)

FLAT

IOI ER

1_r

,,)=:\

j

il e['

P

BELT

GU ID€

e

='-

FlGltRF l5

^e

-.'-/

O

^C

--fi14

UT

pEorr

RETAINEB

IDLER BEARING

'IT

SPRING

OIL DBAIN PLUG

GUABD

MAIilTEiIATCE

your

keep

To

service

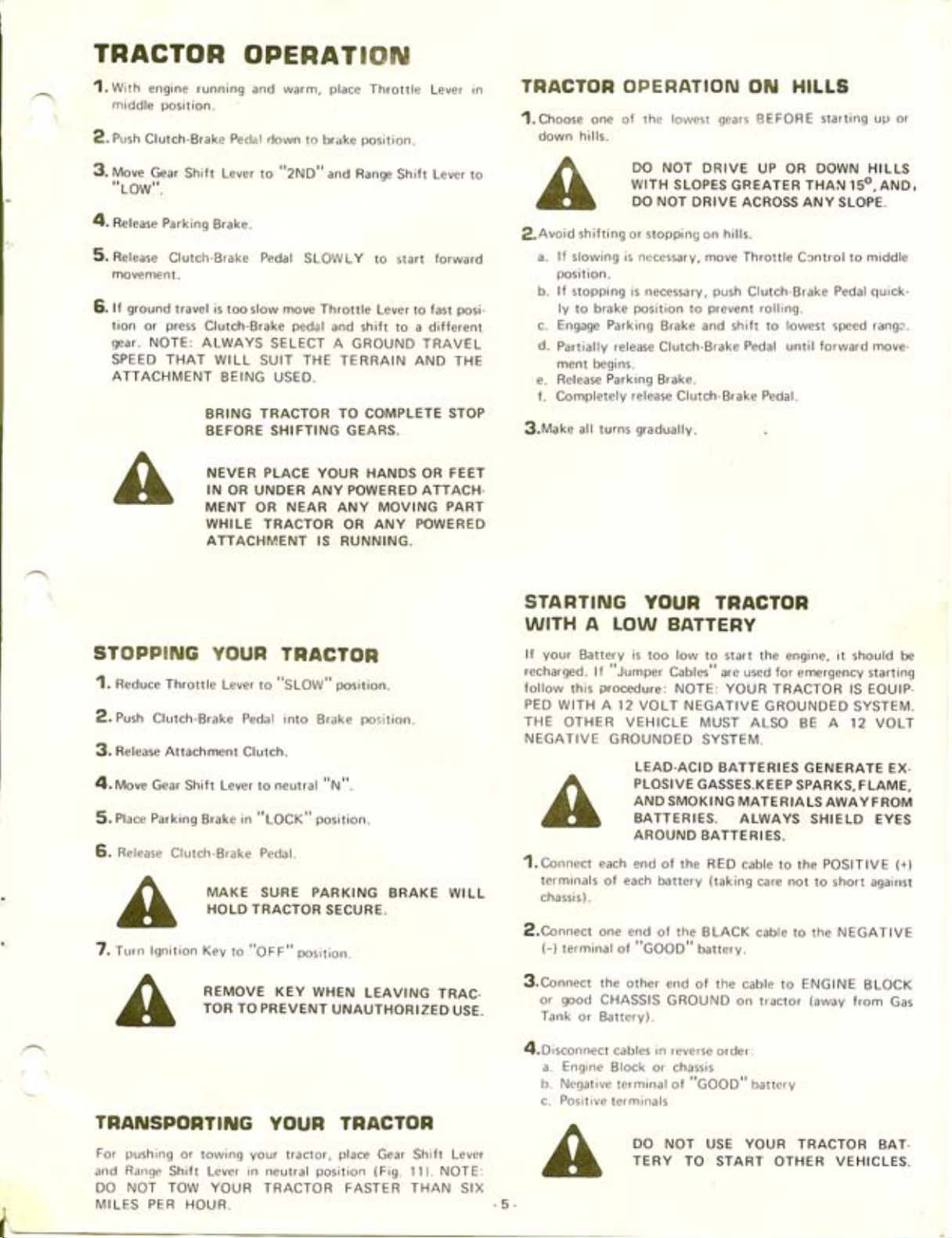

Each time

tractor

using the following

you

l4). The needle should

indicating

tractor.

the battery

A

FIEST

1.

curcr v.BELT TENsroN

A new V-Belt may stretch after

Iion.

considerably

the

a. Secure

b.

c.

d. Releare Clutch Bra[e

NOTE:

BELT

IV]OVEIV]ENT WITH

POSITION,

V.B E LTS.

2.cHaruce

a. Drain Oil

b. Refill

o

4 HOUPS:

lf Clutch Brake

is

V-Belt

Clutch Brake

V-Belt tension) by tieing to

Hold Nut

lt.

Bo

Flat ldler in frame

l\,4ove

loosen) V-Belt tension. Tighten Bolt.

rrp

{to

mately vertical

FOR

TENSIONED PROPERLY,

ENGTNE

Changing Oil alter the

break-in

Note: Be careful not to allow

when chanqinq oil.

residue which miqht be damaqing to

'16)

(Fig.

p.

Ca

Engine

(SC,

SD or SE) Oil. ln winter

'10W30

treme

SE). Capacity

FILL.

(SC,

cold

running better,longer;

Maintenance Schedule.

your

start

tractor,

move towards

is being charged as

DISCONNECT

PREVENT

FORE

JUSTMENT

REPAIR.

to the

out of adjustment and

inside

on

position.

CHECK

NOT START WITHOUT FULLY

SING

LONGER V-BELT

ACCIDENTA

MAKING

(EXCEPT

Pedal, ln

front or rear

pedal

Flat ldler

of

slot

Pedal.

TO MAKE

CLUTCH.BRAKE PEDAL.

THROTTLE CONTROL IN MIDDLE

AND ALWAYS REPLACE

orL

first

with Engine warm. Unscrew

catch

and

Oil

SD or SE) or 10W40

(below

is

3-

in

Oil

(Fig.

17).

ooF.) use S.A.E. 5W20

pints.

1/2

check

the

SPABK

perform

your

+

you

PLUG WIRE

necessary

Ammeter

(charging)

operate the

mark

L STARTING

ANY INSPECTION, AD.

CARBURETOR} OR

first few hours

the

position

drive

must

axle.

and

vertical

re'tensioned.

be

posltion

loosen

down

return to

of the

in

brake

Iront

1/4 inch

lt shorrld

SURE TRACTOR DOES

oI

(Fig.

position,

(relaxing

Flat ldler

(to

tighten),

approxi

DEPRES-

opera'

15), is

LIFE. AI-WAYS KEEP

START

TRACTOR

WITH SEARS

two

hours

dirt to

help eliminate

will

your

enter the

Engine.

Engine

Oil Drain

a suitable container. Replace

ln

summer

{below

NOTE: DO

32oF.)

(SC,

use S.A.E. 30

use

or

SD

SE).

(SC,

NOT

S.A.E.

ln ex'

SDor

OVER

(Fig.

TO

BE-

Cap

CI.IT AWAY VIFW

kvENrcaP

I

t

I

,,o, * J

1a

li

ll

l-ll

tx&

BATTERY

TUAE

AATTE RY

CELL

FNEOUETUTLY:

,I.

cHEcK BATTERY

Electrolyte

a.

even with bottoms

tilled water i, necessary.

b. Keep Battery and Terminals

solution level in

of tubes in cells

NOTEi DO NOT

each Battery Cell should tre

clean. Refer to

c. Keep Battery bolts tight.

d. Keep Vent Caps tight and small Vent

open.

e. Recharge

electrolyte

2. cHEcK

pressure

Tire

3.

clearu AtR scREEN

Air Screen and Guard

and chaff to

SLOWLY at 3

falls

PH EssuRE

TrRE

{ront

in

prevent

below

and

(Fig.

Engine

amperes

1.225.

rear Tires should

must

21)

damage

(Fig.

18).

Add dis-

OVERFILL.

page

holes in

iI

specific

be

gravity

be l2

kept free of dirt

from overheating.

10.

caps

of

pounds.

fJ

EVERY

HOT.IRS:

FJ

l,cnecr ENGTNE

A

fi,',,i?1"fi:'x,'^,l,?it:

otL LEVEL

o'|L

LEVEL

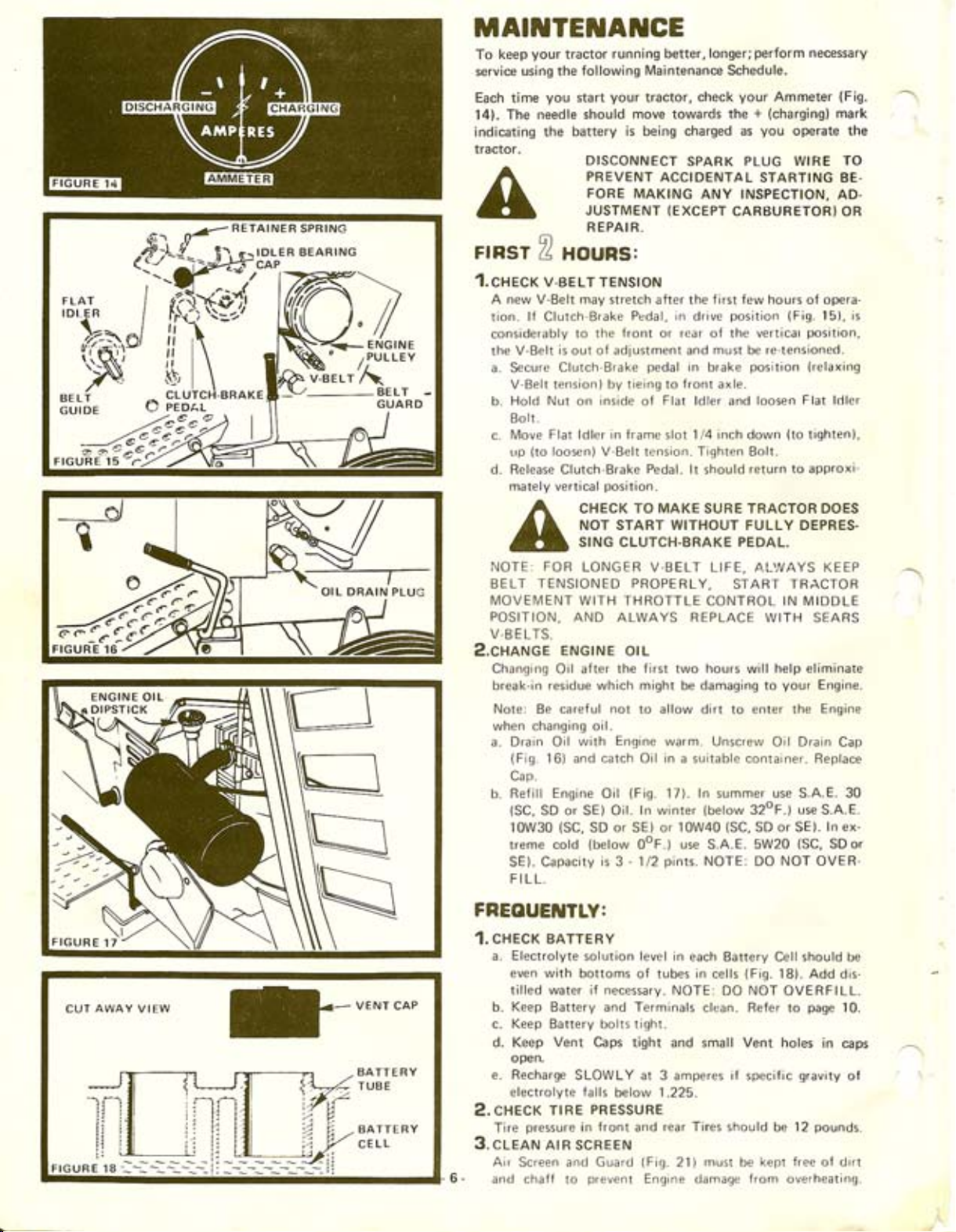

STEE R ING G EAA

\

SECTOR ANO ARM

GREASE FITTING

Several minutes

Level with Tractor

push

clcan,

after stopping Engine,

on level

it

down

tight for

Oil Levet. lf necessary,

reached.

winter

10W40

S.A.E. 5W20

FILL.

Luantcare

2.

There

Using a Gre€se

Extreme Prc,ssure

al)le at

3. otL

Place

move

a.

l). Front

ln

summer

(below

32oF.1

(SC,

SD or

(SC,

sTEERtNG AND FRoNT

are six Grease

your

local

Prvor

against

ldler

,

PotNTs

several drops of

{,ach

Bearing

Remove

Remove Retainer

Plastic

lvlove ldler

posed

Shaft.

RetuIn

Retainer

Axle

ldler

Spring, and

Prvot

rnfa

use S.A.E:30

SE). ln exlreme

SD or

Gun,

Lubricatinq

Sears

other, especially:

(Fig.

and

and Shaft to original

(Fig.'19)

EUENYZF] HOURS:

{EVERY 15 HOURS

IN

VERY

DUSTY

IF OPERATING

CONDITIONS}

qround.

few

a

seconds, remove

add Oii until

u5s S.A.E.

Fittings

give

Servico Centerj.

10W30

NOTE:

SE).

on

each Grease Fittinq

Grease

SAE 30 Oil

15)

Cap.

lrom ldler

Spriog

Shaft outward

reposition

check Engine

Wipe

dipstick

"FULL"

(SC,

SD or SE) Oil. ln

(SC,

SD or SE) or

(below

cold

DO

NOT

wHEELs

your

Tractor

Anttlex No.

points

at

ShaIt.

and

position,

Cap.

Oil

(Fig.

17)

and read

mark is

ooF.) use

OVER.

(Fig.

19).

two shots o,

(Avail-

I

parts

where

lubricate

replace

ex-

STEERING

BELL

CRANK

GBEASE

FITTING

FBONT

GREASE FITTING

(LEFT

& RIGHT}

SPINOLE

FRONT

GREASE

(L€FT

&

FIGUR

WHE EL

FITTITlG

BIGHT)

E 19

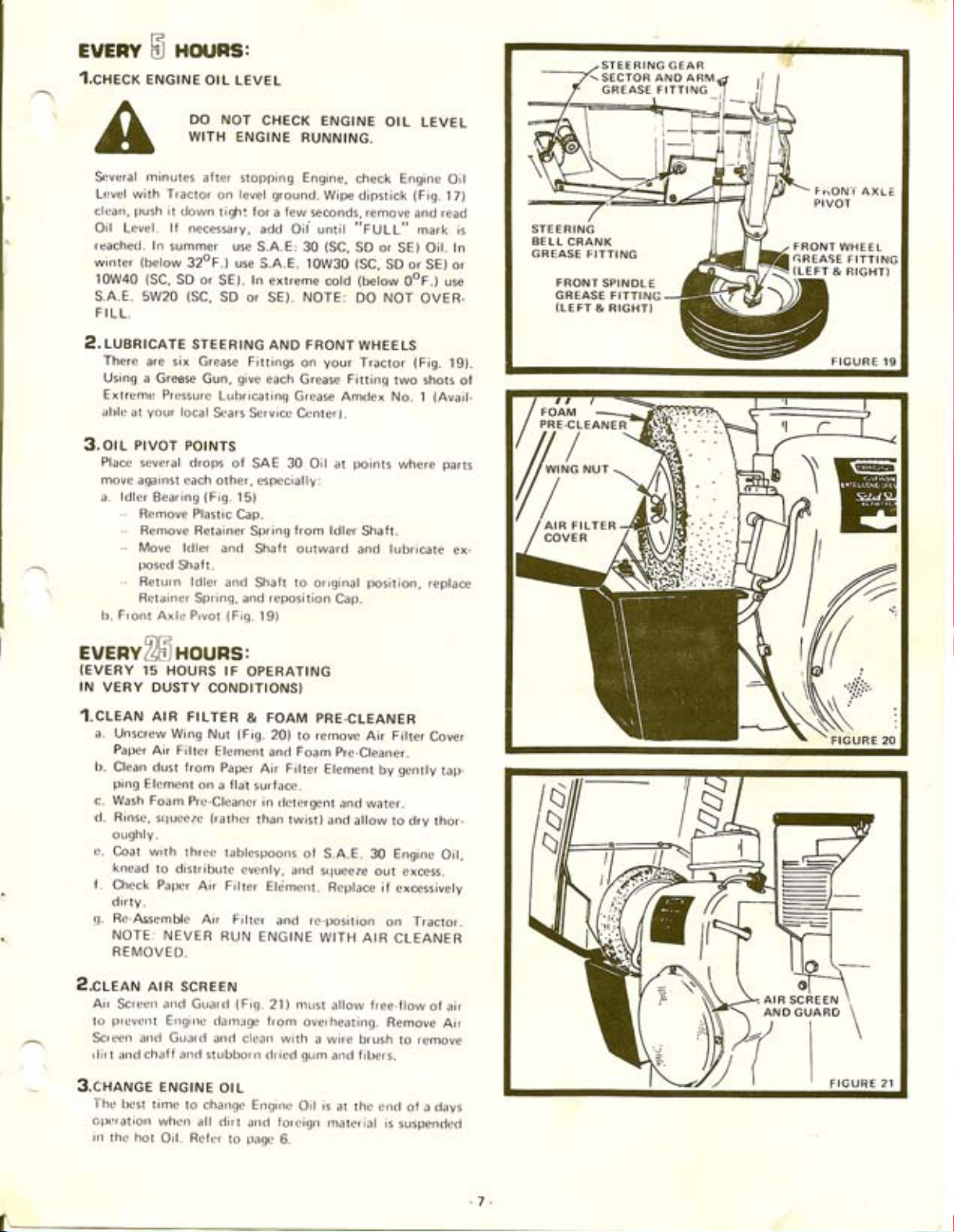

l.cLEAN

a. Unscrew

b.

c.

d.

c.

f.

ArR FTLTER

Wing

Paper

Clean

ping

Wash Foam Prc-Cleaner

Rinse,

oughly.

Coat with

knead

Check Paper

Filter

Air

dust Irom Paper

Element

on a flat

s{lueezc

three

to distribute

Air

dirry.

q.

Re

Assemble

NOTE:

REI\4OVED,

2.crrnru

Aii

to

Screen and Guard

{li[t

3.cxaruce ENGTNE

'l-lie

operat;on

in

ArR

Soeen and Guard

prevorlt

chaff and

arrd

l)cst

time to change

thc hot

Air Filter

NEVER

scnEEN

Engrne

wheD

all

Oil. Refcl

& FoAM PRE-CLEANER

(Fiq.

Nut

Element

(rathcr

RUN ENGINE

darn:rge from

and clenn with

stubborn dried

otL

dirt and toreign

20)

and Foam

Air Filter

surface_

in

dctergent

than twjst)

tablespoons

evenly,

Filter

EI€iment.

and reposition

(Fiq.

21) must

Engine

pagc

to

6.

to remove

of

ancl s(lueeze

overheating.

a wire

gL]m

Oil is

Filter

Air

pre-Cleaner.

Element

and water.

and

S_A.E. 30 Engine

allow

gently

by

to dry thor_

out excess.

Replace

if excessively

on Tractol.

WITH

AIR CLEANER

allow free

aod fibers.

at thc end

material

brush

flow

Remove

remove

to

of a days

is

suspended

Cover

tap

Oil,

of air

Air

'f,[,6

AIB SCREEN

AND GUABD

FIG

UR E

21

-7 -

----

$

FIGURE

22

GURE 23

TRANSAXLE

FILLER PLUG

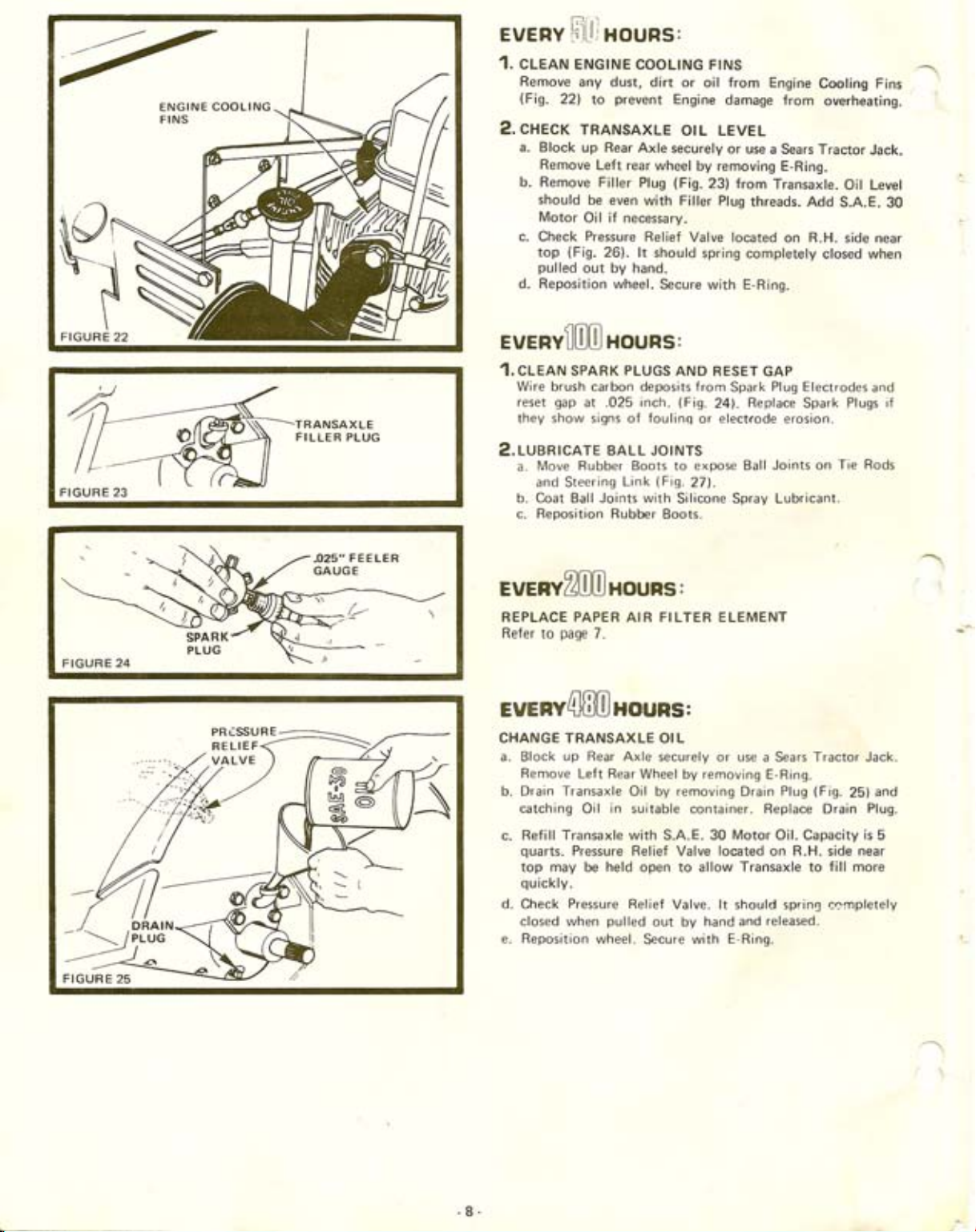

EvERY

1, cLEAN ENGTNE

Remove

lFis.

cHEcK

2.

a. Block up Rear

b. Remove Filler

c. Check Pressure

d. Reposition

evenvfl00

CLEAN SPARK PLUGS

1.

Wire brush carbon deposits Irom

reset

they show signs of

LUBRTCATE

2.

a.

b.

c.

5l[]]xouns,

cooLtNG FtNs

any dust, dirt or

22)

Remove

should

l\4otor

top

pulled

prevent

to

TRANSAXLE

Axle

Left rear

Plug

be

even with Filler

Oil if necessary.

(Fig.

26). lt

out by hand.

wheel. Secure

Engine

otL LEVEL

securely or

wheel by removing E-Ring.

(Fig.

Relief Valve

should spring

xouns:

AND RESET GAp

gap

at .025

l\4ove Rubber Boots to expose Ball

and Steerinq

Coat

Ball Joints

Reposition

inch.

{Fig. 24).

foulinq

BALL

JotNTs

(Fig.27).

Link

with

Rubber Boots.

Silicone Spray Lubricant.

from

oil

23) from

Ptug

Engine

damage from

use a Sears

threads. Add

located on B-H- side near

completely closed

Cooling Fins

Tractor

Transaxle.

with E-Ring.

Plug

Spark

Replace

Electrodes

Spark

or elect(ode erosion.

Joants on

overheating.

Jack.

Oil Level

S.A.E.

when

and

Plugs

Tie Rods

30

iI

FIGUR E 25

.O25" FEELER

evenvZ00xouns:

REPLACE

Reler to

PAPER

paqe

AIR FILTER ELEMENT

7.

evenv4ECIxouns:

CHANGE TRANSAXLE OIL

a. Block

b. Drain Transaxle Oil by removing

c.

d. Check Pressure

e. Reposition

up Rear

Remove

catching Oil in suitable

Left

Rear

Axle securely

Wheel

by

container.

use

or

removing

Drain

a Sears Tractor Jack.

E-Ring.

(Fig.

Plug

Replace

Drain

Befill Transaxle with S.A.E. 30 l\4otor Oil. Capacity is 5

quarts.

top

quickly.

closed when

Pressure

may

Relief Valve located on

held

be

open to allow

Relief Valve. lt should spring c..npletely

pulled

out by hand

wheel.

Secure

with E'Ring.

Transaxle to fill more

and

R.H.

released.

25)

Plug.

side near

and

I,

Loading...

Loading...