Sears 788.94360 Assembly, Operating Instructions And Parts List

ASSEMBLY.

OPE'RATING

INSTRUCTIONS

AND

PARTS LIST

FOR

SEARS

MOTOR

SCOOTER

------

MODEL NUMBER

788.94360-'----_

The

Model

Number

will

be

found

on a

plate

fastened to chassis

under

the

fuel

cock.

Always

mention

the

Model

Number

in all

correspondence

regurding

the

SEARS

MOTORSCOOTER

or

when

ordering

repair parts.

,----

HOW

TO ORDER REPAIR PARTS

------,

All

parts listed herein may be

ordered

through

SEARS,

ROEBUCK

AND

CO. or SIMPSONS -

SEARS

LIMITED.

When

ordering

spare

parts

by

mail

from

the mail.

order

house

which

serves the ter-

ritory

in

which

you live, selling prices

will

be'

furnished

on

request

or

parts

will

be

shipped

at

prevailing

prices and

you

will

be

billed

accordingly.

WHEN ORDERING

REPAIR

PARTS,

ALWAYS GIVE

THE

FOLLOW-

ING

INFORMATION

AS

SHOWN IN

THIS

LIST:

1. The

PART

NUMBER.

3.

The MODEL NUMBER

788.94360

2. The

PART

NAME. 4. The

NAME

of

item-Motor

scooter.

,.----

COAST TO COAST

NATION-WIDE

-----,

SERVICE

FROM

SEARS

FOR

YOUR

SEARS

MOTOR

SCOOTER

SEARS,

ROEBUCK

AND

CO. and

SIMPSONS

-

SEARS

LIMITED in

Canada back

up

your

investment

with

quick,

expert

mechanical

service and

genuine

SEARS

re-

placement

parts.

If

and

when

you need repairs

or

service,

calion

us

to

protect

your

investment

in this fine piece

of

equipment.

f •

127A7

SEARS.

ROEBUCK

AND

CO

..

U.S.A.

IN

CANADA.

SIMPSONS

-

SEA~S

LIMITED

INTRODUCTION

This

modelofmotor

scooter

hasamodern

type

of

engine

in

which

the

distribution

is

realised

by

the

crankshaft

(rotary

valve

distribution);

furthe-

moreit'is

provided

with

a 4

speed

gear

boxinor-

der

to runinexcellent

condition

by

climbing

the

most

various

slopes

andtotake

the

greatest

pos-

sible

advantage

of

its pick -

up

qualities.

The

carburettor,

installed

on

the

crankcase,

is

in

direct

communication

with

the

pre-compres-

sion

chamber

in

corrispondence

to

the

external

diameter

of

one

of

the

crankshaft

flywheels

(see

fig.

10):

the

periphery

of

the

flywheel

rotates

very

close to

the

crankcase,

without

touching

it;

a

portioninthe

periphery

of

said

webisground

off,

and

controls

the

fuel flow to

the

pre-com-

pression

chamber,

thus

acting as a

rotary

valve.

The recess

on

the

web

periphery

has

been

shaped

in

suchaway

as to

give

the

maximum

volumetric

efficiency,

thus

obtaining

an

asymme-

trical

distribution

diagram.

It

should

be

noted

that

crankweb

and

crank-

case

are

kept

gas

tight

by

the

film

of

oil

which

rorms

between

them

and

not

by

direct

contact;

in this

way

the

system

is

not

subjec'

to

wear

by

friction, as

is

usually

the

case

with

similar

devices.

The

intake

pipeisvery

short;

itistherefore

only

the

carburettor

which

slows

down

the

flow

or

fresh

chargetothe

engine.

The

advantages

ofacorrect

reeding

system

are

therefore

clear;

more

poweratlow

revs,

and

greater

engine

elasticity. The

intake

pipe

leads

into

the

pre-compression

chamber

and

the

fresh

charge

directly

contacts

the

con. rod

big

end;

in

this

way

the

bearings

are

so efficiently

lubricated

as to

permitareductionofthe

percentage

oil con-

ten

in

the

gasoline

(2%).

The

improvement

which

the

rotary

alve

bringstothe

thermo-dynamic

performance

of

the

e

gine

can

be

appreciated

by

considering

the

at-

ness

of

the

power

'curve;

this,

asiswell

know,

renders

the

engine

capable

or

functioning

over

a

wide

rpm

range

and

of

adjusting

itsel

aU'oma-

tically,

with

slight

variation

of

speed,

'0

all

forms

or

resistance

which

the

scooter

must

ove

come

(head

wind,

gradients

etc.).

The

proverbial

climbing

ability

0'

this

motor

scooter

is

enhanced

in

this

model.

All

gradients

normally

encountered

on

main

roads

can

easily

be

climbed

in

4th

gear,

even

with

two

people

on

board;

the

most

various

slopes

can

be

climbed

at

speed

in

3rd

or

2nd

gear,

while

the

st

gear

gives

initial

acceleration

and

is

particulary

userul

on

bad

surfaces

and

side

roads.

Another

advan

age

0'

the

rotary

valveistha

eliminates

back

pressure,

i.

e.

prevents

some

of

the

fresh

fuel

from

being

pushed

back

from

he

pre-compression

chamber

towards

the

carbu-

rettor

and

wasted,

at

the

beginning

of

the

down-

wardstroke

of

the

piston.

Engine

performance

is

also

improved

by

the

use

ofaspherical

headed

piston

and

a

combu-

stion

chamber

on

the

cylinder

head

of

a special

form

to

give

to

higher

turbulence,

thus

resulting

in

higher

compression

ratio

and

thence

increase

in

both

specific

power

and

out-pu·.

In

conclusion,

for

easing

star

ing

the

carbu-

rettor

has

been

equiped

withastarter

jet

and

is

or

he

the

type

mounted

on

automobiles.

It

is

housedinthe

air

cleaner,

hasaplate-shaped

slide

valve

and

immersed

jets:

this

has

reduced

ruel

consumption

and

improved

the

general

performan-

ce

of

the

engine.

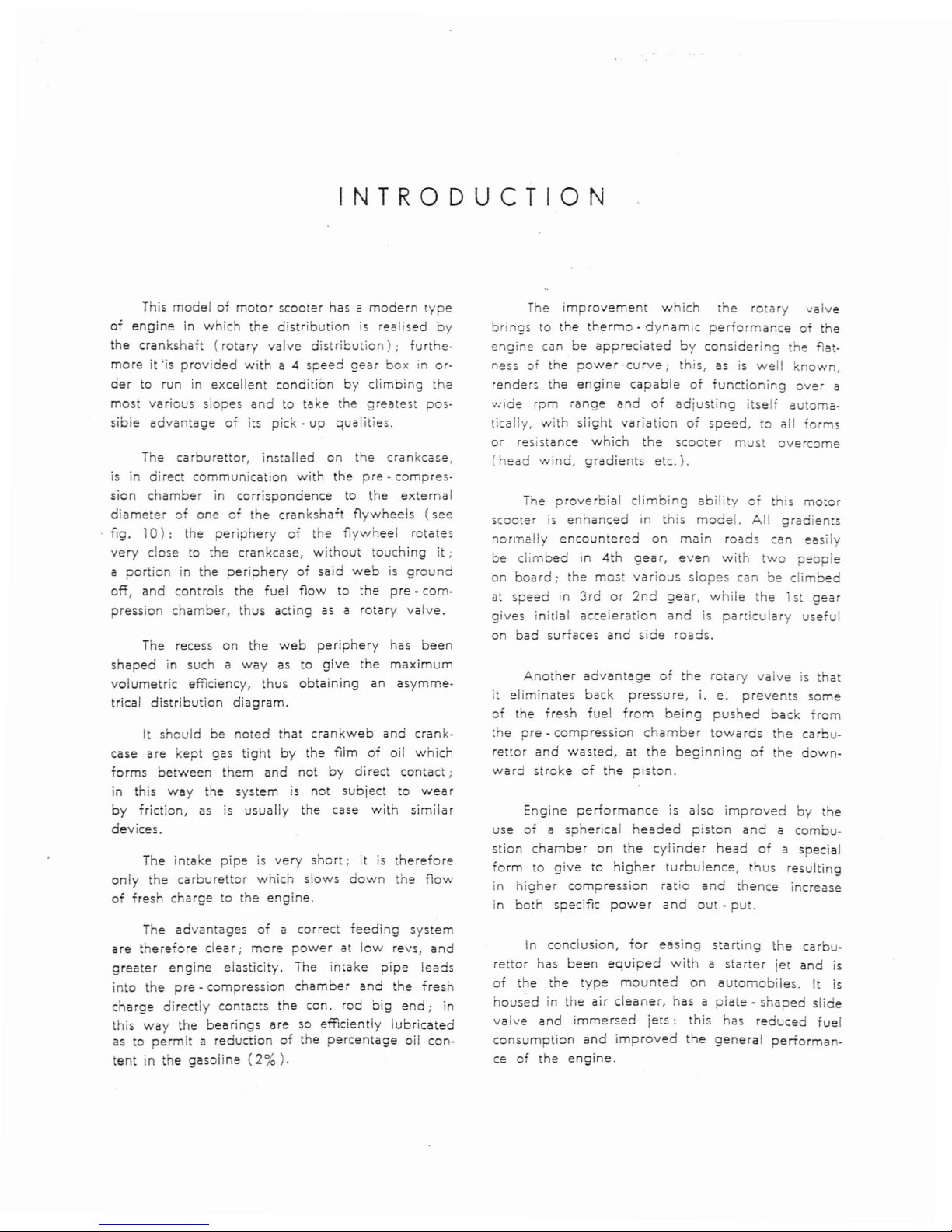

la<:ltion01Irlm.

Number

Serial

numbers

are

preceded

by

preTixas,

VlB1T,

lor

frame;

VlB

1 M, for

engine.

serial

number

Fig. 2 -

Fig. 1 . Sears Motor

Scooler

WARNING

In

order

to

~eep

I'0'.H

scooter

in

perfect

running

condition

und

no to

void

the

guarantee,

always

have

your

machine

repaired

et a

Sears,

Roebuck

and

Co.

Store.

Special

care

shouldbetaken

with

regardtothe

fuel

mixture

which

should

be

regular

gasoline

and

oil

of

the

make,

grade

and

in

the

amount

prescribed

in this

booklet.

Ethyl

gasoline

should

never

be

used.

Do

not

use

Allstate

compounded

motor

oil

or

other

Praemium

Heavy

Duty Oil

with

detergents.

The

inexperienced

operator

should

exercise

caution

in

applying

front

wheel

brake,

to

avoid

locking.

1. Gear chllnge

tWtStgrip

with

clutch

control

lever·2.Front

brake

lever.3.

Throttle con·

trol

grip.4.

Light

and

dim-

mer

switch~5.

Front

br~ke

jaws.-6.

Rear

breepedal

-

7.

Kickstarter -8.Geer

shil.

ter-9.

Reer

brake

iaws

..

10.

Clute -

11.

Carburettor,

air

cleaner·

12.

Starter

push

pull

rod·

13.

Fuel cock.

14.

Button

to

operate

for

pivoting

the

saddle

unit.

Fig. 3 -

Control.

ofS••

n

Scooter

I:

~

.1

~

....--:

\)

j

I

l

I

t12)

//

-")

I,

---~.~--------

~

..

,.

\.:..

_

.....

\

--

3 -

---------

//

(

.

__

,21

--

------.~

......

,\

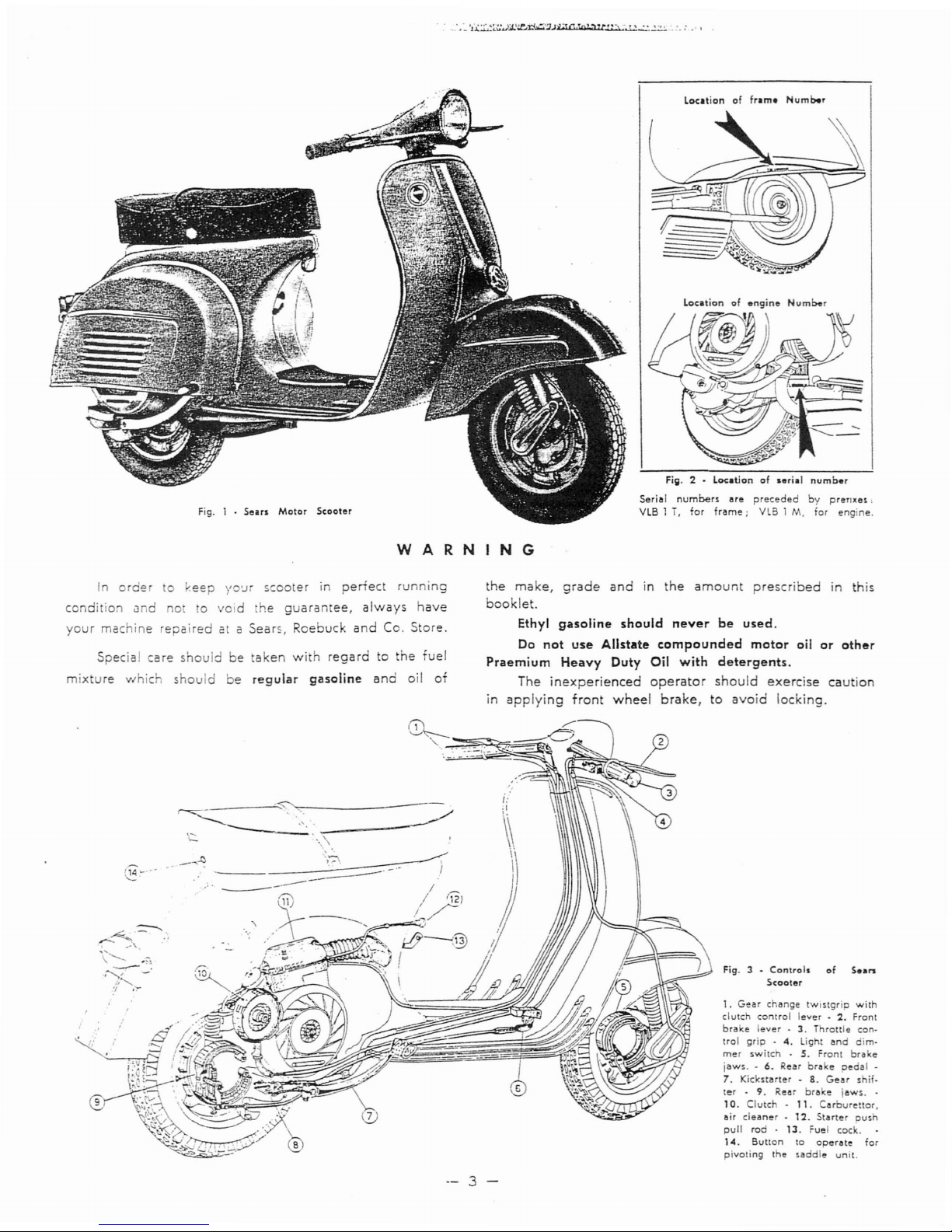

Fig. 4 •

Engine

inst.lI.tion

and

sUlpensionl.

1.

Steering

column

and

front

suspension·

2.

Engine

3.

Crankcase

half,

clutch

side,

wit

swinging

arm.4.

Rear

suspension

spring

with

hy.

draulic

damper.

MAIN

SPECIFICATIONS

Transmission.

Directly

from

engine

to

rear

wheel

through

clutch,

cushion

drive

and

gear

box.

Starting.-By

means

of

kickstarter,

right

hand

side

of

scooter.

Fuel

consumption:

(Gasoline.

oil

mixture)

107

miles

per

gal.

Max.

speed

58.5

m.p.h.

Wheel

base

47.2

in.

Max.

width

on

handlebars

26.3

in.

Max.

length

of

the

scooter

69.6

in.

Max.

height

41

in.

Min.

height

of

floorboard

8.7

in.

Turning

circ:le

55

in.

Weight

(unladen)

195

Ibs.

to

to

to

to

1.

Coil in

flywheel

magneto

_

2.

H.i.externat

coil -3.Ro.

tor

cam·4.Breaker.S.Con-

den.er•6.

Sparkplug.7.

En.

gine

cut·

outanswitch.

Fig. 5 •

Ignition

diagram

transmission

ratios:

14.46

10.28

7.31

5.36

J

;'1"

\

5"

Engine

to

wheel

Fi

rst

Second

Third

Fourth

J

t;<

coil.

Clutch.-Wet

type;

multi

plate,

with

facings

of

cork

composition

applied

to

the

driving

discs.

Ignition.-By

flywheel

magneto

and

external

ignition

Gear

box.

- 4 -

speed

drive

with

mesh

gears

in

oil

bath.

Its

two-cable

control

is

coupled

with

that

of

the

clutch,

on

left

hand

side

of

handlebars.

cc.

(8.87

cu.

in)

mm.

(2.24

in.)

mm.

(2.24

in.)

145.45

57

57

7

HP

7.5:

1

Frame..Of

pressed

and

spot-welded

steel

sheet,

with

stream-lined

monocoque-type

structu

re.

Suspension.

- Both

front

and

rear

wheel:

coil

spring

and

hydraulic

shock

absorber.

Engine.-Two-stroke,

flat

cast

iron

cylinder

and

cast

aluminium

alloy

cylinder

head.

Cooling

effected

by

centrifugal

fan

which

is

embodied

in

the

flywheel

of

the

magneto.

Displacement

Bore

Stroke

Effective

powerat5000

rpm

Compression

ratio

-4-

Lubrication. -Bythe

oil in

rue

I

ixture

for

pis

'on,

cylinder,

wrist

pi

,co.

rod,

crankshaft,

main

bea-

rings. Bot clu c

and

gear

box

o

",ateinoil

bat

Carburettor.-With

float-cham-

ber

(see

fig.11);

air

cleaner

moun-

tedonthe

engine.

Air

goestothe

carburettor

through

a

large

inlet

tube

andasilencing

chamber

with

~"ter.

Model0carburettor:

DeWOr-

to

SI

20/i7

D -

Ven

uri

17

mm.

(

".67)

- Main jet

102/100

(0".

04

) - Idler jet

42/100

(0".0163)

- Air-vent for

main

jet

160/100

(0"

.063)-Mixer

type

E 1. - Air

ventoidler

jet

160/100

(0"

.063)

.

Spray

nozzle

200/100

(0"

.07B8)

-

Starter

jet

60/100

(0".0236)

Floa

chamber

fuel

level

20.5

mm.

(0."807==0."039).

Feeding.

- Fuel

feed

to

he

carburettor

is

provided

for

by

gravi'y

(see

fig.

1)

with

gasoline

- oil

mixture.

Fuel

tank.

- Total

capacity:

2,03

gals.;

Reserve:

VI

,'3

gal.;

Three-way

cock:«open»

- «

closed»

- «

reserve

».

Muffier. -

Expansion

and

absorption

combined

type.

Handlebars.-Pressure

die

cas

in

ligh

alloy

and

desig

ed

so as 0

house

both

trapezoidal

shaped

head-

lamp

a d

~peedo

eter.

All

he

con

rei

cables

and

elec-

trical

wires

to

is

group

are

concealed

herein.

(See

Tlg.

3).

Steering

column.-The

steering

column

bears

the

ha

dlbears,

clamped

on

its

top

end,

and

the

front

wheel

swinging

hub,

pivoted

at its

bottom

end

throughastub

axle.

Lighting

and

horn..By

flywheel

magneto,

feeding

bot

ead

lamp(wo-bea

), tail

lamp,

horn

and

stop

light

(see

fig.

9).

Brakes. -

Expanding

type.

Font

brake:

co

trol

lever

on

right

hand

side

of

a

dlebars.

REar

brake:

con

rol

pedal

on

right

hand

side

of

floo

board.

The

rear

brake

jaws

are

hinged

on

indepen-

detpivots.

Wheels.-Of

pressed

steel

sheet,

interchangeable

and

easily

removable,

since

they

are

assembled

in

an

auto-

mobile

- like

system.

Tires:

dia.

3.5x10

in.

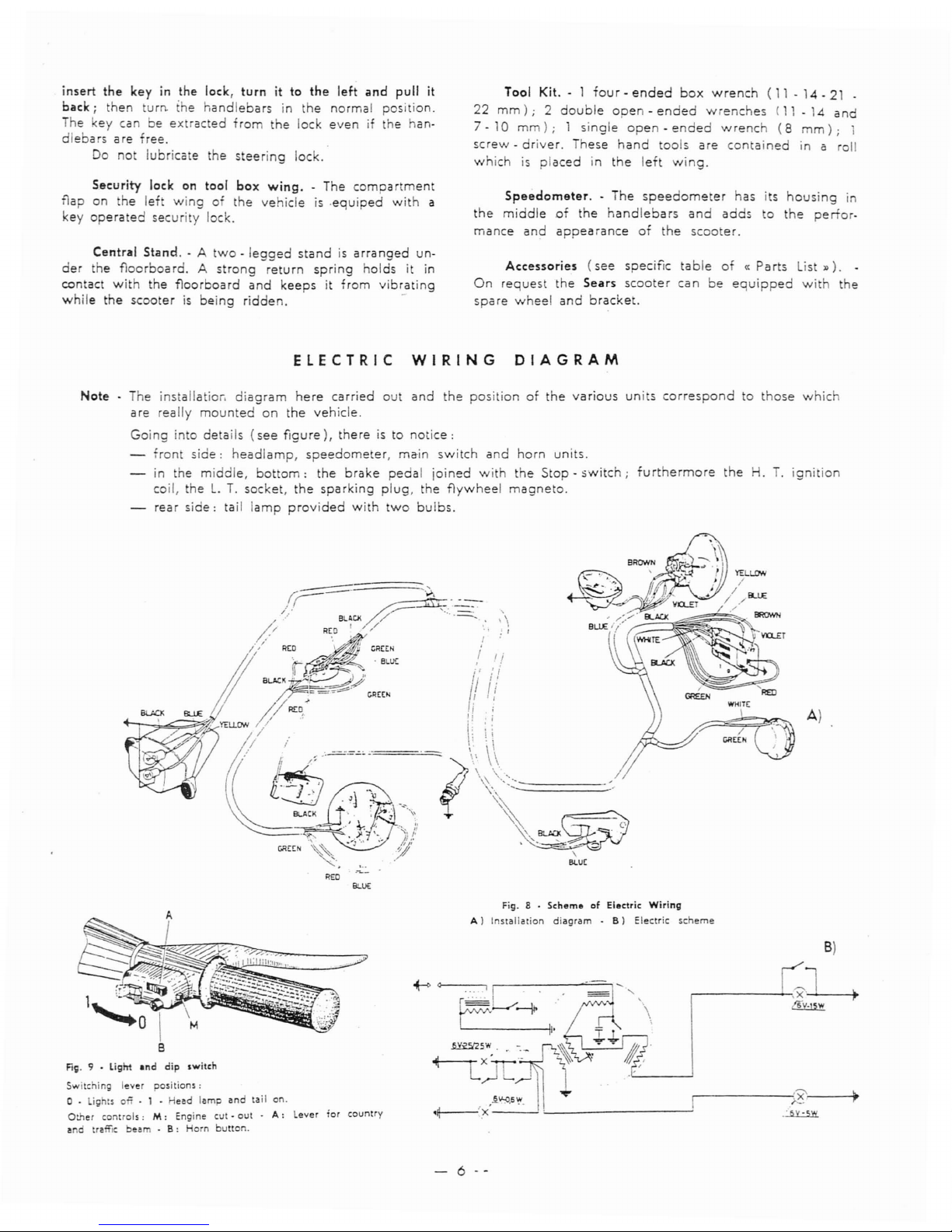

Steering

Lock. - A

suitable

security

lockisarranged

o e fra e, nEa

the

handlebars.

Turn

the

handlebars

to

e left,

then

rotate

the

key

and

push

inwards,

so

tha

i' t rusts

the

sliding

bar

against

the

steering

column.

To

ease

the

insertion

of

t e

sliding

bar

into

the

hole

0'

t e

steering

column,

slightly

turn

the

handlebars.

from

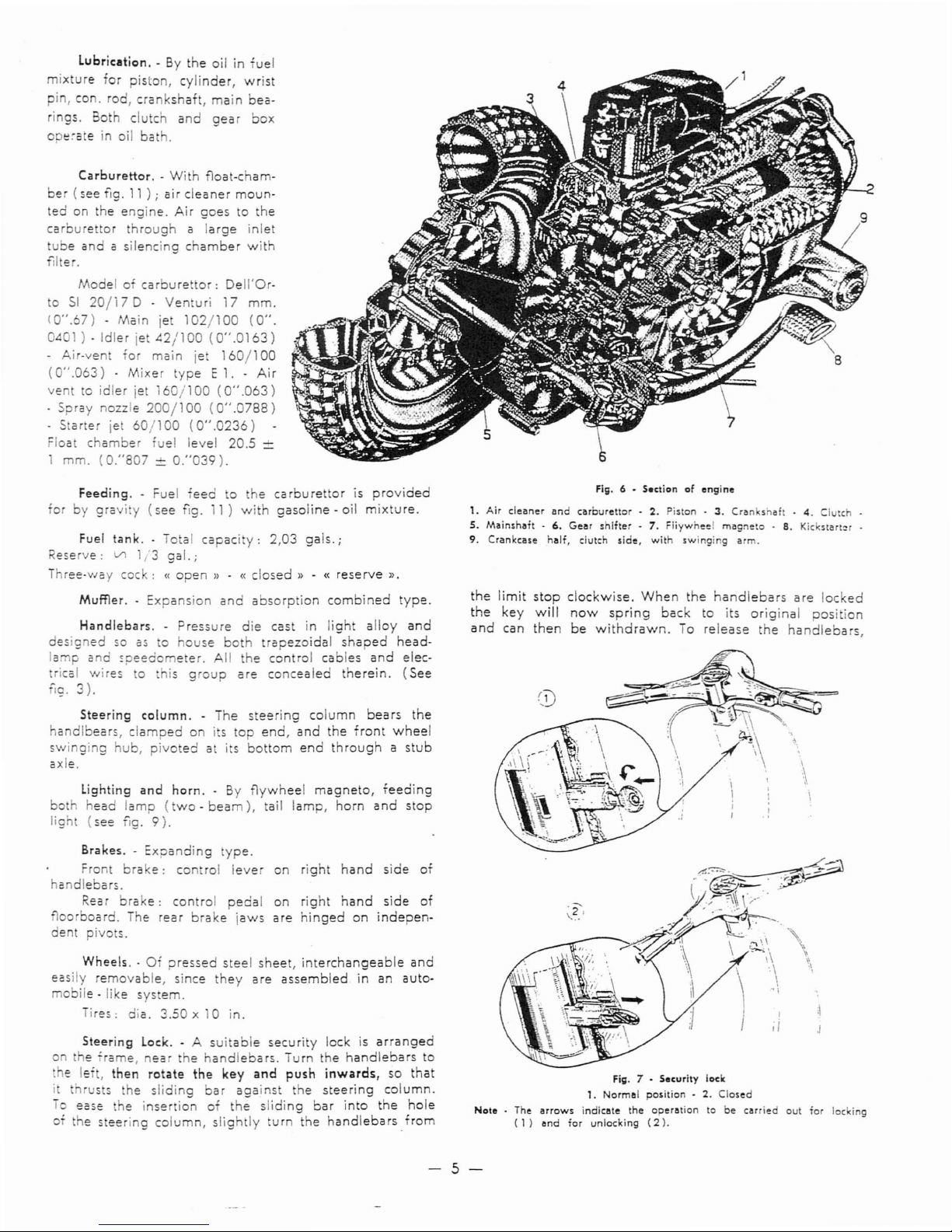

Fill. 6 -

Sectionofengine

1. Air

cleaner

and

carburettor-2.

Piston -3.Crankshaft.4.

Clutch

S.

Mainshaft-6.

Gear

shifter-7.

Fliywheel

magneto.8.

Kickstart~r

9.

Crankcase

half,

clutch

side,

with

swinging

arm.

the

limit

stop

clockwise.

When

the

handlebars

are

locked

the

key

will

now

spring

back

to

its

original

posi

ion

and

can

then

be

withdrawn.

To

release

the

handlebars,

Fill. 7 -

Security

lock

1.

Normal

position-2.

Closed

Note

. The

arrows

indicate

the

operationtobe

carried

out

for

locking

(

1)

and

for

unlocking

(2).

-5-

insert

the

keyinthe

lock,

turn

it to

the

left

and

pull

it

back i

then

turn. the

handlebars

in

the

normal position.

The key

canbeex

racted

from

the

lock

evenifthe han-

dlebars

are

free.

Do

no lubricate

the

steering

lock.

Security lock on tool

box

wing.

- The

compartment

flap

on

the

left

wingofthe

vehicleis.equiped

with

a

key

operated

security lock.

Central

Stand.

- A

two-legged

standisarra

nged

un-

der

the

floorboard.

A

strong

return

spring

holdsitin

contact

with

the

floorboard

and

keepsitfrom

vibrating

while

the

scooterisbeing

ridden.

-

Tool

KiL-1

four-ended

box

wrench(1-14-21-

22

mm);

2

double

open-ended

wrenches

(11 - 14

and

7·

10

mm);

1

single

open·

ended

wrench

(8

mm);

1

screw-driver.

These

hand

tools

are

contained

in a roll

whichisplaced

in

the

left

wing.

Speedometer.

- The

speedometer

has

its

housing

in

the

middle

of

the

handlebars

and

adds

to

the

perfor.

mance

and

appearance

of

the

scooter.

Accessories

(see

specific

table

of«Parts

ist

»).

-

On

request

the

Sears

scooter

can

be

equipped

with

the

spare

wheel

and

bracket.

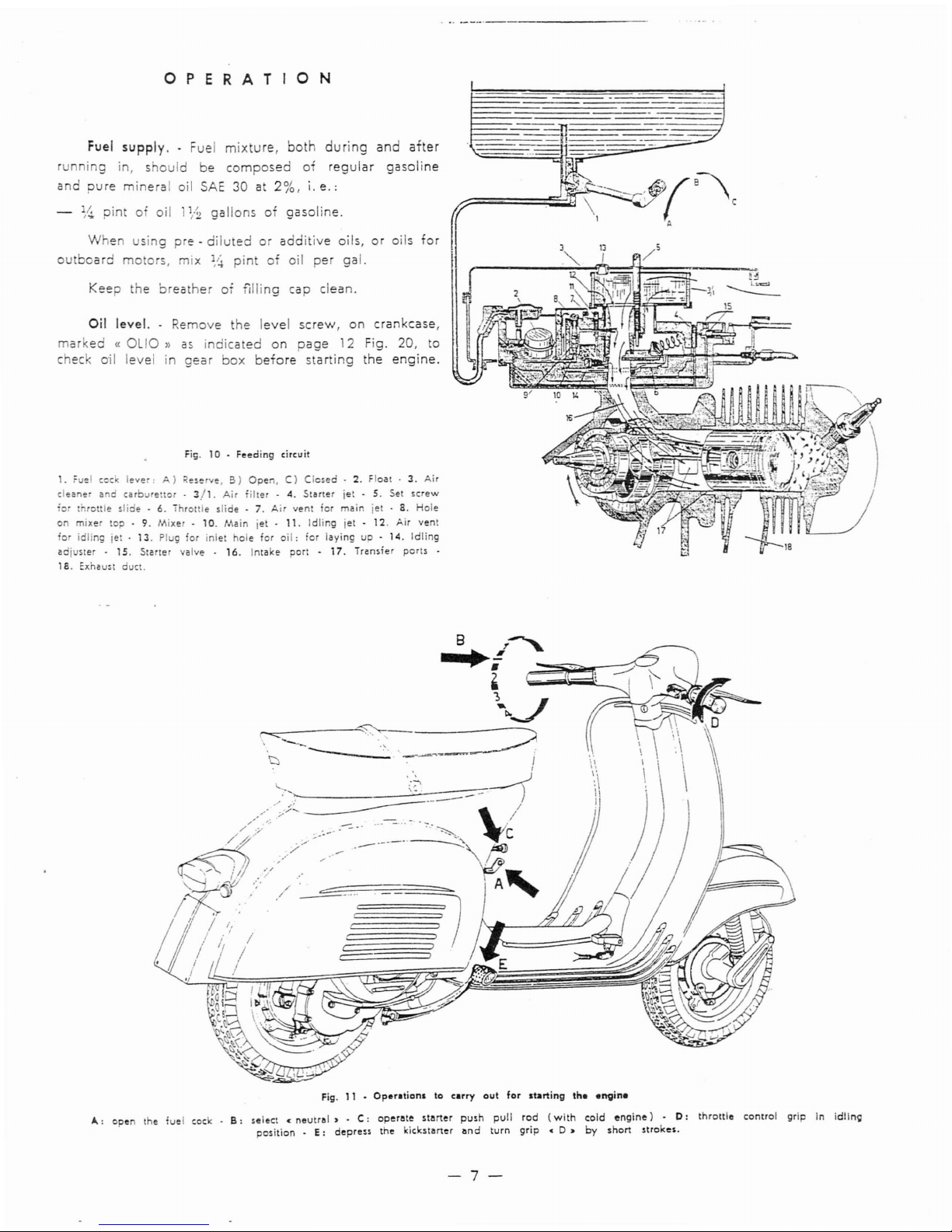

ELECTRIC

WIRING

DIAGRAM

Note·

he installatior,

diagram

here

carried

out

and

the

positionofthe

various

units

correspond

to

those

which

are

really

mounted

on

the

vehicle.

Going

in0details

(see

figure),

thereisto

notice:

fron

side:

headlamp,

speedometer,

main

switch

and

horn

units.

in

the

middle,

bottom:

the

brake

pedal

joined

with

the

Stop·

switch;

furthermore

the

H.T.ignition

coil,

thel.T.

socket,

the

sparking

plug,

the

flywheel

magneto.

rear

side:

tail

lamp

provided

with

two

bulbs.

A)

REO

eu)€

Fill. 9 • ligftt

Ind

dip

switch

Switching

I~ver

positions:

o .

lightson- 1 -

Heed

lamp

and

tail

on.

Other

controls:

M:

Enoine

cut·

out-A:

lever

for

country

end

traffic

beam•B:

Horn

button.

Fig_

8 •

SchemeofElectric

Wiring

A)

Installation

diagram-B)

Electric

scheme

B)

+-0

.,.,

--.-.-......,.'

r------~=..,

r----------:2·---·~

'-------------'

.:u:.s.w.

- 6

--

OPERATION

Fuel

supply..Fuel

mixture,

both

during

and

after

r n

ing

in,

should

be

composed

of

regular

gasoline

and

pure

mineral

oil

SAE

30 at

2%,

i.

e.:

%

pintofoil

1

1

,.2

gallonsofgasoline.

When

using

pre·

dilutedoradditive

oils,oroils

for

o

board

mo

ors,

mix

%

pint

of

oil

per

gal.

Keep

the

brea

her

OT

filling

cap clean.

Oil

level.

. Remove the

level

screw,

on

crankcase,

mar.

ed«OLIO»

as

indicated

on

page

12 Fig. 20,

to

chec o'il

levelingear

box

before

starting

the

engine.

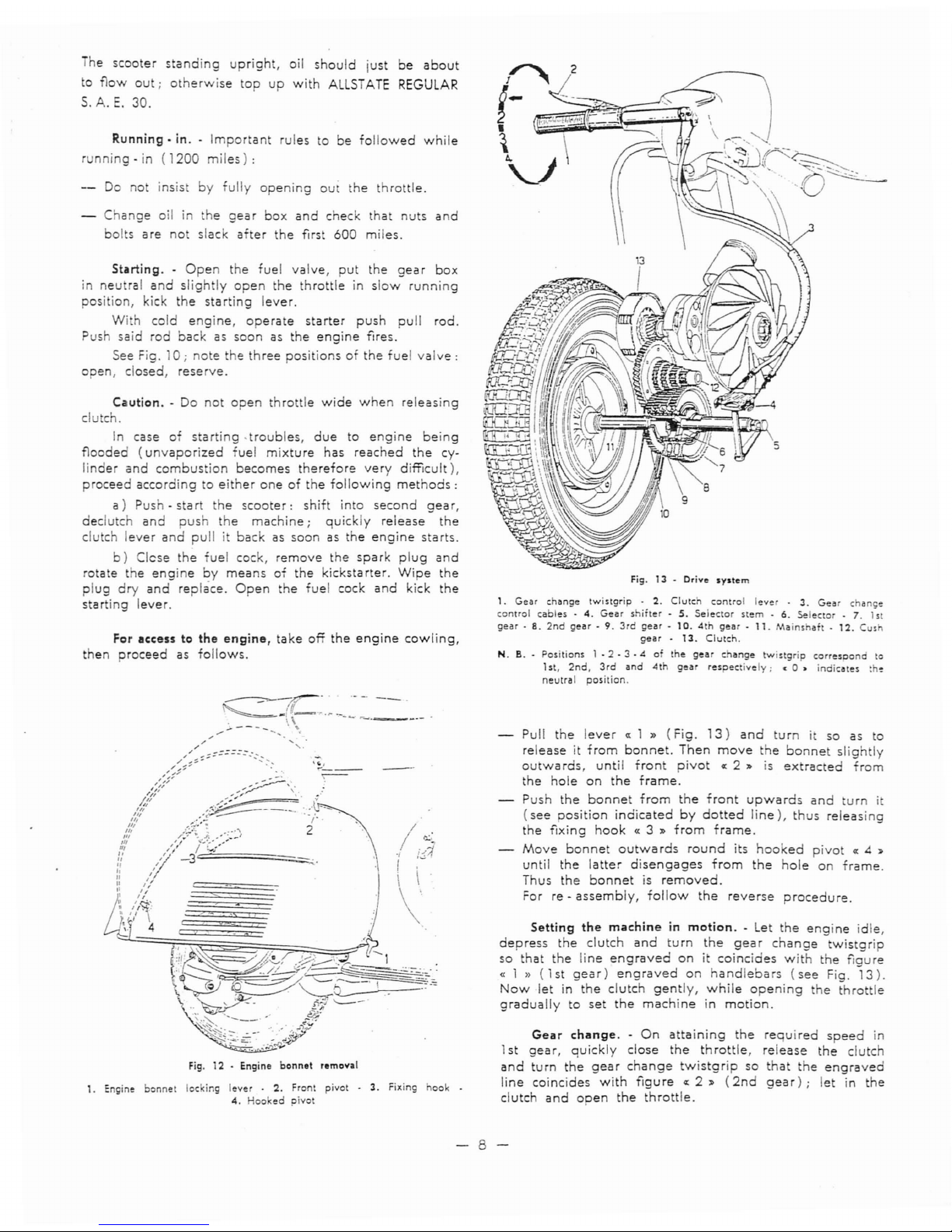

Fig.10.

Feeding

circuit

1.

Fu~1

cock

lever:A)<eserve,

B)

Open,C)Closed·2.Float·3.Air

c1eane

and

carburenor.3/1.

Air

'ilter-4.

Stoner

iet - 5. Set

screw

'or

thronle

slide·6.Throltle

slide-7.

Air

ven

for moin iel .8.Hole

on

mixer

top'9.Mixer·

10.

Main

iet -

11.

Idling iet .

12.

Air

vent

for

idling iet .

13.

Plug

ior

inlet

hole

for

oil:

ror

layingup-

14.

Idling

odj Sler -

15.

Stoner

valve -

16.

Intake

port·

17.

Transfer

ports·

1

a.

Exhaust duct.

.....

~-..-

OW

------

.-

3-

-'

-'

.----=-_~!

B

•

Fig. 11 •

Operotionltocarry

out

for

starting

the

."Vin.

A:

open

the

fuel

cock _B:select<neutrol•.C:

ope

rote

storter

push

pull

rod

(with

cold

engine)•D:

throttle

control

grip In

idling

position.E:

depre..the

kickstorter

ond

turn

grip

<

D.

by

short

stroke

•.

-7-

he

scooter

standing

upright,

oil

should

just

be

about

to

flow

out;

otherwise

top

up

with

ALLSTATE

REGULAR

S.A.E.

30.

Running.

in. -

Important

rulestobe

followed

while

running-in

(1200

miles):

Do

not insist

by

fully

opening

out

the

throttle.

Change

oil in

the

gear

box

and

check

that

nuts

and

bolts

are

not

slack

after

the

first

600

miles.

Starting.-Open

the

fuel

valve,

put

the

gear

box

in

neutral

and

slightly

open

the

throttleinslow

running

posi ion, kick

the

starting

lever.

With

cold

engine,

operate

starter

push

pull

rod.

Push

said

rod

backassoonasthe

engine

fires.

See

Fig.

10;

note

the

three

positionsofthe

fuel

valve:

open,

closed,

reserve.

Caution.

- Do

not

open

throttle

wide

when

releasing

clutch.

In

case

of

starting

.troubles,

due

to

engine

being

flooded

(unvaporized

fuel

mixture

has

reached

the

cy-

linder

and

combustion

becomes

therefore

very

difficult),

proceed

accordingtoeither

oneofthe

following

methods:

a)

Push-start

the

scooter:

shift

into

second

gear,

declutch

and

push

the

machine;

quickly

release

the

clutch

lever

and

pullitbackassoonasthe

engine

starts.

b)

Clese

the

'uel

cock,

remove

the

spark

plug

and

rotate

the

engine

by

means

of

the

kickstarter.

Wipe

the

plug

dry

and

replace.

Open

the

fuel

cock

and

kick

the

starting

lever.

For

ac:c:esstothe

engine,

take

ofT

the

engine

cowling,

then

proceed

as

follows.

.~~--

Fig.

12 • Engine

bonnet

removal

1. Engine

bonnet

locking

lever.2.

Front pivot .3.Fixing hook .

4.

Hooked

pivot

Fig.13.

Drive

system

1.

Gear

change

twistgrip.2.

Clutch

control

lever .3.Ge..change

control

cables-4.

Gear

shifter

-S.Selector

stem-6.

Selector.

7. 1st

gear

- 8.

2nd

gear-9.

3rdge..-10.

4th

gear·

11.

Mainshal.12.

Cush

gear-13.

Clutch.

N. B. - Positions

1·2

- 3

.401the

gear

change

twistgrip

corresoond

to

1st.

2nd,

3rd

and

4th

gear

respec

ively;•0»

indicates

,he

neutral

position.

Pull

the

levera:1 »

(Fig.

13)

and

turnitso

as

to

releaseitfrom

bonnet.

Then

move

the

bonnet

slightly

outwards,

until

front

pivota:2"

is

extracted

from

the

hole

on

the

frame.

Push

the

bonnet

from

the

front

upwards

and

turn

it

(see

position

indicated

by

dotted

line),

thus

releasing

the

fixing

hook

« 3 "

from

frame.

Move

bonnet

outwards

round

its

hooked

pivota:4 "

until

the

latter

disengages

from

the

hole

on

frame.

Thus

the

bonnet

is

removed.

For re -

assembly,

follow

the

reverse

procedure.

Setting

the

machineinmotion.

- Let

the

engine

idle,

depress

the

clutch

and

turn

the

gear

change

twistgrip

so

that

the

line

engraved

onicoincides

with

the

fiaure

«

1»

(1st

gear)

engraved

on

handlebars

(see

Fig.

13).

Now

let in

the

clutch

gently,

while

opening

the

throttle

gradually

to

set

the

machine

in

motion.

Gear

change.-On

attaining

the

required

speed

in

1st

gear,

quickly

close

the

throttle,

release

the

clutch

and

turn

the

gear

change

twistgrip

so

that

the

engraved

line

coincides

with

figurea:2"

(2nd

gear);

let in

the

clutch

and

open

the

throttle.

-8-

Repeat his

procedure

for

changing

into

3rd

and

4th

gear

and

for

changing

down.

See

he

dr:'/e

$ystem

on

Fig. 13.

hen

you

reduce

he

speedofyour

machine,

change

down

withou

elary'o

avoid

irregular

engine

running

and

stallinga'low

revs.

Do

no

turn

the

gear

change

wistgrip

while

the

e

gineisno

running.

As

soon

as

gear

change

troubles

arise,

particularly

w e

he

con rol

becomes

ha rd,

customers

should

have

eir

machines

adjusted

byaSears

Store.

Slow

running

adjustment.

- 0

hand

toolisreauir-

ed

'or

his

job.

Idling revs

can

be

raised

or

red~ced

respectively

by

simply

tightening

or

slac

ening

the

knurled

slot

ed

screw

on air

cleaner

steel

sheet

cover

(No.5,

Fig.

0).

This

screw

controls

the

throttle

slide

valve.

The

adjuster

screw

for

the

throttre

control

cable

is

installed

on

the

air

cleaner

case.

This

screw

is

to

be

reset

only

when

necessary

and

while

dismantling

and

e -

assembling.

Opposite

to

said

adjuster

screw

there

is

on

the

air

cleaner

caseaplugged

hole

for

access

to

~--=--v

. . / .

i'~-/'

I

Fig.14.

Dismantling

the

front

wheel.

a

ohe

screw

(sprigloaded);

see

Fig.

10

No.

14.

This

screw

controls

the

flow

of

carburated

air

through

he

duc

from

the

idling

jet,

and

consequently

the

idling

evs.

We

recommend

that

customers

refrain

from

re-

setti g this

screw

unless

absolutely

necessary

or

during

dismantling

and

re -

assembling

operations

that

should,

anyway,

be

entrusted

to a

Sears

Store.

Stopping

the

engine.-Push

the

earthing

button.

This will

leave

the

cylinder

fulloffuel

vapours,

and

the

next start

will

be

much

easier.

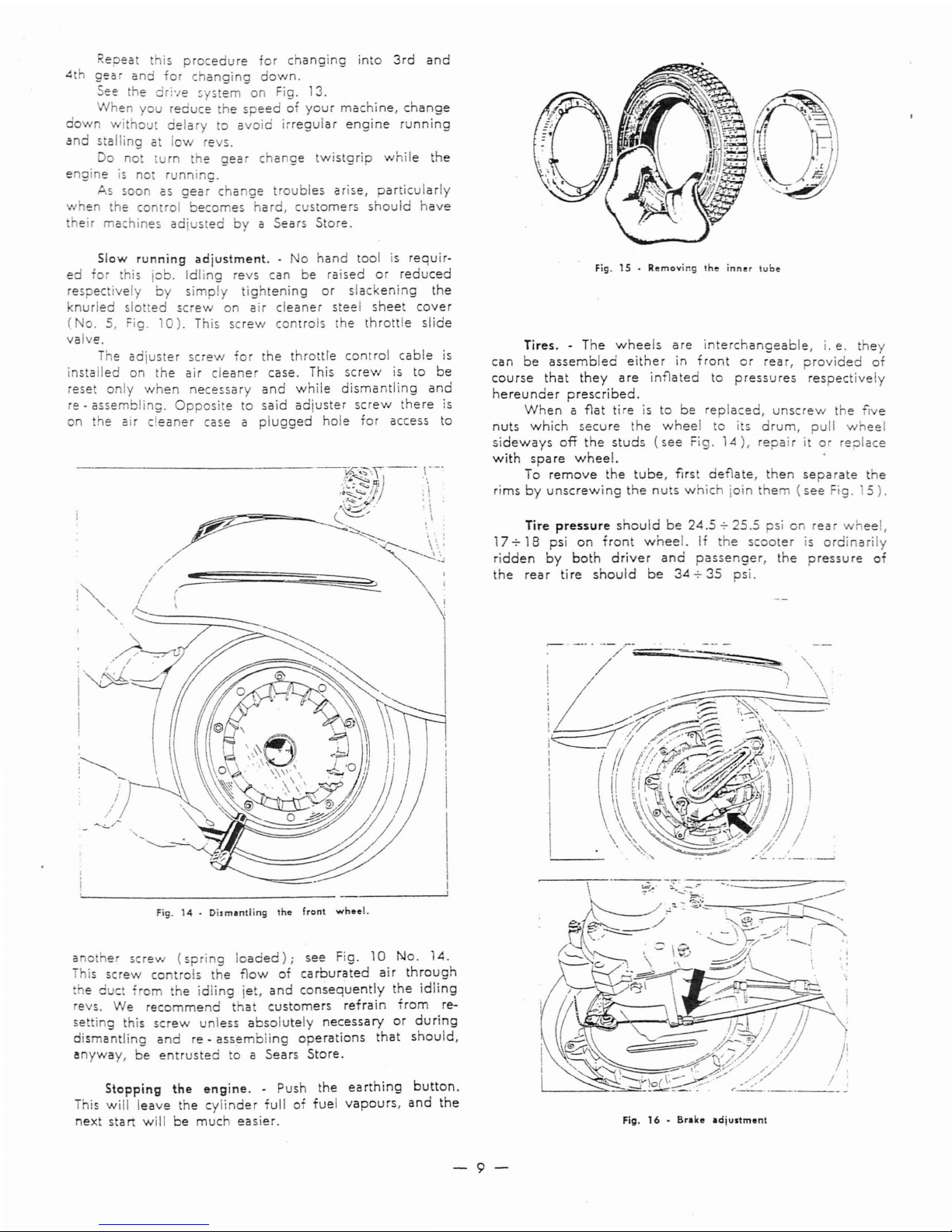

Fig.15•

Removing

Ihe

inner

lube

Tires. - The

wheels

are

interchangeable,

i.e.they

can

be

assembled

either

in

front

or

rear,

provided

of

course

that

they

are

inflated

to

pressures

respectively

hereunder

prescribed.

When

a flat

tireisto

be

replaced,

unscrew

the

five

nuts

which

secure

the

wheel

to its

drum,

pull

wheel

sideways

off

the

studs

(see

Fig.

14),

repa

ir i

or

replace

with

sparewheel.

To

remove

the

tube,

first

deflate,

then

separate

the

rimsbyunscrewing

the

nuts

which

join

them

(see

Fig.

5).

Tire

pressure

should

be

24.5.,.

25.5

psionrear

wheel,

17.,. 18 psi

on

front

wheel.

If

he

scooter

is

ordinarily

ridden

by

both

driver

and

passenger,

the

pressure

of

the

rear

tire

should

be

34.,.35

psi.

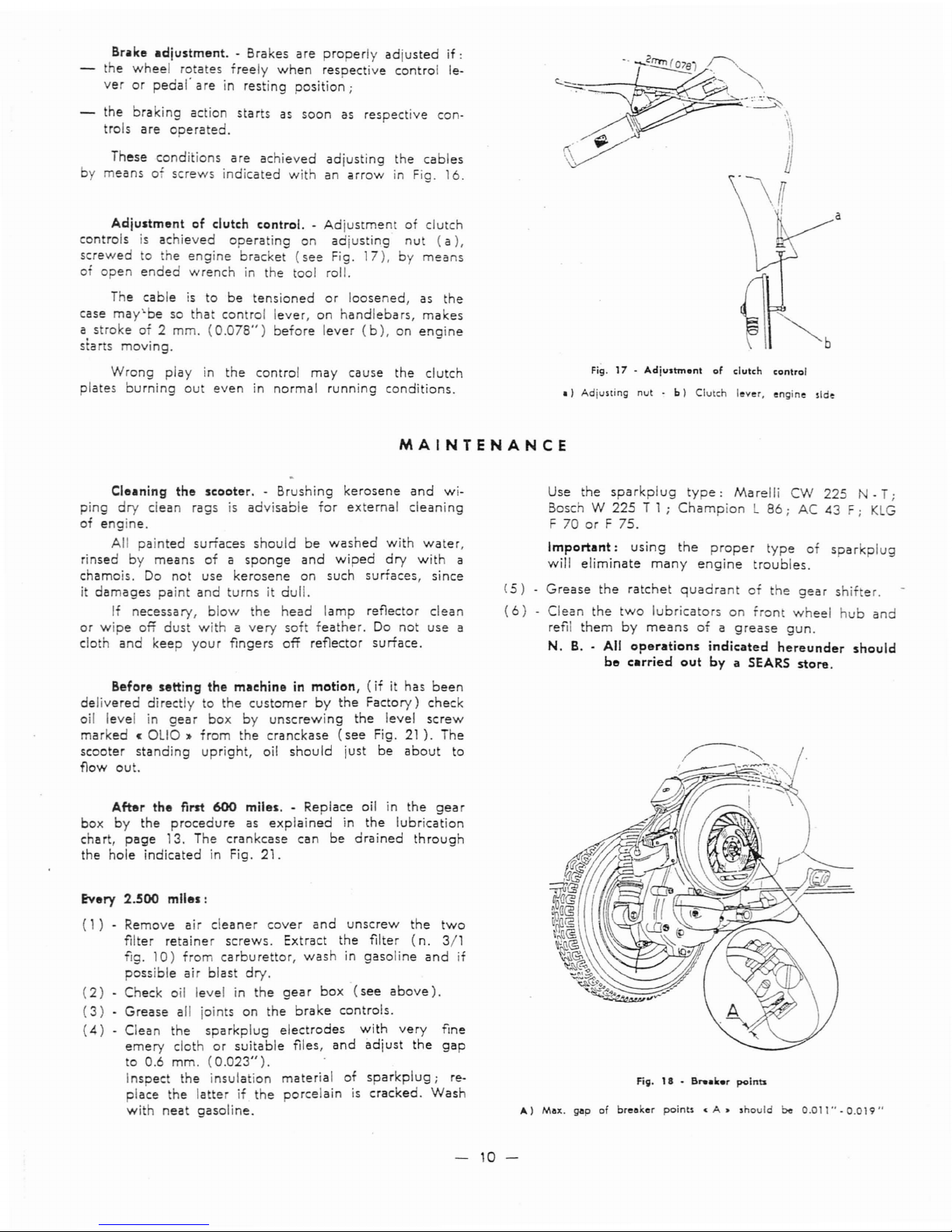

Fig.16-

Brake

adjustment

-9-

Br~ke

adjustment.

- Brakes

are

properly

adjusted

if:

the

wheel

r~tates

freely

when

respective

control

le-

verorpedal

areinresting

position;

the

brakino

action

starts

as

soon

as

respective

con-

trols

are

~Derated.

These

conditions

are

achieved

adjusting

the

cables

by

meansofscrews

indicated

with

an

arrowinFig.

16.

Adjustment

of

clutch

control.-Adjustment

of

clutch

controlsisachieved

operating

on

adjusting

nut

(a),

screwed

to

the

engine

bracket

(see

Fig.

17),

by

means

of

open

ended

wrench

in

the

tool roll.

The

cable

is

to

be

tensioned

or

loosened,

as

the

case

may'be

so

that

control

lever,

on

handlebars,

makes

a

strokeof2

mm.

(0.078")

before

lever

(b),

on

engine

starts

moving.

Wrong

play

in

the

control

may

cause

the

clutch

plates

burning

out

even

in

normal

running

conditions.

Fig.17-

Adjustm.nt

of

dutch

control

.)

Adiusting

nut-b)

Clutch

I~v~r.

~ngine

sld~

a

MAINTENANCE

Cleaning

the

scooter.-Brushing

kerosene

and

wi-

ping

dry

clean

ragsisadvisable

for

external

cleaning

of

engine.

All

painted

surfaces

should

be

washed

with

water,

rinsed

by

means

ofasponge

and

wiped

dry

with

a

chamois.

Do

not

use

kerosene

on

such

surfaces,

since

it

damages

paint

and

turnsitdull.

If

necessary,

blow

the

head

lamp

reflector

clean

or

wipe

off

dust

withavery

sof

feather.

Do

not

use

a

cloth

and

keep

your

fingers

off

reflector

surface.

Before

setting

the

machineinmotion,

(ifithas

been

delivered

di rectlytothe

customer

by

the

Factory)

check

oil level in

gear

box

by

unscrewing

the

level

screw

marked

«

OLIO»

from

the

cranckase

(see

Fig.

21

).

The

scooter

standing

upright,

oil

should

just

be

about

to

flow

out.

After

the

first

600

miles.-Replace

oil in

the

gear

box

by

the

procedure

as

explained

in

the

lubrication

chart,

page

13. The

crankcase

can

be

drained

through

the

hole

indicated

in Fig. 21.

Every 2.

.500

miles:

(1)-

Remove

air

cleaner

cover

and

unscrew

the

two

filter

retainer

screws.

Extract

the

filter

(n.

3/1

fig.

10)

from

carburettor,

washingasoline

and

if

possible

air

blast

dry.

(2)

-

Check

oil level in

the

gearbox

(see

above).

(3)

•

Grease

all joints

on

the

brake

controls.

(4)

-

Clean

the

spa

rkplug

electrodes

with

very

fine

emery

cloth

or

suitable

files,

and

adjust

the

gap

to

0.6

mm.

(0.023").

.

InsDect

the

insulation

material

of

sparkplug;

re-

pla'ce

the

latterifthe

porcelainiscracked.

Wash

with

neat

gasoline.

Use

the

sparkplug

type:

Marelli

CW

225 N -

T;

Bosch W 225 T 1 ;

Champion

L

86;

AC 43

F;

KLG

F 70orF 75.

Important:

using

the

proper

type

of

spa

rkplug

will

eliminate

many

engine

troubles.

(S)

Grease

the

ratchet

quadrant

of

the

gear

shifter.

(6)

Clean

the

two

lubricators

on

front

wheel

hub

and

refil

them

by

means

ofagrease

gun.

N.B.- All

operations

indicated

hereunder

should

be

carried

out

by

a SEARS

store.

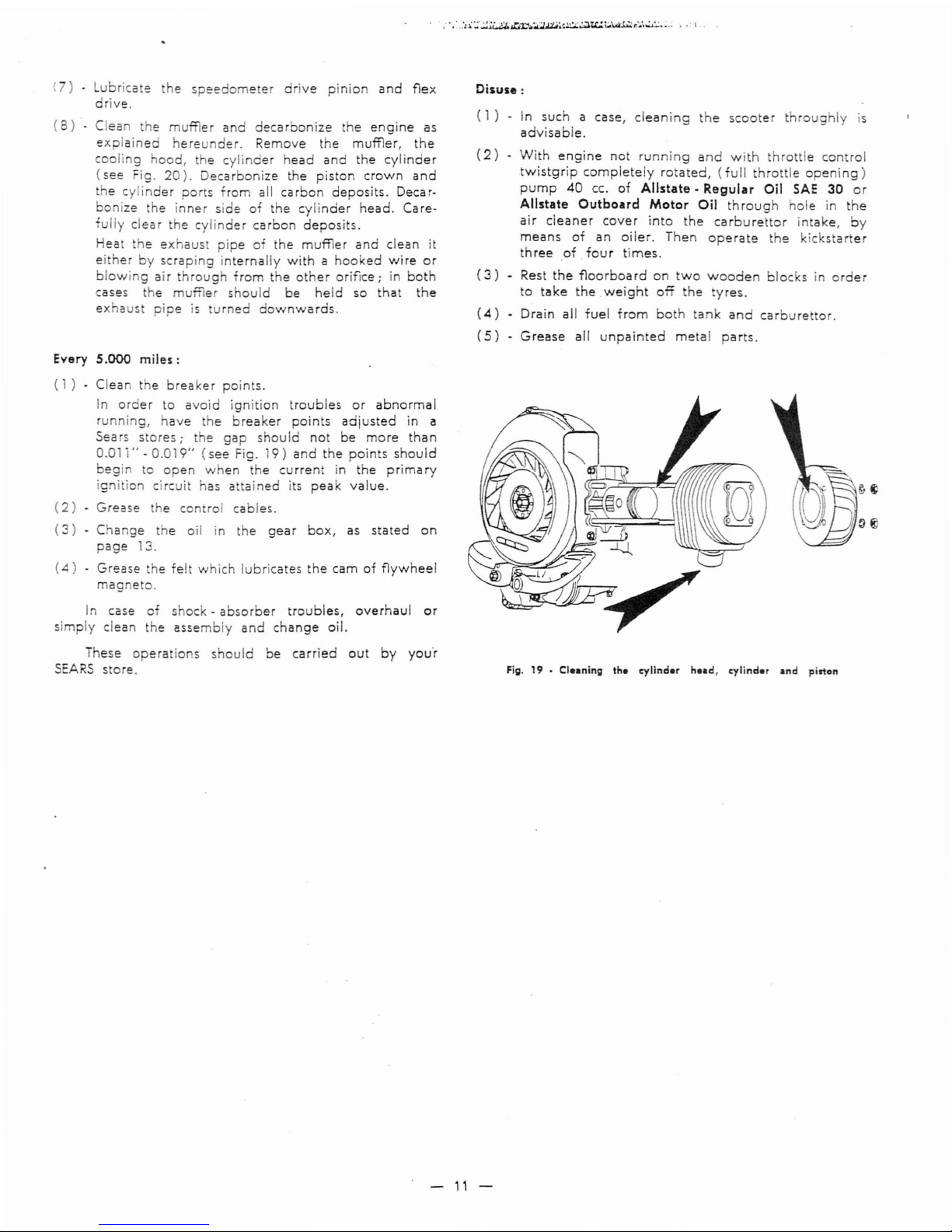

Fig.18- a....... r

points

A)

Max.

gapofbreaker

points

«A.

should

be

0.011"-0.019"

-

10-

e

speedometer

dive

pinion

and

flex

(7)

ubricate

drive.

(8)

- Clea

the

muffler

and

decarbonize

the

engine

as

explained

hereunder.

Remove

the

muffler,

the

cooling

hood,

t e

cylinder

head

and

the

cylinder

(see

Fig.

20).

Decarbonize

the

piston

crown

and

the

cylinder

ports

from

all

carbon

deposits.

Decar-

bonize

the

inner

side

of

the

cylinder

head.

Care-

fully

clear

he

cylinder

carbon

deposits.

Hea

the

exhaust

pipeofthe

muffler

and

clean

it

ei

herbyscraping

internally

withahooked

wire

or

blowing

air

through

from

the

other

orifice;inboth

cases

the

muffler

should

be

held

so

that

the

exhaust

pipe

is

urned

downwards.

Every

5.000

miles:

(1)-Clean

the

breaker

points.

In

order

to

avoid

ignition

troubles

or

abnormal

running,

have

the

breaker

points

adjusted

in a

Sears

stores;

the

gap

should

not

be

more

than

0.01

"-

0.019"

(see

Fig.

9)

and

the

points

should

begin

to

open

when

the

current

in

the

primary

ig i ion circui

has

attained

its

peak

value.

(2)-Grease

he

control

cables.

(3)

Change

the

oil in

the

gear

box,

as

stated

on

page

13.

(4)

Grease

the

felt

which

lubricates

the

camofflywheel

magneto.

In

case

of

shock-absorber

troubles,

overhaul

or

simply

clean

the

assembly

and

change

oil.

These

operations

should

be

carried

out

by

you'r

SEARS

store.

Disuse:

(

1)

In

suchacase,

cleaning

the

scooter

throughly

is

advisable.

(2)

With

engine

not

running

and

with

throttle

control

twistgrip

completely

rotated,

(full

throttle

opening)

pump

40

cc.

of

Allstate·

Regular

Oil

SAE

30

or

Allstate

Outboard

Motor

Oil

through

hole

in

the

air

cleaner

cover

into

the

carburettor

intake,

by

means

of

an

oiler.

Then

operate

the

kicks

arter

three

of

four

times.

(3)

- Rest

the

floorboard

on

two

wooden

blocksinorder

to

tllke

the

weight

off

the

tyres.

(4)

• Drain all

fuel

from

both

tank

and

carburet

or.

(5)

Grease

all

unpainted

metal

parts.

Fig. 19 - Cleaning

th.

cylind.r

h.ad,

cylinder and pilton

-11

-

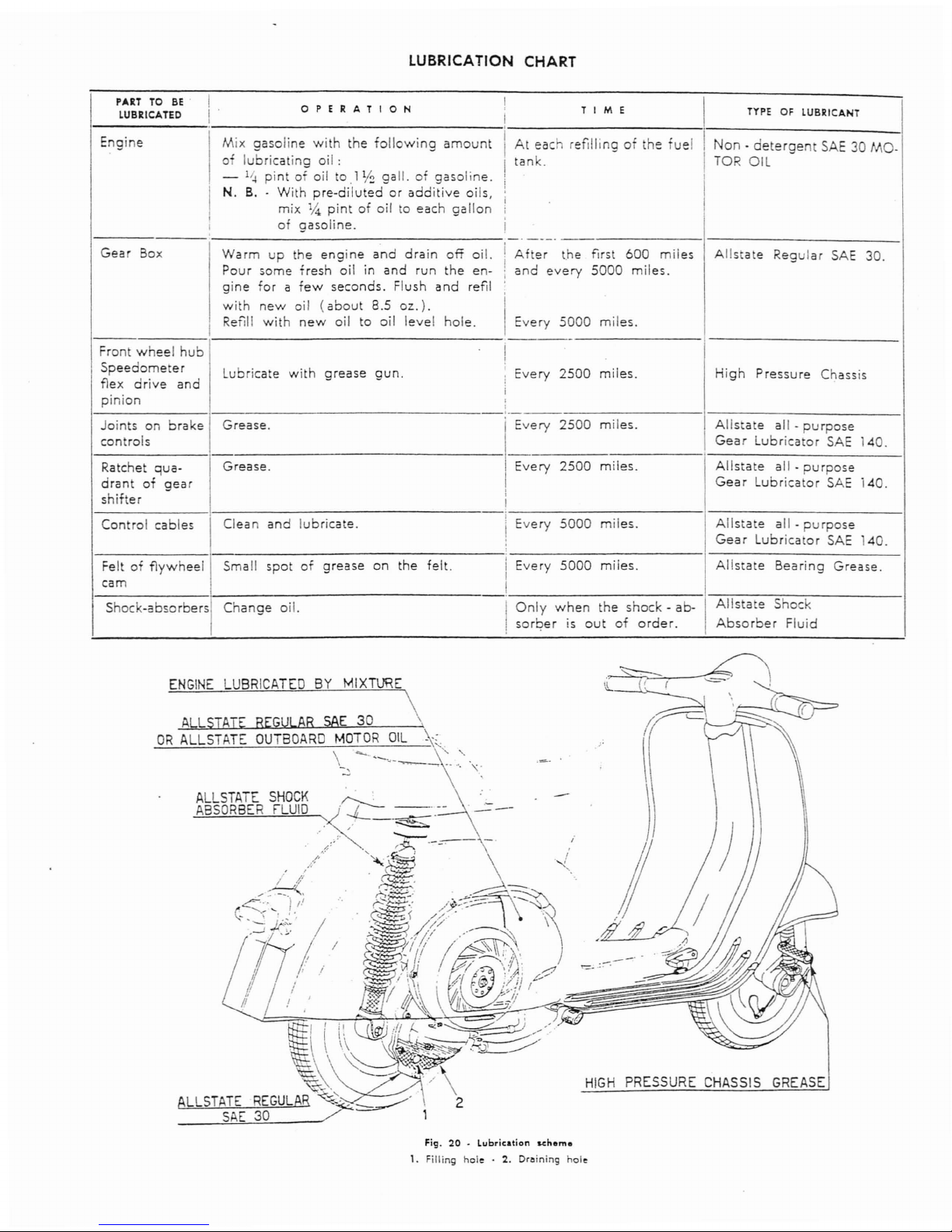

LUBRICATION CHART

PART

TO

BE

.

I

OPERATION

I

I

LUBRICATED

I

I

T I

III

E

TYPEOFLUBRICANT

Engine

Mix

gasoline

with

the

following

amount

i

At

each

refillingofthe

uel

i

Non·

detergent

SAE30MO-

I

I

of

lubricating

oil:

!

tank.

I

TOR OIL

-

l~

pintofoil

to.l

V:!

gall.ofgasoline.

I

N. B

..

With

pre-dilutedoradditive

oils,

I

i

mix %

pintofoil to

each

gallon

;

I

of

gasoline.

I

i

._-_.

Gear

Box

Warm

up

the

engine

and

drain

off

oil.

i

Af

er

the

first

600

miles

Allsta

e

Regular

SAE

30.

Pour

some

fresh

oil

in

and

run

the

en-iand

every

5000

miles.

gine

forafew

seconds.

Flush

and

refil

with

new

oil

(about

8.5

oz.).

i

I

Refill

with

new

oil

to

oil

level

hole.

I

Every

5000

miles.

-

Front

wheel

hub

I

Speedometer

!

Lubricate

with

grease

gun.

Every

2500

miles.

High

Pressure

Chassis

flex

drive

and

i

i

pinion

,

Joints

on

brake

Grease.

Every

2500

miles.

Allstate

all -

purpose

controls

Gear

Lubricator

SAE

140.

Ratchet

qua-

Grease.

Every

2500

miles.

Allstate

all -

purpose

drant

of

gear

Gear

Lubricator

SAE

140.

shifter

i

Control

cables

Clean

and

lubricate.

i

Every

5000

miles.

Allstate

all -

purpose

i

Gear

Lubricator

SAE

40.

Feltofflywheel

Small

spot

of

the

felt.

I

Every

5000

miles.

Allstate

Bearing

Grease.

grease

on

I

I

cam

I

Shock-absorbers

Change

oil.

I

Only

when

the

shock-ab-

Allstate

Shock

!

sorber

is

out

of

order.

Absorber

Fluid

ALLSTATE

SHOCK

ABSORBER

fLUID

ALLSTATE

REGULAR

SAE

30

ENGINE

LUBRICATED

BY

MIXTURE

\

\

1

OR

ALLSTATE

OUTBOARD

MOTOR

OIL-'".

\

--.

'-"--...-~

.~..~.

\;.

~

'L

f (

;;

I

\

;

~"

HIGH

PRESSURE

CHASSIS

GREASE

Fig_20. Lubrication scheme

1.

Filling

hole.2.

Dr.ining

hole

LoeA

T1NG

TROUBLES

AND

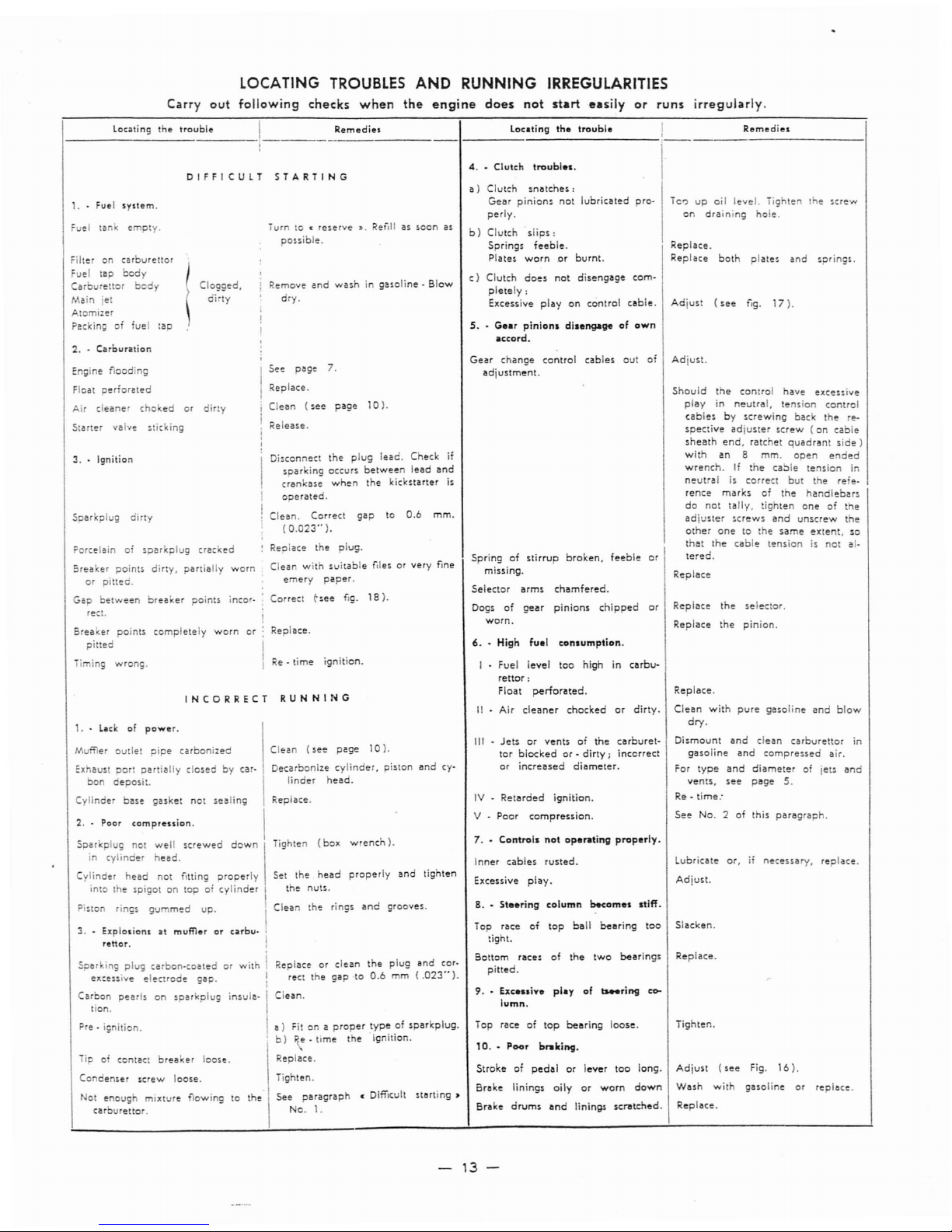

RUNNING IRREGULARITIES

Carry

out

following

checks

when

the

engine

does

not

start

easily

or

runs

irregularly.

Locati ng

the

trouble

I

R.emedies

Loc.ting

the

trouble!

Remedies

1---------.----

1

-------.---------1--------------:---------------1

4.•Clulch

trouble

•.

DIFFICULT

STARTING

INCORRECT

RUNNING

1. -

Lockofpower.

Tur toc:reserve

:l.

Refill as

~oon

as

po,sible.

I

See

page

7.

i

Replace.

replace.

iighten.

Adjust

(see

Fig.

16).

Wash

with

gasoline

or

Replace.

Replace.

Clean

with

pure

gasoline

and

blow

dry.

Replace

the

seleclor.

Replace

the

pinion.

Replace.

See

No.2of

this

paragraph.

Adjust.

Dismount

and

clean

carburettor

in

gasoline

and

compressed

air.

For

type

and

diameter

of

jets

and

vents,

see

page

5.

Re-time:

Lubricate

or,ifnecessary.

replace.

Slacken.

Should

the

control

have

excessive

play

in

neutral,

tension

control

cablesbyscrewing

back

the

re-

spective

adjuster

screw

(on

cable

sheath

end,

ratchet

quadrant

side)

with

an

8

mm.

open

ended

wrench.tfthe

cable

tension

in

neutraliscorrect

but

the

re'e·

rence

marks

of

the

handlebars

do

not

tally,

tighten

oneofthe

adjuster

,crew,

and

unscrew

the

ocher

onetothe

same

extent,

so

that

the

cable

tensionisnot

ai-

lered.

Replace

Adjust.

Replace.

Replace

both

plates

and

spring'.

Adjust

(see

f,g.

17).

Te')upoil

level.

Tighten

the

screw

on

draining

hole.

6.

High

fuel

consumption.

I

Fuel

level

too

highincarburettor:

Float

perforated.

II

Air

cleaner

chocked

or

dirty.

Inner

cables

rusted.

Excessive

play.

8

.•

Steering

column

become••tiff.

Top

raceoftop

bearing

loose.

III -

Jetsorventsofthe

carburet-

tor

blockedor-

dirty;

incorrect

or

increased

diameter.

7.•Control.

not

operating

properly,

9

.•

Exce

..inployof_ring

c0-

lumn.

Springofstirrup

broken,

feeble

or

missing.

Selector

arms

chamfered.

Dogsofgear

pinions

chipped

or

worn.

IV

-

Retarded

ignition.

V -

Poor

compression.

Gear

chanoe

control

cables

out

of

adjustm;nt.

10

.•

Poor

braking.

Strokeofpedalorlever

too

long.

Brake

linings

oilyorworn

down

Brake

drums

and

lininit'

SCrlltcned.

Top

raceoflop

ball

bearing

too

light.

Bottom

racesofthe

two

bearings

pitted.

5.

-

Gear

pinion.

di.engageofown

.ccord.

a)

Clutch

snotches:

Gear

pinions

not

lubricated

pro·

perly.

b)

Clutch

slips:

Springs

feeble.

Plates

wornorburnt.

c}

Clutch

does

not

disengage

com-

pletely:

Excessive

playoncontrol

cable.

mm.

gap

to

0.6

Replace.

Tighten.

See

paragraph

• Difficult

starting»

No.1.

Replaceorclean

the

plug

and

cor·

rect

the

gap

to

0.6mm(.023'·).

Clean.

a)

Fitona

proper

typeofsparkplug.

b)Re-

time

the

ignition.

Clean

the

ring,

and

grooves.

Tighten

(box

wrench).

Set

the

head

properly

and

tighten

the

nuts.

Replace.

Clean

(see

page

10).

Decarbonize

cylinder,

piston

and

cy-

linder

head.

Clean.

Correct

(0.023"

).

:

Replace

the

plug.

Clean

with

suitable

flies

or

very

fine

emery

paper.

Correct

(-see fig.

18).

!

:

Replace.

I

I

Re-time

ignition.

,

,

Remove

and

washingasoline-Blow

dry.

Clean

(see

page

10).

i

Release.

i

!

I

Disconnect

the

plug

lead.

Check

if

I

sparking

occurs

between

lead

and

crankase

when

the

kickstarter

is

!

operated.

!

Clogged,

dirty

Cylinder

ba,e

gasket

not

sealing

2.

Poor

compression.

I

Soarkplug

not

well

screwed

down

\

in

cylinder

head.

Cylinder

head

not

fitting

properly

into

the

spigotontop0'cylinder

I

Piston

rings

gu

med

up.

I

3.•Explosionsatmufflerorcarburettor.

!

Sparking

plug

carbon-coatedorwith

i

excessive

electrode

gap.

I

Carbon

pearl,onsparkplug

insula-,'

tion.

Pre -

ignition.

i

iip

of

contact

breaker

loose.

Condenser

screw

loose.

Not

enoug'

mixture

flowing

to

carburettor.

Muffler

outlet

pipe

carbonized

:xhaust

pOr!

partially

closedbycar·

bo

oeposit.

Breaker

points

completely

worn

or

pitted

3..Ignition

Timing

wrong.

Porcelain0sparkplug

cracked

Breaker

points

dirty,

partially

worn

or

pitted.

Gap

between

breaker

points

incor·

rect.

Engine

flooding

Float

perforated

Air

cleaner

choedor

dirty

Starter

vaIve

'tick

ing

Sparkplug

dirty

Filteroncarburettor

Fuel

tap

body

Carboetor

bedy

Main

jet

Atomizer

Packingoffuel

tap

2.-Carcuntion

1. Fuel

system.

~

ueItan

empty.

-

13-

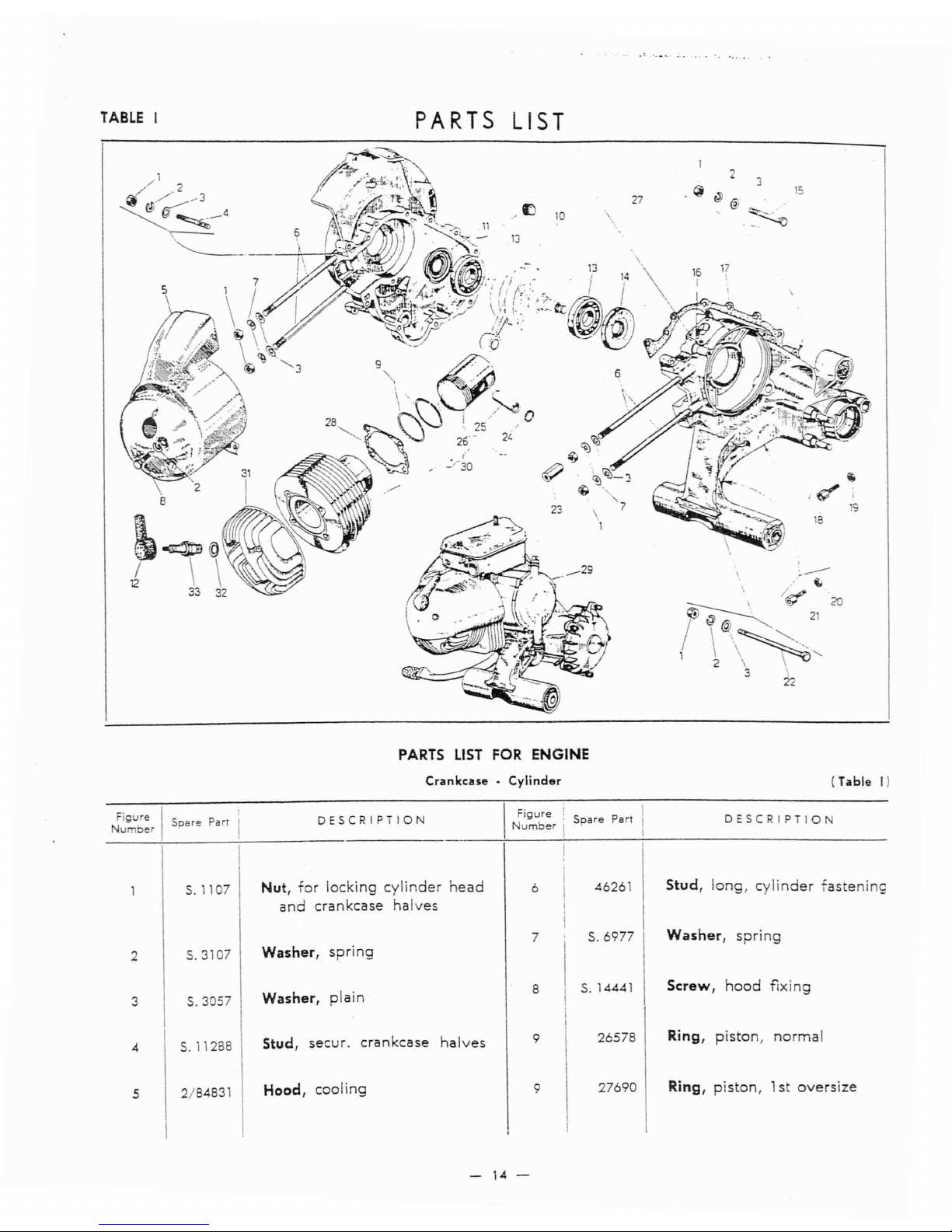

TABLE

I

PARTS LIST

2

"

@

15

27

@

,I:)

10

\

-.

~

"

16

17

;

18

.

-----

" (,;

"

/~.

/~

21

2C

1

\\~,

2 \ \

3 ,

22

- 14 -

9

Figure I

umbe

Spare

Par

DESCRIPTIO

I

~~~~:r

I

Spare

Part

DESCRIPTION

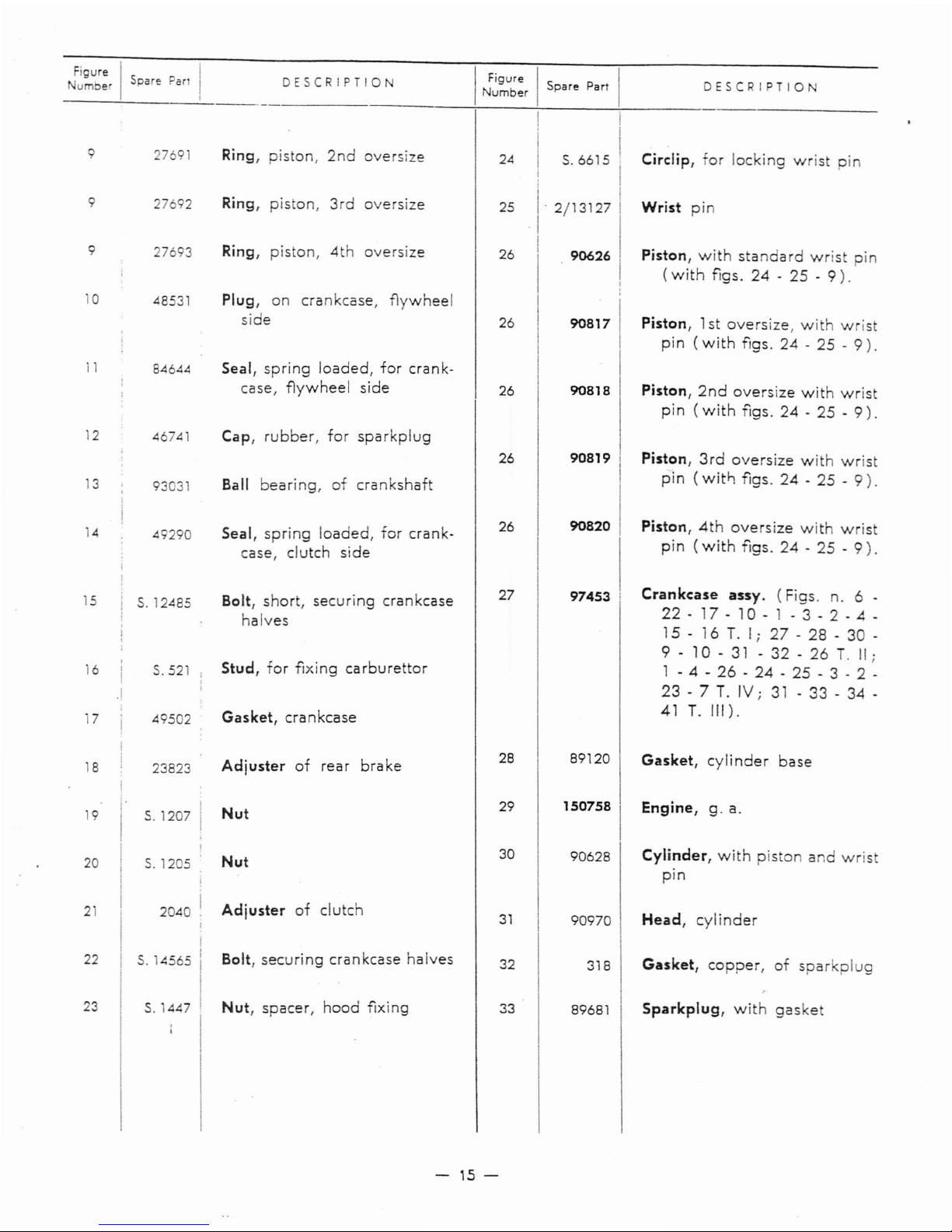

9 2769

Ring,

piston,

2nd

oversize

I

24

I

S.6615

!

Circlip,

for

locking

wrist

pin

90626

9

9

10

27692

27693

48531

Ring,

piston,

3rd

oversize

Ring,

piston,

4th

oversize

Plug,

on

crankcase,

f1ywheel

side

25

26

26

I

I'

2/13127

I

I

I

90817

Wrist

pin

Piston,

with

standard

wrist

pin

(with

figs.

24-25-9).

Piston,1st

oversize,

with

wrist

pin

(with

figs.

24-25

-

9).

11

84644 Seal,

spring

loaded,

for

crank-

case,

f1ywheel

side

26

90818

Piston,

2nd

oversize

with

wrist

pin

(with

figs.

24-25

-

9).

12

46741

Cap,

rubber,

for

sparkplug

3

93031

Ball

bearing,

of

crankshaft

26

90819

Piston,

3rd

oversize

with

wrist

pin

(witf:

figs.

24-25

-

9).

14

49290

Seal,

spring

loaded,

for

crank-

case,

clutch

side

26

90820

Piston,

4th

oversize

with

wrist

pin

(with

figs.

24-25

-

9).

15

16

17

S.

12485

S.521

49502

Bolt,

short,

securing

crankcase

halves

Stud,

for

fixing

carburettor

Gasket,

crankcase

27

97453

.

Crankcase

assy.

(Figs.

n. 6 .

22

- 17 - 10 - 1 - 3 - 2 - 4 -

15 - 16T.Ii

27

- 28 - 30 -

9

-

10-31

- 32 - 26T.II

i

1 - 4 -

26

-

24.25

- 3 - 2 .

23

- 7T.IVi31

- 33 - 34 -

41

T.

III).

2040

23823

S,1205

I

S.

4565 I

Head,

cylinder

Cylinder,

with

piston

and

wris

pin

Engine,

g.

a.

Gasket,

copper,

of

sparkplug

Gasket,

cylinder

base

318

90970

89120

1507581

90628

32

30

31

28

29

Nut

Bolt,

securing

crankcase

halves

Adjuster

of

clutch

Nut

Adjuster

of

rear

brake

I

I'

S.1207

I

I

I

I

19

18

20

2

22

23

S.1447

Nut,

spacer,

hood

fixing

33

89681

Sparkplug,

with

gaske

-

15-

Loading...

Loading...