SETTING-UP INSTRUCTIONS MAINTENANCE MANUAL REPAIR INSTRUCTIONS AND PARTS LIST FOR

MOTOR CYCLE

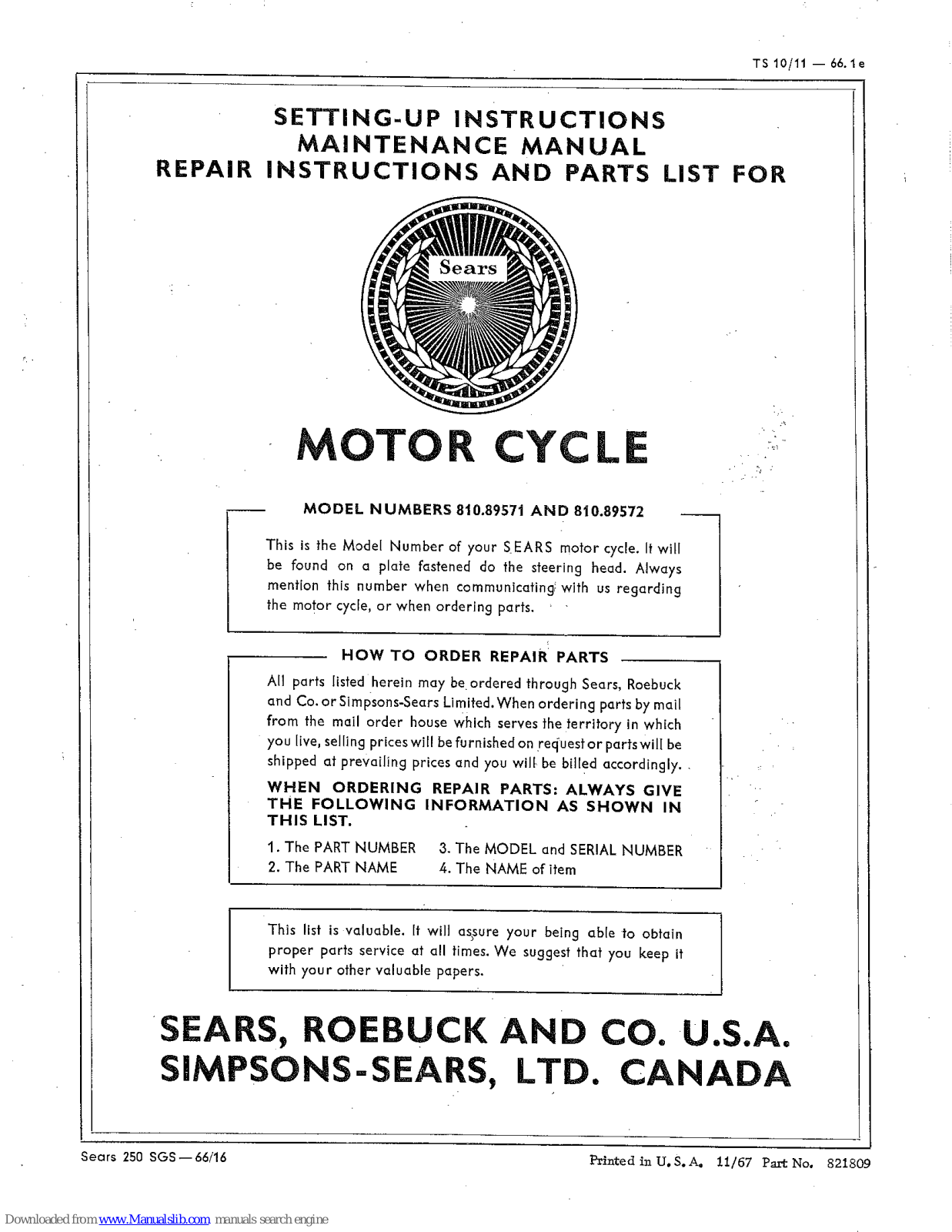

MODEL NUMBERS 810 89571 AND 810 90572

This is the Model Number of your SEARS motor cycle. It will be found on a plate fastened do the steering head. Always mention this number when communicating with us regarding the motor cycle, or when ordering parts.

HOW TO ORDER REPAIR PARTS

All parts listed herein may be ordered through Sears, Roebuck and Co. or Simpsons-Sears Limited. When ordering parts by mail from the mail order house which serves the territory in which you live, selling prices will be furnished on request or parts will be shipped at prevailing prices and you will be billed accordingly

WHEN ORDERING REPAIR PARTS: ALWAYS GIVE THE FOLLOWING INFORMATION AS SHOWN IN THIS LIST.

2. The PART NAME

1. The PART NUMBER 3. The MODEL and SERIAL NUMBER 4. The NAME of item

This list is valuable. It will assure your being able to obtain proper parts service at all times. We suggest that you keep it with your other valuable papers.

SEARS, ROEBUCK AND CO. U.S.A. SIMPSONS-SEARS, LTD. CANADA

Sears 250 SGS - 66/16

SEARS MOTOR CYCLE

MODEL NUMBERS 810.89571 AND 810.89572

BATTERY SERVICE INSTRUCTION for Types 6 B 7 and 6 B 8

- 1. Fill the battery with electrolyte of battery grade to a liquid level of 10 mm (3/8") above the separators. The specific gravity should be 1,27 - 1,28 at 20° C (70°F) For tropical climates the specific gravity should be 1,22 - 1,23 at 30° (85° F) A tropical climate is considered one in which water never freezes.

- 2. Allow the battery to stand for at lease two (2) hours but no more than

- 2. Allow the battery to stand for at lease two (2) hours but no more than five (5).

- 3. Connect the battery for charging, plus to plus terminal and minus to minus terminal. The charging rate should be adjusted to 0,7 A approx. It is normal, when the charging current drops at the end of the charge. Observe specific gravity of electrolyte and voltage. When they remain constant, continue charging for three (3) hours. Final voltage per cell 2,6 2,7 volts. The total charging time will be 12 15 hours as experienced. If the temperature of the electrolyte exceeds 45°C (115°F), the charge must be interrupted, until the battery is cooled down.

- 4. Install the clean and dry battery, check the polarity, tighten securely the hold-downs, apply a thin film of mineral grease on the terminals. LIQUID LEVEL CONTROL. The liquid level should be maintained 10 mm (3/8") above the plates after the charge. If the level drops fill in only pure distilled water. If refilling is necessary in short intervals, the charging device should be checked.

If the battery is not in use for longer periods, it should be recharged monthly with half the current as mentioned above. High-Rate Chargers should be used only for a later recharging, but not

for the first installation. In this case also the temperature of the electrolyte should never exceed 45°C (115°F).

The battery is dry charged and may be used in emergency after standing of two (2) hours. But in this case there should follow a longer driving period of several hours or the battery should be recharged after short time.

Please observe these instructions and have your battery charged regularly. A long trouble-free life will be your reward.

SPECIAL OIL

Packed with your machine you will find one litre tin of special motor oil with oil additive and a further two plastic bottles of oil additive. Use the engine oil from the tin for the first filling of the oil tank (left tank opening). For the next two oil tank fillings mix the contents of one of the bottles with additive to the motor oil and stir thoroughly. Obey instructions regarding oil quality.

Models 810.89571 810.89572

Ref. TS 10/11-Ed. 5 Sears SGS

CORRECTION to Maintenance Manual No. 821809

Section 1 "SPECIFICATIONS"

NOTE: Ignition advance: 0.208 to 0.224 in. (5,3 to 5,7 mm) before T.D.C. on rear piston.

The torque figures for tightening bolts and screws are:

Figures with mark + are changed resp. newly added:

| Engine fixing bolts | 50 | - | Ft. | Lb.+ |

|---|---|---|---|---|

| Cylinder head screws | 21 | • | Ft. | Lb. |

| Primary drive sprocket | 108 | Ft. | Lb. | |

| Clutch hub tightening nut | 108 | Ft. | Lb. | |

| Gearbox sprocket | 108 | Ft. | Lb. | |

| Swing fork shaft nut | - 43 | - | Ft. | Lb. |

| Shock absorber joint bolt | - 43 | - | Γt. | Lb. |

| Axle for rear and front wheel | - 43 | - | Ft. | Lb. |

| Rear sprocket fixing screw | - 18 | - | Ft. | LЪ. |

| Fastening screws of oil pump Max. | 4,5 | - | Ft. | ĻЬ. |

| Crankcase screws resp | ||||

| Crankcase cover screws | - 6 | - | Ft. | Lb.+ |

| Brake cam fastening | - 7 | - | Ft. | Lb.+ |

Section 2 "SETTING-UP INSTRUCTIONS"

Final Work

- 2. Pull throttle twist grip on handlebar and afterwards put handlebar with rubber supplement levers pointing slightly downwards on top bridge of fork (watching the "securing pin against turning"), fit fixing clamp and tighten the four bolt screws.

- 2a. There are two new screws at the toolbox. Use new screws for mounting the handlebar (see point 2).

4a. Fix brake cable to hand lever on R.H. half of the handlebar.

- a. See under 4

- b. Push brake lever on hub backward

- c. See under 4

- d. Release brake lever on hub so the cable covering fits into the bracket of the adjusting screw.

- e. Loosen adjusting screw until the clearance to the lever is 3/4 in. Tighten the lock nut.

821822

- 7a. Attention: Fill in 1 1/2 pints of motor oil. When refilling do not open the level screw, as this shows minimum level and in any case oil will overflow on proper filling. When refilling after repair (engine completely dry) fill in 1.7 pints of motor oil.

- 9. Screw on tail light housing (connect green to green and grey to grey cable end).

- 10. Mount gear shift lever as individually wanted.

- 11. Mount rear brake lever and adjust individually so as to achieve correct braking effect.

12. See inspection chart (page 3-8) for predelivery inspection.

Additional hint to Section 3 part 4 "Inspection and Adjustment" page 3-9 "Adjusting the oil pump":

With new oil pump the normal oil consumption at average cruising speeds (about 40 m.p.h.) is 1 pint of oil to approx. 90-100 miles. With higher speeds and much riding on full throttle, oil consumption rises to 1 pint for about 75 miles. If oil consumption is within this range, don't change oil pump adjustment.

Section 6 "REPAIR INSTRUCTIONS", Page 20,

Ignition advance: 0.208 to 0.224 in. (5.3-5.7 mm).

Page 7-5, Ref. No. 1

For the two top piston rings on the piston, we ask you to use following spare part numbers: 253.2.10.260.1 Piston ring 45 mm dia.

| TRECON | T.TUB - | +5 mm ura | ||||

|---|---|---|---|---|---|---|

| 253,2.10.260.3 | Piston | ring, | overside | I, | 45,5 mm | dia. |

| 253.2.10.260.4 | Piston | ring, | oversize | II | , 46 mm c | lia. |

Page 7-5 Ref. No. 3

The pistons will be delivered complete with piston rings. We ask to order them with following spare part numbers:

| 253.2.10.206.0 | ` . | Piston | cmpl., n | normal 45 | mт | dia. | |

|---|---|---|---|---|---|---|---|

| 253.6.10.206.0 | Piston | compl., | oversize | I 4 | +5,5 mm o | lia. | |

| 253.7.10.206.0 | Piston | compl., | oversize | II. | 46 mm o | lia. |

Therefore following numbers are no more valuable:

253.1006.2, 253.1006.6 and 253.1006.7

Page 7-5 Ref. No. 6

Instead of 253.1015.0 read 270.1.10.015.0 Crankshaft compl.

Page 7-5 Ref. No. 18 Instead of 250.1100.0 read 270.1.11.000.0 0il Pump compl.

Page 7-15 Ref. No. 10 Instead of 250.1540.2 read 250.1.15.040.0 Air Filter compl.

821822

- Page 7-19 Ref. No. 12 and 12a Instead of 270.1.22.127.0 resp. 128.2227.0 read 270.1.227.0 Fuel cock compl.

- Page 7-19 Read under Ref. No. 20 24456 Fuel pipe sleeve (for fuel cock) 2 pieces 250.2219 Fuel pipe sleeve (for fuel tank) 2 pieces (new spare part to part 2)

under Ref. No. 22 only Instead of 900.0902/07 read 253.1.22.021.0 Fuel pipe complete (with two pieces 250.2219)

- Page 7-19 Raf. No. 33 Instead of 22887.1 read 900.1034 Hexagon head screw - M8 x 90 DIN 931

- Page 7-19 Ref. No. 41 Instead of 900.1001 read 901.1104 Hexagon head screw - M8 x 140 DIN 931-8G

- Page 7-23 Ref. No. 41 Instead of 128.2508 read 357.1.25.016.1 Rubber for foot rest

- Page 7-29 Ref. No. 51 Instead of 24773 Hexagon nut M6 DIN 934 read 900.2933 Hat nut M6 DIN 1587

- Page 7-31 Ref. No. 3a Instead of 901.4808 read 900.4846 Spring pin 6 x 16 DIN 1481

- Page 7-33 Ref. No. 61 Instead of 050.2.6203 read 25483 Ferule

- Page 7-35 Ref. No. 7 Instead of 175.4011.2 read 253.1.40.211.2 Brake operating lever

- Page 7-37 Ref. No. 41 Instead of 253.2810.0 read 128.2810.0 Rear chain

- Page 7-41 Ref. No. 46 Instead of 902.0743 read 250.5205.2 Cable plug

- Page 7-43 Without Ref. No. Instead of 253.2.70.010.0 read 253.3.70.010.0 Set of tools complete

SUPPLEMENT:

900.0133 Container with additive-oil 900.0134 Container with motor oil SAE 50 with additive-oil

Page 7-27 Between part 21 and 25a will be mounted 253.1.21.270.1 Guide bush (sleeve) 1 piece per shock absorber

Page 7-28 and 29 One washer will be mounted at the lower bore on the support for mudguard (Part 2): 250.3025 Disc 2 pieces

Sears 250 SGS - 66/16d

We are glad to learn that you have become owner of a

SEARS MOTORCYCLE

In more than half a century of producing bicycles and motorcycles our machines have been acknowledged international as products combining both broad experience and technology. To help this SEARS motorcycle to be your best friend, please read this rider's handbook carefully in order to become acquainted with the correct handling procedure and adjustments which are required from time to time.

If you have any questions about your motorcycle, please apply to your dealer who will be happy to assist you.

Contents

| Preface II | ||

|---|---|---|

| Section 1 | SPECIFICATIONS | 1 — 1 |

| Section 2 | SETTING UP INSTRUCTIONS | 2 — 1 |

| Section 3 | OPERATING AND MAINTENANCE | |

| Part 1 Operating Tips | 3 — 1 | |

| Part 2 Controls | 3 — 3 | |

| Part 3 Riding Tips | 3 — 4 | |

| Part 4 Inspection and Adjustment | 3 — 8 | |

| Section 4 | WIRING DIAGRAMM | 4 — 1 |

| Section 5 | TROUBLE SHOOTING | 5 — 1 |

| Section 6 | REPAIR INSTRUCTIONS | |

| Part 1 Special Tools | 6 — 1 | |

| Part 2 Engine | 6 — 3 | |

| Part 3 Chassis | 6 — 13 | |

| Part 4 Electrical Equipment | 6 — 17 | |

| Section 7 | SPARE PARTS LIST | 7 — 1 |

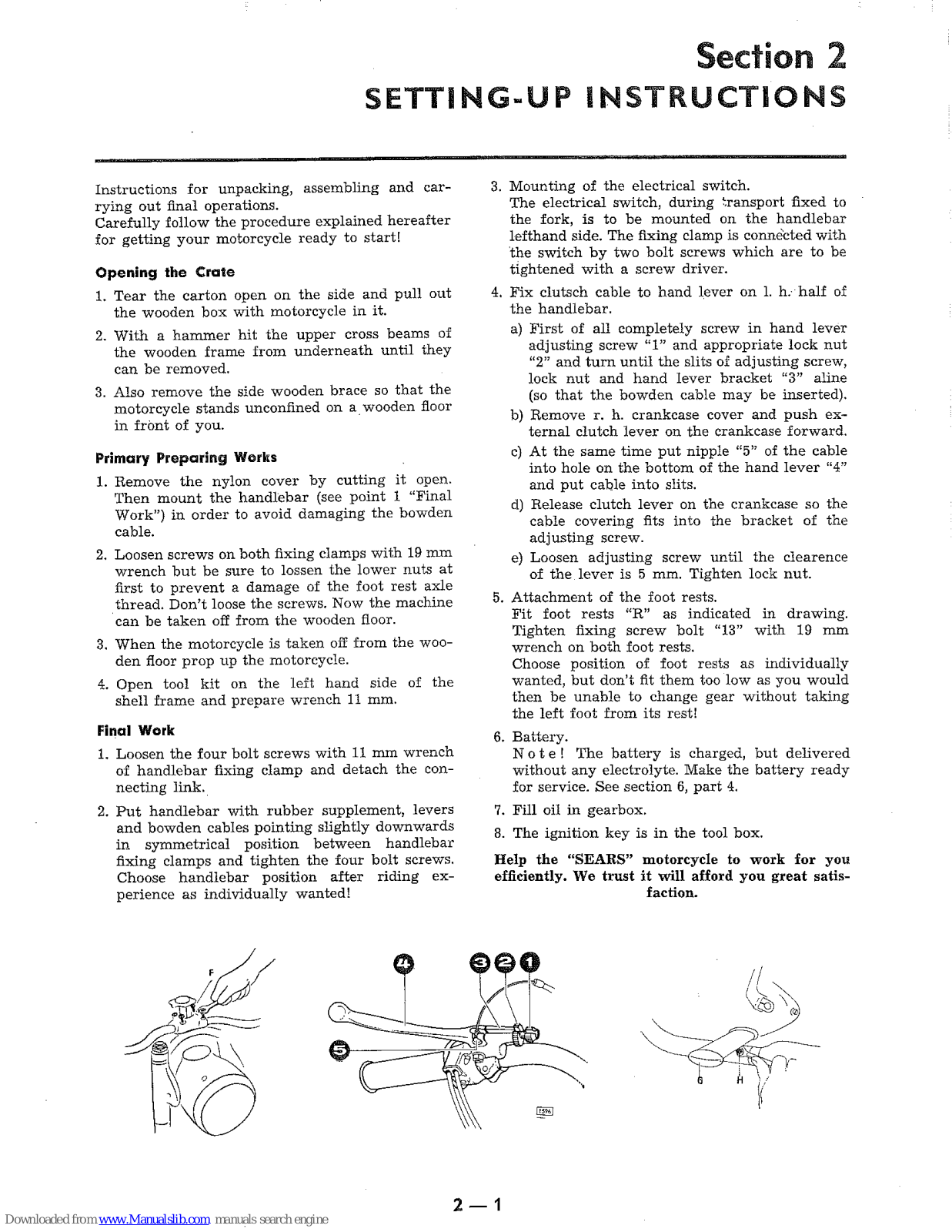

Section 1 SPECIFICATIONS

Engine

Number of cylinders: 1 split single-cylinder Bore: 2×1.77 in. (2×45 mm) Stroke: 3.07 in. (78 mm) Cubic capacity: 248 c.c. Compression ratio: 6.2:1 Peak performance: 16.5 HP at 5800 r.p.m. Maximum torque: 2.3 mkg at 3200 r.p.m. Ignition advance: 0.256 in. to 0.276 in. (6.5 mm to 7 mm) Spark plug: SEARS No. 60400 Spark gap of plug: 0.024 in. to 0.028 in. (0.6 to 0.7 mm) Lubrication: by oil-pump Cooling: air-cooled by wind in riding. Carburettor Puch-single throttle-slide carburettor Type P 32/1 1,28 in. (32 mm) diameter with needle jet Air filter: Wet air filter with starting disc

Main jet: No. 150 Position of needle: Clamp-spring clamped to 4th notch from top (see "Adjusting the carburettor") Idler jet: 40 Throttle-slide: width of slit: 0,748 in. (19 mm) Idler screw: about 1/2 turn open

Battery-Ignition-Lighting

Voltage regulating Puch D. C generator Performance of generator: 6 V 45/60 W Battery capacity: 6 V, 7 Ah Headlamp: 6,70 in. (170 mm) light outlet Main head light: 6 V 45/40 W.

Gearbox

Transmission from engine to gearbox: 51:22 i = 2,31

Transmission in gearing 1st gear: 22: 8 i = 2.75

2nd gear: 18:12 i = 1,5 3rd gear: 15:15 i = 1 4th gear: 13:17 i = 0.76

Transmission from gearbox to rear wheel 46:15; i = 3,07

Total Transmission:

| 1 st gear: i == 19,5 | 3 rd gear: i | = 7,1 | |

|---|---|---|---|

| 2 nd gear: i = 10,6 | 4 th gear: i | = 5,4 | |

| Clutch: Multiple-disc | clutch, friction | disks | run- |

ning in oil bath

Chain

Front chain of engine: Duplex-sheet roller chain 3,8 × 5,16 in. Diameter of sheet 0,196 in. (5 mm) Number of sheets: 64 Rear chain: Roller chain ½ × 5/16 in.; 118 rollers, 1 block, 2 connecting links

Wheels

Rim size: Drop center rim 1,85 × 16 in. (21/2 × 16 in. DIN 7816) Tire size: 3,00 × 16 in. front. 3,50 × 16 in. rear.

Tire pressure

Front wheel: 14,5 lb/squ. in. (1,0 atü) Rear wheel: 20 lb/squ. in. (1,4 atü) with pillion passenger 29 lb/squ. in. (2.0 atü)

Front and rear brake

Brake drum: diameter 7,08 in. (180 mm) Width of the brake lining: 1,575 in. (40 mm)

Fuel tank

Capacity 3,35 gals. (12,6 litres) of which 0,53 gals. (2 litres) are reserve fuel

Performance Data

Top speed: about 68,34 m.p.h. (110 km/h), 1 person riding upright;

Fuel consumption: about 0,70 gals. of petrol and about 1/s pint of oil for 62,13 miles (100 km) at approximately 43,5 m.p.h.

Hill climbing capacity: with pillion passenger about 40%

Action radius: about 210 miles (340 km) with one tank filling

Measurements

Lenght 78,10 in. (1970 mm) Height 36,22 in. (920 mm) Width 24,60 in. (620 mm) Wheel distance: 52,55 in. (1345 mm) Road clearance: 5,91 in. (140 mm) Saddle height: 28,9 in. (735 mm)

Weights

Weight without fuel, toolkit, and battery 300 lbs. (136 kg).

The torque figures for tightening bolts and screws are:

| Engine fixing bolts | • | • | 36 | ft. lb. | ||

|---|---|---|---|---|---|---|

| Cylinder head screws | • . • | 21 | ft. lb. | |||

| Primary drive sprocket | • | • | 108 | ft. Ib. | ||

| Clutch hub tightening nut . | • | • | 108 | ft. lb. | ||

| Gearbox sprocket 15 teeth . | • | • | 108 | ft. lb. | ||

| Swing fork shaft nut | • | 43 | ft. lb. | |||

| Shock absorber joint bolt . | 43 | ft. lb. | ||||

| Axle for rear and front whee | 1 | 43 | ft. lb. | |||

| Rear sprocket fixing screw | 18 | ft. lb. |

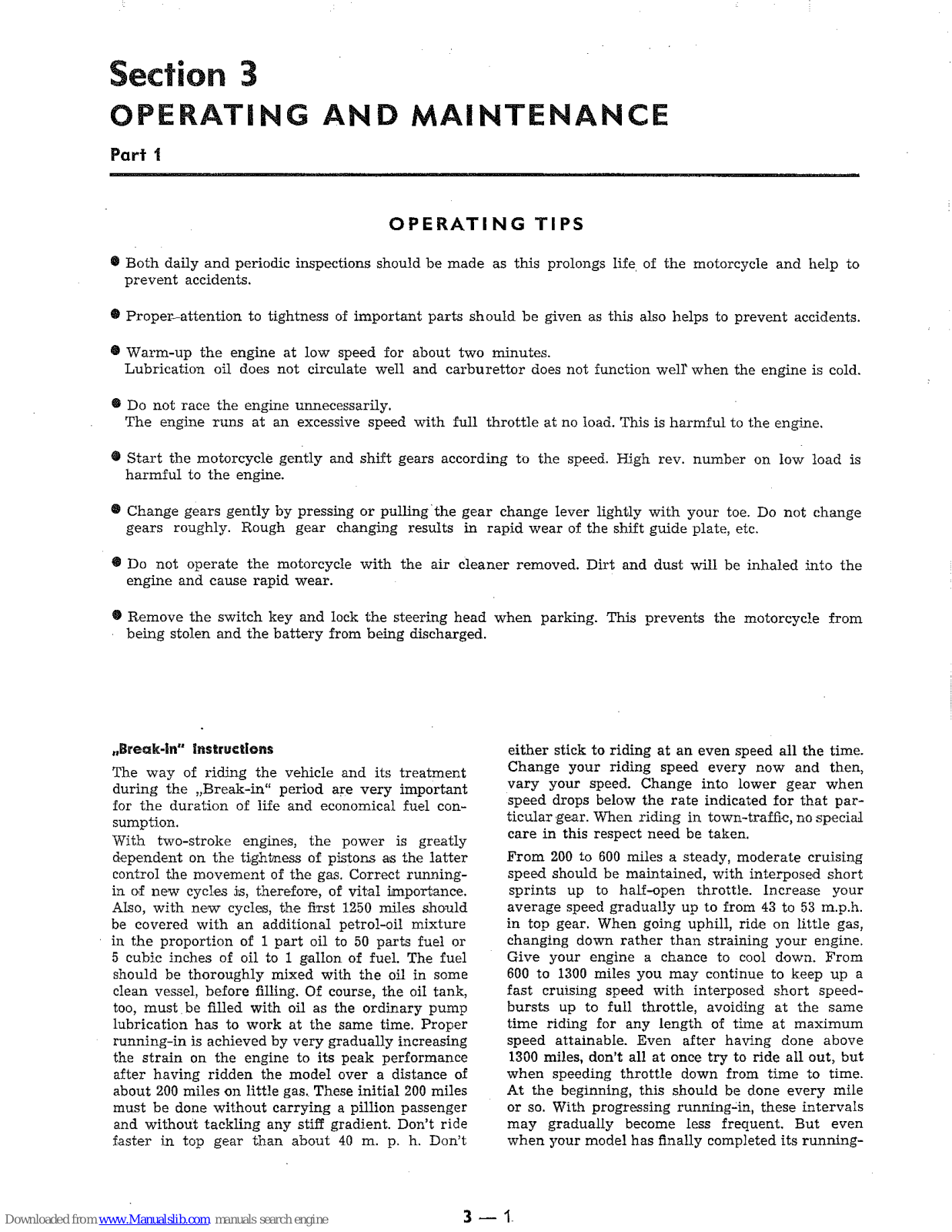

Section 2 SETTING-UP INSTRUCTIONS

Instructions for unpacking, assembling and carrving out final operations.

Carefully follow the procedure explained hereafter for getting your motorcycle ready to start!

Opening the Crate

- 1. Tear the carton open on the side and pull out the wooden box with motorcycle in it.

- 2. With a hammer hit the upper cross beams of the wooden frame from underneath until they can be removed.

- 3. Also remove the side wooden brace so that the motorcycle stands unconfined on a wooden floor in front of you.

Primary Preparing Works

- 1. Remove the nylon cover by cutting it open. Then mount the handlebar (see point 1 "Final Work") in order to avoid damaging the bowden cable.

- 2. Loosen screws on both fixing clamps with 19 mm wrench but be sure to lossen the lower nuts at first to prevent a damage of the foot rest axle thread. Don't loose the screws. Now the machine can be taken off from the wooden floor.

- 3. When the motorcycle is taken off from the wooden floor prop up the motorcycle.

- 4. Open tool kit on the left hand side of the shell frame and prepare wrench 11 mm.

Final Work

- 1. Loosen the four bolt screws with 11 mm wrench of handlebar fixing clamp and detach the connecting link.

- 2. Put handlebar with rubber supplement, levers and bowden cables pointing slightly downwards in symmetrical position between handlebar fixing clamps and tighten the four bolt screws. Choose handlebar position after riding experience as individually wanted!

-

3. Mounting of the electrical switch.

- The electrical switch, during transport fixed to the fork, is to be mounted on the handlebar lefthand side. The fixing clamp is connected with the switch by two bolt screws which are to be tightened with a screw driver.

-

4. Fix clutsch cable to hand lever on l. h. half of the handlebar.

- a) First of all completely screw in hand lever adjusting screw "1" and appropriate lock nut "2" and turn until the slits of adjusting screw, lock nut and hand lever bracket "3" aline (so that the bowden cable may be inserted).

- b) Remove r. h. crankcase cover and push external clutch lever on the crankcase forward.

- c) At the same time put nipple "5" of the cable into hole on the bottom of the hand lever "4" and put cable into slits.

- d) Release clutch lever on the crankcase so the cable covering fits into the bracket of the adjusting screw.

- e) Loosen adjusting screw until the clearence of the lever is 5 mm. Tighten lock nut.

5. Attachment of the foot rests.

Fit foot rests "R" as indicated in drawing. Tighten fixing screw bolt "13" with 19 mm wrench on both foot rests.

Choose position of foot rests as individually wanted, but don't fit them too low as you would then be unable to change gear without taking the left foot from its rest!

6. Batterv.

Note! The battery is charged, but delivered without any electrolyte. Make the battery ready for service. See section 6, part 4.

- 7. Fill oil in gearbox.

- 8. The ignition key is in the tool box.

Help the "SEARS" motorcycle to work for you efficiently. We trust it will afford you great satisfaction.

Section 3 OPERATING AND MAINTENANCE

Part 1

OPERATING TIPS

- Both daily and periodic inspections should be made as this prolongs life of the motorcycle and help to prevent accidents.

- Proper-attention to tightness of important parts should be given as this also helps to prevent accidents.

- Warm-up the engine at low speed for about two minutes. Lubrication oil does not circulate well and carburettor does not function well when the engine is cold.

- Do not race the engine unnecessarily. The engine runs at an excessive speed with full throttle at no load. This is harmful to the engine.

- Start the motorcycle gently and shift gears according to the speed. High rev. number on low load is harmful to the engine.

- Change gears gently by pressing or pulling the gear change lever lightly with your toe. Do not change gears roughly. Rough gear changing results in rapid wear of the shift guide plate, etc.

- Do not operate the motorcycle with the air cleaner removed. Dirt and dust will be inhaled into the engine and cause rapid wear.

- Remove the switch key and lock the steering head when parking. This prevents the motorcycle from being stolen and the battery from being discharged.

"Break-in" Instructions

The way of riding the vehicle and its treatment during the "Break-in" period are very important for the duration of life and economical fuel consumption.

With two-stroke engines, the power is greatly dependent on the tightness of pistons as the latter control the movement of the gas. Correct runningin of new cycles is, therefore, of vital importance. Also, with new cycles, the first 1250 miles should be covered with an additional petrol-oil mixture in the proportion of 1 part oil to 50 parts fuel or 5 cubic inches of oil to 1 gallon of fuel. The fuel should be thoroughly mixed with the oil in some clean vessel, before filling. Of course, the oil tank, too, must be filled with oil as the ordinary pump lubrication has to work at the same time. Proper running-in is achieved by very gradually increasing the strain on the engine to its peak performance after having ridden the model over a distance of about 200 miles on little gas. These initial 200 miles must be done without carrying a pillion passenger and without tackling any stiff gradient. Don't ride faster in top gear than about 40 m. p. h. Don't

either stick to riding at an even speed all the time. Change your riding speed every now and then, vary your speed. Change into lower gear when speed drops below the rate indicated for that particular gear. When riding in town-traffic, no special care in this respect need be taken.

From 200 to 600 miles a steady, moderate cruising speed should be maintained, with interposed short sprints up to half-open throttle. Increase your average speed gradually up to from 43 to 53 m.p.h. in top gear. When going uphill, ride on little gas. changing down rather than straining your engine. Give your engine a chance to cool down. From 600 to 1300 miles you may continue to keep up a fast cruising speed with interposed short speedbursts up to full throttle, avoiding at the same time riding for any length of time at maximum speed attainable. Even after having done above 1300 miles, don't all at once try to ride all out, but when speeding throttle down from time to time. At the beginning, this should be done every mile or so. With progressing running-in, these intervals may gradually become less frequent. But even when your model has finally completed its running-

OPERATING TIPS

in period, it will be expedient — when driving at speed — to throttle down just for a short time. It is advisable to run in your model without stopping over some distances longer than 70 miles. We point out once more that too low revolutions are also unfavourable. Change speed in time, that is, from top to 3rd at about 27 m.p.h., from 3rd to 2nd at about 20 m.p.h. and from 2nd to 1st at about 12 m.p.h.

Important!

During the period of "Break-In" don't fail to repeatedly examine all screws, bolts and nuts, in particular those holding the engine (as also those of the rear engine suspension) nor fail to perform controls, tests and lubricating just as prescribed (Service-Station). You are also earnestly advised to drain the oil from the gearbox after about 500 miles, and to rinse it with rinsing-oil and then to fill it up with fresh oil.

Fuel

The Cycle is not run on a petrol-oil mixture. The fuel and lubricating oil are kept separate, the fuel being filled into the right half of the tank and the oil into the left half.

Insure that dirt or dust not become mixed with the fuel.

Insure that water does not become mixed with the fuel.

Lubricatina oil

For engine lubrication (in the oil tank): Always use a good grade oil. Use only nondetergent oil. At temperatures over 50° F (10° C) SAE 50.

At temperatures over 50° F (10° C) 5AM 50. At temperatures from +15° F (-10° C) to 50° F (+10° C) SAE 40

At temperatures below +15° F (-10° C) SAE 30. For gearbox and telescope forks: Use heavy oil in summer, in winter a thin winter oil. Thicker oils may cause the clutch to stick or lead to stiffness in the front fork.

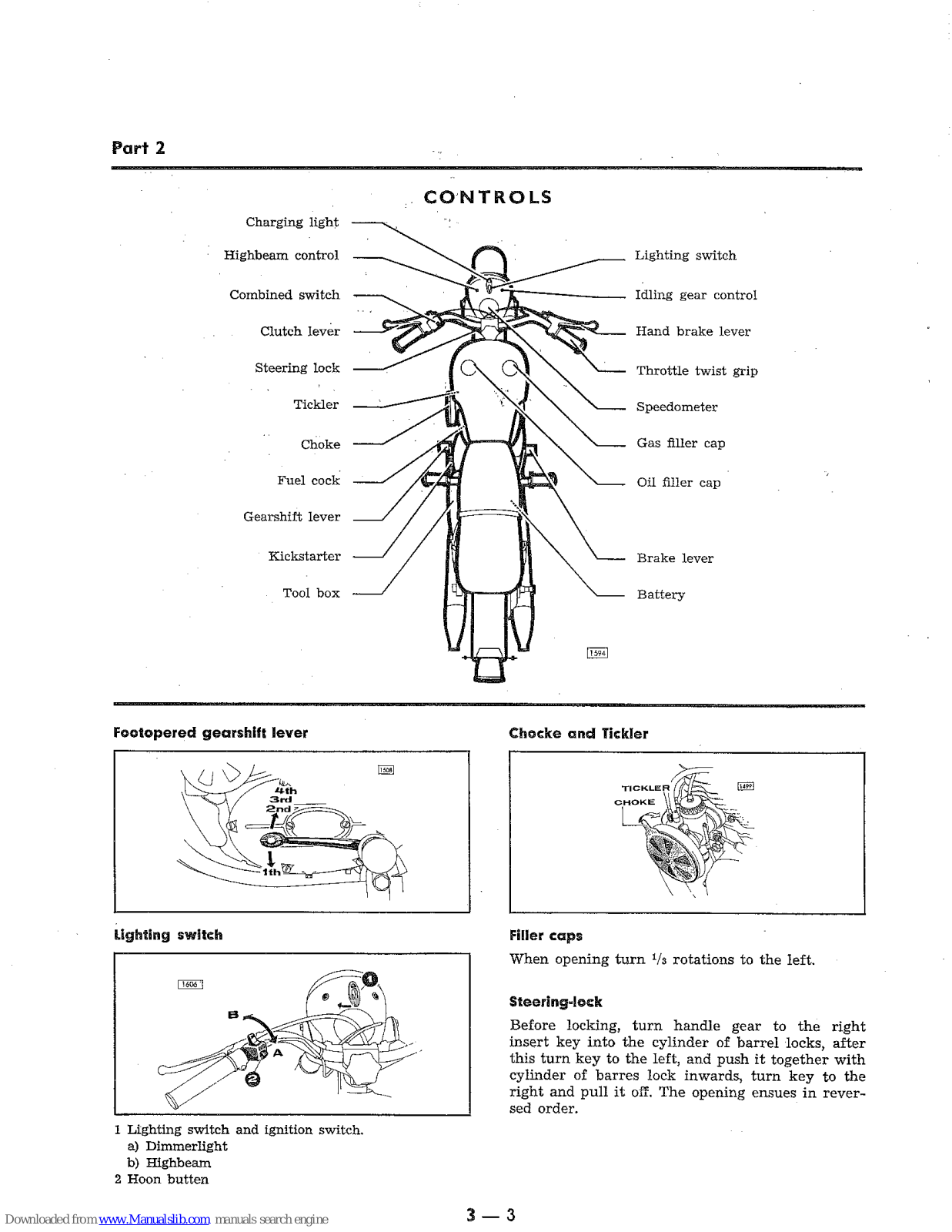

Part 2

Footopered gearshift lever

Lighting switch

Lighting switch and ignition switch. a) Dimmerlight b) Highbeam 2 Hoon butten

Chocke and Tickler

Filler caps

When opening turn 1/3 rotations to the left.

Steering-lock

Before locking, turn handle gear to the right insert key into the cylinder of barrel locks, after this turn key to the left, and push it together with cylinder of barres lock inwards, turn key to the right and pull it off. The opening ensues in reversed order.

PIDING TIPS

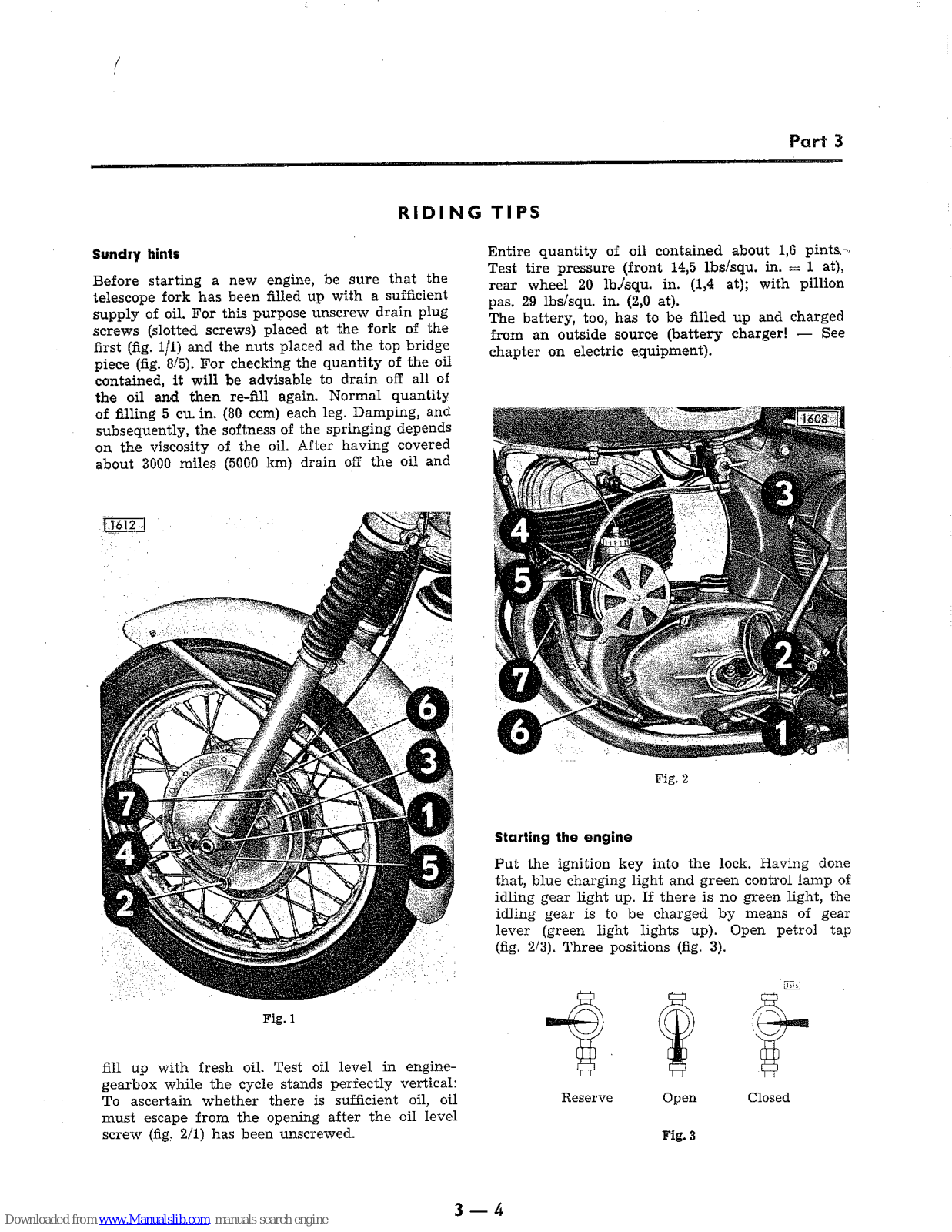

Sundry hints

Before starting a new engine, be sure that the telescope fork has been filled up with a sufficient supply of oil. For this purpose unscrew drain plug screws (slotted screws) placed at the fork of the first (fig. 1/1) and the nuts placed ad the top bridge piece (fig. 8/5). For checking the quantity of the oil contained, it will be advisable to drain off all of the oil and then re-fill again. Normal quantity of filling 5 cu in. (80 ccm) each leg. Damping, and subsequently, the softness of the springing depends on the viscosity of the oil. After having covered about 3000 miles (5000 km) drain off the oil and

fill up with fresh oil. Test oil level in enginegearbox while the cycle stands perfectly vertical: To ascertain whether there is sufficient oil, oil must escape from the opening after the oil level screw (fig. 2/1) has been unscrewed.

Entire quantity of oil contained about 1,6 pints.~ Test tire pressure (front 14,5 lbs/squ. in. = 1 at), rear wheel 20 lb/squ, in (1.4 at): with pillion nas. 29 lbs/squ. in. (2.0 at).

The battery, too, has to be filled up and charged from an outside source (battery charger! - See chapter on electric equipment).

Fig. 2

Starting the engine

Put the ignition key into the lock. Having done that, blue charging light and green control lamp of idling gear light up. If there is no green light, the idling gear is to be charged by means of gear lever (green light lights up). Open petrol tap (fig. 2/3). Three positions (fig. 3).

Close the starter disc on the air filter (fig. 2/4). The carburettor is provided with a special starter carburettor. The twist grip is turned to full throttle position, then the tickler (fig. 2/5) on the float housing is repeatedly depressed at short intervals, until petrol flows over the opening of the chamber containing starting petrol (fig. 9/1). In summer it is unnecessary to close the starter disc. It suffices to depress the tickler a few times, and there is no need for the fuel to overflow

Open the twist grip 1/4 at most before kick-starting. Depress the kickstarter smartly,

Let the engine warm up a little at a moderate number of revolutions, particularly in winter. If there is a tendency to refuse to fire or to stall, briefly depress the tickler button and open the starter disc, after the engine has got warm.

A hot engine will start without using the tickler or closing the starter disc with 1/4 gas at most. Should the engine have cooled down already and fail to start, the tickler can be operated briefly again. Use of the tickler with a hot engine involves the danger of getting too fat a mixture. If the carburettor has been flooded with the engine hot, the mixture is much too fat and the engine will not start. In such a case start with full throttle repeatedly, until the engine is running.

Important! Before kickstarting: don't start the engine with the ignition switched off.

Stopping the engine

Stop the engine by taking out the ignition. Always switch off the ignition. Then turn off the petrol tap. Otherwise, if the cycle is standing on an incline or resting sideways, the carburettor may overflow, which will lead to starting difficulties (flooding the engine). In this case the overflown petrol should be drained off by the same screw (fig. 11/1) situated in the bottom of the crankcase.

The stand is put down with the left foot. Then, with your right foot, step smartly on the stand shoe, at the same time drawing the maschine upwards and backwards upon both legs.

Riding and gear changing

Operating of gear lever: Push foot gear lever (fig. 2/2) down for lower (slower) gears, draw upwards for higher (faster) gears. Always declutch well before changing gear! Gear shifts work easily, don't force your change speed lever.

Putting gears into neutral: Press the gear lever down until you feel it to be free: the 1st gear is then in. Then with the point of your toe, slowly draw upwards, until engagement in neutral is felt. Neutral should not be engaged between 2nd and 3rd or 3rd and top gears. Before changing down, do not turn off gas intirely. After starting, change into 2nd at about 10--12 m.p.h., into 3rd at about 30 m.p.h. The flexibility of the engine is such that it can bi run slowly even in top and the accelera-

tion is good when the throttle is opened. Below 25 m.p.h., however it is not advisable to run all the time in top and the third gear may be used permanently without hesitation for lower cruising speeds. For instance in town-traffic, acceleration of up to 45 m.p.h. are permissable in 3rd gear. although this speed should not be maintained in 3rd for any length of time. The gear ratios have been selected for sporting rides. Thus to obtain high average speed in hilly country, the difference of ratio between top and 3rd gear is not too great. On mountain roads when the speed has dropped to some 40 mph change down to 3rd. This applies above all to sporting riders. The excellent pull of the engine allows of outstanding hill climbing performance even at low engine revs. but the speed will be lower than when a timely changedown has been effected.

Brakes

Braking effect and braking reliability are particularly good with excles with rear wheel springing as the wheels do not give in braking. Make it your rule always to use both brakes. Try it and you will get used to it! You need not hesitate or be nervous to apply the front wheel brake! Its effect is even greater than that of the rear brake on account of the rising load on the wheel. Only when the road is slippery or icy you will have to be careful. Always brake your mount when approaching a bend. Braking on a bend increases the likelihood of a dangerous skid. Vilolent and sudden braking on slipperv bends, particularly with the front wheel brake, is dangerous. You get less braking effect with the wheels locked and the risk of skidding is greater. The brakes are therefore to be "felt" rather then forced. The brakes are soft and very efficient, which greatly facilitates good braking.

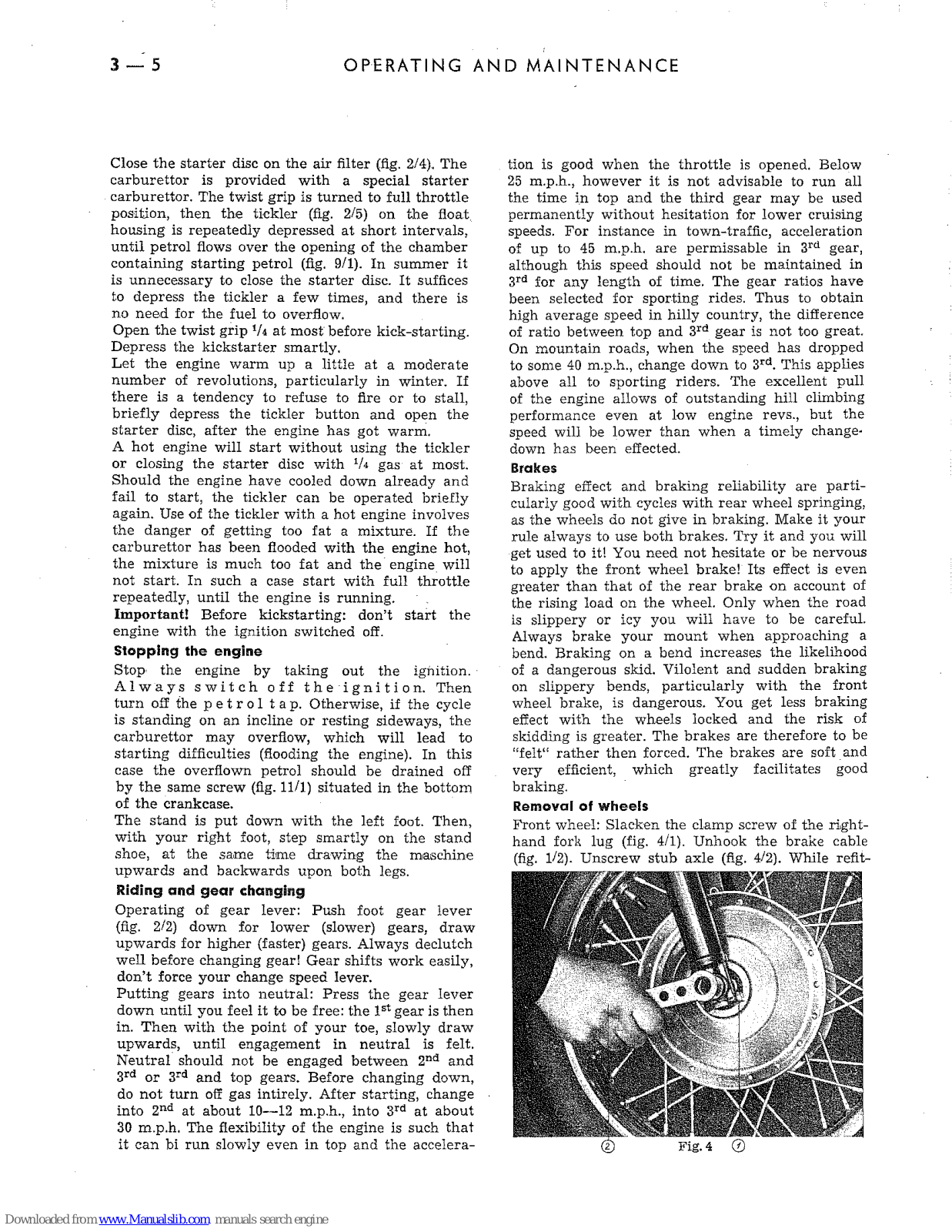

Removal of wheels

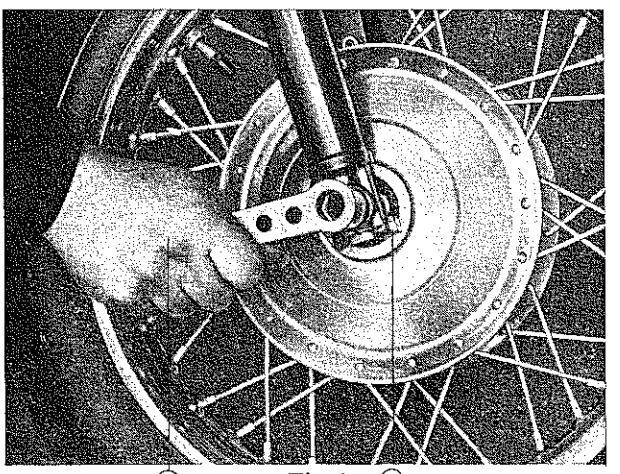

Front wheel: Slacken the clamp screw of the righthand fork lug (fig. 4/1). Unhook the brake cable (fig. 1/2). Unscrew stub axle (fig. 4/2). While refit-

Fig. 4 🤇

ting, insert the bolt of the brake plate in the hook of the spring fork (fig. 1/3) and then screw up the stub axle. Drive fork down on the springs several

times before tightening the clamp screw on the right-hand fork lug. Rear wheel: Unhook brake rigging, after having loosened winged nut (fig. 5/1). Unscrew stub axle by means of spark plug wrench. Pull out the intermediate part left-hand (fig. 5/2) — representing brake-stop — and pull the carrier of brake-drum from the flexible coupling. Incline the machine and remove the wheel from under the mud-guard. The hinged part of the rear wheel mud-guard can be taken off by unscrewing it. This makes it possible to remove the rear wheel without inclining the model as in a side car model. Grease stub axle when reassembling.

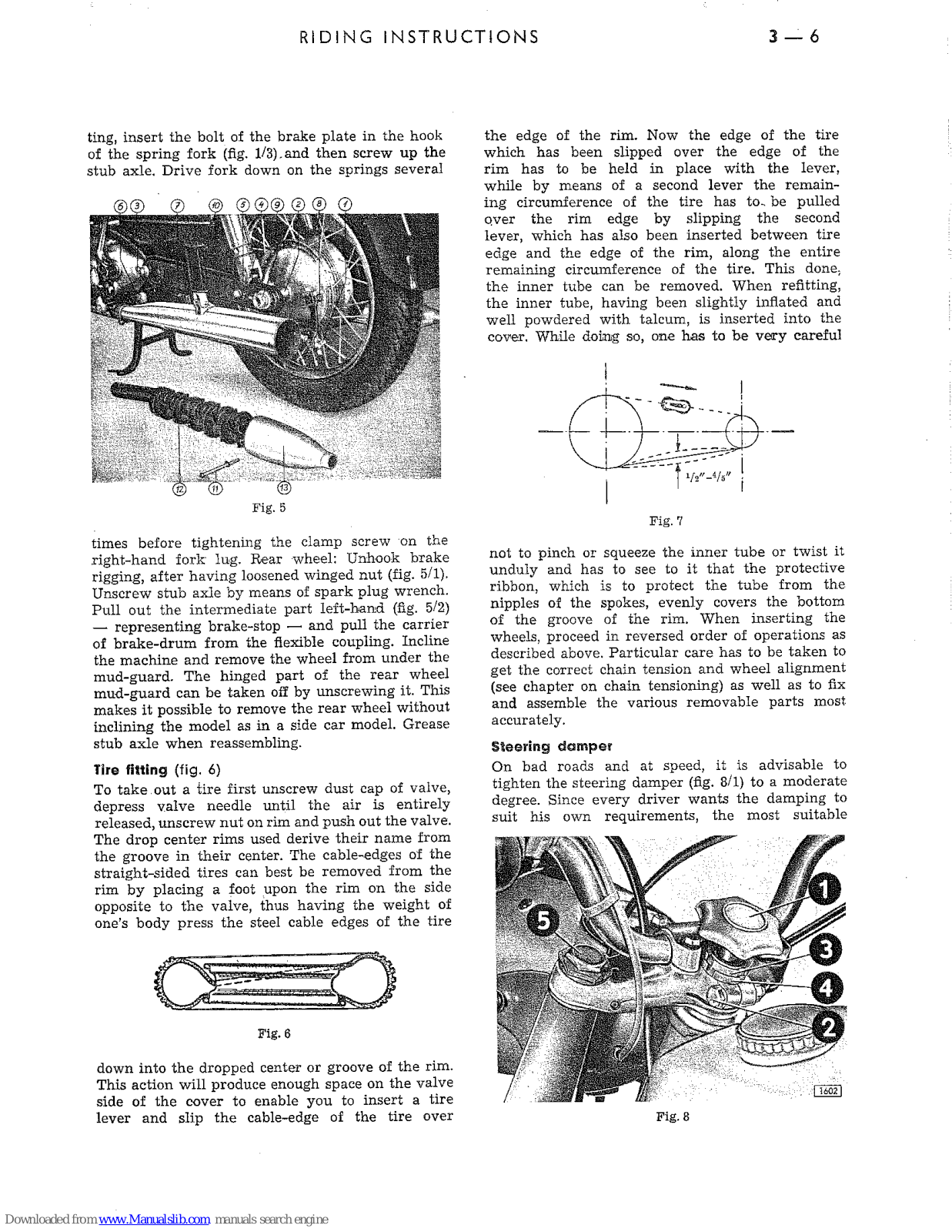

Tire fitting (fig. 6)

To take out a tire first unscrew dust cap of valve, depress valve needle until the air is entirely released, unscrew nut on rim and push out the valve. The drop center rims used derive their name from the groove in their center. The cable-edges of the straight-sided tires can best be removed from the rim by placing a foot upon the rim on the side opposite to the valve, thus having the weight of one's body press the steel cable edges of the tire

Fig. 6

down into the dropped center or groove of the rim. This action will produce enough space on the valve side of the cover to enable you to insert a tire lever and slip the cable-edge of the tire over

the edge of the rim. Now the edge of the tire which has been slipped over the edge of the rim has to be held in place with the lever, while by means of a second lever the remaining circumference of the tire has to, be pulled over the rim edge by slipping the second lever, which has also been inserted between tire edge and the edge of the rim, along the entire remaining circumference of the tire. This done, the inner tube can be removed. When refitting, the inner tube, having been slightly inflated and well powdered with talcum, is inserted into the cover. While doing so, one has to be very careful

Fig. 7

not to pinch or squeeze the inner tube or twist it unduly and has to see to it that the protective ribbon, which is to protect the tube from the nipples of the spokes, evenly covers the bottom of the groove of the rim. When inserting the wheels, proceed in reversed order of operations as described above. Particular care has to be taken to get the correct chain tension and wheel alignment (see chapter on chain tensioning) as well as to fix and assemble the various removable parts most accurately.

Steering damper

On bad roads and at speed, it is advisable to tighten the steering damper (fig. 8/1) to a moderate degree. Since every driver wants the damping to suit his own requirements, the most suitable

Fig. 8

tension is found out by trial. The outstanding roadholding qualities of Model 250 allows of riding under all conditions with the damper left slack. Thus there is no need to tighten it up too much. It must, however, neither be left too loose!

Riding hints

Fuel consumption and wear of the cycle are largely dependent on how the motorcycle is being used. High speeds necessarily mean high consumption. Much variation of speed. constantly turning the twist grin sharp braking on bends increase wear and consumption with any vehicle. The most favourable consumption figures are obtained with a uniform speed. The fuel and oil consumption of our models are extremely low, and the rider should not unnecessarily increase it by bad riding. Letting in the clutch with a jerk, powerful braking, wrenching at the twist grip at lower engine speeds, brisk gear changing, possibly without proper declutching or regard to engine revs. inconsiderate riding on the worst roads; all these are additional stresses which can only add to the wear. A good rider never jerks his cycle and his gear change proclaims itself only by the gradually changing revolutions of the engine.

IMPORTANT HINTS

The engine knocks

Knocking (pinking) is a metallic ringing sound in the engine, sometimes irregular but mostly synchronized with the firing stroke. The cause of this too rapid (detonating) combustion of the mixture is a fuel too poor in anti-knock quality. The anti-knock value of fuels is dependent on their octane number — the higher the latter, the greater the freedom from knocking.

Standard brand fuels at the present time are approximately octane 72. With these, the 250 c.c. engine runs without knocking, except perhaps briefly when opening out the throttle. Fuels not sufficiently knock-free are bad for the engine and should not be used. If a knocking fuel must be used in case of no other being available, ride carefully and not above average speeds. Permanent knocking must be prevented. Such preventatives are: Advance ignition not to exceed about 0,256 in. (6,5 mm). Rich mixture: If the engine should knock up to half throttle screw up screw for air regulating; lift jet needle, above half throttle fit

larger main jet. Reduce compression ratio by fitting two cylinder head gaskets.

All these preventatives against knocking tend to diminish performance and to raise consumption. However, this trouble inherent to unsuitable fuels, must be accepted when using them.

Adjusting the carburettor

For this work see section 6 part 2.

Spark plua

There is no such thing as a standard plug which will suit all types of engines equally well. Manufacturers of plugs therefore produce a diversity of types to meet the working conditions of various types of engines.

Use SEARS-plugs only (No. 60400)! in case you have none with you, only such plugs should be used as are signified by their makers as suitable for air-cooled sports engines. Plugs for water cooled engines are unsuitable.

We would particularly stress the fact unsuitable plugs, with too low resistance to overheating, and those which start to glow, may damage the engine. Plugs for sport engines are sometimes known as "cold" plugs, since they do not become too hot even with hot engines.

In case of doubt, it is better to employ a plug which is too "cold", which may perhaps oil up sometimes when running slowly but cannot damage the engine in any way.

It is advisable to screw up the plugs by hand as tightly as possible, before using a wrench to avoid damage to the thread.

Plugs made to be dismantled must not be put into a vice, but taken to pieces with a box spanner only.

Muffler (Silencer)

With two-stroke engines, the silencer is not an unavoidable nuisance, but an important element in the control of the gas flow through the engine. The engine and silencer of our cycles are designed to cooperate most efficiently with one another and to the best advantage.

Any alteration in the silencer spoils the tuning and unfavourably effects performance and consumption.

The inside of the silencer should be cleaned from time to time as obstructions have an unfavourable influence.

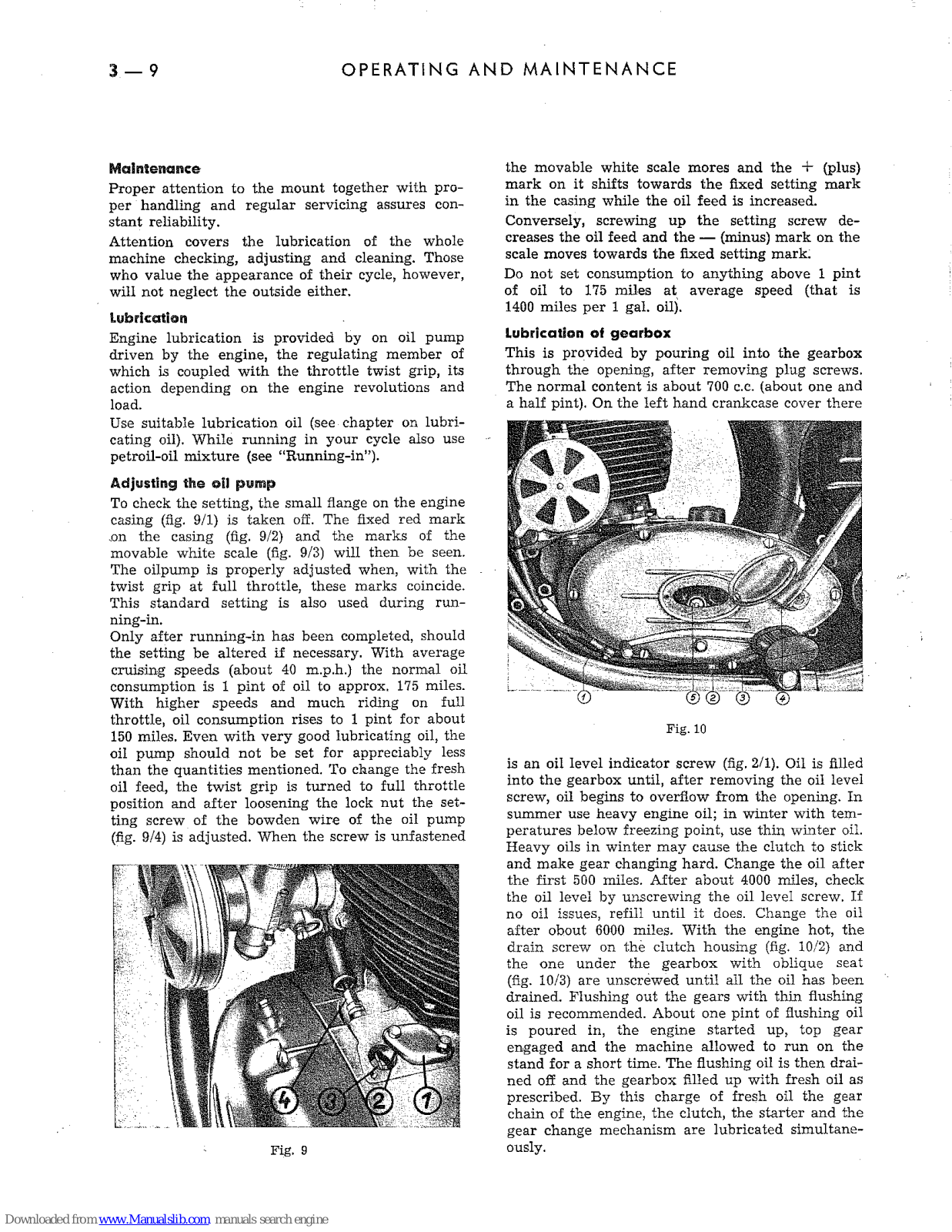

INSPECTION AND ADJUSTMENT

Daily Inspection

Inspect the motorcycle yourself. Prober inspection prolongs the life of the motorcycle.

- 1. Does steering handle operate lightly?

- 2. Is front brake lever play 3/4"?

- 3. Is rear brake pedal travel 8/4"?

- 4. Does clutch work properly?

- 5. Do front and rear cushions work properly?

6. Do head light, tail light, and stop light turn on?

- 7. Does horn sound properly?

- 8. Is engine oil up to full mark on gauge?

9. Does fuel tank contain sufficient gasoline?

- 10. Does oil tank contain sufficient oil?

- 11. Is front tire pressure correct?

- 12. Is rear tire pressure correct?

- 13. Is colour of exhaust gas proper?

|

EDELIVERY

PECTION 2) |

BI |

REAK-

AFTEF |

IN

{ |

А |

ALW

FTER |

AYS

EVER |

Y |

|

|---|---|---|---|---|---|---|---|---|

| PRI | AS | 500 | 1500 | 3000 | 3000 | 500 | 1500 | 3000 | 6000 | ITEMS | |

| | | 0 | • | ۲ | 1 Clean (decarbonize) cylinder and exhaust assembly | ||||

| ۲ | ۵ | • | 2 Clean spark plug | |||||

| • | • | ۲ | 0 | 0 | ۲ | 3 Clean and oil air filter 3) | ||

| ٠ | ۲ | • | 4 Clean fuel strainer and connecting screws for oil pipe | |||||

| • | • | ۲ | ۵ | 5 Clean carburetor and adjust the engine idling | ||||

| • | ۲ | ۲ | 0 | ۲ | ۲ | 6 Adjust clutch | ||

| • | ٩ | ۲ | ۲ | • | 7 Adjust ignition timing | |||

| 8 Fill oil tank and bleed 4) the oil pipe | ||||||||

| 0 | 0 | • | 0 | 0 | ۲ | 9 Chek oil pump setting | ||

| 0 | 10 Chek brake linings | |||||||

| • | • | • | 11 Adjust front brake | |||||

| • | • | - | ۲ | ۲ | 12 Adjust rear brake | |||

| - | - | - | -[ | - | 0 | 13 Check chain and engine sprocket | ||

| 1 | • | ۲ | 0 | · 0 | 6 | • | 14 Adjust and lubricate drive chain | |

| - | ٥ | 15 Lubricate hobs | ||||||

| - | - | ۲ | 16 Lubricate steering bearing | |||||

| - | - | 17 Fill up telescopic fork oil | ||||||

| - | 0 | 18 Change telescopic fork oil | ||||||

| - | - | - | - | 0 | 19 Change shock absorber oil | |||

| 20 Inspect tightness of bolts and nuts | ||||||||

| • | 6 | 0 | 0 | 6 | 0 | 21 Inspect tightness of cylinder head screws | ||

| • | • | 0 | - | - | 0 | 0 | 22 Lubricate chassis | |

| • | • | 0 | 0 | • | • | 23 Lubricate control cables | ||

| _ | 6 | 24 Check motor oil in gearbox | ||||||

| _ | -1 | ••• | • | 25 Change motor oil in gearbox 5) | ||||

| • | -| | - |

| |

26 Fill and load battery | ||||

| -[ | • | 27 Check battery acid | ||||||

| • | • | • | • | 0 | 0 | ٥ |

28 Inspect lighting system, charging control and carbon

brushes |

|

| 0 | • | • | 29 Inspect horn sound | |||||

| 0 | 0 | 0 | • | 30 Check tyre pressure | ||||

| • | - | - | 0 | 31 Clean and lubricate drive chain | ||||

2) At mail orders the predelivery inspection is not executed — take care that this inspection is done. 3) Every 500 miles on extremely dusty conditions. 4) Every time when oil tanks is empty; THEREFORE BE CAREFUL TANK WILL NOT BE EMPTY. 5) At least twice a year.

Maintenance

Proper attention to the mount together with proper handling and regular servicing assures constant reliability.

Attention covers the lubrication of the whole machine checking, adjusting and cleaning. Those who value the appearance of their cycle, however, will not neglect the outside either.

Lubrication

Engine lubrication is provided by on oil pump driven by the engine, the regulating member of which is coupled with the throttle twist grip, its action depending on the engine revolutions and load.

Use suitable lubrication oil (see chapter on lubricating oil). While running in your cycle also use petroil-oil mixture (see "Running-in").

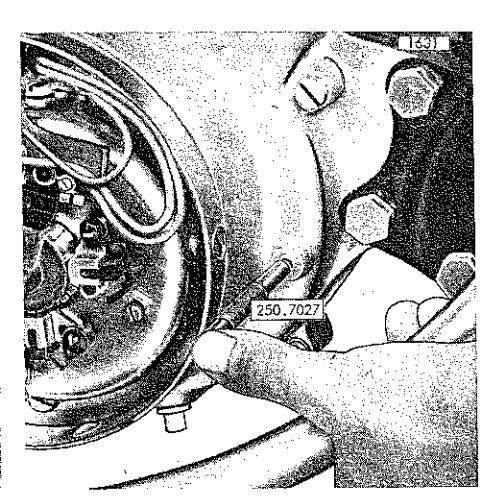

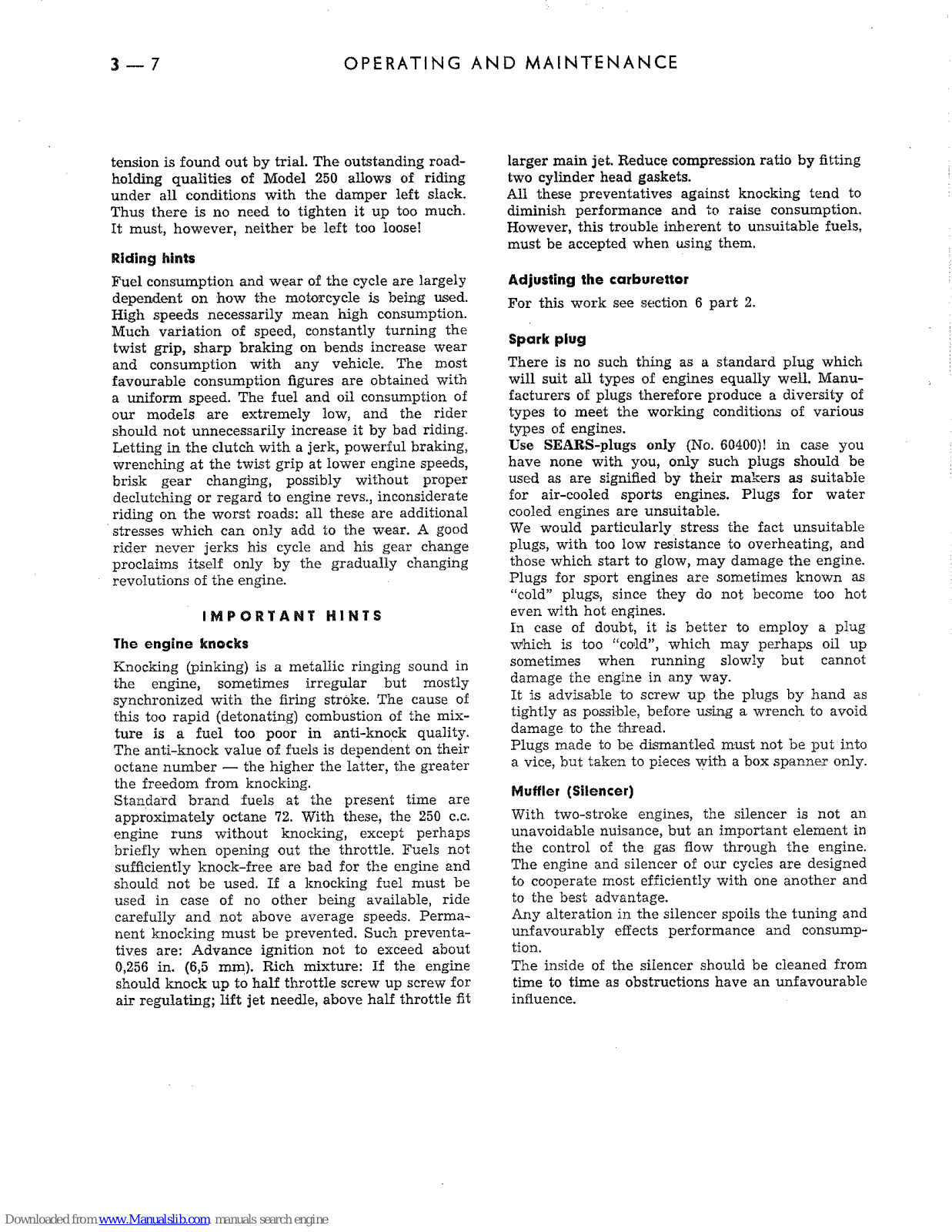

Adjusting the oil pump

To check the setting, the small flange on the engine casing (fig. 9/1) is taken off. The fixed red mark on the casing (fig. 9/2) and the marks of the movable white scale (fig. 9/3) will then be seen. The oilpump is properly adjusted when, with the twist grip at full throttle, these marks coincide. This standard setting is also used during running-in.

Only after running-in has been completed, should the setting be altered if necessary. With average cruising speeds (about 40 m.p.h.) the normal oil consumption is 1 pint of oil to approx. 175 miles. With higher speeds and much riding on full throttle, oil consumption rises to 1 pint for about 150 miles. Even with very good lubricating oil, the oil pump should not be set for appreciably less than the quantities mentioned. To change the fresh oil feed, the twist grip is turned to full throttle position and after loosening the lock nut the setting screw of the bowden wire of the oil pump (fig. 9/4) is adjusted. When the screw is unfastened

Fig. 9

the movable white scale mores and the + (plus) mark on it shifts towards the fixed setting mark in the casing while the oil feed is increased.

Conversely, screwing up the setting screw decreases the oil feed and the — (minus) mark on the scale moves towards the fixed setting mark.

Do not set consumption to anything above 1 pint of oil to 175 miles at average speed (that is 1400 miles per 1 gal, oil).

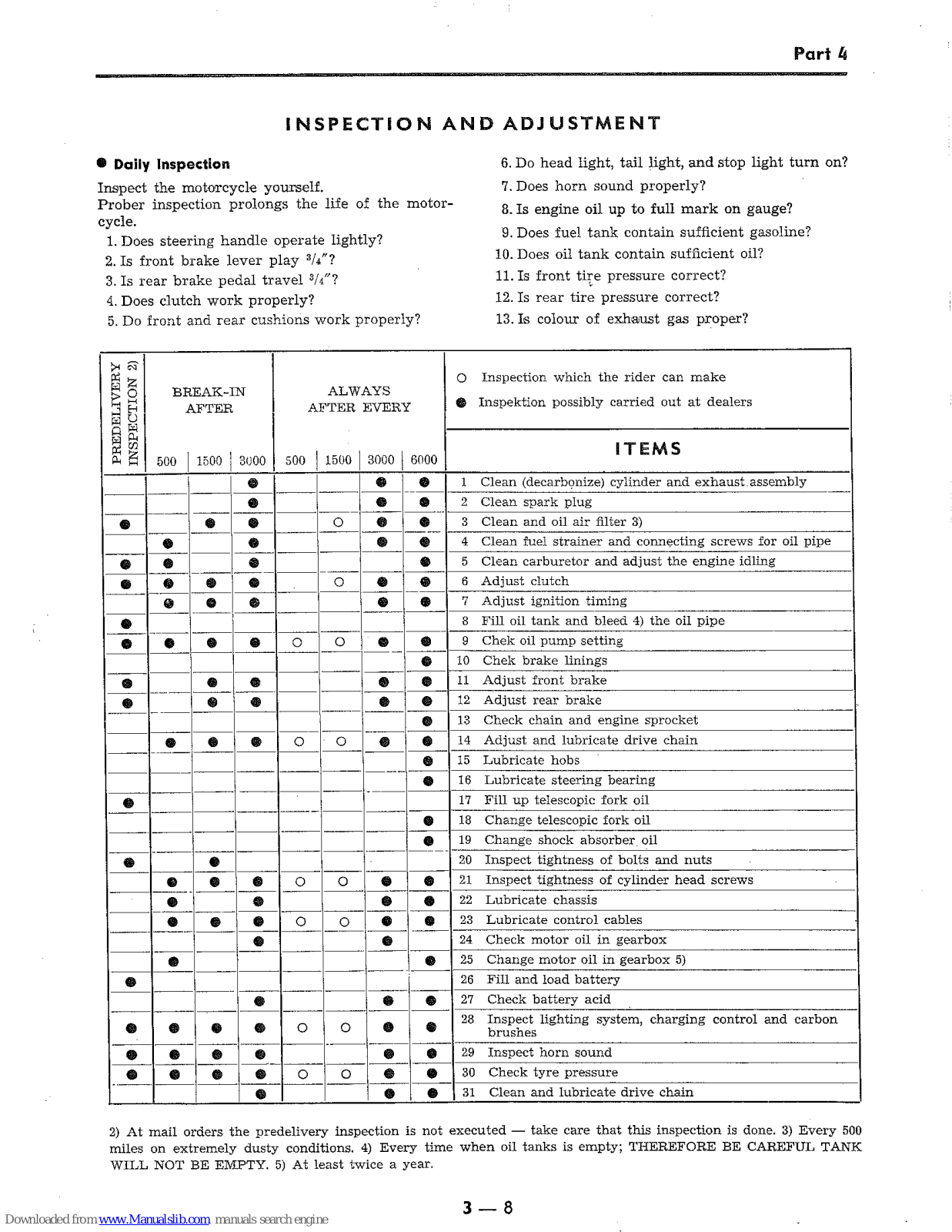

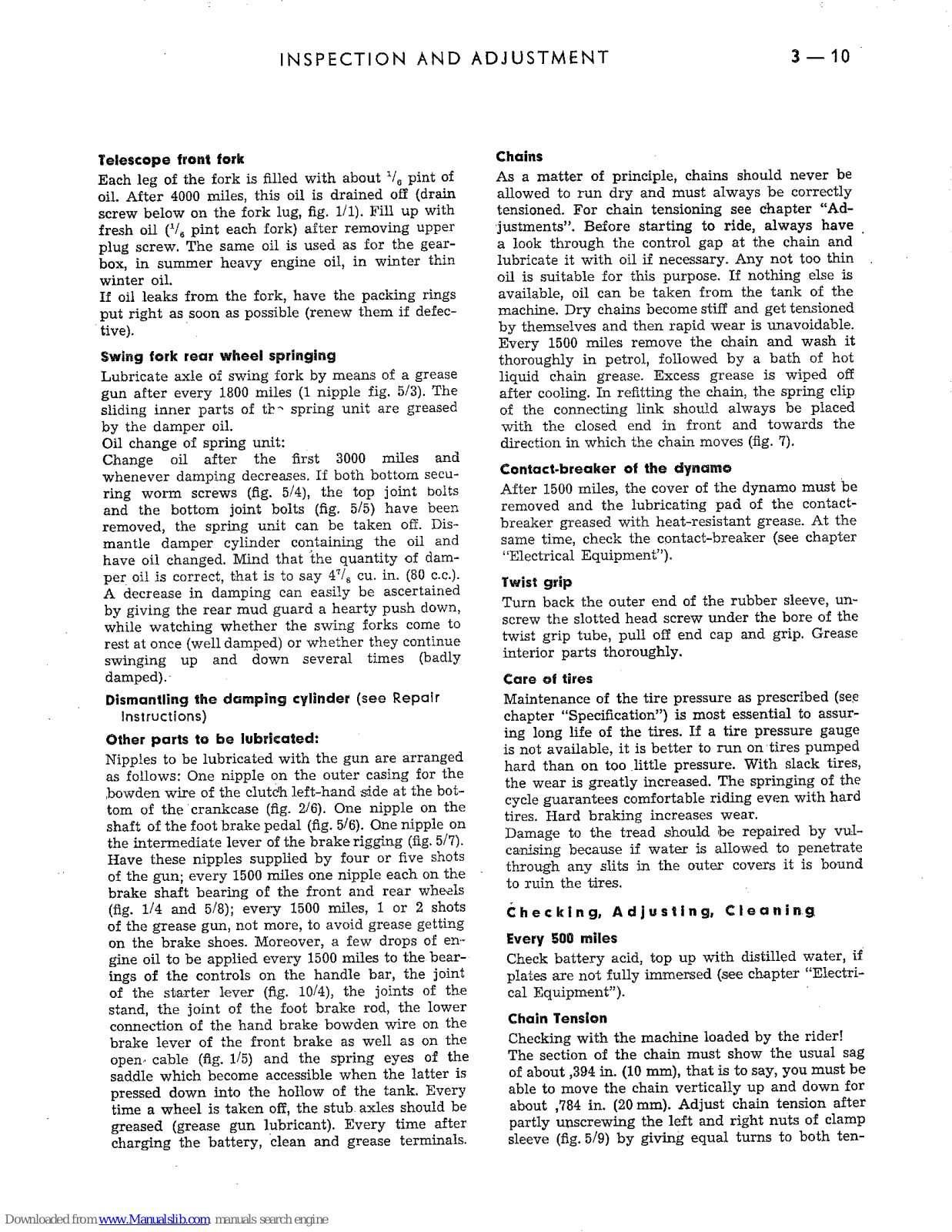

Lubrication of gearbox

This is provided by pouring oil into the gearbox through the opening, after removing plug screws. The normal content is about 700 c.c. (about one and a half pint). On the left hand crankcase cover there

Fig. 10

is an oil level indicator screw (fig. 2/1). Oil is filled into the gearbox until, after removing the oil level screw, oil begins to overflow from the opening. In summer use heavy engine oil; in winter with temperatures below freezing point, use thin winter oil. Heavy oils in winter may cause the clutch to stick and make gear changing hard. Change the oil after the first 500 miles. After about 4000 miles, check the oil level by unscrewing the oil level screw. If no oil issues, refill until it does. Change the oil after obout 6000 miles. With the engine hot, the drain screw on the clutch housing (fig. 10/2) and the one under the gearbox with oblique seat (fig. 10/3) are unscrewed until all the oil has been drained. Flushing out the gears with thin flushing oil is recommended. About one pint of flushing oil is poured in, the engine started up, top gear engaged and the machine allowed to run on the stand for a short time. The flushing oil is then drained off and the gearbox filled up with fresh oil as prescribed. By this charge of fresh oil the gear chain of the engine, the clutch, the starter and the gear change mechanism are lubricated simultaneously.

Telescope front fork

Each leg of the fork is filled with about 1/6 pint of oil. After 4000 miles, this oil is drained off (drain screw below on the fork lug, fig. 1/1). Fill up with fresh oil (1/6 pint each fork) after removing upper plug screw. The same oil is used as for the gearbox, in summer heavy engine oil, in winter thin winter oil.

If oil leaks from the fork, have the packing rings put right as soon as possible (renew them if defective).

Swing fork rear wheel springing

Lubricate axle of swing fork by means of a grease gun after every 1800 miles (1 nipple fig. 5/3). The sliding inner parts of the spring unit are greased by the damper oil.

Oil change of spring unit:

Change oil after the first 3000 miles and whenever damping decreases. If both bottom securing worm screws (fig. 5/4), the top joint bolts and the bottom joint bolts (fig. 5/5) have been removed, the spring unit can be taken off. Dismantle damper cylinder containing the oil and have oil changed. Mind that the quantity of damper oil is correct, that is to say 47/8 cu. in. (80 c.c.). A decrease in damping can easily be ascertained by giving the rear mud guard a hearty push down, while watching whether the swing forks come to rest at once (well damped) or whether they continue swinging up and down several times (badly damped).

Dismantling the damping cylinder (see Repair Instructions)

Other parts to be lubricated:

Nipples to be lubricated with the gun are arranged as follows: One nipple on the outer casing for the bowden wire of the clutch left-hand side at the bottom of the crankcase (fig. 2/6). One nipple on the shaft of the foot brake pedal (fig. 5/6). One nipple on the intermediate lever of the brake rigging (fig. 5/7). Have these nipples supplied by four or five shots of the gun; every 1500 miles one nipple each on the brake shaft bearing of the front and rear wheels (fig. 1/4 and 5/8): every 1500 miles. 1 or 2 shots of the grease gun, not more, to avoid grease getting on the brake shoes. Moreover, a few drops of engine oil to be applied every 1500 miles to the bearings of the controls on the handle bar, the joint of the starter lever (fig. 10/4), the joints of the stand, the joint of the foot brake rod, the lower connection of the hand brake bowden wire on the brake lever of the front brake as well as on the open cable (fig. 1/5) and the spring eyes of the saddle which become accessible when the latter is pressed down into the hollow of the tank. Every time a wheel is taken off, the stub axles should be greased (grease gun lubricant). Every time after charging the battery, clean and grease terminals.

Chains

As a matter of principle, chains should never be allowed to run dry and must always be correctly tensioned. For chain tensioning see chapter "Adjustments". Before starting to ride always have a look through the control gap at the chain and lubricate it with oil if necessary. Any not too thin oil is suitable for this purpose. If nothing else is available, oil can be taken from the tank of the machine. Dry chains become stiff and get tensioned by themselves and then rapid wear is unavoidable. Every 1500 miles remove the chain and wash it thoroughly in petrol. followed by a bath of hot liquid chain grease Excess grease is wiped off after cooling. In refitting the chain, the spring clip of the connecting link should always be placed with the closed end in front and towards the direction in which the chain moves (fig. 7).

Contact-breaker of the dynamo

After 1500 miles, the cover of the dynamo must be removed and the lubricating pad of the contactbreaker greased with heat-resistant grease. At the same time, check the contact-breaker (see chapter "Electrical Equipment").

Twist grip

Turn back the outer end of the rubber sleeve, unscrew the slotted head screw under the bore of the twist grip tube, pull off end cap and grip. Grease interior parts thoroughly.

Care of tires

Maintenance of the tire pressure as prescribed (see chapter "Specification") is most essential to assuring long life of the tires. If a tire pressure gauge is not available, it is better to run on tires pumped hard than on too little pressure. With slack tires, the wear is greatly increased. The springing of the cycle guarantees comfortable riding even with hard tires. Hard braking increases wear.

Damage to the tread should be repaired by vulcanising because if water is allowed to penetrate through any slits in the outer covers it is bound to ruin the tires.

Checking, Adjusting, Cleaning

Every 500 miles

Check battery acid, top up with distilled water, if plates are not fully immersed (see chapter "Electrical Equipment").

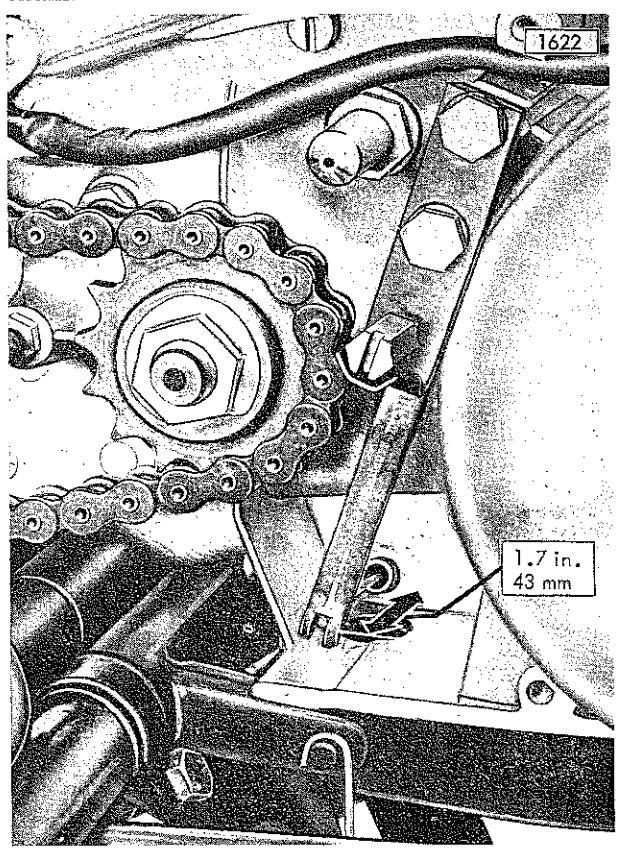

Chain Tension

Checking with the machine loaded by the rider! The section of the chain must show the usual sag of about ,394 in. (10 mm), that is to say, you must be able to move the chain vertically up and down for about ,784 in. (20 mm). Adjust chain tension after partly unscrewing the left and right nuts of clamp sleeve (fig. 5/9) by giving equal turns to both ten-

OPERATING AND MAINTENANCE

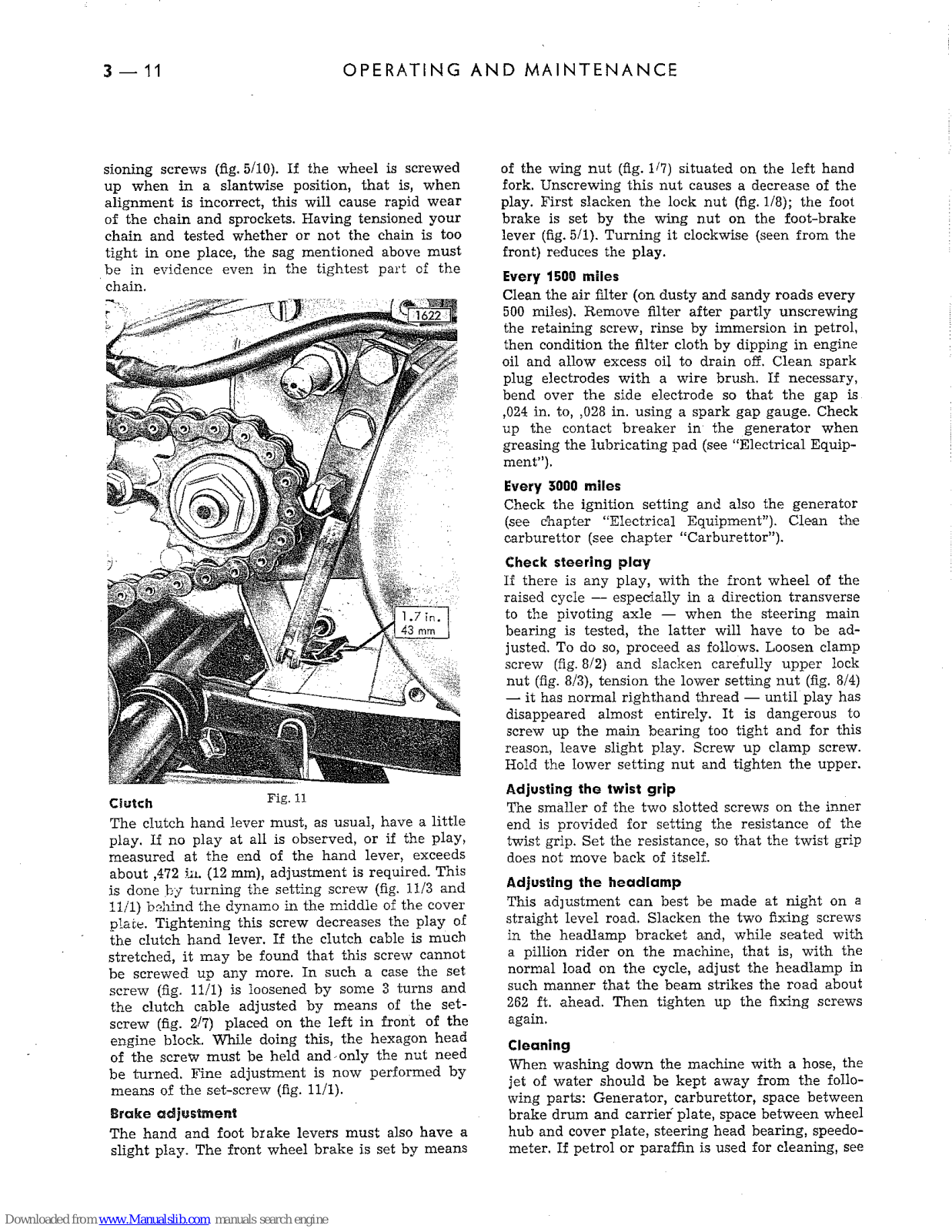

sioning screws (fig. 5/10). If the wheel is screwed up when in a slantwise position, that is, when alignment is incorrect, this will cause rapid wear of the chain and sprockets. Having tensioned your chain and tested whether or not the chain is too tight in one place, the sag mentioned above must be in evidence even in the tightest part of the chain.

Clutch

Fig. 11

The clutch hand lever must, as usual, have a little play. If no play at all is observed, or if the play, measured at the end of the hand lever, exceeds about ,472 in. (12 mm), adjustment is required. This is done by turning the setting screw (fig. 11/3 and 11/1) behind the dynamo in the middle of the cover plate. Tightening this screw decreases the play of the clutch hand lever. If the clutch cable is much stretched it may be found that this screw cannot be screwed up any more. In such a case the set screw (fig. 11/1) is loosened by some 3 turns and the clutch cable adjusted by means of the setscrew (fig. 2/7) placed on the left in front of the engine block. While doing this, the hexagon head of the screw must be held and only the nut need be turned. Fine adjustment is now performed by means of the set-screw (fig. 11/1).

Brake adjustment

The hand and foot brake levers must also have a slight play. The front wheel brake is set by means

of the wing nut (fig. 1/7) situated on the left hand fork. Unscrewing this nut causes a decrease of the play. First slacken the lock nut (fig. 1/8); the foot brake is set by the wing nut on the foot-brake lever (fig. 5/1). Turning it clockwise (seen from the front) reduces the play.

Every 1500 miles

Clean the air filter (on dusty and sandy roads every 500 miles). Remove filter after partly unscrewing the retaining screw, rinse by immersion in petrol, then condition the filter cloth by dipping in engine oil and allow excess oil to drain off. Clean spark plug electrodes with a wire brush. If necessary, bend over the side electrode so that the gap is ,024 in. to, ,028 in. using a spark gap gauge. Check up the contact breaker in the generator when greasing the lubricating pad (see "Electrical Equipment").

Every 3000 miles

Check the ignition setting and also the generator (see chapter "Electrical Equipment"). Clean the carburettor (see chapter "Carburettor").

Check steering play

If there is any play, with the front wheel of the raised cycle — especially in a direction transverse to the pivoting axle — when the steering main bearing is tested, the latter will have to be adjusted. To do so, proceed as follows. Loosen clamp screw (fig. 8/2) and slacken carefully upper lock nut (fig. 8/3), tension the lower setting nut (fig. 8/4) — it has normal righthand thread — until play has disappeared almost entirely. It is dangerous to screw up the main bearing too tight and for this reason, leave slight play. Screw up clamp screw. Hold the lower setting nut and tighten the upper.

Adjusting the twist grip

The smaller of the two slotted screws on the inner end is provided for setting the resistance of the twist grip. Set the resistance, so that the twist grip does not move back of itself.

Adjusting the headlamp

This adjustment can best be made at night on a straight level road. Slacken the two fixing screws in the headlamp bracket and, while seated with a pillion rider on the machine, that is, with the normal load on the cycle, adjust the headlamp in such manner that the beam strikes the road about 262 ft. ahead. Then tighten up the fixing screws again.

Cleaning

When washing down the machine with a hose, the jet of water should be kept away from the following parts: Generator, carburettor, space between brake drum and carrier plate, space between wheel hub and cover plate, steering head bearing, speedometer. If petrol or paraffin is used for cleaning, see

that it does not get into the brakes as the brake linings may become defective.

Electrical Equipment

For this work see section 6, part 4.

O V E R H A U L I N G

General

The work described can be carried out by any rider who is technically minded. Small manipulations which would be obvious to the latter are not therefore described in detail. Those not versed in such work had better leave it to an expert. Thoroughness and cleanliness should be the principles observed in overhauling.

Decarbonising the engine

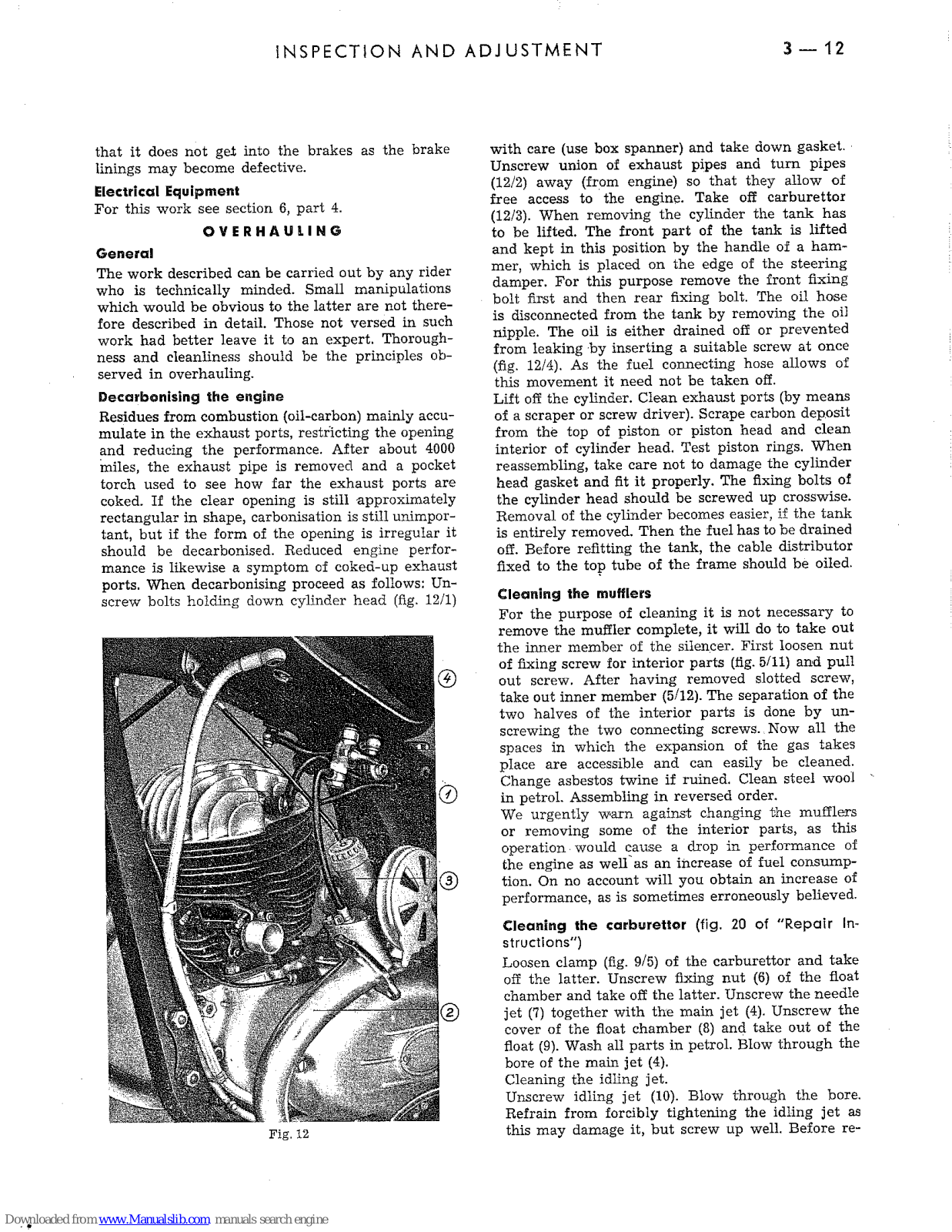

Residues from combustion (oil-carbon) mainly accumulate in the exhaust ports, restricting the opening and reducing the performance. After about 4000 miles, the exhaust pipe is removed and a pocket torch used to see how far the exhaust ports are coked. If the clear opening is still approximately rectangular in shape, carbonisation is still unimportant, but if the form of the opening is irregular it should be decarbonised. Reduced engine performance is likewise a symptom of coked-up exhaust ports. When decarbonising proceed as follows: Unscrew bolts holding down cylinder head (fig. 12/1)

Fig. 12

with care (use box spanner) and take down gasket. Unscrew union of exhaust pipes and turn pipes (12/2) away (from engine) so that they allow of free access to the engine. Take off carburettor (12/3). When removing the cylinder the tank has to be lifted. The front part of the tank is lifted and kept in this position by the handle of a hammer, which is placed on the edge of the steering damper. For this purpose remove the front fixing bolt first and then rear fixing bolt. The oil hose is disconnected from the tank by removing the oil nipple. The oil is either drained off or prevented from leaking by inserting a suitable screw at once (fig. 12/4). As the fuel connecting hose allows of this movement it need not be taken off.

Lift off the cylinder. Clean exhaust ports (by means of a scraper or screw driver). Scrape carbon deposit from the top of piston or piston head and clean interior of cylinder head. Test piston rings. When reassembling, take care not to damage the cylinder head gasket and fit it properly. The fixing bolts of the cylinder head should be screwed up crosswise. Removal of the cylinder becomes easier, if the tank is entirely removed. Then the fuel has to be drained off. Before refitting the tank, the cable distributor fixed to the top tube of the frame should be oiled.

Cleaning the mufflers

For the purpose of cleaning it is not necessary to remove the muffler complete, it will do to take out the inner member of the silencer. First loosen nut of fixing screw for interior parts (fig. 5/11) and pull out screw. After having removed slotted screw, take out inner member (5/12). The separation of the two halves of the interior parts is done by unscrewing the two connecting screws. Now all the spaces in which the expansion of the gas takes place are accessible and can easily be cleaned. Change asbestos twine if ruined. Clean steel wool in petrol. Assembling in reversed order.

We urgently warn against changing the mufflers or removing some of the interior parts, as this operation would cause a drop in performance of the engine as well as an increase of fuel consumption. On no account will you obtain an increase of performance, as is sometimes erroneously believed.

Cleaning the carburettor (fig. 20 of "Repair Instructions")

Loosen clamp (fig. 9/5) of the carburettor and take off the latter. Unscrew fixing nut (6) of the float chamber and take off the latter. Unscrew the needle jet (7) together with the main jet (4). Unscrew the cover of the float chamber (8) and take out of the float (9). Wash all parts in petrol. Blow through the bore of the main jet (4).

Cleaning the idling jet.

Unscrew idling jet (10). Blow through the bore. Refrain from forcibly tightening the idling jet as this may damage it, but screw up well. Before re-

fitting, close the throttle twist grip so that the jet needle is visible in the lower part of the carburettor. Push the needle jet (7) with main jet on to the jet needle (11) and then only start to put parts in place and to tighten threads. Before putting on the float housing cover, insert the float needle (12) in the guide of the cover (8). Finally, the petrol pipe, the tap and its filter are to be cleaned. The tap must be unscrewed for this purpose.

Electrical equipment

Everything we need to know regarding servicing

of the electrical equipment is quoted under the appropriate heading (see "Repair Instructions").

Overhauling the brakes

When the wheels have been removed, the brake plates together with the brake shoes can be taken out of the brake drum.

Never use petrol or paraffin on the brake linings!

If the rivets of the brake linings are worn down the lining should be renewed. This work should be done by an expert motor mechanic.

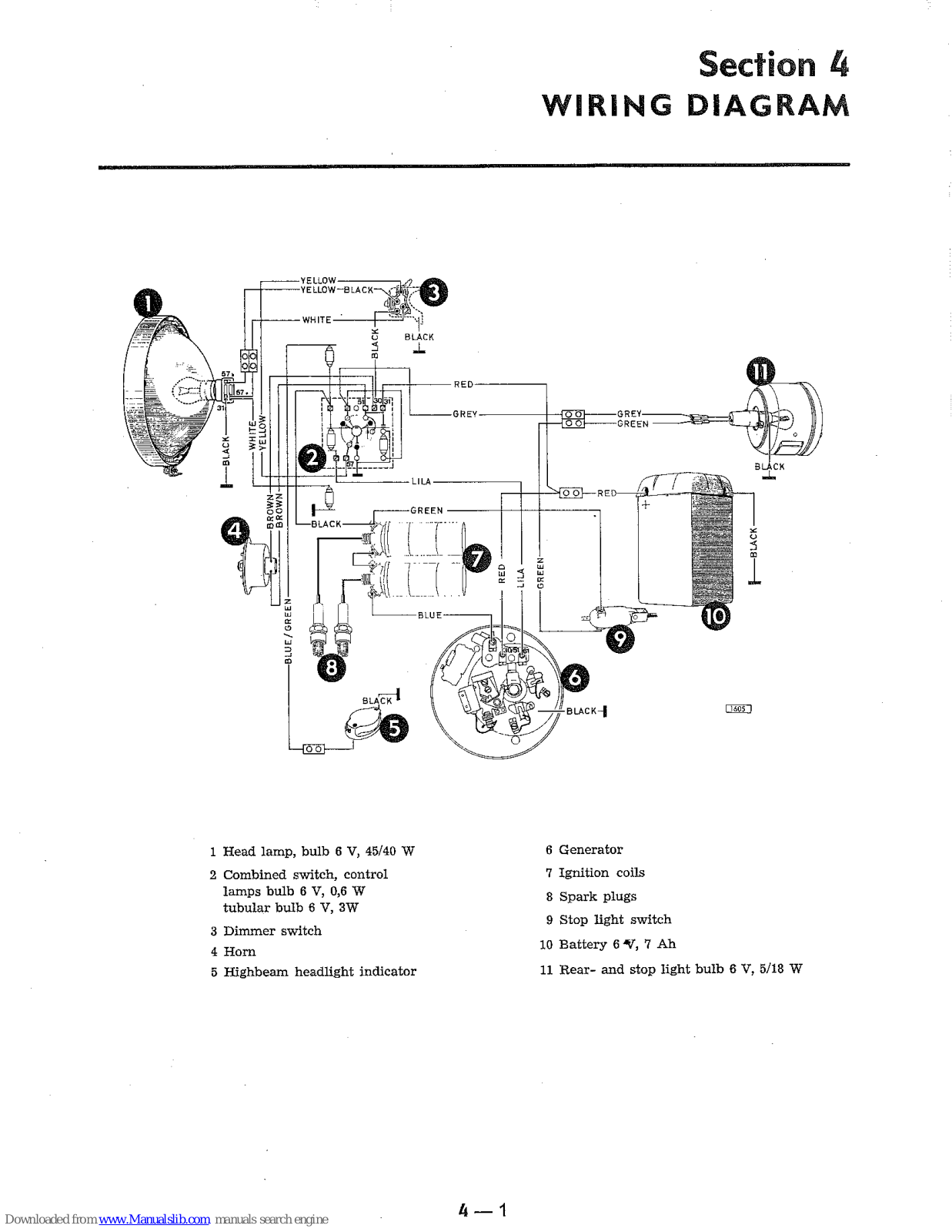

Section 4 WIRING DIAGRAM

- 1 Head lamp, bulb 6 V, 45/40 W

- 2 Combined switch, control lamps bulb 6 V, 0,6 W tubular bulb 6 V, 3W

- 3 Dimmer switch

- 4 Horn

- 5 Highbeam headlight indicator

6 Generator

- 7 Ignition coils

- 8 Spark plugs

- 9 Stop light switch

- 10 Battery 6 V, 7 Ah

- 11 Rear- and stop light bulb 6 V, 5/18 W

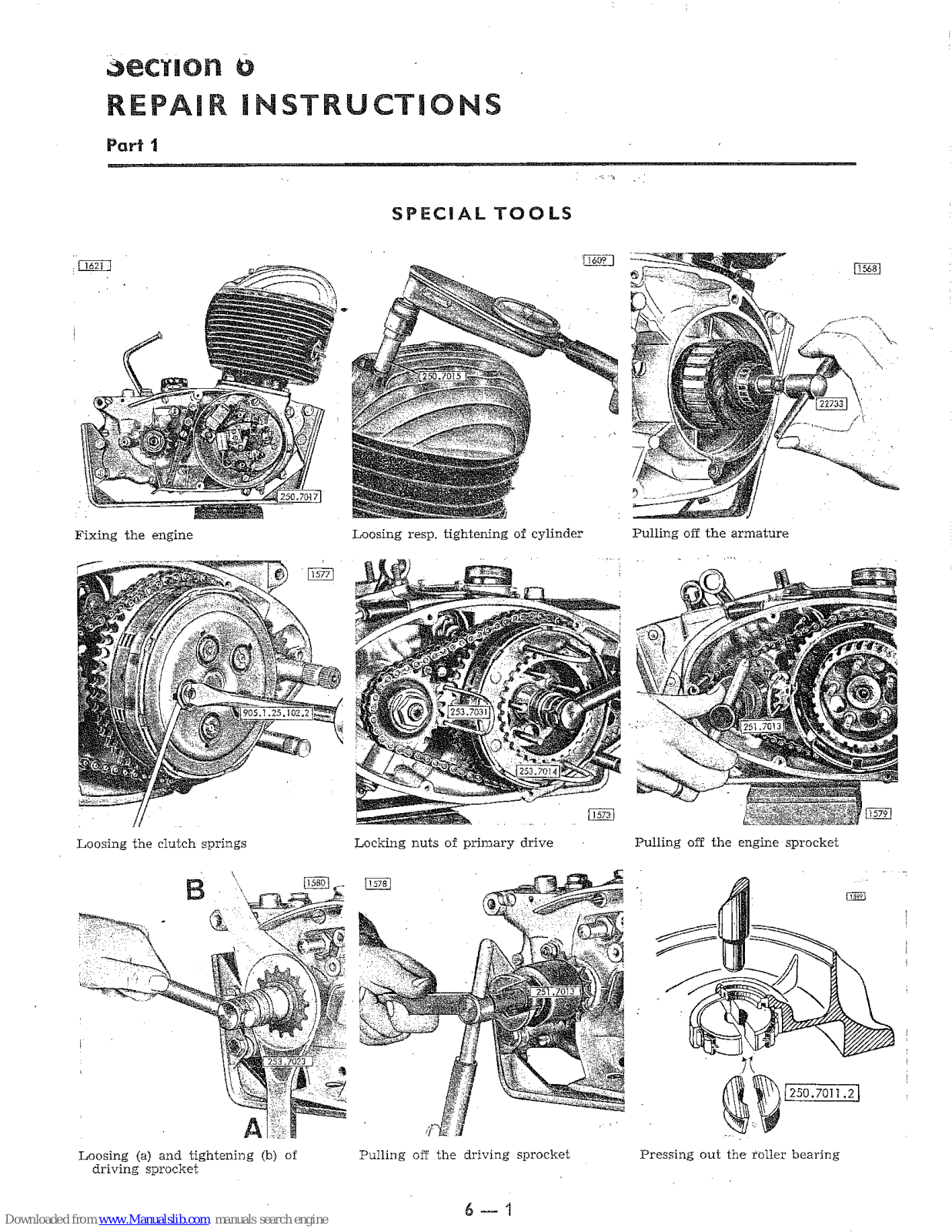

Section 5 TROUBLE SHOOTING

As long as operating and maintenance instructions are closely observed, there is no reason for troubles to be expected. If however troubles occur, it is of supreme importance to locate an overcome the trouble immediately in order to prevent more costly damages.

more cosily damages. Inadequate handling in case of defect must be avoided at any rate. Consult in time a reliable workshop. For all requests for information and orders of spare parts it is indispensable to quote the characteristic number of the vehicle. Here after are given some hints for the loscalization and renair of some defects

| Trouble | Cause | Remedy |

|---|---|---|

| Engine does not start |

Operating error (fuel

cock closed) defective ignition i. e. spark too weak, misfires |

First remedy error, operate starting

aid, open fuel cock, refuel. Check plug for spark. Detach igni- tion wire from plug, hold it at about 0.5 cm distance from zentral electro- de and crank the engine. Spark good: Inspect fuel feed and carburettor (see below). Spark insufficient: Check spark upon cylinder cover. Hold ignition wire at about 0.5 cm distance from earth (e. g. cylinder cover), crank the engine. Spark good: Inspect sparkplug gap, reset. Spark insufficient: Inspect breaker point gap, contact break points, abble constitution |

| Fuel supply interrupted. |

By operating the tickler, check car-

burettor for fuel. No fuel in carbu- rettor: Repair float needle and/or fuel supply. |

|

| Engine does not start | Short-circuiting button jammed resp. ignition key no contact. | Set right. |

|

Vehicle bent or fallen

over with open fuel cock. |

Start with throttle wide open. If

necessary, open drain plug (crank- case bottom) and drain the necessary amount of fuel. |

|

|

Trickler or starting aid

operated with warm en- gine, engine drowned. |

Remedy as above. | |

|

Engine produces a few

sparks before stopping |

Fuel supply partly or

entirely interrupted. |

If there is no operating error (see

above), check float chamber for fuel or jets for dirt or water. Inspect fuel supply to carburettor by pulling the fuel line from carburettor. In this way check lines, filters etc. for cloggings by proceding in the direc- tion towards the fuel tank. |

|

Engine starts, but

kicks back |

Ignition too much

advanced. |

Reset ignition timing. |

| difficultly from could |

Electrical equipment:

Spark-plug gap too wide. Thermal value of spark-plug to high. Carburettor: Jets clogged, starting aid not operated. |

For nominal value and remedy see

Specifications. |

| difficultly in very frosty weather | The colder it is, the harder the engine starts. |

Use winter grade oil of high quality

(in gearbox), which facilitates cran- king. |

|

Items to be observed for starting.

Operate the starting aid, operate the tickler, open the throttle by 1 /s. If engine starts, let it warm up at low speed; do not open throttle completely before operating tempe- rature has been reached. Push back starting aid as soon as possible. |

||

|

Engine starts, but difficult-

ly from warm |

Mixture too rich

because of exaggerated use of starting aid or tickler. |

Open throttle completely during starting process. |

|

Engine runs, but

misfires, fires back, stops |

Lack of fuel in car-

burettor or tank, fuel cock closed, fuel feed |

Remedy the respective cause. |

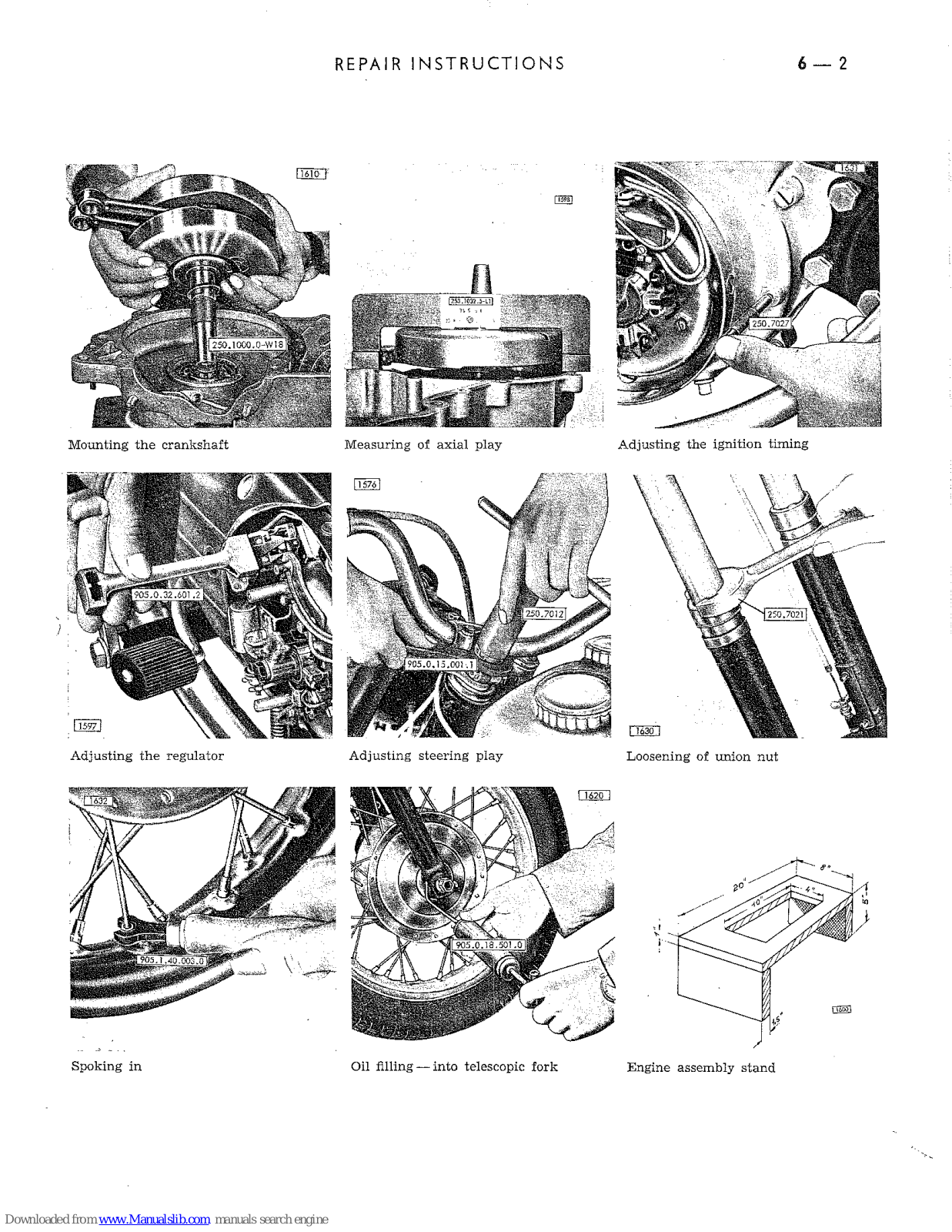

TROUBLE SHOOTING

| Trouble | Cause | Remedy |

|---|---|---|

| stops when throttle is being opened |

Main jet clogged, water

before main jet. |

Remedy as above. |

| irregulary with misfiring |

Ignition misfires due to

incorrect working of contact breaker elec- trodes shortcircuited by foreign body or oil car- bon, spark-plug gap too wide e. g. owing to ex- cessive wear of plug electrodes, spark-plug carbonized or oily or under lead tarnish (tracking current along insulator), insulator cracked e. g. owing to incandescent ignition (sparkover in the plug), ignition lead loose, broken, ignition lead with accidental ground. |

For repair see respective section. |

|

Engine runs, butoutput

insufficient |

Engine misfires induc-

tion and compression bad, mixture too rich or too lean, ignition point improper, exhaust blocked, engine carbo- nized, crankcase oil seal rings leaky, breather screw loose. |

For repair see respective sections. |

| runs hot after a while |

Improper ignition

timing, insufficient lub- rication, exhaust blocked, engine carbo- nized, cooling air insuf- ficient due to dirt on cooling ribs. |

Adjust ignition, clean the engine. |

|

consumes too much

carburettor reports (backfires) |

Starting aid working all

the time, fuel consump- tion due to leakage in pipes, carburettor floo- ding (float valve leaky). When engine hot: Plug too hot, preignition due to combustion products upon plug or in combus- |

For repair see respective sections. |

| knoeks, pinks |

Improper fuel (insuffi-

cient knockresistance), too much spark advance. Mechanical causes: Bigend bearing, crank- shaft bearing, gudgeon pin worn out, too much piston play. |

For repair see respective. |

| hisses |

Insulator or plug bro-

ken, plug insufficiently tightened, plug sealing or faying surface of cylinder cover defective, breather screw not tightened. |

Remedy the respective cause or con-

sult workshop. |

|

Engine stops by itself:

Gradually after misfiring |

Insufficient fuel fee due

to gas bubbles, water or dirt in carburettor, plug carbonized, oily. |

Remedy as above. |

| suddenly |

Fuel tank empty, fuel

feed interrupted, jets clogged. Misfires owing to interruption or short circuit. |

Remedy as above. |

|

Engine does not stop when

switched off, but goes on running regularly |

Plug is not switched off

because shortcirculating button (resp. ignition switch) defective. |

Shut off fuel cock, repair button (switch). |

| Carburettor fire |

Backfiring in the car-

burettor owing to too lean mixture, handling with open fire. |

- If fuel cock accessible shut fuel

supply and open throttle fully so as to empty the carburettor. Use spe- cial extinguisher, choke flames by |

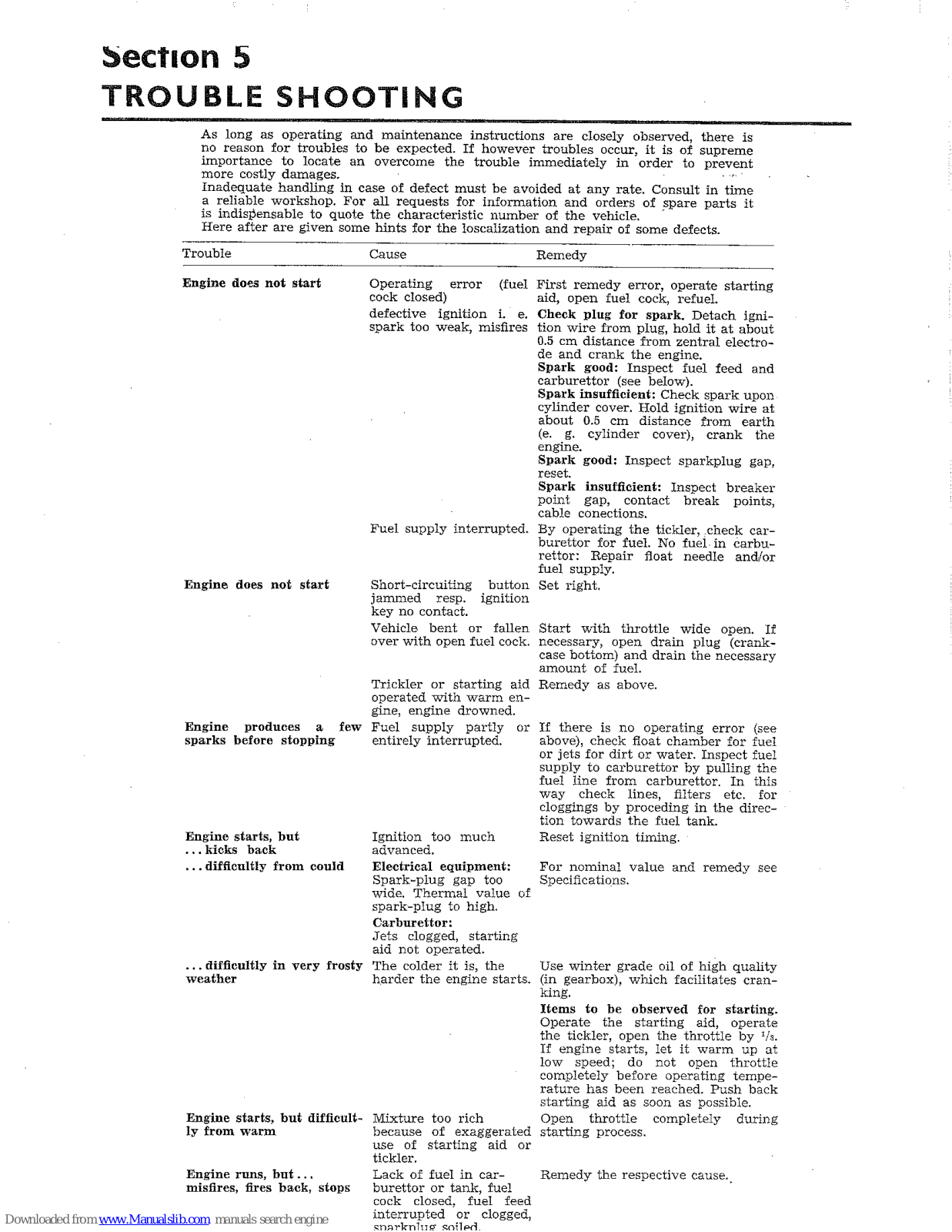

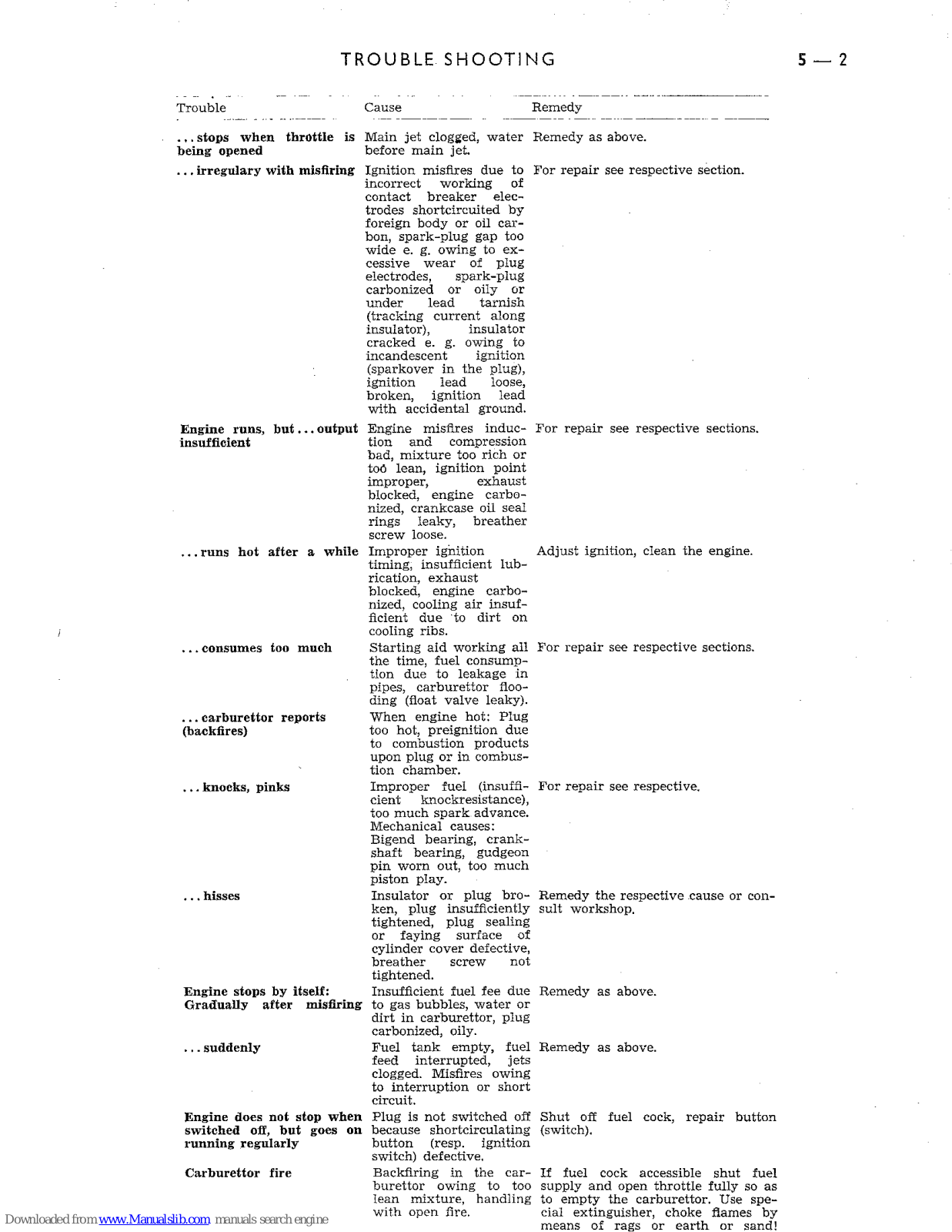

Section 6 REPAIR INSTRUCTIONS

Part 1

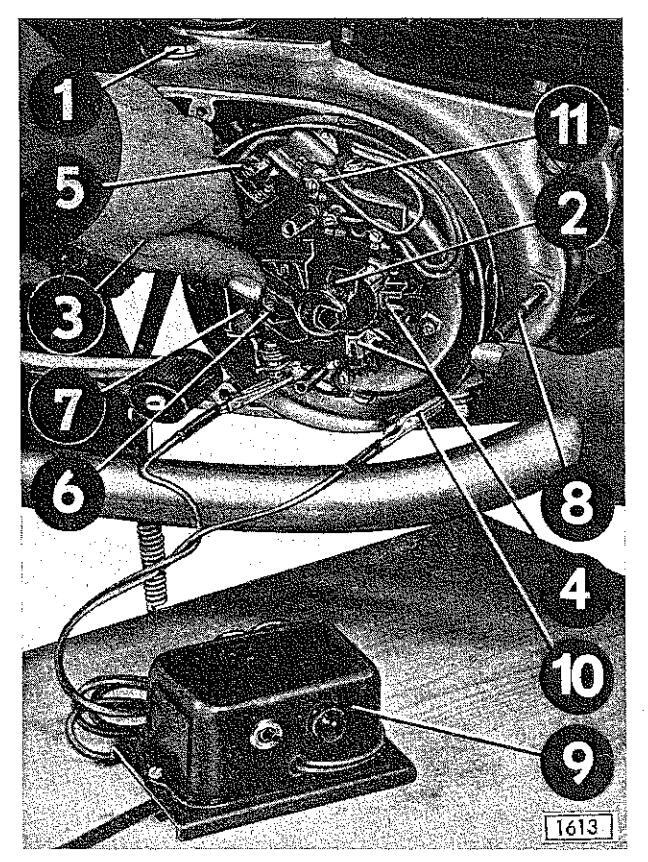

SPECIAL TOOLS

Loosing (a) and tightening (b) of driving sprocket

Pulling off the driving sprocket

Pressing out the roller bearing

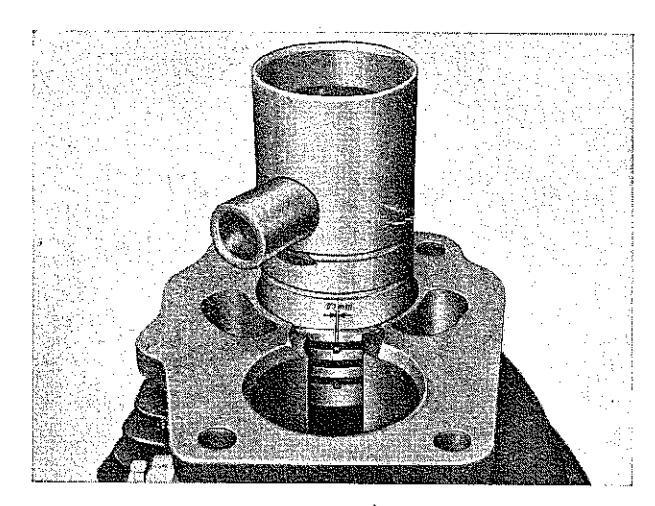

Mounting the crankshaft

Measuring of axial play

Adjusting the ignition timing

Adjusting the regulator

Adjusting steering play

Loosening of union nut

Spoking in

Oil filling — into telescopic fork

Engine assembly stand

Part 2

ENGINE

DISMANTLING OUT OF FRAME

- 1. Loosen battery clamp screw. This disconnects battery from ground.

- 2. Loosen clamp screw of foot brake lever and take off brake lever.

- 3. Remove crankcase cover on the right-hand side after unscrewing the three retaining screws.

- 4. Turn rear wheel until chain master link appears. Remove master link, lift chain from gearbox sprocket, replace master link.

- 5. Screw adjusting screw of clutch lever (fig. 2/1) at engine block so far out that the clutch lever can be taken out of its guide, unhitch cable from slit in clutch lever. (Do not lose slit nipple!)

- 6. Remove cover for generator, disconnect generator cable from connection plate and pull it out of generator housing.

- 7. Unscrew nuts of upper rear engine mounting screw, lift fairing plate fromscrew ing cover of carburettor housing, remove throttle piston and cover from Bowden cable.

- 8. Loosen mounting screw of flexible speedometer drive and remove it together with clamp of generator cables (fig. 1/5), pull out flexible speedometer drive.

- Loosen shackle of carburettor and pull off carburettor, pull out throttle piston after unscrewend, unscrew slotted screw on the opposite side of the frame, remove fairing plate.

- 10. Pull plug cable from spark plug.

- 11. Undo the three cable straps holding Bowden cables and oil hose together, unscrew connecting screw of oil hose from engine block and pull it out, put open hose end quickly into filling hole of oil tank (fig. 1/1).

- 12. Unscrew nuts at exhaust pipe flanges (box wrench!), loosen clamp at tube supporting foot rests and remove exhaust pipes.

- 13. Unscrew nut of forward mounting screw of fuel tank and pull out screw (be careful not to lose spacers), unscrew lock nut and nut of rear fuel tank attachment and knock out screw lightly, until holding washers release the tongues of the tank, so that the tank can be raised (fig. 1/2). Fix tank in raised position by pushing under it a hammer or wooden wedge that rests on the

Fig. 1: Chassis after removal of engine

- 1 Oil hose put into filling hole

- 2 Fuel tank raised

- 3 Connecting hose

- 5 Clamp of generator cables

- 6 Clamp of guide tube of clutch cable

hand wheel of the steering damper. The connecting hose (fig. 1/3) permitts this movement, so there is no need of draining off the fuel. However, the engine is more easily accessible if the fuel tank is removed completely. For this purpose, drain off fuel and remove connecting hose (fig. 1/3).

- 14. Detach Bowden cable for oil pump from lever on upper frame support (fig. 1/4).

- 15. Unscrew lock nut of engine mounting screw (top, front), remove clamp of guide tube for clutch cable (fig. 1/6), pull guide tube out of crankcase.

- 16. Unscrew nuts of the engine mounting screws, pull out screws, remove both tongues of forward engine support.

- 17. Raise front part of engine block slightly so that rear attachment becomes free, lift engine out

Fig. 2: Engine block. right side view

- 1 Adjusting screw of

- 4 Gearbox sprocket 5 Stav bolt

- lutch lever 2 Armature of generator

- 3 Armature extractor

- 6 Nut of speedometer gear spindle bolt

- 7 Stud of crankcase

of frame. If the fuel tank has been removed. lift it out to the left: if the tank has only been raised, raise engine block a bit and remove it to the right (on account of the fuel cock).

DISMANTLING ENGINE (using the Engine Repair Stand No. 250 7017).

Cylinder head:

- 1 Unscrew spark plugs.

- 2. Unscrew cylinder head screws by means of box wrench (spec.tool No. 250.7015) (proceeding crosswise from outside to inside) and lift off cylinder head, taking care not to damage the gasket.

Cylinder and pistons

- 1. Unscrew nuts of cylinder base flange and lift off cylinder, taking care not to damage the pistons now falling forward against the crankcase with the connecting rod.

- 2. Mark the pistons, remove snapring from face of wrist pin by means of round-nose pliers, push out wrist pin, but be careful not to interchange them, and take off piston.

On no account should the skirt of the piston be cleaned by removing the oil carbon, even if it is quite black. The piston rings must move freely in their grooves. Do not remove piston rings without good reasons! Rings that are stuck and their grooves should be thoroughly cleaned of carbon. When removing the piston rings, do not damage or unduly stretch them. Do not interchange them and put them back into their correct position. Rings blackened along the greater

part of their circumference indicate their failure to provide a gas-tight fit and should be replaced by new rings.

Crankcase cover. left-hand side

- 1 IInscrew clamp screw of foot-operated gearchange lever and pull off gearchange lever

- 2. Unscrew camping holt of kickstarter lever, take off lever (do not lose thrust bolt with spring) and pull the hub of the kickstarter lever off its

- 3. Unscrew retaining screws of the left-hand crankcase cover and remove cover Do not damage the mating surfaces! Do not lose thrust washer of kickstarter shaft! When removing crankcase cover, the oil will

drain out, so place a fan underneath engine!

Clutch, gegrbox sprocket and generator

1. Unscrew the five collar nuts retaining the clutch springs, using a screw-driver with recess. For this purpose the spring retainers must be lifted from their retaining grooves by means of another screw-driver (see fig. 3). Remove clutch thrust plate and clutch discs. Take out compression nins and hall

Fig. 3: Unscrewing the collar nuts

- 2. Insert clutch hub holder (spec. tool No. 253.7014 consisting of some old clutch discs welded together) and chain sprocket clamp (Part No.253.7031). On the right side of engine block first unscrew stay bolt (fig. 2/5), then flatten lock disc of the retaining nut of the gearbox sprocket (fig. 2/4). Unscrew nut and remove sprocket with extractor tool (Part No. 250.7013). Remove cotter pin (Woodruff kev).

- 3. Remove carbon brusher of generator, unscrew mounting screws and remove base plate. Remove the armature (fig. 2/3) by means of the extractor screw (Part No. 22733) (fig. 2/3).

- 4. Clutch hub holder and chain sprocket clamp remain in position. Now flatten lock discs of the

clutch hub retaining nuts and of the engine sprocket. Unscrew nuts of the clutch hub with the socket wrench (fig. 4) and pull clutch hub from the shaft.

Fig. 4: Dismantling the clutch: Unscrewing the hub locking screw

Unscrew retaining nut of the engine sprocket and remove the sprocket with the extractor tool (Part No. as above) (fig. 5).

Fig. 5: Extracting the engine sprocket

Now engine sprocket, primary chain and clutch drum can be removed simultaneously. Remove bushing and thrust collar clutch drum as well as woodruff-key and spring washer from the crankshaft stub.

Starter

- 1. Remove dog clutch gear of kickstarter together with spring.

- 2. Remove snapring from intermediate gear and remove intermediate gear.

Oil pump

Remove safety wire, unscrew mounting bolts and take off pump.

Crankcase

- 1. Knock out both crankcase locating pins (fig. 2/7) with the aid of a drift pin.

- 2. Unscrew catch guide with catch and spring from the right-hand half of the crankcase.

- 3. Unfasten connecting screws and remove righthand half of crankcase. As the crankshaft runs in a roller bearing in the right-hand half of the crankcase, this half can be removed without the aid of a tool. Under no circumstances should the two halves of the crankcase be separated forcibly by means of a screw-driver or a similar tool. (Be careful of the 0,1 mm [0,00394 in.] spacers underneath the races of crankshaft roller bearing and mainshaft roller bearing!)

Gearbox and Crankshaft

- 1. Pull out mainshaft (fig. 12/1) and remove mainshaft gears. Take thrust collar and roller bearing out of race in the left-hand half of the crankcase.

- 2. Remove gearshift rail with gearshift yokes.

- 3. Remove countershaft (fig. 10/1) with gears and thrust collar for the right-hand roller bearing. Take roller bearing out of race in the right-hand half of the crankcase.

- 4. After dismantling the gearbox the crankshaft can be pressed out. (Do not knock it out!)

Gearchange

This part should not be dismantled except in case of breakage, of any part failing to function properly, or for the purpose of getting the faces of the housing smoothed for a better gas-tight fit.

- 1. Unscrew the countersunk screw (fig. 9/7), now shim plates and spring housing (fig. 9/3) and shift guide plate with curved gates (fig. 9/8) can be removed.

- 2. Dismantle snapring from interior gear shift lever and remove the latter with rachet wheel (fig. 8). Push out guide sleeve.

- 3. Unfasten countersunk screw (fig. 9/1) and nut (fig. 7/4) and remove supporting plate (fig. 7/1).

Speedometer drive

- 1. Unscrew nut (fig. 2/6) from speedometer gearspindle bolt which carries the driving helical gear and press out spindle bolt.

- 2. Remove securing pin from driven helical gear by means of a punch, then remove helical gear downwards and pull out shaft upwards. The bearing bush should not be pressed out. If this is really considered necessary, the securing pin must be bored out.

Wash all engine parts in kerosene or other solvent. The mating surfaces of crankcase and cover are cleaned with the aid of a scraper.

To examine the gearbox there is no need to dismonthe the left-hand grankcase cover and the clutch The oil need not be drained either.

While the engine is still hanging in the frame and the driving chain has not vet been removed the gearbox sprocket (brake rear wheel!) and the armature of the generator (engage gear and brake rear wheel!) are pulled off. The removed engine is laid on the left-hand case cover (all the oil runs into the clutch space), then the crankcase pins are knocked out and the crankcase connecting screws are unfastened. After removal of the right-hand half of the crankcase the gearbox is freely accessihle

For removing the kickstarter gears or the oil nump. as also for exchanging the front (engine-to-clutch) chain, the engine can be left in the frame. After dismantling the left-hand foot rest, the clutch lever and the kickstarter lever, the left-hand crankcase cover is removed. (Place a vessel underneath it to collect the oil flowing out.) Now the clutch is dismantled and removed together with the engine sprocket. Then the front chain can be exchanged, or the kickstarter gears or the oil nump can be removed. The oil pump should not be dismantled except for good reasons.

Pressing out of Bearings

When pressing out defective bearings, proceed as follows

To avoid damaging the bearing seat through the processes of pressing them out and in, it is advisable to warm the crankcase to about 140° F. (about 60° C.), so that it feels hot to your hand.

(Use of Electric Hot Plate: when using an open flame place a flat metal plate between the flame and the crankcase.)

a) Left-hand crankcase

- 1 Knock out worm drive of oil pump and exterior small ball bearing by means of a mandrol

- 2. Press out seal ring and large interior ball bearing in the direction towards the crankcase with a mandrel whose diameter is slightly smaller than that of seal ring.

b) Right-hand crankcase

For pressing out the roller bearing employ special tool No. 250.7011.2 (fig. 6). The right-hand seal ring is pressed out only if defective.

Seal rinas

With two-stroke engines a proper gas-tight seal of the crankcase is indispensable to efficient engine performance. The seals used are rings made of oilproof rubber. The part adjoining the shaft must have a sharp edge. The tension of the spiral spring must be such as to make the ring fit snugly and tigthly along its entire circumference. The shaft itself must be perfectly smooth, without play, and must not knock. For exchanging the seal rings as

well as the bearings a press with suitable stamps and base-parts has to be used. When fitting these rings care must be taken not to tear their edges.

Fig 6. Pressing out the roller bearing

ENGINE REASSEMBLING

Bearinas

Test bearing for easy running lack of axial play and firm seating on shaft and in the housing. Bad fit on the shaft can be overcome by fitting a new bearing. If the seats in the crankcase have been damaged, a new crankcase will have to be installed. a) Left-hand crankcase

-

- 1. Press in large interior ball bearing from inside

- 2. Press in seal ring from outside, its sealing edge facing outward. The worm drive of the oil nump and the small exterior ball bearing are not assembled until the two halves of the crankcase have been screwed together

b) Right-hand crankcase

- 1. Press in right-hand seal ring from inside with its sealing edge facing inward.

- 2. Press in first ball-bearing and then roller bearing from inside.

- c) Crankshaft

Before pressing the crankshaft with its long journal into the left-hand half of the crankcase, heat crankcase together with bearing as described, then oil the ball bearing. After the crankshaft has been pressed in, its axial play (0.00787 in.) has to be checked by means of a crankshaft distance gauge in the following way: Place the distance gauge (Part No. 253.1032.5 L 1) on the level surface of the left-hand crankcase and test if the

measuring face marked (+) (35.5) touches the shoulder oft the crankweb without play. If there is still some play eliminate it by inserting 0.00394 in thick spacers. Should it prove necessarv to use four or more spacers, the crankshaft had better be removed agin an half the snagers inserted at the long shaft journal so that the crankshaft remains well centered The measuring should be caried out without the gasket.

Fig 6a. Distance gauge for crankshaft