Page 1

삼 흥

정 판

DIVISION 22

BASIC FIELD MANUAL

FOR

MICROWAVE OVEN

MODEL 721.80042700

721.80049700

721.80044700

721.80043700

721.81043700

June, 2007

MODEL 721.80042

721.80049

721.80044

721.80043

721.81043

Page 2

CAUTION

SAFETY PRECAUTIONS

PRECAUTIONS TO BE OBSERVED BEFORE AND

DURING SERVICING TO AVOID POSSIBLE EXPOSURE

TO EXCESSIVE MICROWAVE ENERGY

a. Do not operate or allow the oven to be operated with the door open.

b. Make the following safety checks on all ovens to be serviced before activating the

magnetron or other microwave source, and make repairs as necessary; (1) Interlock

operation, (2) proper door closing, (3) seal and sealing surfaces (arcing, wear, and

other damage), (4) damage to or loosening of hinges and latches, (5) evidence of

dropping or abuse.

c. Before turning on microwave power for any service test or inspection within the

microwave generating compartments, check the magnetron, wave guide or

transmission line, and cavity for proper alignment, integrity, and connections.

d. Any defective or misadjusted components in the interlock, monitor, door seal, and

microwave generation and transmission systems shall be repaired, replaced, or

adjusted by procedures described in this manual before the oven is released to the

owner.

e. A Microwave leakage check to verify compliance with the Federal performance standard should

be performed on each oven prior to release to the owner.

• Proper operation of the microwave ovens requires that the magnetron be assembled to the

wave guide and cavity. Never operate the magnetron unless it is properly installed.

• Be sure that the magnetron gasket is properly installed around the dome of the tube whenever

installing the magnetron.

• Routine service safety procedures should be exercised at all times.

• Untrained personnel should not attempt service without a thorough review of the test

procedures and safety information contained in this manual.

Page 3

TABLE OF CONTENTS

(Page)

SAFETY PRECAUTIONS

----------------------------------------------------------------------------------------------------

Inside front page

SPECIFICATIONS

--------------------------------------------------------------------------------------------------------------------------------

1-1

CAUTIONS

------------------------------------------------------------------------------------------------------------------------------------------

2-1

INSTALLATIONS

----------------------------------------------------------------------------------------------------------------------------------

3-1

OPERATING INSTRUCTIONS

----------------------------------------------------------------------------------------------------------------

4-1

CONTROL PANEL

-------------------------------------------------------------------------------------------------------------------------

4-1

CONTROL PANEL INSTRUCTIONS

------------------------------------------------------------------------------------------------

4-2

OVERALL CIRCUIT DIAGRAM

---------------------------------------------------------------------------------------------------------------

5-1

SCHEMATIC DIAGRAM

-----------------------------------------------------------------------------------------------------------------

5-1

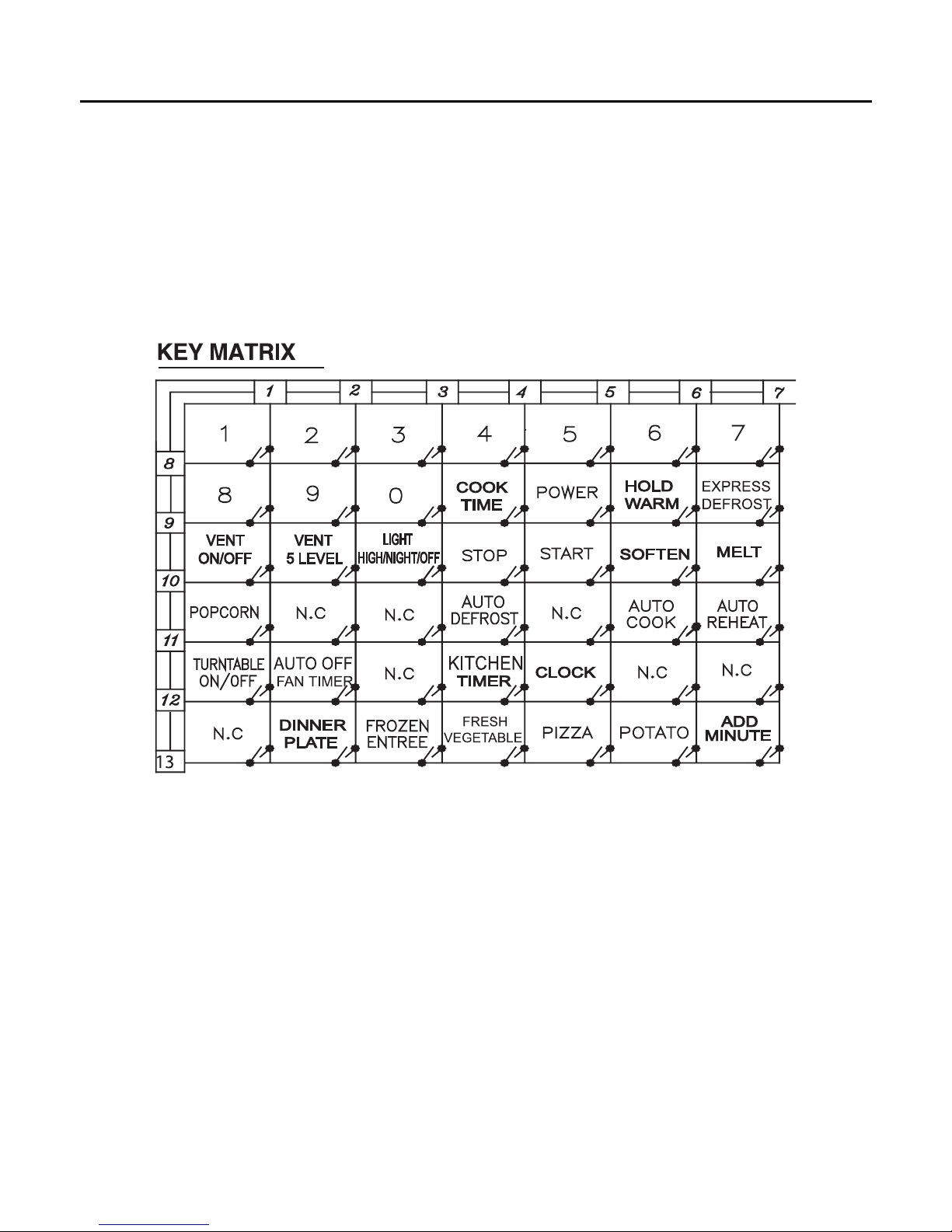

MATRIX CIRCUIT FOR TOUCH KEY BOARD

-----------------------------------------------------------------------------------

5-2

GENERAL INFORMATION FOR SERVICE

-----------------------------------------------------------------------------------------------

6-1

GENERAL PRECAUTIONS IN USE

-------------------------------------------------------------------------------------------------

6-1

TRIAL OPERATION

-----------------------------------------------------------------------------------------------------------------------

6-1

FEATURES AND SPECIFICATIONS FEATURES

-------------------------------------------------------------------------------

6-1

SERVICE INFORMATION

----------------------------------------------------------------------------------------------------------------------

7-1

PRECAUTIONS AND REPAIR SERVICE TIPS

-----------------------------------------------------------------------------------

7-1

MICROWAVE LEAKAGE TEST

-------------------------------------------------------------------------------------------------------

7-2

POWER OUTPUT MEASUREMENT

------------------------------------------------------------------------------------------------

7-3

DISASSEMBLY INSTRUCTIONS

-----------------------------------------------------------------------------------------------------

7-4

INTERLOCK SYSTEM

------------------------------------------------------------------------------------------------------------------

7-12

INTERLOCK CONTINUITY TEST

---------------------------------------------------------------------------------------------------

7-14

TEST AND CHECKOUT PROCEDURES AND TROUBLE SHOOTING

-------------------------------------------------

7-15

A. TEST PROCEDURES

--------------------------------------------------------------------------------------------------------

7-15

B. CHECKOUT PROCEDURES

----------------------------------------------------------------------------------------------

7-18

C. TROUBLE SHOOTING

------------------------------------------------------------------------------------------------------

7-21

EXPLODED VIEW

--------------------------------------------------------------------------------------------------------------------------------

8-1

PART REFERENCE LIST

---------------------------------------------------------------------------------------------------------------------

9-1

FOREWORD

Read this Manual carefully. Failure to adhere to or observe the information in this Manual may result in exposing

yourself to the Microwave Energy normally contained within the oven cavity.

Page 4

1-1

Rated Power Consumption

----------------------------------

1500W maximum (Microwave oven+Cook top lamps+Ventilation fan)

Microwave Output

------------------------------------------------

1000W (IEC60705)

Adjustable 100W through 1000W, 10 steps

Frequency

---------------------------------------------------------

2450 MHz ± 50 MHz

Power Supply

---------------------------------------------------

120 VAC, 60 Hz

Rated Current

---------------------------------------------------

14 Amp. (Microwave oven+Cook top lamp+Ventilation fan)

Magnetron Cooling

--------------------------------------------

Forced Air Cooling

Rectification

------------------------------------------------------

Rectification Voltage Double Half-Wave

Door Sealing

-----------------------------------------------------

Choke System

Safety Devices

--------------------------------------------------

Magnetron Thermal Fuse:

Open at 90°C ± 5°C

Fuse(20A)

Primary Interlock Switch

Secondary Interlock Switch

Interlock Monitor Switch

Magnetron

--------------------------------------------------------

2M214-161GP

High Voltage Capacitor

--------------------------------------

Capacitor: 1.0µF, 2.1 KV AC

High Voltage Diode

-------------------------------------------

Diode; 350mA, 9.0 KV

Cook top Lamp

-------------------------------------------------

125 V, 30 W

Cavity Lamp

-----------------------------------------------------

125 V, 30 W or 40 W

Timer

---------------------------------------------------------------

Digital, up to 99 mim. 99 sec. (in each cooking stage)

Tray

-----------------------------------------------------------------

Tempered Safety Glass

Overall Dimensions

-------------------------------------------

29

15

/16"(W)x167/16"(H)x1511/16"(D)

Oven Cavity Size

----------------------------------------------

219/16"(W)x91/4"(H)x141/8"(D)

Effective Capacity of Oven Cavity

-----------------------

1.6 Cu.ft.

Accessories

------------------------------------------------------

Owner’s Manual & Cooking Guide, Installation Manual,

Exhaust Adapter, Exhaust Damper, Mounting Kit and Two

Filters, Rotating Ring Assembly.

SPECIFICATIONS

Page 5

• DO NOT operate on a 2-wire extension cord during

repair and use.

• NEVER TOUCH any oven components or wiring during

operation.

• BEFORE TOUCHING any parts of the oven, always

remove the power plug from the outlet.

• For about 30 seconds after the oven stops, an electric

charge remains in the high voltage capacitor. When

replacing or checking, you must discharge the high

voltage capacitor by shorting across the two terminals

with an insulated screwdriver.

• Remove your watches whenever working close to or

replacing the Magnetron.

• DO NOT touch any parts of the control panel circuit. A

resulting static electric discharge may damage this

P.C.B.

• NEVER operate the oven with no load.

• NEVER injure the door seal and front plate of the oven

cavity.

• NEVER put iron tools on the magnetron.

• NEVER put anything into the latch hole and the interlock

switches area.

• Proper operation of the microwave oven requires that

the magnetron be assembled to the waveguide and

cavity. Never operate the magnetron unless it is

properly installed.

• Be sure that the magnetron gasket is properly

installed around the dome of the tube whenever

installing the magnetron.

2-1

CAUTIONS

Unlike other appliances, the microwave oven is

high-voltage and high-current equipment.

Though it is free from danger in ordinary use,

extreme care should be taken during repair.

Gasket

ANTENNA

COOLING FIN

MAGNETRON

CHASSIS GROUND

FILAMENT

TERMINALS

MAGNETRON

MICROWAVE RADIATION

Personnel should not be exposed to the

microwave energy which may radiate from the

magnetron or other microwave generating

device if it is improperly used or connection.

All input and output microwave connections,

waveguide, flange, and gasket must be secure

never operate the device without a microwave

energy absorbing load attached.

Never look into an open waveguide or antenna

while the device is energized.

THE OVEN IS TO BE SERVICED ONLY

BY PROPERLY QUALIFIED SERVICE

PERSONNEL.

Page 6

PRECAUTIONS ON INSTALLATION

A. Plug the power supply cord into a 120V AC, 60Hz,

single-phase power source with a capacity of 15A

or 20A.

B. Avoid placing the unit in a location where there is

direct heat or splashing water.

C. Install the unit on the mounting plate firmly.

D. Place the unit as far away as possible from TV,

radio, etc. to prevent interference.

GROUNDING INSTRUCTIONS

For personal safety, this appliance must be fully

grounded at all times.

In the event of an electrical short circuit, grounding

reduces the risk of electrical shock.

The plug must be plugged into an outlet that is

properly installed and grounded.

3-1

INSTALLATIONS

BEFORE YOU BEGIN, READ THE FOLLOWING INSTRUCTIONS COMPLETELY AND CAREFULLY.

CAUTION

This unit is equipped with a 3-prong plug for your

safety. If the wall outlet is a grounded 3-hole type,

the unit will be grounded automatically.

WARNING

Improper use of the grounding plug can result in a

risk of electric shock.

Do not, under any circumstances, cut or remove

the third ground prong from the power cord plug.

Properly Polarized

and Grounded

Outlet

Plug with Ground

Prong

Page 7

4-1

OPERATING INSTRUCTIONS

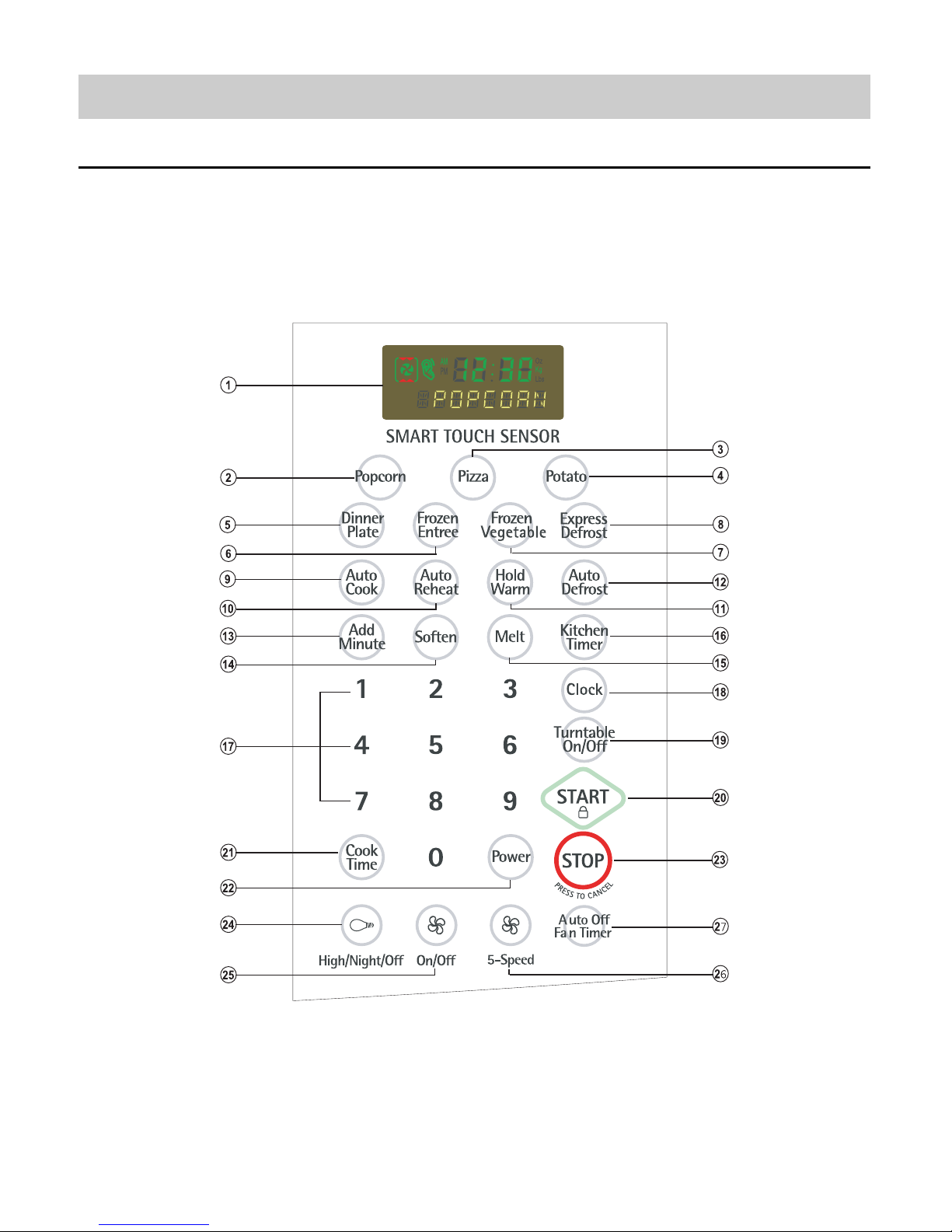

CONTROL PANEL

Page 8

1. Display. The display includes a clock and

indicators to tell you time of day, cooking time

settings, cook powers, quantities, weights and

cooking functions selected.

2. Popcorn. Touch this pad to pop popcorn with

the sensor feature. The oven ’s sensor will tell

the oven how long to cook depending on the

amount of humidity it detects from the popcorn.

3. Pizza. Touch this pad to reheat one or several

slices of pizza without entering a cook time or

power.

4. Potato. Touch this pad to cook potatoes without

entering a cook time or power.

5. Dinner Plate. Touch this pad to cook without

entering a cook time or power.

6. Frozen Entree. Touch this pad to cook a 10 - to

20 - ounce (284 to 567 g) frozen entree without

entering a cook time or power.

7. Frozen Vegetable. Touch this pad to cook

without entering a cook time or power.

8. Express Defrost. Touch this pad to express

defrost. “GROUND BEEF 1.0 LBS TOUCH

START” will appear in the display.

9. Auto Cook. Touch this pad to cook

microwavable foods without entering a cook

time or power.

10. Auto Reheat. Touch this pad to reheat

microwavable foods without entering a cook

time or power.

11. Hold Warm. Touch this pad to keep hot,

cooked foods safely warm in your oven for up

to 99 minutes, 99 seconds. Hold Warm can be

used by itself, or it can automatically follow a

cooking cycle.

12. Auto Defrost. Touch this pad followed by

Number Pads to thaw frozen meat by weight.

13. Add Minute. Touch this pad to cook for 1

minute at 100% cook power, or to add extra

minutes at the set cook power to your cooking cycle.

14. Soften. Touch this pad to soften utter,ice

cream, cream cheese, or frozen juice.

15. Melt. Touch this pad to melt butter or

margarine, chocolate, cheese, or

marshmallows.

16. Kitchen Timer. Touch this pad to set the

kitchen timer.

17. Number Pads. Touch number pads to enter

cooking times, cook powers, quantities,

weights, or food categories.

18. Clock. Touch this pad to enter the correct time

of day.

19. Turntable On/Off. Touch this pad to turn off

the turntable. “T/TABLE OFF” will appear in the

display.

20. START. Touch this pad to start a function.If

you open the door after the oven begins to

cook, retouch START.

21. Cook Time. Touch this pad followed by

Number Pads to set a cooking time.

22. Power. Touch this pad after the cook time has

been set, followed by a Number Pad to set the

amount of microwave energy released to cook

the food. The higher the number, the higher the

microwave power or “cooking speed.”

23. STOP. Touch this pad to erase an

incorrect command, cancel a program during

cooking, or to clear the Display.

24. Light ( ). Touch this pad to turn the light on

high, night (low) or off.

25. Fan ( ) On/Off. Touch this pad to turn the

fan on or off.

26. Fan ( ) 5 Speed. Touch this pad to choose

one of 5 fan speeds.

27. Auto Off Fan timer. Touch this pad followed by

Number pad to set a time for the fan stopping

automatically

NOTE: If you try to enter incorrect instructions,

you will not hear any tones. Touch STOP/Clear

and re-enter the instructions.

4-2

CONTROL PANEL INSTRUCTIONS

Page 9

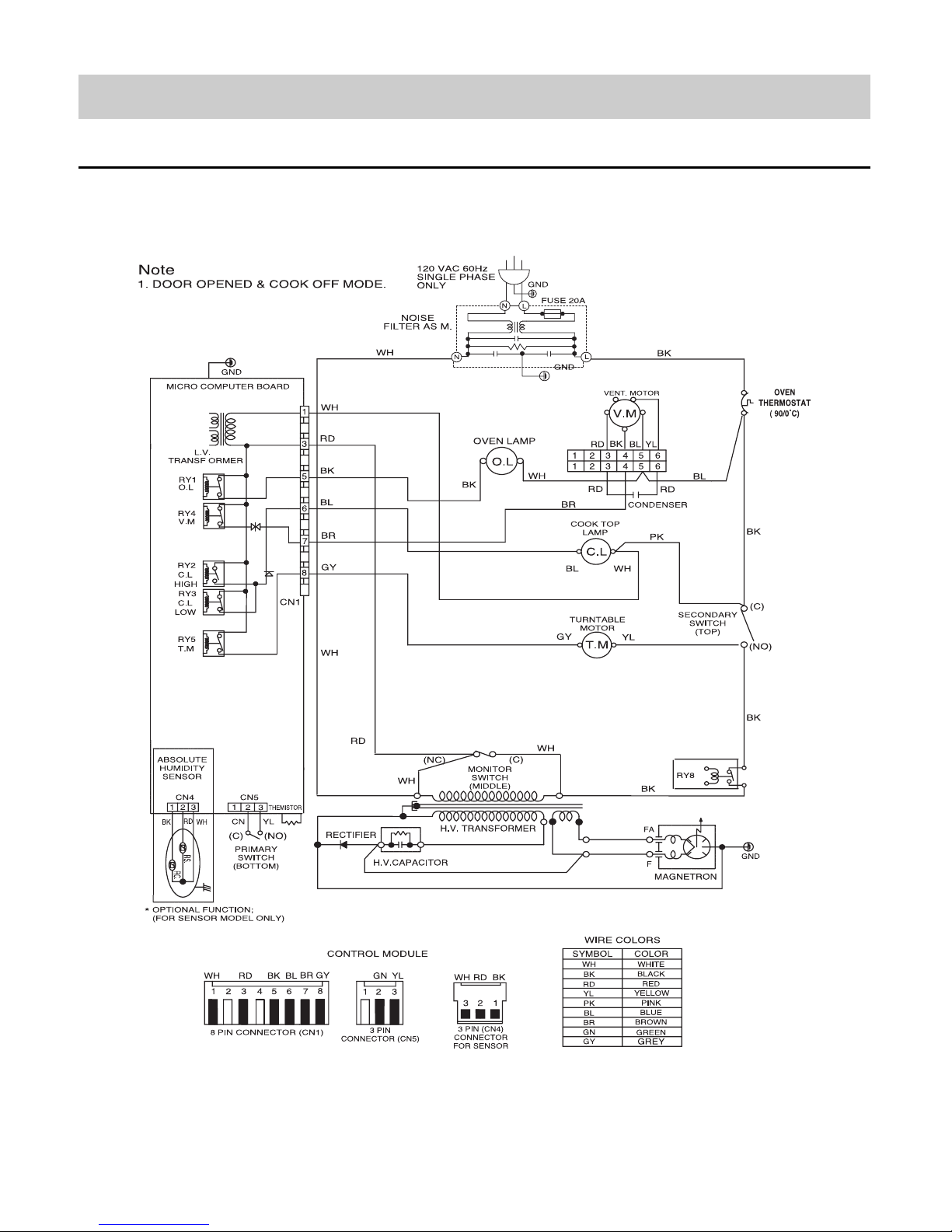

5-1

OVERALL CIRCUIT DIAGRAM

SCHEMATIC DIAGRAM

Page 10

5-2

MATRIX CIRCUIT FOR TOUCH KEY BOARD

Page 11

GENERAL PRECAUTIONS IN USE

A. Never operate the unit when it is empty.

Operating the oven with no load may shorten the

life of the magnetron. Whenever cooking dry foods

(dried fish, bread, etc.) or a small amount of food,

be sure to put a glass of water into the cooking

compartment. The glass turntable may become hot

after operating, be careful when touching it.

B. Aluminum foil should be avoided because it will

disrupt cooking and may cause arcing. However,

small pieces may be used to cover some parts of

food to slow the cooking. Any aluminum foil used

should never be closer than 2.5 cm to any side wall

of the oven.

TRIAL OPERATION

After installation, the following sequences and results

should be checked carefully.

A. Put a container filled with water (about 1 liter) into

the oven, and close the door tightly.

B. Set cooking time for 10 minutes by touching “1”

and then “0” three times. “1, 0, 0, 0” appears in

the display window.

C. Touch the START key.

Make sure the cavity light comes on. The unit will

begin cooking and the display window will show the

time counting down by seconds.

D. After about 5 minutes, make sure the primary

interlock switch, the secondary interlock switch and

the interlock monitor switch operate properly by

opening and closing the door several times. Touch

the START key each time the door is closed.

E. Continue operating the unit. Two short and a long

beep sound signal is heard when the time is up.

The unit will shut off automatically.

F. Confirm the water is hot.

G. Finally, measure the output power according to

“POWER OUTPUT MEASUREMENT” on

page 7-3.

FEATURES AND SPECIFICATIONS

FEATURES

A. The safety systems incorporated in this model are:

(1) Primary interlock switch

(2) Secondary interlock switch

(3) Interlock monitor switch

(4) Choke system

(5) Magnetron thermostat

(6) Oven cavity thermostat

(Note: This thermostat located on the oven

cavity will open and stop the unit from operation

only if a high temperature is reached, such as,

a fire created by overcooking food.)

B. Any one of 10 power output levels ranging 100W to

1000W can be selected by the touch control and

electronic computer system.

6-1

GENERAL INFORMATION FOR SERVICE

Page 12

PRELIMINARY

A. SINCE NEARLY 2,100 VOLTS EXISTS IN SOME

CIRCUITS OF THIS UNIT REPAIRS SHOULD BE

CARRIED OUT WITH GREAT CARE.

The filament leads of magnetron carry High

Voltage with respect to ground. Extreme caution

must be exercised. Never plug the unit into a

power source to determine which component is

defective in high voltage section.

B. TO AVOID POSSIBLE EXPOSURE TO

MICROWAVE ENERGY LEAKAGE, THE

FOLLOWING PRECAUTIONS MUST BE TAKEN

BEFORE SERVICING.

(1) Before the power is applied:

(a) Make sure the primary interlock switch, the

secondary interlock switch and the interlock

monitor switch operate properly by opening

and closing the door several by opening and

closing the door several times.

(b) Make sure the perforated screen and the

dielectric choke of the door are correctly and

firmly mounted.

(2) After power is applied:

(a) Make sure the interlock switch mechanism

is operating properly by opening and closing

the door.

(b) Check microwave energy leakage must bebelow

the limit of 5 mW/cm2.

(All service adjustments should be made for

minimum microwave energy leakage

readings).

(3) Do not operate the unit until it is completely

repaired, if any of the following conditions exist.

The unit must not be operated.

(a) The door does not close firmly.

(b) The hinge is broken.

(c) The door seal is damaged.

(d) The door is bent or warped, or there is any

other visible damage on the unit that may

cause microwave energy leakage.

NOTE: Always keep the seal clean.

(e) Make sure that there are no defective parts

in the interlock mechanism.

(f) Make sure that there are no detective parts

in the microwave generating and transmission

assembly (especially waveguide).

(4) The following items should be checked after the

unit is repaired:

(a) The interlock monitor switch is connected

correctly and firmly.

(b) The magnetron gasket is properly positioned

and mounted.

(c) The waveguide and the oven cavity are intact.

(no microwave energy leakage)

(d) The door can be properly closed and the

safety switches work properly.

(e) The unit must stop when the door is opened or

the time is up.

The unit must not be operated with any of the above

components removed or by-passed.

7-1

SERVICE INFORMATION

PRECAUTIONS AND REPAIR SERVICE TIPS

Page 13

CAUTIONS

• Be sure to check microwave leakage prior to

servicing the oven if the oven is operative prior to

servicing.

• The service personnel should inform the

manufacture importer, or assembler of any certified

oven unit found to have a microwave emission level

in excess of 5 mW/cm2and should repair any unit

found to have excessive emission levels at no cost to

the owner and should ascertain the cause of the

excessive leakage. The service personnel should

instruct the owner not to use the unit until the oven has

been brought into compliance.

• If the oven operates with the door open, the service

personnel should:

- Tell the user not to operate the oven.

• The service personnel should check all surface and

vent openings for microwave leakage.

• Check for microwave leakage after every servicing. The

power density of the microwave radiation leakage

emitted by the microwave oven should not exceed

4 mW/cm2. Always start measuring of an unknown field

to assure safety for operating personnel from radiation

leakage.

EQUIPMENT

•

TESTER (VOLTS-DC, AC, Ohmmeter)

• Microwave survey meter

- Holaday HI-1500

HI-1501

- Narda 8100

8200

• 600 cc non conductive material beaker (glass or

plastic), inside diameter: approx. 8.5 cm (31/2in.)

• Glass thermometer: 100°C or 212°F (1 deg scale)

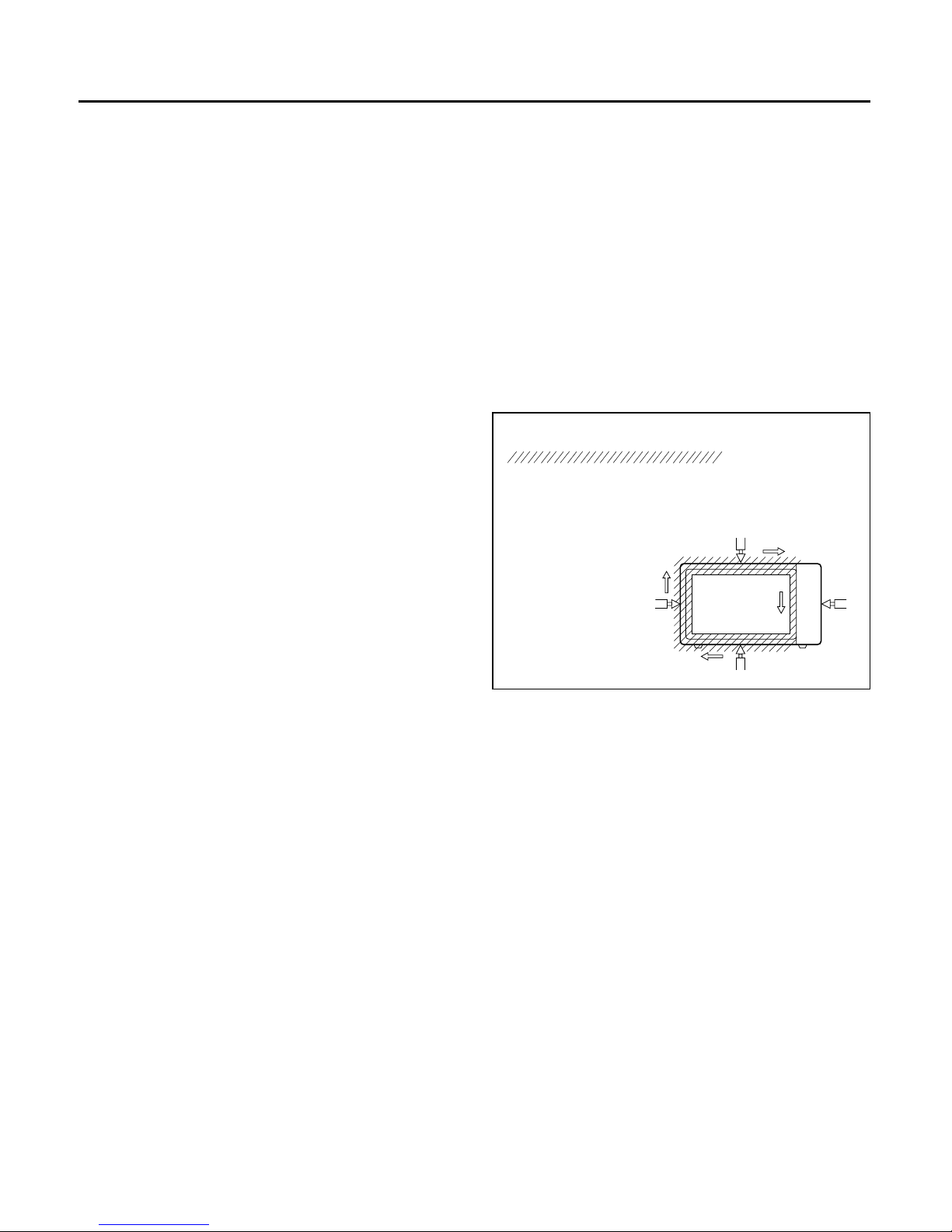

MEASURING MICROWAVE ENERGY

LEAKAGE

• Pour 275±15cc of 20±5°C(68±9°F) water in a beaker

which is graduated to 600 cc, and place the beaker

on the center of the turntable.

• Set the energy leakage monitor to 2,450 MHz and

use it following the manufacturer's recommended

test procedure to assure correct result.

• When measuring the leakage, always use the 2-inch

(5cm) spacer supplied with the probe.

• Operate the oven at its maximum output.

• Measure the microwave radiation using and

electromagnetic radiation monitor by holding the

probe perpendicular to the surface being measured.

Move probe along shaded area.

Probe scanning speed

Less than 2.5 cm/sec. ( 1 in/sec)

7-2

MICROWAVE LEAKAGE TEST

Page 14

MEASUREMENT WITH THE OUTER CASE

REMOVED

(1) When you replace the magnetron, measure for

microwave energy leakage before the outer case

is installed and after all necessary components

are replaced or adjusted. Special care should be

taken in measuring the following parts.

- Around the magnetron

- The waveguide

WARNING: AVOID CONTACTING ANY HIGH

VOLTAGE PARTS.

MEASUREMENT WITH A FULLY

ASSEMBLED OVEN

(1) After all components, including the outer

panels, are fully assembled, measure for

microwave energy leakage around the door

viewing window, the exhaust opening and air

inlet openings.

(2) Microwave energy leakage must not exceed the

values prescribed below.

NOTES:

Leakage with the outer panels removed - less

than 5 mW/cm2.

Leakage for a fully assembled oven (“Before the

latch switch (primary) is interrupted”) with the door

in a slightly opened position - less than 2 mW/cm2.

NOTE WHEN MEASURING

(1) Do not exceed meter full scale deflection.

(2) The test probe must be removed no faster than

1 inch/sec (2.5cm/sec) along the shaded area,

otherwise a false reading may result.

(3) The test probe must be held with the grip portion

of the handle. A false reading may result if the

operator’s hand is between the handle and the

probe.

(4) When testing near a corner of the door, keep

the probe perpendicular to the surface making

sure the probe horizontally along the oven

surface, this may possibly cause probe damage.

RECORD KEEPING AND NOTIFICATION

AFTER MEASUREMENT

(1) After adjustment and repair of any microwave

energy interruption or microwave energy blocking

device, record the measured values for future

reference. Also enter the information on the

service invoice.

(2) Should the microwave energy leakage not be

more than 2 mW/cm2after determining that all

parts are in good condition, functioning properly

and genuine replacement parts which are listed in

this manual have been used.

(3) At least once a year, have the electromagnetic

energy leakage monitor checked for calibration

by its manufacturer.

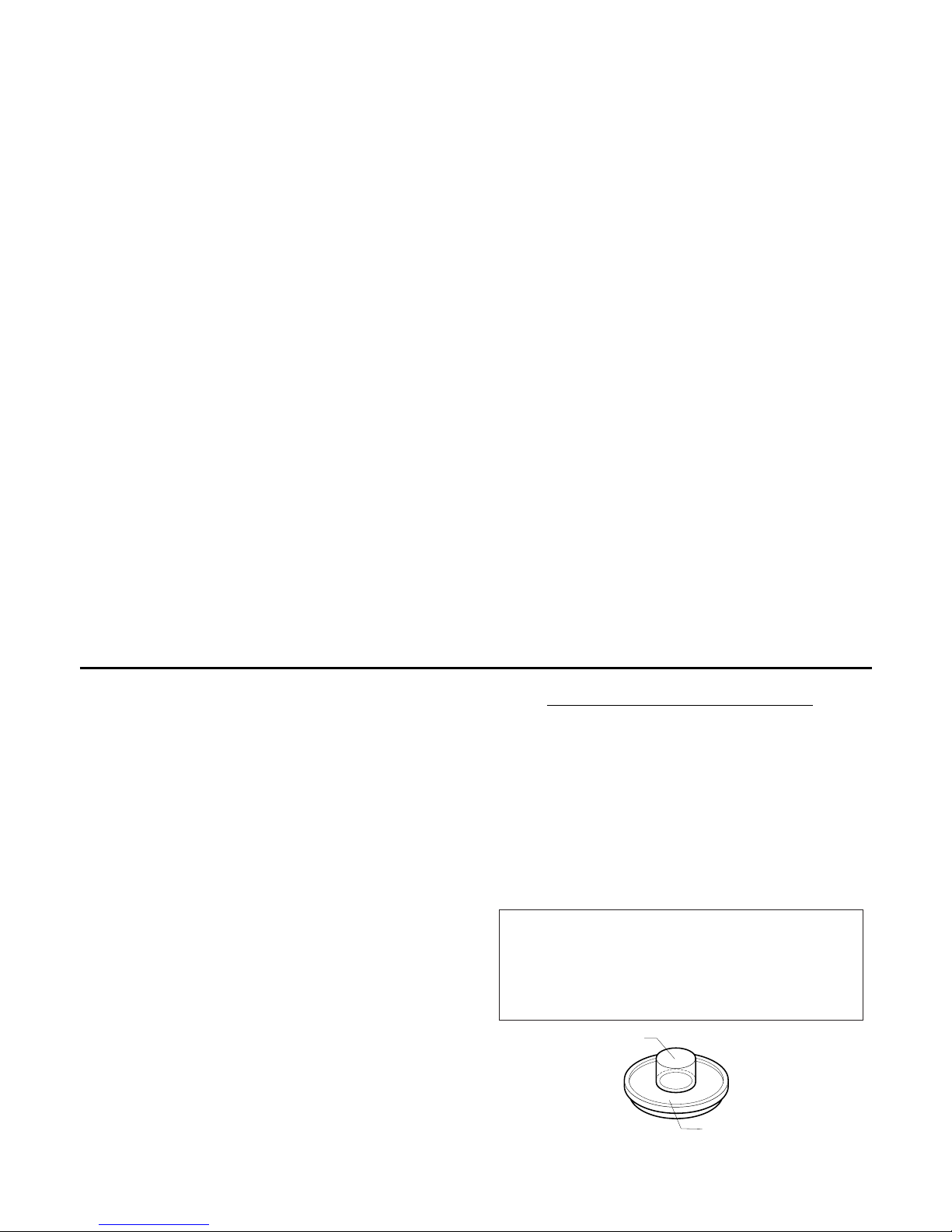

(1) Microwave power output measurement is made

with the microwave oven supplied at its rated voltage and

operated at its maximum microwave power setting with a

load of (1000±5) g of potable water.

(2) The water is contained in a cylindrical borosilicate

glass vessel having a maximum material thickness

of 1/8" (3 mm) and an outside diameter of approximately

7.6" (190mm).

(3) The oven and the empty vessel are at ambient

Temperature(T0) prior to the start of the test.

(4) The initial temperature (T1) of the water is

(10±1)°C (50°F). It is measured immediately before the

water is added to the vessel. After addition of the water to

the vessel, the load is immediately placed on the center

of the turntable which is in the lowest position and the

microwave power switched on.

(5) The time T for the temperature of the water to rise

by a value ∆T of (10±1)°K is measured, where T is the

time in seconds and ∆T is the temperature rise.

The initial and final water temperatures are selected so

that the maximum difference between the final water

temperature and the ambient temperature is 5°K.

(6) The microwave power output P in watts is calculated

from the following formula :

4187 Mw(T2 –T1)+0.55Mc(T2 –T0)

T

is measured while the microwave generator is

operating at full power. Magnetron filament heat-up

time is not included. (about 3 sec)

(7) The water is stirred to equalize temperature

throughout the vessel, prior to measuring the final

water temperature.

(8) Stirring devices and measuring instruments are

selected in order to minimize addition or removal of

heat.

7-3

POWER OUTPUT MEASUREMENT

P =

WATER LOAD

TURNTABLE

Where

P is the microwave power output, in watts:

Mw is the mass of the water, in grams:

Mc is the mass of the container, in grams:

T0 is the ambient temperature, in ¡C:

T1 is the initial temperature of the water, in ¡C:

T2 is the final temperature of the water, in ¡C:

t

is the heating time in seconds, excluding the magnetron filament heat- up time.

Page 15

IMPORTANT NOTES:

UNIT MUST BE DISCONNECTED FROM ELECTRICAL OUTLET WHEN MAKING REPAIRS, REPLACEMENTS, ADJUSTMENTS AND CONTINUITY CHECKS. WAIT AT LEAST ONE MINUTE,

UNTIL THE HIGH VOLTAGE CAPACITOR IN THE

HIGH VOLTAGE POWER SUPPLY HAS FULLY

DISCHARGED.

THE CAPACITOR SHOULD BE DISCHARGED BY

USING INSULATED WIRE - I.E. TEST PROBE

CONNECTED TO 10K-OHM RESISTOR IN SERIES

TO GROUND.

WHEN RECONNECTING THE WIRE LEADS TO

ANY PART, MAKE SURE THE WIRING CONNECTIONS AND LEAD COLORS ARE CORRECTLY

MATCHED ACCORDING TO THE OVERALL CIRCUIT DIAGRAM. (ESPECIALLY SWITCHES AND

HIGH VOLTAGE CIRCUIT.)

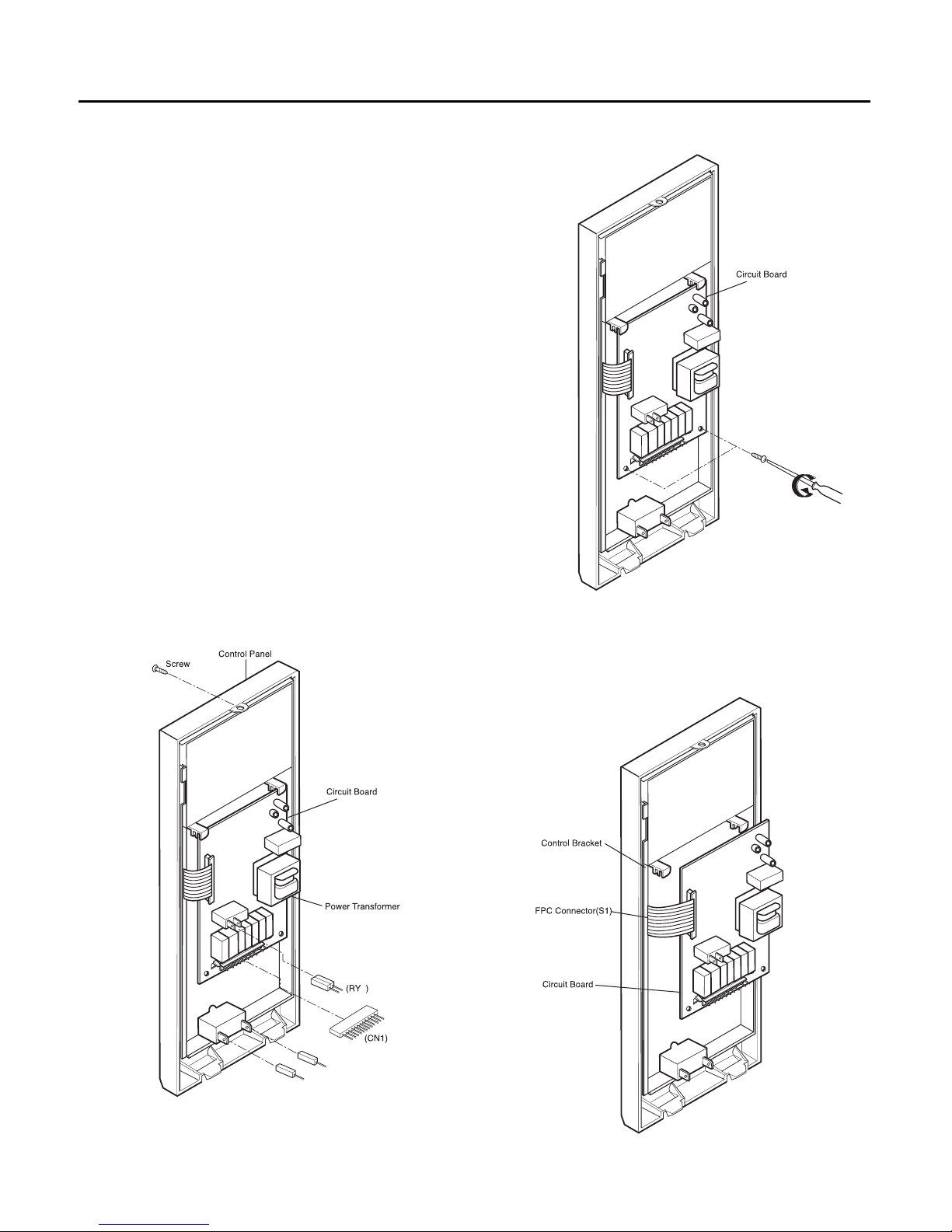

A. REMOVING POWER AND CONTROL

CIRCUIT BOARD (Figures 1, 2 and 3)

(1) Remove a screw securing the control panel

assembly to the oven cavity.

(2) Remove the control panel with pushing it upward.

(3) Remove the connectors (CN1) and wire leads

(Relay8) from the circuit board.

(4) Remove 3 screws securing the circuit board.

(5) Remove the FPC connector from the terminal

socket following “HOW TO REMOVE THE FPC

CONNECTOR” on the next page.

(6) Remove the circuit board from the control bracket

carefully.

7-4

DISASSEMBLY INSTRUCTIONS

Figure 1

8

Figure 2

Figure 3

Page 16

7-5

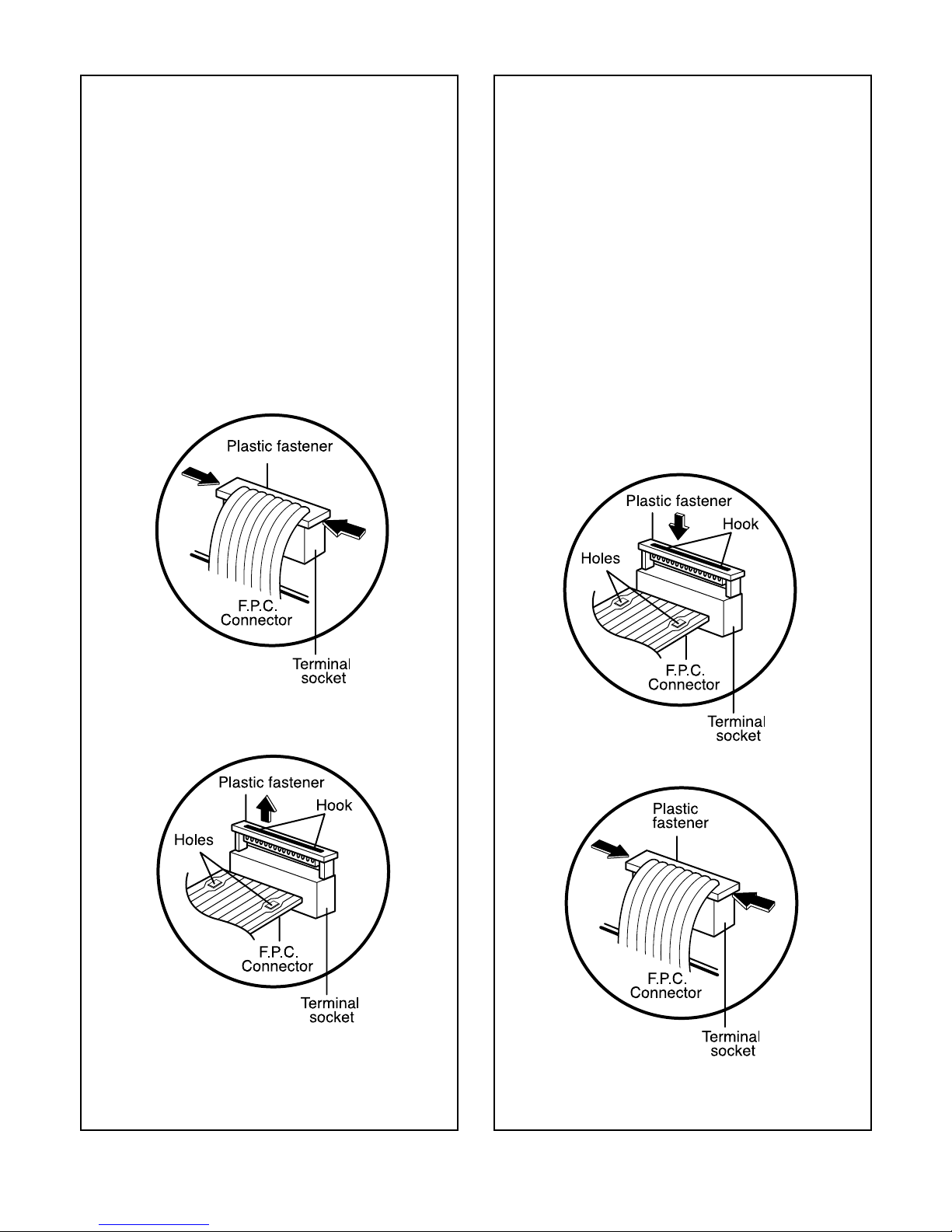

HOW TO REMOVE THE F.P.C. CONNECTOR

Follow the steps below as illustrated in Figures 4

and 5 to remove the F.P.C. connector.

(1) Hold the edges of the plastic fastener with

thumb and forefinger.

(Figure 4)

(2) Lift up the lever of the plastic fastener from

the terminal socket by lightly pressing the

lever end with forefinger.

(Figure 5)

(3) Remove the F.P.C. connector from the

terminal socket.

HOW TO INSERT THE F.P.C. CONNECTOR

Follow the steps below as illustrated in Figures 6

and 7 to insert the F.P.C. connector.

(1) Insert the F.P.C. connector into the terminal

socket securely with the fingers.

(2) Hold the plastic fastener with thumb and

forefinger of the other hand, and push it

slowly into the terminal socket. (Figure 6)

NOTE: When reconnecting the F.P.C

connector make sure that the holes

on the F.P.C. connector are properly

engaged with the hooks on the plastic

fastener

(3) Lock the level of the plastic fastener into the

hook of the terminal socket securely by

releasing the fingers.

(Figure 7)

Figure 4

Figure 5

Figure 7

Figure 6

Page 17

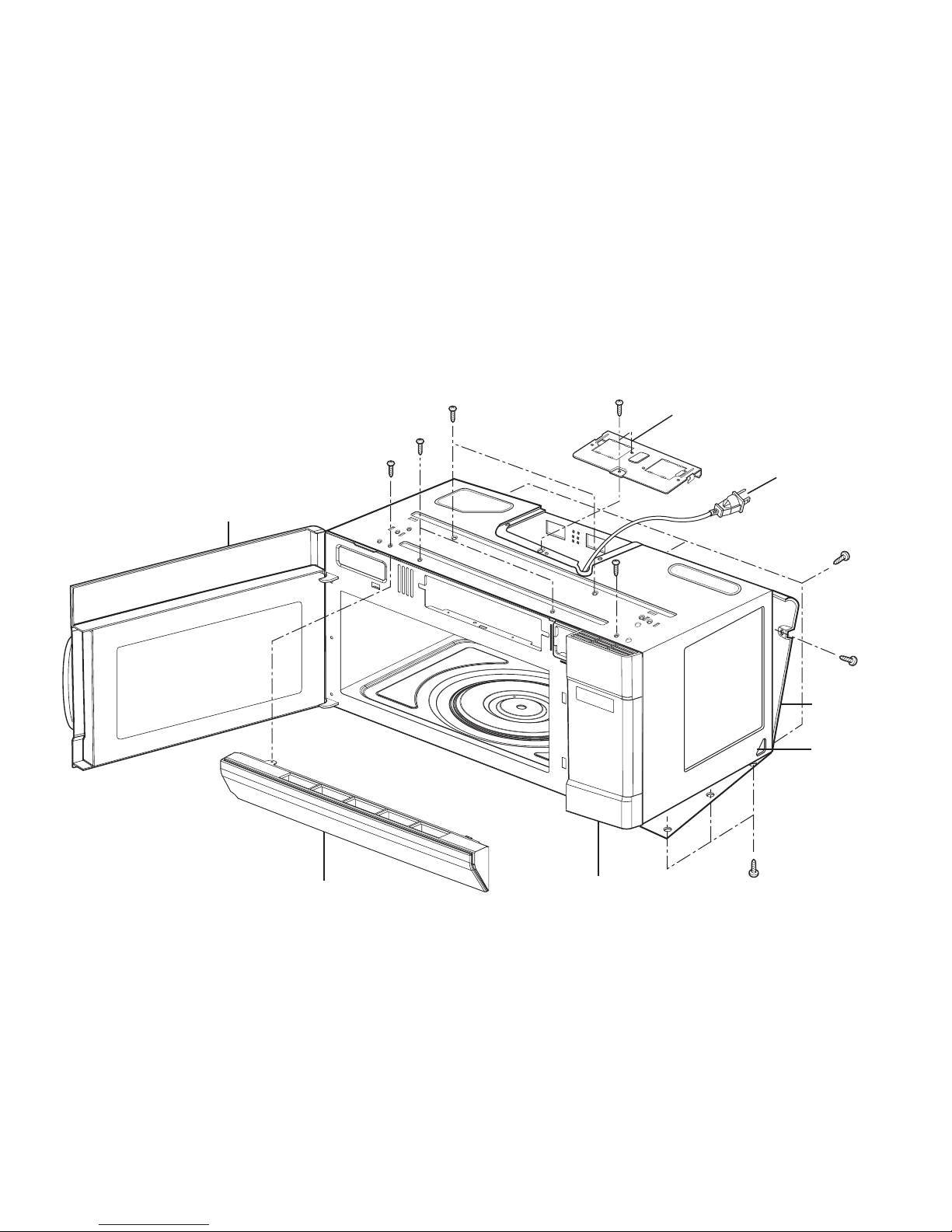

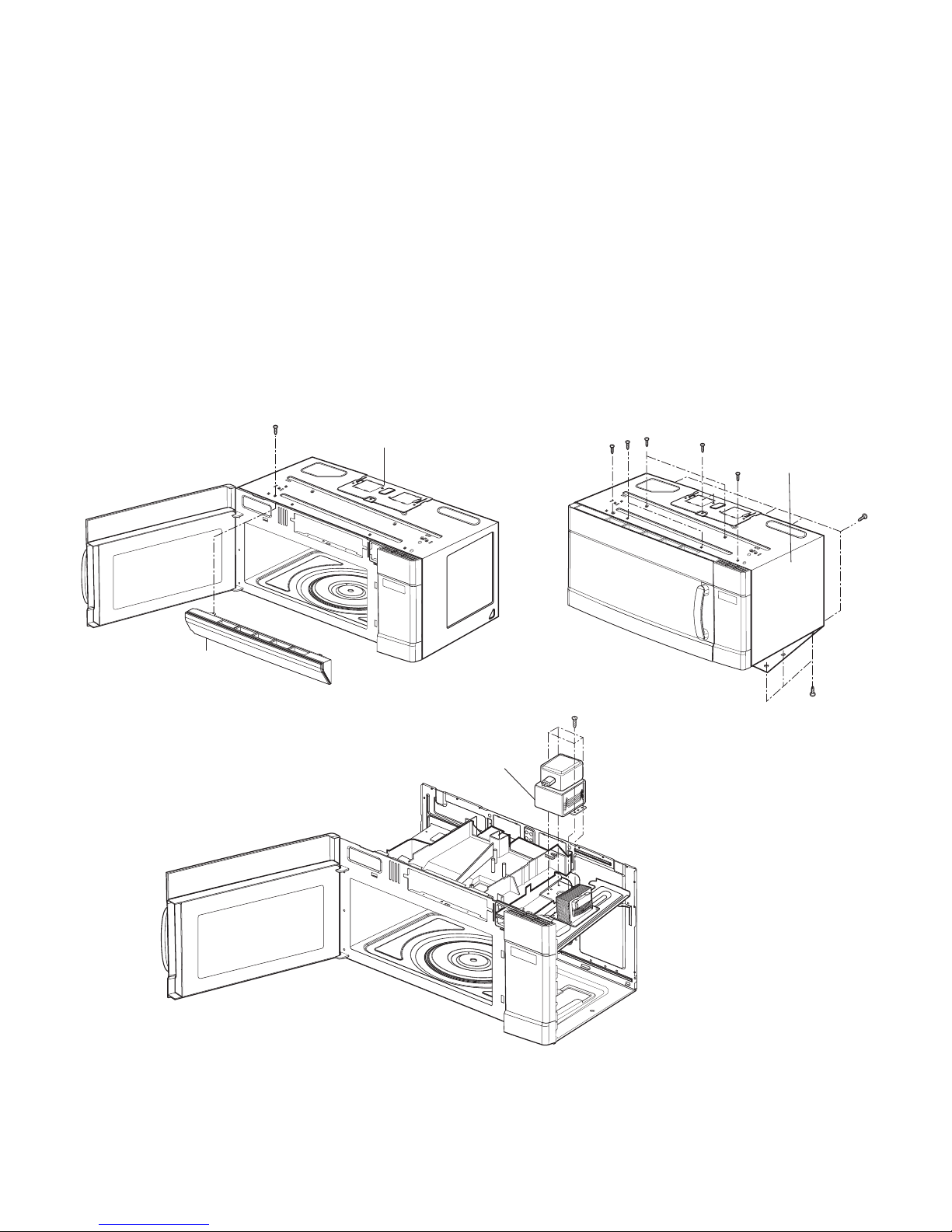

B. REMOVING THE OUT CASE(Figure 8)

(1) Remove the vent grille by removing two screws

securing it to the out case.

(2) Remove two screws securing it to the front

bracket.

(3) Remove two screws securing it to the air duct.

(4) Remove the mounting plate by turning the two

screws securing it to the out case.

(5) Remove the base plate by removing four screws

securing it to the out case. Remove the Mount,

All from the out case by removing two screws

securing it to the out case.

(6) Remove four screws from the rear section.

(7) Remove the outcase with pushing it back.

7-6

Vent Grille

Mount,All

Power code

Mounting

Plate

Out Case

Controller

Door

Figure 8

Page 18

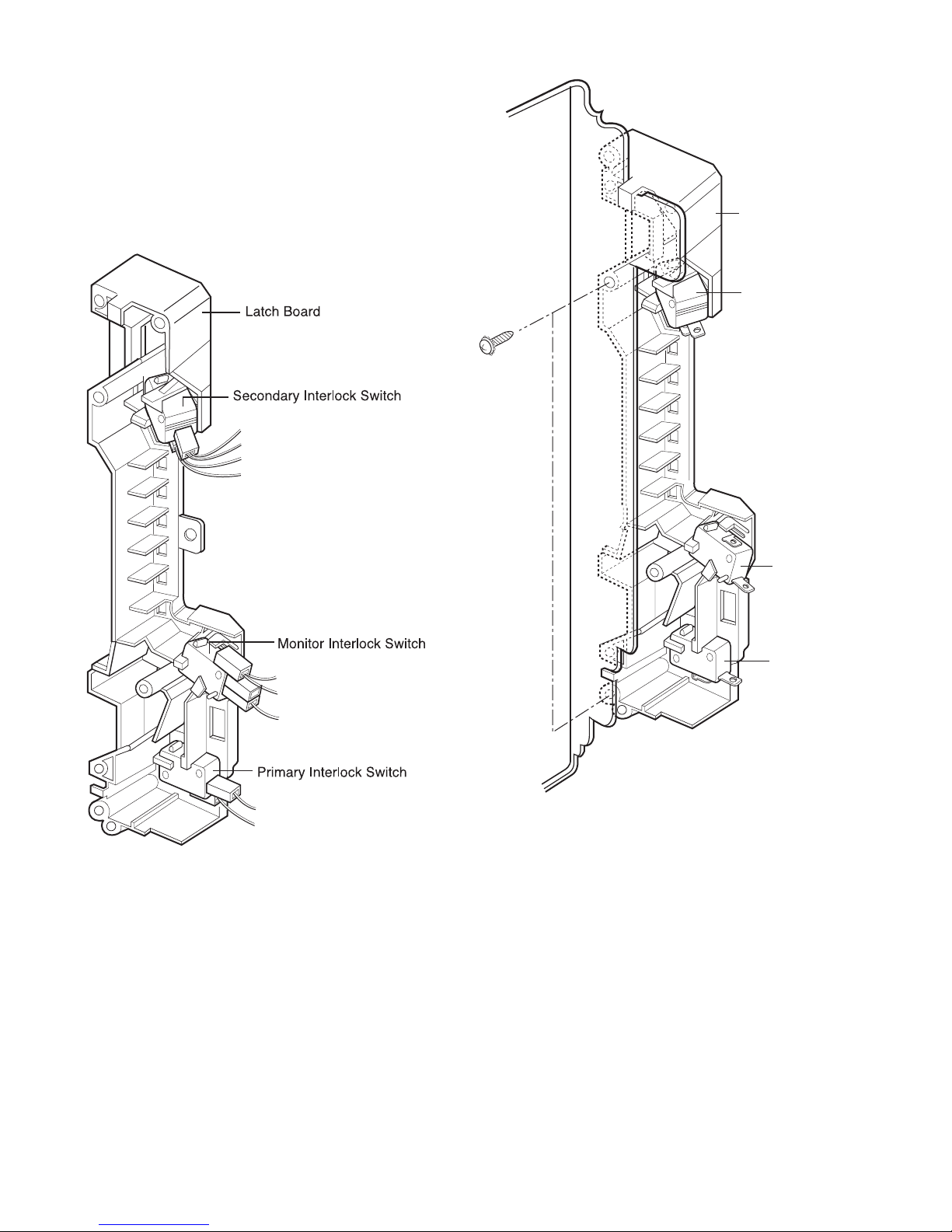

C. REMOVING THE DOOR INTERLOCK

SWITCHES (Figures 9,10)

(1) Disconnect the wire leads from the interlock

switches.

(2) Remove two screws securing the Latch Board.

(3) Make necessary replacements and check

microwave energy leakage according to

“ADJUSTMENT PROCEDURE” on page 7-12.

Latch Board

Secondary

Interlock Switch

Interlock

Monitor Switch

Primary

Interlock Switch

Figure 9

Figure 10

7-7

Page 19

D. REMOVING MAGNETRON

(Figures 11 Through 13)

(1) Remove the vent grille.

(2) Remove mount, all.

(3) Remove outcase.

(4) Disconnect the wireleads.

(5) Remove the three screws and Magnetron very

carefully.

NOTES:

• When removing the magnetron, make sure that its

dome does not hit any adjacent parts, or it may be

damaged.

• When replacing the magnetron, be sure to install

the magnetron gasket in the correct position and be

sure that the gasket is in good condition.

• After replacing the magnetron, check for

microwave energy leakage with a survey meter

Check microwave energy leakage must be below

the limit of 5 mW/cm2. (All service adjustments

should be made for minimum microwave energy

leakage readings.)

7-8

Figure 11

Figure 13

Figure 12

Outcase

vertgrille

mount all

Magnetron

Page 20

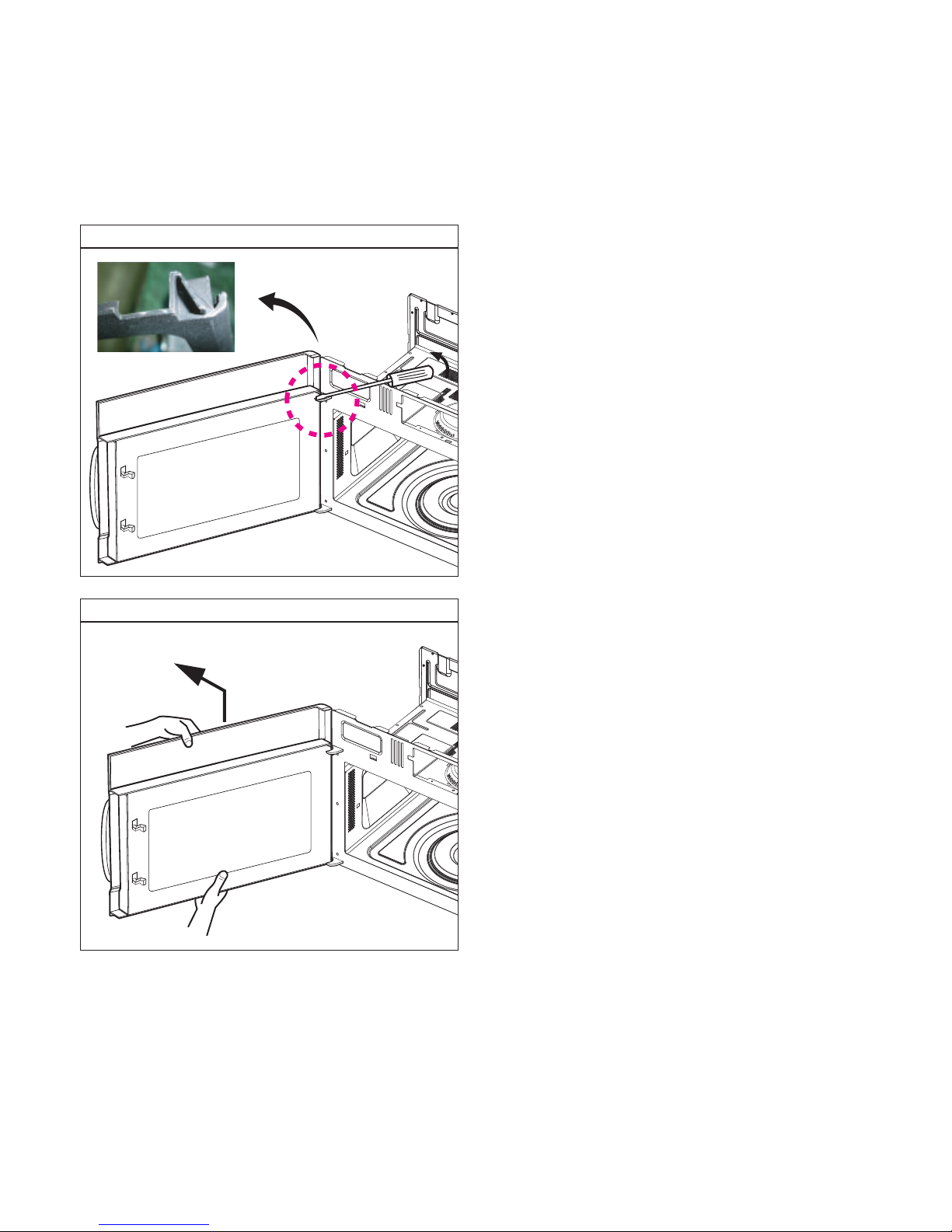

E. DOOR ASSEMBLY / REMOVAL

1) Open the door.

2) Remove the choke cover very carefully with a flatblade screwdriver.

CAUTION : Be careful not to damage door seal plate

by screwdriver.

3) Lift up and push the door.

7-9

Remove door assembly

Remove door assembly

Page 21

F. ASSEMBLING DOOR

(1) When mounting the door assembly to the oven

assembly, be sure to adjust the door assembly

parallel to the chassis. Also adjust so the door has no

play between the inner door surface and oven frame

assembly. If the door assembly is not mounted

properly, microwaves may leak from the clearance

between the door and the oven.

G. REMOVING THE VENTILATION FAN

ASS'Y

(1) Remove the mounting plate by removing two screws

securing it to the back plate.

(See Figure 16)

(2) Remove the two screws securing the MOUNT,

ALL and one screw securing the ventilation fan

ASS'Y. (See Figure 17)

(3) Carefully pull the ventilation motor ASS'Y out of

the microwave oven. (See Figure 18)

7-10

Space

Figure 16

Figure 17

Figure 18

Page 22

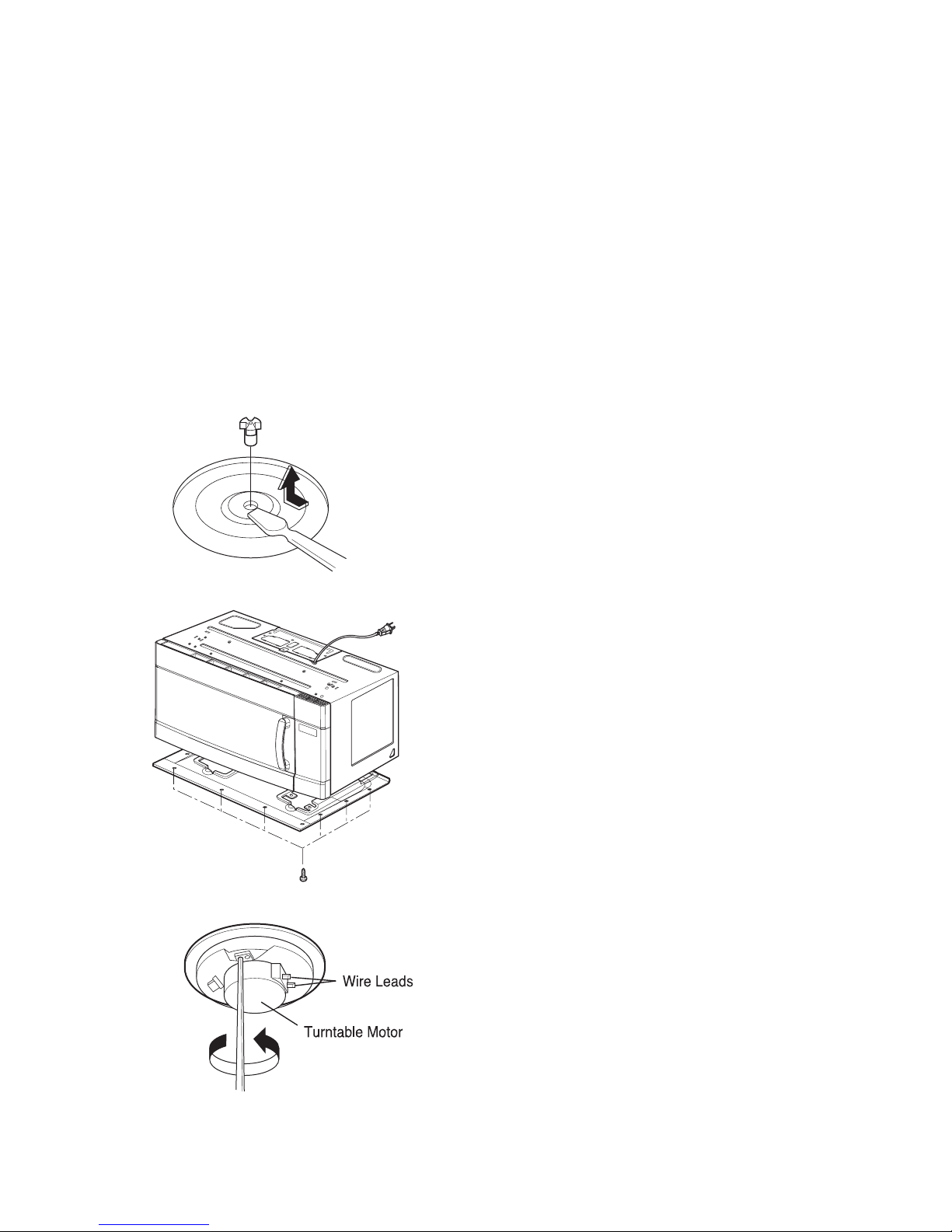

H. REMOVING THE TURNTABLE MOTOR

(1) Remove the turntable.

(2) Remove the turntable shaft VERY CAREFULLY

with a slotted screwdriver. (Figure 19)

(3) Remove the base plate by removing eight screws

securing it to the oven cavity. (Figure 20)

(4) Disconnect the leadwire from the turntable motor

terminals.

(5) Remove a screw securing the turntable motor to

the oven cavity ASS'Y. (Figure 21)

NOTES:

• Remove the leadwire from the turntable motor

VERY CAREFULLY.

• Be sure to grasp the connector not the wires when

removing.

7-11

Figure 21

Figure 19

Figure 20

Page 23

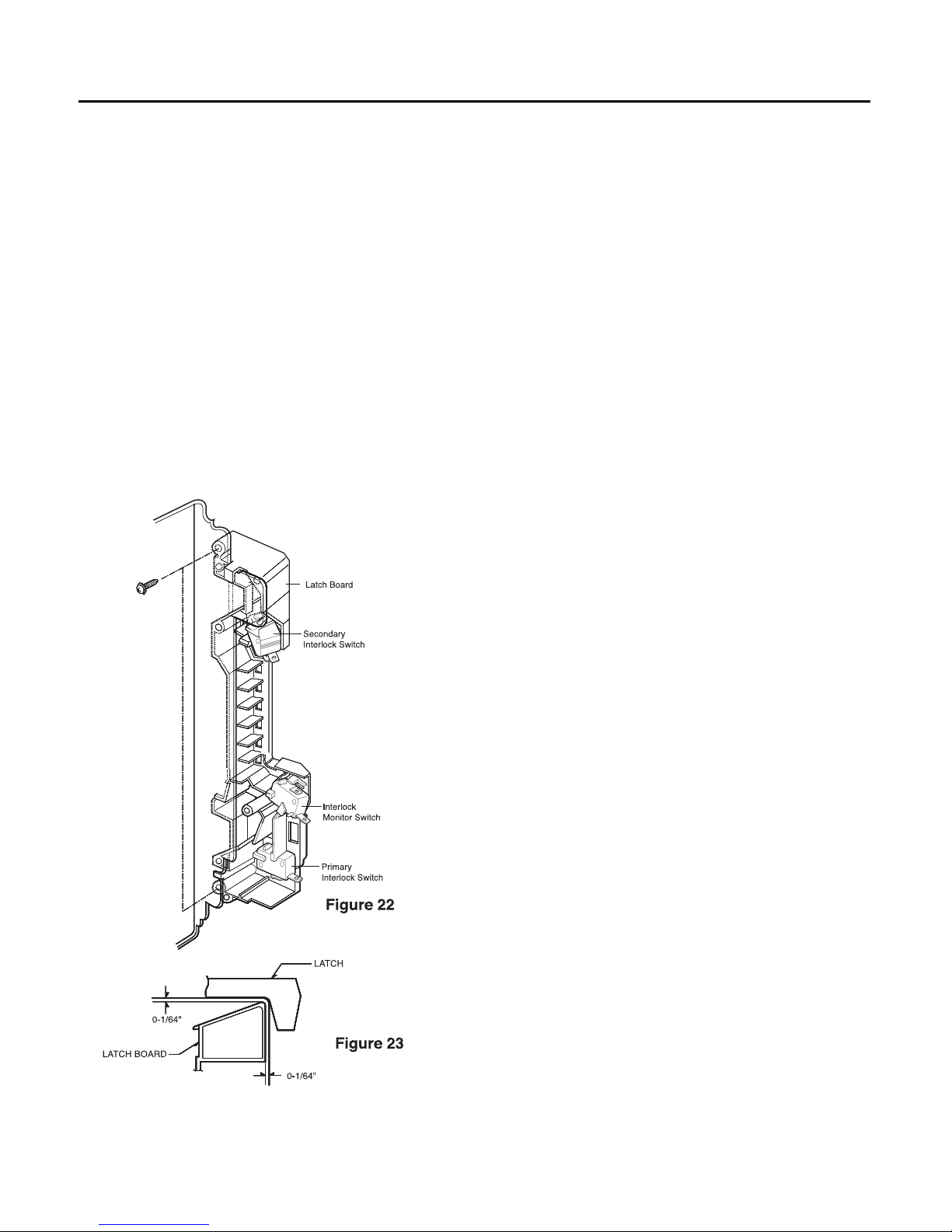

ADJUSTMENT PROCEDURES

To avoid possible exposure to microwave energy

leakage, adjust the door latches and interlock

switches, using the following procedure.

The Interlock Monitor and Primary Interlock Switch act

as the final safety switch protecting the user from

microwave energy. The terminals between “COM” and

“NC” of the Interlock Monitor must close when the door

is opened. After adjusting the Interlock Monitor Switch,

make sure that it is correctly connected.

Mounting of the primary/monitor/secondary switches to

the latch board.

CHECK THE DOOR LATCH AND SWITCH

CLOSING.

NOTE:

The outer cover of the microwave oven is

removed.

(1) Set the microwave oven on its side so that you can

see the latch board and the switches, as shown in

Figure 22.

(2) Close the door tightly and check gaps A and B to

be sure they are no more than 1/64" (0.5 mm).

See Figure 23 for close-up view of gaps A and B

(door latches). If all gaps are less than 1/64"

(0.5 mm), adjustment of the latch board may not

be necessary. Go to Steps 5 and 6 to check the

sequence of the switches.

NOTE:

To correct sequence of the Primary Interlock

Switch, Secondary Interlock Switch and the

Interlock Monitor Switch is very important.

If any gap is larger than 1/64" (0.5 mm), you will

need to adjust the latch board”. Go to step 3

and follow all steps in order.

ADJUST THE LATCH AND SWITCH CLOSING

(3) Loosen the two screws holding the plastic latch

board as shown.

(4) With the oven door closed tightly, move the latch

board upward toward the top of the oven and/or

away from the door latch until the gaps are less

than 1/64" (0.5 mm).

Hold the latch board tightly in this position until you

check the sequence of the switches in steps 5

and 6.

7-12

INTERLOCK SYSTEM

INTERLOCK MECHANISM

The door lock mechanism is a device which has been specially designed to eliminate completely microwave

activity when the door is opened during cooking and thus to prevent the danger resulting from the microwave

leakage.

Page 24

TEST THE LATCH AND SWITCH SEQUENCE

(5) Open the oven door slowly. Watch the door latch,

the Secondary Switch. Release Rod and Lever

on the switches to make sure they are zero to the

body of the switches in the following sequence:

- Primary Interlock Switch

- Secondary Interlock Switch

- Interlock Monitor Switch

Adjust the latch board until the switches operate in

this sequence. See Steps 3 and 4.

(6) Close the oven door slowly and be sure it is tightly

closed. Watch the three switches to make sure

they are zero to the body of the switches in the

following sequence:

- Interlock Monitor Switch

- Primary Interlock Switch

- Secondary Interlock Switch

NOTE: The Interlock Monitor Switch is an added

safety check on the Primary and

Secondary Interlock Switches. If the

Primary and Secondary Interlock Switches

allow the oven to operate with the door

open, the Monitor Switch will blow the

fuse.

(7) When you achieve the proper sequence of

switches in Steps 5 and 6, tighten the latch board

screws at that point.

TEST THE MICROWAVE ENERGY LEAKAGE

Make sure the microwave energy leakage is below the

limit of 1mW/cm2(with a 275 ml water load) and

5mW/cm2(with a 275 ml water load without the

cabinet) when measured with a survey meter.

7-13

Page 25

A. PRIMARY INTERLOCK SWITCH TEST

When the door is opened slowly, an audible click

should be heard at the same time or successively

at intervals and the latches should activate the

switches with an audible click.

If the latches do not activate the switches when the

door is closed, the switches should be a adjusted

in accordance with the adjustment procedure.

Disconnect the wire lead from the primary switch.

Connect the ohmmeter leads to the common

(COM) and normally open (NO) terminal of the

switch. The meter should indicate an open circuit

in the door open condition.

When the door is closed, the meter should indicate

a closed circuit.

When the primary switch operation is abnormal,

make the necessary adjustment or replace the

switch only with the same type of switch.

B. SECONDARY INTERLOCK SWITCH TEST

Disconnect the wire lead from the secondary

switch.

Connect the ohmmeter leads to the common

(COM) and normally open (NO) terminals of the

switch. The meter should indicate a open circuit in

the door open condition. When the door is closed,

meter should indicate an closed circuit. When the

secondary switch operation is abnormal, make the

necessary adjustment or replace the switch only

with the same type of switch.

C. MONITOR SWITCH TEST

Disconnect the wire lead from the monitor switch.

Connect the ohmmeter leads to the common

(COM) and normally closed (NC) terminals of the

switch. The meter should indicate closed circuit in

the door open condition. When the door is closed,

meter should indicate an open circuit. When the

monitor switch operation is abnormal, replace with

the same type of switch.

NOTE: After repairing the door or the interlock

system, it is necessary to do this continuity

test before operating the oven.

7-14

INTERLOCK CONTINUITY TEST

COMPONENTS TEST PROCEDURE RESULTS

SWITCHES Check for continuity of the Door Door

(Wire leads removed) switch with an Ohm-meter open closed

Primary

Switch

Monitor

Switch

Secondary

Switch

NOTE: After checking for the continuity of switches, make sure that they are

connected correctly.

WARNING : FOR CONTINUED PROTECTION AGAINST EXCESSIVE RADIATION

EMISSION, REPLACE ONLY WITH IDENTICAL REPLACEMENT PARTS.

TYPE NO. SZM-V16-FA-63 OR VP-533A-OF OR V-5230Q FOR PRIMARY SWITCH

TYPE NO. SZM-V16-FA-62 OR VP-532A-OF OR V-5220Q FOR MONITOR SWITCH

TYPE NO. SZM-V16-FA-63 OR VP-533A-OF OR V-5230Q FOR SECONDARY SWITCH

NO

COM

NC

COM

NO

COM

Page 26

7-15

TEST AND CHECKOUT PRECEDURES AND TROUBLESHOOTING

CAUTIONS

1. DISCONNECT THE POWER SUPPLY CORD FROM THE OUTLET WHENEVER REMOVING THE OUTER CASE

FROM THE UNIT. PROCEED WITH THE TEST ONLY AFTER DISCHARGING THE HIGH VOLTAGE CAPACITOR

AND REMOVING THE LEAD WIRES FROM THE PRIMARY WINDING OF THE HIGH VOLTAGE TRANSFORMER.

2. ALL OPERATIONAL CHECKS WITH MICROWAVE ENERGY MUST BE DONE WITH A LOAD (1 LITER OF

WATER IN CONTAINER)IN THE OVEN.

A. TEST PROCEDURES

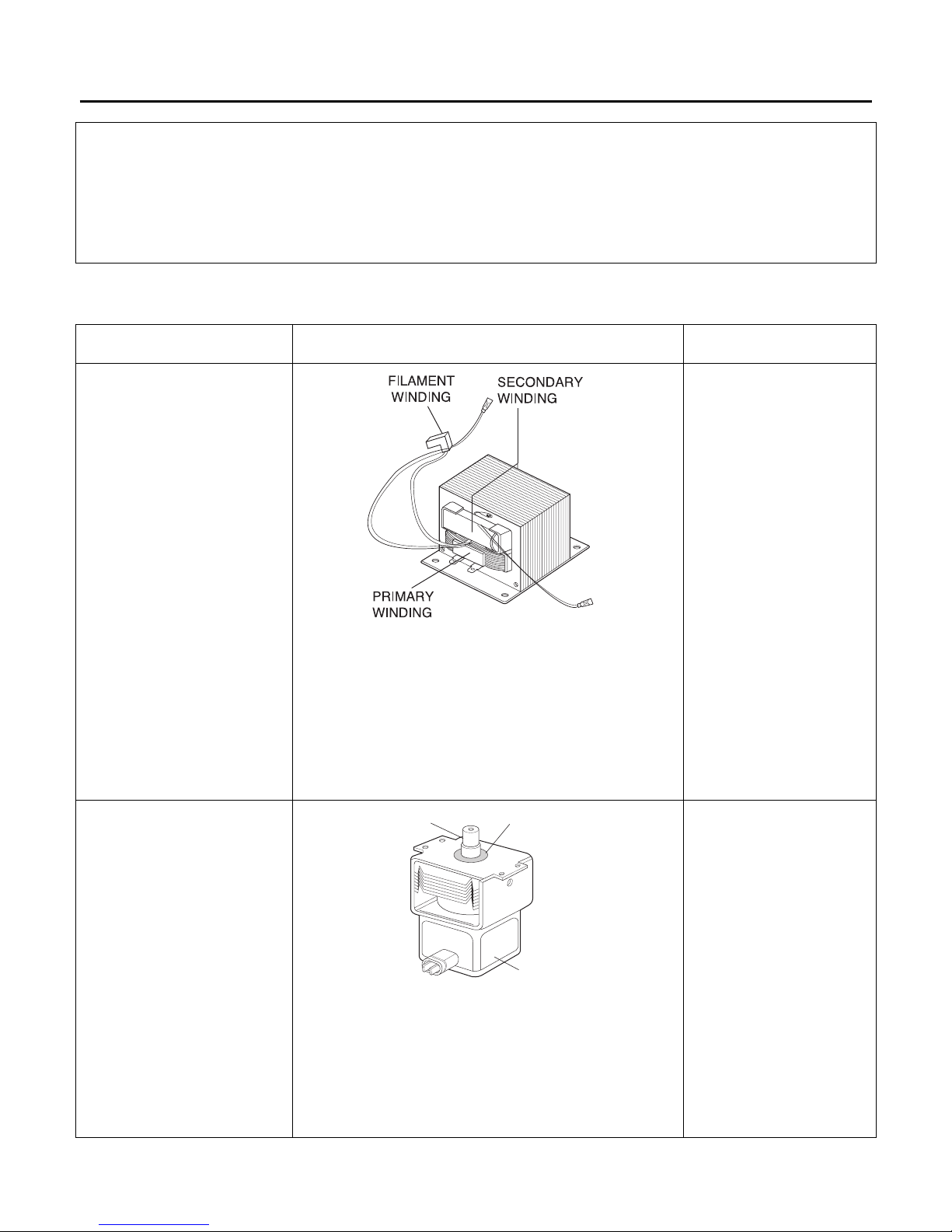

H.V.Transformer

MAGNETRON

1. Remove wire leads.

2. Measure resistance. (ohm meter scale: Rx1)

• Primary winding

• Secondary winding

• Filament winding

3. Measure resistance. (ohm meter scale: Rx1000)

• Primary winding to ground

• Filament winding to ground

1. Remove wire leads. Install the magnetron seal in

the correct position.

Check that the seal is in good condition.

2. Measure resistance. (ohm meter scale: Rx1)

• Filament terminal

3. Measure resistance. (ohm meter scale: Rx1000)

• Filament to chassis

Normal: Less than 1 ohm

Abnormal: Infinite

Normal: Infinite

COMPONENTS TEST RESULTS

Approx. 0.3 to 0.5 ohms

Approx. 65 to 120 ohms

0 ohm

Normal: Infinite

Normal: Infinite

Antenna

Gasket

Chassis

Page 27

7-16

COMPONENTS TEST RESULTS

Normal:

Approximately 9V

Abnormal :

Approximately 0V

Normal:

Approximately 0V or

a value displayed in

mV Will be seen.

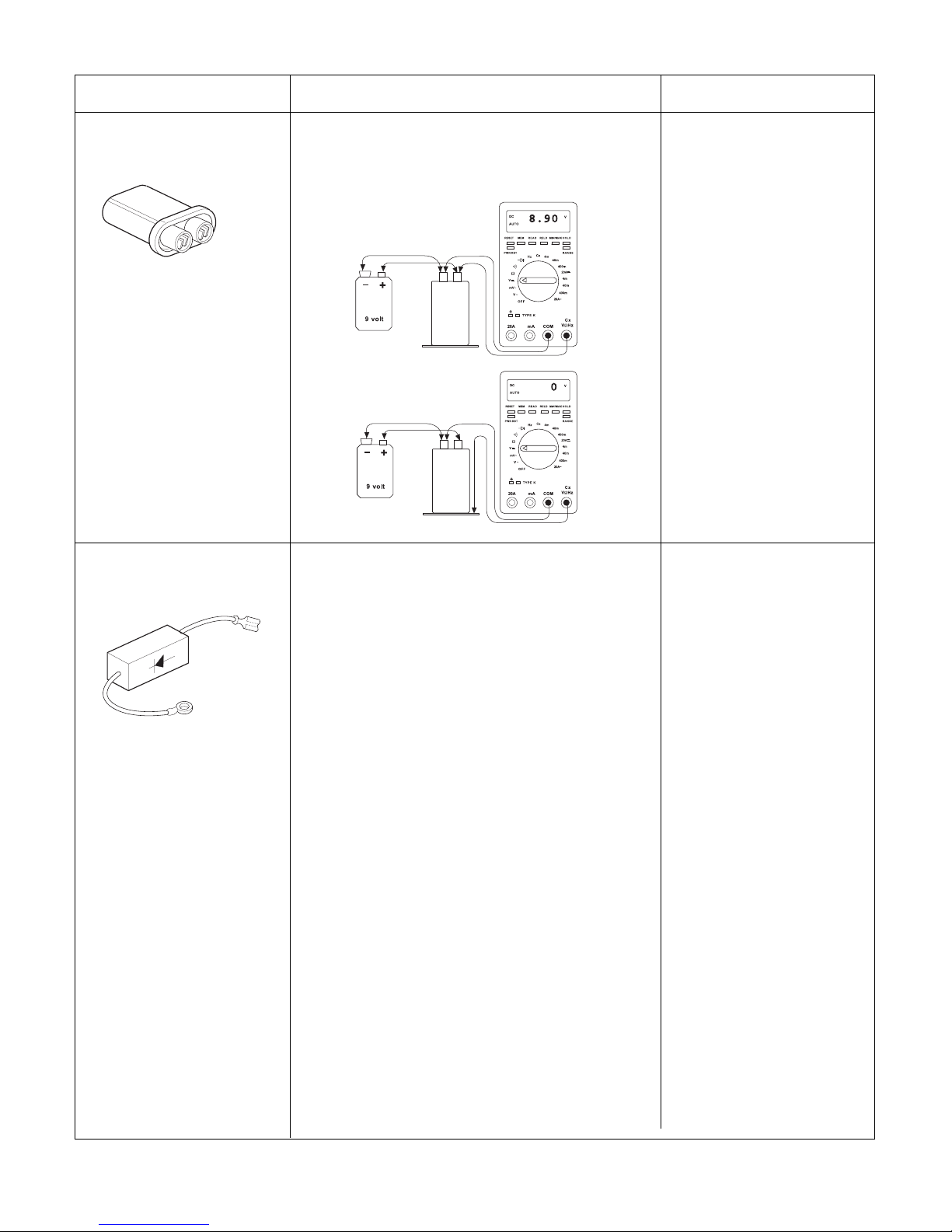

H.V.Capacitor

H.V.Diode

(RECTIFIER)

STEP 1. Test the diode to see if it is shorted.

Procedure:

1. Select the ohm scale on the meter.

2. Place the meter leads across the diode as pictured in

Figure 1. The reading should be “40M,” “OL,” or a

reading of infinity.

3. Reverse the meter leads. The reading should again

indicate a reading of infinity. If the diode shows

“infinity” in BOTH directions, it is NOT shorted.

4. If the diode is not shorted, proceed to step 2.

STEP 2. Test the diode for forward biasing.

Procedure:

1. Select the DCV scale on the meter.

2. Using the meter, battery, and jumper wire, connect the

items as illustrated in Figure 2.

This has the positive side of the battery connected to

the cathode of the diode.

3. The diode should be forward biased therefore a

voltage reading of approximately 4.7 VDC to 6.4 VDC

will be read depending on meter, battery strength, etc.

(Note: If the meter leads were reversed, a negative

voltage of the same amount would be seen.)

STEP 3. Test the diode for reverse biasing.

Procedure:

1. Using the same scale on the meter, connect the

positive side of the battery to the anode of the diode

as illustrated in Figure 3.

2. The diode should be reverse biased therefore a

reading of 0 volt or a value displayed in mV will be

seen. (The display will be erratic changing values

rapidly in the mV scale.)

Normal:

Approximately

4.7-6.4V

Normal:

Approximately 0V

1. Check DC 9V battery before performing tests.

2. Select the DCV scale on the meter.

3. Using the meter, battery, and jump wire,

connect the items as illustrated in figures.

• Terminal to terminal

• Terminal to case

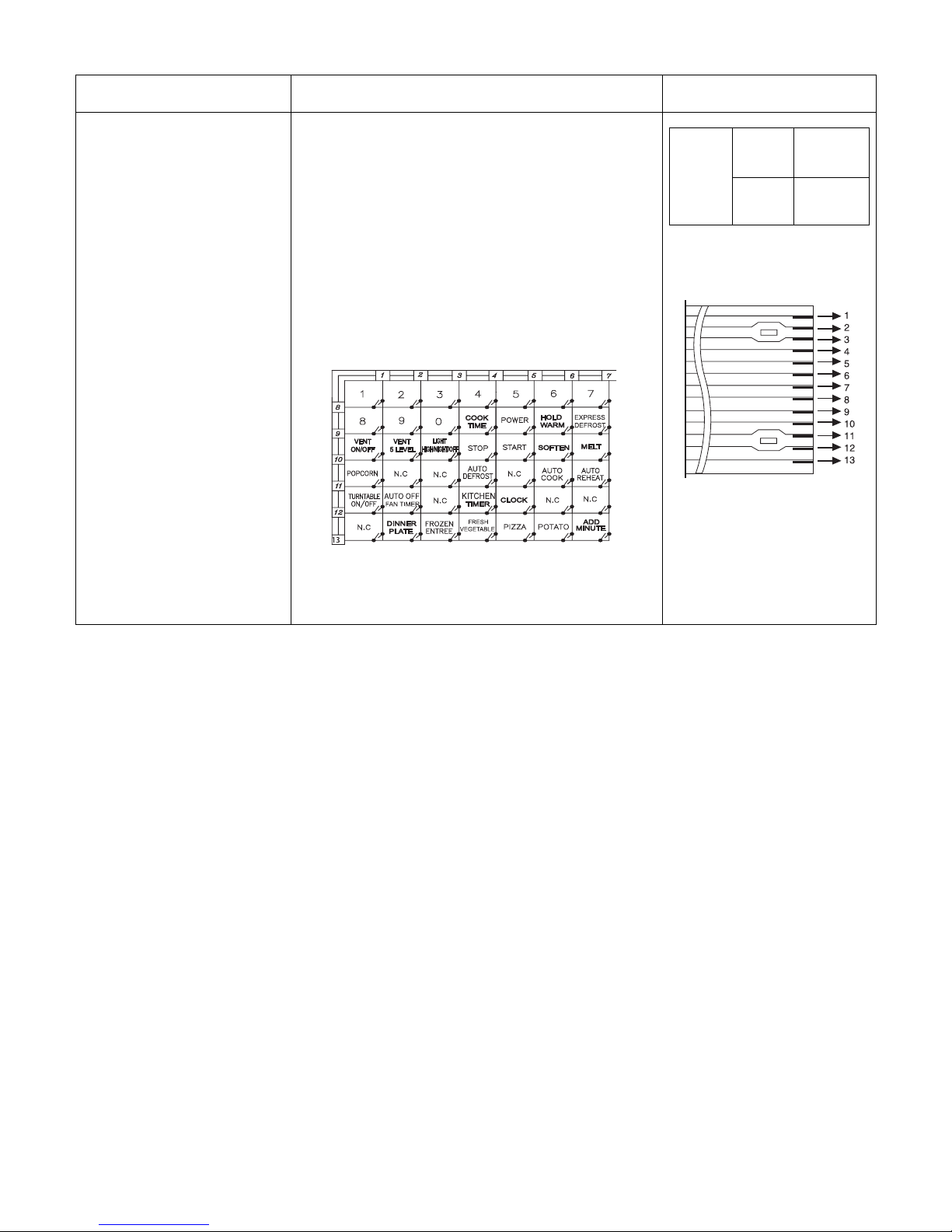

Page 28

7-17

COMPONENTS TEST RESULTS

Measure the resistance between terminal

pins of connector KEY CONNECTOR.

NOTE:

When reconnecting the FPC connector,

make sure that the holes on the FPC

connector are properly engaged with hooks

on the plastic fastener.

MATRIX CIRCUIT FOR

TOUCH KEY BOARD

CONNECTOR(KEY CON)

TOUCH KEY BOARD

Resistance

value

When

touched

Less than

400 ohms

When not

touched

More than

1 mega ohm

FPC CONNECTOR

Top

NOTES:

• A MICROWAVE ENERGY TEST MUST ALWAYS BE PERFORMED WHEN THE UNIT IS SERVICED FOR

ANY REASON.

• MAKE SURE THE WIRE LEADS ARE IN THE CORRECT POSITION.

• WHEN REMOVING THE WIRE LEADS FROM THE PARTS, BE SURE TO GRASP THE CONNECTOR, NOT

THE WIRES.

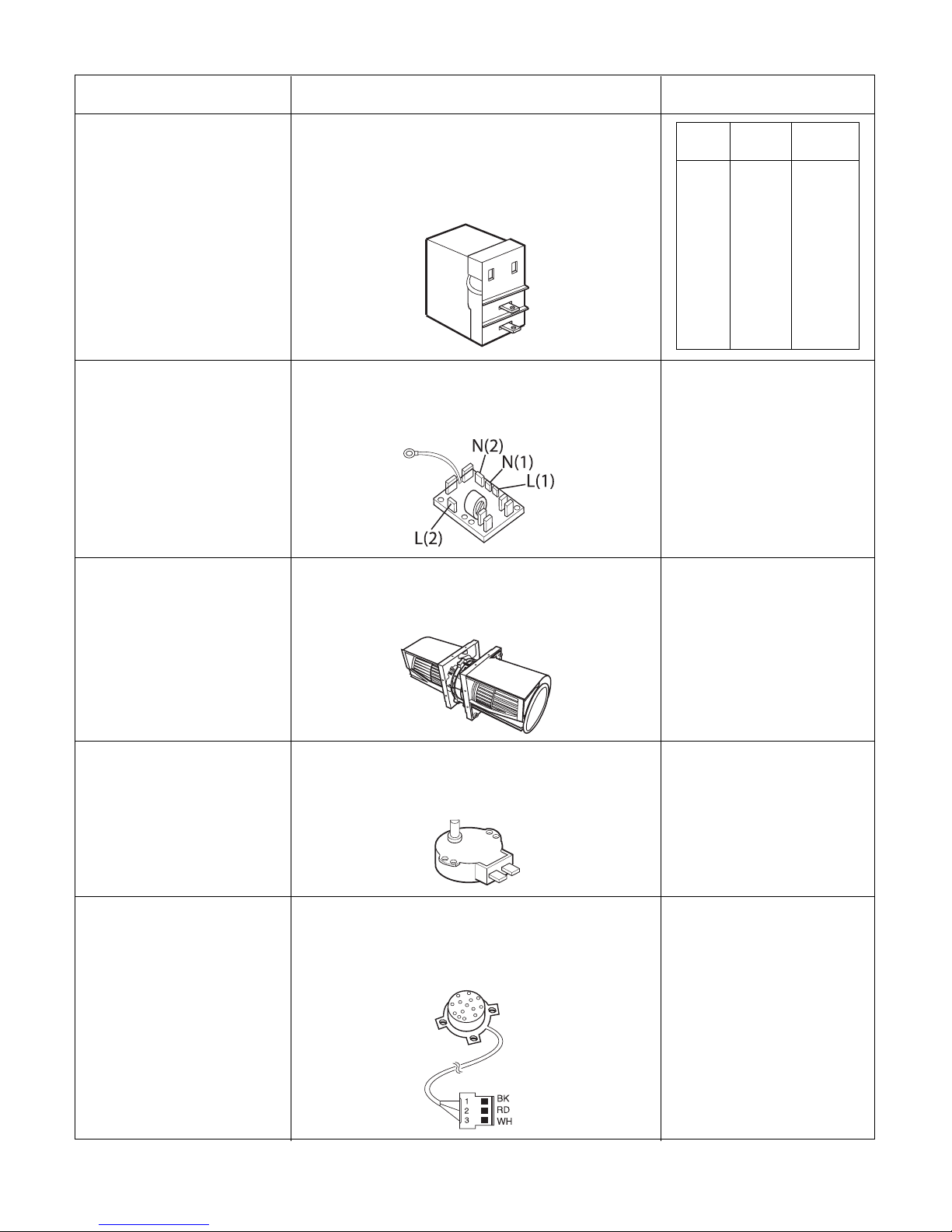

Page 29

7-18

COMPONENTS TEST RESULTS

Nmornal:

L(1)-L(2)(coil):Less than 1 ohm

N(1)-N(2)(coil):Less than 1 ohm

Abnormal:infinite

Normal:

L(1) or L(2)-N(1) or N(2)(resistor):

1.5M ohms

Abnormal: 0 ohms

1. Measure continuity.

(ohm meter scale: Rx1)

2. Remove the lead wires and operate

oven at power level 1 through power level 10.

1. Unplug microwave oven or disconnect power.

2. Remove wires.

3. Measure resistance (ohm meter scale: Rx1000)

Relay 8

Noise Filter

1. Remove wire leads.

2. Measure resistance.

(ohm meter scale: Rx1)

Normal:

Approximately

20 to 40 ohm

Abnormal: Infinite.

Ventilation Motor

1. Remove wire leads.

2. Measure resistance.

(ohm meter scale: Rx1000)

Normal:

Approximately

2.5 to 3.5 Kohms

Abnormal:

Infinite or several.

Turntable Motor

1. Disconnect sensor connector from

micom computer board.

2. Measure resistance terminal to

terminal (ohm meter scale: Rx1000)

Normal:

Approximately

BK-RD: 6.0 Kohms

RD-WH: 3.0 Kohms

BK-WH: 3.0 Kohms

Abnormal:

Infinite or approx. 0 ohm

Absolute Humldlty

Sensor

(For sensor model)

Power

Level

Open

Close

1

2

3

4

5

6

7

8

9

10

4 Sec

6 Sec

8 Sec

10 Sec

12 Sec

14 Sec

16 Sec

18 Sec

20 Sec

22 Sec

18 Sec

16 Sec

14 Sec

12 Sec

10 Sec

8 Sec

6 Sec

4 Sec

2 Sec

0 Sec

Page 30

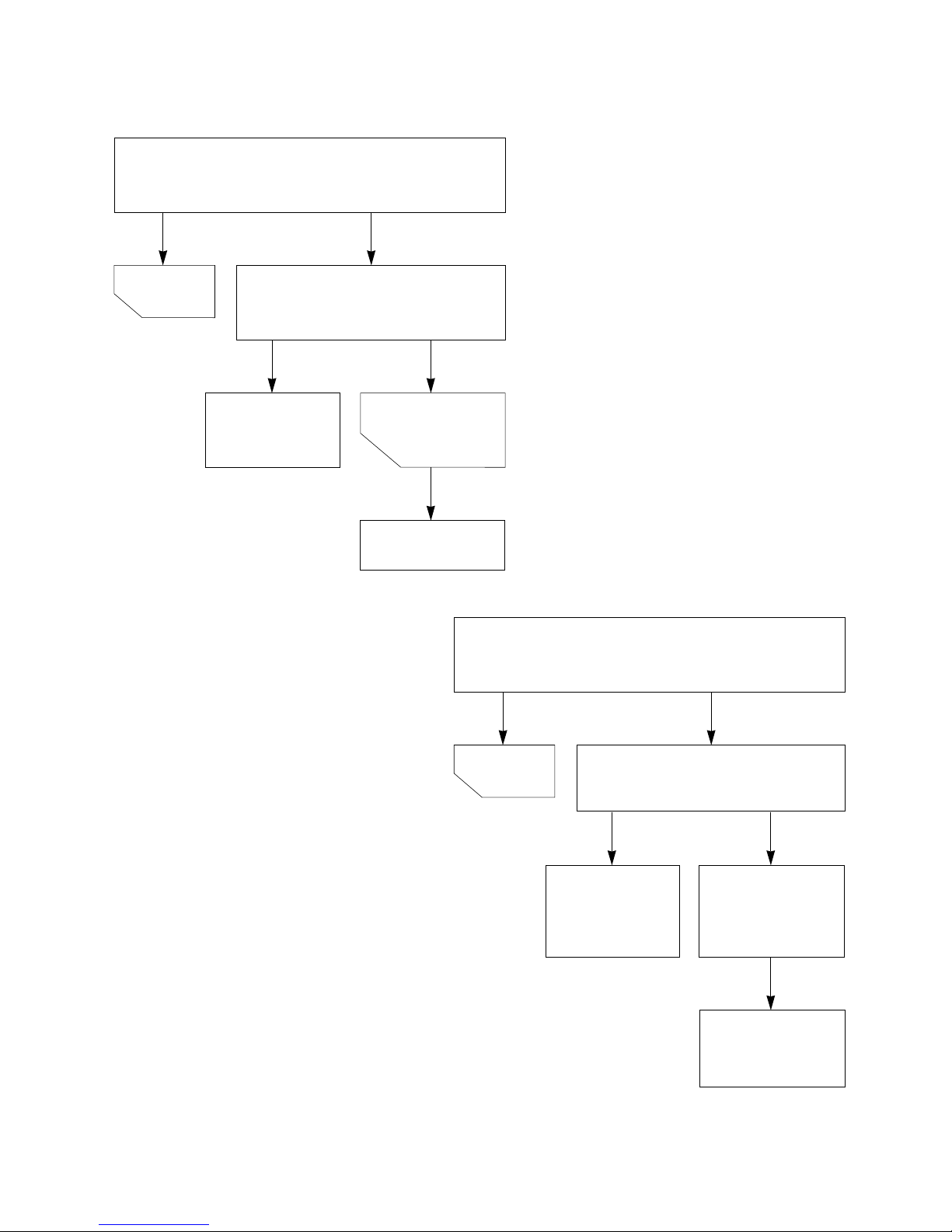

B. CHECKOUT PROCEDURES

(1) CHECKOUT PROCEDURES FOR FUSE BLOWING

CAUTION: REPLACE BLOWN FUSE WITH 20 AMPERE FUSE.

NOTES:

• If the fuse is blown by an improper switch operation, replace all switches and the fuse at the same time.

After replacing the defective switches with new ones, make sure that they are correctly connected.

• Check for microwave energy leakage according to INTERLOCK ADJUSTMENT PROCEDURES on page

7-12 when the primary interlock, secondary interlock switches and/or the interlock monitor switches are

adjusted or replaced.

7-19

PROBLEMS CAUSES

Fuse blows immediately after

the door is closed.

Fuse blows immediately after

the door is opened.

Fuse blows when the door is closed and START

key is touched.

Improper operation of the primary interlock, secondary

interlock switches and/or the interlock monitor switch.

Malfunction of the high voltage transformer; the high

voltage capacitor including the diode, the magnetron,

the blower motor or the circuit board.

Page 31

7-20

(2) CHECKOUT PROCEDURES FOR RELAY.

- PROBLEM (A) -

Oven lamp turn on without touching START key

when the door is closed.

Remove the mate connector of I/O

CON from the circuit board.

Does the unit still operate?

Replace the

circuit board

Replace

RELAY1

NO

NO

YES

YES

GOOD

Defective

RELAY1

- PROBLEM (B) -

Oven lamp turn on When the door is closed and

START key is touched.

Measure the voltage at pin NO.

35 of U01

Voltage reading: -5 Vdc

Replace the

circuit board

Defective

RELAY1 or poor

connection of

RELAY1

Replace

RELAY1 or correct

the connection.

YES

NO

NO

YES

GOOD

Page 32

(3) CHECKOUT PROCEDURES FOR CIRCUIT

BOARD

The following symptoms indicate a defective circuit

board.

1) The start function fails to operate but the high

voltage Systems, the interlock switches, the door

sensing and the relay check good.

2) The unit with a normal relay continuously operates.

3) Proper temperature measurement is not obtained.

4) The buzzer does not sound or continues to sound.

5) Some segments of one or more digits do not light

up, or they continue to light up, or segments light

when they should not.

6) Wrong figures appear.

7) The figures of all digits.

8) Some of the indicators do no flicker light up.

9) The clock does not keep time properly.

7-21

NOTE: A MICROWAVE ENERGY LEAKAGE TEST MUST ALWAYS BE PERFORMED WHEN THE UNIT IS

SERVICED FOR ANY REASON.

Page 33

7-22

C. TROUBLE SHOOTING

Before following this troubleshooting read “TRIAL OPERATION” on page 6- 1.

• “DISPLAY” Problems, “A” thru “C”

• “HELP UP” Problems, “D” thru “E” • “BUZZER Problems, “F”

PROBLEM - A: “PLEASE SET TIME OF DAY” does not appear in display window when power supply cord is

plugged into wall outlet.

PROBLEM - B: Display does not show correct numbers and/ or

correct indications when programmed.

Check: 1. POWER SUPPLY

2. FUSE (See “CHECKOUT PROCEDURES FOR FUSE BLOWING: on page 7- 18)

3. OVEN CAVITY THERMOSTAT

1

1

Page 34

7-23

PROBLEM - C: Unit does not heat up even if display counts down when

START key is touched for “HIGH POWER” cooking.

Check: 1. PRIMARY AND SECONDARY INTERLOCK SWITCHES

2. THERMOSTAT

1

2

Page 35

7-24

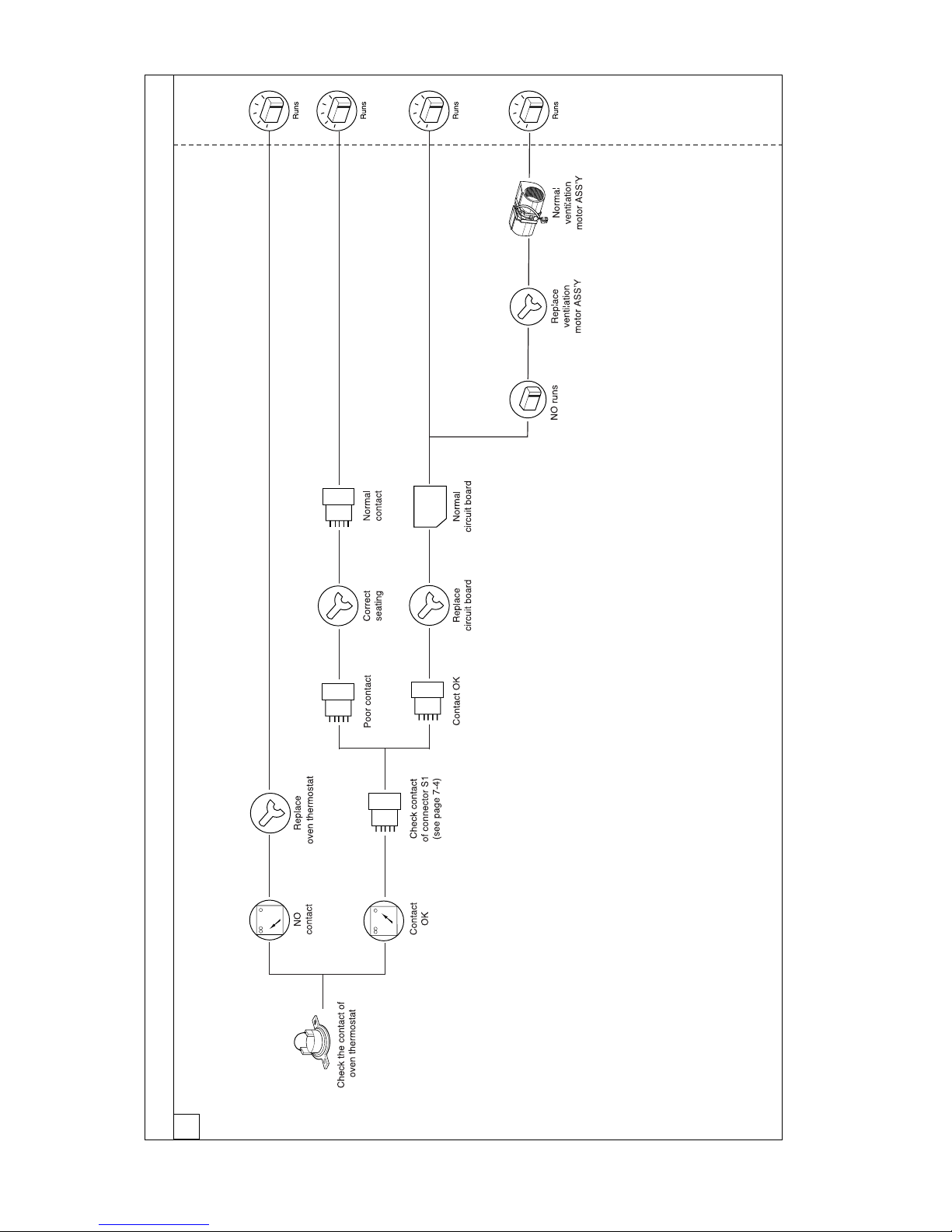

PROBLEM - D: No buzzing when touching the key, between

stages or at end of cooking

1

Page 36

7-25

PROBLEM - E: Ventilation fan does not operate when “FAN HIGH/ LOW” key is touched.

1

Check: 1. POWER SUPPLY

2. FUSE

Page 37

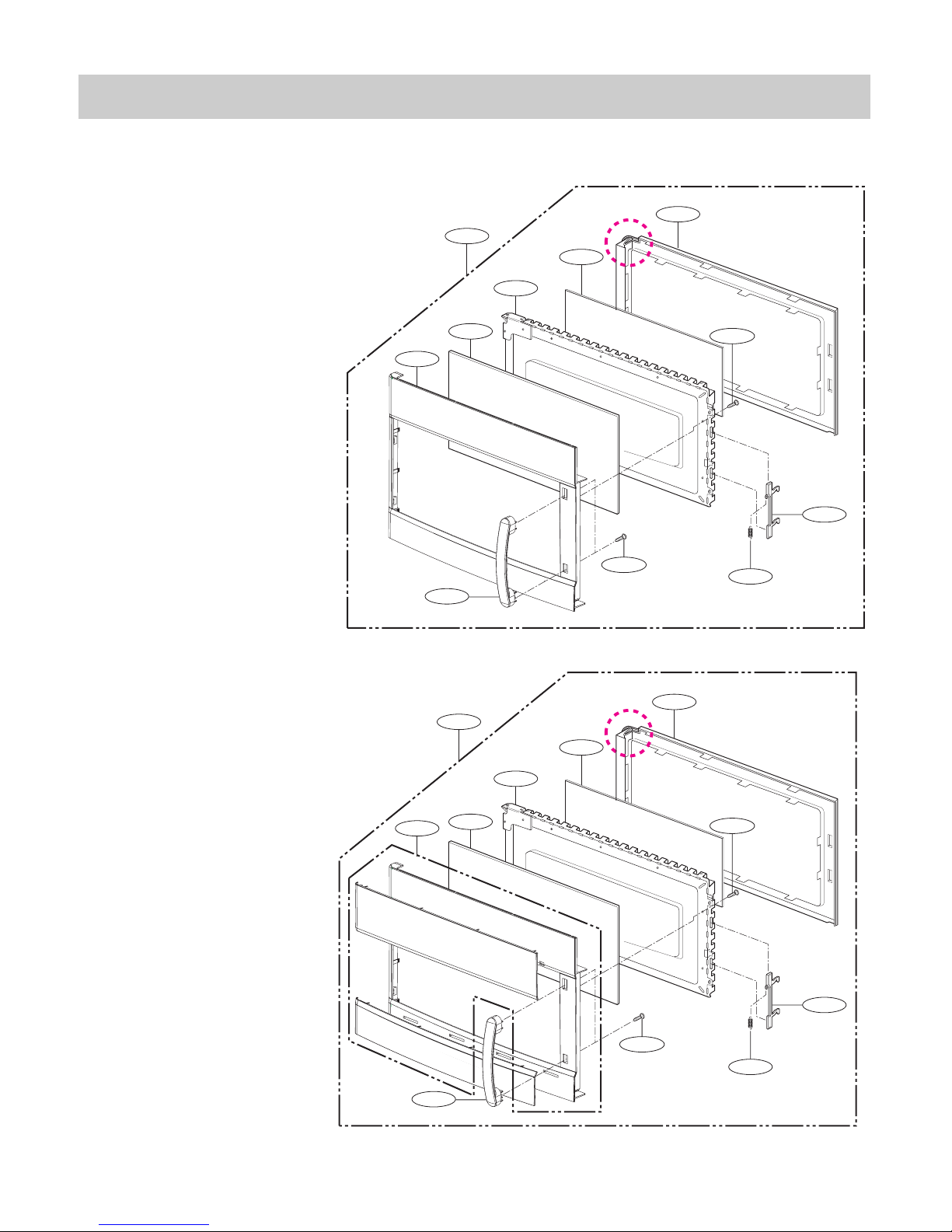

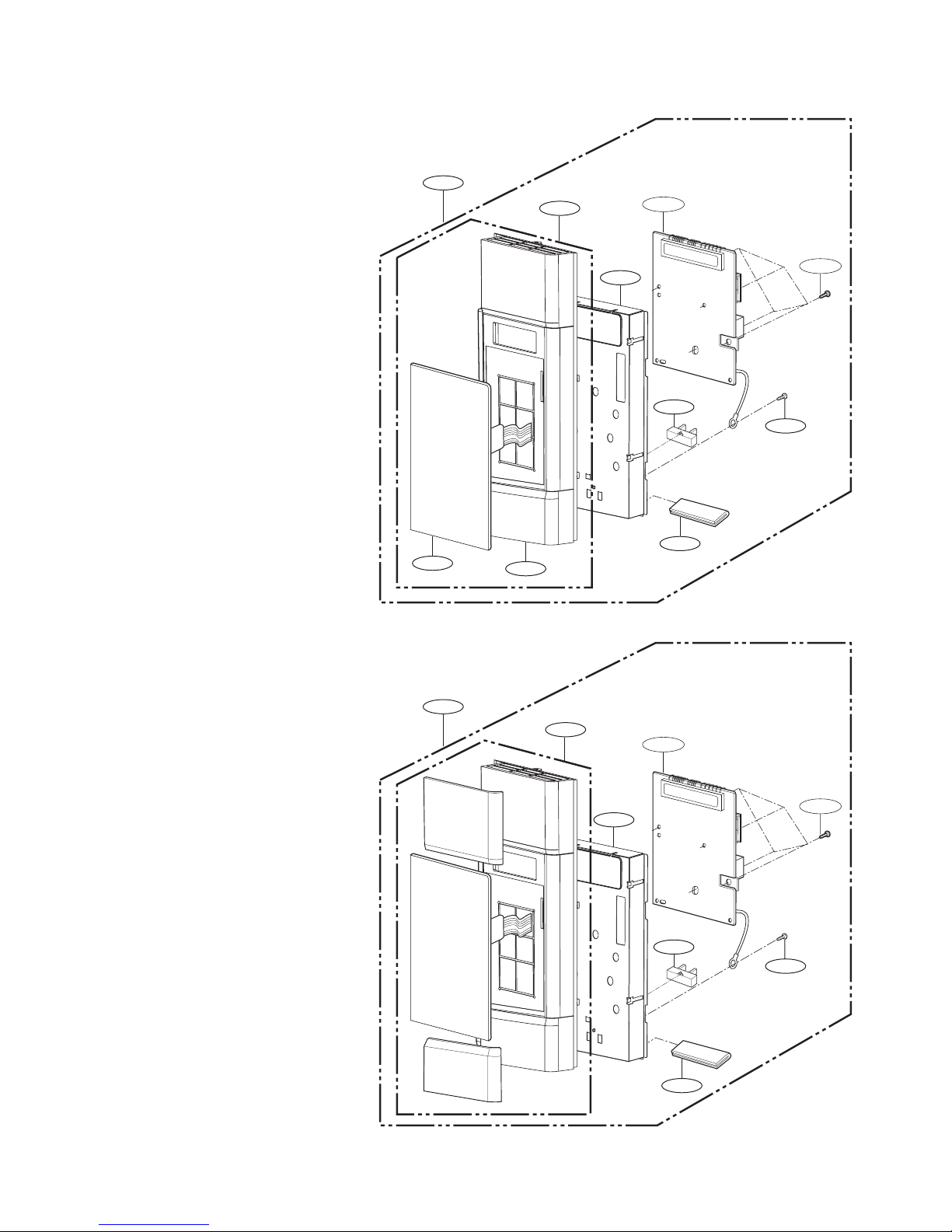

-8-1-

EXPLODED VIEW

DOOR PARTS

#EV#

1005

1004

1002

1000

1003

1008

1009

1007

1006

W109

W109

1005

1004

1002

1000

1381

1008

1009

1007

1006

W109

W109

For Model : 721.80049700

721.80042700

721.80044700

For Model : 721.80043700

721.81043700

Page 38

-8-2-

CONTROLLER PARTS

#EV#

2018

2018

2008

*07

2004

2008

2000

2002

W101

*07

2004

2381

2381

2006

W106

W101

2006

W106

For Model : 721.80049700

721.80042700

721.80044700

For Model : 721.80043700

721.81043700

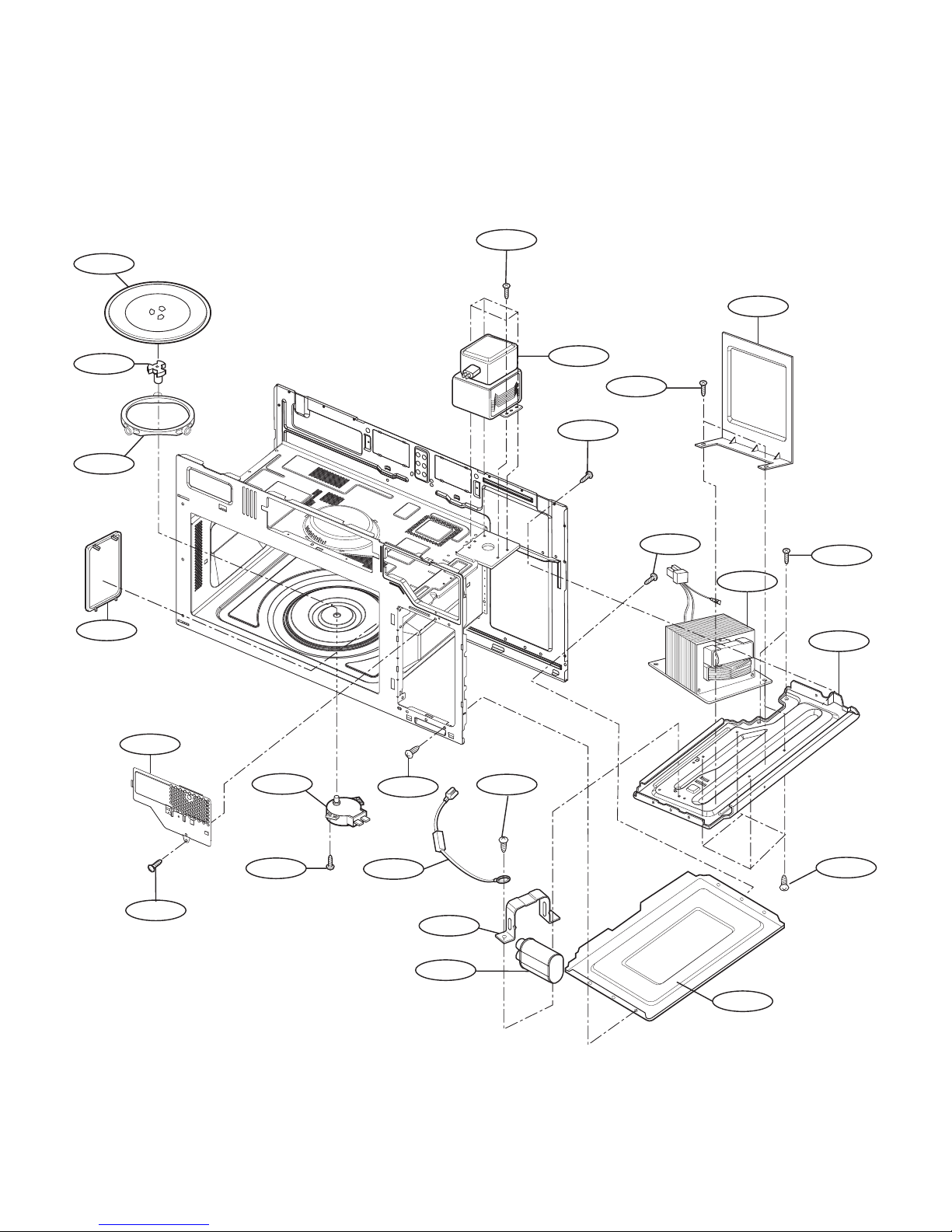

Page 39

W108

3028

5036

6000

W118

W109

3001

5038

W138

W142

3025

3024

3011

W118

3026

3026

6001

3010

For Model

721.80042

721.80044

For Model

721.80049

721.8

721.81043

0043

W138

W142

W105

3029

3003

-8-3-

OVEN CAVITY PARTS

#EV#

Page 40

-8-4-

4002

4000

4003

4002

4004

4001

W102

LATCH BOARD PARTS

#EV#

Page 41

-8-5-

INTERIOR PARTS (I)

W109

5008

3002

3012

3008

3009

3034

3037

W105

5035

5002

W101

5018

W109

W109

5034

W101

W101

W108

5000

5039

W108

5009

W101

#EV#

Page 42

-8-6-

5011

5004

W136

3027

5015

5045

5037

5038

5006

5010

5016

5014

W109

W108

5337

5058

5044

5043

3004

W101

5041

5001

5024

INTERIOR PARTS (II)

#EV#

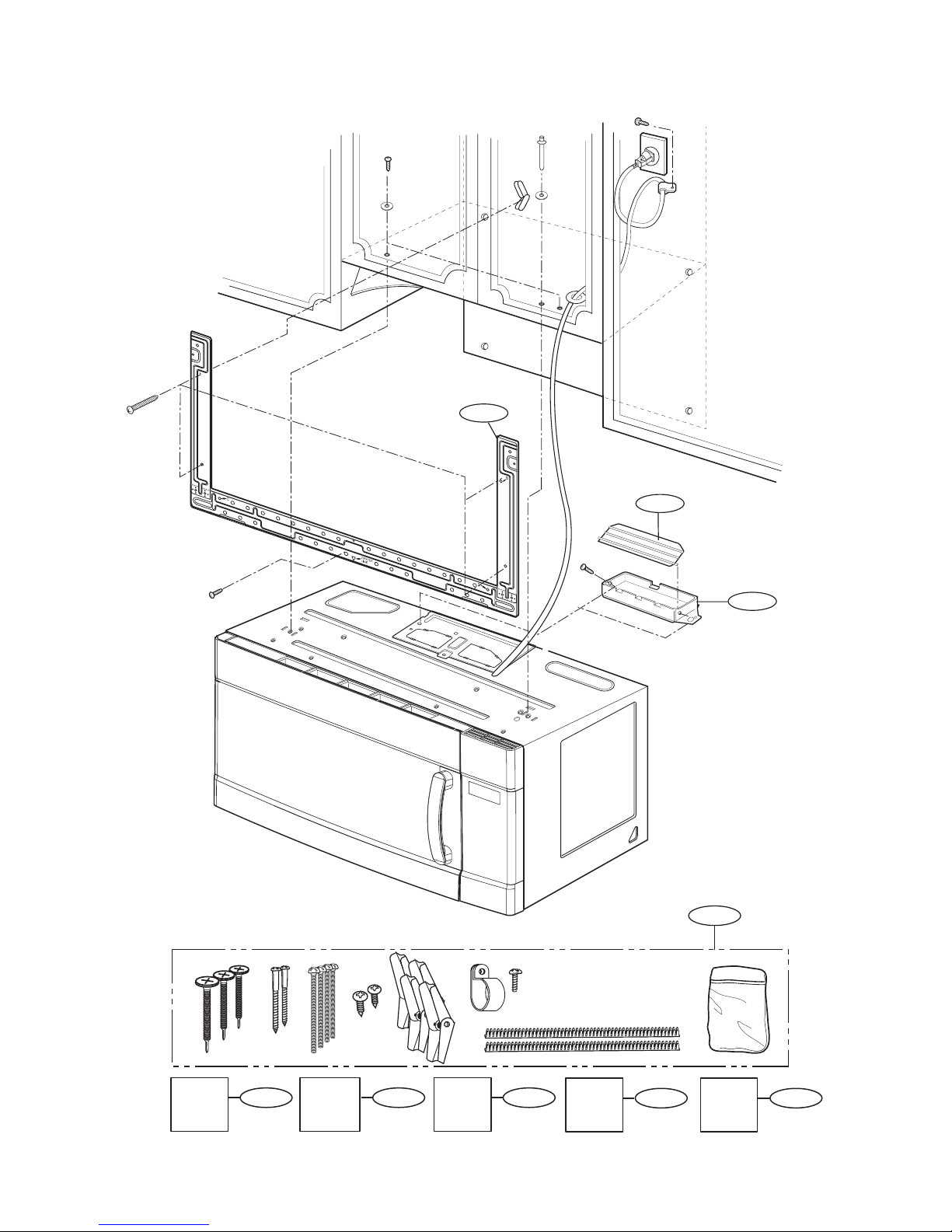

Page 43

-8-7-

INSTALLATION PARTS

6011

6008

6010

VINYL

BAG

6009

*01

OWNERS

MANUAL

*05

COOKING

GUIDE

LABEL

*04

INSTALLATION

MANUAL

*06-1

UPPER

TEMPLATE

*06-2

WALL

TEMPLATE

#EV#

Loading...

Loading...