Page 1

v

V

Kenmore

CLARIFYING FILTER

-- HOW TO INSTALL --

-- HOW IT WORKS m

-- CARE OF --

-- SPECIFICATIONS --

-- REPAIR PARTS-

PRINTED IN U.S.A.

Page 2

I WARRANTY I

SEARS RESIDENTIAL WATER FILTER I/I/

in accordance with our instructions, Sears will repair, free of charge, detects in material [_//

or workmanship in this water filter. I/l)

FULL FIVE YEAR WARRANTY AGAINST LEAKS _lll

For five years from the date of purchase, Sears will furnish and install a new current [_/I

model water filter tank, free of charge, if the tank develops a leak. I///

TO OBTAIN WARRANTY SERVICE, SIMPLY CONTACT THE NEAREST SEARS SER- _//1

VICE CENTER THROUGHOUT THE UNITED STATES. This warranty applies only I(((

while this product is in use in the United States." ))))

This warranty gives you specific legal rights, and you may have other rights which [_/_

vary from state to state, lit/

Sears, Roebuck and Co., Dept. 731-CR-W, Sears Tower, Chicago, IL 60684 t1/1

I///

T///

If you want you r clarifying filter professional ly installed, talk to you r Sears Salesperson who will arrange

a prompt, quality installation by Sears Authorized Installers.

SEARS INSTALLATION POLICY

All installation labor arranged by Sears shall be

performed in a neat, workmanlike manner in

accordance with generally accepted trade prac-

tices. Further, all installations shall comply with

all local codes, regulations and ordinances.

Customer shall also be protected, during installa-

tion, by insurance relating to Property Damage,

Workman's Compensation and Public Liability.

SEARS INSTALLATION WARRANTY

In addition to any warranty extended to you on

the Sears merchandise involved, which warranty

becomes effective the date the merchandise is

installed, should the workmanship of any Sears

arranged installation prove faulty within one

year, Sears will, upon notice from you, cause

such faults to be corrected at no additional cost

to you.

Page 3

I TABLE OF CONTENTS

PAGE

NO.

SECTION 1

SECTION 2

SECTION 3

SECTION 4

SECTION 5

SECTION 6

SECTION 7

Safety Guides .............................................. 4

What Your Clarifying Filter Will Do .............................. 4

Water System Tests .......................................... 5

Where To Install The Filter .................................... 6

Planning Your Installation ..................................... 6-8

Step-by-Step Guides To Install ................................. 9-14

Water Filter TimerlRecharge Setup ............................. 15-16

Timer Features .............................................. 16-17

How The Filter Works ........................................ 17

Helpful Hints Checklist...Before You Call For Service ............... 18

Keep The Filter Frorn Freezing ................................. 19

Specifications/Dimensions ..................................... 19

Sweat Soldering Tips ......................................... 2( _

SECTION 8

Repair Parts ................................................ 21-23

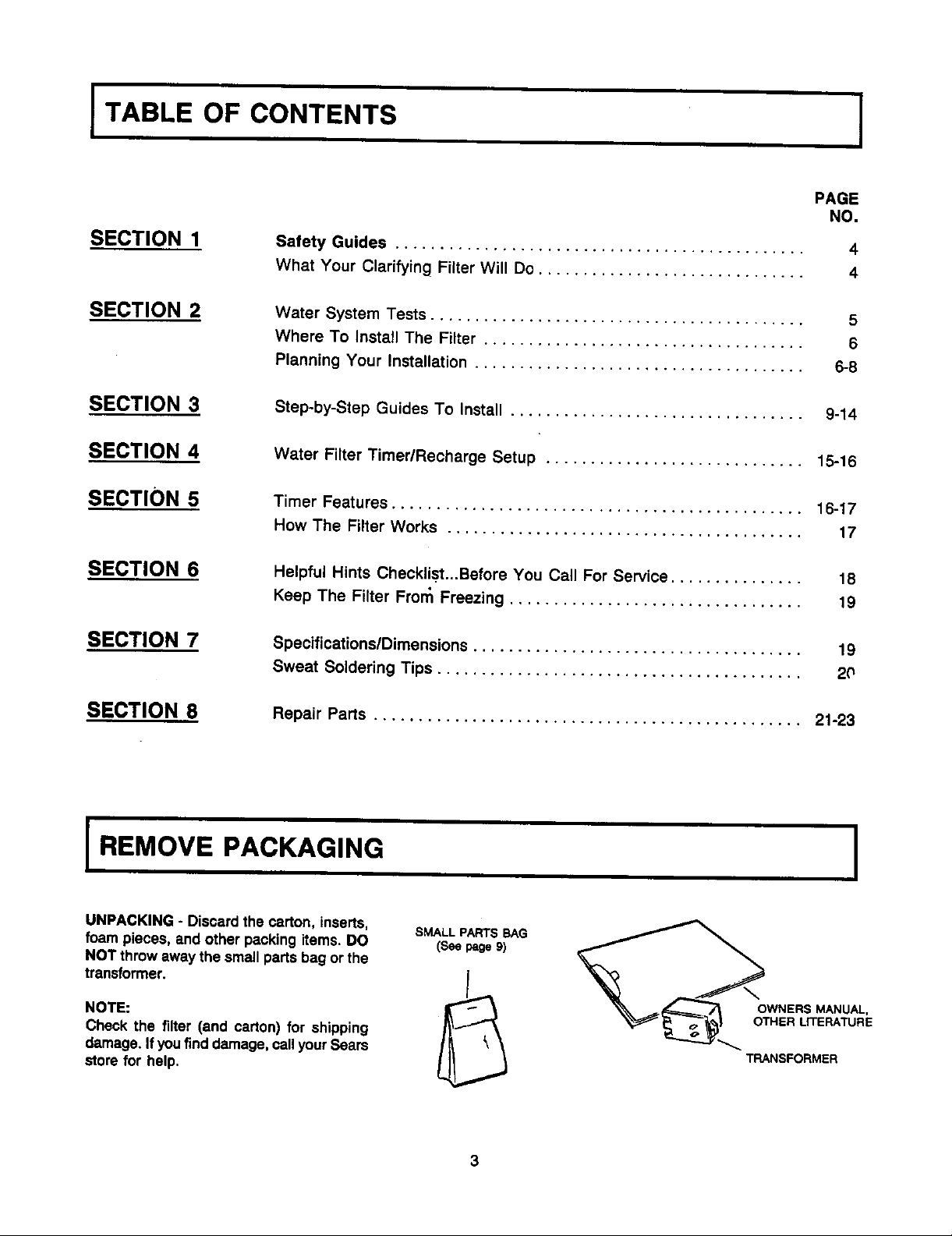

REMOVE PACKAGING I

UNPACKING - Discard the carton, inserts,

foam pieces, and other packing items. DO

NOT throw away the small parts bag or the

transformer.

NOTE:

Check the filter (and carton) for shipping

damage, If you find damage, call your Sears

store for help.

SMALL PARTS BAG

(See page 9)

OWNERS MANUAL,

OTHER LITERATURE

TRANSFORMER

Page 4

• Read all steps, guides and rules carefully before

installing and using your new water filter. Follow all

steps exactly to correctly install. Failure to follow

them could cause personal injury or property damage.

Reading this book will also help you to get all of the

benefits from your water filter.

• Check with your local public works department for

plumbing and sanitation codes. You must follow

their guides as you install your filter.

• Protect the filter and piping from freezing, see page I

19. Damage from freezing voids the filter warrant.

• Use only LEAD-FREE SOLDER AND FLUX, as re-

quired by Federal and State codes, when install-

ing soldered copper plumbing.

PLEASE READ AND COMPLY WITH THE

FOLLOWING GUIDES TO PREVENT DAMAGE.

TO THE FILTER OR OTHER PROPERTY, PER-

SONAL INJURY, OR POSSIBLE FATAL SHOCK.

• THIS FILTER WORKS ON 24 VOLTS ONLY.

BE SURE TO USE THE TRANSFORMER INCLUD-

ED, AND PLUG IT INTO A 120V OUTLET.

• Be sure the electric outlet for the

transformer is grounded the right way.

• Unplug the transformer right away if the

power cable should become damaged or frayed.

Make repairs before plugging back into the

power outlet.

• Always unplug the filter from electrical

power before removing outer valve covers.

• Your clarifying filter will clean your water as stated

below. It will not soften hard water or remove iron.

It will not purify polluted water or make it safe to

drink.

When you see this sign in the book, • something could be damaged, or someone hurt, if the guide is not followed

exactly.

• Connect the filter to the houee COLD water

(1200 max.) pipe only. DO NOT CONNECT TO

HOT WATER.

WHAT YOUR CLARIFYING FILTER WILL DO

A Sears Clarifying Filter takes sediments such as dirt,

sand, silt, clay, and fine organic matter out of water. You

can see sediments in water by filling a clear drinking

glass. When held up to light, you can see the particles

floating in the water, or settled to the bottom of the glass.

The filter is filled with "filter aggregate" mineral that traps

and holds the sediments as the water flows through it.

The Clarifier is sometimes installed alone, but is often

followed by a wamr softener. Besides softening the water,

the water softener catches sediments that may get

through the filter. Sears Water Analysis Laboratory will

test your water and tell you what equipment you need

(see page 5).

NOTE: If you will install the clarifying filter along with a

Sears Solution Dispensing System, read the dispensing

system owners manual for treating a private well before

installing.

4

Page 5

I SECTION 21 BEFORE YOU START TO INSTALL

HELPFUL INFORMATION

If you know little about plumbing skills, we suggest

you get a book on the subject. There are many good

books for do-it-yourselfers on the basics of plumbing.

WATER SYSTEM TESTS

HAS YOUR WATER SUPPLY HAD A CHEMICAL

ANALYSIS? Sears has many kinds of water treating

units (see page 6) to correct different water problems.

To know the kind and size of unit you need, you must

first know what elements are in your house water

supply. A chemical analysis shows the type and

amounts of elements in water. If your water needs

analysis, call or write your nearest Sears store for

help.

CHECK YOUR WATER PRESSURE - For your filter

to work right, a water pressure of no lower than 20

pounds per square inch (psi) is needed in the house

water pipes. The highest pressure allowed in the

• water pipes is 125 psi. If pressure is over 125 psi, buy and

install a pressure reducing valve in the water inlet pipe

to the filter. NOTE: If water pressure during the day is 100

psi or more, pressure during the night may go over 125

psi.

If you have a well water system, look at the pressure

gauge to find the water pressure. Call your local water

department if you have city water. They will tell you

what the water pressure is where you live.

You can get a low cost book from Sears Plumbing and

Heating departments that will help you. If you have

soldered before, some basic sweat soldering tips are

on page 20 of this manual.

CHECK YOUR WATER FLOW RATE - A water flow

of 51/2 to 7 gallons per minute is needed. A lower flow

will keep your filter from working as well as it should.

To make an easy check of your flow rate, do the

following. You will need a 1 gallon container (can, jar,

pail, etc.).

1. Fully open 2 cold water faucets close to the point

water enters the house.

2. With both faucets open, fill the gallon container at

1 faucet while looking at a watch or clock to see

how many seconds it takes.

,

Empty the container and go to the second faucet

(be sure BOTH faucets are still on). Fill the gallon

container at the second faucet and see how many

seconds it takes.

4. Turn off both faucets. Now add the number of

seconds it took to fill the container at both faucets.

5. A total of 35 seconds, or less, means the system

flow rate is good.

FACTS AND FIGURES TO KEEP

Fill in the blanks below and keep this book in a

safe place so you always have these facts.

Water Filter Model No. 1"

Serial Number 1

Date Installed

1" Get from the rating decal on the filter.

Iron Content Parts Per Million

*pH __ Taste And/Or Odor __

Water Pressure __ Pounds/Square Inch

Water Flow Rate __ Gallons Per Minute

* The acidity or alkalinity measure of water.

Page 6

I SECTION 21 BEFORE YOU START TO INSTALL I

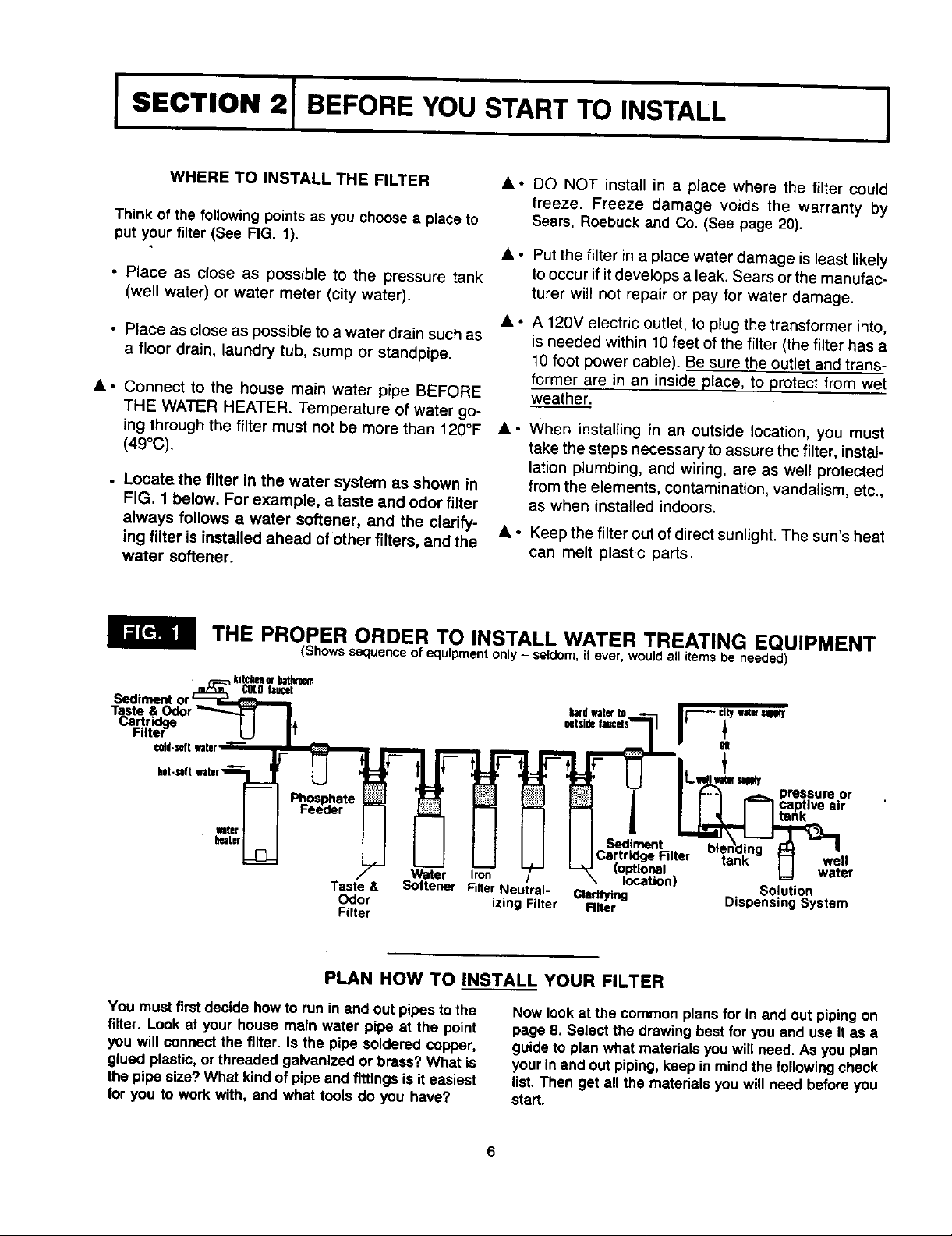

WHERE TO INSTALL THE FILTER

Think of the following points as you choose a place to

put your filter (See FIG. 1).

• Place as close as possible to the pressure tank

(well water) or water meter (city water).

• Place as close as possible to a water drain such as

a. floor drain, laundry tub, sump or standpipe.

• • Connect to the house main water pipe BEFORE

THE WATER HEATER. Temperature of water go-

ing through the filter must not be more than 120°F

(49°C).

• Locate the filter in the water system as shown in

FIG. 1 below. For example, a taste and odor filter

always foltows a water softener, and the clarify-

ing filter is installed ahead of other filters, and the

water softener.

• • DO NOT install in a place where the filter could

freeze. Freeze damage voids the warranty by

Sears, Roebuck and Co. (See page 20).

Put the filter in a place water damage is least likely

to occur if it develops a leak. Sears or the manufac-

turer will not repair or pay for water damage,

A 120V electric outlet, to plug the transformer into,

is needed within 10 feet of the filter (the filter has a

10 foot power cable). Be sure the outlet and trans-

former are in an inside place, to protect from wet

weather.

When installing in an outside location, you must

take the steps necessary to assure the filter, instal-

lation plumbing, and wiring, are as well protected

from the elements, contamination, vandalism, etc.,

as when installed indoors.

Ae

Keep the filter out of direct sunlight. The sun's heat

can melt plastic parts.

THE PROPER ORDER TO INSTALL WATER TREATING EQUIPMENT

(Shows sequence of equipment only - seldom, if ever, would all items be needed)

. ._-. kitClmD =

Sediment or "_--E_._.._q

Taste & Odor _ I

Cartridge II I+

Filter . _ |"

k0t-sdt .-at. -,_

mid-aft .ter '_" .......

COLO faucet

I I Phosphate

I I Feeder

water

F It._ . +aso

J_.] I o, r:+ ng w+',,

Taste &

Odor

Fitter

PLAN HOW TO INSTALL YOUR FILTER

You must first decide how to run in and out pipes to the

filter. Look at your house main water pipe at the point

you will connect the filter. Is the pipe soldered copper,

glued plastic, or threaded galvanized or brass? What is

the pipe size? What kind of pipe and fittings is it easiest

for you to work with, and what tools do you have?

Water Iron -- \ location) ^ _ ,.=_.., _ _

_oftener Filter Neutral- C • PPIr_:-- _olunon

l_d _rattr tQ _-_ I r"--'-'-- cltt mlw mlftt

utside faucetsl"l I l--+

Sed ment b en

/_1 _ (optional t_l water

izing Fitter _R_er 'e Dispensing System

Now look at the common plans for in and out piping on

page 8. SeLect the drawing best for you and use it as a

guide to plan what materials you will need, As you plan

your in and out piping, keep in mind the folk)wing check

list. Then get all the materials you will need before you

start.

6

Page 7

I SECTION 2 I BEFORE YOU START TO INSTALL

I

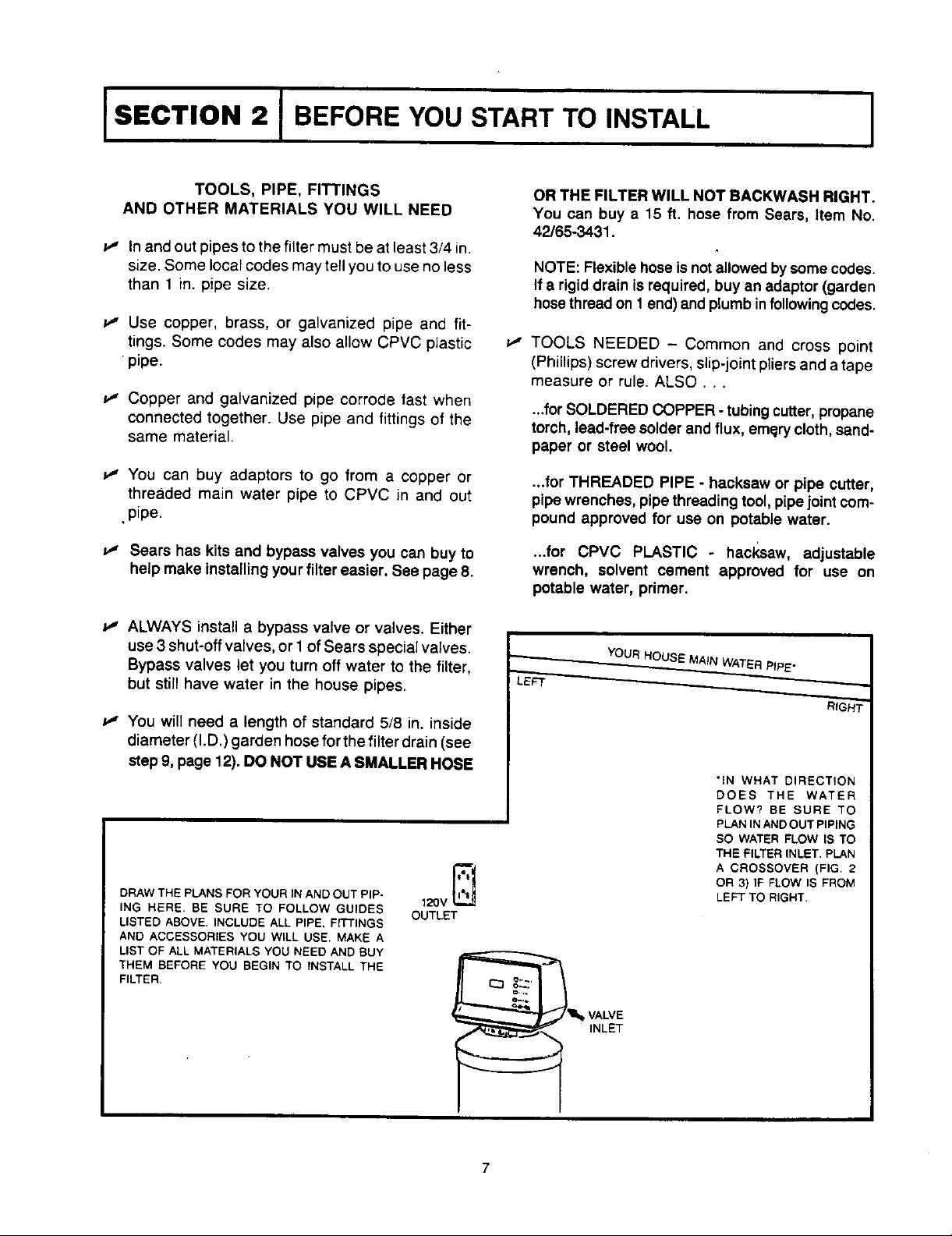

TOOLS, PIPE, FITTINGS

AND OTHER MATERIALS YOU WILL NEED

In and out pipes to the filter must be at least 3/4 in.

size. Some local codes may tell you to use no less

than 1 in. pipe size.

Use copper, brass, or galvanized pipe and fit-

tings. Some codes may also allow CPVC plastic

pipe.

t,_ Copper and galvanized pipe corrode fast when

connected together. Use pipe and fittings of the

same material.

You can buy adaptors to go from a copper or

threaded main water pipe to CPVC in and out

• pipe.

v,' Sears has kits and bypass valves you can buy to

help make installing your filter easier• See page 8.

v" ALWAYS install a bypass valve or valves. Either

use 3 shut-off valves, or 1 of Sears special valves.

Bypass valves let you turn off water to the filter,

but still have water in the house pipes.

OR THE FILTER WILL NOT BACKWASH RIGHT.

You can buy e 15 ft. hose from Sears, Item No.

42/65-3431.

NOTE: Flexible hose is not allowed by some codes.

If a rigid drain is required, buy an adaptor (garden

hose thread on 1 end) and plumb in following codes.

p,

TOOLS NEEDED - Common and cross point

(Phillips) screw drivers, slip-joint pliers and a tape

measure or rule. ALSO...

...for SOLDERED COPPER - tubing cutter, propane

torch, lead-free solder and flux, emery cloth, sand-

paper or steel wool.

...for THREADED PIPE - hacksaw or pipe cutter,

pipe wrenches, pipe threading tool, pipe joint com-

pound approved for use on potable water.

...for CPVC PLASTIC - hacl_saw, adjustable

wrench, solvent cement approved for use on

potable water, primer.

--..........____. YOUR HOUSE MAIN WATER PIPE"

v," You will need a length of standard 5/8 in. inside

diameter (I.D.) garden hose for the filter drain (see

step 9, page 12). DO NOT USE A SMALLER HOSE

DRAW THE PLANS FOR YOUR IN AND OUT PIP-

ING HERE. BE SURE TO FOLLOW GUIDES

LISTED ABOVE. INCLUDE ALL PIPE, FITTINGS

AND ACCESSORIES YOU WILL USE. MAKE A

LIST OF ALL MATERIALS YOU NEED AND BUY

THEM BEFORE YOU BEGIN TO INSTALL THE

FILTER.

1'20V

OUTLET

;=={,

*IN WHAT DIRECTION

DOES THE WATER

FLOW? BE SURE TO

PLAN IN AND OUT PIPING

SO WATER FLOW IS TO

THE FILTER INLET, PLAN

A CROSSOVER (FIG, 2

OR 3) IF FLOW IS FROM

LEFT TO RIGHT,

VALVE

INLET

Page 8

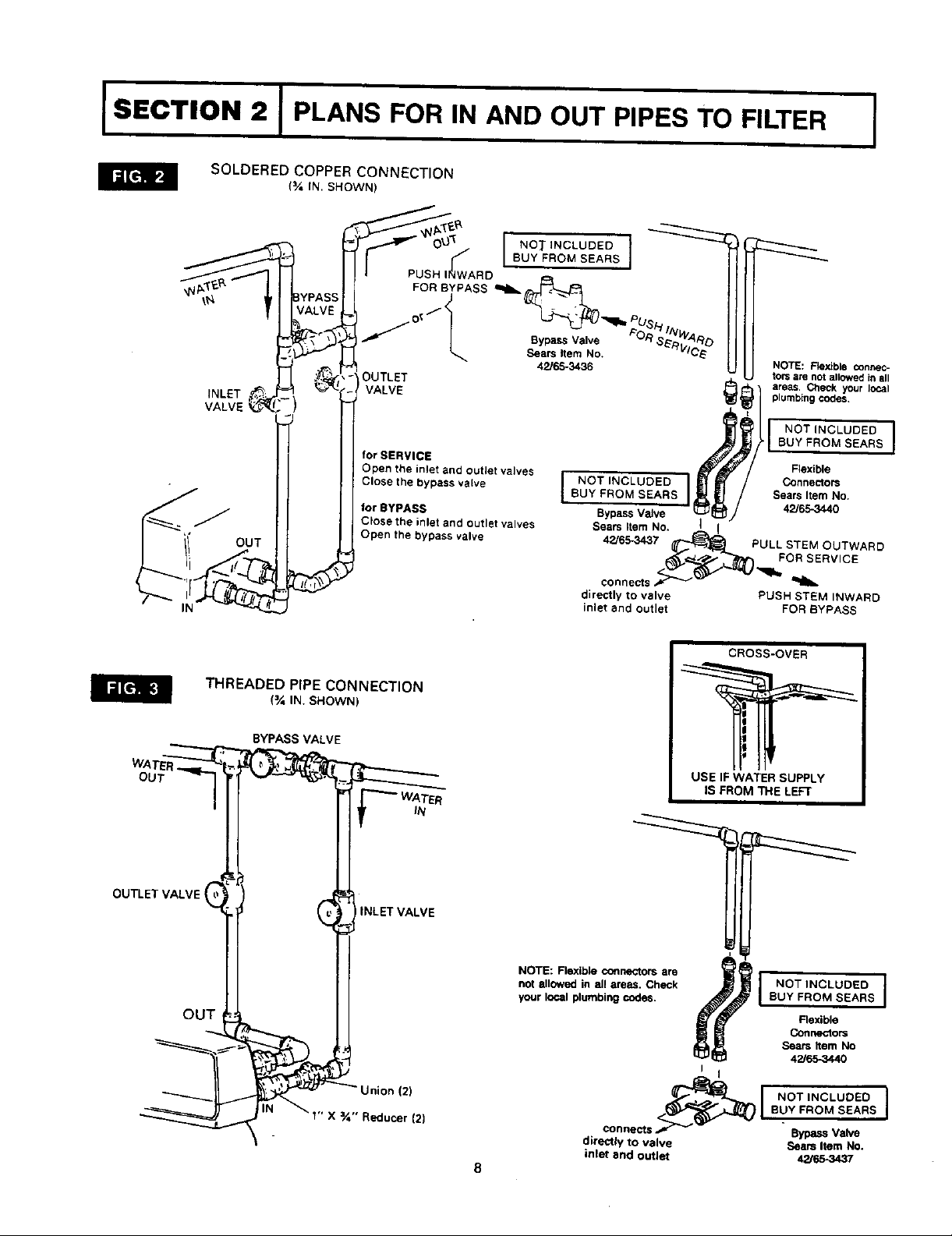

I SECTION 2 J PLANS FOR IN AND OUT PIPES TO FILTER I

SOLDERED COPPER CONNECTION

{_/, IN. SHOWN)

INLET

VALVE

OUT

IN

THREADED PIPE CONNECTION

(3/4 IN. SHOWN)

PUSH, BD I NOT INCLUDED

FOR BYPASS _J_,_._ pus/.I IN_ lOB

OUTLET

VALVE

for SERVICE

Open the inlet and outlet valves

Close the bypass valve

tot BYPASS

Close the inlet and outlet valves

Open the bypass valve

BUY FROM SEARS .

Bypass Valve S_R .A/_D

Sears Item No. vtc_

47./65-3436

I NOT INCLUDED BUY FROM SEARS

Sears Item No.

directly to valve

inlet and outlet

I

Bypass Vtdve

42/65-3437

connecL_

NOTE: Flexible connec-

tors am not allowed in all

areas, Check your local

plumbing codes,

NOTINCLUDED

BUY FROM SEARS

Connectors

Sears Item No.

42/65-3440

I

PULL STEM OUTWARD

FOR SERVICE

PUSH STEMINWARD

FOR BYPASS

CROSS-OVER

Flexible

OUTLET VALVE C

OUT

BYPASS VALVE

i

F'-'-WATER

I INLET VALVE

Union (2)

_" Reducer (21

NOTE: Flexible connectors ere

not allowed in all areas. Check

your local plumbing codes.

connects F Bypass Valve

directly to valve Sears Item No.

inlet and outlet 42/65-3437

USE IF WATER SUPPLY

IS FROM "II"IE LEFT

NOT tNCLUOED

BUY FROM SEARS

Fh_xitde

Connectors

Sears Item No

42/65-3440

I I

_J NOT INCLUDED 7

BUY FROM SEARS

Page 9

I SECTION 3 I STEP BY STEP GUIDES TO INSTALL

Close the shut-off valve on the house main water

• I. pipe, near the water meter or pressure tank, to

turn off the water.

r-_. Shut off the gas or electric supply to the water

heater.

• 3. Open the highest and lowest water faucets in

your house to let water drain from the pipes.

Close faucets after water has drained.

Take all the small parts from the parts bag and

4. lay out neatly where you can easily see and get

to them as they are needud.

NOTE: The inlet screen is not used on the clarifying

filter, and can be discarded.

Shutoff Shutofl Pressure

Valve Valve Tank

Meter Pump I'

Electrical

Gas

Valve

Panel

SMALL PARTS BAG ITEMS

(_) INLET _'_ _NLET-OUTLET

SCREEN _ ADAPTOR (2) CLIP (2)

(-_ WASHER OR

GROUND

O _J GASKET (2)

5, INSTALL INLET AND OUTLET ADAPTORS OR

SEARS BYPASS VALVE, ITEM NO. 42/65-3437.

NOTE: If you will install the bypass valve, the adap-

tors are not used. If you do not install the bypass

valve, you must use the adaptors.

INLET AND OUTLET ADAPTORS (Adaptors

am

and clips are small parts bag items.) - Push the

adaptors into the valve inlet and outlet ports

(FIG. 5 and 7) as far as they will go. Both adap-

tors are the same and fit either valve port. SNAP

THE 2 LARGE HOLDING CLIPS INTO PLACE,

FROM THE TOP DOWN AS SHOWN. BE SURE

THEY SNAP FIRMLY INTO PLACE, SO THE

ADAPTORS WILL NOT PULL OUT...GO TO

STEP 6.

CLAMP (2) _ I] |NLET.OUTLE T

___________ TUBE (2)

_INL_r-OUTLE¢

_ _ NUT (2)

® _ GROUNDWIRE,

_, Q= SCREWS AND NUTS

TRANSFORMER

INSTALLING INLET AND OUTLET

ADAPTORS OR BYPASS VALVE

Clips (2)

SEALS //4

PLACED tN OR

ONLY. CLIP SNAPS P/

INTO INNER GROOVES

(SEE FIG. 7)

Adaptors

9

Page 10

I SECTION 3 STEP BY STEP GUIDES TO INSTALL I

BYPASS VALVE ITEM NO. 42/65-3437 - If not

L

D. already done, put a light coating of silicone grease

or Vaseline on the bypass valve o-rings.

Push the bypass valve into the filter valve as far as

it will go (FIG. 5, 6 and 7). SNAP THE 2 LARGE

HOLDING CLIPS INTO PLACE, FROM THE TOP

DOWN AS SHOWN. BE SURE THEY SNAP FIRMLY

IN PLACE, SO THE BYPASS VALVE WILL NOT

PULL OUT. GO TO STEP 7.

6, INSTALLING 3 VALVE BYPASS, OR SEARS

BYPASS VALVE, ITEM NO. 42/65 3436, AND

PIPES (FIG. 8).

Cut the house main water pipe where you wilt

a, connect the filter. Loosely put together pipe, fit-

tings, and the 3 valves or Sears special bypass

valve. Place valve(s) within easy reach.

SIDE VIEW

/_-_CLIP

Valve Body

|ntet or Out_et

INSTALLING BYPASS VALVE

ITEM NO. 42/65-3436, OR

3-VALVE BYPASS

SINGLE VALVE BYPASS

IN

(Push all the way in)

TURN BYPASS VALVE

UPStDF.- DOWN TO

CONNECT TO FLOOR

LEVEL PLUMBING

END VIEW

Of

Bypass Venire

3-VALVE BYPASS

IMPORTANT: WHEN LOOKING AT THE FRONT OF

THE FILTER, THE INLET IS ON THE RIGHT SIDE.

IF WATER IN YOUR HOUSE MAIN WATER PIPE

RUNS FROM LEFT TO RIGHT, BE SU RE TO USE A

_CROSS-OVER" AS SHOWN IN FIG. 2 AND 3,

PAGE 8.

If all pipe, fittings and valves fit together good,

b, tighten all threaded joints (use pipe dope on

outside threads), or solder atl joints following the

soldering tips on page 20.

Filter

FiRer

inlet

10

Page 11

I SECTION 3 I STEP BY STEP GUIDES TO INSTALL

I

CONNECT THE FILTER

7. (Refer to your plan drawing on page 7, and to page

8.)

- SOLDER COPPER OR CPVC PIPE

Read the important note in step 6. Then put the

a. gaskets, tubes and nuts shown in FIG. 9, or the

flexible connectors * (Sears kit, page 8) onto the

inlet-outlet adaptors or bypass valve.

NOTE: The nuts, tubes and gaskets are for 3/4 in.

plumbing connection. For 1 in. connection, do not

use the nuts, tubes and gaskets. From your local

hardware store, buy 2 sweat adaptors (1 in. female

thread x 1 in. sweat) and plumb directly to the in-

stallation adaptors or bypass valve. Threads on the

installation adaptors and bypass valve are 1 in. pipe

thread.

Measure, cut and put all pipe and fittings

b. together up to the main water pipe, or to the

bypass valve(s) you installed in step 6.

When all piping fits together good, solder (or

C. solvent cement CPVC) all joints following tips

on page 20.

INLET-OUTLET FITTINGS

Gasket

Tube

Inlet an0 Outlet

Aclaptors

• CAUTION: BEFORE SOLDERING, DISCONNECT

NUTS (FIG. 9) ATTHE ADAPTORS OR BYPASS

VALVE. THIS WILL STOP THE HEAT, CAUSED

BY THE SOLDERING, FROM GOING INTO THE

FILTER VALVE AND MELTING PLASTIC PARTS.

After plumbing cools, put nuts back on and tighten.

- THREADED PIPE

Read the important note in step 6. Then

all

measure, cut, thread and put together pipe and

fittings from the inlet-outlet adaptors (or bypass

valve) up to the main water pipe, or to the

bypass valves installed in step 6.

NOTE: For 1" connection, use a 1" fitting directly

on the installation adaptors or bypass valve. Threads

on the adaptors or bypass valve are 1 in. male pipe.

Include union fittings or flexible connectors*

Cut pipe lengths exact for correct aligning, and to

Cm

prevent stress on the filter valve. Use pipe dope

or teflon tape on all outside threads.

CAUTION: BE VERY CAREFUL WHEN Pu'r-FING

PIPE FITTINGS ONTO THE PLASTIC THREADS

OF THE INLET-OUTLET ADAPTORS, OR THE

BYPASS VALVE. DO NOT CROSS-THREAD. DO

NOT OVERTIGHTEN.

b. (Sears kit, page 8).

*Flexible connectors are not allowed in all areas. Check your local plumbing codes.

8, Fasten or support all piping (use pipe hangers)

to keep the weight of the plumbing off of the

11

filter inlet and outlet fittings, so they do not leak

or break.

Page 12

i

I s oT,o. 3 I sT P BY sT p Gu,oEs TO,.S .L I

CONNECT A VALVE DRAIN HOSE

9° The valve drain fitting has standard garden

hose threads. Connect a 5/8" I.D. MINIMUM size

garden hose to it, Put the other end of the hose over

the floor drain (FIG. 10), or into a laundry tub, sump,

standpipe or other suitable drain. CHECK YOUR

LOCAL CODES.

dram

drain

IMPORTANT NOTES:

Flexible drain hose is not allowed in all areas. SEE

NOTE ON PAGE 7.

• Leave an air gap of about 1-t/2" between the end of

the hose and the drain. This gap is needed so you

don't get a back-flow of sewer water into the filter. DO

NOT put the end of the hose down into the drain or

connect without an air gap.

• Place or support the hose so it does not kink or have

sharp bends. FASTEN THE END OF THE HOSE TO

A BRICK OR OTHER HEAVY OBJECT SO WATER

PRESSURE WILL NOT MAKE IT "WHIP."

Keep the hose lower than the drain fitting. (In some

homes, to get to a drain you must raise the hose and

run it over-head. If you need an over-head drain, do

not raise the hose more than 8' above the floor or the

filter will not work as it should.

SUMP

,_ Dram Hose

_.. 1_,'_ '' Air Gap

Laumdry Tub

--- - _ Floor Drain

_____ STAN DPIPE

1-1 2' Support in some

manner at this point

"-_-_ _1 Standpipe

12.

Page 13

I S C ,O. 3 ] sT p BY s.E. GU,OES ,NSTA'L I

10, TESTING YOUR PLUMBING WORK FOR

WATER LEAKS.

Look at the picture in FIG. 11 showing your kind of

bypass valve(s). On a single valve, slide the stern into

SERVICE. On a 3-valve system, open the inlet and

outlet valves and close the bypass valve.

OPEN A HOT AND COLD WATER FAUCET TO

a. LET AIR OUT OF THE FILTER AND HOUSE

PIPES.

Fully open the shut-off valve in the house main

b.

water pipe to turn on the water.

After water from the faucets runs smooth with no

C. more air bubbles, close them.

d. Check your plumbing work for leaks and fix right

away if any are found. READ THE CAUTION

NOTE AFTER STEP 7C (SOLDERED COPPER

OR CPVC PIPE), PAGE 11.

VALVE

BYPASS VALVES

SINGLE

PULLSTEM

OUTWARD

FOR

SERVICE

Push

Inward

For

Ou.e_ "" "_F_ _'_ ",,.

(brass)

Push

Inward

Bypass

For

PUSH

INWARD

FOR

SERVICE

11 INSTALL GROUNDING WIRE BETWEEN

• THE FILTER IN AND OUT PIPES

The house cold water pipe (iron or copper) is often

used to ground all electric outlets in the home. Outlets

are grounded to protect you from shock when you

touch any electric appliance plugged into the outlet. If

you didn't install a 3-valve bypass, or a brass single

bypass valve (FIG, 11), the cold water pipe ground is

broken.

• To restore the ground, take the clamps (2), screws

(2), nuts (2) and ground wire that were in the small

parts bag. Install across the iron or copper in and out

pipes as shown in FIG. 12. Be sure good contact is

made between the pipe and the clamps. Fasten the

ground wire tightly between the clamps.

IMPORTANT: Be sure the cold water pipe has direct

metal to metal contact all the way to the ground.

Plastic, rubber or other electrically insulating parts

such as hoses, fittings, washers or gaskets can break

the direct metal to metal contact. Also check the

water meter (city water) or the well pump. Install #4

copper jumper wires, clamped tightly on both ends,

across insulated parts (FIG. 13).

COLD WATER PIPE GROUND

Ground

Wire

Cramp (2)_ _

From

Valve To

Outlet Valve

|nlet

WATER METER JUMPER WIRE

Water Meter

#4 Groundwire

13,

Page 14

I SECTION 3 I STEP BY STEP GUIDES TO INSTALL

I

12. FILTER

ELECTRIC POWER OUTLET FOR YOUR

The filter works on 24 volt, 60 Hz electric power. The

included transformer changes standard 120 volt AC

FASTEN THE POWER CABLE AND PLUG IN

13. THE TRANSFORMER

Looking at FIG. 14, fasten the 2 power cable lugs (1

under each screw) to the transformer as shown.

Tighten both screws, then plug the transformer into

the outlet.

NOTE: When you plug in the transformer, 12:00 AM

and SU begin to flash in the face plate display.

14. SANITIZING THE WATER FILTER

Care is taken at the factory to keep your filter

clean and sanitary, Materials used to make the filter

will not infect or contaminate your water supply, and

will not cause bacteria to form and grow. However, if

sanitizing is needed, do the following.

house power to 24 volts. You must plug the transformer

into a 120 volt outlet only. Be sure the outlet is always

"live" so spmeone cannot turn it off by mistake.

CONNECTING TRANSFORMER

Transformer

i I - r--

\_/ _ Power Cable (Hook either lead

under either transformer terminaL)

Press and hold button [] on the face plate

a. until RCHG be-_gins to flash in the face plate

display, starting a backwash.

After 5 to 10 minutes, press

button [] again to start fast

rinse. Wait about 1 minute, THEN TURN OFF WATER

TO THE FILTER AT THE MAIN SUPPLY VALVE.

Press button [] once more to return the valve to

service.

bll

NOTE: If bypass valve, Item No. 42/65-3437 is install-

ed, or if plumbing is too rigid to move, also disconnect

the outlet side and move the filter away from plumbing.

C. hypochlorlte into the valve inlet as far as

NOTE: You can buy calcium hypochlorite in tablet or

granular form using trade names such as Perchloren

and HTH.

Carefully remove the large plastic clip at the

filter valve inlet (FIG. 7, page 10) and pull the

adaptor out.

Put 1 teaspoon (0.1 ounce) of calcium

possible.

dll

e.

f.

gll

While the filter is backwashing, do step 15. Then

make the timer settings beginning on page 15.

ha

Carefully reconnect the plumbing.

Turn on the water supply.

Open the nearest filtered water faucet until you

can smell chlorine, then close the faucet.

DO NOT USE WATER FOR ABOUT 45

MINUTES.

After the 45 minutes, see step a to start a

backwash. The filter will complete this

backwash in about 35 minutes.

When the backwash is over, open filtered

water faucets until chlorine odor is gone, then

close.

15. TURN ON THE GAS (OR ELECTRIC)

SUPPLY TO THE WATER HEATER AND

LIGHT THE PILOT.

14.

Page 15

I SECTION 4 I WATER FILTER TIMER/RECHARGE SETUP

1• SET THE TIMER

After the transformer is plugged into the elec-

tricaL ouUet (step 13, page 14), 12:00 AM SUnday

began to flash in the time display, Set the time of day,

present day of week, days and/or time of recharge.

display

buttons

/

A. SET TIME OF DAY

1. Press the PRESENT TIME AND DAY button []

once. The hour display flashes.

2. Press the SET/CLEAR button [] until the present

hour of the day shows in the display. Be sure AM

for morning hours, or PM for afternoon and even-

ing hours shows.

NOTE: Press button [] and quickly release to move

the hour display ahead I at a time to the correct hour.

Or, hold button [] to move the display ahead 2 hours

each second, to the correct hour.

3. Press button [] once to steady the hour display,

and minutes begin to flash. Repeat step 2 to set

the correct minutes,

4. Press button [] again to steady the minute dis-

play (day will begin flashing). Figure 15 shows the

timer set at 3:30 PM.

I

B. SET PRESENT DAY OF WEEK

1. Press the SET/CLEAR button [] to set the pre-

sent day of the week in the display.

NOTE: Press button [] and quickly release to move

the day display 1 at a time. Or, hold button [] to move

C, SET DAYS OF RECHARGE (BACKWASH)-

NOTE, IF YOU HAVE A WATER SOFTENER OR

OTHER AUTOMATIC FILTER: A good water flow rate

is needed for proper recharging and/or backwashing

of all water conditioners. To help assure good water

flow, you should offset the timers on each conditioner

so recharges do not occur on the same days, or at

the same time.

...Most Sears water softeners are factory set (many

are adjustable) to recharge from 2:00 to 4:00 AM.

...Set the clarifying filter to recharge on different

days, or...

...Set the clarifying filter to recharge either 2 hours

before or after other equipment, or...

...Offset the timers on all equipment to beqin re-

charging at 12:00, 2:00 and 4:00 AM, or 1:00,

3:00 and 5:00 AM, etc.

the day display ahead 2 days each second.

2. Press button [] again to steady the entire display.

Figure 15 shows the timer set at TUesday.

1. Read, "HOW OFTEN SHOULD YOU RECHARGE

(BACKWASH) THE FILTER", page 16.

NOTE: The timer is factory programmed to

recharge on Monday, Wednesday and Saturday.

2. Press the RECHARGE DAY button [] and

SUnday begins to flash.

...if you want recharges on Sunday (from table), press

the SET/CLEAR button [] to display ON.

...If you do not want Sunday recharges, press button

[] to display OFF.

3. Press button [] again to display a flashing

MOnday. As you did in step 2 above, press button

[] to display ON for recharge on Monday, or OFF

for no recharge on Monday.

15.

continued

Page 16

I SECTION 4 I WATER FILTER TIMER/RECHARGE SETUP

4. Press button [] for every day of the week, each

time using button [] to display ON (for recharge)

or OFF (no recharge) as needed.

D. SET TIME OF RECHARGE (BACKWASH)

The filter is factory set to begin recharge at 2:00 AM,

ending at about 2:40 AM. If a different recharge time

is desired, or needed (see note under step C, page

15) do the following.

1. Press the RECHARGE TIME button [] once, to

display a flashing 2:00 AM, the factory setting.

HOW OFTEN SHOULD YOU RECHARGE

(BACKWASH) THE FILTER?

The clarifier needs backwashing when you can see

sediments in the water, or when faucet water

pressure drops. When that happens depends on

how much sediment is in the water supply, and how

much water your household uses. You can use the

following table as a guide.

5. After setting ON or OFF for Saturday, press but-

ton [] to return the present time in the display.

2. Press the SET/CLEAR button [] until the desired

recharge starting time shows in the display.

NOTE: Press button [] and quickly release to move

the display ahead 1 hour at a time. Or, hold button

[] to move the display ahead 2 hours each second.

3. Press button [] to return the present time.

RECHARGE (BACKWASH) GUIDE

WATER CONDITION RECHARGES PER WEEK

normal sediments, dirt, etc. 1

normal sediments, dirt, etc., 2-3

WITH iron

high sediments, dirt, etc. 2

high sediments, dirt, etc., 3-4

WITH iron

NOTE: The timer is factory programmed for Monday, Wednes-

day and Saturday recharge.

I SECTION 5 I TIMER FEATURES

VACATION

The day you leave on vacation or other long absence,

press (DO NOT HOLD) the VACATION ON/OFF

button I-_. VAC begins to flash in the display. The

timer will keep time but the filter will not recharge

and waste water.

When you return, press the VACATION button []

again to return the filter to service, and the correct

time of day in the display. Remember to do this or

RECHARGE NOW

For times you expect to use more water than usual,

use the RECHARGE NOW feature. Press the RE-

CHARGE NOW-HOLD button [] and hold in for 3

16.

the filter will not recharge and you will soon have

sediments in your water supply.

NOTE: While in VACATION, the filter will go through a

recharge if the RECHARGE NOW feature (See be-

low) is used.

NOTE: To shut off the water supply to the filter, use

the plumbing bypass valve(s)... FIG. 11, page 13.

seconds. RCHG begins to flash in the display and a

recharge starts right away. You will have filtered

water when the recharge is over in about 35 minutes.

Page 17

TIMER "POWER-OUTAGE MEMORY"

If e_ectrical power to the timer goes off, the "memory"

buitt into timer circuitry keeps all settings for 6 hours

(minimum) or more. The display is blank and the'filter

will not recharge. When electrical power comes on, 1

of 2 things will happen.

1. The present time of day will show, mean-

. ing the timer memory has kept all settings.

NOTE: tf the filter was in a recharge when power

was lost, it will now finish the cycle.

HOW YOUR CLARIFYING FILTER WORKS

2. The display will show a time, but it will be

flashing. The timer memory did not keep the

time settings and they must be reset (page 15),

The flashing display is to remind you to reset

the timer.

NOTES:

When power comes on, the flashing display re-

turns to a time of 12:00 AM Sunday, then begins to

keep time again, if you do not reset all time set-

tings, the filter will recharge 3 days each week.

However, recharges will most likely be on the

wrong days and at the wrong time.

If the filter was in a recharge when power went off,

the valve will return to service position without

finishing the recharge cycle.

FILTERED

WATER OUT

WATER

IN

The clarifying filter is filled with a mineral called "filter

aggregate." This mineral looks something like coame

sand. During service (FIG. 16) water goes into the filter

and DOWN through the bed of mineral. The mineral

takes the dirt, sand, silt, clay and other sediments out

of the water and holds it in the bed. Clear, clean water

goes out of the filter arid into the house pipes.

RECHARGE

BACk'3NASH - After a time, the mineral needs clean-

ing to flush out all the sediments held by the mineral.

This cleaning is called backwash. In backwash, water

flows UP through the mineral. The dirt and other

sediments flush out of the mineral, out the top of the

filter, and to the drain. Backwash is about 25 minutes

long.

FAST RINSE - After backwash, the water flow changes

direction and goes downward through the filter at a

fast rate. Dirt and other sediments, left at the bottom

of the mineral bed, are flushed to the drain. The fast

rinse is about 5 minutes tong. Then, the filter returns

to service.

BYPASS

WATER OUT WATER

17.

rN

BACKWASH

"_25 minutes)

Mineral

Bed

SERVICE

FAST RINSE

(5 minutes)

FILTERED

WATER OUT WATER

IN

. C;ain

Mir_rar

Bed

Page 18

I SECTION 6 I CARE OF YOUR FILTER

BEFORE YOU CALL FOR SERVICE

HELPFUL HINTS CHECKLIST...TO HELP YOU SAVE MONEY

By making a few easy checks, you can often avoid an unneeded service call. If your water filter fails to work,

check these things. If, after making the checks it still does not work right, call your Sears Service Department.

I

FILTER WILL NOT BACKWASH

(Water contains sediments, iron, dirt, sand, etc.)

_-] MANUAL BYPASS VALVE(S) IN BYPASS

3-valve bypass, open the inlet and outlet valves, close

the bypass valve.

_'_ TRANSFORMER UNPLUGGED AT THE

and correct. Reset the times, then use the RECHARGE

NOW feature (See page 16).

r_ FUSE BLOWN, CIRCUIT BREAKER POP-

Reset times and use the RECHARGE NOW feature.

NOTE: SEE "TIMER POWER-OUTAGE MEMORY,"

PAGE 17.

[] TIMER IN THE VACATION (VAC) POSITION

POSITION - See FIG. 11, page 13. Move stem

in single bypass valve to SERVICE. In a

WALL OUTLET, OR POWER CABLE

DISCONNECTED - Check for loss of power

PED, OR CIRCUIT SWITCHED OFF - Replace

fuse, reset circuit breaker, or switch circuit on.

- Press the VACATION button once to return

the filter to service (page 16).

HOUSE WATER PRESSURE LOW

I_ WELL PUMP PRESSURE SET TOO LOW -

Adjust to a MINIMUM of 20 psi.

I'_ BACKWASH NEEDED MORE OFTEN TO

KEEP FIL1;ER MINERAL BED CLEAN - Set

the timer for more recharges (See pages 15

and 16).

r-_ TIMER NOT PROGRAMMED FOR

NOW feature.

[] VALVE DRAIN HOSE PLUGGED - Hose must

RECHARGES - See pages 15 and 16 to select

and program a schedule. Use the RECHARGE

not have kinks, sharp bends, or any water flow

blockage. (See page 12.)

18.

Page 19

I SECTION 6 I CARE OF YOUR FILTER

KEEP THE FILTER FROM FREEZING

.

Pull the holding clip to remove the drain fitting, with

drain hose attached, from the valve.

If the filter is installed where it could freeze (summer

cabin, lake home, etc.), you must drain al! water from

it to stop possible freeze damage. To drain the filter -

6.

Looking at FIG. 5 on page 9, remove tt_e plastic

clips and pull the adaptors or bypass valve from

the inlet and outlet.

1. Close the shut-off valve on the house main water

pipe, near the water meter or pressure tank.

. Move the filter close to the floor drain. SLOWLY

and CAREFULLY (the filter is heavy) tip the filter

2. Open a faucet in the filtered water pipes to vent

pressure in the filter.

over so the valve inlet and outlet are over the drain.

Allow water to drain from tank. DO NOT REST THE

FILTER ON THE INLET AND OUTLET FITTINGS

.

Looking at FIG. 11 on page 13, move the stem in

OR THEY WILL BREAK.

a single bypass valve to bypass. Close the inlet

and outlet valve in a 3-valve bypass system, and

open the bypass valve.

.

Tip the bottom of the filter up a few inches and hold

until all water has drained. Leave the filter laying

like this until you are ready to use it. Plug the inlet

4. Unplug the transformer at the wall outlet.

I SECTION 7 OTHER THINGS TO KNOW

i

end outlet with rags to keep dirt, bugs, etc. out.

SPECIFICATIONS

TYPE OF FILTERING MINERAL

AMOUNT OF FILTERING MINERAL

WATER PRESS. LIMITS (Min.-Max.)

MAXIMUM WATER TEMPERATURE

MINIMUM WELL PUMP CAPACITY

MIN, PIPE SIZE TO FILTER

BACKWASH FLOW RATE*

SERVICE FLOW RATE

(at max, pressure drop of 10 psi)

CAPACITY

MICRON RATING

"at 35 PSI inlet pressure

Aggregate

1.0 Cu. Ft. (.028 Cu M)

20 to 125 PSI (1.4 to 8.4 Kg/Sq/Cm)

120 F (,_.9 C)

270 Gal/Hr (1022 Liter/Hr)

3/4 In. (lgMM)

4.5 Gal/Min (17 Uter/Min)

6.6 GaliMin (25 Liter/Min)

8600 Gal (32553 Liters)

25

DIMENSIONS

18"(_

(13g.s cm)

i r

Freeboard

DiA.

_1- 11,,-I1,,

[ (27.9 cm)

II I

I rlteldDU1_t

CAPACITY DETERMINED UNDER WQA STANDARD S-200 TEST CONDITIONS FOR FILTER GROUP IV, AND

MAY VARY WITH LOCAL WATER CHARACTERISTICS.

(124.5 ¢r_ I

lg.

Page 20

SECTION 7 I OTHER THINGS TO KNOW

SWEAT SOLDERING TIPS

MEASURING PIPE LENGTHS: Always be sure to

include the length of pipe that goes inside the fitting.

On 3/4" pipe, this length is about 3/4".

about 3/,- : I

engagement NO YES

_i i

CUTTING PIPE: Turn the pipe cutter back and forth

around the outside of the pipe. Tighten the pipe cutter

slowly with each turn until all the way through the

pipe. To keep from crushing or distorting the pipe, do

not tighten the cutter too much at a time. File burrs

from cut ends.

CLEAN PIPE AND FITTING SOLDERING SUR-

FACES: With emery cloth, fine sandpaper or steel

wool, clean the end of the pipe and inside of the fitting.

Clean surfaces until they shine. Do not grind off too

much material, making the fit too loose.

Wrap nearby, already soldered joints with a wet cloth

so solder does not melt.

Let soldered joint_ cool slowly. Sudden cooling can

crack or weaken the solder.

SOLDERING: Light the torch and set to a moderate

flame. Move the flame over and around the joint to

heat pipe and fitting. In a short time, touch the end of

the solder wire to the tip of the fitting. DO NOT PLACE

SOLDER IN THE FLAME. The solder will melt and

draw into the connection when the pipe and fitting are

at the rig ht temperature. Run the solder around the lip

until the joint is full. Do not overfill as solder will run

into and harden inside the fitting. Being careful not to

touch the pipe with your hands, make a quick swipe

around the joint with a cloth to take off excess solder.

clean surfaces

thoroughly

CHECK THE FIT: Push the pipe into the fitting as far

as it will go. Use some force to slip together, but do

not hammer or pound. If too tight, clean surfaces until

fit is good.

PUT ON PASTE FLUX: Freely apply paste flux on

both cleaned surfaces. Place pipe into the fitting and

turn to spread the paste around.

BEFORE SOLDERING, READ THESE SAFETY

GUIDES.

• Keep torch flame away from walls, the water softener,

and other materials that will burn.

• Do not touch newly soldered pipe with your hands.

For a good sweat solder joint, the pipe and fitting must

not have any water inside them. Water, when heated

by the torch, weakens the solder and often the joint

will leak. If you can not keep the inside of the pipe dry,

wad up a piece of bread into a ball. After putting paste

flux on both the pipe and fitting, place the bread wad

into the pipe and poke in several inches. Put the pipe

and fitting together and solder. The bread absorbs

moisture while you are soldering. When the water is

turned on, the bread dissolves and is flushed out an

open faucet.

LEAKING CONNECTIONS: You can try to reheat

and resolder a leaking joint, but it's usually best to

start over. Turn off the water, reheat and take the pipe

and fitting apart. Take off all old solder, cleaning down

to the copper surface. Apply new paste flux and

solder again.

20.

Page 21

I SECTION 8 I REPAIR PARTS... SEARS WATER FILTER

.._ 12 _ | _ VALVE COVER

c...,F,.., .oo.. NO 62S 3,8230

11:"_ $ _,_,,_,_ ._1 _'_ ,.,J SCREWS (2)...See page 22

_'_E" ._"_' _ L_---_,,.. KEY PART

! _.'//:'__ 116 NO. NUMBER DESCRIPTION

1 7105047 Bottom Distributor & Standpipe

18

19

VALVE ASSEMBLY

..,See page 22

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

2O

21

22

23

7092202

7088855

7096183

900039

7079092

7088033

7088041

900300

7108304

708433O

7084306

7095373

7090323

9OO562

9OO6O31

7089047

900596

7090315

7092210

505647

501783

501782

7097684

7097668

Mineral Tank

Top Distributor

O-Ring, 2-3/4 x 3

O-Ring, 1-1/16 x 1-1/14

O-Ring, 2-718 x 3-1/4

Clamp Retainer (2 req.)

Clamp Section (2 req.)

Screw, #4.40 x 1/4 (2 req.)

Face Plate - Timer

Power Cord

Wire Harness

Transformer, 24V-10VA

Top Cover

Screw, #6 x 9/16 (4 req.)

Screw, #8-18 x 1/2 (2 red.)

Cover Bracket

Speed Nut

Bottom Cover

i Shroud

Mineral, 1 cu. ft.

Filter Sand, 10 Ibs.

Gravel, 17 Ibs.

Instruction Card

Owners Manual (F642-2890)

21.

• Not

illustrated

Page 22

__ CLARIFIER, MODEL NO. 625.348230

3O

68

67

69

54

53

52

51

22.

Page 23

I SECTION 8 I REPAIR PARTS... SEARS WATER FILTER

CLARIFIER, MODEL NO. 625.348230

VALVE ASSEMBLY

PARTS LIST

KEY PART

NO. NUMBER DESCRIPTION

3O

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

900120

7070462

900857

7064974

503288

7066439

"7080653

509537

900041

7077927

1205500

507369

507615

900570

507371

900535

900568

7082053

7081764

1219600

7092642

7092634

7081756

9001006

7103964

Screw, #6.18 x 3/8 (2 req.)

Motor

Screw, #6-20 x 3/6 (2 req.)

Motor Plate

Bearing

Cam and Gear

Clip (Drain)

Flow Plug

O-Ring, 5/8 x 13/16

Drain Hose Adaptor

Clip (2 req.) *

Installation Nut (2 req.) *

Installation Tube (2 req.),

Washer (2 req.),

Installation Adaptor (2 req.)*

O-Ring, 15/16 x 1-3/16 (2 req.)*

Screen (inlet)* []

Valve Body

Seal

Spring

Plug (Drain Seal)

O-Ring, 3/8 x 9/16

Rotor Seal

O-Ring, 3-3/8 x 3-5/8

Rotor & Disc

KEY PART

NO. NUMBER DESCRIPTION

55 7082087

56 7064372

57 7064380

58 7085263

59 7074123

60 7077472

61 7030713

62 7070412

63 900373

64 120375

65 500726

66 160505

67 7081201

68 7100940

69 900064

• 4920901

7092163

• Not illustrated

[] Although included in the small parts bag,

screen is not used on the Clarifying Fitter.

Wave Washer

O-Ring, 3/4 x 15116

O-Ring, 7/16 x 5/8

Valve Cover

Screw, #10-14 x 2 (5 req.)

Expansion Pin

Switch (2 req.)

Screw, #4-24 x 1-118

"C" Clamp (2 req.)e

Nut (2 req.)*

Ground Wire-,

Screw, 1/4-20 (2 req.)*

Clip (Nozzle & Venturi)

Plug

O-Ring, 1/4 x 3/8 (2 req.)

Small Parts Bag (Includes all

items marked with *)

Seal Kit (Incl. Key Nos. 48, 51,

52, 53, 56 and 57)

23.

Page 24

Kenmore

CLARIFYING FILTER

Now that you have purchased your clarifying filter, should a need ever exist

for repair parts or service, simply contact any Sears Service Center. Be sure

to provide all pertinent facts when you call or visit.

The model number of your filter is found on the rating decal. This decal

is on backside of the filter top cover.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE FOLLOWING

INFORMATION:

- PART NUMBER

- MODEL NUMBER

All parts listed may be ordered from any Sears Service Center.

If the parts you need are not stocked locally, your order will be electronically

transmitted to a Sears Repair Parts Distribution center for handling.

When Sears arranges the installation, you can be sure the job is done right.

We will arrange for professional workmanship...and we'll take care of the

entire project. What's more, during installation you get insured protection...

against property damage and also against accidents to workmen. All you

have to do is talk to your Sears salesperson or call your nearest Sears store

today for detailed information.

- PART DESCRIPTION

- NAME OF ITEM

F642-2890 7097668 (3/91)

Loading...

Loading...