Sears 625.34929 User Manual

OWNERS

MANUAL

MODEL NO.

625.349290

CAUTION

Read All Safety

Guides Before

You Start to

Install Your

Dispensing System

SAVE THIS MANUAL

PRINTED IN U S A

-- HOW TO INSTALL-

- HOW IT WORKS-

- CARE OF-

-- SPECIFICATIONS --

-- REPAIR PARTS--

Sears, Roebuck and Coo, Chicago, IL 60684 U.S.A.

TABLE OF CONTENTS

PAGE NO,

Safety Guides ........................................ 3

What Does The Dispensing System Do ....... 3-4

Tools and Materials Needed ......................... 5

Put The System Together ........................ 6

Locating and Solution Injecting ................ 7

Installing ...................................... 8-10

SEAl'S sOWT ONO SPENS,NGSYSTEM

FULL ONE YEAR WARRANTY ON SOLUTION DISPENSING SYSTEM

PAGE NO.

Electrical Wiring ............................ 11

Solutions to Feed and Feed Rate ............. 12-14

Controls and Features ........................... 14

Keeping The System in Working Order _..... 15-17

Dimensions and Specifications ................. 17

Repair Parts ................................... 18-19

For one year from the date of purchase, when this Solution Dispensing System is in-

stalled and maintained according to our instructions, Sears will repair defects in

material or workmanship in the Solution Dispensing System, free of charge.

WARRANTY SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS

SERVICE CENTER IN THE UNITED STATES. This warranty applies only while this pro-

duct is in use in tile United States.

This warranty gives you specific legal rights, and you may have other rights which vary

from state to state.

Sears, Roebuck and Co. Dept. 731-CR-W, Sears Tower, Chicago, IL 60684

If you want your solution dispensing system professionally installed, talk to your Sears Salesman. He

wilt arrange for a prompt, quality installation by Sears Authorized Installers

SEARS INSTALLATION POLICY

All installation labor arranged by Sears shall be

performed in a neat, workmanlike manner in

accordance with generally accepted trade prac-

rices. Further, all installations shall comply with

all local laws, codes, regulations and ordinances.

Customer shall also be protected, during installa-

tion, by insurance relating to Property Damage,

Workman's Compensation and Public Liability

SEARS INSTALLATION WARRANTY

In addition to any war ranty extended to you on the

Sears merchandise involved, which warranty

becomes effective the date the merchandise is

installed, should the workmanship of any Sears

arranged installation prove faulty within one year,

Sears will, upon notice from you, cause such

faults to be corrected at no additional cost to you.

I SAFETY GUnDES

A Read all steps, guides and rules carefully

before installing and using your new Solution

Dispensing System. Follow all steps exactly to

correctly install. Failure to follow them could

cause personal injury or property damage.

Reading this book will also help you to get all

of the benefits from your dispensing system.

A Protect the Solution Dispensing System and

tubing from freezing. Damage from freezing

voids the warranty.

When you see this sign in the book, A something could be damaged, or someone hurt if theguideisnot

followed exactly.

A Check with your local public works depart-

ment for plumbing, electric and sanitation

codes. You must follow their guides as you

install your dispensing system.

A Be sure the electric outlet for the solution pump

is grounded the right way to protect the user

from injury or possible fatal shock.

WHAT DOES YOUR SOLUTJO

Water is one of the best soSvents known to man, It

dissolves and picks up part of everything it

touches_ As water filters through the earth and

rock strata, it absorbs minerals such as calcium,

magnesium, iron and hydrogen sulfide (rotten

egg odor), If the water is not treated and improved

in some way, it may be useless, Feeding solutions

into the water is a good way to treat the water.

Your Sears Solution Dispensing System treats the

following kinds of water problems, DO NOT USE

THE SYSTEM IN AN ATTEMPT TO PURIFY

POLLUTED WATER.

(1) IRON WATER -- MAX. 20 PPM

(2) HYDROGEN SULFIDE WATER -- MAX, 20

PPM

(3) ACID WATER -- 4.0 pH and ABOVE.

(4)ACID WATER AND IRON BACTERIA,

HYDROGEN SULFIDE, OR HIGH AMOUNTS

OF IRON -- MAX. 20 PPM TOTAL and 4.0 pH.

The following briefly describes each of these

water problems

(1) IRON WATER -- One of the most common

elements in the earth's crust, iron causes water

problems all over the world. It makes rust stains

on almost everything it touches, gives water a

(NOTE: BACTERIAL IRON and IRON BACTERIAarethe same )

metal taste and causes many other problems_ The

2 main forms of iron are FERROUS and FERRIC

Ferrous or CLEAR WATER iron is the most

common type. Water with ferrous iron is clear

when taken from a fauceL After standing for 15 to

30 minutes, the water turns to a yellow or brown

color.

Ferric or RED WATER iron is rusty or brown as it's

taken from the faucet, After standing for awhile

the iron will settle out.

BACTERIAL iron is another kind of ferric iron.

When this water is taken from a faucet and left

standing for several hours, it forms slimy, stringy,

mud-like clumps.

TREATING IRON WATER -- Adding chlorine to

the water and then filtering it is a good way to

remove both the ferrous and ferric forms of iron,

Chlorine also kills iron bacteria. A Sears Solution

Dispensing System feeds household laundry

bleach into the water system ahead of the pressure

tank, The chlorine in the bleach oxidizes the iron.

Then a Sears Automatic Clarifier and a Sears

3

WHAT YOUR SOLUT OI

water softener, installed on the outlet side of the

pressure tank, filters and softens the water If you

do not like a remaining chlorine taste, Sears has

taste and odor filters to remove it,

(2) HYDROGEN SULFIDE WATER -- Many water

supplies corrtain hydrogen sulfide (sulphur)

Dissolved hydrogen sulfide gas, in underground

water, gives the water a bad taste and/or odor

similar to rotten eggs This water is often corro-

sive and may stain sinks and faucets

A Sears Solution Dispensing System feeding

chlorine, oxidizes hydrogen sulfide and other

sulfides making them tasteless and odorless If

the water has both hydrogen sulfide and iron,

Sears urges you to install an Automatic Clarifier

along with the dispensing system InstallaSears

Taste and Odor filter to remove chlorine taste

and odor

(3) ACID WATER-- Water is measured on a pH

scale of 0to 14. Water with a pH of 7 0 is neutral,

and over 70 it's basic (alkaline) If the pH is less

than 7 0, the water contains too much acid Acid

water corrodes galvanized and copper plumbing,

and makes red or blue-green stains on plumbing

fixtures, dishes and clothes It often addsa bitter

taste to the water because of dissolved copper or

iron caused by the corroding

Sears Neutralizer Compound, Stock No 42-

34475, fed into the water by a Sears Solution

Dispensing System raises the pH to 7.0making it

neutral Neutralized, the water will no longer

corrode or stain

(4) ACID WATER, AND IRON BACTERIA, HY-

DROGEN SULFIDE OR HIGH AMOUNTS OF

IRON -- A mixture of Sears Neutralizing Com-

pound, Stock No 42-34475, and chlorine treats

acid water that also has iron, bacteria or hydro-

gen sulfide The neutralizer raises the pH of the

water to help the chlorine oxidize the iron or

hydrogen sulfide Oxidized, the iron or hydrogen

sulfide is filtered with a Sears Automatic Clarifier.

I WATER SYSTEM TESTS

HAS YOUR WATER SUPPLY HAD CHEMICAL

ANALYSIS? A chemical analysis tells you the

types and amounts of elements in the water,

These facts determine what size and type of water

treating equipment is needed, and how to cor-

rectly use it If your water needs analysis, call or

write your nearest Sears store for help_

CHECK YOUR WATER SUPPLY SYSTEM

PRESSURE For your solution dispensing system

to work right, water system pressure must be less

than 75 psi If pressure is over 75 psi, buy and

install a pressure reducing valve or adjust the

pump pressure switch NOTE: If daytime pressure

is 60 psi or more, pressure during the night hours

may go over 75 psi.

If you have a well water system, look at the

pressure gauge to find the water pressure. Call

your local water department if you have city water.

They will tell you what the water pressure is where

,ou live

KEEP A RECORD OF YOUR

WATER SYSTEM FACTS

System Pressure (psi) __ Hardness __ (gpg)

Iron Content (parts per million) __ pH __

Tastes, odors or other

i

4

TREATING WELL WATER

PRE-TREATING PRIVATE WELL SYSTEMS

HAVING IRON BACTERIA -- Before you put the

dispensing system together and install it, chlor-

inate the well if it contains more than 10 parts per

million (ppm) of bacterial iron. Use the following

steps.

NOTE: If you don't chlorinate the well, you may

have iron in your water for up to 2 months after

you install the solution dispensing system

1_ For each 50 gallons of water in the well, pour 1

quart of ordinary household bleach into it. On

some wells, you can pour the bleach through the

breather pipe. On others, you may have to remove

the well seal

NOTE: You will probably have to estimate how

much water is in the well and use atrial and error

method of treatment, or else ask a qualified well

technician.

,&CAUTION: This much chlorine, at one time,

could exhaust the activated carbon in a taste

and odor filter° If you have a taste and odor

filter in your water system, by pass it to keep

the chlorine out while doing this pre4reating.

2. Pour several gallons of water into the well to

flush the bleach down to the water level

3 Open all faucets in the house, 1 at a time.

Close each faucet when you can smell the

bleach• Keep the water system closed for a

minimum of 2 hours If possible, keep closed

overnight

4. After 2 hours, or the next morning, open all

faucets and let the water run until clear and the

bleach odor is gone

TOOLS AND MATERIALS

TOOLS NEEDED -- You will need common and

cross point (Phillips) screw drivers, a slip-joint

pliers, tape measure or rule, and a sharp knife.

Depending on the kind of pipes you have in your

house, other tools you may need are ....

. .for SOLDERED COPPER -- tubing cutter,

propane torch, solid-core solder, paste flux, emery

cloth, sandpaper or steel wool

.....for THREADED PIPE-- hacksaw or pipe cutter,

pipe wrenches, pipe threading tool, pipe joint

compound

• . •for CPVC PLASTIC -- hacksaw, adjustable

wrench, solvent cement, fine emery cloth.

MATERIALS -- Depending on where and how you

install the Solution Dispensing System (page 7),

you may have all the things needed. Things not

included with the systemthatyoumayneedare••

If you have to install an electrical outlet (page

11), you will need materials meeting electrical

wiring codes, rWire, outlet box, receptacle, wire

nuts or tape, etc.

. • Jf you will pump solution directly into the well

(see pages 7 and 8) you may need more tubing

Read the note under step 2 on page 8

• • •If you will pump solution into the water system

between the well pump and pressure tank (see

pages 7 and 10), you may need some of the pipe

fittings shown in FIG. 6, page 10

5

PUT YOUR DISPENSING

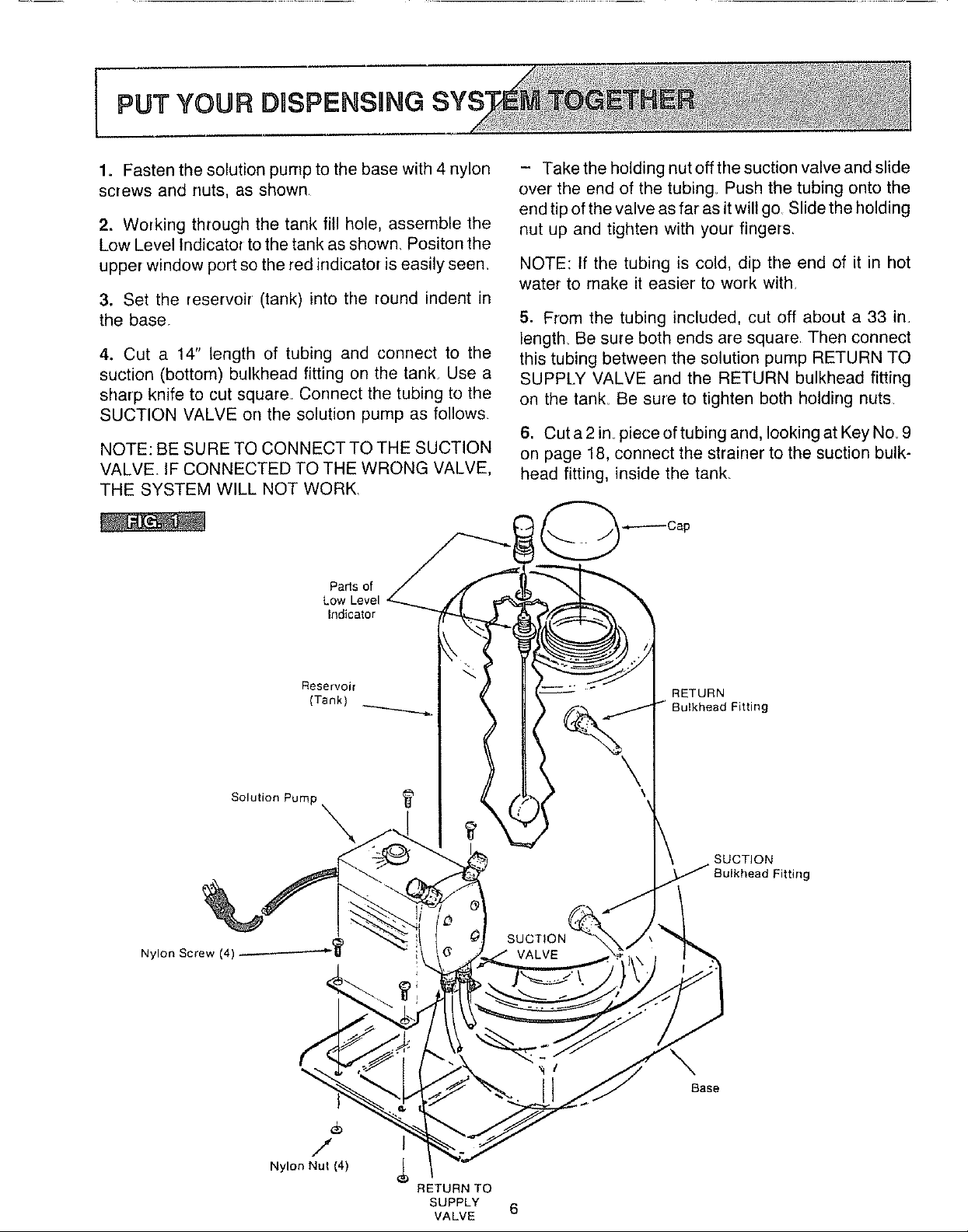

1, Fasten the solution pump to the base with 4 nylon

screws and nuts, as shown

2. Working through the tank fill hole, assemble the

Low Level Indicator to the tank as shown, Positon the

upper window port so the red indicator is easily seen_

3. Set the reservoir (tank) into the round indent in

the base

4. Cut a 14" length of tubing and connect to the

suction (bottom) bulkhead fitting on the tank, Use a

sharp knife to cut square. Connect the tubing to the

SUCTION VALVE on the solution pump as follow&

NOTE: BE SURE TO CONNECT TO THE SUCTION

VALVE IF CONNECTED TO THE WRONG VALVE,

THE SYSTEM WILL NOT WORK,

Parts of

Low Level

Indicator

- Take the holding nut off the suction valve and slide

over the end of the tubing. Push the tubing onto the

end tip of the valve as far as it will go, Slide the holding

nut up and tighten with your finger&

NOTE: If the tubing is cold, dip the end of it in hot

water to make it easier to work with,

5. From the tubing included, cut off about a 33 in,

length, Be sure both ends are square Then connect

this tubing between the solution pump RETURN TO

SUPPLY VALVE and the RETURN bulkhead fitting

on the tank_ Be sure to tighten both holding nuts.

6. Cut a 2 in piece of tubing and, looking at Key No_9

on page !8, connect the strainer to the suction bulk-

head fitting, inside the tank

Solution Pump "_

Nylon Screw (4) __

Reservort

(Tank)

RETURN

Bulkhead Fitting

SUCTION

Fitting

Base

/

Nylon Nut (4)

I

RETURN TO

SUPPLY

VALVE

6

Loading...

Loading...