Page 1

S__A/_S

OWNER'S

MANUAL

MODEL NO,

917,242440

£RIIFT$ I:IN+'

Caution:

Read and follow

all Safety Rules

and Instructions

Before Operating

This Equipment

Sears, Roebuck and Co., Chicago, IL 60684 U.S.A.

ELECTRIC LIFT

ACTUATOR KIT

for GARDEN TRACTORS

• Assembly

• Operation

• Customer

Responsibilities

• Repair Parts

Page 2

Safe Operation Practices for Ride-On Mowers

SAFETY RULES

IMPORTANT: THIS CUTTING MACHINE IS CAPABLE OF AMPUTATING HANDS AND FEET AND THROWING

OBJECTS. FAILURE TO OBSERVE THE FOLLOWING SAFETY INSTRUCTIONS COULD RESULT IN SERIOUS

INJURY OR DEATH.

I. GENERAL OPERATION

• Read, understand, and follow all instructionsin the manual

and on the machine before starting.

• Only allow responsible adults, who are familiar with the

instructions,to operate the machine.

• Cleartheareaofobjeotesuch as recks, toys,wire, etc., which

could be picked up andthrown by the blade.

• Be surethe area is clear of otherpeople beforemowing.Stop

machineif anyone enters the area.

• Never carrypassengers.

• Donotmow inreverse unlessabsolutelynecessary. Always

lookdown and behind before and whilebacking.

• Be aware of the mower dischargedirectionand do not point

it at anyone. Do notoperate the mower without either the

entire grass catcher or the guard in place.

• Slow down before turning.

• Never leave a runningmachineunattended. Alwaysturnoff

blades, set parking brake, stop engine, and remove keys

before dismounting.

• Turn off bladeswhen notmowing.

• Stop engine before removing grass catcher or unclogging

chute.

• Mow only in daylightor good artificiallight.

• Do not operate the machine while under the influence of

alcoholordrugs.

• Watch for trafficwhen operatingnear orcrossingroadways.

• Use extracarewhen loading or unloadingthe machineintoa

trailer or truck.

I1. SLOPE OPERATION

Slopes are a major factor related to loss-of-controland tipover

accidents,whichcan result in severe injury or death. All slopes

requireextracaution. If youcannotbackupthe slopeor ifyoufeel

uneasyon it, do not mow it.

DO:

• Mow upand downslopes, not across.

• Remove obstaclessuch as rocks,tree limbs, etc.

• Watch for holes, ruts, or bumps. Uneven terrain could

overturnthe machine. Tallgrass can hide obstacles.

• Use slowspeed. Choose a low gear sothatyouwillnot have

tostop or shiftwhile on the slope.

• Followthemanufactureer'srecommendations forwheel weights

or counterweightsto improvestability.

• Use extra care with grass catchers or other attachments.

These can change the stabilityof the machine.

• Keep all movement on the slopes slow and gradual. Do not

make sudden changes inspeed ordirection.

• Avoid startingor stoppingon a slope. If tires lose traction,

disengagethe blades and proceed slowly straightdown the

slope.

DO NOT:

• Donot turnonslopes unlessnecessary,andthen, turnslowly

and gradually downhill,if possible.

• Do not mow near drop-offs, ditches,or embankments. The

mowercouldsuddenlyrum overif a wheel isover the edgeof

a cliff or ditch,or if an edge cavesin.

• Do not mow on wet grass. Reduced traction could cause

sliding.

• Donottrytostabilizethemachinebyputtingyourfootonthe

ground.

• Do not use grasscatcher on steep slopes.

IlL CHILDREN

Tragic accidents can occur if the operator is not alert to the

presenceof children. Childrenare oftenattracted to the machine

andthe mowingactivity. Neverassume that children willremain

where youlast sawthem.

• Keepchildrenoutofthemowingarea andunderthe watchful

care of anotherresponsible adult.

• Be alert and turn machine off ifchildren enter the area.

• Before and when backing,look behind and down for small

children.

• Never carry children. They may fall off and be seriously

injuredor interferewiththe safe machineoperation.

• Never allow childrento operate the machine.

• Use extra care when approaching blind corners, shrubs,

trees, or otherobjectsthat may obscurevision.

IV. SERVICE

• Use extra care in handling gasoline and other fuels. They

are flammable and vapors are explosive.

Use only an approved container.

Never remove gas cap or add fuel with the engine

running. Allowengineto coolbefore refueling. Do not

smoke.

Never refuel the machine indoors.

Never storethe machine orfuel container insidewhere

there is an openflame, such as a water heater.

• Never run a machine inside a closedarea.

• Keepnutsandbolts,especiallyblade attachment bolts,tight

and keep equipment in goodcondition.

• Never tamper with safety devices. Check their proper

operationregulady.

• Keepmachinefree of grass,leaves, orotherdebris build-up.

Clean. oil or fuel spillage. Allow machine to cool before

storing.

• Stop and inspect the equipment if you strike an object.

Repair, if necessary, before restarting.

• Never make adjustmentsorrepairswiththe engine running.

• Grass catcher components are subject to wear, damage,

and deterioration,whichcould exposemovingparts or allow

objects to be thrown. Frequently check components and

replacewithmanufacturer'srecommendedparts,when nec-

essary.

• Mower blades are sharp andcan cut. Wrap the blade(s) or

wear gloves, and use extra caution whenservicing them.

• Check brake operation frequently. Adjust and service as

required.

Look for this symbol to point out impor-

tant safety precautions. It means

CAUTION!!! BECOME ALERT!!! YOUR

SAFETY IS INVOLVED.

CAUTION: Always disconnect spark

plug wireand place wire where itcannot

&

contact spark plug in order to prevent

accidental starting when setting up,

transporting, adjusting or making

repairs.

2

Page 3

CONGRATULATIONS on yourpurchase of a Sears Elec-

tric Lift Actuator Kit. It has been designed, engineered

and manufactured to give you thebestpossibledependa-

bilityand performance.

Should you experience any problemsyou cannot easily

remedy, please contact yournearest Sears Service Cen-

ter/Department. We have competent,well trainedtechni-

ciansand the proper toolsto serviceor repairthisunit.

Please read and retain thismanual. The instructionswill

enable you to assemble and maintain your Lift Kit prop-

erly.Always observe the "SAFETY RULES".

MODEL

NUMBER 917.242440

SERIAL

NUMBER

DATE OF

PURCHASE

THE MODEL AND SERIAL NUMBERS WILL BE

FOUND ON A DECAL LOCATED IN THE BAG

OF PARTS. ATTACH DECAL TO YOUR TRAC-

TOR FOR FUTURE REFERENCE.

YOU SHOULD RECORD BOTH SERIAL NUMBER

AND DATE OF PURCHASE AND KEEP IN A SAFE

PLACE FOR FUTURE REFERENCE.

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

• Follow a regular schedule in maintaining, caring for

and usingyourElectricliftkit.

• Follow the instructionsunder "Operation" and "Cus-

tomer Responsibilities"sectionsof thisOwner's Manual.

LIMITED ONE YEAR WARRANTY ON

CRAFTSMAN ATTACHMENTS

Forone year from thedate of purchase, when thiselectric lift attachmentis maintainedaccording totheoperating and

maintenance instructionsintheowner'smanual, Searswillrepairfree ofchargeanydefectin materialorworkmanship.

Thiswarranty does notcover:

• Expendable itemswhich becomewornduring normal use.

• Repairs necessarybecause of operatorabuse or negligence,includingthefailure to maintainthe equipment

accordingto instructionscontainedinthe owner's manual.

• Attachments used for commercialor rentalpurposes.

WARRANTY SERVICE ISAVAILABLE BY RETURNING THE CRAFTSMAN ELECTRIC LIFT KITTO THE NEAREST

SEARS SERVICE CENTER/DEPARTMENT INTHE UNITED STATES. THIS WARRANTY APPLIES ONLY WHILE

THIS PRODUCT IS IN USE IN THE UNITED STATES.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

SEARS, ROEBUCK AND CO., D/817 WA, HOFFMAN ESTATES, ILLINOIS. 60179

TABLE OF CONTENTS

SAFETY RULES ............................................................ 2

WARRANTY ................................................................... 3

PARTS ORDERING/SERVICE ..................................... 3

CARTON CONTENTS ............................................... 4-6

COMMON SET-UP ........................................................ 7

GEAR DRIVE REAR ASSEMBLY ................................. 8

HYDRO REAR ASSEMBLY .......................................... 9

ASSEMBLY TO VERT. ENGINE GT ...................... 10-13

ASSEMBLY TO HORZ. ENGINE GT .......................... 14

ELECTRICAL ASSEMBLY ..................................... 15-16

OPERATION ................................................................ 17

CUSTOMER RESPONSIBILITIES .............................. 17

REPAIR PARTS ..................................................... 18-22

3

Page 4

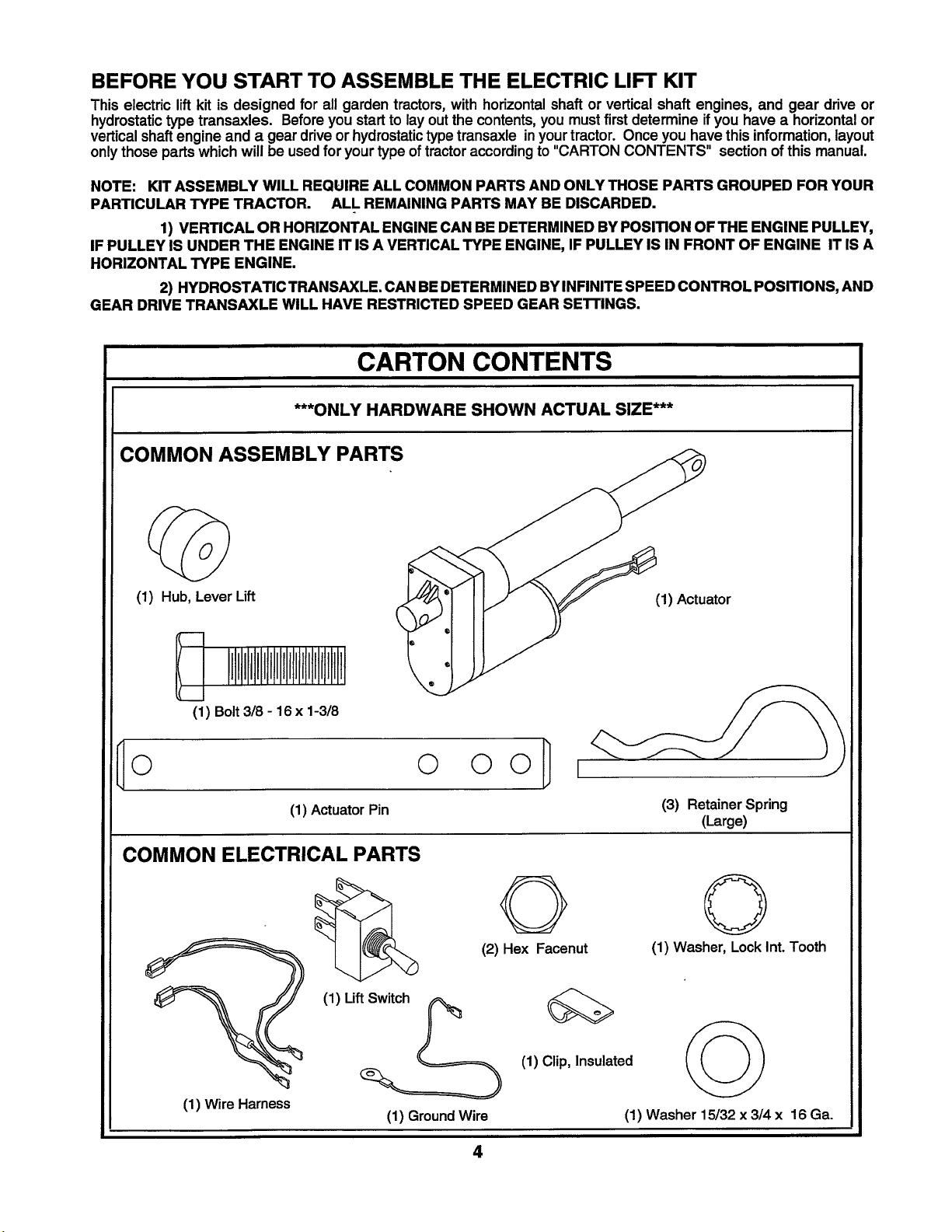

BEFORE YOU START TO ASSEMBLE THE ELECTRIC LIFT KIT

This electric lift kit is designed for all garden tractors, with horizontalshaft or vertical shaft engines, and gear drive or

hydrostatic type transaxles. Before you start to lay out the contents, you must first determine if you have a horizontal or

vertical shaft engine and a gear drive or hydrostatic type transaxle inyour tractor. Once you have this information, layout

only those parts which will be used for your type of tractor according to "CARTON CONTENTS" section of this manual.

NOTE: KIT ASSEMBLY WILL REQUIRE ALL COMMON PARTS AND ONLY THOSE PARTS GROUPED FOR YOUR

PARTICULAR TYPE TRACTOR. ALL REMAINING PARTS MAY BE DISCARDED.

1) VERTICAL OR HORIZONTAL ENGINE CAN BE DETERMINED BY POSITION OF THE ENGINE PULLEY,

IF PULLEY IS UNDER THE ENGINE IT IS A VERTICAL TYPE ENGINE, IF PULLEY IS IN FRONT OF ENGINE IT IS A

HORIZONTAL TYPE ENGINE.

2) HYDROSTATIC TRANSAXLE. CAN BE DETERMINED BYINFINITE SPEED CONTROL POSITIONS, AND

GEAR DRIVE TRANSAXLE WILL HAVE RESTRICTED SPEED GEAR SE'n'INGS.

CARTON CONTENTS

***ONLY HARDWARE SHOWN ACTUAL SIZE***

COMMON ASSEMBLY PARTS

(1) Hub, Lever Lift

(1) Bolt 3/8 - 16 x 1-3/8

0 0 O0 I

(1) Actuator Pin

COMMON ELECTRICAL PARTS

O

(2) Hex Facenut

(1) Actuator

(3) RetainerSpring

(Large)

Q

(1) Washer, LockInt.Tooth

(1) Wire Harness

(1) Lift_

(1) GroundWire

4

(1) Clip, Insulated

(1) Washer 15/32 x 3/4 x 16 Ga.

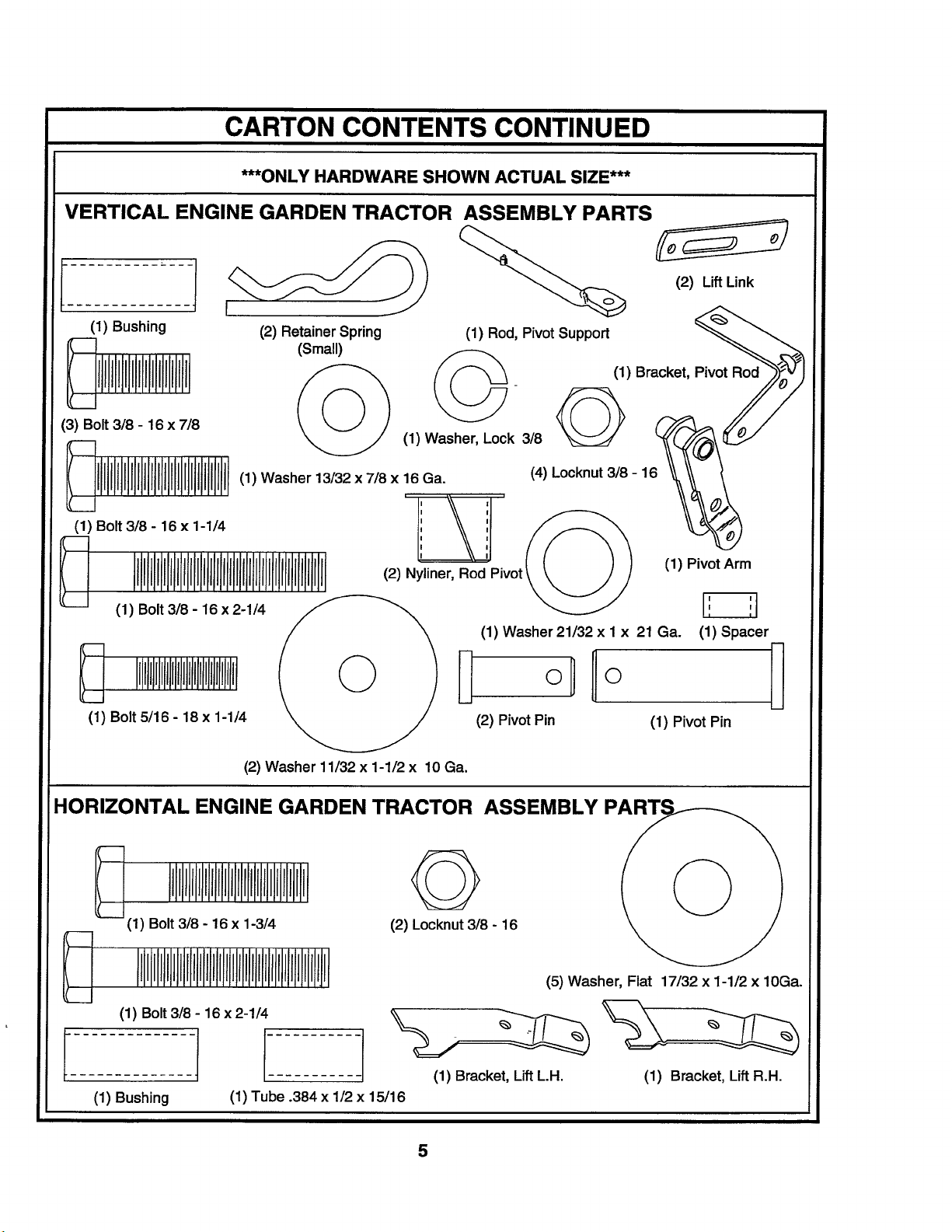

Page 5

CARTON CONTENTS CONTINUED

***ONLY HARDWARE SHOWN ACTUAL SIZE***

VERTICAL ENGINE GARDEN TRACTOR ASSEMBLY PARTS

i_ j))-_ _ (2) LiftLink

(1) Bushing (2) RetainerSpring (1) Rod,Pivot Support _.._

(Small)

(1) Bracket,

(1) Washer 13/32 x 7/8 x 16Ga. (4) Locknut 3/8 - 1

I I

(1) Bolt318- 16 x 1-1/4 1 ',

I I

I I

(2) Nyliner, Rod Pivot (1) Pivot Arm

P_vot_

(1) Bolt 3/8 - 16x 2-1/4

(1) Washer21/32 x 1 x 21 Ga. (1) Spacer

(2) PivotPin (1) Pivot Pin

(2) Washer 11/32 x 1-1/2 x 10Ga.

HORIZONTAL ENGINE GARDEN TRACTOR ASSEMBLY

rIIIJIllflII

_(1) Bolt 3/8 - 16 x 1-3/4

(2) Locknut 3/8- 16

(5) Washer, Flat 17/32 x 1-1/2 x 10Ga.

(1) Bolt 3/8 - 16 x 2-1/4

(1) Bushing

1

(1) Tube .384 x 1/2 x 15/16

iI (1) Bracket, LiftL.H.

(1) Bracket, Lift R.H.

Page 6

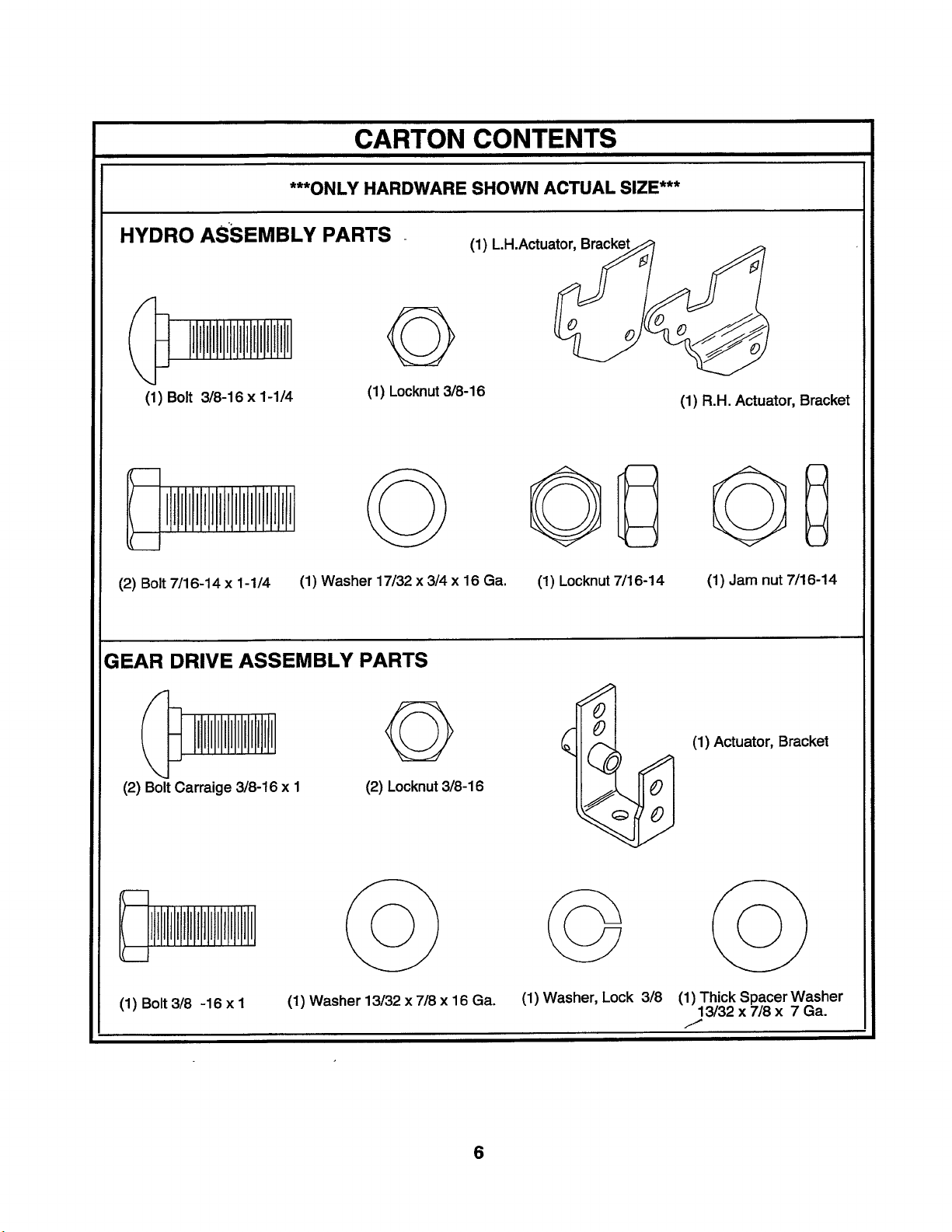

CARTON CONTENTS

***ONLY HARDWARE SHOWN ACTUAL SIZE***

HYDRO ASSEMBLY PARTS

G

(1) Bolt 3/8-16 x 1-1/4

(2) Bolt 7/16-14 x 1-1/4

GEAR DRIVE ASSEMBLY PARTS

(1) Washer 17/32 x 3/4 x 16 Ga. (1) Locknut7/16-14

(1) Locknut3/8-16

(1) LH.Actuator

(1) R.H. Actuator, Bracket

GD

(1) Jam nut7/16-14

(2) BoltCarraige 3/8-16 x I

(1) Bolt3/8 -16 x I

G

(2) Locknut3/8-16

(1) Washer 13/32 x 7/8 x 16 Ga.

6

0

,J

%

(1) Washer, Lock 3/8

(1) Actuator, Bracket

(1) Thick Spacer Washer

13/32 x 7/8 x 7 Ga.

/

Page 7

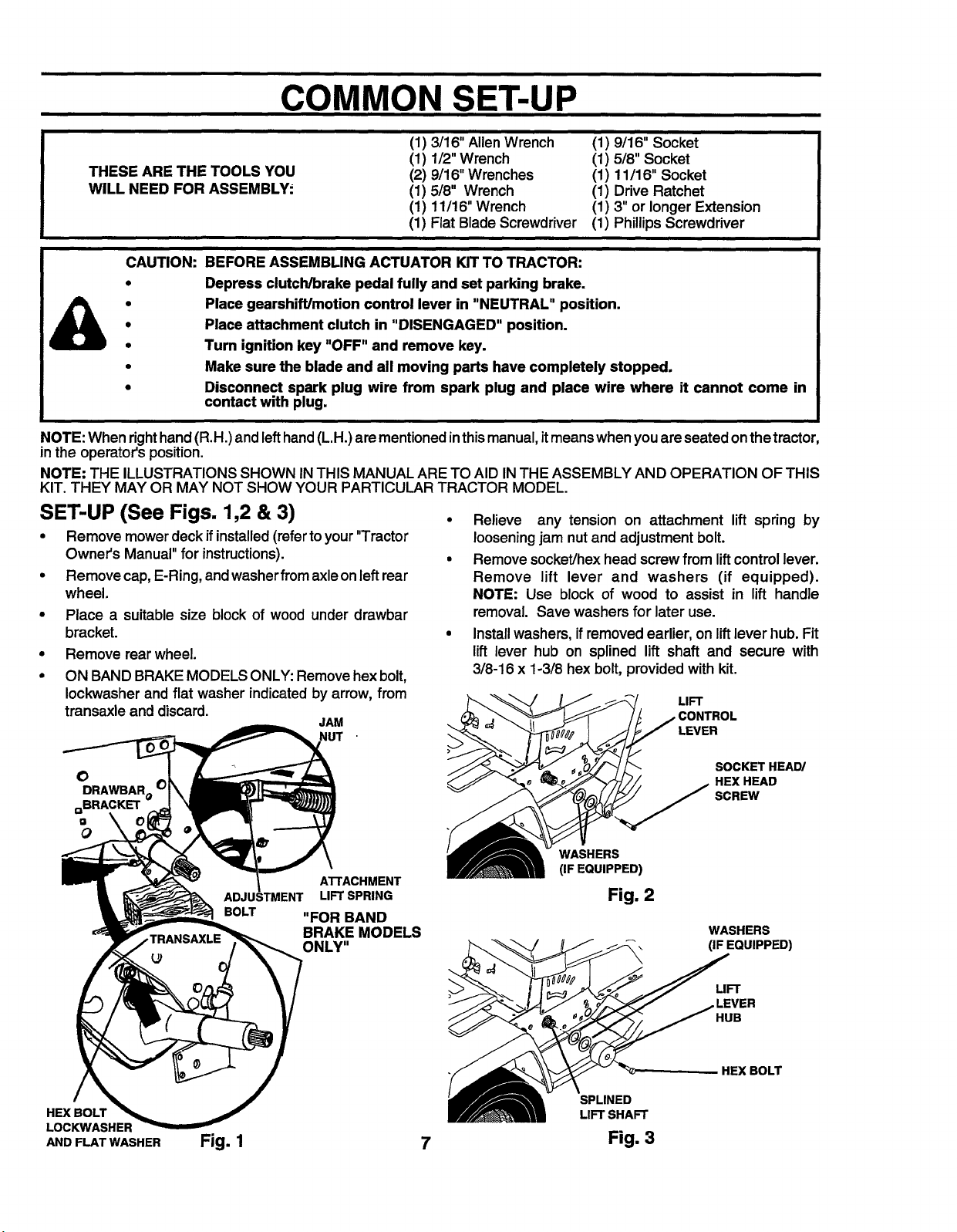

COMMON SET-UP

i

THESE ARE THE TOOLS YOU

WILL NEED FOR ASSEMBLY.

(1) 3/16" Allen Wrench

(1) 1/2" Wrench

(2) 9/16" Wrenches

(1) 5/8" Wrench

(1) 11/16" Wrench

(1) FiatBlade Screwdriver

(1) 9/16" Socket

(1) 5/8" Socket

(1) 11/16" Socket

(1) Drive Ratchet

(1) 3"or longerExtension

(1) PhillipsScrewdriver

CAUTION: BEFORE ASSEMBLING ACTUATOR KITTO TRACTOR:

Depress clutch/brake pedal fully and set parking brake.

Place gearshift/motion control lever in "NEUTRAL" position.

Place attachment clutch in "DISENGAGED" position.

Turn ignition key "OFF" and remove key.

Make sure the blade and all moving parts have completely stopped.

Disconnect spark plug wire from spark plug and place wire where it cannot come in

contact with plug.

NOTE: Whenright hand (R.H.) andleft hand (L.H.) arementionedinthis manual, itmeans when youare seated onthetractor,

in the operator'sposition.

NOTE: THE ILLUSTRATIONS SHOWN IN THIS MANUALARE TO AID INTHE ASSEMBLY AND OPERATION OF THIS

KIT. THEY MAY OR MAY NOT SHOW YOUR PARTICULAR TRACTOR MODEL.

SET-UP (See Figs. 1,2 & 3)

• Remove mower deck if installed(referto your "Tractor

Owner's Manual" for instructions).

• Remove cap, E-Ring, and washerfrom axle on left rear

wheel.

• Place a suitable size block of wood under drawbar

bracket.

• Remove rear wheel.

• ON BAND BRAKE MODELS ONLY: Remove hex bolt,

Iockwasher and flat washer indicated by arrow, from

transaxle and discard.

JAM

NUT

• Relieve any tension on attachment lift spring by

loosening jam nutand adjustmentbolt.

• Remove socket/hex head screw from lift control lever.

Remove lift lever and washers (if equipped).

NOTE: Use block of wood to assist in lift handle

removal. Save washers for later use.

• Install washers, if removed earlier, on lift lever ]]ub.Fit

lift lever hub on splined lift shaft and secure with

3/8-16 x 1-3/8 hex bolt, provided with kit.

LIFT

LEVER

O

DRAWBARo(

QBRACKET

Q

Q

HEX BOLT

LOCKWASHER

AND FLATWASHER

ATrACHMENT

LIFT SPRING

BOLT

"FOR BAND

BRAKE MODELS

ONLY"

Fig. 1 7

SOCKET HEAD/

HEX HEAD

SCREW

WASHERS

(IFEQUIPPED)

Fig. 2

WASHERS

(IF EQUIPPED)

LIFT

LEVER

HUB

HEX BOLT

SPLINED

LIFT SHAFT

Fig. 3

Page 8

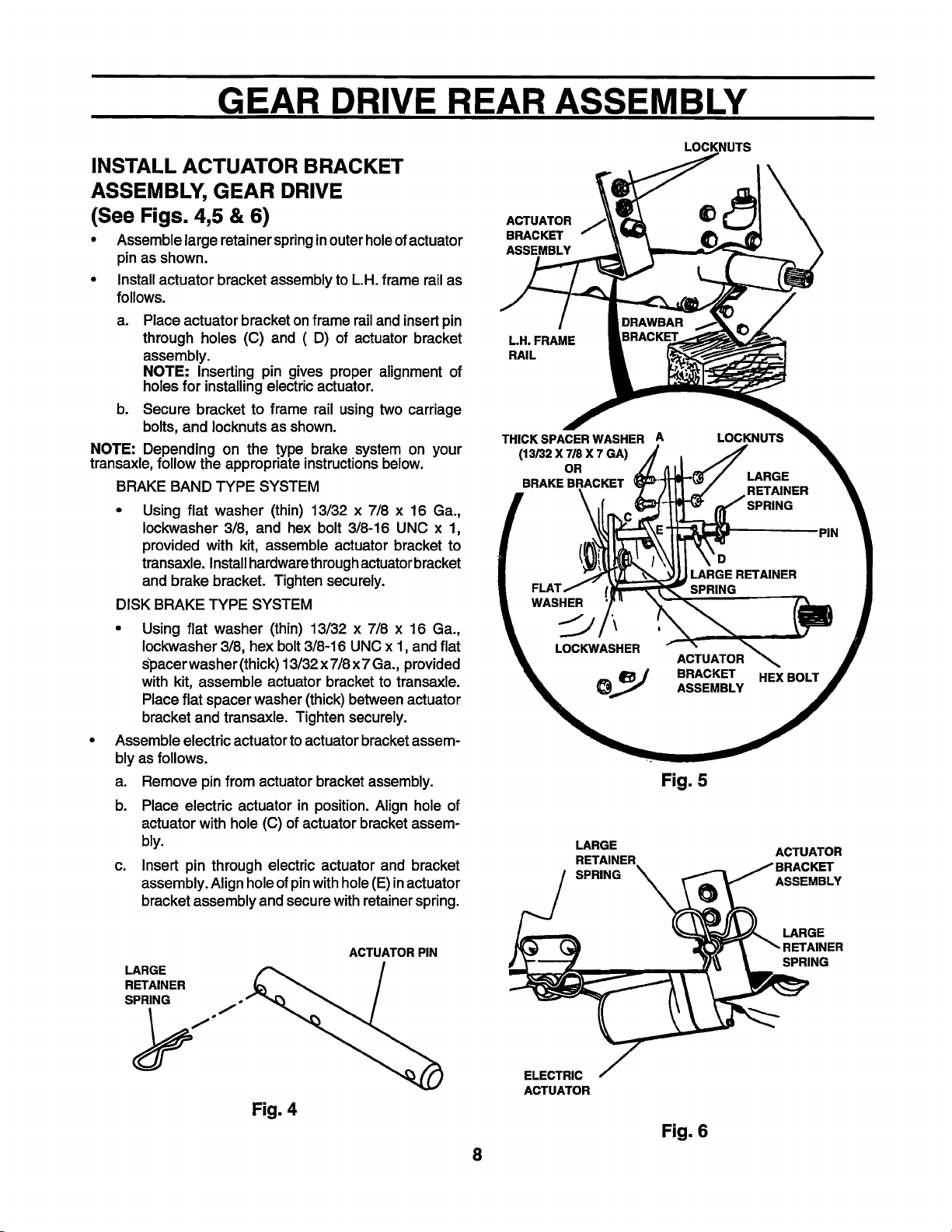

GEAR DRIVE REAR ASSEMBLY

INSTALL ACTUATOR BRACKET

ASSEMBLY, GEAR DRIVE

(See Figs. 4,5 & 6)

• Assemblelarge retainerspringinouterholeofactuator

pin as shown.

• Installactuatorbracket assemblytoLH. frame railas

follows.

a. Place actuator bracket on frame rail and insert pin

through holes (C) and (D) of actuator bracket

assembly.

NOTE: Inserting pin gives proper alignment of

holesfor installingelectric actuator.

b. Secure bracket to frame rail using two carriage

bolts,and Iocknutsas shown.

NOTE: Depending on the type brake system on your

transaxle, followthe appropriate instructionsbelow.

BRAKE BAND TYPE SYSTEM

• Using flat washer (thin) 13/32 x 7/8 x 16 Ga.,

Iockwasher 3/8, and hex bolt 3/8-16 UNC x 1,

provided with kit, assemble actuator bracket to

transaxle. Installhardwarethroughactuatorbracket

and brake bracket. Tighten securely.

DISK BRAKE TYPE SYSTEM

• Using flat washer (thin) 13/32 x 7/8 x 16 Ga.,

Iockwasher 3/8, hex bolt 3/8-16 UNC x 1, and flat

Spacerwasher (thick) 13/32 x 7/8x 7 Ga., provided

with kit, assemble actuator bracket to transaxle.

Place flat spacer washer (thick) between actuator

bracket and transaxle. Tighten securely.

Assemble electric actuator to actuator bracket assem-

bly as follows.

a. Remove pin from actuator bracket assembly.

b. Place electric actuator in position. Align hole of

actuator with hole (C) of actuator bracket assem-

bly.

c. Insert pin through electric actuator and bracket

assembly. Align holeof pinwith hole (E)in actuator

bracket assembly and secure with retainer spring.

LOCKNUTS

ACTUATOR

BRACKET

ASSEMBLY

L.H. FRAME

RAIL

THICK SPACER WASHER A LOCKNUTS

(13/32 X 7/8 X 7 GA)

OR

BRAKE BRACKET

_D PIN

m ;LARGE RETAINER II

I SPRING |

\w,s I

_,, _J BRACKET HEX BOLT _ r

Fig. 5

LARGE ACTUATOR

RETAINER

SPRING ASSEMBLY

tKET

LARGE

RETAINER

SPRING

LARGE

ACTUATOR PIN

SPRING

J

ELECTRIC

ACTUATOR

Fig. 4

Fig. 6

8

Page 9

HYDRO REAR ASSEMBLY

INSTALL ACTUATOR BRACKET

ASSEMBLY, HYDRO (See Fig. 7)

• Remove upper hex bolt securingtransaxle bracketto

LH frame rail,as indicatedby arrow.

• Fitleftandrightactuatorbracketstogether,bentbracket

to inside. Slide actuatorbracketassemblyup against

insideof LH frame rail, as shown.

• Assemble 3/8-16 x 1carriageboltthroughLHframe rail

and uppercorner holes of actuatorbracketassembly,

as shown. Hand tighten3/8-16 Iocknuton bolt.

• Insert7/16-14 x1-1/4 hexboltfrom insidetractorframe

railsthroughRH actuatorbracket,drawbar,LH frame

rail and transaxle bracket as shown. Hand tighten

Iocknuton hex bolt

• While holding jamnut on inside of actuator bracket

assembly, insert remaining 7/16-14 x 1-1/4 hex bolt

from outsidethroughtransaxle bracket, LH frame rail

and actuatorbracketassemblyandthreadintojamnut,

as shown.

• Tighten allhardware securely.

HEX BOLT

JAMNUT (THIN) INSIDE)

LH. FRAME

RAIL

ASSEMBLE ELECTRIC ACTUATOR

TO BRACKETS, HYDRO

(See Figs. 8 & 9)

• Assemblelargeretainerspringinouterhole ofactuator

pinas shown.

NOTE: useend of actuator pinwith only onehole.

• Place actuator inplace and align hole inactuatorwith

holesinactuator bracket assembly.

• Insertactuatorpin through holes in bracket assembly,

actuatorand flat washer. Retain with large retainer

springat innermosthole locationas shown.

ACTUATOR PIN_

Fig. 8

ELECTRIC

ACTUATOR

FLATWASHER

LARGE

RETAINER

SPRING

L.H. FRAME

RAIL

R.i

ACTUATOR

BRACKET

SKID BRACKET

R.H. ACTUATOR

BRACKET"

©

L.H. ACTUATOR

BRACKEI

_EMOVE HEX

BOLT AND

DISCARD

.TRANSAXLE

BRACKET

ACTUATOR PIN

ELECTRIC

ACTUATOR

LARGE

RETAINER

SPRING

FLATWASHER

ACTUATOR PIN

ACTUATOR

BRACKET

LARGE

RETAINER

SPRING

Fig. 7 9 Fig. 9

Page 10

ASSEMBLY FOR VERTICAL ENGINE MODELS

LIFT KIT ASSEMBLY TO GT

w/VERTICAL ENGINE

(See Figs. 10 thru 16)

PREPARATION

• Remove height indicatoron LH side of tractor frame.

Save all partsexcept hexboltfor reassembly.

FLAT

WASHER

HEX BOLT

SNAP-OUT

COVER

HEIGHT

INDICATOR 7 -

LOCK

WASHER

FLAT

WASHER

Fig. 10

ASSEMBLE PIVOT ARM ASSEMBLY

• Assemble bothliftlinks betweensides of pivot arm as

shown. Securewithlargerpivot pin and small retainer

spring.

NOTE: Slots inliftlinksare not centered andmust be

assembledcorrectly.To assemble holdpivotarmwith

bent end towards you and downwards. Positionlift

linkssoslotisto leftand narrowedge isat bottom(see

inset)

• Place spacerbetweenthe two linksand insertsmaller

pivotpin. Secure withsmall retainerspring.

• Installtwo nylinersintopivot bracket as shown.

NYLINER

PIVOT ARM

NYLINER

LIFT LINKS

Slide21/32 x 1 x 21 Ga. washeronto pivot rodsupport

up to nibs. Set aside for later use.

NIBS

PIVOT ROD

SUPPORT

21/32 X 1 X 21 GA.

WASHER

Fig. 11

SMALL

RETAINER

SPRINGS

SPACER

BE SURE SLOT IS

TO LEFT AND

NARROW EDGE IS

TO BOI-rOM

BENT END OF

PIVOT ARM

0

LARGER

PIVOT PIN

SMALLER

PIVOT PIN

INSET

10

Fig. 12

Page 11

ASSEMBLY FOR VERTICAL ENGINE MODELS

ASSEMBLE PIVOT ROD BRACKET

Installpivot rodbracketto insideof R.H. frame fail'using

two hex bolts3/8-16 x 7/8 and two 3/8-16 Iocknuts.

1. Be sure parking brake isengaged. Positionpivot

rodbracket to insideof R.H. frame railand install

one hex boltthroughuppermountinghole._Jnstall

Iocknuton hex bolttooutsideof frame rail.

2. Disengage parking brake, and installremaining

hex boltand Iocknutas shown.

Tightenhardwaresecurely. Besureto engage parking

brake after pivot rod bracket is installed.

VIEW FROM UNDER TRACTOR

3/8-16 LOCKNUT

1

PARKING BRAKE

DISENGAGED

ROD BRACKET

3/8-16 X 718

HEX BOLT

PIVOT ROD BRACKET

318-16 X 718

BOLT

UPPER

.MOUNTING

HOLE

_,RIGHT HAND

FRAME RAIL

PARKING BRAKE

ENGAGED

Fig. 13

11

RIGHT HAND

FRAME RAIL

Page 12

ASSEMBLY FOR VERTICAL ENGINE MODELS

INSTALL PIVOT ARM ASSEMBLY

Raise link assembly until nylinersare in4inewithhole

inLH sideoftractorframe. Insertpivotrodsupportwith

washerthroughnylinersinpivotarm,asshown.Loosely

assembly to hex bolt 3/8-16 x 718 and lock washer

throughholein LH side offrame. Do nottightenat this

time.

Assembleflattenedend ofpivot rodsupportto under-

side of pivot rodbracket usinghex bolt3/8-16 x 1-1/4,

flat washer and Iocknut and tighten securely. Now

tighten previouslyassembled 3/8-16 x 7/8 hexbolt.

318-16 X 718 LOCK NYUNERS AND

HEX BOLT WASHER PIVOT ARM FLAT

3/8-16 X 1-1/4 WASHER

HEX BOLT

VIEW FROM UNDER TRACTOR

PIVOT ROD BRACKET

Fig. 14

12

3/8-16 X 7/8 LOCK

HEX BOLT

HOLE IN LH SIDE

OF TRACTOR

FLAT

NYLINERS AND

PIVOT ARM

ASSEMBLY

318-16 LOCKNUT PIVOT ROD

SUPPORT

Page 13

ASSEMBLY FOR VERTICAL ENGINE MODELS

ATTACH ACTUATOR & LIFT LINKS

1 Insertactuatorarm and bushingbetweenpivotarmsas

shown.Secure with3/8-16 x2-1/4 hexboltandIocknut.

NOTE: Be sure that bolt is assembled in direction

shown.

2 Positionone lift linkon each sideofthe liftshaftbracket

as shown. Insert smaller pivot pin and secure with

small retainer spring.

LIFT

SHAFT

BRACKET

SMALL SMALLER

RETAINER PIVOT PIN

SPRING _ LIFT LINK

HEX BOLT

LIFT UNK

(ONE ON EACH SIDE OF

LIFT SHAFT BRACI_'T)

(ONE ON EACH SIDE OF

LIFT SHAFT BRACKET)

BRACKET

REASSEMBLE HEIGHT INDICATOR

Reassembleheightindicatorpreviouslyremovedadd-

ingtwospacerwashersand replacinghexboltwiththe

5/16-18 x 1-1/4 hexboltprovidedwiththis kit. Ensure

height indicatoris showingcorrect position of deck.

This may be adjustedafter final assembly of deck by

loosening hex bolt and moving height indicator to

correctpositionin relationto deck, retightenhex bolt

and replace snap-out cover. Assemble all parts in

order shown.

FLAT

WASHER

LOCK

WASHER

NEW HEX BOLT ADD SPACER

SNAP-OUT

SMALL Fig. 16

RETAINER

SPRING

HEIGHT

INDICATOR

FLAT

WASHER

ACTUATOR

ARM

Fig. 15

13

2

1

LOCKNUT

VIEW FROM

UNDER TRACTOR

PIVOT PIN

HEX BOLT

PIVOT ARMS

ACTUATOR

ARM

BUSHING

Page 14

ASSEMBLY FOR HORIZONTAL ENGINE MODELS

LIFT KIT ASSEMBLY TO GT

w/HORiZONTAL ENGINE

(See Figs. 17 and 18)

• Assemble L.H. and R.H. lift brackets to lift shaft

assembly arm using hex bolt 3/8-16 x 1-3/4, five

washers,one tube, andone Iocknutas shown.

NOTE: When assembling lift brackets, make sure top

of L.H. and R.H. brackets are positionedon lift shaft

assemblyarm (offset to the right).

a. Inserthex boltthrough R.H. liftbracket.

b. Place tube and two washerson bolt.

c. Enter bolt throughhole of liftshaftassembly arm.

d. Placethreewashers, L.H.liftbracket, and Iocknut

on boltand tighten securely.

NOTE: The five washers are not used when assembling

lift mechanismto sleeve hitch. See your sleeve hitch

manualwhen installingthis electricliftactuator ontractors

soequipped.

L.H. LIFT

BRACKET

BRACKET

LIFT

SHAFT

ASSEMBLY

ARM

.IFT

BRACKET

R.H. LIFT

BRACKET I

Assemble extension arm of electric actuator to L.H.

and R.H. lift brackets using hex bolt 3/8-16 x 2-1/4,

bushing,and Iocknut.

a. Insertbushingin hole of actuatorarm.

b. Position actuator arm between L.H. and R.H. lift

brackets.

c. Insert hex bolt through hole (B) of L.H. lift bracket

goingthroughactuatorarm and R.H. liftbracket.

d. Place Iocknuton boltand tightensecurely.

LOCK'NUT

MALE

RS

Fig. 17

LIFT

HARNESS

TUBE_

R.H. LIFT

BRACKET

ELECTRIC

ACTUATOR

LH. LIFT

BRACKET

14 Fig. 18

Page 15

COMMON ELECTRICAL ASSEMBLY

WIRING ASSEMBLY FOR ALL

TRACTORS

(See Figs. 19 thru 24)

I_ BEFORE WORKING ON ELECTRICAL

Locatethe blackplasticplugin upperrightor left side

of dash. Remove plug and assemble lift switch.

NOTE: Pluglocation may be differentthanshown.

a. Secure one nut to liftswitchas shown.

b. Enter lift switch in dash hole (with Keyway down)

Connect ground wire (black single wire) to lift switch.

a. Viewing liftswitch from under hood, connect black

b. Connect opposite end (eyelet) under the right or

SYSTEM DISCONNECT BATrERY. RE-

CONNECT BATrERY WHEN FINISHED.

from underside of dash, placing flat washer, inter-

nal tooth Iockwasher and nutoverthreaded area of

lift switch. Tighten nut securely.

wire to upper left hand side terminal of switch.

left upper rear battery support nut. Support nut

(indicated byarrow) located on insideof right or left

side panel.

LIFT

SWITCH

BLACK

{GROUND)

WIRE

RIGHT OR LEFT UPPER

REAR SUPPORT BOLT

Fig. 20

RIGHT OR

PANEL

Fig. 19

PLUG

Fig. 21

15

Page 16

COMMON ELECTRICAL ASSEMBLY

• Connect lifthamess to electricactuator.

a. Connect male connector of harness to female

connector of electric actuator.

• Viewing lift switch from under hood connect lift har-

ness to lift switch.

a. Connect yellow wire of lift harness to lower right

terminal of lift switch.

b. Connect double red wire of lift harness to lower

left terminal of lift switch.

c. Connect single red wire to upper right terminal.

• Secure wiring harness.

a. Remove Iocknut (underside of tractor) on L.H.

saddle bolt.

b. Install insulated clip over bolt as shown. Replace

Iocknut and tighten securely.

c. Insert wiring harness in clip as shown.

• Raise hood, insert female connector of lift harness

into male connector of tractor harness.

• Ensure wire routing does not allow wires to rest on

sharp edges or near moving parts.

SHIFT L.H. DASH

GATE BOLT

COVER

WIRING

HARNESS

INSULATED

BLACK

(GROUND)

WIRE

(TOP)

LOWER

DOUBLE

RED WlRE

Fig. 22

LIFT

VIEWED FROM

BEHIND DASH

SINGLE

RED WIRE

YELLOW

WIRE

Fig. 23

FEMALE CONNECTOR

HARNESS)

MALE CONNECTOR

_RACTOR HARNESS)

DASH

(CUTAWA_

O

VIEWED FROM

LEFT SIDE OF

TRACTOR

Fig. 24

REASSEMBLE TRACTOR

• Reinstall rear wheel and mower deck, if removed

earlier.

• Remove wood block.

• Reconnect spark plug wire.

• Retighten liftassist spring bolt.

16

Page 17

OPERATION

Make sureall Boltsand Nuts are tight, Retainer Springs

are secure.

READ THE "RULES FOR SAFE OP-

ERATION" CAREFULLY BEFORE OP-

ERATING YOUR ELECTRIC ACTUA-

TOR.

.

Ignition Switch must be "ON" to operate Electric

Actuator.

2.

AfteryouinstallLiftSwitchfollow markingsalreadyon

dashboard.

.

Ifyou hear a ratcheting sound, you know you are fully

raised or fully lowered. Release Switch promptly after

ratchetingbegins.

GROU ND WHEN TURNING CORNERS,

LIFT ATTACHMENT OUT OF THE

REVERSING OR TRANSPORTING.

THE ELECTRIC ACTUATOR IS

EQUIPPED WITH AN OVERLOAD CIR-

CUIT THAT WILL TRIP WHEN OVER-

LOADED.

UNIT WILL AUTOMATICALLY RESET

AFTER 10 SECONDS.

J

J

CUSTOMER RESPONSABILITIES

LUBRICATION

.

The Electric Actuator is lubricated for normal life. If

Actuator is disassembled for repair, upon reassembly

lubricate with high performance extreme pressure

lubricating grease.

2.

Apply a light coat of grease to threaded areas and

Pivot Points.

17

Page 18

REPAIR PARTS

ELECTRIC ACTUATOR-- MODEL NUMBER 917.242440

GEAR DRIVE, HORIZONTAL ENGINE TYPE TRACTOR

3

31

47

14

7

2

8

7

9

2O

2O

18

Page 19

REPAIR PARTS

ELECTRIC ACTUATOR- - MODEL NUMBER 917.242440

GEAR DRIVE, VERTICAL ENGINE TYPE TRACTOR

13

15

14

2

12

31

34

36 / _-/_t-JI "1_I_,_I 6

37 10_'@ /

14

24

26

19

Page 20

REPAIR PARTS

ELECTRIC ACTUATOR- - MODEL NUMBER 917.242440

HYDROSTATIC DRIVE, VERTICAL ENGINE TYPE TRACTOR

14

31

42

43

35 44

39

4O

20

12

14

2O

19

2O

20

Page 21

REPAIR PARTS

ELECTRIC ACTUATOR- - MODEL NUMBER 917.242440

KEY PART

NO. NO.

1 4171R

2 74520636

3 74520628

4 5948J

5 74760622

6 19131407

7 19172410

8 5949J

9 5947J

10 10040600

11 74760620

12 5950J

13 74760614

14 4939M

15 139276

16 138908

17 19211621

18 138914

19 138948

20 73800600

21 19131416

22 138912

23 138905

24 138947

25 138909

26 127017X

27 8984R

28 7320R

29 7319R

30 19151216

31 124371X

32 105624X

33 677A886

34 72270608

35 140877

36 4940M

37 74760616

38 9698R

39 74780720

40 73350700

41 73800700

42 72140620

43 140876

44 140875

45 19171216

46 74760520

47 19112410

DESCRIPTION

Clip, Insulated

Bolt, Hex 3/8-16 x 2-1/4 Grade 5

Bolt, Hex 3/8-16 x 1-3/4 Grade 5

Bracket, LiftL.H.

Bolt, Hex 3/8-16 x 1-3/8

Washer 13/32 x 7/8 x 7 Ga.

Washer 17/32 x 1-1/2 x 10 Ga.

Tube .384 x 1/2 x 15/16

Bracket,LiftR.H.

Washer, Lock

Bolt, Hex 3/8-16 x 1-1/4

Bushing .384 x 1/2 x 1-1/4

Bolt, Hex 3/8-16 x 7/8

Spring, Retainer

Nyliner

Arm, Pivot

Washer 21/32 x I x 21 Ga.

Rod, PivotSupport

Pin, Pivot

Locknut3/8-16

Washer 13/32 x 7/8 x 16 Ga.

Bracket,Pivot Rod

Link,Lift

Pin, Pivot

Spacer

Harness, LiftKit

Switch, Lift

Nut, Switch

Washer, LockInt.Tooth

Washer 15/32 x 3/4 x 16 Ga.

Electric,Actuator

Hub, LeverLift

Bracket,AssemblyActuator, Gear Drive

Bolt, Carriage 3/8-16 x 1

Pin, Actuator

Spring, Retainer

Bolt, Hex 3/8-16 x 1

Wire, Ground

Bolt,Hex 7/16-14 x 1-1/4

Jam Nut7/16-14

Locknut7/16-14

Carraige Bolt3/8-16 x 1-1/4

LH ActuatorBracket,Hydro

RH Actuator Bracket, Hydro

Washer 17/32 x 3/4 x 16 Ga.

Bolt, Hex 5/16-18 x 1-1/4

Washer 11/32 x 1-1/2 x 10 Ga.

21

Page 22

REPAIR PARTS

ELECTRIC ACTUATOR- - MODEL NUMBER 917.242440

J 3

s

2

4

7

8

9

/

I

10

f

KEY

NO.

2

3

4

5

6

7

\ /

\ 14

\

\

\

\

\ I

PART

NO.

1862J

1863J

8331J

1857J

1865J

1864J

677A149

13

\

\6

DESCRIPTION

Screw- SI. Fil. Hd. Mach. No. 10-

32 x 1-5/8

Lockwasher- No. 10

HousingCover

CoverGasket

Snap Ring

RetainingRing

SpringWasher (Use 3 or 4 as

req'd.)

22

KEY

NO.

8

9

10

11

12

13

14

\

\

\.

PART

NO.

674A281

1859J

1861J

673A218

1860J

1858J

12

DESCRIPTION

Pawl & RampWasher

Out put Gear

Motor - 12V

Connector Body Kit

Not Serviced Separately Order

complete actuator Part# 124371X

Thrust Washer

Intermediate Gear

Page 23

SERVICE NOTES

23

Page 24

OWNER'S

MANUAL

MODEL NO.

917.242440

[RRFT$ AN°

ELECTRIC LIFT

ACTUATOR KIT

for GARDEN TRACTORS

Each liftkit has itsown model number.

This liftkit when mountedto your tractorisnot visiblyaccessible. There-

fore, the model plate (included in parts bag) has convenient self-stick

adhesive for placement on tractor. Always mention the model number

when requesting service or repair parts.

IF YOU NEED

REPAIR SERVICE

OR PARTS:

FOR REPAIRSERVICE, CALL

THIS TOLL FREENUMBER:

1-800-4-REPAIR

(1-800-473-7247)

FOR REPLACEMENT PARTS

INFORMATIONAND

ORDERING, CALL THIS

TOLL FREE NUMBER:

1-800-FON-PART

(1-800-366-7278)

All parts listed herein may be ordered from any Sears, Roebuck and Co.

Service Center and most Retail Stores.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE FOLLOW-

ING INFORMATION:

• PRODUCT - ELECTRIC LIFT ACTUATOR KIT

• MODEL NUMBER -917.242440

• PART NUMBER

• PART DESCRIPTION

Your Sears merchandise has added value whenyou consider Sears has

service units nationwide staffed with Sears trained technicians.., profes-

sional technicians specifically trained to insure that we meet our pledge

to you, we service what we sell.

Sears, Roebuck and Co., Chicago, IL 60684 U.S.A.

142176 11.10.93 PRINTED IN U.S.A.

Loading...

Loading...